Submitted:

19 July 2025

Posted:

22 July 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

Materials and Methods

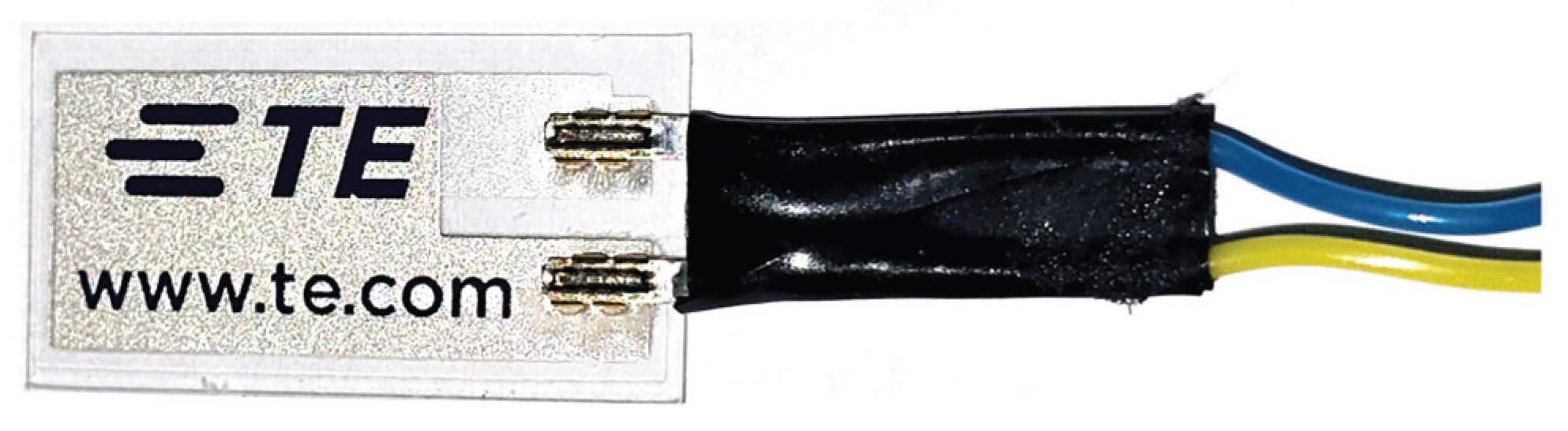

2.1. PVDF Transducers

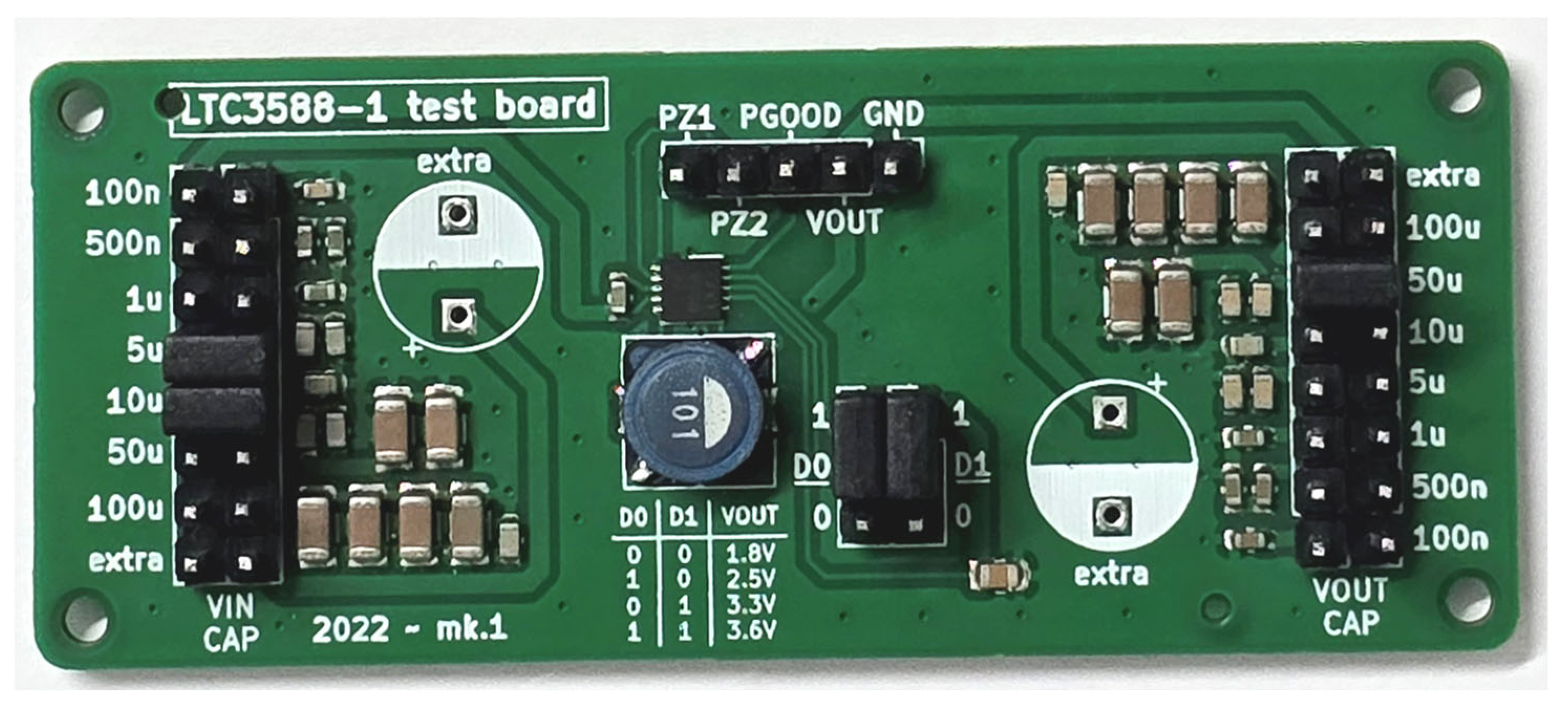

2.2. Integrated Circuit For Energy Storage

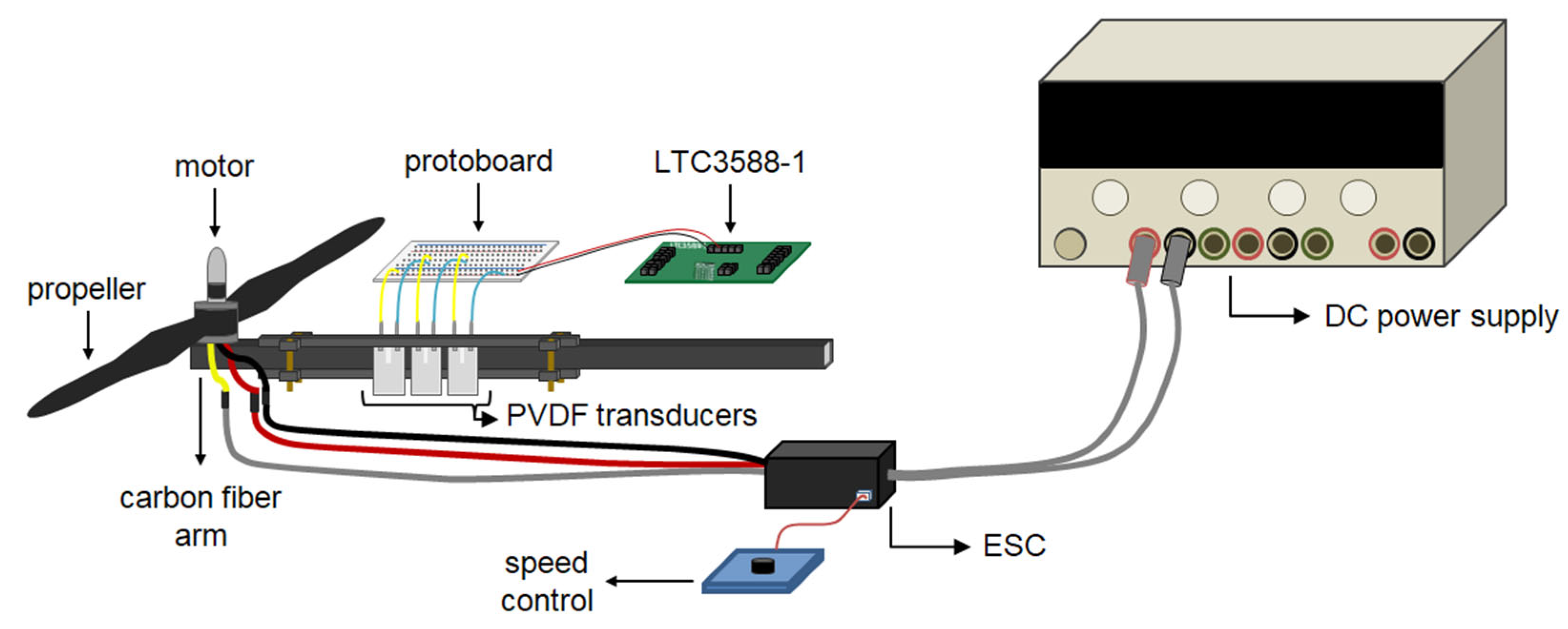

2.3. Characterization of Motor and PVDF Transducer Performance

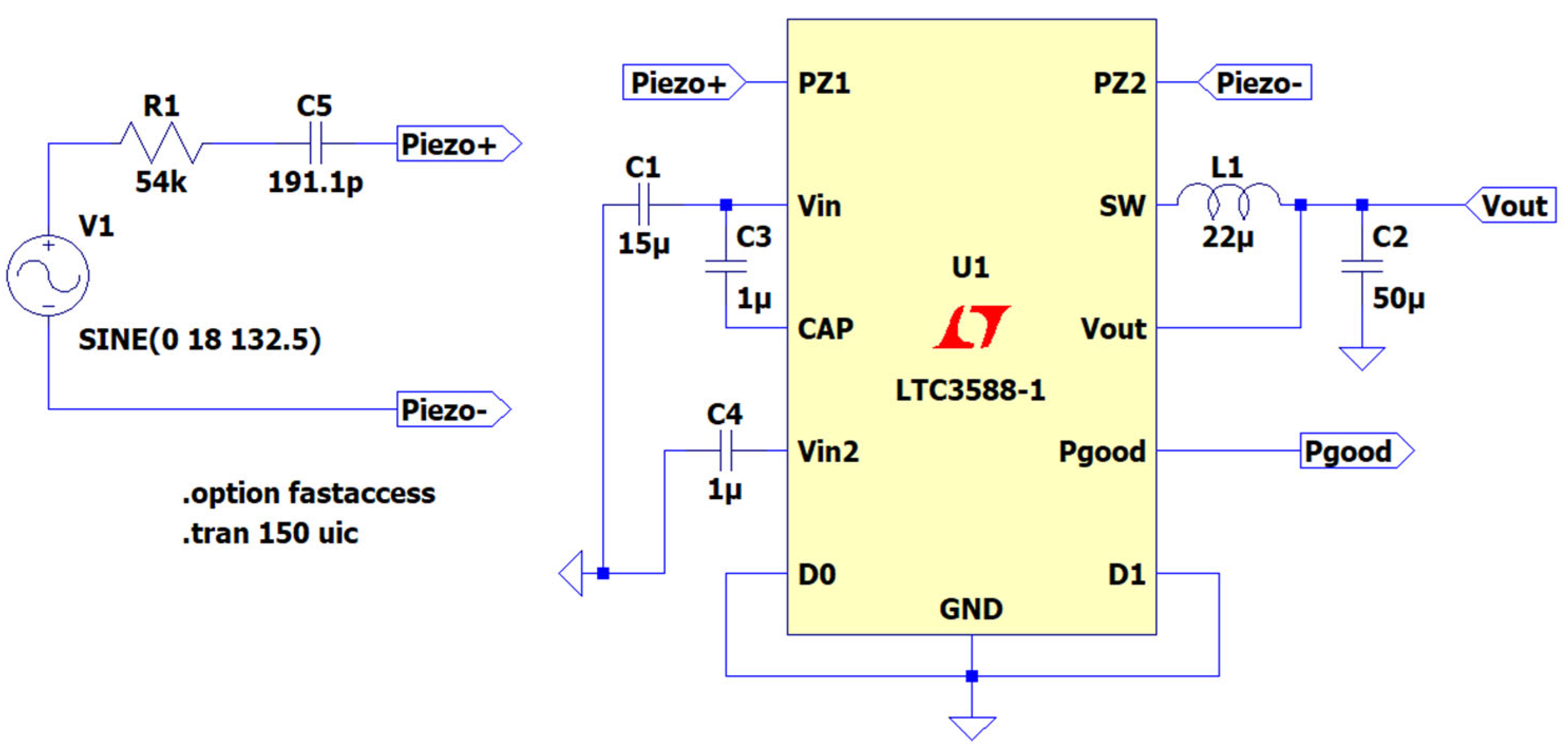

2.4. Computational simulation of EH electronic Circuits

2.5. Experimental Evaluation of the EH System

3. Results and Discussion

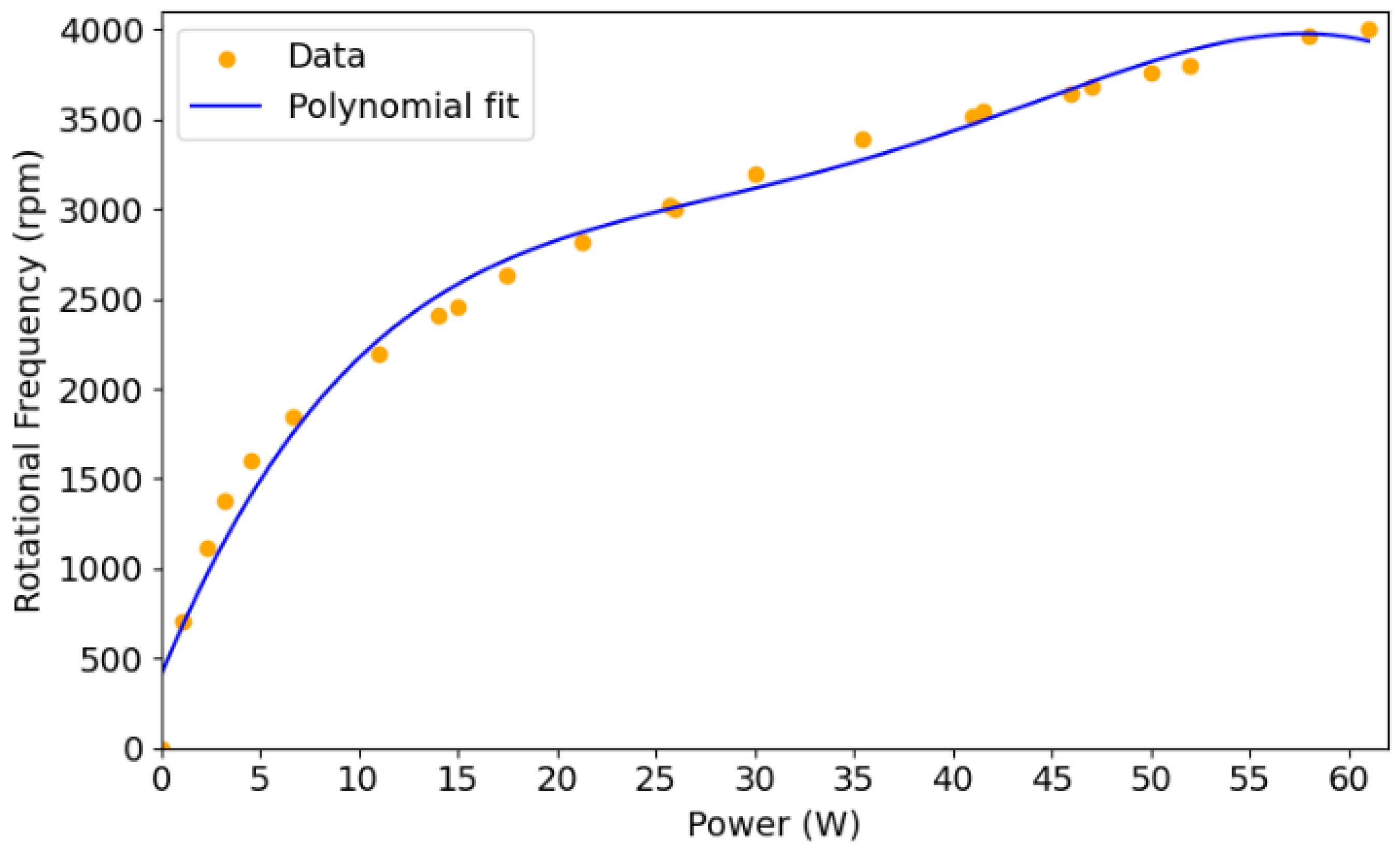

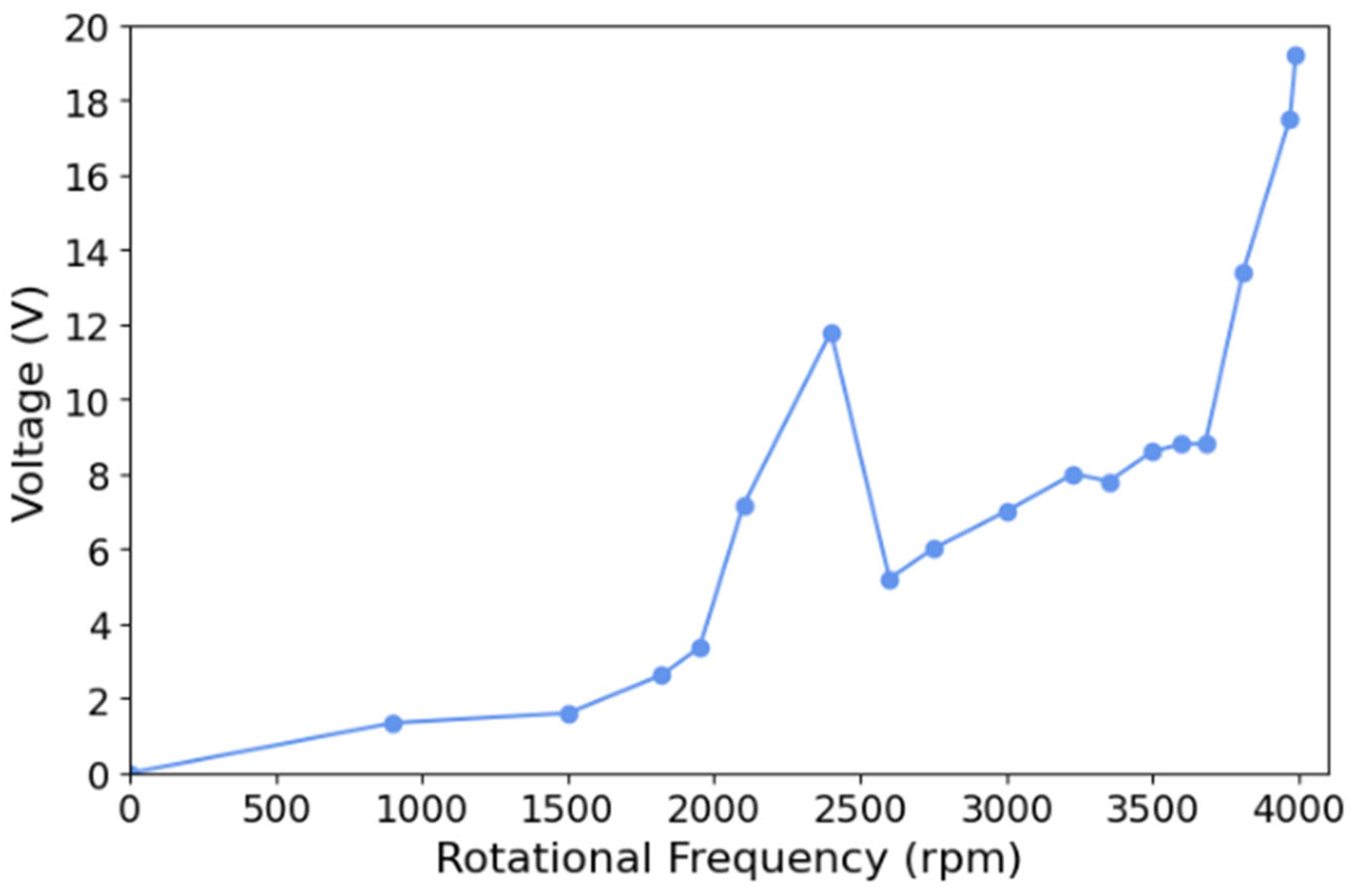

3.1. Results of the Motor and PVDF transducer characterizations

3.2. Simulation and Experimental Results of the EH Electronic Circuits

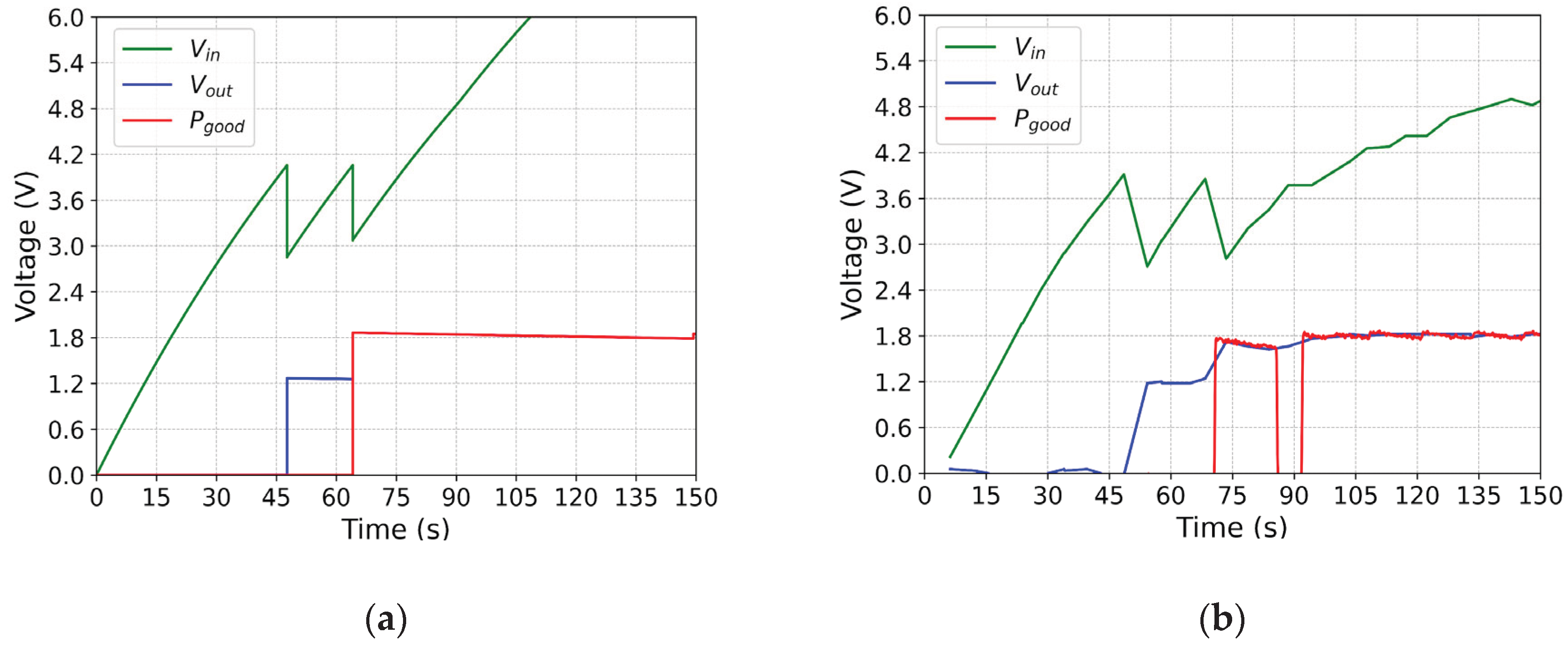

3.2.1. Output Voltage of 1.8 V

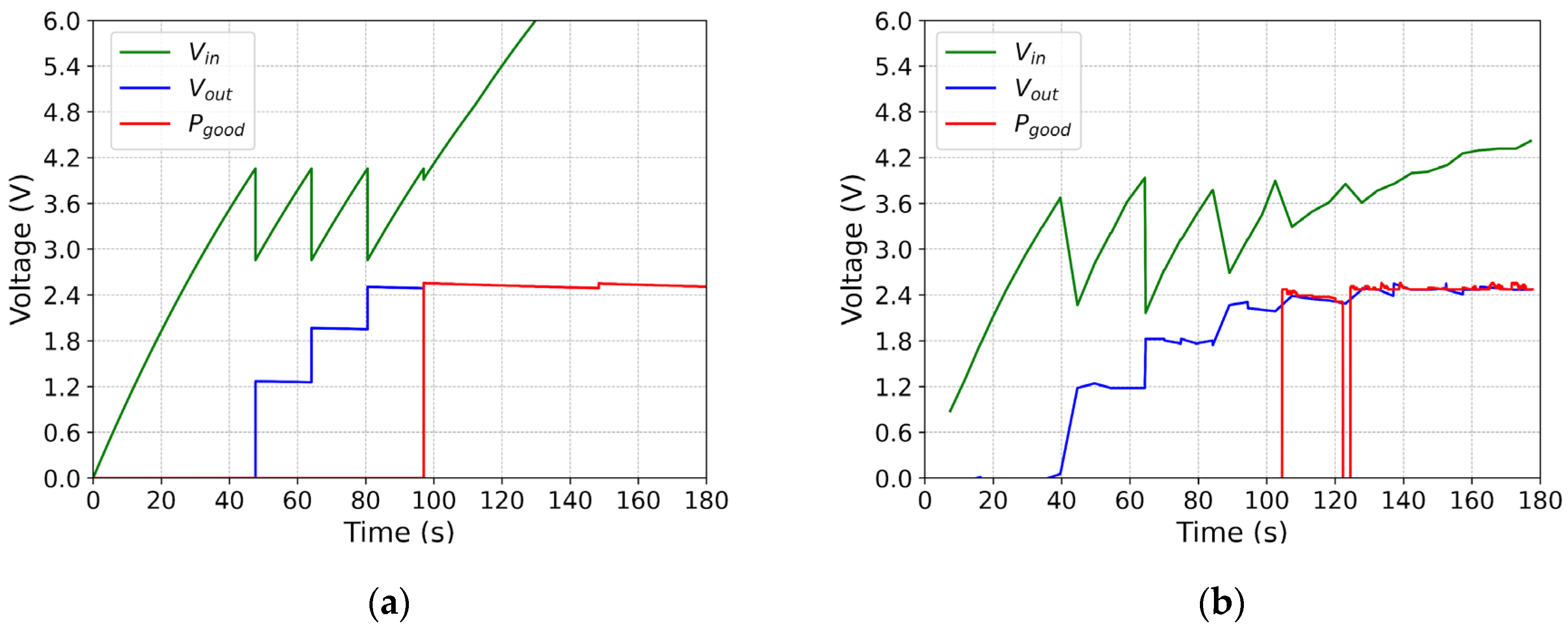

3.2.2. Output Voltage of 2.5 V

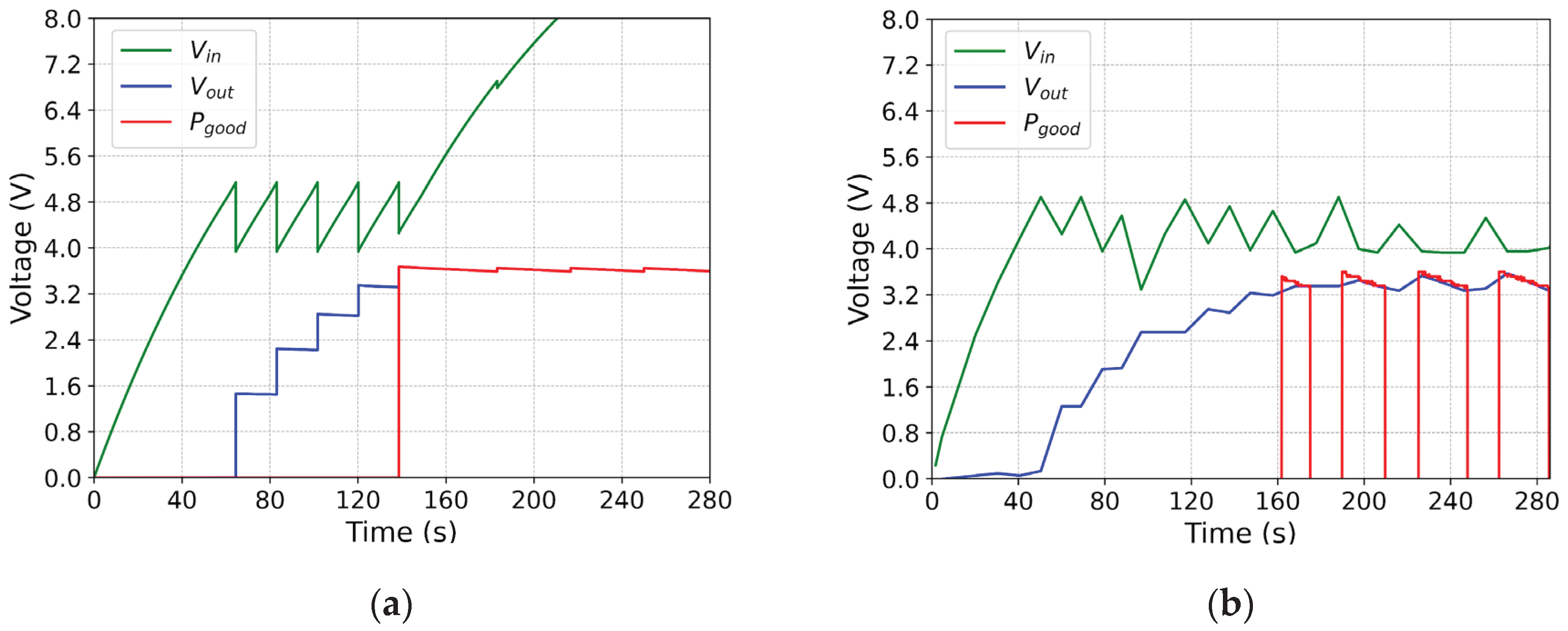

3.2.3. Output Voltage of 3.3 V

3.2.4. Output Voltage of 3.6 V

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EH | Energy harvesting |

| UAV | Unmanned Aerial Vehicle |

| PVDF | Polyvinylidene fluoride |

| IC | Integrated circuit |

| Vin | Input Voltage |

| Vout | Regulated Output Voltage |

| Cin | Input capacitor |

| Cout | Output capacitor |

| Pgood | Power good comparator |

| GND | Ground |

References

- Na, Y.; Kim, S.; Mallem, S.P.R.; Yi, S.; Kim, K.T.; Park, K. Energy harvesting from human body heat using highly flexible thermoelectric generator based on Bi2Te3 particles and polymer composite. J. Alloys Compd. 2022, 924, 166575. [Google Scholar] [CrossRef]

- Yuan, J.; Zhu, R. A fully self-powered wearable monitoring system with systematically optimized flexible thermoelectric generator. Appl. Energy 2020, 271, 115250. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, H.; Chen, Z.; Wang, Z.; Jiang, L.; Lu, G.; Li, X.; Chen, R.; Jin, J.; Kang, H.; et al. Stretchable nanolayered thermoelectric energy harvester on complex and dynamic surfaces. Nano Lett. 2020, 20, 4445–4453. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K.; Kim, M.S.; Lee, S.; Kim, C.; Kim, Y.J. Wearable thermoelectric generator for harvesting human body heat energy. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Feenstra, J.; Granstrom, J.; Sodano, H. Energy harvesting through a backpack employing a mechanically amplified piezoelectric stack. Mech. Syst. Signal Process. 2008, 22, 721–734. [Google Scholar] [CrossRef]

- Hu, C.; Behdinan, K.; Moradi-Dastjerdi, R. PVDF energy harvester for prolonging the battery life of cardiac pacemakers. Actuators 2022, 11. [Google Scholar] [CrossRef]

- Zhang, S.L.; Jiang, Q.; Wu, Z.; Ding, W.; Zhang, L.; Alshareef, H.N.; Wang, Z.L. Energy harvesting-storage bracelet incorporating electrochemical microsupercapacitors self-charged from a single hand gesture. Adv. Energy Mater. 2019, 9. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Xu, L.L.; Ryu, C.H.; Kumar, A.; Hong, S. Do; Jeon, D.H.; Cho, J.Y.; Ahn, J.H.; Joo, Y.H.; Jeong, I.W.; et al. Wearable shoe-mounted piezoelectric energy harvester for a self-powered wireless communication system. Energies 2022, 15. [Google Scholar] [CrossRef]

- Keddis, S.; Mitry, R.; Schwesinger, N. Piezoelectric flow harvesting for in-pipe metering systems. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XII, Denver, Colorado, United States, Vol. 10595., 15 March 2018. [Google Scholar]

- Li, L.; Zhang, X.; Song, C.; Huang, Y. Progress, challenges, and perspective on metasurfaces for ambient radio frequency energy harvesting. Appl. Phys. Lett. 2020, 116. [Google Scholar] [CrossRef]

- Sherazi, H.H.R.; Zorbas, D.; O’flynn, B. A comprehensive survey on RF energy harvesting: applications and performance determinants. Sensors 2022, 22. [Google Scholar] [CrossRef]

- Selim, K.K.; Smaili, I.H.; Yehia, H.M.; Ahmed, M.M.R.; Saleeb, D.A. piezoelectric sensors pressed by human footsteps for energy harvesting. Energies 2024, 17, 2297. [Google Scholar] [CrossRef]

- Tahir, H.R.; Malengier, B.; Sujan, S.; Langenhove, L.V. Embroidery triboelectric nanogenerator for energy harvesting. Sensors 2024, 24, 3782. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Cai, F.; Chen, Y.; Chen, T.; Lu, P. Advanced applications of porous materials in triboelectric nanogenerator self-powered sensors. Sensors 2024, 24, 3812. [Google Scholar] [CrossRef] [PubMed]

- Newby, S.; Mirihanage, W.; Fernando, A. Wearable, knitted 3D spacer thermoelectric generator with detachable p-n junctions for body heat energy harvesting. Sensors 2024, 24, 5140. [Google Scholar] [CrossRef] [PubMed]

- Nekui, O.D.; Wang, W.; Liu, C.; Wang, Z.; Ding, B. IoT-based heartbeat rate-monitoring device powered by harvested kinetic energy. Sensors 2024, 24, 4249. [Google Scholar] [CrossRef]

- Qian, C.; Ye, F.; Li, J.; Tseng, P.; Khine, M. Wireless and battery-free sensor for interstitial fluid pressure monitoring. Sensors 2024, 24, 4429. [Google Scholar] [CrossRef]

- Han, S.; Xiao, Q.; Liang, Y.; Chen, Y.; Yan, F.; Chen, H.; Yue, J.; Tian, X.; Xiong, Y. using flexible-printed piezoelectric sensor arrays to measure plantar pressure during walking for sarcopenia screening. Sensors 2024, 24, 5189. [Google Scholar] [CrossRef]

- Dan, S.; Yano, Y.; Wang, J. Batteryless BLE module with a piezoelectric element mounted on a shoe sole. Sensors 2024, 24, 2829. [Google Scholar] [CrossRef]

- Jamil, M.N.B.M.; Omar, M.; Ibrahim, R.; Bingi, K.; Faqih, M. Rectenna system development using harmonic balance and s-parameters for an RF energy harvester. Sensors 2024, 24, 2843. [Google Scholar] [CrossRef]

- Li, J.; Ren, W.; Luo, Y.; Zhang, X.; Liu, X.; Zhang, X. Design of fluxgate current sensor based on magnetization residence times and neural networks. Sensors 2024, 24, 3752. [Google Scholar] [CrossRef]

- Du, X.; Zhang, H.; Cao, H.; Hao, Z.; Nakashima, T.; Tanaka, Y.; Jiao, P.; Mutsuda, H. double-swing spring origami triboelectric nanogenerators for self-powered ocean monitoring. Energies 2024, 17, 2981. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, G.; Lou, Y.; Li, M.; Hu, J.; Li, J.; Cui, W.; Yu, A.; Zhai, J. Elastic self-recovering hybrid nanogenerator for water wave energy harvesting and marine environmental monitoring. Sensors 2024, 24, 3770. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Cai, J.; Zhu, X. An advanced Hall element array-based device for high-resolution magnetic field mapping. Sensors 2024, 24, 3773. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-R.; Huang, P.-C.A.; Wang, Y.-R.; Huang, P.-C. A magneto-electric device for fluid pipelines with vibration damping and vibration energy harvesting. Sensors 2024, 24, 5334. [Google Scholar] [CrossRef] [PubMed]

- Ligęza, P. Electromagnetic energy harvester using pulsating airflows—reeds waving in the wind. Energies 2024, 17, 4834. [Google Scholar] [CrossRef]

- Soares, I.N.; Altafim, R.A.C.; Altafim, R.A.P.; Moreira, M. de M.A.C.; Sousa, F.S.I. de; Afonso, J.A.; Carmo, J.P.; Flauzino, R. de A. Investigation of a magnetic levitation architecture with a ferrite core for energy harvesting. Energies 2024, 17, 5315. [Google Scholar] [CrossRef]

- Chukwurah, U.; McTaggart-Cowan, G. Harvesting electric energy using thermoelectric generators in a residential heating application. Energies 2024, 17, 2562. [Google Scholar] [CrossRef]

- Markakis, E.K.; Alonistioti, N.; Aragonés, R.; Oliver, J.; Ferrer, C. Transforming industrial maintenance with thermoelectric energy harvesting and NB-IoT: a case study in oil refinery applications. Sensors 2025, 25, 703. [Google Scholar] [CrossRef]

- Shen, H.; Lv, Y.; Kong, Y.; Han, Q.; Chen, K.; Geng, Z.; Dong, M.; Chu, F. Triboelectric nanogenerator-embedded intelligent self-aligning roller bearing with the capability of self-sensing, monitoring, and fault diagnosis. Sensors 2024, 24, 7618. [Google Scholar] [CrossRef]

- Huang, X.; Wei, B.; Ling, Z.; Yang, F.; Pang, H. A low-frequency vibration sensor based on ball triboelectric nanogenerator for marine pipeline condition monitoring. Sensors 2024, 24, 3817. [Google Scholar] [CrossRef]

- Wackwitz, K.; Bodecker, H. Drone Market Size, Forecast 2025-2030, Market Developments & Regulations. Drone Industry Insights, Hamburg, Germany, 2025. Available online: https://droneii.com/product/drone-market-report (accessed on 29 April 2025).

- Kazak, A.; Grishin, I.; Makoveichuk, K.; Dorofeeva, A.; Mayorova, A. The use of UAVS and helicopters in forest fires monitoring and extinguishing in hard-to-reach areas. E3S Web Conf. 2023, 402, 02008. [Google Scholar] [CrossRef]

- Fernández, L.J.C.; Castañeda, M.A.P.; Ariza, L.L.C.; Gómez, Y.T.B. UAV data collection in hard-to-reach areas from a wireless sensor network. In Proceedings of the 2022 IEEE 40th Central America and Panama Convention (CONCAPAN), Panama, Panama, 09-12 November 2022. [Google Scholar]

- Rigoni, G.; Pinotti, C.M. ; Bhumika; Das, D., Ed.; Das, S.K. Delivery with UAVs: a simulated dataset via ATS. In Proceedings of the 2022 IEEE 95th Vehicular Technology Conference: (VTC2022-Spring), Helsinki, Finland, 22 June 2022. [Google Scholar] [CrossRef]

- Park, J.; Kim, S.; Suh, K. A comparative analysis of the environmental benefits of drone-based delivery services in urban and rural areas. Sustain. 2018, 10, 888. [Google Scholar] [CrossRef]

- Cui, S.; Yang, Y.; Gao, K.; Cui, H.; Najafi, A. Integration of UAVs with public transit for delivery: Quantifying system benefits and policy implications. Transp. Res. Part A Policy Pract. 2024, 183, 104048. [Google Scholar] [CrossRef]

- Mahbub, M.; Saym, M.M.; Jahan, S.; Paul, A.K.; Vahid, A.; Hosseinalipour, S.; Barua, B.; Yeh, H.G.; Shubair, R.M.; Taleb, T. A holistic survey of UAV-assisted wireless communications in the transition from 5G to 6G: State-of-the-art intertwined innovations, challenges, and opportunities. J. Netw. Comput. Appl. 2025, 237, 104131. [Google Scholar] [CrossRef]

- Nomikos, N.; Gkonis, P.K.; Bithas, P.S.; Trakadas, P. A survey on UAV-aided maritime communications: deployment considerations, applications, and future challenges. IEEE Open J. Commun. Soc. 2023, 4, 56–78. [Google Scholar] [CrossRef]

- Michez, A.; Broset, S.; Lejeune, P. Ears in the sky: potential of drones for the bioacoustic monitoring of birds and bats. Drones 2021, 5, 9. [Google Scholar] [CrossRef]

- Nielsen, M.L.K.; Sprogis, K.R.; Bejder, L.; Madsen, P.T.; Christiansen, F. Behavioural development in southern right whale calves. Mar. Ecol. Prog. Ser. 2019, 629, 219–234. [Google Scholar] [CrossRef]

- Kavwele, C.M.; Hopcraft, J.G.C.; Davy, D.; Torney, C.J. Automated and repeated aerial observations of GPS-collared animals using UAVs and open-source electronics. Ecosphere 2024, 15. [Google Scholar] [CrossRef]

- Colefax, A.P.; Kelaher, B.P.; Pagendam, D.E.; Butcher, P.A. assessing white shark (carcharodon carcharias) behavior along coastal beaches for conservation-focused shark mitigation. Front. Mar. Sci. 2020, 7, 519539. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Turvey, S.T.; Sun, Z.; Tan, Z.; Yang, Q.; Long, W.; Wu, X.; Yang, D. Thermal infrared imaging from drones can detect individuals and nocturnal behavior of the world’s rarest primate. Glob. Ecol. Conserv. 2020, 23, e01101. [Google Scholar] [CrossRef]

- Sherstjuk, V.; Zharikova, M.; Sokol, I. Forest fire-fighting monitoring system based on UAV team and remote sensing. In Proceedings of the 2018 IEEE 38th International Conference on Electronics and Nanotechnology (ELNANO), Kyiv, UKraine, 24-26 April 2018. [Google Scholar] [CrossRef]

- Wardihani, E.D.; Ramdhani, M.; Suharjono, A.; Setyawan, T.A.; Hidayat, S.S.; Helmy; Widodo, S. ; Triyono, E.; Saifullah, F. Real-time forest fire monitoring system using unmanned aerial vehicle. J. Eng. Sci. Technol. 2018, 13, 1587–1594. [Google Scholar]

- Jibon, Z.A.; Adnan, M.A.; Nora, N.T.; Akash, M.M.H.; Ahammed, F. Development of an autonomous UAV for seed and fertilizer distribution in precision agriculture. In Proceedings of the 2023 14th International Conference on Computing Communication and Networking Technologies (ICCCNT), Delhi, India, 06-08 July 2023. [Google Scholar] [CrossRef]

- Macedo, F.L.; Nóbrega, H.; de Freitas, J.G.R.; Ragonezi, C.; Pinto, L.; Rosa, J.; Pinheiro de Carvalho, M.A.A. Estimation of productivity and above-ground biomass for corn (zea mays) via vegetation indices in Madeira Island. Agric. 2023, 13, 1115. [Google Scholar] [CrossRef]

- Maktab Dar Oghaz, M.; Razaak, M.; Kerdegari, H.; Argyriou, V.; Remagnino, P. Scene and environment monitoring using aerial imagery and deep learning. In Proceedings of the 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini, Greece, 29-31 May 2019. [Google Scholar] [CrossRef]

- Hentschke, M.; de Freitas, E.P.; Hennig, C.H.; da Veiga, I.C.G. Evaluation of altitude sensors for a crop spraying drone. Drones 2018, 2, 25. [Google Scholar] [CrossRef]

- Nanavati, R. V.; Meng, Y.; Coombes, M.; Liu, C. Generalized data-driven optimal path planning framework for uniform coverage missions using crop spraying UAVs. Precis. Agric. 2023, 24, 1497–1525. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Ross, G. Effect of piezo-embedded inverted flag in free shear layer wake. Aerosp. 2019, 6, 33. [Google Scholar] [CrossRef]

- Wei, X.; Yi, Z.; Li, W.; Zhao, L.; Zhang, W. Energy harvesting fueling the revival of self-powered unmanned aerial vehicles. Energy Convers. Manag. 2023, 283, 116863. [Google Scholar] [CrossRef]

- Boucher, R.A.; Boucher, R.J.; Remotely controlled electric airplane. US3957230A. 1975. Available online: https://patents.google.com/patent/US3957230 (accessed on 16 May 2025).

- Boucher, R.J. Sunrise, the World’s First Solar-Powered Airplane. J. Aircr. 1985, 22, 840–846. [Google Scholar] [CrossRef]

- Irving, F.; Morgan, D. The feasibility of an aircraft propelled by solar energy. In Proceedings of the 2nd International Symposium on the Technology and Science of Low Speed and Motorless Flight, Cambridge,MA,U.S.A., 11-13 September 1974. [Google Scholar] [CrossRef]

- MacCready, P.B.; Lissaman, P.B.S.; Morgan, W.R.; Burke, J.D. Sun-powered aircraft designs. J. Aircr. 1983, 20, 487–493. [Google Scholar] [CrossRef]

- Salem, M.S.; Zekry, A.; Shaker, A.; Abouelatta, M. Design and simulation of proposed low cost solar cell structures based on heavily doped silicon wafers. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 05-10 June 2016. [Google Scholar] [CrossRef]

- Liller, J.; Goel, R.; Aziz, A.; Hester, J.; Nguyen, P. Development of a battery free, solar powered, and energy aware fixed wing unmanned aerial vehicle. Sci. Rep. 2025, 15, 6141. [Google Scholar] [CrossRef]

- Koszewnik, A.; Oldziej, D. Performance assessment of an energy harvesting system located on a copter. Eur. Phys. J. Spec. Top. 2019, 228, 1677–1692. [Google Scholar] [CrossRef]

- Wei, G.; Bi, Y.; Li, X.; Xu, D.; Xu, W.; Yang, L.J.; Qin, Y.; Guo, H.; Zhao, X.; Chen, X.; et al. Self-powered hybrid flexible nanogenerator and its application in bionic micro aerial vehicles. Nano Energy 2018, 54, 10–16. [Google Scholar] [CrossRef]

- Tao, K.; Chen, Z.; Yi, H.; Zhang, R.; Shen, Q.; Wu, J.; Tang, L.; Fan, K.; Fu, Y.; Miao, J.; et al. Hierarchical honeycomb-structured electret/triboelectric nanogenerator for biomechanical and morphing wing energy harvesting. Nano-Micro Lett. 2021, 13, 1–16. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Q.; Fang, Z.; Zhou, X.; Wang, R.; Zuo, C. Piezoelectric energy harvesting for flapping wing micro air vehicle and flapping wing sensing based on flexible Polyvinylidene Fluoride. Appl. Sci. 2021, 11, 1166. [Google Scholar] [CrossRef]

- Salah, I.; Hafid, T.; Abdelmajid, B.; Ahmed, E.A.; Jaouad, F. Design of a new antenna structure for an RF energy recovery system on a Uav. In Proceedings of the 2019 7th Mediterranean Congress of Telecommunications (CMT), Fez, Morocco, 24-25 October 2019. [Google Scholar] [CrossRef]

- Pandey, G.K.; Gurjar, D.S.; Yadav, S.; Jiang, Y.; Yuen, C. UAV-assisted communications with RF energy harvesting: a comprehensive survey. IEEE Commun. Surv. Tutorials 2024. [Google Scholar] [CrossRef]

- Anton, S.R.; Inman, D.J. Vibration energy harvesting for unmanned aerial vehicles. In Proceedings of the SPIE 6928, U.S.A., 2008. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Ramadan, K.S.; Evoy, D.; Sameoto, S. A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Magoteaux, K.C.; Sanders, B.; Sodano, H.A. Investigation of an energy harvesting small unmanned air vehicle. In Proceedings of the SPIE 6928, Active and Passive Smart Structures and Integrated Systems, San Diego, California, U.S.A.. [CrossRef]

- Anton, S.R.; Erturk, A.; Inman, D.J. Multifunctional unmanned aerial vehicle wing spar for low-power generation and storage. J. of Aircraft 2012, 49. [Google Scholar] [CrossRef]

- Singh, P.; Ansari, M.A.; Bisoi, A. An analytical analysis of vibrational energy harvesting using piezoelectric energy harvester in a fixed wing unmanned aerial vehicle. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 1514–1525. [Google Scholar] [CrossRef]

- Erturk, A.; Renno, J.M.; Inman, D.J. Modeling of piezoelectric energy harvesting from an L-shaped beam-mass structure with an application to UAVs. J. Intell. Mater. Syst. Struct. 2009, 20, 529–544. [Google Scholar] [CrossRef]

- Pozzi, M.; Guo, S.; Zhu, M. Harvesting energy from the dynamic deformation of an aircraft wing under gust loading. In Proceedings of the SPIE 8348, Health Monitoring of Structural and Biological Systems, 2012. [Google Scholar] [CrossRef]

- Erturk, A.; Bilgen, O.; Fontenille, M.; Inman, D.J. Piezoelectric energy harvesting from macro-fiber composites with an application to morphing-wing aircrafts. In Proceedings of the 19th International Conference on Adaptive Structures and Technologies, Ascona, Switzerland, 06-09 October 2008. [Google Scholar]

- Pozzi, M.; Canziani, A.; Durazo-Cardenas, I.; Zhu, M. Experimental characterisation of macro fibre composites and monolithic piezoelectric transducers for strain energy harvesting. In Proceedings of the SPIE 8348, Health Monitoring of Structural and Biological Systems, 2012. [Google Scholar] [CrossRef]

- Atique, M.S.A.; Yang, C.X. Energy harvesting & wing morphing design using piezoelectric macro fiber composites. In Proceedings of the Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition (IMECE2022), Columbus, Ohio, October 30-November 3 2022. [Google Scholar]

- Sharma, S.; Simha, A.; Venkatesha, R.; Gokhale, V.; Narayana, S. Hermes - wind energy harvesting wireless system for sensing AoA and wind speed. IEEE Robot. Autom. Lett. 2021, 6, 7097–7104. [Google Scholar] [CrossRef]

- Astan, N.; Mohammadzamani, D.; Gholami Parashkoohi, M.; Ebrahimi, E. Energy harvesting and ANFIS modeling of a PVDF/GO-ZNO piezoelectric nanogenerator on a UAV. Open Agric. 2024, 9. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, G.; Zeng, H.; Li, Z.; Wu, W.; Jiang, H.; Zhang, W.; Wu, R.; Huang, Y.; Lei, Z. The preparation, structural design, and application of electroactive Poly(vinylidene fluoride)-based materials for wearable sensors and human energy harvesters. Polymers (Basel). 2023, 15. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and applications of the β phase poly(vinylidene fluoride). Polymers (Basel). 2018, 10, 1–27. [Google Scholar] [CrossRef]

- TE Connectivity, LDT with Crimps Vibration Sensor/Switch. Available online: https://www.te.com/commerce/DocumentDelivery/DDEController?Action=showdoc&DocId=Data+Sheet%7FLDT_with_Crimps%7FA1%7Fpdf%7FEnglish%7FENG_DS_LDT_with_Crimps_A1.pdf%7FCAT-PFS0006 (accessed on 11 June 2023).

- Priya, S.; Song, H.C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; et al. A review on piezoelectric energy harvesting: materials, methods, and circuits. Energy Harvest. Syst. 2017, 4, 3–39. [Google Scholar] [CrossRef]

- Tripathi, P.R.; Thakura, P.; Keshri, R.K.; Ghosh, S.; Guerrero, J.M. Twenty-five years of single-stage buck-boost inverters: development and challenges. IEEE Ind. Electron. Mag. 2022, 16, 4–10. [Google Scholar] [CrossRef]

- Restrepo, C.; Gonzalez-Castano, C.; Giral, R. The Versatile Buck-Boost Converter as Power Electronics Building Block: Changes, Techniques, and Applications. IEEE Ind. Electron. Mag. 2023, 17, 36–45. [Google Scholar] [CrossRef]

- Analog Devices, LTC3588-1 – Nanopower Energy Harvesting Power Supply. Available online: https://www.analog.com/en/products/ltc3588-1.html#part-details (accessed on 01 November 2024).

| Output voltages (V) | Cout | Pgood | ||

| cycles | time (s) | |||

| 1.5 | simulation | 2 | 47.7 | 64.1 |

| experimental | 2 | 54 | 71 | |

| 2.5 | simulation | 4 | 47.7 | 97 |

| experimental | 4 | 45 | 105 | |

| 3.3 | simulation | 5 | 60 | 133 |

| experimental | 5 | 60 | 165 | |

| 3.6 | simulation | 5 | 64.5 | 138.6 |

| experimental | 6 | 60 | 162 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).