Submitted:

22 October 2025

Posted:

23 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

3. Objective

4. Methodology

- Field observations at 12 vertical construction sites in São Paulo (Aug 2022 - Mar 2023). The fieldwork aimed to assess real-world differences between corded and cordless power tools based on Operational Efficiency, Safety and Ergonomics, Energy Usage and Battery Logistics, Tool Durability, Maintenance, Worker behavior, and preferences.

- Conducted semi-structured interviews with 18 site managers and safety technicians, using both open-ended questions and scaled response options (see Appendix A);

- Document analysis of manufacturer specifications and regulatory audits to validate observations; and

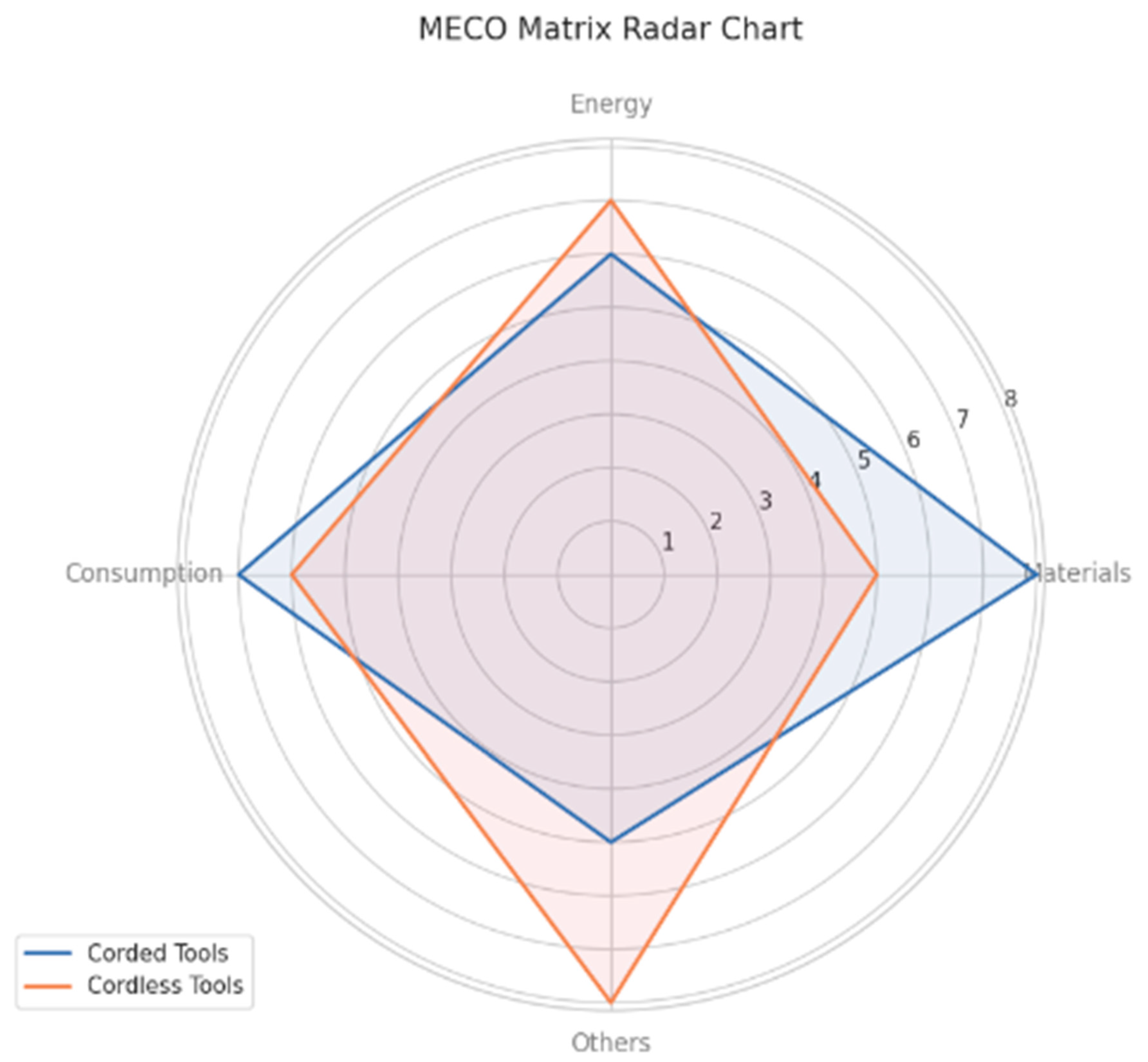

- MECO Matrix Application to compare the environmental consequences of corded vs. cordless tools. The MECO (Materials, Energy, Consumption, Others) matrix is a sustainability analysis tool used to systematically evaluate the resource and energy flows, material inputs, along with other consequences throughout a product's lifecycle.

5. Results and Discussions

5.1. Operational Performance

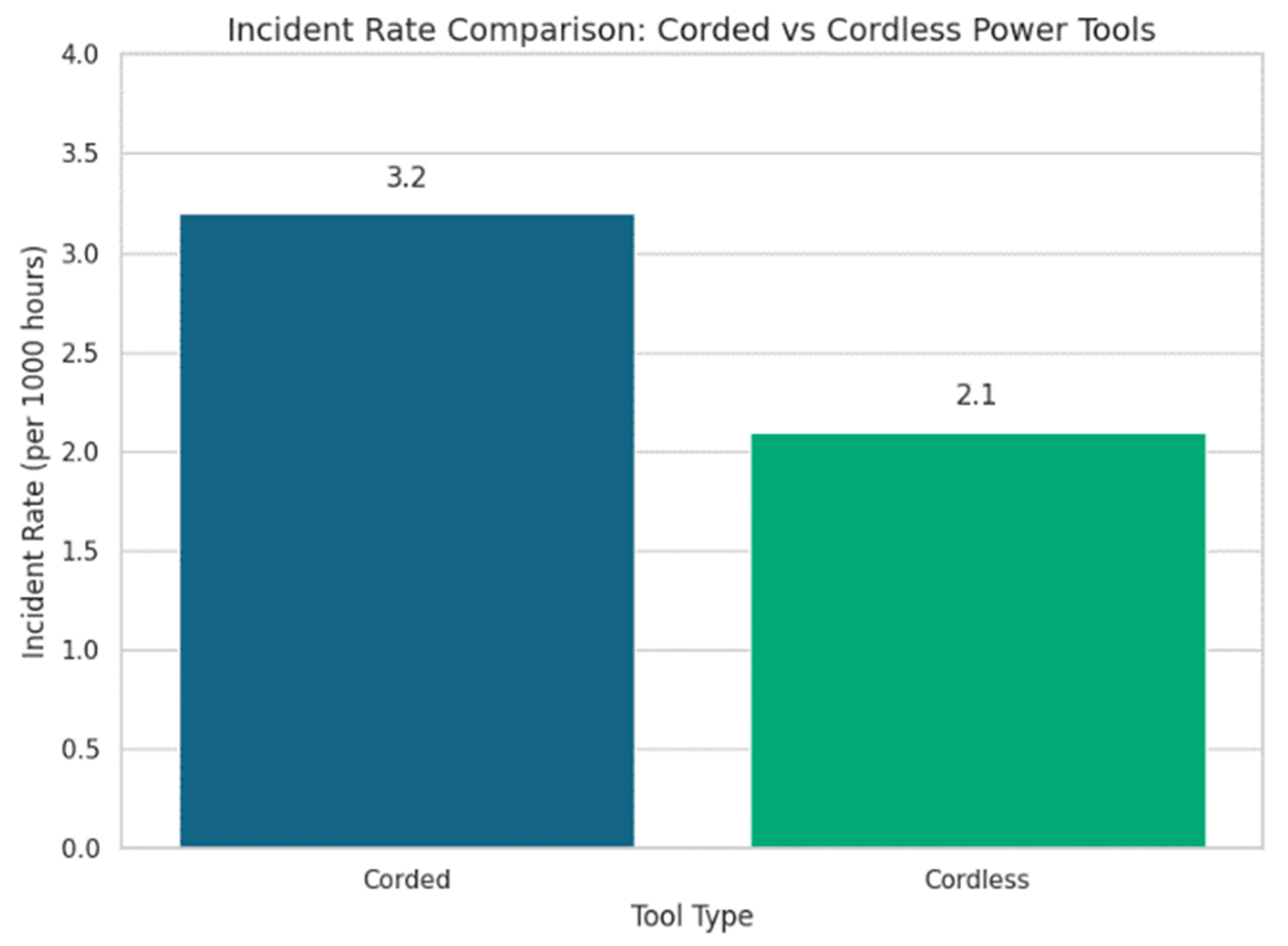

| METRIC | CORDED TOOLS | CORDLESS TOOLS |

|---|---|---|

| Daily Usage (avg) | 5.8 hours | 6.5 hours |

| Downtime due to wiring | 32 min/day | 14 min/day |

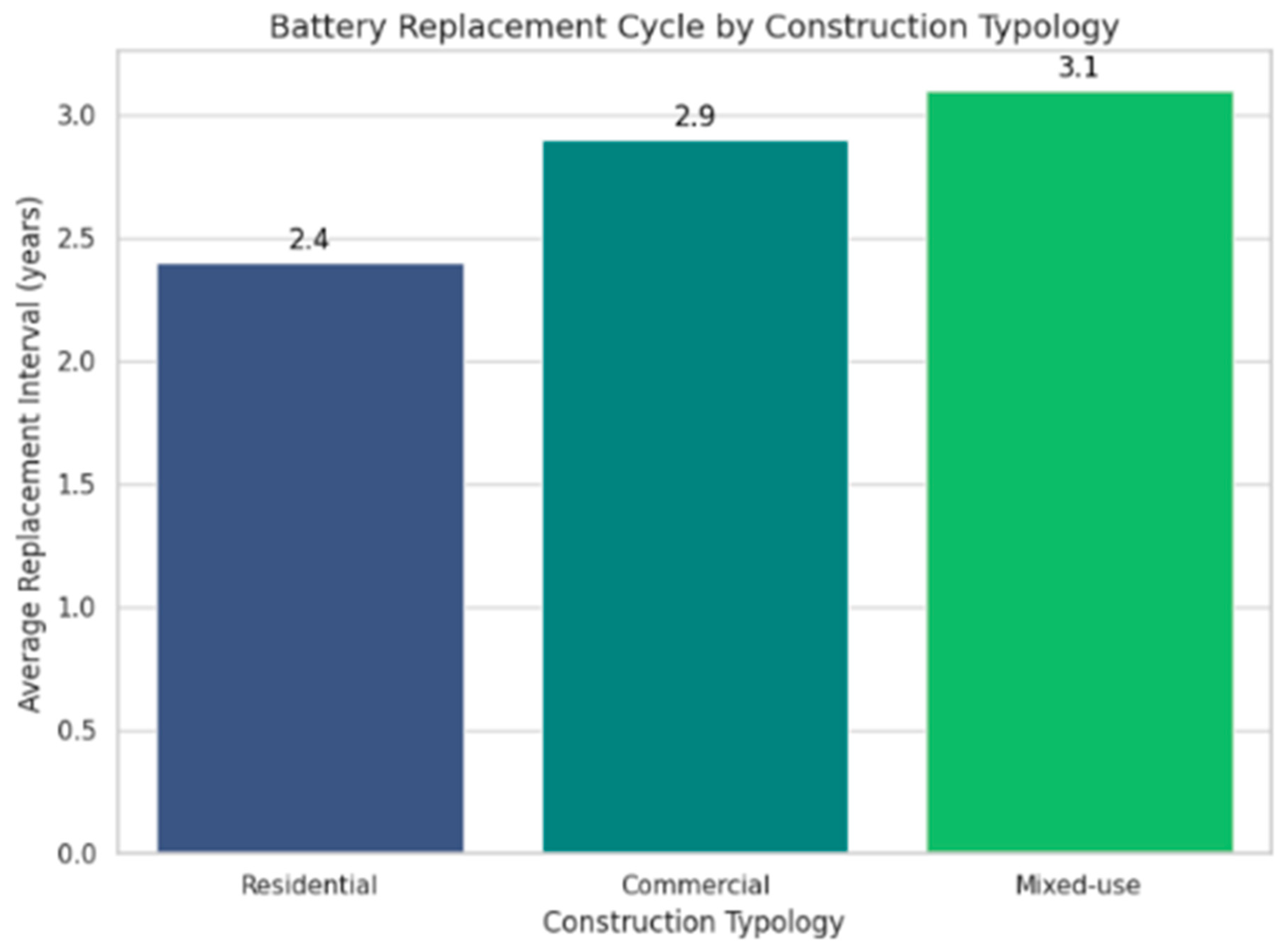

| Battery Replacement Cycle | N/A | 2.8 years |

| Incident Rate (monthly avg) | 4.2 incidents/site | 3.2 incidents/site |

5.2. Environmental Impact (MECO Matrix)

6. Conclusion

Funding

Acknowledgements

| Appendix A. SURVEYS | ||

| TOOL OPERATORS – Survey & Scoring | ||

| Question | Scale Description | |

| How easy is it to use cordless tools compared to corded ones? | 1 = Much harder, 5 = Much easier | |

| How often do you experience battery-related interruptions? | 1 = Very often, 5 = Never | |

| How safe do you feel using cordless tools? | 1 = Very unsafe, 5 = Very safe | |

| How frequently do you replace batteries or repair cordless tools? | 1 = Weekly, 5 = Rarely | |

| How much physical strain do you feel using corded tools? | 1 = Very high, 5 = None | |

| Which tool type feels more efficient for your tasks? | 1 = Strongly prefer corded, 5 = Strongly prefer cordless | |

| SITE MANAGERS – Survey & Scoring | ||

| Question | Scale Description | |

| How do cordless tools impact overall workflow efficiency? | 1 = Negative impact, 5 = Strong positive impact | |

| How do battery replacements affect scheduling and budget? | 1 = Major disruption, 5 = No impact | |

| How often do incidents occur with corded tools vs. cordless tools? | 1 = Corded far worse, 5 = Cordless far worse | |

| How aligned are cordless tools with your sustainability goals? | 1 = Not aligned, 5 = Fully aligned | |

| Are you considering transitioning to cordless tools exclusively? | 1 = Not at all, 5 = Definitely | |

| Source: Prepared by the Author | ||

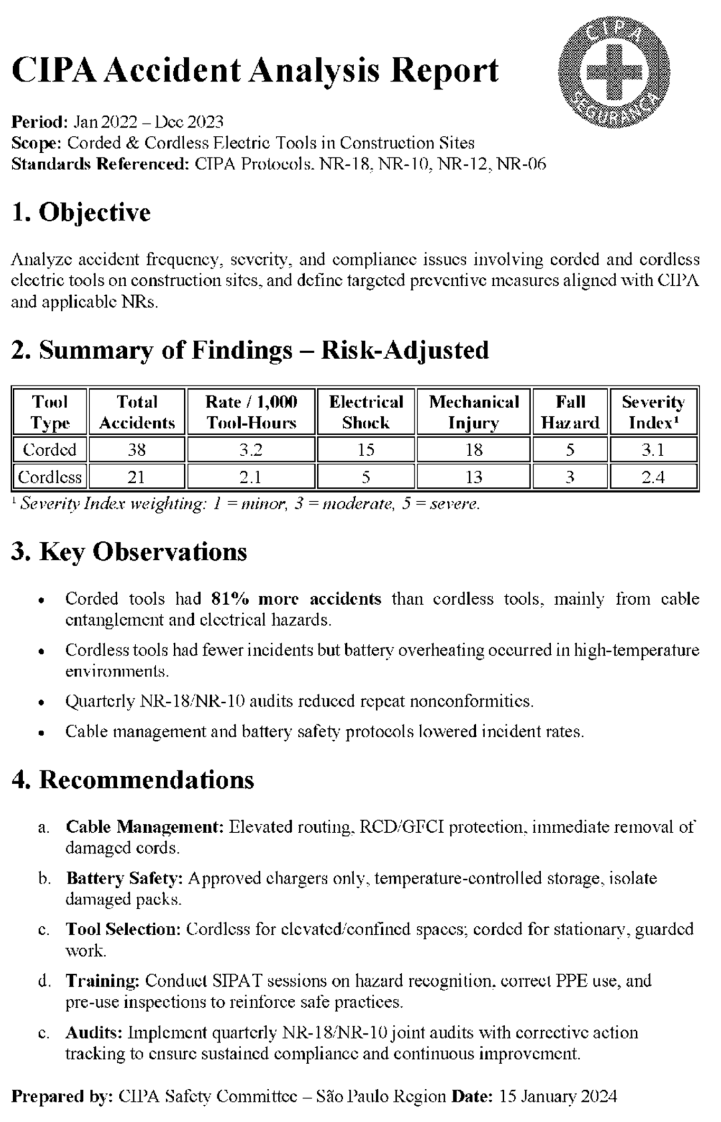

Appendix B. CIPA REPORT OF ACCIDENTS

| Appendix C. BATTERY COMPOSITION AND RECYCLING POTENTIAL | |||||||||

| COMPONENT | % BY WEIGHT | RECYCLABILITY | SOURCE | ||||||

| Lithium | 18% | High | (IEA, 2023) | ||||||

| Cobalt | 12% | Moderate | (USGS, 2022) | ||||||

| Nickel | 10% | High | (ABAL, 2021) | ||||||

| Graphite | 25% | Low | (World Bank, 2020) | ||||||

| Others | 35% | Variable | (ANFAVEA, 2022) | ||||||

| Appendix D. FIELD DATA FROM SÃO PAULO CONSTRUCTION SITES | |||||||||

| METRIC | VALUE | SOURCE | |||||||

| Average daily tool usage | 6.5 hours | Site interviews base on Appendix A | |||||||

| Battery replacement cycle | 2.8 years | Field survey (2022–2023) | |||||||

| Accident reduction (cordless) | 45% fewer incidents | (CIPA, 2023) | |||||||

| Energy cost for charging tools | R$ 0.72/kWh | (ANEEL, 2021) | |||||||

| Tool downtime due to wiring | 18 minutes/day | Observational study | |||||||

| Appendix E. MECO MATRIX DATA INPUTS | |||||||||

| DIMENSION | CORDED TOOLS | CORDLESS TOOLS | SOURCE | ||||||

| Materials | Steel, copper, plastic | Lithium-ion, rare earths | (Bosch, 2023; DeWalt, 2023; Makita, 2023) | ||||||

| Energy | Grid electricity | Rechargeable, solar-compatible | (ANEEL, 2021) | ||||||

| Consumption | 5–7 years | 3–5 years | (Bosch, 2023; DeWalt, 2023; Makita, 2023) | ||||||

| Others | Tripping hazards | Ergonomic benefits | (CIPA/MTE, 2022) | ||||||

References

- ABAL. (2021). Relatório anual da indústria de alumínio no Brasil. Associação Brasileira Do Alumínio. https://abal.org.br/comunicacao-abal/publicacoes/anuarios-e-relatorios/.

- ANEEL. (2021). Tarifas de energia elétrica por distribuidora. Agência Nacional de Energia Elétrica. https://www.gov.br/aneel/pt-br/assuntos/tarifas.

- ANFAVEA. (2022). Anuário da Indústria Automobilística Brasileira 2022. São Paulo: ANFAVEA. Associação Nacional Dos Fabricantes de Veículos Automotores. https://anfavea.com.br/anuario2022/2022.pdf.

- Bosch. (2023). Especificações técnicas de ferramentas elétricas [Catálogo do fabricante]. Bosch Professional. https://www.bosch-professional.com/br/pt/servicos/downloads/catalogos/.

- CIPA. (2023). Relatório comparativo de acidentes com ferramentas elétricas com fio e sem fio: Dados de 2022–2023. Ministério do Trabalho e Emprego, Brasil. Comissão Interna de Prevenção de Acidentes. https://www.gov.br/trabalho-e-emprego/pt-br/acesso-a-informacao/participacao-social/conselhos-e-orgaos-colegiados/comissao-tripartite-partitaria-permanente/normas-regulamentadora/normas-regulamentadoras-vigentes/norma-regulamentadora-no-5-nr-5.

- CIPA/MTE. (2022). Auditorias da Norma Regulamentadora no 18 (NR-18): Segurança e saúde no trabalho na indústria da construção. Governo Federal do Brasil. NR-18. https://www.gov.br/trabalho-e-emprego/pt-br/acesso-a-informacao/participacao-social/conselhos-e-orgaos-colegiados/comissao-tripartite-partitaria-permanente/normas-regulamentadora/normas-regulamentadoras-vigentes/norma-regulamentadora-no-18-nr-18.

- DeWalt. (2023). Especificações técnicas de ferramentas elétricas [Catálogo do fabricante]. DEWALT Brasil. https://br.dewalt.global/suporte/catalogos.

- EC. (2025, March 24). Questions and Answers on the Strategic Projects under the Critical Raw Materials Act. https://ec.europa.eu/commission/presscorner/detail/it/qanda_25_865.

- Farjana, S. H., Huda, N., & Mahmud, M. A. P. (2019). Life cycle assessment of cobalt extraction process. Journal of Sustainable Mining, 18(3), 150–161. [CrossRef]

- Griffin, J., & Sauer, H. (2023, November 15). Trending to Cordless Tools: Manufacturers talk the benefits and innovations of batteries - Electrical Contractor Magazine. https://www.ecmag.com/magazine/articles/article-detail/trending-to-cordless-tools-manufacturers-talk-the-benefits-and-innovations-of-batteries.

- Guzzo, D., Rodrigues, V. P., & Mascarenhas, J. (2021). A systems representation of the Circular Economy: Transition scenarios in the electrical and electronic equipment (EEE) industry. Technological Forecasting and Social Change, 163. [CrossRef]

- Horizon. (2023). Brazil Power Tools Market Size & Outlook, 2030. Grand View Horizon. https://www.grandviewresearch.com/horizon/outlook/power-tools-market/brazil.

- Koese, M., Parzer, M., Sprecher, B., & Kleijn, R. (2025). Self-sufficiency of the European Union in critical raw materials for E-mobility. Resources, Conservation and Recycling, 212, 108009. [CrossRef]

- Kumar, G. R., Bezawada, S. T., Sinno, N., & Ammoun, M. (2019). The impact of ergonomics on employees’ productivity in the architectural workplaces. International Journal of Engineering and Advanced Technology, 8(5), 1122–1132. [CrossRef]

- Oh, S. A., & Radwin, R. G. (1997). The effects of power hand tool dynamics and workstation design on handle kinematics and muscle activity. International Journal of Industrial Ergonomics, 20(1), 59–74. [CrossRef]

- Volínová, L. (2011). Environmental Assessment using MECO Matrix – Case Study. Intensive Programme “Renewable Energy Sources” May 2011, Železná Ruda-Špičák, University of West Bohemia, Czech Republic, Intensive Programme “Renewable Energy Sources.”.

- World Bank. (2017). The Growing Role of Minerals and Metals for a Low Carbon Future. https://documents.worldbank.org/en/publication/documents-reports/documentdetail/207371500386458722/the-growing-role-of-minerals-and-metals-for-a-low-carbon-future.

- World Bank. (2020). Minerals for Climate Action : The Mineral Intensity of the Clean Energy Transition. https://documents.worldbank.org/en/publication/documents-reports/documentdetail/099052423172525564/p16627806f5aa400508f8c0bdcba0878a3e.

| Dimension | Corded Tools | Cordless Tools |

|---|---|---|

| Materials | Steel, copper, plastic | Lithium-ion, cobalt, graphite |

| Energy | Continuous grid use | Rechargeable, solar-compatible |

| Consumption | 5–7 years lifespan | 3–5 years (battery-dependent) |

| Others | High accident risk | Improved ergonomics, lower noise |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).