1. Introduction

Controlled environment agriculture (CEA), particularly indoor farming (IF) facilities have expanded because of increasing controllability on farming by providing high spatial efficiency [

1], year-round production [

1,

2,

3], low water use [

2], low pesticide and herbicide use [

4], etc. [

5,

6,

7,

8]. This in turn increase the labor and energy costs associated with the high-tech instrumentation and high level of production [

9]. Agrivoltaics, by integrating the least-expensive [

10] and easy-to-deploy renewable energy source [

11], solar photovoltaics (PVs), into the agricultural farms [

12,

13], could offer a chance in mitigating the energy costs of CEA buildings operated at agricultural lands [

14]. Agrivoltaic agrotunnels are the most aggressive example of PV-powered IF in practice that could address the energy costs by offering net-zero grid-connected CEA powered with a PV system with considerably low levelized cost of electricity (LCOE) [

15]. Agrivoltaic agrotunnels as well as other IF systems studied in the literature have shown a good profit margin for high value crops such as herbs [

7,

16,

17]. For other greens such as salads, however, they are also economically profitability at a lower rate [

18]. This underscores the need for further investigations on cost optimizations and yield improvements leading to higher profitability levels. One scientific approach would be to reduce the labor and consumable materials costs and increase the revenue by improving the quality of seeds.

Agricultural seeds are sold as commodities, but the quality of all seeds is not the same such that they need to be treated to increase the chance of their germination [

19]. Conventional seed treatments often rely on costly or environmentally harmful chemicals, highlighting the need for more sustainable alternatives [

20]. There are some cutting-edge techniques that can improve the seed quality by boosting the plant growth rate and the transformation of bioactive chemicals, protein, and peroxidase concentrations, as well as the decontamination of the seeds [

21]. Plasma treatment, as one of the common methods is extensively studied in the literature [

22]. Plasma treatment is an environmentally-friendly technology for agriculture [

23], which addresses both bacterial and fungal plant diseases and boosts the yield, which accordingly contributes to higher revenue and higher food security levels [

24]. The positive influences of plasma treatment were investigated on a wide range of crops including wheat [

25,

26], oat [

27], lentil [

28], rice [

29], soybean [

30], pea [

31], rapeseed [

32], radish [

33], hemp [

34], green chiretta [

35], micro-greens [

36], cucumber [

37], and tomato [

38]. Non-thermal plasma (NTP), also referred to as cold plasma, is a form of plasma that remains out of thermodynamic equilibrium and operates at temperatures near room temperature. It can be carefully controlled to avoid causing thermal damage to biological materials [

39]. Plasma is an ionized gas generated under atmospheric or low-pressure conditions. NTP produces reactive species, electromagnetic fields, and UV radiation that alter seed molecules. Common plasma devices in agriculture include dielectric barrier discharge (DBD), microwave, corona, gliding arc, plasma jet, and radiofrequency-based plasma systems [

40]. Typical feed gases include nitrogen (N₂), oxygen (O₂), dry/wet air, noble gases, reactive gases, hydrocarbons, and gas mixtures [

40]. The biologic effects of NTP on various type of commodity seeds, particularly the ones used for traditional farming have been extensively evaluated [

39,

40,

41]. Although there are a few research pieces on the positive impact of NTP activated water or nutrient solution and root-applied NTP treatments on the growth metrics (including yield [

42,

43,

44,

45], leaf area [

43,

44], leaf count [

46], germination rate [

43], chlorophyll content [

43,

47], and mineral uptake [

44,

48]) of CEA cultivation of leafy greens, particularly lettuce, the studies on the direct commodity seed treatments are scarce. One study showed the effectiveness of the direct seed treatments of mung bean, mustard and radish was higher than that of the indirect nutrient water treatments [

20]. Three gas types of air, N

2, and O

2 were utilized in this non-thermal DBD plasma treatment study. For all three gas types, the germination probability of mung bean, mustard and radish was significantly improved after seed treatment. In another study on aeroponic cultivation of two lettuce varieties (Perl Gem and Cervanek), seeds were treated with low-pressure air or DBD plasmas [

49]. Although seed treatments influenced germination and early growth, they had no significant effect on biomass accumulation or the head-to-root ratio in either lettuce cultivars.

Despite the extensively proven advantages of direct and indirect plasma treatments on the growth indicators of a vast majority of crops in the literature, the research results on lettuce are very limited, thereby inconclusive. No significant investigations were conducted on different methods and gas type influences on commodity lettuce seeds. Although other power-to-x applications of plasma are elaborated in the literature [

50], practical power-to-food potentials of plasma for indoor cultivation considering the real conditions and additional costs are not investigated. To fill this research gap, in this study four different lettuce seeds including Red Oakleaf, Black Simpson, Valley Heart Romaine, and Paris Romaine are treated under NTP of N

2, O

2, dry air, and wet air feed gases. The treated and untreated (control) seeds are cultivated in a real full-scale vertical farming facility in an agrotunnel. To determine if it is worthwhile using excess electricity and/or labor to enhance the yield of indoor lettuce crops, the economic trade-off analysis between the revenue improvements and cost increments due to the secondary operating expenditures of plasma reactor on agrivoltaic agrotunnel is carried out.

2. Materials and Methods

The whole research procedure is elaborated in two sections. First, the details of NTP treatments and cultivation experiments are detailed. Finally, the cost and energy analysis methodology is provided.

2.1. Non-Thermal Plasma Experiments

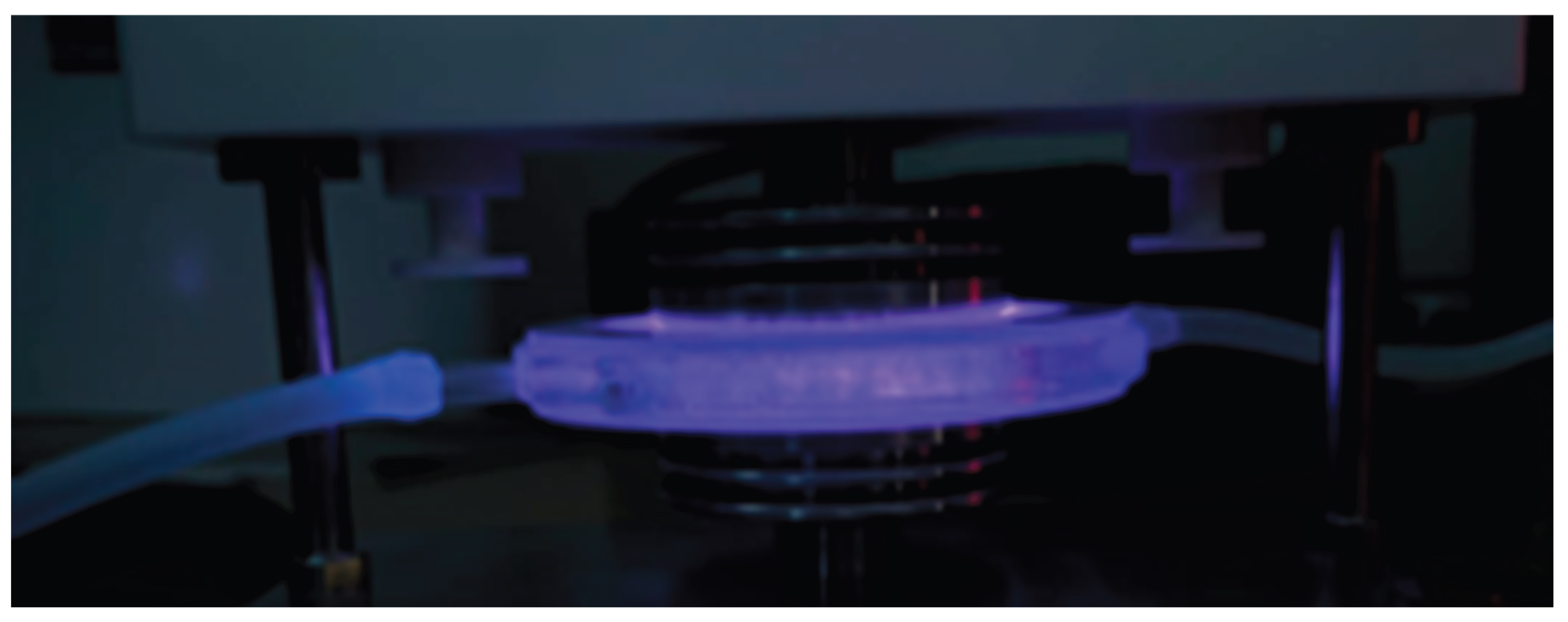

The non-thermal plasma system for seed treatment was operated at room temperature and atmospheric pressure within a disk-type non-thermal plasma reactor (Nanjing Suman Electronics Co., Ltd., China). As shown in

Figure 1, the quartz disk-type reactor, with an outer diameter of 95 mm and an inner diameter of 60 mm, was positioned between the high-voltage and grounded electrodes. The effective discharge zone covered an area of 28.26 cm

2 with a gap of 8 mm. For all seed types, the same treatment conditions were applied: 25 seeds were treated with plasma for 2 min in the quartz disk-type reactor under a power density of 1.9 W.cm

-2 (Input voltage of 30 V and an input current of 2.4 A). The discharge was driven by a 9.0 kHz sinusoidal AC power source with an RMS voltage of 8.5 kV. Different working gases were employed for plasma-assisted seed treatment, including N

2, O

2, and dry air, each introduced at a flow rate of 20 mL min

-1. Wet air with 3.3% water content was obtained by passing dry air through a water bubbler installed upstream of the plasma reactor.

After plasma treatment, the seeds were sown immediately, since the surface activation induced by reactive species is transient. Prolonged storage leads to hydrophobic recovery of the seed coat and diminishes the enhanced water uptake capacity [

26,

49,

51]. Moreover, the plasma-triggered biochemical signaling and enzymatic activities are short-lived, and excessive storage may even result in the accumulation of unfavorable oxidative by-products, thereby reducing the treatment benefits [

30].

Four cultivars, all in lettuce family, were selected to be tested. Red Oakleaf (RO), Black Simpson (BS), Valley Heart Romaine (VHR), and Paris Romaine (PR) were the tested seeds.

Figure 2 presents the treated and non-treated Black Simpson seeds in vial tubes and sterile dishes. There is no visible difference between them. They were planted in different groups of single to multiple seeds per pot. Both treated and non-treated seeds were planted in peat pots by the usual hydroponic substrate used in agrotunnels, a 70/30 mix of coco coir and perlite [

52], to study their performance under real conditions.

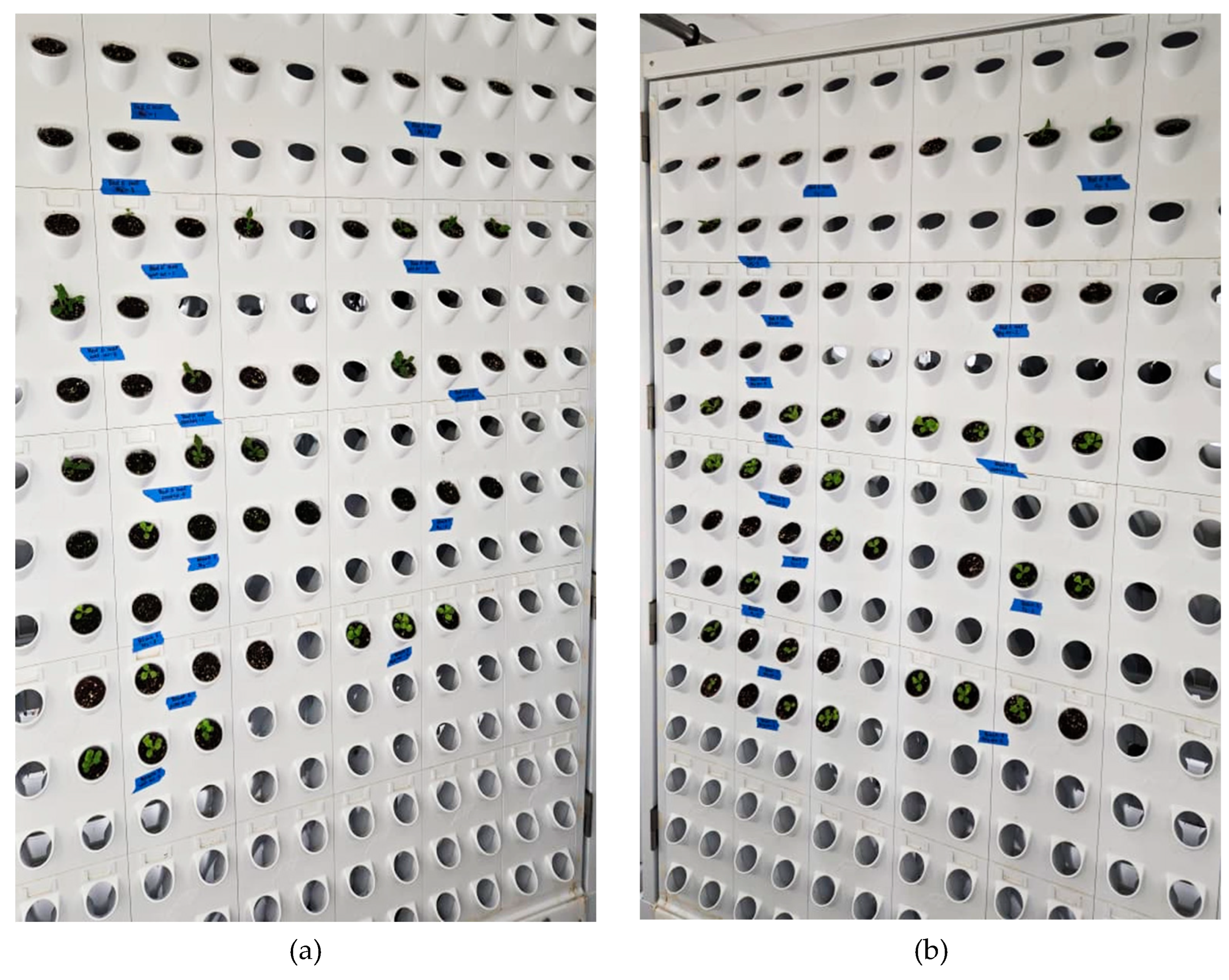

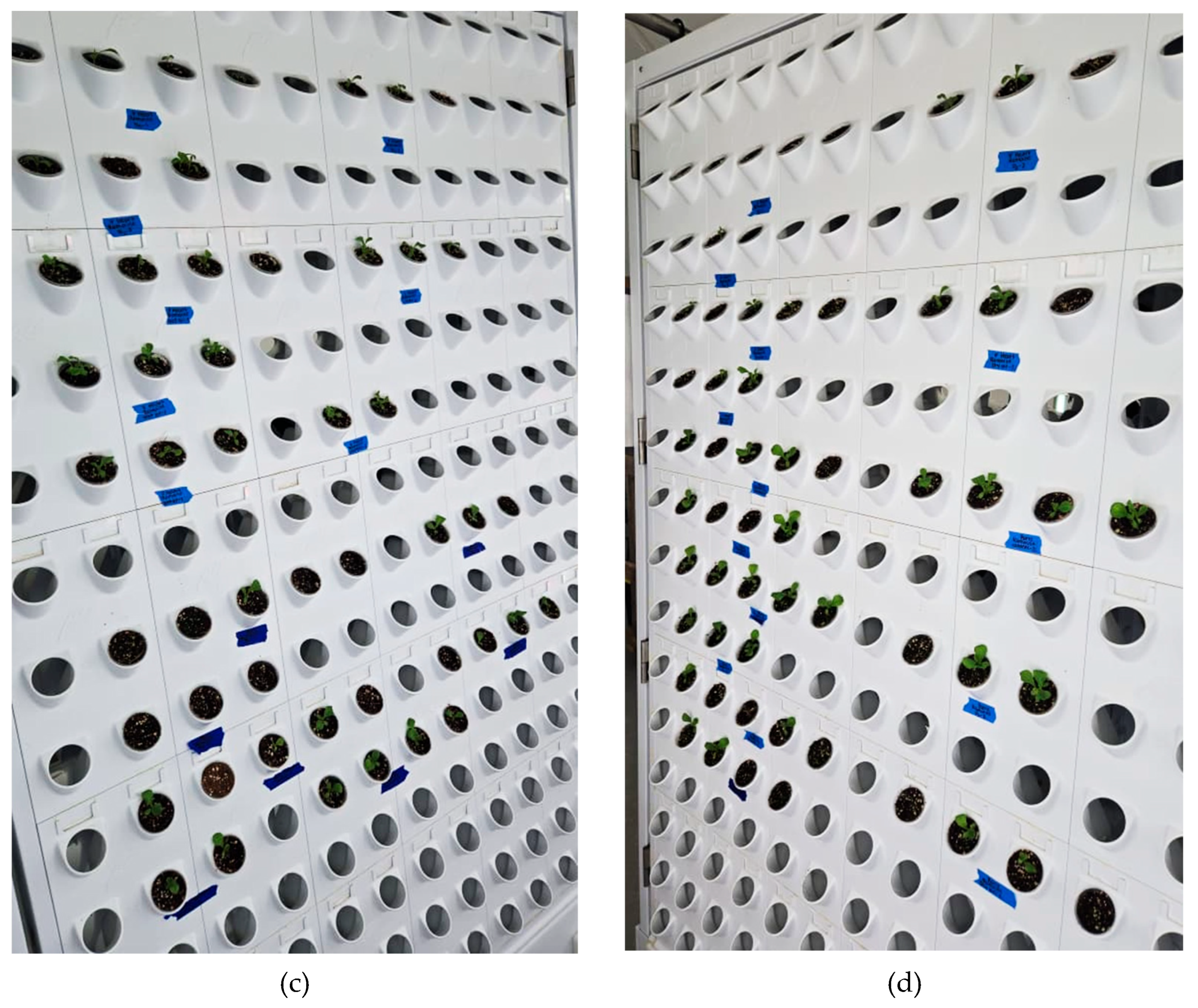

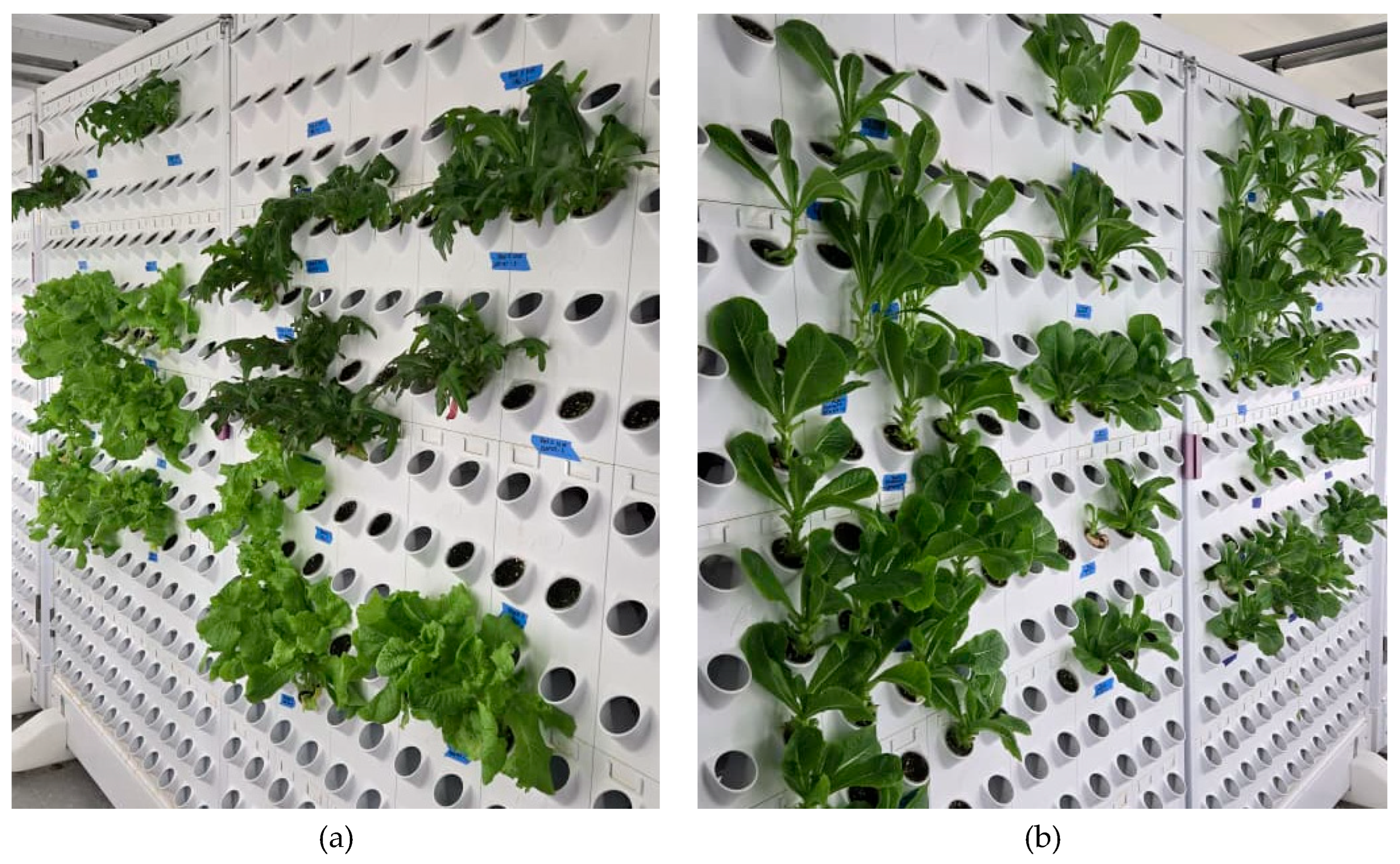

The planted pots were placed on true vertical hydroponic-aeroponic walls [

53] in the agrivoltaic agrotunnel, Ilderton, ON [

15].

Figure 3 shows the layout of the vertical grow walls in the main grow room of the agrotunnel. The germinated pots were placed on the ports on these vertical walls, as shown in

Figure 4.

All seeds were treated identically in identical environmentally controlled conditions. The cups were irrigated by nutrient water, whose pH level was balanced within the range of 6.0-7.0 and the electrical conductivity was maintained between 1.5 and 2.0 mS/cm. The watering cycle was 2 times per day with a 2-minute duration. The grow room was kept at a temperature of between 22 and 23 ◦C with a relative humidity ranging from 50% to 55%.

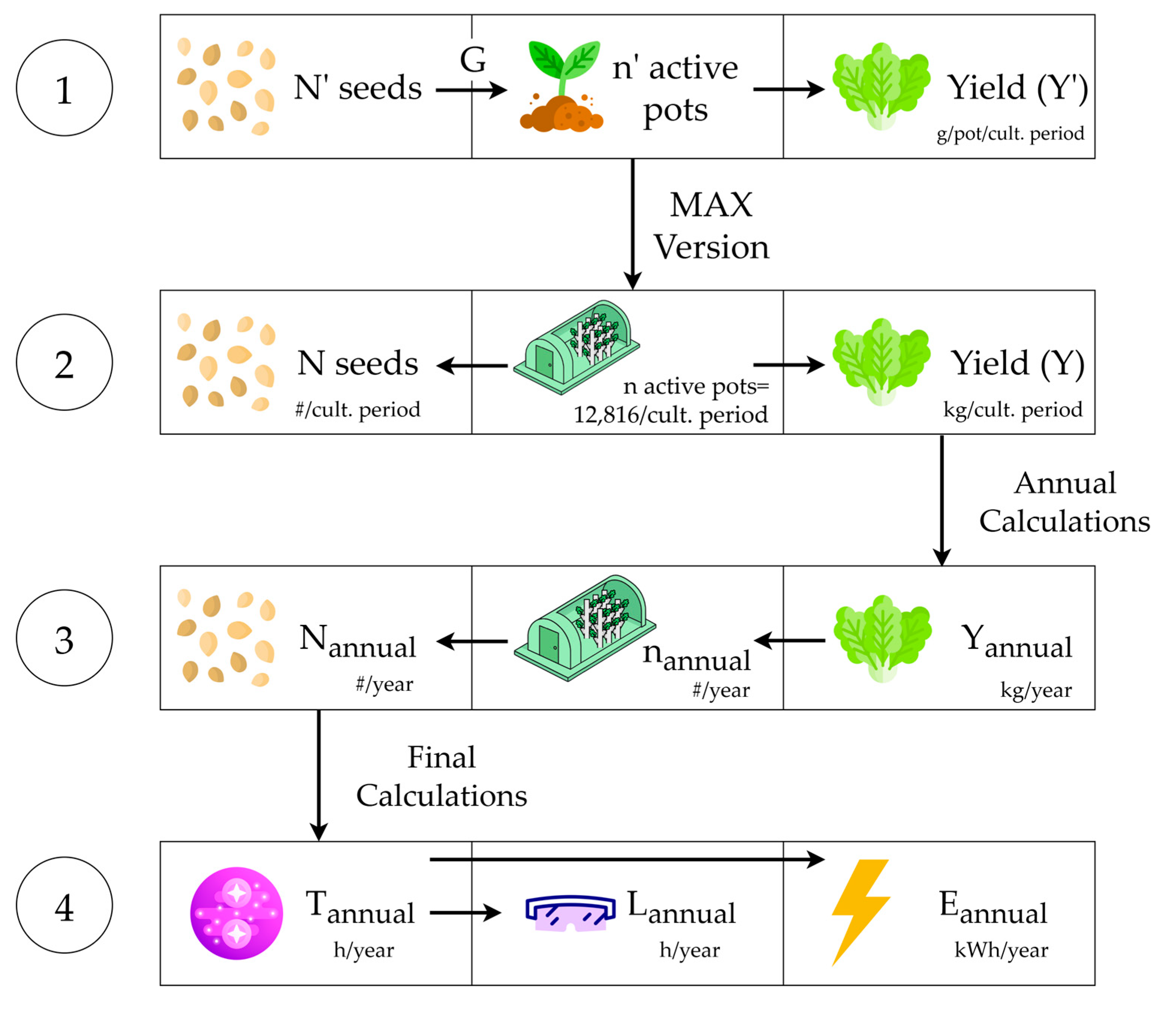

2.2. Energy and Economic Trade-off Analysis

Three main growth metrics of germination rate (G in %), germination time (t

germination in days), and fresh biomass yield (Y’ in kg/cultivation period) were measured and compared between four gas types for NTPs and the control plants. Cultivation period is defined as the time from planting to the last harvest in days. These three metrics were either directly or indirectly connected to the total number of required commodity seeds (N

annual), annual yield (Y

annual in kg/year), annual energy required (E

annual in kWh/year) for plasma treatments, and total labor time dedicated to implementation of treatments (L

annual in h/year), all of which are the main economic drivers in the trade-off analysis.

Figure 5 illustrates the estimation process of annual evaluating metrics (State 3 and 4) for the commercial MAX version of the agrotunnel (12,816 grow ports) based on the experimented data (State 1). State 2 represents the calculations per cultivation period. All the parameters are defined in

Table 1.

Actual number of required seeds per cultivation period is calculated using Equation (1).

All annual parameters (Pa

annual) will be estimated by extrapolating the equivalents calculated during the cultivation period (Pa) to the whole year, as shown in Equation (2).

Energy required for each type of plasma treatment is calculated using the fundamental electrical quantities measured for the current disk-type quartz plasma reactor provided in

Table 2.

To perform the economic analysis, several basic assumptions must be made, and the primary cost per unit values for key operating expenditures should be defined. First, the total number of required seeds per year provides the basis for calculating the annual seed cost, annual treatment labor time, and annual treatment energy, which is defined as the multiplication of the plasma reactor’s power rating (P

NTP) and the annual treatment time (T

annual), as shown in Equation (3). The energy cost for the case study in London, ON, expressed in

$/kWh, was obtained from the utility rates provided by London Hydro [

55].

The average cost of lettuce seeds was considered to be

$1.62 USD per 1,000 seeds [

56,

57,

58]. On the other hand, the annual revenue (R

annual in USD

$/year) can be calculated using Equation (4). The average unit price of organic lettuce was assumed to be

$25.35 USD/kg [

59].

To prepare the reactor for each treatment cycle, the operator must perform several pretreatment tasks, such as removing the treated seeds, cleaning the reactor, and adding the next batch, which takes approximately 10 minutes per cycle. The minimum wage in Ontario, set at $12.67 USD/h, was used as the unit labor cost [60]. The capital cost of the current lab-scale system, including the plasma generator and quartz reactor, with a total operating lifetime of 20,000 hours, is $3,600 USD [61]. The average operation and maintenance (O&M) cost for similar devices is assumed to be 5% of the initial fixed cost [62]. The degradation cost of the equipment can be estimated based on the ratio of the annual treatment time to the total lifetime operating hours.

3. Results

In this section, the results of all measurement and calculation procedures defined in

Figure 5 will be elaborated. The first phase of results will present experimental investigations of the cultivation processes.

Figure 6 shows the mature lettuce plants on grow vertical walls in the agrotunnel, proving the success of cultivation and maintenance experiments. All varieties had a cultivation period (C) of two months.

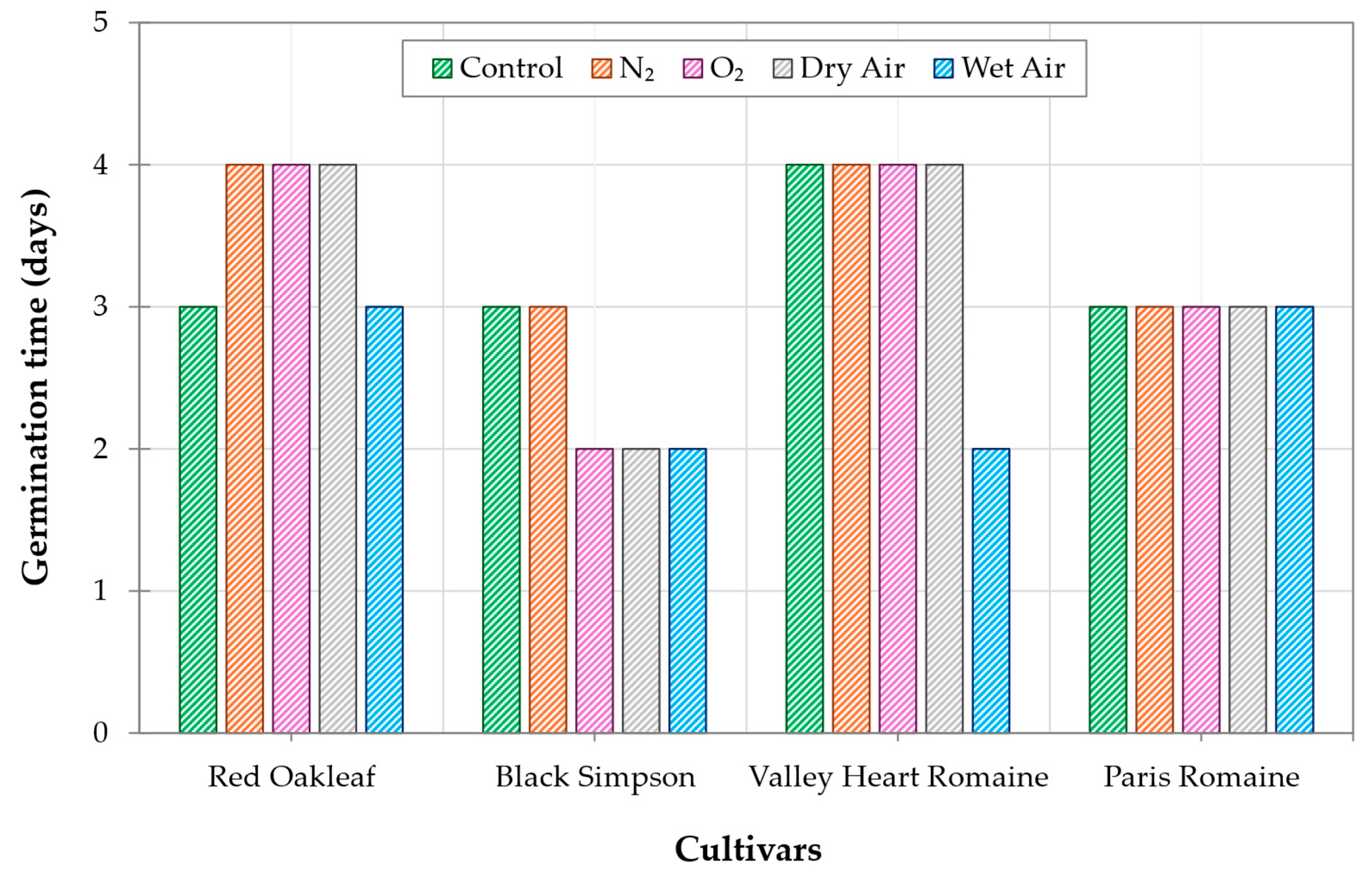

As the first parameter, the germination time was investigated.

Figure 7 presents the germination time of different cultivars under various treatments and the control condition. According to the results, there is no significant difference in t

germination among the treatments. The main variation is attributed to the cultivar type. It should also be noted that the effect of t

germination will be indirectly examined through the yield and cultivation period of the plants. Therefore, t

germination is not considered a parameter to be evaluated independently.

Germination rate (G) is the first key parameter demonstrating the economic effectiveness of plasma treatments, both directly and indirectly. The average G of all treated and control seeds is reported in

Table 4. As shown in

Table 4, for the Red Oakleaf cultivar, the wet air treatment resulted in a germination rate of 50%, compared to 25% for the control seeds (100% improvement). Similarly, for the Black Simpson and Valley Heart Romaine varieties, the wet air treatment again achieved higher G values (81.5% and 82.4%, respectively) compared to the control (63.9% and 69.4%, respectively). Paris Romaine seeds, however, showed a higher G (77.8%) under the O₂ treatment, followed by the control group with 65.8%.

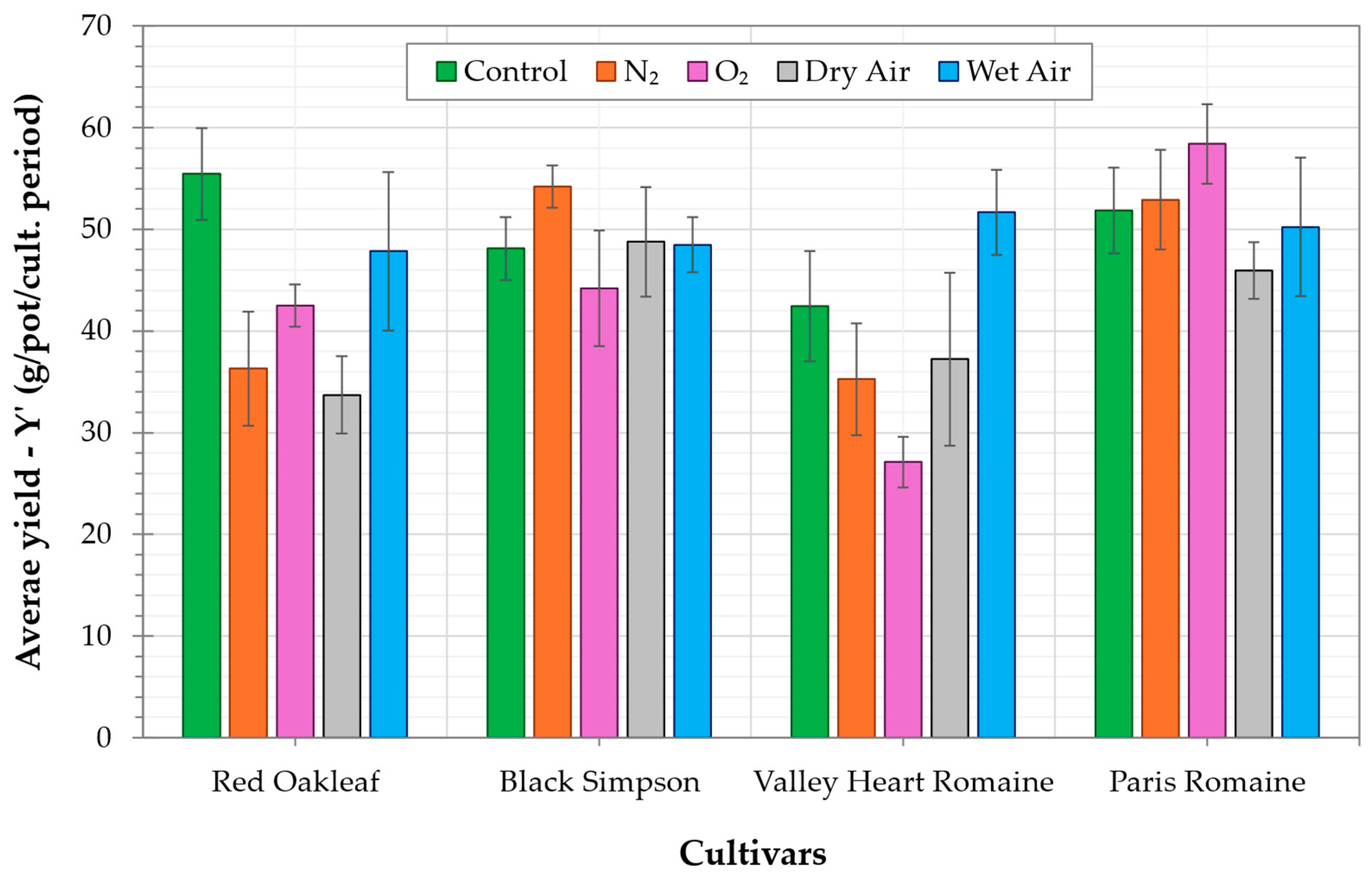

Successful treatments can be identified by evaluating the yield investigations shown by

Figure 8. Wet Air treatment could have the most considerable impact generally, with the most significant achievement on VHR (51.7 vs. 42.5 g/pot/cult.period in control). Treatments of Red Oakleaf seeds were not effective according to the reported results. For Black Simpson, although dry air and wet air treatments could perform reasonably, the most significant influence resulted in N

2 treatment (54.2 vs 48.1 g/pot/cult.period in control). Ultimately, for Paris Romaine, O

2 treatment led to reasonably significant yield (58.4 g/pot/cult.period) compared to control (51.8 g/pot/cult.period).

With the potential for growing organic products in the agrivoltaic agrotunnel [

18], the selection of the BS, VHR, and PR cultivars can provide the key components of a spring mix or green mix lettuce pack [

18]. Therefore, the application of three plasma treatments, N₂, O₂, and wet air, on the selected seeds was investigated, and an economic trade-off analysis considering the secondary costs was conducted.

The key parameters for the successful treatments, as presented in

Table 5, were used for the cost analysis. The germination rate, annual yield, and annual seed requirements were all improved for the NTP-treated seeds of Romaine family compared to that in control. Despite the higher total yield for treated BS seeds, their germination rate was lower than control seeds, which led to more total seed requirements, and more treatment labor in turn. Among the Romaine varieties, VHR seed treatment caused a 21.7% yield improvement (3,973 vs 3,264 kg/year) compared to PR variety with 12.6% (4,491 vs 3,987 kg/year). The germination rate for VHR variety was also higher compared to PR, leading to reduced seed count (93,320 vs 98,838 per year), seed treatment time (124 vs 132 h/year), and labor hours (622 vs 659 h/year).

Table 5 also reveals that the energy consumption of plasma treatments is small and negligible in cost analysis. In conclusion of the final annual calculations, the VHR variety can be identified as the most responsive to the NTP seed treatments. The cost–revenue trade-off analysis is conducted in the following, comparing the wet air-treated seeds with the control seeds.

Table 6 presents the final results of the cost and revenue analysis for the VHR-wet air treatment. The energy cost of the treatments was negligible because solar electricity generation was equal to 177,100 kWh/year [

18] while the entire annual plasma treatment was only 9 kWh. On the other hand, the labor cost represents the largest contribution to the secondary operating expenditures of the NTP process (

$7,882 USD/year). Despite the additional secondary costs associated with the plasma treatments, especially labor, the reduced number of required seeds and the higher yield resulted in an overall 12.0% improvement in the net profit compared to the non-treated seed cultivation (

$92,481 vs.

$82,573 USD/year).

4. Discussion

This article investigated the effect of non-thermal plasma treatments with different feed gases on the germination and growth metrics of different lettuce seeds in practical growing conditions of a vertical indoor farming facility (agrivoltaic agrotunnel). In addition, the economic viability of these practices was studied and compared by conducting the combined revenue-cost trade-off analysis. Four lettuce seeds of Red Oakleaf, Black Simpson, Valley Heart Romaine, and Paris Romaine were tested under four feed gases of N2, O2, dry air, and wet air. A quartz disk-type non-thermal plasma reactor was used with 30 V, 2.4 A, and 2 minutes duration of treatment.

Wet air treatment could generally expose better performance in germination rate (18.7-100% improvement) compared to the equivalent control plants, except for PR, whose germination rate was improved by 18.1% under O

2 treatment. Exposure to O

2 plasma can be attributed to the formation of O

3 and O· radicals, which may mildly oxidize seeds and enhance respiration rates [

33]. However, for seed types with thin seed coats, the same 2-minute O

2 treatment may oxidize membrane proteins beyond the beneficial activation threshold, thereby inhibiting germination (as seen in

Figure 8).

The total fresh weight production, however, was the most important factor in selecting the successful cultivar-treatment combinations. Except for RO, for which there was no significant positive improvement in production yield, wet air, could result in either neutral or significant positive yield increments for the treated cultivars. Unlike O

2- or air-based plasmas, the N₂ discharge primarily generates reactive nitrogen species, including NO, NO

2, and N

2O. Element O may originate from residual gases within the reactor. The differing response of BS seeds compared to VHR and PR seeds attributable to their greater sensitivity to NO

x in certain enzymes, which indicate an area of future work. Thus, except for the N

2-treated BS seeds, which could produce 12.6% more fresh weight but accompanied by a decreased germination rate of 4.3%, both total yield and germination rate of Romaine seeds (VHR and PR) were positively responsive to the wet air and O

2 treatments, respectively. The contrasting results between dry- and wet-air plasma treatments can be attributed to the different reaction pathways induced by the presence of water vapor. In dry air, the discharge predominantly produces O· and O

3, which impose strong oxidative stress on the seed coat, leading to surface hardening and limited water permeability. Conversely, introducing a small fraction of water vapor suppresses O

3 formation while enabling OH· and H

2O

2 generation through O-H

2O reactions. These species cause mild oxidation and introduce polar oxygen-containing groups on the cuticular surface, enhancing water imbibition and germination [

39]. VHR-wet air with 21.7% total yield improvements and 18.7% higher germination rate compared to control, was selected to develop further revenue-cost analyses on the NTP process integrated into the IF system. The observation of somewhat different results among various plant cultivar, as similarly observed in the literature [

26,

27,

34,

35,

49], may be attributed to several factors, including seed or plant genetics, contamination, insufficient plasma processing energy or duration, etc.

This study also revealed that using the current quartz disk-type reactor for a 112 m2 indoor farming facility with 76,896 active ports for a year-round production, would impose a negligible amount of electricity load (9 kWh/year) on the system with a total solar generation of 177,100 kWh/year. Since the current plasma device can only treat a batch of 25 seeds at a time, the operation of this reactor demands for a considerable amount of time, thereby contributing a notable labor cost (44% of total raised revenue due to the wet air treatment of VHR seeds). Although the positive effects of wet air treatment on germination rate and total yield led to an overall 12.0% increase in net profit compared to non-treated seed cultivation, despite the additional labor, O&M, and degradation costs associated with operating NTP reactors, there is a need for future studies to explore alternative commercial- or industrial-scale systems with higher treatment capacities. In addition, there is a significant opportunity to reduce labor costs using an automated system to load and unload seeds for pre- and post-treatment processes. Future research is also needed to investigate the effects of NTP on a wider range of lettuce seed varieties obtained from the same vendors and replicate the experiments multiple times to improve the reliability of the results. Moreover, examining the influence of voltage and treatment duration on seed decontamination and growth enhancement could help further achievements in the techno-economic optimization of the process.

5. Conclusions

This research determined how non-thermal plasma treatments with various feed gases (N₂, O₂, dry air, and wet air) influence the germination and growth characteristics of different lettuce cultivars (Red Oakleaf, Black Simpson, Valley Heart Romaine, and Paris Romaine) under real cultivation conditions in an agrivoltaic agrotunnel. Furthermore, the study assesses the economic feasibility of these treatments through a comprehensive revenue–cost trade-off analysis. Experiments were conducted involving continuous harvesting cycles on mature plants during a cultivation period of two months. The germination time of seeds (treated and control) was varying within a range of 2-4 days. The germination time, however, had an indirect impact on the growth performance of the plants during their lifespan.

Except for treated PR seeds with 77.8% germination rate vs control of 65.8%, wet air plasma treatment could result in higher germination rates (18.7-100% improvement) compared to control (non-treated) seeds. This factor directly indicates the total required seeds for operation of commercial MAX agrotunnel with 12,816 active ports.

In yield analysis, the wet air treatment showed the greatest impact, particularly for the VHR variety (51.7 vs. 42.5 g/pot/cultivation period in the control). The treatments had no notable effect on RO, however. For BS, the N₂ treatment yielded the highest improvement (54.2 vs. 48.1 g/pot/cultivation period), while for PR, the O₂ treatment led to a significant increase (58.4 vs. 51.8 g/pot/cultivation period). Hence, BS, VHR, and RO were selected to conduct further cost-revenue analysis.

Although treated BS seeds produced a higher total yield, their lower germination rate increased the required seed quantity and treatment labor time. Among the Romaine cultivars, VHR showed the best response to NTP treatment, with a 21.7% yield improvement (3,973 vs. 3,264 kg/year) compared to PR’s 12.6% (4,491 vs. 3,987 kg/year). The higher germination rate of VHR also reduced annual seed requirements (93,320 vs. 98,838), treatment time (124 vs. 132 h), and labor hours (622 vs. 659 h). Accordingly, the VHR variety demonstrated the greatest response to NTP treatment with wet air feed gas. The energy consumption of plasma treatments was negligible for all treatments and cultivar types. In contrast, labor costs ($7,882 USD/year) accounted for the largest share of secondary operating costs in the NTP process. Despite these additional expenses, including labor, O&M, and degradation costs, the reduced seed requirements and higher yield led to a 12.0% increase in net profit compared to non-treated cultivation ($92,481 vs. $82,573 USD/year).

Author Contributions

Conceptualization, Y.Z. and J.M.P.; methodology, N.A. and N.Z.; validation, N.A., N.Z., Y.Z. and J.M.P.; formal analysis, N.A., N.Z., Y.Z. and J.M.P.; investigation, N.A. and N.Z.; resources, Y.Z. and J.M.P.; data curation, N.A.; writing—original draft preparation, N.A., N.Z., Y.Z. and J.M.P.; writing—review and editing, N.A., N.Z., Y.Z. and J.M.P.; visualization, N.A. and N.Z.; supervision, Y.Z. and J.M.P.; project administration, Y.Z. and J.M.P.; funding acquisition, Y.Z. and J.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Carbon Solutions @ Western, Mitacs and the Thompson Endowment.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available upon request.

Acknowledgments

The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CEA |

Controlled environment agriculture |

| IF |

Indoor farming |

| PV |

Photovoltaics |

| LCOE |

Levelized cost of electricity |

| NTP |

Non-thermal plasma |

| RO |

Red Oakleaf |

| BS |

Black Simpson |

| VHR |

Valley Heart Romaine |

| PR |

Paris Romaine |

References

- Ahamed, M.S.; Sultan, M.; Monfet, D.; Rahman, M.S.; Zhang, Y.; Zahid, A.; Bilal, M.; Ahsan, T.M.A.; Achour, Y. A Critical Review on Efficient Thermal Environment Controls in Indoor Vertical Farming. Journal of Cleaner Production 2023, 425, 138923. [Google Scholar] [CrossRef]

- Sadek, N.; kamal, N.; Shehata, D. Internet of Things Based Smart Automated Indoor Hydroponics and Aeroponics Greenhouse in Egypt. Ain Shams Engineering Journal 2024, 15, 102341. [Google Scholar] [CrossRef]

- Mitchell, C.A. History of Controlled Environment Horticulture: Indoor Farming and Its Key Technologies. 2022. [CrossRef]

- Stein, E.W. The Transformative Environmental Effects Large-Scale Indoor Farming May Have On Air, Water, and Soil. Air, Soil and Water Research 2021, 14, 1178622121995819. [Google Scholar] [CrossRef]

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical Farming: A Summary of Approaches to Growing Skywards. The Journal of Horticultural Science and Biotechnology 2019, 94, 277–283. [Google Scholar] [CrossRef]

- Ampim, P.A.Y.; Obeng, E.; Olvera-Gonzalez, E. Indoor Vegetable Production: An Alternative Approach to Increasing Cultivation. Plants 2022, 11, 2843. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. Indoor Vertical Farming in the Urban Nexus Context: Business Growth and Resource Savings. Sustainability 2020, 12, 1965. [Google Scholar] [CrossRef]

- Despommier, D. Vertical Farms, Building a Viable Indoor Farming Model for Cities. Field Actions Science Reports. The journal of field actions 2019, 68–73. [Google Scholar]

- Kurnik, J. Chapter 19 - Indoor Farms for Tomorrow’s Cities: Improving Environmental and Economic Performance. In Urban and Regional Agriculture; Droege, P., Ed.; Academic Press, 2023; pp. 533–560 ISBN 978-0-12-820286-9.

- Pearce, J.M.; Sommerfeldt, N. Economics of Grid-Tied Solar Photovoltaic Systems Coupled to Heat Pumps: The Case of Northern Climates of the U.S. and Canada. Energies 2021, 14, 834. [Google Scholar] [CrossRef]

- Sommerfeldt, N.; Pearce, J.M. Can Grid-Tied Solar Photovoltaics Lead to Residential Heating Electrification? A Techno-Economic Case Study in the Midwestern U.S. Applied Energy 2023, 336. [Google Scholar] [CrossRef]

- Cho, J.; Park, S.M.; Park, A.R.; Lee, O.C.; Nam, G.; Ra, I.-H. Application of Photovoltaic Systems for Agriculture: A Study on the Relationship between Power Generation and Farming for the Improvement of Photovoltaic Applications in Agriculture. Energies 2020, 13, 4815. [Google Scholar] [CrossRef]

- Jamil, U.; Bonnington, A.; Pearce, J.M. The Agrivoltaic Potential of Canada. Sustainability 2023, 15, 3228. [Google Scholar] [CrossRef]

- Asgari, N.; Hayibo, K.S.; Groza, J.; Rana, S.; Pearce, J.M. Greenhouse Applications of Solar Photovoltaic Driven Heat Pumps in Northern Environments. Renewable and Sustainable Energy Reviews 2025, 207, 114920. [Google Scholar] [CrossRef]

- Asgari, N.; Jamil, U.; Pearce, J.M. Net Zero Agrivoltaic Arrays for Agrotunnel Vertical Growing Systems: Energy Analysis and System Sizing. Sustainability 2024, 16, 6120. [Google Scholar] [CrossRef]

- Shao, Y.; Zhou, Z.; Chen, H.; Zhang, F.; Cui, Y.; Zhou, Z. The Potential of Urban Family Vertical Farming: A Pilot Study of Shanghai. Sustainable Production and Consumption 2022, 34, 586–599. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. Energy Cost Reduction by Shifting Electricity Demand in Indoor Vertical Farms with Artificial Lighting. Biosystems Engineering 2021, 211, 219–229. [Google Scholar] [CrossRef]

- Asgari, N.; Basdeo, A.; Givans, J.; Pearce, J.M. Lighting and Revenue Analysis of Grow Lights in Agrivoltaic Agrotunnel for Lettuces and Swiss Chard 2025.

- (PDF) Quality Seed Production: A Cornerstone of Modern Agriculture and Allied Sectors Available online:. Available online: https://www.researchgate.net/publication/388273238_Quality_Seed_Production_A_Cornerstone_of_Modern_Agriculture_and_Allied_Sectors (accessed on 2 October 2025).

- Liu, B.; Honnorat, B.; Yang, H.; Arancibia, J.; Rajjou, L.; Rousseau, A. Non-Thermal DBD Plasma Array on Seed Germination of Different Plant Species. Journal of Physics D: Applied Physics 2018, 52, 025401. [Google Scholar] [CrossRef]

- Bhabani, M.G.; Shams, R.; Dash, K.K. Microgreens and Novel Non-Thermal Seed Germination Techniques for Sustainable Food Systems: A Review. Food Sci Biotechnol 2024, 33, 1541–1557. [Google Scholar] [CrossRef]

- Meier, A.; Essumang, D.; Hummerick, M.; Johnson, C.; Kruger, M.; Massa, G.; Engeling, K. Reviewing Plasma Seed Treatments for Advancing Agriculture Applications on Earth and into the Final Frontier. Gravitational Space Res 2021, 9, 133–158. [Google Scholar] [CrossRef]

- Bilea, F.; Garcia-Vaquero, M.; Magureanu, M.; Mihaila, I.; Mildažienė, V.; Mozetič, M.; Pawłat, J.; Primc, G.; Puač, N.; Robert, E.; et al. Non-Thermal Plasma as Environmentally-Friendly Technology for Agriculture: A Review and Roadmap. Critical Reviews in Plant Sciences 2024, 43, 428–486. [Google Scholar] [CrossRef]

- Šerá, B. Non-Thermal Plasma Technology: A Sustainable Solution for Agriculture. In Advances in Seed Quality Evaluation and Improvement; Roy, B., Shukla, G., Dunna, V., Sharma, P., Shukla, P.S., Eds.; Springer Nature: Singapore, 2025; ISBN 978-981-96-5178-8. [Google Scholar]

- and; and; and; and Effect of Cold Plasma Treatment on Seed Germination and Growth of Wheat. Plasma Sci. Technol. 2014, 16, 54. [CrossRef]

- Dobrin, D.; Magureanu, M.; Mandache, N.B.; Ionita, M.-D. The Effect of Non-Thermal Plasma Treatment on Wheat Germination and Early Growth. Innovative Food Science & Emerging Technologies 2015, 29, 255–260. [Google Scholar] [CrossRef]

- Sera, B.; S̆patenka, P.; S̆erý, M.; Vrchotova, N.; Hrus̆ková, I. Influence of Plasma Treatment on Wheat and Oat Germination and Early Growth. IEEE Transactions on Plasma Science 2010, 38, 2963–2968. [Google Scholar] [CrossRef]

- Gutiérrez-León, D.G.; Serrano-Ramírez, T.; López-Callejas, R.; Rodríguez-Méndez, B.G. Non-Thermal Plasma as an Alternative to Enhance the Early Growth Structures in Lentil Plants. Agronomy 2022, 12, 2920. [Google Scholar] [CrossRef]

- Bian, J.-Y.; Guo, X.-Y.; Lee, D.H.; Sun, X.-R.; Liu, L.-S.; Shao, K.; Liu, K.; Sun, H.-N.; Kwon, T. Non-Thermal Plasma Enhances Rice Seed Germination, Seedling Development, and Root Growth under Low-Temperature Stress. Appl Biol Chem 2024, 67, 2. [Google Scholar] [CrossRef]

- Ling, L.; Jiafeng, J.; Jiangang, L.; Minchong, S.; Xin, H.; Hanliang, S.; Yuanhua, D. Effects of Cold Plasma Treatment on Seed Germination and Seedling Growth of Soybean. Sci Rep 2014, 4, 5859. [Google Scholar] [CrossRef] [PubMed]

- Kyzek, S.; Holubová, Ľ.; Medvecká, V.; Tomeková, J.; Gálová, E.; Zahoranová, A. Cold Atmospheric Pressure Plasma Can Induce Adaptive Response in Pea Seeds. Plasma Chem Plasma Process 2019, 39, 475–486. [Google Scholar] [CrossRef]

- Puligundla, P.; Kim, J.-W.; Mok, C. Effect of Corona Discharge Plasma Jet Treatment on Decontamination and Sprouting of Rapeseed (Brassica Napus L.) Seeds. Food Control 2017, 71, 376–382. [Google Scholar] [CrossRef]

- Puligundla, P.; Kim, J.-W.; Mok, C. Effects of Nonthermal Plasma Treatment on Decontamination and Sprouting of Radish (Raphanus Sativus L.) Seeds. Food Bioprocess Technol 2017, 10, 1093–1102. [Google Scholar] [CrossRef]

- Sera, B.; Sery, M.; Gavril, B.; Gajdova, I. Seed Germination and Early Growth Responses to Seed Pre-Treatment by Non-Thermal Plasma in Hemp Cultivars (Cannabis Sativa L.). Plasma Chem Plasma Process 2017, 37, 207–221. [Google Scholar] [CrossRef]

- and; and; and Effects of Atmospheric Pressure Air Plasma Pretreatment on the Seed Germination and Early Growth of Andrographis Paniculata. Plasma Sci. Technol. 2014, 16, 260. [CrossRef]

- Motrescu, I.; Ciolan, M.A.; Calistru, A.E.; Jitareanu, G. Germination and Growth Improvement of Some Micro-Greens under the Influence of Reactive Species Produced in a Non-Thermal Plasma (NTP). Agronomy 2023, 13, 150. [Google Scholar] [CrossRef]

- Guragain, R.P.; Baniya, H.B.; Guragain, D.P.; Pradhan, S.P.; Subedi, D.P. From Seed to Sprout: Unveiling the Potential of Non-Thermal Plasma for Optimizing Cucumber Growth. Heliyon 2023, 9. [Google Scholar] [CrossRef] [PubMed]

- Măgureanu, M.; Sîrbu, R.; Dobrin, D.; Gîdea, M. Stimulation of the Germination and Early Growth of Tomato Seeds by Non-Thermal Plasma. Plasma Chem Plasma Process 2018, 38, 989–1001. [Google Scholar] [CrossRef]

- Leti, L.-I.; Gerber, I.C.; Mihaila, I.; Galan, P.-M.; Strajeru, S.; Petrescu, D.-E.; Cimpeanu, M.-M.; Topala, I.; Gorgan, D.-L. The Modulatory Effects of Non-Thermal Plasma on Seed’s Morphology, Germination and Genetics—A Review. Plants 2022, 11, 2181. [Google Scholar] [CrossRef]

- Ahmed, N.; Yong, L.X.; Yang, J.H.C.; Siow, K.S. Review of Non-Thermal Plasma Technology and Its Potential Impact on Food Crop Seed Types in Plasma Agriculture. Plasma Chem Plasma Process 2025, 45, 421–462. [Google Scholar] [CrossRef]

- Šerá, B.; Scholtz, V.; Jirešová, J.; Khun, J.; Julák, J.; Šerý, M. Effects of Non-Thermal Plasma Treatment on Seed Germination and Early Growth of Leguminous Plants—A Review. Plants 2021, 10, 1616. [Google Scholar] [CrossRef]

- Puccinelli, M.; Carmassi, G.; Lanza, D.; Maggini, R.; Vernieri, P.; Incrocci, L. Effect of Nutrient Solution Activated with Non-Thermal Plasma on Growth and Quality of Baby Leaf Lettuce Grown Indoor in Aeroponics. | EBSCOhost. Available online: https://openurl.ebsco.com/contentitem/doi:10.3390%2Fagriculture15040405?sid=ebsco:plink:crawler&id=ebsco:doi:10.3390%2Fagriculture15040405 (accessed on day month year).

- Than, H.A.Q.; Pham, T.H.; Nguyen, D.K.V.; Pham, T.H.; Khacef, A. Non-Thermal Plasma Activated Water for Increasing Germination and Plant Growth of Lactuca Sativa L. Plasma Chem Plasma Process 2022, 42, 73–89. Plasma Chem Plasma Process 2022, 42, 73–89. [Google Scholar] [CrossRef]

- Mosha, A.H.; Shen, P.; Gao, J.; Elsherbiny, O.; Qureshi, W.A. Optimizing Plasma Discharge Intensities and Spraying Intervals for Enhanced Growth, Mineral Uptake, and Yield in Aeroponically Grown Lettuce. Horticulturae 2025, 11, 650. [Google Scholar] [CrossRef]

- Nicoletto, C.; Falcioni, V.; Locatelli, S.; Sambo, P. Non-Thermal Plasma and Soilless Nutrient Solution Application: Effects on Nutrient Film Technique Lettuce Cultivation. Horticulturae 2023, 9, 208. [Google Scholar] [CrossRef]

- Stoleru, V.; Stratulat, C.; Teliban, G.; Padureanu, S.; Patras, A.; Burlica, R.; Dirlau, D.; Astanei, D.; Beniuga, O. Morphological, Physiological and Productive Indicators of Lettuce under Non-Thermal Plasma. In Proceedings of the 2018 International Conference and Exposition on Electrical And Power Engineering (EPE); October 2018; pp. 0937–0942. [Google Scholar]

- Carmassi, G.; Cela, F.; Trivellini, A.; Gambineri, F.; Cursi, L.; Cecchi, A.; Pardossi, A.; Incrocci, L. Effects of Nonthermal Plasma (NTP) on the Growth and Quality of Baby Leaf Lettuce (Lactuca Sativa Var. Acephala Alef.) Cultivated in an Indoor Hydroponic Growing System. Horticulturae 2022, 8, 251. [Google Scholar] [CrossRef]

- Ruamrungsri, S.; Sawangrat, C.; Panjama, K.; Sojithamporn, P.; Jaipinta, S.; Srisuwan, W.; Intanoo, M.; Inkham, C.; Thanapornpoonpong, S. Effects of Using Plasma-Activated Water as a Nitrate Source on the Growth and Nutritional Quality of Hydroponically Grown Green Oak Lettuces. Horticulturae 2023, 9, 248. [Google Scholar] [CrossRef]

- Jankaitytė, E.; Naučienė, Z.; Degutytė-Fomins, L.; Judickaitė, A.; Žūkienė, R.; Januškaitienė, I.; Kudirka, G.; Koga, K.; Shiratani, M.; Mildažienė, V. Seed Treatment with Cold Plasma Induces Changes in Physiological and Biochemical Parameters of Lettuce Cultivated in an Aeroponic System. Agronomy 2025, 15, 1371. [Google Scholar] [CrossRef]

- Sun, J.; Qu, Z.; Gao, Y.; Li, T.; Hong, J.; Zhang, T.; Zhou, R.; Liu, D.; Tu, X.; Chen, G. Plasma Power-to-X (PP2X): Status and Opportunities for Non-Thermal Plasma Technologies. Journal of Physics D: Applied Physics 2024, 57, 503002. [Google Scholar] [CrossRef]

- Volin, J.C.; Denes, F.S.; Young, R.A.; Park, S.M.T. Modification of Seed Germination Performance through Cold Plasma Chemistry Technology. Crop Science 2000, 40, 1706–1718. [Google Scholar] [CrossRef]

- Mother Earth Coco Plus Perlite Mix | 50L | RHP Certified Natural Plant Growth Media : Amazon. Available online: https://www.amazon.ca/Mother-Earth-Perlite-Certified-Natural/dp/B09QXTJ345 (accessed on 2 October 2025).

- Shadd, A.; Asgari, N.; Pearce, J.M. Effects of Spectral Ranges on Growth and Yield in Vertical Hydroponic–Aeroponic Hybrid Grow Systems for Radishes and Turnips. Foods 2025, 14, 1872. [Google Scholar] [CrossRef]

- Google Finance CAD/USD Currency Exchange Rate & News Available online:. Available online: https://www.google.com/finance/quote/CAD-USD (accessed on 3 April 2025).

- Residential Electricity Rates. Available online: https://www.londonhydro.com/accounts-services/electricity-rates/residential-electricity-rates (accessed on 7 October 2025).

- Black Seeded Simpson Lettuce. Available online: https://www.veseys.com/ca/blackseeded.html (accessed on 7 October 2025).

- Parris Island. Available online: https://www.westcoastseeds.com/products/parris-island (accessed on 7 October 2025).

- Valley Heart Lettuce. Available online: https://www.veseys.com/ca/valleyheartlettuce.html (accessed on 7 October 2025).

- Organic Green Leaf Lettuce (5 Oz) Delivery or Pickup Near Me. Available online: https://www.instacart.ca/products/27298381-organic-green-leaf-lettuce-5-oz (accessed on 7 October 2025).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).