1. Introduction

As semiconductor manufacturing advances into sub-micron and nanometer scales, the need for accurate surface profile prediction during plasma processing becomes increasingly critical. Both plasma etching and deposition processes involve complex surface dynamics, including chemical reactions with reactive radicals, physical sputtering from energetic ions, surface passivation, and geometry-dependent effects. These phenomena are often governed by parameters such as reaction probabilities, sputtering yields, angular distributions, and sticking coefficients, many of which are difficult to measure experimentally and vary significantly across different material systems and process conditions.

To address this challenge, we present SimProfile, a Monte Carlo-based surface profile simulator designed to model both etching and deposition processes within a unified computational framework. SimProfile captures the stochastic nature of plasma-surface interactions by simulating the trajectories and reactions of individual particles, enabling high-resolution modeling of anisotropic and selective profile evolution.

A key feature of SimProfile is its data-driven parameter tuning system, which allows automatic calibration of uncertain model parameters using experimental measurements such as scanning electron microscopy (SEM) images of etched or deposited structures. At the core of this system is a Gaussian Process (GP)-based Bayesian optimization framework, implemented via the scikit-optimize library [

1]. Unlike manual trial-and-error or grid-based parameter sweeps, GP optimization constructs a probabilistic surrogate model of the objective function, typically defined as the discrepancy between simulated and experimental profiles and iteratively selects new parameter sets that minimize this loss. By balancing exploration and exploitation through acquisition functions such as Expected Improvement, the method efficiently searches high-dimensional parameter spaces while minimizing computational cost. This approach significantly reduces human intervention and enhances the reliability and reproducibility of simulation-based process modeling.

In this study, we introduce the architecture and workflow of SimProfile, describe the underlying Monte Carlo physical modeling approach, and detail the implementation of the GP-based Bayesian optimization framework for parameter calibration. The methodology is demonstrated using an plasma etching case study, where SimProfile successfully reproduces experimental trench profiles with high fidelity. Beyond this example, the framework is extensible to a wide range of etching and deposition systems, establishing SimProfile as a general-purpose, data-calibrated simulator for advancing predictive plasma process modeling.

2. Experimental Methods

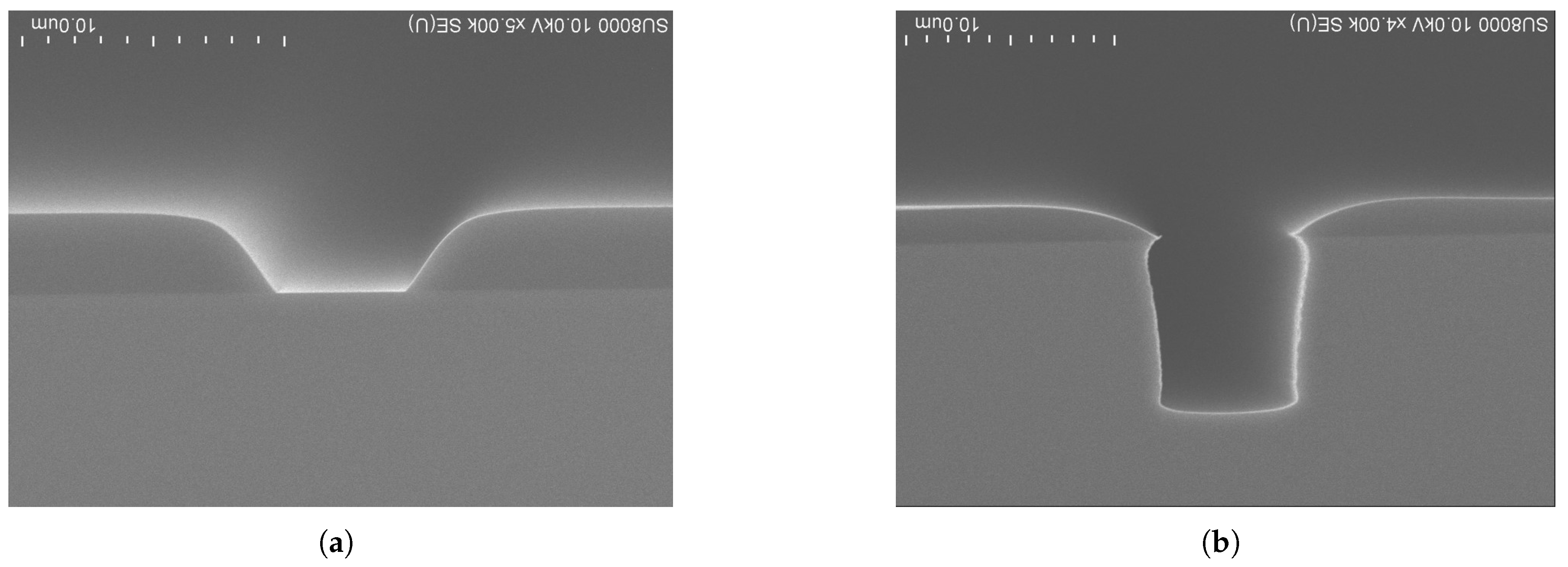

The experiments were conducted using an ULVAC NE-550 inductively coupled plasma (ICP) etching system. The substrates were silicon wafers patterned with photoresist-defined trenches using standard photolithography techniques. The etching gases consisted of sulfur hexafluoride () and oxygen (), with flow rates fixed at 20 sccm for both species. The chamber pressure was maintained at 2 Pa throughout the process.

The plasma was generated with an ICP source power of 500 W, while the substrate bias was controlled via a 20 W pulsed RF (PF) bias. The electrostatic chuck (ESC) was temperature-controlled and maintained at 20 °C during etching. The total process time was set to 300 seconds. A summary of the etching recipe is provided in

Table 1.

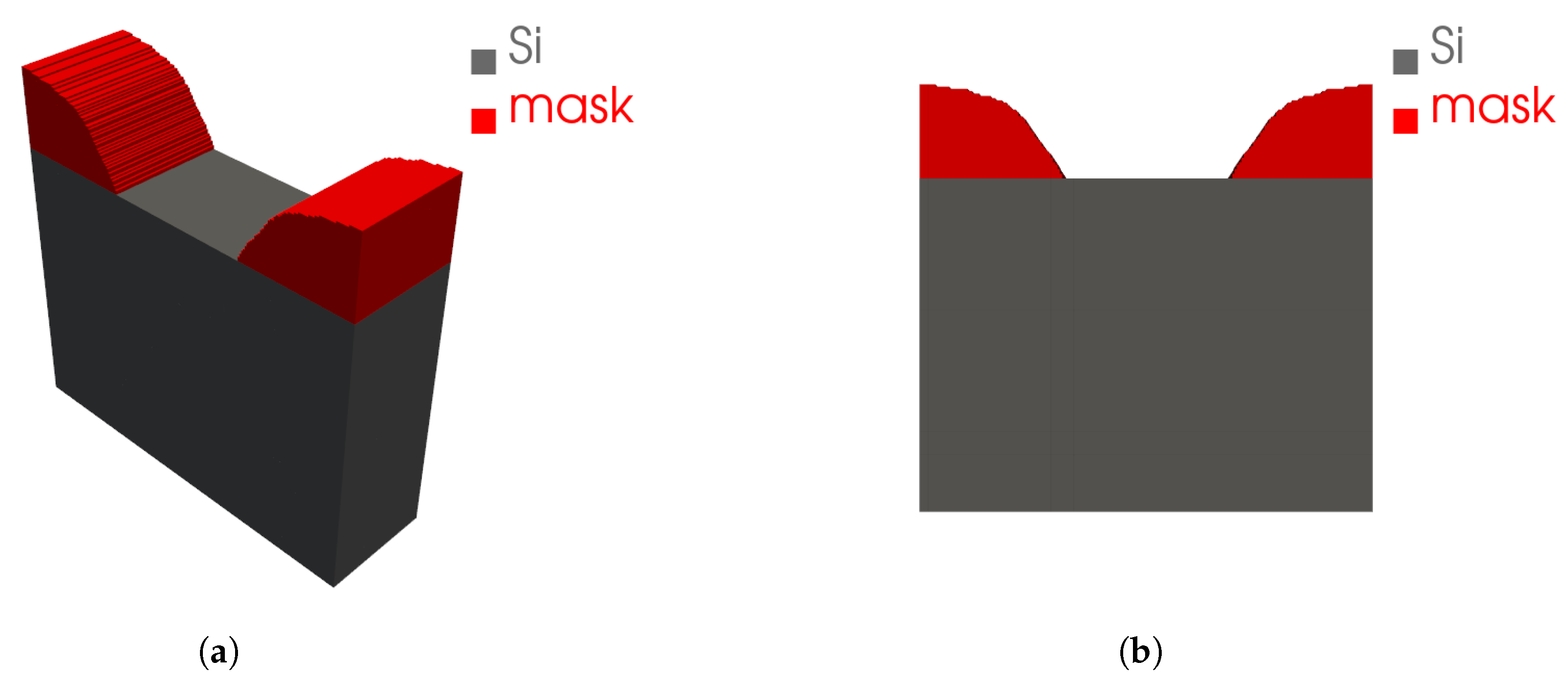

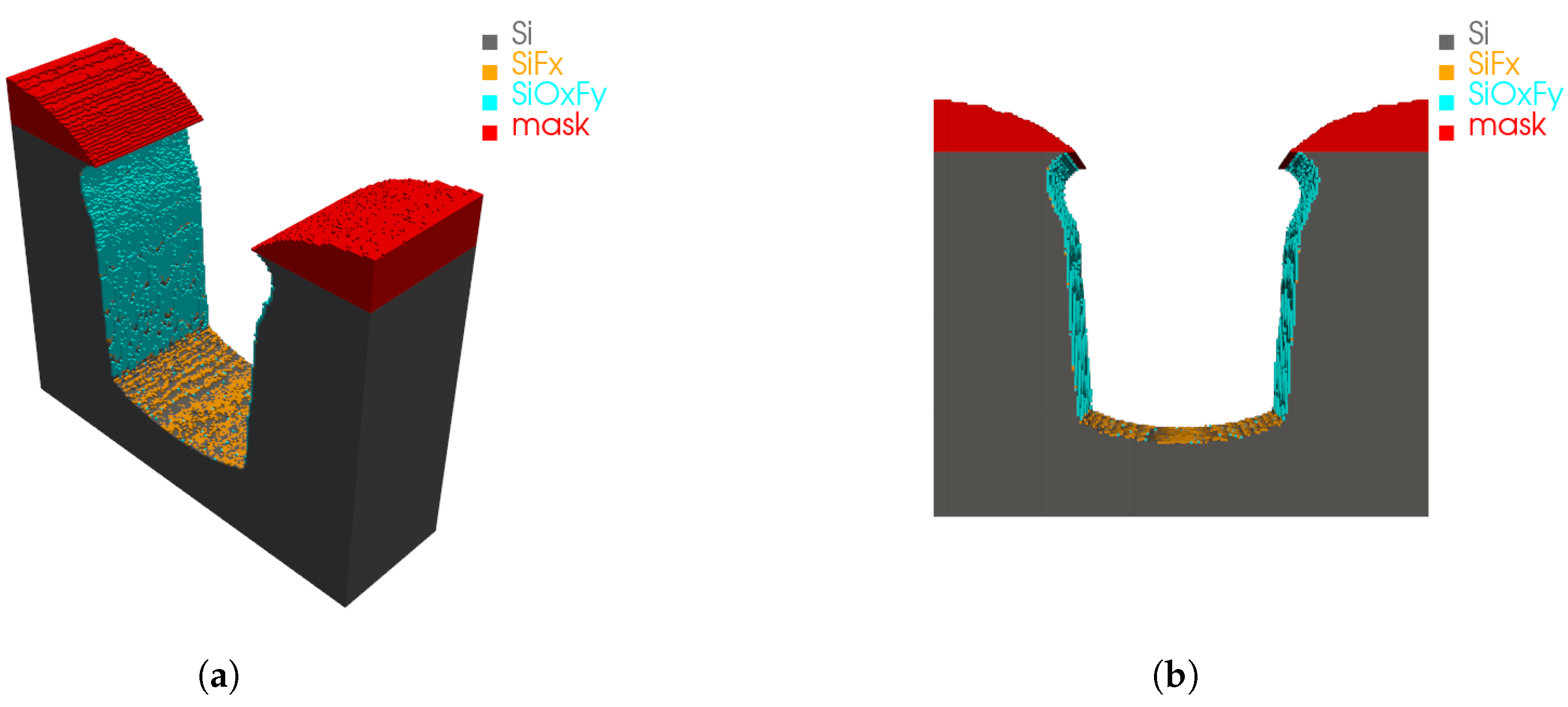

Prior to etching, scanning electron microscopy (SEM) was used to characterize the patterned photoresist trenches, as shown in

Figure 1(

a). After plasma exposure, the etched trench profiles were similarly imaged to evaluate the etching behavior, as shown in

Figure 1(

b).

3. Surface Profile Simulation

SimProfile adopts a traditional cell-based model [

2] to represent material occupancy in space, as commonly used in Monte Carlo profile simulators. The computational domain is discretized into a 3D grid of cells, where each cell holds a state variable: a value of 1 indicates the presence of solid material, and 0 represents a gas-phase (vacuum) region. The temporal evolution of the surface is modeled by tracking the trajectories and interactions of individual gas-phase particles as they propagate toward and interact with solid-phase cells.

In the current implementation, gas-phase collisions are neglected, assuming a free molecular regime. When a gas-phase particle enters a solid cell, a probabilistic reaction model is invoked to determine whether a chemical or physical interaction occurs. The relevant reactions and their associated rules are listed in

Table 2.

Chemical reactions are primarily governed by the energy threshold of the incident particle and are assumed to be independent of the incidence angle. These reactions include processes such as silicon-fluorine etching or deposition from precursor radicals. In contrast, physical interactions, such as ion-induced sputtering, are strongly dependent on the incidence angle due to the angular nature of the sputter yield . However, reliable sputtering yield data for different materials (e.g., Si, mask, oxide) and ion species under a wide range of conditions is limited in the literature.

SimProfile employs an empirical sputtering yield model [

3], described by Eq.

1, which captures the angular dependence of sputtering yields. The model parameters

,

f, and

are material-specific and can be adjusted to fit experimental data. This model effectively represents the increase in sputter yield at oblique angles, peaking at

, followed by a decrease at grazing angles due to reflection effects.

If a gas-phase particle encounters a solid cell and no reaction occurs, it is reflected. The reflection behavior is determined based on the surface material type and is governed by a hybrid reflection model combining specular and diffuse (Maxwellian) components. The probability of each mode is controlled by a simplified material-independent reflection coefficient in

Table 2. This coefficient is critical in shaping profile features such as undercut beneath the mask, as it influences the lateral flux of reflected particles toward the sidewalls.

4. Data-Driven Parameter Calibration

To achieve quantitative agreement between simulation and experiment, SimProfile integrates a Bayesian optimization framework based on Gaussian Process (GP) regression, implemented via the scikit-optimize library. Unlike manual trial-and-error or grid-based parameter sweeps, Bayesian optimization efficiently balances exploration and exploitation by constructing a probabilistic surrogate model of the objective function and iteratively selecting promising parameter configurations.

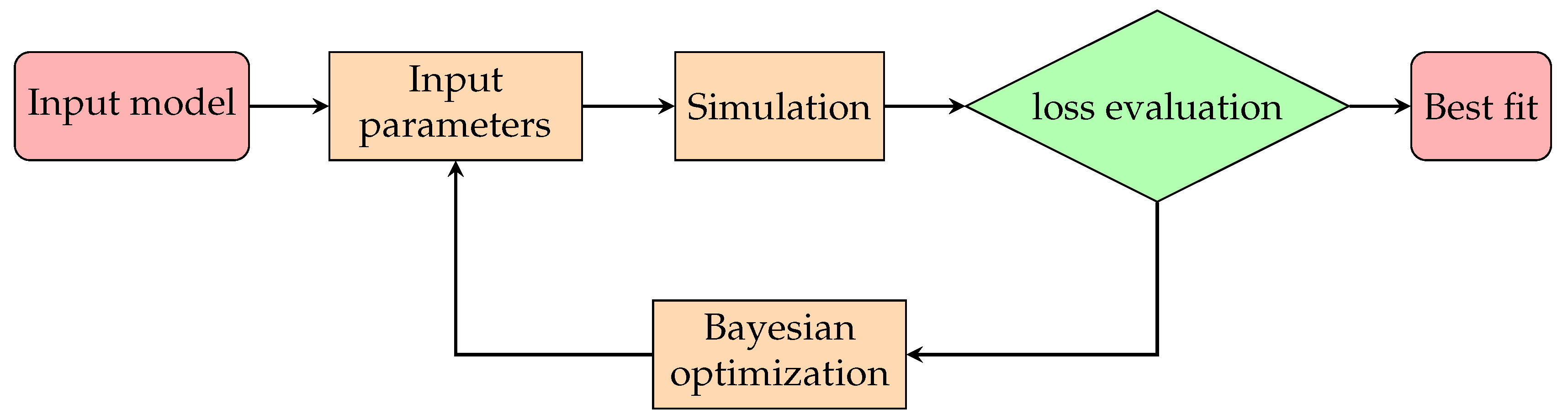

The parameter calibration workflow is illustrated in

Figure 2. First, the initial photoresist mask profile is extracted from experimental SEM images and converted into the cell-based simulation domain (see

Figure A1(a),(b)). A set of tunable parameters—such as sputtering yield coefficients, angular reflection ratios, and chemical reaction probabilities—are defined with prior ranges (listed in

Table 2). These parameters constitute the search space for the optimization process.

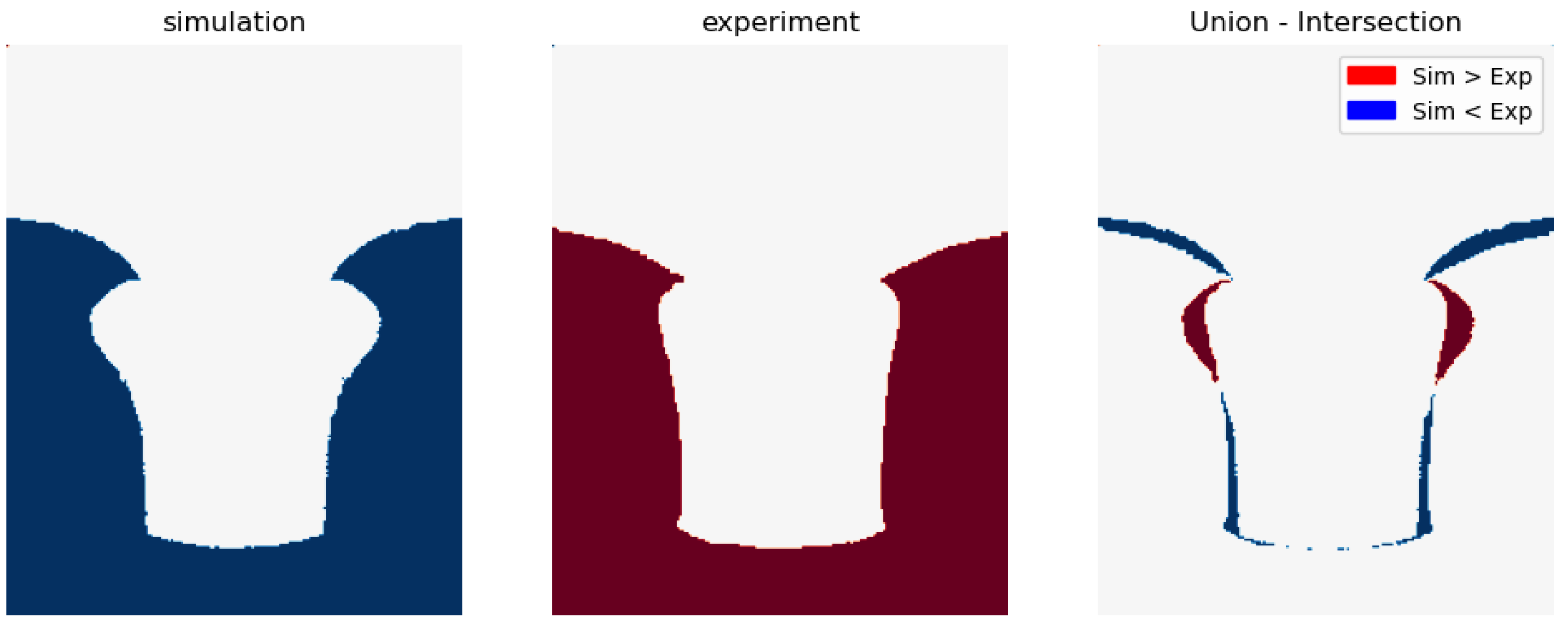

Following each simulation run, the resulting surface profile is quantitatively evaluated through a loss function inspired by the Intersection-over-Union (IoU) metric widely used in computer vision. Specifically, the loss is formulated as the union minus intersection between the simulated and experimental profiles, as depicted in

Figure 3. The evaluated loss is subsequently fed into the Gaussian Process (GP) optimizer implemented in scikit-optimize (gp_minimize), which adaptively updates the parameter set in an iterative manner to minimize the discrepancy between the simulated and experimental profiles.

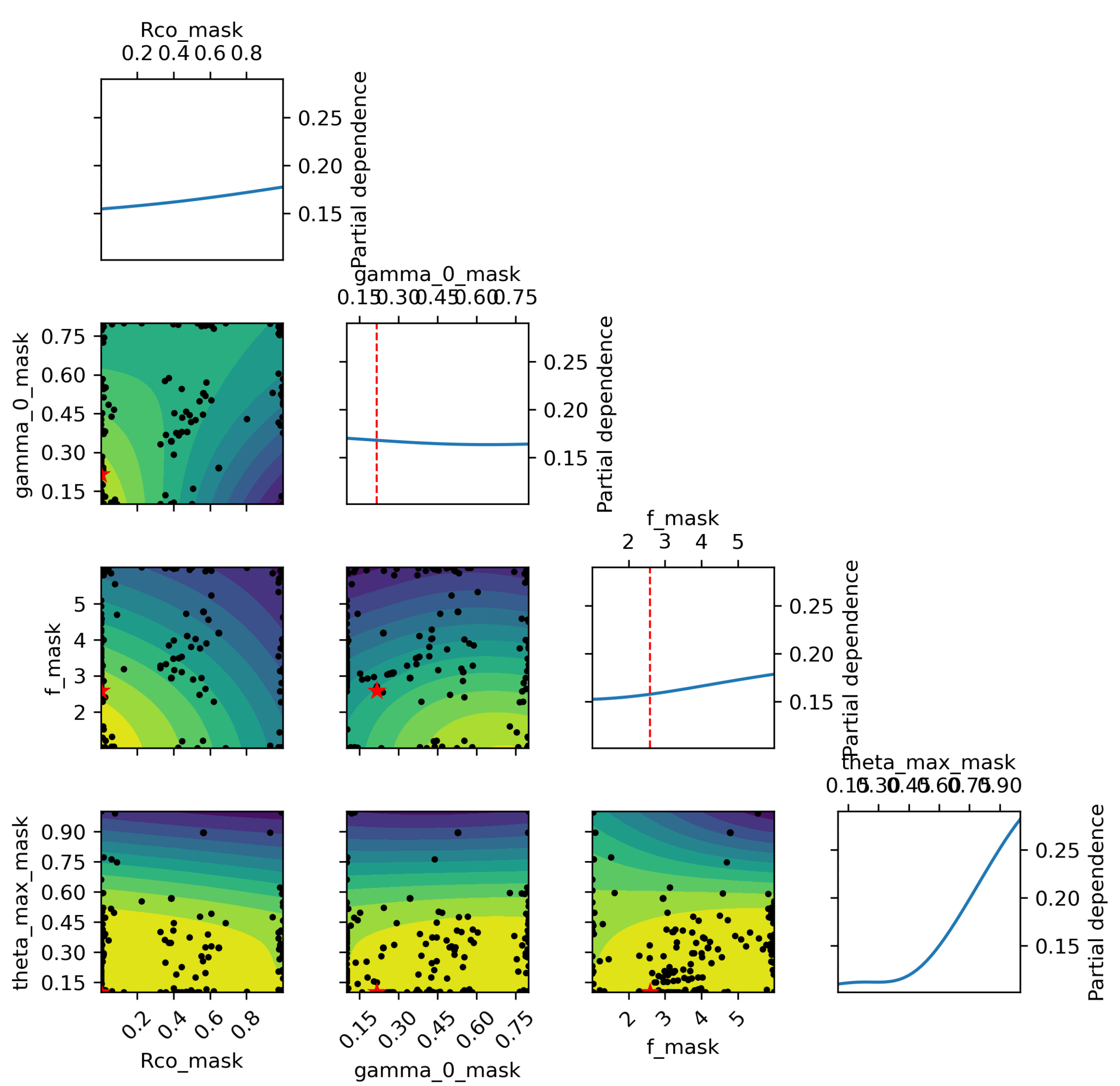

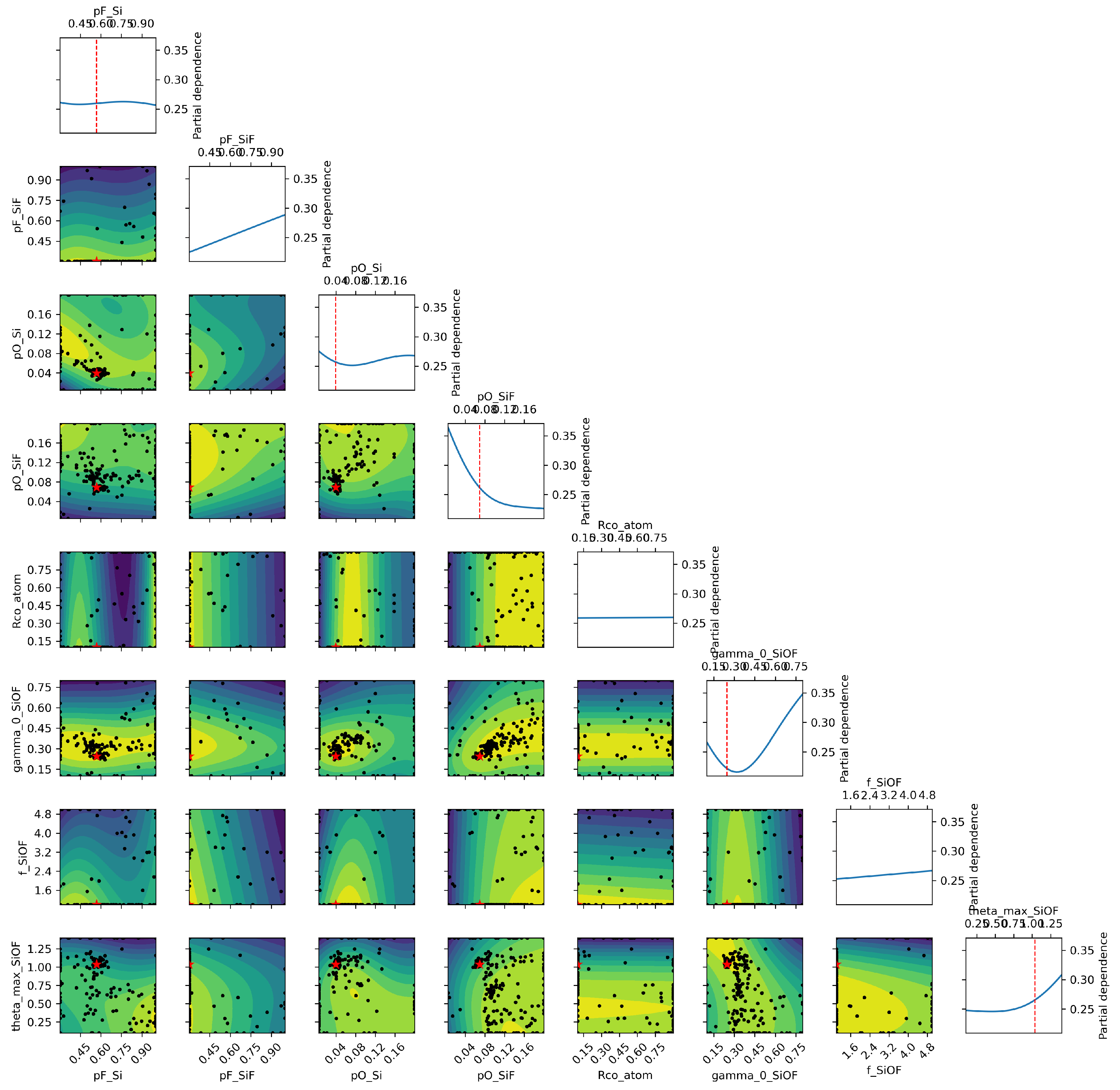

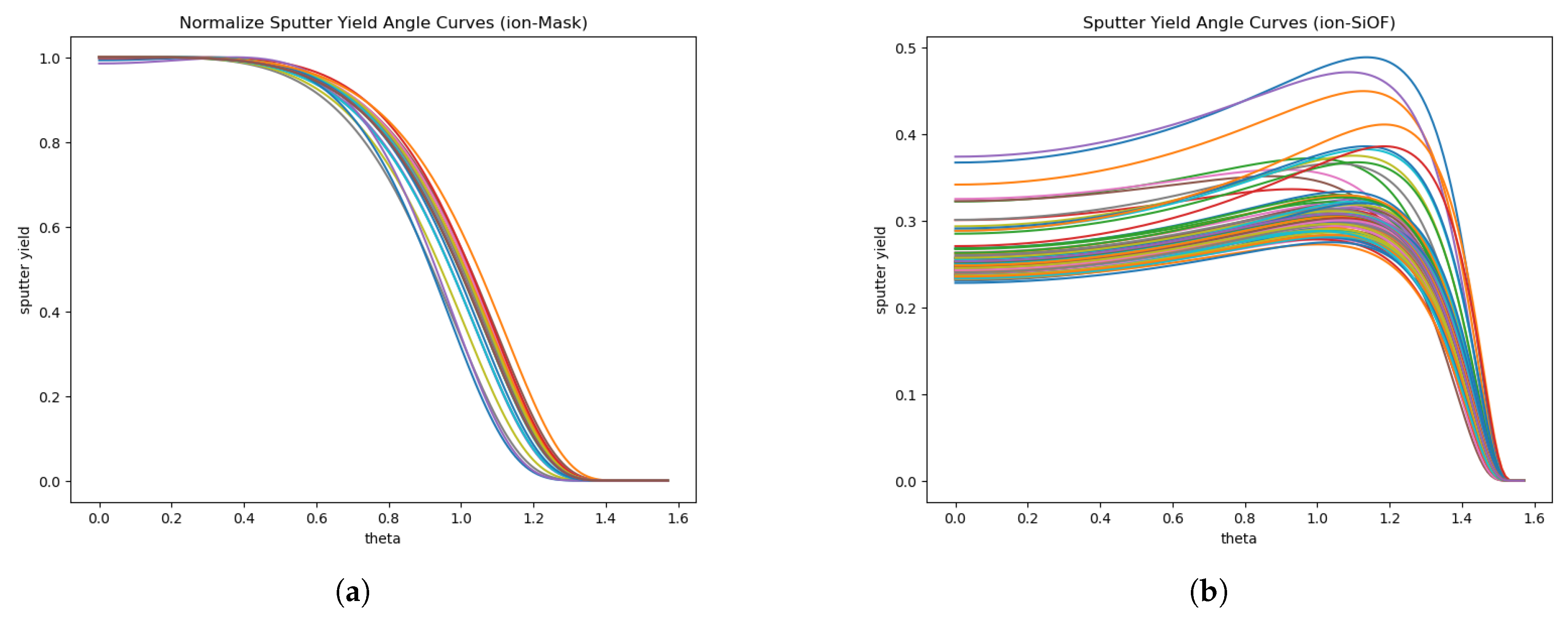

Because the etching behavior of the photoresist mask is predominantly governed by ion bombardment, the parameter fitting is carried out in two stages. In the first stage, we focus on calibrating the sputtering yield parameters of the mask material under ion incidence. The fitted angular dependence of the normalized sputtering yield is shown in

Figure 4(a), revealing that the mask yield gradually decreases beyond an incidence angle of approximately 45°. In the second stage, the optimized mask sputter-yield parameters are fixed, and the remaining parameters which are related to Si and SiOF reactions are tuned to reproduce the etched trench profiles. This stage determines key morphological features such as the etch depth and the extent of undercut formation. We found that the sputtering yield of SiOF plays a dominant role in shaping the final profile, with the effective yield peaking in the 60°-80° angular range shown in

Figure 4(b).

During the optimization process, the Gaussian Process (GP) optimizer models the relationship between simulation parameters and the corresponding loss values obtained from each iteration. By constructing a probabilistic surrogate of the objective landscape, GP optimization balances exploration of uncertain regions and exploitation of promising parameter areas. The acquisition function—such as Expected Improvement (EI)—determines the next sampling point based on both predicted mean and uncertainty, allowing the optimizer to efficiently approach the global optimum with relatively few evaluations.

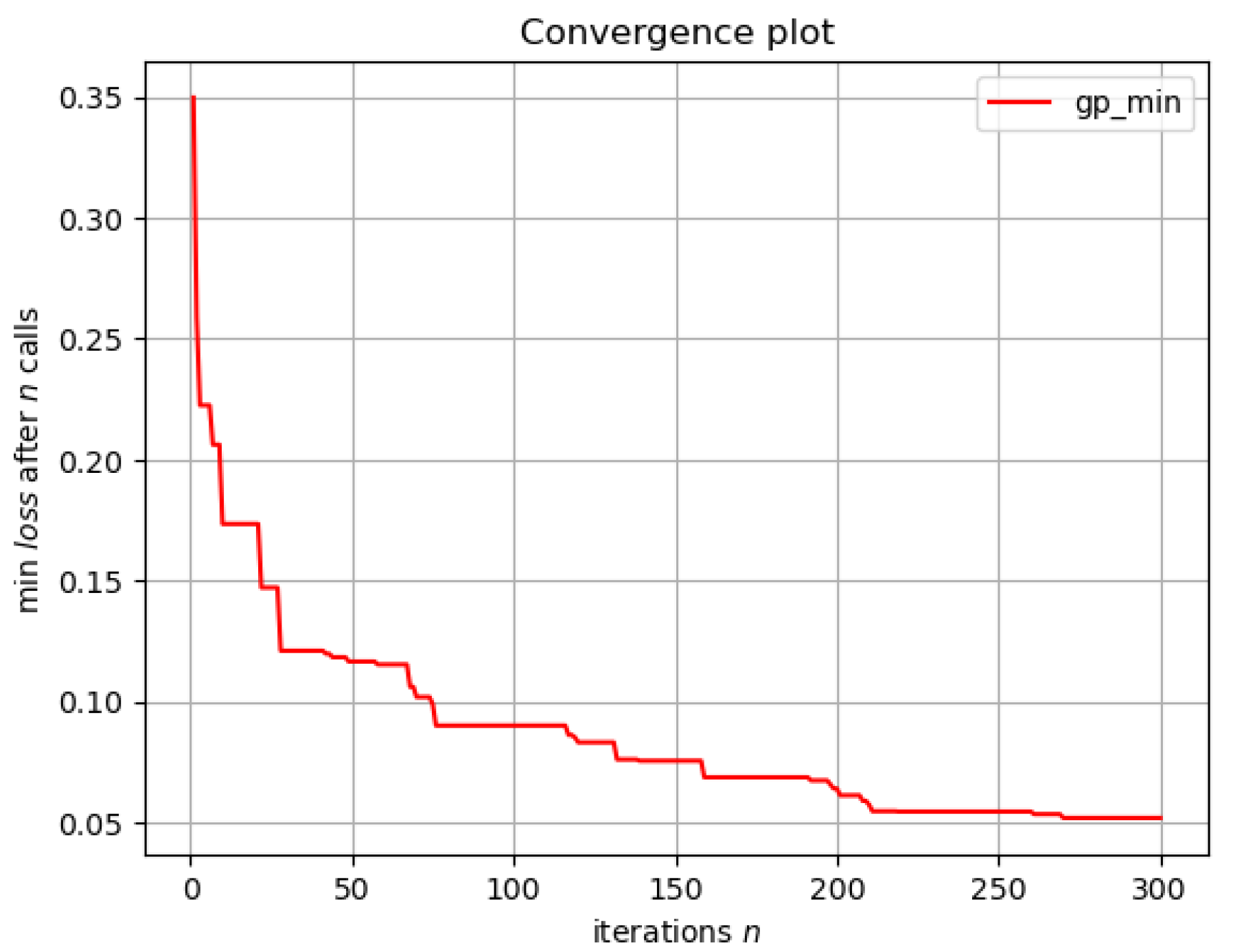

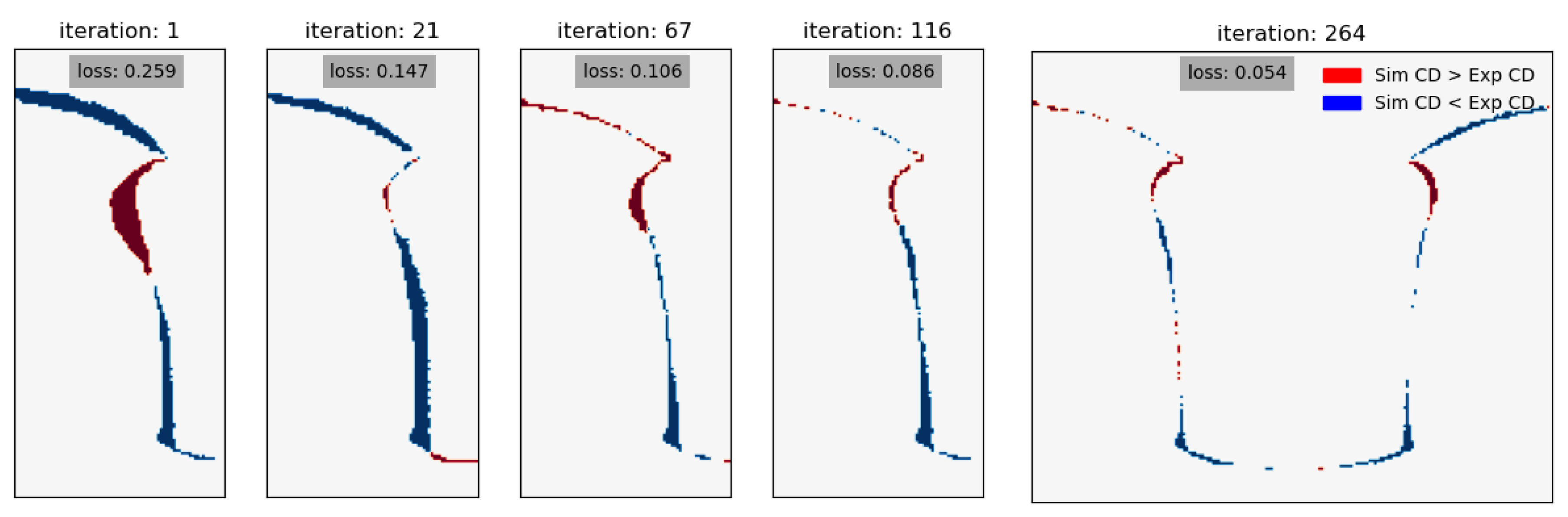

As shown in

Figure 5, the optimization converges rapidly, yielding the best-fit parameter set within approximately 260 iterations. The evolution of the loss (IoU-based similarity) across iterations is plotted in

Figure 6, illustrating the steady improvement in the agreement between simulated and experimental profiles. Thanks to the multi-threaded computation architecture of SimProfile, each iteration takes only about 3-4 minutes, allowing the entire 300 iterations optimization to complete within roughly 15 hours.

To further interpret the optimization process, Partial Dependence Plots (PDPs) are employed to visualize the marginal influence of each parameter on the loss function while averaging over others (

Figure A2,

Figure A3). In total, 300 parameter points were evaluated to assess sensitivity. The parameter set marked with a star corresponds to the best-fit case (

Figure 7(a),(b)). The slopes of the PDP curves indicate that the reflection coefficient contributes only marginally to loss variation, whereas sputtering-yield-related parameters—such as

and

exert a dominant influence.

This combination of Monte Carlo simulation, Bayesian optimization, and PDP-based interpretability enables SimProfile not only to match experimental results with minimal human intervention but also to provide clear physical insight into the parameter dependencies underlying complex plasma-surface interactions.

5. Conclusions

SimProfile is a precise, fast, and customizable Monte Carlo surface simulator capable of modeling the complex chemical and physical reactions involved in both etching and deposition processes. Its multicore parallel implementation provides the computational efficiency required for iterative parameter optimization. By employing Gaussian Process-based hyperparameter optimization, we demonstrated how reliable process parameters can be extracted even in cases where detailed reaction data are unavailable. Specifically, by comparing simulated and experimental profiles through an intersection-based loss function, the method successfully identifies key parameters for the challenging silicon etching system. This data-driven framework can be readily extended to other plasma etching and deposition chemistries, offering a powerful tool for both understanding the underlying physicochemical mechanisms and guiding process window discovery in semiconductor manufacturing.

Appendix A

Figure A1.

initial profile.

Figure A1.

initial profile.

Figure A2.

Partial Dependence Plots (Mask-Ion sputter yield).

Figure A2.

Partial Dependence Plots (Mask-Ion sputter yield).

Figure A3.

Partial Dependence Plots.

Figure A3.

Partial Dependence Plots.

References

- Head, T.; Kumar, M.; Nahrstaedt, H.; Louppe, G.; Shcherbatyi, I. scikit-optimize/scikit-optimize. 2021. [Google Scholar] [CrossRef]

- Marcos, G.; Rhallabi, A.; Ranson, P. Monte Carlo simulation method for etching of deep trenches in Si by a SF6/O2 plasma mixture. Journal of Vacuum Science & Technology A 2002, 21, 87–95. [Google Scholar] [CrossRef]

- Yamamura, Y.; Itikawa, Y.; Itoh, N. Angular dependence of sputtering yields of monatomic solids. Nagoya Institute of Technology Report 1983, IPPJ-AM-26. Available online: http://dpc.nifs.ac.jp/IPPJ-AM/IPPJ-AM-26.pdf.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).