Submitted:

28 September 2025

Posted:

30 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Classification and Properties

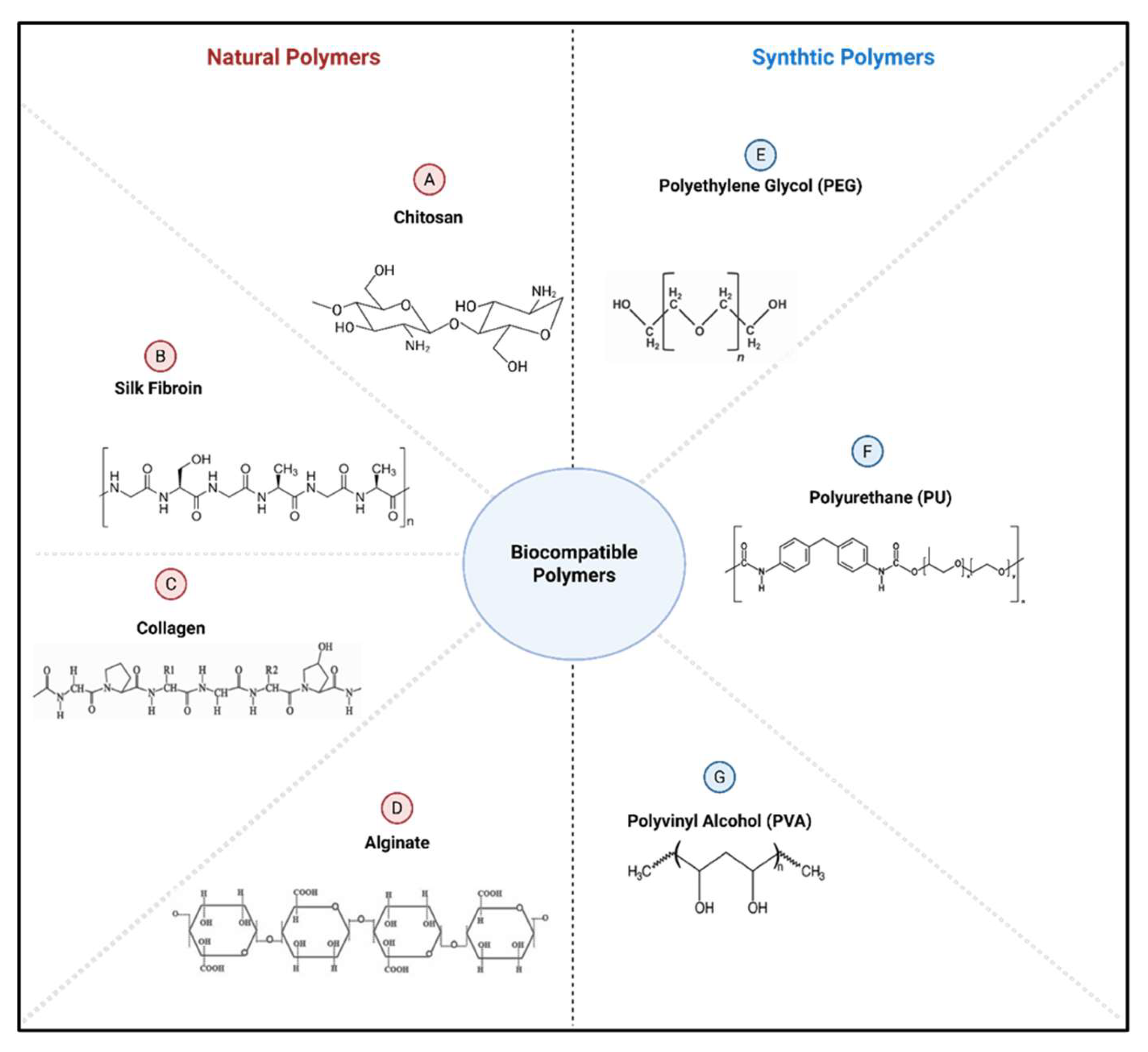

2.1. Biocompatible Polymers

2.1.1. Natural Biocompatible Polymers

- Chitosan;

- Silk Protein;

- Collagen;

- Alginate;

2.1.2. Synthetic Biocompatible Polymers

- Polyethylene Glycol (PEG);

- Polyurethane (PU);

- Polyvinyl Alcohol (PVA);

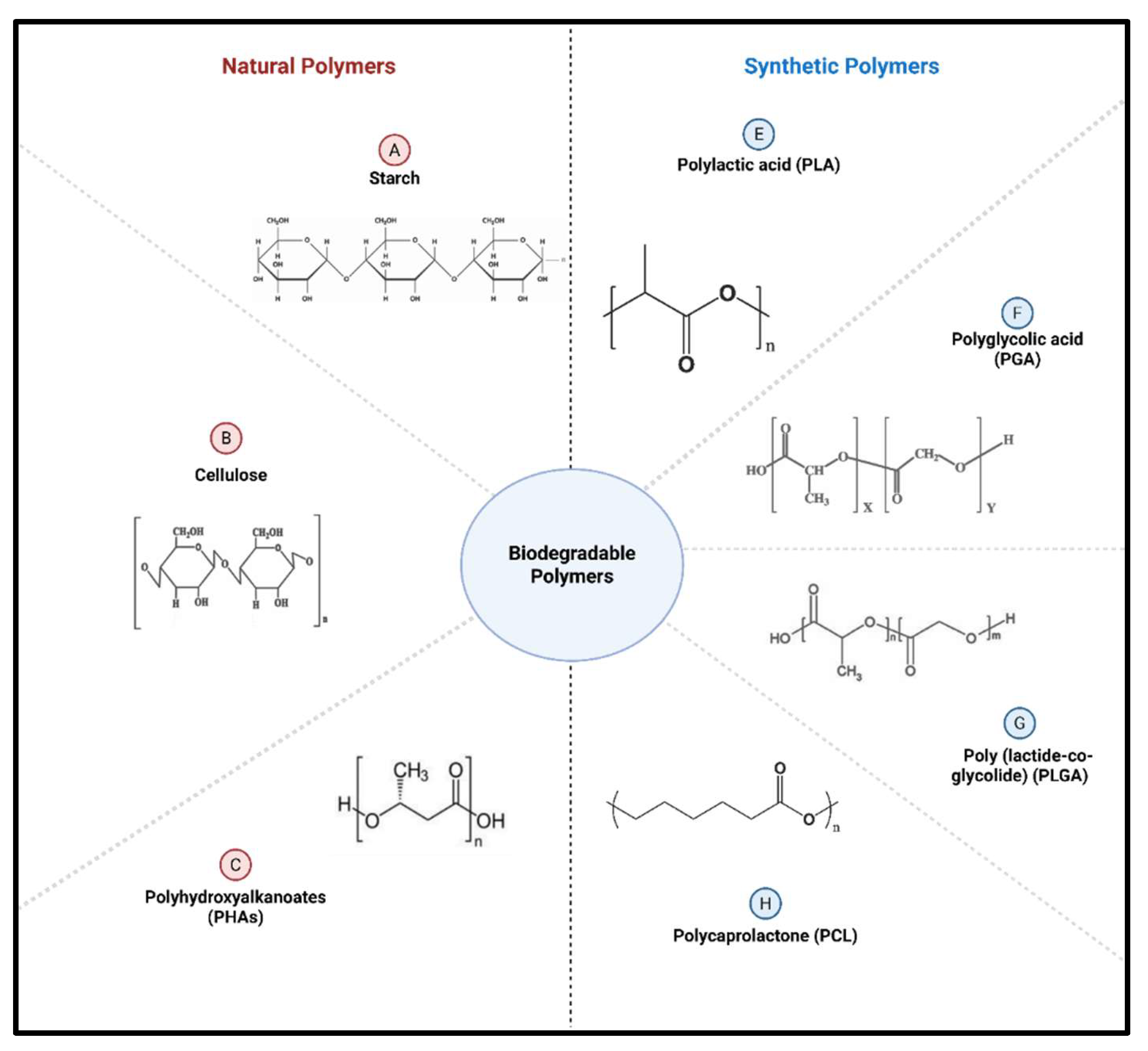

2.2. Biodegradable Polymers

2.2.1. Natural Biodegradable Polymers

- Starch;

- Cellulose;

- Polyhydroxyalkanoates (PHAs);

2.2.2. Synthetic Biodegradable Polymers

- Polylactic acid (PLA);

- Polyglycolic acid (PGA);

- Poly (lactide-co-glycolide) (PLGA);

- Polycaprolactone (PCL);

2.3. Key Physicochemical and Biological Properties

2.3.1. Degradation Mechanisms

2.3.2. Biocompatibility Metrics

2.3.3. Mechanical and Thermal Characteristics

3. Recent Technological Advancements

3.1. Surface Modification and Functionalization

3.1.1. PEGylation

3.1.2. Chemical and Plasma Treatments

- Chemical treatments;

- Plasma treatment;

3.2. Stimuli-Responsive Polymers

3.2.1. Temperature-Responsive Polymers

3.2.3. Redox-Sensitive Systems

3.3. Bio-Based and Green Synthesis

3.3.1. Renewable Sources (Lignin, Starch, Bacterial Fermentation)

3.3.2. Green Solvents and Catalysis

3.3.3. Eco-Friendly Processing Techniques

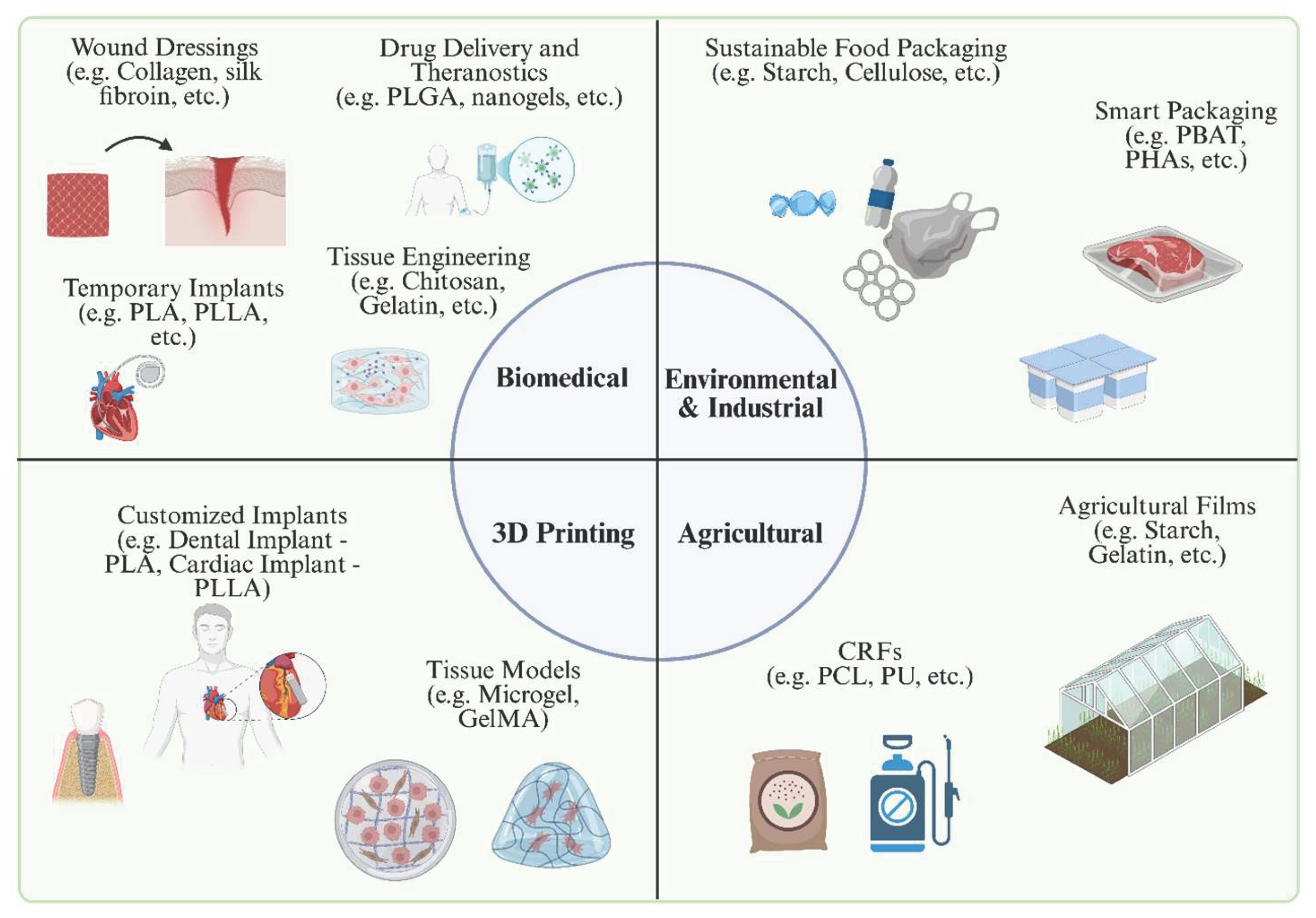

4. Applications in Key Sectors

4.1. Biomedical Applications

4.1.1. Drug Delivery Vehicles and Diagnostics

4.1.2. Tissue Engineering Scaffolds

- Bone Tissue Engineering;

- Cartilage Tissue Engineering;

- Neural Tissue Engineering;

- Skin and Wound Healing;

- Vascular and Cardiac Tissue Engineering;

- Other Soft Tissue Applications;

- Smart and Stimuli-Responsive Scaffolds;

4.1.3. Temporary Implants and Wound Healing Materials

- Temporary Implants;

- Wound Healing Materials;

4.2. Environmental and Industrial Uses

4.2.1. Sustainable Packaging Alternatives

- Natural Biopolymers for Packaging;

- Synthetic Biodegradable Polyesters;

- Blends, Composites, and Compatibilization;

- Active, Antioxidant, and Smart Packaging;

- Industrial Applications and Cross-Sector Relevance;

4.2.2. Agricultural Applications

- Biodegradable Mulch Films and Crop Covers

- Controlled- and Slow-Release Fertilizers

4.3. Additive Manufacturing and 3D Printing

4.3.1. Custom Implants

4.3.2. Dental and Craniofacial Applications

4.3.3. Tissue Models and Hydrogel Bioinks

4.3.4. Advanced Additive Manufacturing Technologies

4.3.5. Stimuli-Responsive and 4D Printing

5. Challenges and Limitations

5.1. Mechanical Property Enhancement

5.2. Degradation Kinetics and By-Products

5.3. Scalability and Cost

5.4. Regulatory and Standardization Issues

6. Future Prospects

6.1. Smart and Multi-Responsive Polymers

6.2. Integration with Bioelectronics and Sensors

6.3. Clinical Translation and Industrial Scalability

6.4. Circular Economy and Recyclability

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe • Enabling a Sustainable Future. Available online: https://plasticseurope.org/ (accessed on 24 September 2025).

- Booth, J.-P.; Mozetič, M.; Nikiforov, A.; Oehr, C. Foundations of Plasma Surface Functionalization of Polymers for Industrial and Biological Applications. Plasma Sources Sci. Technol. 2022, 31, 103001. [Google Scholar] [CrossRef]

- Plastic Pollution Is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD. Available online: https://www.oecd.org/en/about/news/press-releases/2022/02/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.html (accessed on 24 September 2025).

- Andanje, M.N.; Mwangi, J.W.; Mose, B.R.; Carrara, S. Biocompatible and Biodegradable 3D Printing from Bioplastics: A Review. Polymers 2023, 15, 2355. [Google Scholar] [CrossRef]

- Maurya, A.K.; de Souza, F.M.; Dawsey, T.; Gupta, R.K. Biodegradable Polymers and Composites: Recent Development and Challenges. Polymer Composites 2024, 45, 2896–2918. [Google Scholar] [CrossRef]

- Nalawade, S.P.; Picchioni, F.; Janssen, L.P.B.M. Supercritical Carbon Dioxide as a Green Solvent for Processing Polymer Melts: Processing Aspects and Applications. Progress in Polymer Science 2006, 31, 19–43. [Google Scholar] [CrossRef]

- Kurowiak, J.; Klekiel, T.; Będziński, R. Biodegradable Polymers in Biomedical Applications: A Review—Developments, Perspectives and Future Challenges. International Journal of Molecular Sciences 2023, 24, 16952. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, C.; Varghese, D.; Krishna, J.S.; Boominathan, T.; Rakeshkumar, R.; Dineshkumar, S.; Brahmananda Rao, C.V.S.; Sivaramakrishna, A. Recent Advances in Biodegradable Polymers – Properties, Applications and Future Prospects. European Polymer Journal 2023, 192, 112068. [Google Scholar] [CrossRef]

- Nanda, H.S.; Yang, L.; Hu, J.; Mao, H.; Jiang, S. Frontiers | Editorial: Biodegradable Polymers for Biomedical Applications. [CrossRef]

- Ibrahim, H.M.; El-Zairy, E.M.R. Chitosan as a Biomaterial — Structure, Properties, and Electrospun Nanofibers. In Concepts, Compounds and the Alternatives of Antibacterials; Bobbarala, V., Ed.; InTech, 2015 ISBN 978-953-51-2232-6.

- Oliver-Cuenca, V.; Salaris, V.; Muñoz-Gimena, P.F.; Agüero, Á.; Peltzer, M.A.; Montero, V.A.; Arrieta, M.P.; Sempere-Torregrosa, J.; Pavon, C.; Samper, M.D.; et al. Bio-Based and Biodegradable Polymeric Materials for a Circular Economy. Polymers 2024, 16, 3015. [Google Scholar] [CrossRef] [PubMed]

- Kurowiak, J.; Klekiel, T.; Będziński, R. Biodegradable Polymers in Biomedical Applications: A Review—Developments, Perspectives and Future Challenges. IJMS 2023, 24, 16952. [Google Scholar] [CrossRef] [PubMed]

- Castro, J.I.; Valencia-Llano, C.H.; Valencia Zapata, M.E.; Restrepo, Y.J.; Mina Hernandez, J.H.; Navia-Porras, D.P.; Valencia, Y.; Valencia, C.; Grande-Tovar, C.D. Chitosan/Polyvinyl Alcohol/Tea Tree Essential Oil Composite Films for Biomedical Applications. Polymers 2021, 13, 3753. [Google Scholar] [CrossRef]

- Chandarana, C.; Bonde, S.; Sonwane, S.; Prajapati, B. Chitosan-Based Packaging: Leading Sustainable Advancements in the Food Industry. Polym. Bull. 2025, 82, 5431–5462. [Google Scholar] [CrossRef]

- Zafar, W.; Tabassum, M.; Jia, X.; Yang, B.; Liu, H.; Xu, G.; Zafar, M.N. Chitosan-Based Bionanocomposites for Elimination of Hazardous Environmental Contaminants and Food Packaging: A Comprehensive Review. Sustainable Materials and Technologies 2025, 45, e01524. [Google Scholar] [CrossRef]

- Liu, Y.; Gilchrist, A.E.; Heilshorn, S.C. Engineered Protein Hydrogels as Biomimetic Cellular Scaffolds. Advanced Materials 2024, 36, 2407794. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.; Lee, J.; Park, T.Y.; Yang, Y.J.; Cha, H.J. Diverse Silk and Silk-like Proteins Derived from Terrestrial and Marine Organisms and Their Applications. Acta Biomaterialia 2021, 136, 56–71. [Google Scholar] [CrossRef] [PubMed]

- Schmuck, B.; Greco, G.; Pessatti, T.B.; Sonavane, S.; Langwallner, V.; Arndt, T.; Rising, A. Strategies for Making High-Performance Artificial Spider Silk Fibers. Adv Funct Materials 2024, 34, 2305040. [Google Scholar] [CrossRef] [PubMed]

- Gholipourmalekabadi, M.; Sapru, S.; Samadikuchaksaraei, A.; Reis, R.L.; Kaplan, D.L.; Kundu, S.C. Silk Fibroin for Skin Injury Repair: Where Do Things Stand? Advanced Drug Delivery Reviews 2020, 153, 28–53. [Google Scholar] [CrossRef]

- Senthilkumar, D.; Don, T.-M.; Liao, Y.-J.; Kuo, C.-Y. The Art of Biodegradable Polymer Design for the Treatments against Osteomyelitis. International Journal of Biological Macromolecules 2025, 285, 138347. [Google Scholar] [CrossRef]

- Kanoujia, J.; Raina, N.; Kishore, A.; Kaurav, M.; Tuli, H.S.; Kumar, A.; Gupta, M. Revealing the Promising Era of Silk-Based Nanotherapeutics: A Ray of Hope for Chronic Wound Healing Treatment. Naunyn-Schmiedeberg’s Arch Pharmacol 2025, 398, 6617–6641. [Google Scholar] [CrossRef]

- You, C.; Wang, C.; Ma, Z.; Yu, Q.; Liu, S. Review on Application of Silk Fibroin Hydrogels in the Management of Wound Healing. International Journal of Biological Macromolecules 2025, 298, 140082. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, Q.; Xu, X.; Liu, Z.; Cheng, G.; Long, D.; Cheng, L.; Dai, F. Recent Advances in Silk Fibroin-Based Composites for Bone Repair Applications: A Review. Polymers 2025, 17, 772. [Google Scholar] [CrossRef]

- Puerta, M.; Gomez-Maldonado, D.; Restrepo-Osorio, A.; Peresin, M.S. Self-Assembled Green Composites of Silk Fibroin and Microfibrillated Cellulose. MRS Bulletin 2025, 50, 846–855. [Google Scholar] [CrossRef]

- Sabarees, G.; Vishvaja, S.; Raghuraman, S.; Velmurugan, V.; Alagarsamy, V.; Raja Solomon, V.; Padmini Tamilarasi, G. Collagen-Based Nanofibers: Revolutionizing Therapeutics for Impaired Wound Healing. International Journal of Polymeric Materials and Polymeric Biomaterials 2025, 74, 1128–1156. [Google Scholar] [CrossRef]

- Sionkowska, A. Collagen Blended with Natural Polymers: Recent Advances and Trends. Progress in Polymer Science 2021, 122, 101452. [Google Scholar] [CrossRef]

- Davison-Kotler, E.; Marshall, W.S.; García-Gareta, E. Sources of Collagen for Biomaterials in Skin Wound Healing. Bioengineering 2019, 6, 56. [Google Scholar] [CrossRef]

- Furtado, M.; Chen, L.; Chen, Z.; Chen, A.; Cui, W. Development of Fish Collagen in Tissue Regeneration and Drug Delivery. Engineered Regeneration 2022, 3, 217–231. [Google Scholar] [CrossRef]

- Wosicka-Frąckowiak, H.; Poniedziałek, K.; Woźny, S.; Kuprianowicz, M.; Nyga, M.; Jadach, B.; Milanowski, B. Collagen and Its Derivatives Serving Biomedical Purposes: A Review. Polymers 2024, 16, 2668. [Google Scholar] [CrossRef]

- Ding, C.; Yi, Y.; Cheng, K.; Wang, Y.; Wang, S.; Zhang, M. Full Life Cycle Green Preparation of Collagen-Based Food Packaging Films Using Halocynthia Roretzi as Raw Material. Food Chemistry 2024, 455, 139943. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Wang, Q.; Xu, W.; Yang, M.; Guo, W.; He, S.; Liu, W. Alginate-Based Hydrogels Mediated Biomedical Applications: A Review. International Journal of Biological Macromolecules 2024, 279, 135019. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.; Azad, A.K.; Sulaiman, W.M.A.W.; Kumarasamy, V.; Subramaniyan, V.; Alshehade, S.A. Alginate-Based Encapsulation Fabrication Technique for Drug Delivery: An Updated Review of Particle Type, Formulation Technique, Pharmaceutical Ingredient, and Targeted Delivery System. Pharmaceutics 2024, 16, 370. [Google Scholar] [CrossRef] [PubMed]

- Hariyadi, D.M.; Islam, N. Current Status of Alginate in Drug Delivery. Advances in Pharmacological and Pharmaceutical Sciences 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Dong, Z.; Xu, J.; Lun, P.; Wu, Z.; Deng, W.; Sun, P. Dynamic Cross-Linking, Self-Healing, Antibacterial Hydrogel for Regenerating Irregular Cranial Bone Defects. ACS Appl. Mater. Interfaces 2024, 16, 39035–39050. [Google Scholar] [CrossRef]

- Metha, C.; Pawar, S.; Suvarna, V. Recent Advancements in Alginate-Based Films for Active Food Packaging Applications. Sustainable Food Technol. 2024, 2, 1246–1265. [Google Scholar] [CrossRef]

- D’souza, A.A.; Shegokar, R. Polyethylene Glycol (PEG): A Versatile Polymer for Pharmaceutical Applications. Expert Opinion on Drug Delivery 2016, 13, 1257–1275. [Google Scholar] [CrossRef]

- Jahani, A.; Nassira, H. Polyethylene Glycol-Based Materials: Transformative Applications in Biomedicine and the Food Industry. MCH 2024, 3, 1–25. [Google Scholar] [CrossRef]

- Jafri, N.H.S.; Jimat, D.N.; Wan Nawawi, W.M.F.; Ahmad Nor, Y.; Amid, A. Effect of Incorporating Cellulose Nanofibers and Lemongrass Essential Oil in Polyvinyl Alcohol-Polyethylene Glycol/Glycerin Hydrogel for Wound Dressing. IIUMEJ 2024, 25, 99–115. [Google Scholar] [CrossRef]

- Verma, V.S.; Pandey, A.; Jha, A.K.; Badwaik, H.K.R.; Alexander, A. ; Ajazuddin Polyethylene Glycol–Based Polymer-Drug Conjugates: Novel Design and Synthesis Strategies for Enhanced Therapeutic Efficacy and Targeted Drug Delivery. Appl Biochem Biotechnol 2024, 196, 7325–7361. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane Types, Synthesis and Applications – a Review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Cui, M.; Chai, Z.; Lu, Y.; Zhu, J.; Chen, J. Developments of Polyurethane in Biomedical Applications: A Review. Resources Chemicals and Materials 2023, 2, 262–276. [Google Scholar] [CrossRef]

- Jayalath, P.; Ananthakrishnan, K.; Jeong, S.; Shibu, R.P.; Zhang, M.; Kumar, D.; Yoo, C.G.; Shamshina, J.L.; Therasme, O. Bio-Based Polyurethane Materials: Technical, Environmental, and Economic Insights. Processes 2025, 13, 1591. [Google Scholar] [CrossRef]

- Hedir, G.; Stubbs, C.; Aston, P.; Dove, A.P.; Gibson, M.I. Synthesis of Degradable Poly(Vinyl Alcohol) by Radical Ring-Opening Copolymerization and Ice Recrystallization Inhibition Activity. ACS Macro Lett. 2017, 6, 1404–1408. [Google Scholar] [CrossRef]

- Hedayati, H.R.; Khorasani, M.; Ahmadi, M.; Ballard, N. Preparation of Well-Defined Poly(Vinyl Alcohol) by Hydrolysis of Poly(Vinyl Acetate) Synthesized by RAFT Suspension Polymerization. Polymer 2022, 246, 124674. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Lan, W. Fabrication of Antibacterial Chitosan-PVA Blended Film Using Electrospray Technique for Food Packaging Applications. International Journal of Biological Macromolecules 2018, 107, 848–854. [Google Scholar] [CrossRef] [PubMed]

- Rahman Khan, M.M.; Rumon, Md.M.H. Synthesis of PVA-Based Hydrogels for Biomedical Applications: Recent Trends and Advances. Gels 2025, 11, 88. [Google Scholar] [CrossRef]

- Trigui, K.; Magnin, A.; Putaux, J.-L.; Boufi, S. Poly(Vinyl Alcohol)/Oxidized Cellulose Nanofibril Composite Films with High Nanofiller Content for Enhanced Packaging Applications. Journal of Industrial and Engineering Chemistry 2025, 148, 602–613. [Google Scholar] [CrossRef]

- Omidian, H.; Wilson, R.L. PLGA Implants for Controlled Drug Delivery and Regenerative Medicine: Advances, Challenges, and Clinical Potential. Pharmaceuticals 2025, 18, 631. [Google Scholar] [CrossRef]

- Arruda, T.R.; Machado, G.D.O.; Marques, C.S.; Souza, A.L.D.; Pelissari, F.M.; Oliveira, T.V.D.; Silva, R.R.A. An Overview of Starch-Based Materials for Sustainable Food Packaging: Recent Advances, Limitations, and Perspectives. Macromol 2025, 5, 19. [Google Scholar] [CrossRef]

- Chouhan, A.; Tiwari, A. Production of Polyhydroxyalkanoate (PHA) Biopolymer from Crop Residue Using Bacteria as an Alternative to Plastics: A Review. RSC Adv. 2025, 15, 11845–11862. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Biduski, B.; Silva, W.M.F.D.; Colussi, R.; Halal, S.L.D.M.E.; Lim, L.-T.; Dias, Á.R.G.; Zavareze, E.D.R. Starch Hydrogels: The Influence of the Amylose Content and Gelatinization Method. International Journal of Biological Macromolecules 2018, 113, 443–449. [Google Scholar] [CrossRef]

- Perez-Rea, D.; Bergenståhl, B.; Nilsson, L. Development and Evaluation of Methods for Starch Dissolution Using Asymmetrical Flow Field-Flow Fractionation. Part I: Dissolution of Amylopectin. Anal Bioanal Chem 2015, 407, 4315–4326. [Google Scholar] [CrossRef] [PubMed]

- Handbook of Polymer Applications in Medicine and Medical Devices; Modjarrad, K. , Ebnesajjad, S., Plastics Design Library, Eds.; Plastics design library handbook series; Elsevier Science: Oxford, 2014; ISBN 978-0-323-22169-6. [Google Scholar]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. npj Mater Degrad 2022, 6, 68. [Google Scholar] [CrossRef]

- Karnwal, A.; Rauf, A.; Jassim, A.Y.; Selvaraj, M.; Al-Tawaha, A.R.M.S.; Kashyap, P.; Kumar, D.; Malik, T. Advanced Starch-Based Films for Food Packaging: Innovations in Sustainability and Functional Properties. Food Chemistry: X 2025, 29, 102662. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Yang, Y.; Zhang, D.; Hao, G. Multifunctional Natural Starch-Based Hydrogels: Critical Characteristics, Formation Mechanisms, Various Applications, Future Perspectives. Carbohydrate Polymers 2025, 357, 123458. [Google Scholar] [CrossRef]

- Alipournazari, P.; Pourmadadi, M.; Abdouss, M.; Rahdar, A.; Pandey, S. Enhanced Delivery of Doxorubicin for Breast Cancer Treatment Using pH-Sensitive Starch/PVA/g-C3N4 Hydrogel. International Journal of Biological Macromolecules 2024, 265, 130901. [Google Scholar] [CrossRef] [PubMed]

- Kadri, H.J.; Ahmed, F.; Rahman, Md.H.; Mondal, Md.I.H. Synthesis and Characterisation of Starch-g-Polyacrylamide-Co-Polylactic Acid Hydrogel for the Potential Wound Dressing Application. Polym. Bull. 2025, 82, 7917–7941. [Google Scholar] [CrossRef]

- Costa, T.B.; Matias, P.M.C.; Sharma, M.; Murtinho, D.; Rosa, D.S.; Valente, A.J.M. Recent Advances on Starch-Based Adsorbents for Heavy Metal and Emerging Pollutant Remediation. Polymers 2024, 17, 15. [Google Scholar] [CrossRef] [PubMed]

- Junka, A.; Bartoszewicz, M.; Dziadas, M.; Szymczyk, P.; Dydak, K.; Żywicka, A.; Owczarek, A.; Bil-Lula, I.; Czajkowska, J.; Fijałkowski, K. Application of Bacterial Cellulose Experimental Dressings Saturated with Gentamycin for Management of Bone Biofilm in Vitro and Ex Vivo. J Biomed Mater Res 2020, 108, 30–37. [Google Scholar] [CrossRef]

- Shah, T.V.; Vasava, D.V. A Glimpse of Biodegradable Polymers and Their Biomedical Applications. e-Polymers 2019, 19, 385–410. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable Polymers- A Review on Recent Trends and Emerging Perspectives. J Polym Environ 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Dalton, B.; Bhagabati, P.; De Micco, J.; Padamati, R.B.; O’Connor, K. A Review on Biological Synthesis of the Biodegradable Polymers Polyhydroxyalkanoates and the Development of Multiple Applications. Catalysts 2022, 12, 319. [Google Scholar] [CrossRef]

- Kumar, S.; Thakur, K. Bioplastics - Classification, Production and Their Potential Food Applications. Jour. Hill Agricul. 2017, 8, 118. [Google Scholar] [CrossRef]

- Lalonde, J.N.; Pilania, G.; Marrone, B.L. Materials Designed to Degrade: Structure, Properties, Processing, and Performance Relationships in Polyhydroxyalkanoate Biopolymers. Polym. Chem. 2025, 16, 235–265. [Google Scholar] [CrossRef]

- McAdam, B.; Brennan Fournet, M.; McDonald, P.; Mojicevic, M. Production of Polyhydroxybutyrate (PHB) and Factors Impacting Its Chemical and Mechanical Characteristics. Polymers 2020, 12, 2908. [Google Scholar] [CrossRef]

- Suzuki, M.; Tachibana, Y.; Kasuya, K. Biodegradability of Poly(3-Hydroxyalkanoate) and Poly(ε-Caprolactone) via Biological Carbon Cycles in Marine Environments. Polym J 2021, 53, 47–66. [Google Scholar] [CrossRef]

- Tebaldi, M.L.; Maia, A.L.C.; Poletto, F.; De Andrade, F.V.; Soares, D.C.F. Poly(-3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV): Current Advances in Synthesis Methodologies, Antitumor Applications and Biocompatibility. Journal of Drug Delivery Science and Technology 2019, 51, 115–126. [Google Scholar] [CrossRef]

- Jin, A.; Del Valle, L.J.; Puiggalí, J. Copolymers and Blends Based on 3-Hydroxybutyrate and 3-Hydroxyvalerate Units. IJMS 2023, 24, 17250. [Google Scholar] [CrossRef] [PubMed]

- Perveen, K.; Masood, F.; Hameed, A. Preparation, Characterization and Evaluation of Antibacterial Properties of Epirubicin Loaded PHB and PHBV Nanoparticles. International Journal of Biological Macromolecules 2020, 144, 259–266. [Google Scholar] [CrossRef]

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent Advances in the Development of Biodegradable PHB-Based Toughening Materials: Approaches, Advantages and Applications. Materials Science and Engineering: C 2018, 92, 1092–1116. [Google Scholar] [CrossRef]

- Keskin, G.; Kızıl, G.; Bechelany, M.; Pochat-Bohatier, C.; Öner, M. Potential of Polyhydroxyalkanoate (PHA) Polymers Family as Substitutes of Petroleum Based Polymers for Packaging Applications and Solutions Brought by Their Composites to Form Barrier Materials. Pure and Applied Chemistry 2017, 89, 1841–1848. [Google Scholar] [CrossRef]

- Kalva, S.N.; Zakaria, Y.; Velasquez, C.A.; Koç, M. Tailoring the Mechanical and Degradation Properties of 3DP PLA/PCL Scaffolds for Biomedical Applications. REVIEWS ON ADVANCED MATERIALS SCIENCE 2025, 64, 20250098. [Google Scholar] [CrossRef]

- Vengadesan, E.; Morakul, S.; Muralidharan, S.; Pullela, P.K.; Alarifi, A.; Arunkumar, T. Enhancement of Polylactic Acid (PLA) with Hybrid Biomass-Derived Rice Husk and Biocarbon Fillers: A Comprehensive Experimental Study. Discov Appl Sci 2025, 7, 161. [Google Scholar] [CrossRef]

- Pullarkad Bharathan, S.; Johnsy, G.; Raju, A.P.; Guthige, M.R.; Gowdahalli Mantelingachar, C.; Vasudevan, V.; Madan, R.; Kumar, R. Sustainable Antimicrobial Packaging Films: Effectiveness of Epsilon-Poly-L-Lysine in PLA/PBAT Blend Films. Sustainable Food Technol. 2025; 10.1039.D5FB00286A. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, J.; Ren, X. Natural Fiber-Based Biocomposites. In Green Biocomposites. In Green Biocomposites; Green Energy and Technology; Jawaid, M., Sapuan, S.M., Alothman, O.Y., Eds.; Springer International Publishing: Cham, 2017; ISBN 978-3-319-46609-5. [Google Scholar]

- Ghanbarzadeh, B.; Almasi, H. Biodegradable Polymers. In Biodegradation - Life of Science; Chamy, R., Ed.; InTech, 2013 ISBN 978-953-51-1154-2.

- Shin, H.; Kim, H.; Lee, J.; Sadeghi, K.; Seo, J. PBAT/PGA Blend Films for Sustainable Packaging: Effect of PGA on Physicochemical and Morphological Changes during Abiotic Degradation. Food Packaging and Shelf Life 2025, 51, 101589. [Google Scholar] [CrossRef]

- Qiu, X.; Li, S.; Li, X.; Xiao, Y.; Li, S.; Fen, Q.; Kang, X.; Zhen, P. Experimental Study of β-TCP Scaffold Loaded with VAN/PLGA Microspheres in the Treatment of Infectious Bone Defects. Colloids and Surfaces B: Biointerfaces 2022, 213, 112424. [Google Scholar] [CrossRef] [PubMed]

- Tu, S.; Mai, S.; Shu, D.; Huang, Y.; Nie, Z.; Wang, Y.; Yang, W. Microfluidic-Based Preparation of PLGA Microspheres Facilitating Peptide Sustained-Release. Materials Letters 2024, 368, 136675. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J. Biodegradable Polymers and Polymer Blends. In Handbook of Biopolymers and Biodegradable Plastics; Elsevier, 2013; pp. 109–128 ISBN 978-1-4557-2834-3.

- Firoozi, N.; Rezayan, A.H.; Tabatabaei Rezaei, S.J.; Mir-Derikvand, M.; Nabid, M.R.; Nourmohammadi, J.; Mohammadnejad Arough, J. Synthesis of Poly(ε-Caprolactone)-Based Polyurethane Semi-Interpenetrating Polymer Networks as Scaffolds for Skin Tissue Regeneration. International Journal of Polymeric Materials and Polymeric Biomaterials 2017, 66, 805–811. [Google Scholar] [CrossRef]

- Gedik, B.; Erdem, M.A. Electrospun PCL Membranes for Localized Drug Delivery and Bone Regeneration. BMC Biotechnol 2025, 25, 31. [Google Scholar] [CrossRef]

- Yao, X.; Yang, X.; Lu, Y.; Qiu, Y.; Zeng, Q. Review of the Synthesis and Degradation Mechanisms of Some Biodegradable Polymers in Natural Environments. Polymers 2024, 17, 66. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A Review on Degradation Mechanisms of Polylactic Acid: Hydrolytic, Photodegradative, Microbial, and Enzymatic Degradation. Polymer Engineering & Sci 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Kliem, S.; Kreutzbruck, M.; Bonten, C. Review on the Biological Degradation of Polymers in Various Environments. Materials 2020, 13, 4586. [Google Scholar] [CrossRef]

- Rosa, V.; Silikas, N.; Yu, B.; Dubey, N.; Sriram, G.; Zinelis, S.; Lima, A.F.; Bottino, M.C.; Ferreira, J.N.; Schmalz, G.; et al. Guidance on the Assessment of Biocompatibility of Biomaterials: Fundamentals and Testing Considerations. Dental Materials 2024, 40, 1773–1785. [Google Scholar] [CrossRef]

- Chen, Y.; Su, Y.-C.; Roffler, S.R. Polyethylene Glycol Immunogenicity in Nanomedicine. Nat Rev Bioeng 2025. [Google Scholar] [CrossRef]

- Liu, R.; He, T.; Li, R.; Wang, S.; Lai, C.; Zhang, K. Comparison of Different Types of Poly-L-Lactic Acid Microspheres In Vitro and In Vivo Studies. Aesthetic Surgery Journal Open Forum 2024, 6, ojae091. [Google Scholar] [CrossRef]

- Filippi, M.; Born, G.; Chaaban, M.; Scherberich, A. Natural Polymeric Scaffolds in Bone Regeneration. Front. Bioeng. Biotechnol. 2020, 8, 474. [Google Scholar] [CrossRef]

- Farjaminejad, S.; Farjaminejad, R.; Hasani, M.; Garcia-Godoy, F.; Abdouss, M.; Marya, A.; Harsoputranto, A.; Jamilian, A. Advances and Challenges in Polymer-Based Scaffolds for Bone Tissue Engineering: A Path Towards Personalized Regenerative Medicine. Polymers 2024, 16, 3303. [Google Scholar] [CrossRef]

- Shah, Y.A.; Bhatia, S.; Al-Harrasi, A.; Oz, F.; Khan, M.H.; Roy, S.; Esatbeyoglu, T.; Pratap-Singh, A. Thermal Properties of Biopolymer Films: Insights for Sustainable Food Packaging Applications. Food Eng Rev 2024, 16, 497–512. [Google Scholar] [CrossRef]

- Kalva, S.N.; Zakaria, Y.; Velasquez, C.A.; Koç, M. Tailoring the Mechanical and Degradation Properties of 3DP PLA/PCL Scaffolds for Biomedical Applications. REVIEWS ON ADVANCED MATERIALS SCIENCE 2025, 64, 20250098. [Google Scholar] [CrossRef]

- Hetemi, D.; Pinson, J. Surface Functionalisation of Polymers. Chem. Soc. Rev. 2017, 46, 5701–5713. [Google Scholar] [CrossRef]

- Aditya, T.; Allain, J.P.; Jaramillo, C.; Restrepo, A.M. Surface Modification of Bacterial Cellulose for Biomedical Applications. International Journal of Molecular Sciences 2022, 23, 610. [Google Scholar] [CrossRef]

- Sun, W.; Liu, W.; Wu, Z.; Chen, H. Chemical Surface Modification of Polymeric Biomaterials for Biomedical Applications. Macromolecular Rapid Communications 2020, 41, 1900430. [Google Scholar] [CrossRef]

- Gao, Y.; Joshi, M.; Zhao, Z.; Mitragotri, S. PEGylated Therapeutics in the Clinic. Bioengineering & Translational Medicine 2024, 9, e10600. [Google Scholar] [CrossRef]

- Yadav, D.; Dewangan, H.K. PEGYLATION: An Important Approach for Novel Drug Delivery System. Journal of Biomaterials Science, Polymer Edition 2021, 32, 266–280. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Zhang, J.; Zhao, M.; Tang, S.; Cheng, X.; Zhang, W.; Li, W.; Liu, X.; Peng, H.; Wang, Q. Effects of Polyethylene Glycol on the Surface of Nanoparticles for Targeted Drug Delivery. 2021. [Google Scholar] [CrossRef]

- Hoang Thi, T.T.; Pilkington, E.H.; Nguyen, D.H.; Lee, J.S.; Park, K.D.; Truong, N.P. The Importance of Poly(Ethylene Glycol) Alternatives for Overcoming PEG Immunogenicity in Drug Delivery and Bioconjugation. Polymers (Basel) 2020, 12, 298. [Google Scholar] [CrossRef]

- Kurul, F.; Doruk, B.; Topkaya, S.N. Principles of Green Chemistry: Building a Sustainable Future. Discover Chemistry 2025, 2, 1–25. [Google Scholar] [CrossRef]

- Godinho, B.M.D.C.; Ogier, J.R.; Quinlan, A.; Darcy, R.; Griffin, B.T.; Cryan, J.F.; O’Driscoll, C.M. PEGylated Cyclodextrins as Novel siRNA Nanosystems: Correlations between Polyethylene Glycol Length and Nanoparticle Stability. International Journal of Pharmaceutics 2014, 473, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Hoang Thi, T.T.; Pilkington, E.H.; Nguyen, D.H.; Lee, J.S.; Park, K.D.; Truong, N.P. The Importance of Poly(Ethylene Glycol) Alternatives for Overcoming PEG Immunogenicity in Drug Delivery and Bioconjugation. Polymers 2020, 12, 298. [Google Scholar] [CrossRef]

- Md, C.; P, C.; E, C.; L, K.; L, T.; M, M.; T, H.; Ml, R.; C, B.; An, E.; et al. Comparative Pharmacokinetics of Two Extended Half-Life FVIII Concentrates (Eloctate and Adynovate) in Adolescents with Hemophilia A: Is There a Difference? PubMed.

- Makharadze, D.; del Valle, L.J.; Katsarava, R.; Puiggalí, J. The Art of PEGylation: From Simple Polymer to Sophisticated Drug Delivery System. Int J Mol Sci 2025, 26, 3102. [Google Scholar] [CrossRef] [PubMed]

- Robella, M.; Vaira, M.; Argenziano, M.; Spagnolo, R.; Cavalli, R.; Borsano, A.; Gentilli, S.; De Simone, M. Exploring the Use of Pegylated Liposomal Doxorubicin (Caelyx®) as Pressurized Intraperitoneal Aerosol Chemotherapy. Front. Pharmacol. 2019, 10. [Google Scholar] [CrossRef] [PubMed]

- Makharadze, D.; del Valle, L.J.; Katsarava, R.; Puiggalí, J. The Art of PEGylation: From Simple Polymer to Sophisticated Drug Delivery System. Int J Mol Sci 2025, 26, 3102. [Google Scholar] [CrossRef]

- Zaky, M.F.; Hammady, T.M.; Gad, S.; Alattar, A.; Alshaman, R.; Hegazy, A.; Zaitone, S.A.; Ghorab, M.M.; Megahed, M.A. Influence of Surface-Modification via PEGylation or Chitosanization of Lipidic Nanocarriers on In Vivo Pharmacokinetic/Pharmacodynamic Profiles of Apixaban. Pharmaceutics 2023, 15, 1668. [Google Scholar] [CrossRef]

- Demirel, E.; Karaca, E.; Yuksel Durmaz, Y. Effective PEGylation Method to Improve Biocompatibility of Graphene Derivatives. European Polymer Journal 2020, 124, 109504. [Google Scholar] [CrossRef]

- Kesharwani, P.; Kumar, V.; Goh, K.W.; Gupta, G.; Alsayari, A.; Wahab, S.; Sahebkar, A. PEGylated PLGA Nanoparticles: Unlocking Advanced Strategies for Cancer Therapy. Molecular Cancer 2025, 24, 1–37. [Google Scholar] [CrossRef]

- Nemani, K.; Annavarapu, R.K.; Mohammadian, B.; Raiyan, A.; Heil, J.; Haque, M.; Abdelaal, A.; Sojoudi, H. Surface Modification: Surface Modification of Polymers: Methods and Applications (Adv. Mater. Interfaces 24/2018). Advanced Materials Interfaces 2018, 5. [Google Scholar] [CrossRef]

- T, A.; Jp, A.; C, J.; Am, R. Surface Modification of Bacterial Cellulose for Biomedical Applications. PubMed 2022. [Google Scholar]

- Kurhade, R.R.; Shaikh, M.S.; Nagulwar, V.; Kale, M.A. Advancements in Carboxymethyl Cellulose (CMC) Modifications and Their Diverse Biomedical Applications: A Comprehensive Review. International Journal of Polymeric Materials and Polymeric Biomaterials 2025, 74, 1043–1067. [Google Scholar] [CrossRef]

- Yang, Q.; Pan, X. Introducing Hydroxyl Groups as Cellulose-Binding Sites into Polymeric Solid Acids to Improve Their Catalytic Performance in Hydrolyzing Cellulose. Carbohydrate Polymers 2021, 261, 117895. [Google Scholar] [CrossRef]

- Chen, J.; Garcia, E.S.; Zimmerman, S.C. Intramolecularly Cross-Linked Polymers: From Structure to Function with Applications as Artificial Antibodies and Artificial Enzymes. Acc. Chem. Res. 2020, 53, 1244–1256. [Google Scholar] [CrossRef] [PubMed]

- Musa, A.A.; Bello, A.; Adams, S.M.; Onwualu, A.P.; Anye, V.C.; Bello, K.A.; Obianyo, I.I. Nano-Enhanced Polymer Composite Materials: A Review of Current Advancements and Challenges. Polymers 2025, 17, 893. [Google Scholar] [CrossRef]

- Sharma, H.; Arora, G.; Singh, M.K.; Rangappa, S.M.; Bhowmik, P.; Kumar, R.; Debnath, S.; Siengchin, S. From Composition to Performance: Structural Insights into Polymer Composites. Next Materials 2025, 8, 100852. [Google Scholar] [CrossRef]

- Musa, A.A.; Bello, A.; Adams, S.M.; Onwualu, A.P.; Anye, V.C.; Bello, K.A.; Obianyo, I.I. Nano-Enhanced Polymer Composite Materials: A Review of Current Advancements and Challenges. Polymers 2025, 17, 893. [Google Scholar] [CrossRef] [PubMed]

- Laurano, R.; Boffito, M.; Torchio, A.; Cassino, C.; Chiono, V.; Ciardelli, G. Plasma Treatment of Polymer Powder as an Effective Tool to Functionalize Polymers: Case Study Application on an Amphiphilic Polyurethane. Polymers 2019, 11, 2109. [Google Scholar] [CrossRef]

- Primc, G.; Mozetič, M. Surface Modification of Polymers by Plasma Treatment for Appropriate Adhesion of Coatings. Materials 2024, 17, 1494. [Google Scholar] [CrossRef]

- Bhatt, P.; Kumar, V.; Subramaniyan, V.; Nagarajan, K.; Sekar, M.; Chinni, S.V.; Ramachawolran, G. Plasma Modification Techniques for Natural Polymer-Based Drug Delivery Systems. Pharmaceutics 2023, 15, 2066. [Google Scholar] [CrossRef]

- Koodaryan, R.; Hafezeqoran, A. Surface Modification of Dental Polymers by Plasma Treatment: A Review.

- Pidhatika, B.; Widyaya, V.T.; Nalam, P.C.; Swasono, Y.A.; Ardhani, R. Surface Modifications of High-Performance Polymer Polyetheretherketone (PEEK) to Improve Its Biological Performance in Dentistry. Polymers 2022, 14, 5526. [Google Scholar] [CrossRef]

- Sundriyal, P.; Sahu, M.; Prakash, O.; Bhattacharya, S. Long-Term Surface Modification of PEEK Polymer Using Plasma and PEG Silane Treatment. Surfaces and Interfaces 2021, 25, 101253. [Google Scholar] [CrossRef]

- Hu, L.; Wan, Y.; Zhang, Q.; Serpe, M.J. Harnessing the Power of Stimuli-Responsive Polymers for Actuation. Advanced Functional Materials 2020, 30, 1903471. [Google Scholar] [CrossRef]

- Ofridam, F.; Tarhini, M.; Lebaz, N.; Gagnière, É.; Mangin, D.; Elaissari, A. pH-Sensitive Polymers: Classification and Some Fine Potential Applications. Polymers for Advanced Technologies 2021, 32, 1455–1484. [Google Scholar] [CrossRef]

- Bratek-Skicki, A. Towards a New Class of Stimuli-Responsive Polymer-Based Materials – Recent Advances and Challenges. Applied Surface Science Advances 2021, 4, 100068. [Google Scholar] [CrossRef]

- Das, S.S.; Bharadwaj, P.; Bilal, M.; Barani, M.; Rahdar, A.; Taboada, P.; Bungau, S.; Kyzas, G.Z. Stimuli-Responsive Polymeric Nanocarriers for Drug Delivery, Imaging, and Theragnosis. Polymers 2020, 12, 1397. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Weber, C.; Schubert, U.S.; Hoogenboom, R. Thermoresponsive Polymers with Lower Critical Solution Temperature: From Fundamental Aspects and Measuring Techniques to Recommended Turbidimetry Conditions. [CrossRef]

- Yuan, Y.; Raheja, K. ; B. Milbrandt, N.; Beilharz, S., Tene, S., Oshabaheebwa, S., A. Gurkan, U., S. Samia, A.C., Eds.; Karayilan, M. Thermoresponsive Polymers with LCST Transition: Synthesis, Characterization, and Their Impact on Biomedical Frontiers. 2023. [Google Scholar] [CrossRef]

- Sharker, K.K.; Shigeta, Y.; Ozoe, S.; Damsongsang, P.; Hoven, V.P.; Yusa, S. Upper Critical Solution Temperature Behavior of pH-Responsive Amphoteric Statistical Copolymers in Aqueous Solutions. ACS Omega 2021, 6, 9153–9163. [Google Scholar] [CrossRef]

- Kotsuchibashi, Y. Recent Advances in Multi-Temperature-Responsive Polymeric Materials. Polymer Journal 2020, 52, 681–689. [Google Scholar] [CrossRef]

- Halligan, E.; Zhuo, S.; Colbert, D.M.; Alsaadi, M.; Tie, B.S.H.; Bezerra, G.S.N.; Keane, G.; Geever, L.M. Modulation of the Lower Critical Solution Temperature of Thermoresponsive Poly(N-Vinylcaprolactam) Utilizing Hydrophilic and Hydrophobic Monomers. Polymers 2023, 15, 1595. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, J.; Peng, J.; Ye, T.; Wang, Y.; Huang, R.; Zhang, Y.; Ren, Y.; Zhou, Y.; Tang, D. Carboxyl-Functionalized Dual pH/Temperature-Responsive Poly(N-Vinylcaprolactam) Microgels Based on Isogenous Comonomers for Smart Window Applications. Journal of Colloid and Interface Science 2025, 678, 1–10. [Google Scholar] [CrossRef]

- Xiang, N.; Lin, Y.; Qin, Z.; Su, T.; Xie, X.; Ji, H. Temperature-Responsive Gating Chitosan-Based Microcapsules for Controlled Release of Urea Fertilizers. Carbohydrate Polymers 2025, 348, 122929. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Guo, Y.; Inomata, K. Lower Critical Solution Temperature Behavior of Poly(2-Chloroethyl Vinyl Ether-Alt-Maleic Anhydride) in Organic Media. Polymer Journal 2010, 42, 901–904. [Google Scholar] [CrossRef]

- Concilio, M.; Beyer, V.P.; Remzi Becer, C. Thermoresponsive Polymers in Non-Aqueous Solutions. 2022. [Google Scholar] [CrossRef]

- Korpanty, J.; Wang, C.; Gianneschi, N.C. Upper Critical Solution Temperature Polymer Assemblies via Variable Temperature Liquid Phase Transmission Electron Microscopy and Liquid Resonant Soft X-Ray Scattering. Nature Communications 2023, 14, 3441. [Google Scholar] [CrossRef]

- Le, M.; Huang, W.; Chen, K.-F.; Lin, C.; Cai, L.; Zhang, H.; Jia, Y.-G. Upper Critical Solution Temperature Polymeric Drug Carriers. Chemical Engineering Journal 2022, 432, 134354. [Google Scholar] [CrossRef]

- Stetsyshyn, Y.; Raczkowska, J.; Harhay, K.; Gajos, K.; Melnyk, Y.; Dąbczyński, P.; Shevtsova, T.; Budkowski, A. Temperature-Responsive and Multi-Responsive Grafted Polymer Brushes with Transitions Based on Critical Solution Temperature: Synthesis, Properties, and Applications. Colloid and Polymer Science 2020, 299, 363–383. [Google Scholar] [CrossRef]

- Yang, L.; Yuan, Q.-Y.; Li, T.-T.; Lou, C.-W.; Hung, C.; Lin, J.-H. Recent Developments and Applications of pH-Responsive Polymers. Textile Research Journal 2025, 95, 2248–2272. [Google Scholar] [CrossRef]

- AlSawaftah, N.M.; Awad, N.S.; Pitt, W.G.; Husseini, G.A. pH-Responsive Nanocarriers in Cancer Therapy. Polymers 2022, 14, 936. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, Y.; Zou, Y.; Lu, C.; Li, N.; Shi, Z.; Li, X.; Lai, X. Ultra-Sensitive pH Responsive Hydrogels with Injectable and Self-Healing Performance for Controlled Drug Delivery. International Journal of Pharmaceutics: X 2025, 9, 100334. [Google Scholar] [CrossRef]

- Twal, S.; Jaber, N.; Al-Remawi, M.; Hamad, I.; Al-Akayleh, F.; Alshaer, W. Dual Stimuli-Responsive Polymeric Nanoparticles Combining Soluplus and Chitosan for Enhanced Breast Cancer Targeting. 2024. [Google Scholar] [CrossRef]

- Kim, T.M.; Subba, S.H.; Hwang, Y.K.; Kim, S.G.; Park, J.; Jin, E.-J.; Park, S.Y. Electrical and Fluorescence in Situ Monitoring of Tumor Microenvironment-Based pH-Responsive Polymer Dot Coated Surface. Talanta 2025, 281, 126840. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Shi, X.; Tian, Y.; Gao, F. pH-Responsive Polymer Nanomaterials for Tumor Therapy. Front. Oncol. 2022, 12. [Google Scholar] [CrossRef]

- Iftikhar, I.; Barkat, K.; Badshah, S.F.; Ashraf, M.U.; Mehmood, Y.; Anjum, I.; Shazly, G.A.; Metouekel, A.; Younous, Y.A.; Bourhia, M. Formulation of pH Responsive Polymeric Hydrogels for Prolonged Delivery of Famciclovir with Biosafety Evaluation. Scientific Reports 2025, 15, 18686. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Huang, T.; Liu, Y.; Chen, L.; Liao, S.; Gong, X.; Bello, M.G.; Zhu, W.; Huang, S.; Zhang, X. Loading Curcumin on Hyperbranched Polymers Functionalized Zein via the Phenol-Yne Click Reaction as pH-Responsive Drug Delivery System for Chemotherapy and Photodynamic Therapy. International Journal of Biological Macromolecules 2025, 293, 139750. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Hao, P.; Wang, W.; Guo, G.; Wu, C.; Ge, R. Development and Characterization of a Poly(Amino Acid)-Based pH-Responsive Dual-Mode Antibacterial Nanoparticles Dental Restorative Resin. Journal of Applied Polymer Science 2025, 142, e57570. [Google Scholar] [CrossRef]

- Jiao, X.; Chong, X.; Du, H.; Yang, M.; Zhu, Z.; Ma, Z.; Wen, Y. Development of pH and Enzyme Dual Responsive Chitosan/Polyaspartic Acid Nanoparticle-Embedded Nanofibers for Fruit Preservation. International Journal of Biological Macromolecules 2025, 297, 139903. [Google Scholar] [CrossRef]

- Shin, S.; Kim, S.; Hong, S.; Kim, N.; Kang, J.; Jeong, J. Tuning the Swelling Behavior of Superabsorbent Hydrogels with a Branched Poly(Aspartic Acid) Crosslinker. Gels 2025, 11, 161. [Google Scholar] [CrossRef]

- Huo, M.; Yuan, J.; Tao, L.; Wei, Y. Redox-Responsive Polymers for Drug Delivery: From Molecular Design to Applications. [CrossRef]

- Xu, L.; Cao, Y.; Xu, Y.; Li, R.; Xu, X. Redox-Responsive Polymeric Nanoparticle for Nucleic Acid Delivery and Cancer Therapy: Progress, Opportunities, and Challenges. Macromolecular Bioscience 2024, 24, 2300238. [Google Scholar] [CrossRef]

- Kilic Boz, R.; Aydin, D.; Kocak, S.; Golba, B.; Sanyal, R.; Sanyal, A. Redox-Responsive Hydrogels for Tunable and “On-Demand” Release of Biomacromolecules. Bioconjugate Chem. 2022, 33, 839–847. [Google Scholar] [CrossRef]

- Dabas, R.; Kamaly, N. Redox-Responsive Nanogels for Precision Protein Delivery. European Polymer Journal 2024, 215, 113183. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, X.; Du, J.; Chen, X.; Xue, Y.; Zhang, J.; Yang, X.; Chen, X.; Xie, J.; Ju, S. Redox-Responsive Polymer Micelles Co-Encapsulating Immune Checkpoint Inhibitors and Chemotherapeutic Agents for Glioblastoma Therapy. Nature Communications 2024, 15, 1118. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Dai, C.; Xie, Z.; You, X.; Li, K.; Wu, J.; Huang, H. Redox Responsive Polymeric Nanoparticles Enhance the Efficacy of Cyclin Dependent Kinase 7 Inhibitor for Enhanced Treatment of Prostate Cancer. Chinese Chemical Letters 2024, 35, 109170. [Google Scholar] [CrossRef]

- Cherri, M.; Stergiou, P.S.; Ahmadian, Z.; Povolotsky, T.L.; Thongrom, B.; Fan, X.; Mohammadifar, E.; Haag, R. Redox-Responsive Hydrogels Loaded with an Antibacterial Peptide as Controlled Drug Delivery for Healing Infectious Wounds. Advanced Healthcare Materials 2024, 13, 2401289. [Google Scholar] [CrossRef]

- Meng, X.; Shen, Y.; Zhao, H.; Lu, X.; Wang, Z.; Zhao, Y. Redox-Manipulating Nanocarriers for Anticancer Drug Delivery: A Systematic Review. Journal of Nanobiotechnology 2024, 22, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Kaur, R.; Pathak, L.; Vyas, P. Biobased Polymers of Plant and Microbial Origin and Their Applications - a Review. Biotechnology for Sustainable Materials 2024, 1, 1–21. [Google Scholar] [CrossRef]

- Serra Sampaio, M.; Wojcieszak, R.; Itabaiana Junior, I. Synthesis of Bio-Based Polymers and Adjuvants through Biomass Valorization: Challenges and Opportunities. ChemCatChem 2024, 16, e202301126. [Google Scholar] [CrossRef]

- Adetunji, A.I.; Erasmus, M. Green Synthesis of Bioplastics from Microalgae: A State-of-the-Art Review. Polymers 2024, 16, 1322. [Google Scholar] [CrossRef] [PubMed]

- Beena Unni, A.; Muringayil Joseph, T. Enhancing Polymer Sustainability: Eco-Conscious Strategies. Polymers 2024, 16, 1769. [Google Scholar] [CrossRef]

- Anastas, P.; Eghbali, N. Green Chemistry: Principles and Practice. 2009. [Google Scholar] [CrossRef] [PubMed]

- Stavila, E.; Yuliati, F.; Adharis, A.; Arya Laksmono, J.; Iqbal, M. Recent Advances in Synthesis of Polymers Based on Palm Oil and Its Fatty Acids. 2023. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Qiu, S.; Zhang, J.; Cheng, Z.; Song, L.; Hu, Y. Innovative Design and Green Synthesis of Bio-Based Non-Isocyanate Polyurethanes: Efficient Combination of Cardanol and Carbon Dioxide with High Fire Safety and Robust Adhesion. Chemical Engineering Journal 2024, 482, 148846. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, Y.; Zhao, Z.; Wang, J.; Chen, Y.; Qian, L.; Fang, Z.; Song, R.; Song, P. Green Synthesis of Bio-Based Flame Retardant/Natural Rubber Inorganic-Organic Hybrid and Its Flame Retarding and Toughening Effect for Polylactic Acid. International Journal of Biological Macromolecules 2024, 256, 128378. [Google Scholar] [CrossRef] [PubMed]

- Post, C.; Maniar, D.; Jongstra, J.A.; Parisi, D.; Voet, V.S.D.; Folkersma, R.; Loos, K. Enzymatic Bulk Synthesis, Characterization, Rheology, and Biodegradability of Biobased 2,5-Bis(Hydroxymethyl)Furan Polyesters. Green Chem. 2024, 26, 8744–8757. [Google Scholar] [CrossRef]

- Almustafa, W.; Grishchuk, S.; Redel, M.; Schubert, D.W.; Grun, G. Solvent-Free Processing of i-P3HB Blends: Enhancing Processability and Mechanical Properties for Sustainable Applications. Polymers 2025, 17, 2231. [Google Scholar] [CrossRef]

- Ramezani, M.; Getya, D.; Gitsov, I.; Browning Monroe, M.B. Solvent-Free Synthesis of Biostable Segmented Polyurethane Shape Memory Polymers for Biomedical Applications. 2024. [Google Scholar] [CrossRef]

- Pellis, A.; Weinberger, S.; Gigli, M.; Guebitz, G.M.; Farmer, T.J. Enzymatic Synthesis of Biobased Polyesters Utilizing Aromatic Diols as the Rigid Component. European Polymer Journal 2020, 130, 109680. [Google Scholar] [CrossRef]

- Herrlé, C.; Fadlallah, S.; Toumieux, S.; Wadouachi, A.; Allais, F. Sustainable Mechanosynthesis of Diamide Tetraols Monomers and Their Enzymatic Polymerization. [CrossRef]

- Post, C.; Maniar, D. ; A. Jongstra, J.; Parisi, D.; D. Voet, V.S.; Folkersma, R.; Loos, K. Enzymatic Bulk Synthesis, Characterization, Rheology, and Biodegradability of Biobased 2,5-Bis(Hydroxymethyl)Furan Polyesters. 2024. [Google Scholar] [CrossRef]

- Kimura, H.; Ogura, Y. Biodegradable Polymers for Ocular Drug Delivery. Ophthalmologica 2001, 215, 143–155. [Google Scholar] [CrossRef]

- Ha, C.-S.; Gardella, J.A. Surface Chemistry of Biodegradable Polymers for Drug Delivery Systems. Chem. Rev. 2005, 105, 4205–4232. [Google Scholar] [CrossRef]

- Wu, H.-Q.; Wang, C.-C. Biodegradable Smart Nanogels: A New Platform for Targeting Drug Delivery and Biomedical Diagnostics. Langmuir 2016, 32, 6211–6225. [Google Scholar] [CrossRef]

- Eckmann, D.M.; Composto, R.J.; Tsourkas, A.; Muzykantov, V.R. Nanogel Carrier Design for Targeted Drug Delivery. J. Mater. Chem. B 2014, 2, 8085–8097. [Google Scholar] [CrossRef] [PubMed]

- Doppalapudi, S.; Jain, A.; Domb, A.J.; Khan, W. Biodegradable Polymers for Targeted Delivery of Anti-Cancer Drugs. Expert Opinion on Drug Delivery 2016, 13, 891–909. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, J.; Mura, S.; Brambilla, D.; Mackiewicz, N.; Couvreur, P. Design, Functionalization Strategies and Biomedical Applications of Targeted Biodegradable/Biocompatible Polymer-Based Nanocarriers for Drug Delivery. Chem. Soc. Rev. 2013, 42, 1147–1235. [Google Scholar] [CrossRef]

- Pan, J.; Liu, Y.; Feng, S.-S. Multifunctional Nanoparticles of Biodegradable Copolymer Blend for Cancer Diagnosis and Treatment. Nanomedicine 2010, 5, 347–360. [Google Scholar] [CrossRef] [PubMed]

- Calzoni, E.; Cesaretti, A.; Polchi, A.; Di Michele, A.; Tancini, B.; Emiliani, C. Biocompatible Polymer Nanoparticles for Drug Delivery Applications in Cancer and Neurodegenerative Disorder Therapies. JFB 2019, 10, 4. [Google Scholar] [CrossRef]

- Sendil, D.; Bonney, I.M.; Carr, D.B.; Lipkowski, A.W.; Wise, D.L.; Hasirci, V. Antinociceptive Effects of Hydromorphone, Bupivacaine and Biphalin Released from PLGA Polymer after Intrathecal Implantation in Rats. Biomaterials 2003, 24, 1969–1976. [Google Scholar] [CrossRef] [PubMed]

- Ozeki, T.; Kaneko, D.; Hashizawa, K.; Imai, Y.; Tagami, T.; Okada, H. Improvement of Survival in C6 Rat Glioma Model by a Sustained Drug Release from Localized PLGA Microspheres in a Thermoreversible Hydrogel. International Journal of Pharmaceutics 2012, 427, 299–304. [Google Scholar] [CrossRef]

- Ungaro, F.; d’Angelo, I.; Coletta, C.; d’Emmanuele Di Villa Bianca, R.; Sorrentino, R.; Perfetto, B.; Tufano, M.A.; Miro, A.; La Rotonda, M.I.; Quaglia, F. Dry Powders Based on PLGA Nanoparticles for Pulmonary Delivery of Antibiotics: Modulation of Encapsulation Efficiency, Release Rate and Lung Deposition Pattern by Hydrophilic Polymers. Journal of Controlled Release 2012, 157, 149–159. [Google Scholar] [CrossRef]

- Tahara, K.; Miyazaki, Y.; Kawashima, Y.; Kreuter, J.; Yamamoto, H. Brain Targeting with Surface-Modified Poly(d,l-Lactic-Co-Glycolic Acid) Nanoparticles Delivered via Carotid Artery Administration. European Journal of Pharmaceutics and Biopharmaceutics 2011, 77, 84–88. [Google Scholar] [CrossRef]

- Kapoor, D.N.; Bhatia, A.; Kaur, R.; Sharma, R.; Kaur, G.; Dhawan, S. PLGA: A Unique Polymer for Drug Delivery. Ther. Deliv. 2015, 6, 41–58. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, H.; Luo, Y.; Chen, Y.; Wang, M.; Wu, C.; Hu, P. Recent Applications of PLGA in Drug Delivery Systems. Polymers 2024, 16, 2606. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, J.; Jing, D.; Ding, J. “Wet-state” Mechanical Properties of Three-dimensional Polyester Porous Scaffolds. J Biomedical Materials Res 2006, 76A, 264–271. [Google Scholar] [CrossRef]

- Giram, P.S.; Wang, J.T.-W.; Walters, A.A.; Rade, P.P.; Akhtar, M.; Han, S.; Faruqu, F.N.; Abdel-Bar, H.M.; Garnaik, B.; Al-Jamal, K.T. Green Synthesis of Methoxy-Poly(Ethylene Glycol)- Block -Poly( l -Lactide- Co -Glycolide) Copolymer Using Zinc Proline as a Biocompatible Initiator for Irinotecan Delivery to Colon Cancer in Vivo. Biomater. Sci. 2021, 9, 795–806. [Google Scholar] [CrossRef]

- Aw, L. Interfacial Bioengineering to Enhance Surface Biocompatibility. Medical device technology 2002, 13. [Google Scholar]

- Huang, S.; Chen, H.-J.; Deng, Y.-P.; You, X.; Fang, Q.; Lin, M. Preparation of Novel Stable Microbicidal Hydrogel Films as Potential Wound Dressing. Polymer Degradation and Stability 2020, 181, 109349. [Google Scholar] [CrossRef]

- Bačáková, L.; Novotná, K.; Pařízek, M. Polysaccharides as Cell Carriers for Tissue Engineering: The Use of Cellulose in Vascular Wall Reconstruction. Physiol Res 2014, S29–S47. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Xu, L.; Xu, L.; Deng, L. Radiation Cross-Linked Gelatin/Sodium Alginate/Carboxymethylcellulose Sodium Hydrogel for the Application as Debridement Glue Paste. Polym. Bull. 2022, 79, 725–742. [Google Scholar] [CrossRef] [PubMed]

- Oh, G.-W.; Kim, S.-C.; Kim, T.-H.; Jung, W.-K. Characterization of an Oxidized Alginate-Gelatin Hydrogel Incorporating a COS-Salicylic Acid Conjugate for Wound Healing. Carbohydrate Polymers 2021, 252, 117145. [Google Scholar] [CrossRef]

- Ozdil, D.; Aydin, H.M. Polymers for Medical and Tissue Engineering Applications: Polymers for Medical and Tissue Engineering Applications. J. Chem. Technol. Biotechnol. 2014, 89, 1793–1810. [Google Scholar] [CrossRef]

- Liu, X.; Holzwarth, J.M.; Ma, P.X. Functionalized Synthetic Biodegradable Polymer Scaffolds for Tissue Engineering. Macromolecular Bioscience 2012, 12, 911–919. [Google Scholar] [CrossRef]

- Ma, P.X.; Zhang, R. Synthetic Nano-Scale Fibrous Extracellular Matrix. J. Biomed. Mater. Res. 1999, 46, 60–72. [Google Scholar] [CrossRef]

- Schofer, M.D.; Fuchs-Winkelmann, S.; Gräbedünkel, C.; Wack, C.; Dersch, R.; Rudisile, M.; Wendorff, J.H.; Greiner, A.; Paletta, J.R.J.; Boudriot, U. Influence of Poly(L-Lactic Acid) Nanofibers and BMP-2–Containing Poly(L-Lactic Acid) Nanofibers on Growth and Osteogenic Differentiation of Human Mesenchymal Stem Cells. The Scientific World JOURNAL 2008, 8, 1269–1279. [Google Scholar] [CrossRef] [PubMed]

- Chang, P.; Liu, B.; Liu, C.; Chou, H.; Ho, M.; Liu, H.; Wang, D.; Hou, L. Bone Tissue Engineering with Novel rhBMP2-PLLA Composite Scaffolds. J Biomedical Materials Res 2007, 81A, 771–780. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Wang, Q.; Xie, W.; Ye, W.; Zhong, L.; Huge, J.; Wang, Y. Performance of 3D Printed PCL / PLGA / HA Biological Bone Tissue Engineering Scaffold. Polymer Composites 2021, 42, 3593–3602. [Google Scholar] [CrossRef]

- Lin, C.-C.; Fu, S.-J.; Lin, Y.-C.; Yang, I.-K.; Gu, Y. Chitosan-Coated Electrospun PLA Fibers for Rapid Mineralization of Calcium Phosphate. International Journal of Biological Macromolecules 2014, 68, 39–47. [Google Scholar] [CrossRef]

- Fujita, M.; Kinoshita, Y.; Sato, E.; Maeda, H.; Ozono, S.; Negishi, H.; Kawase, T.; Hiraoka, Y.; Takamoto, T.; Tabata, Y.; et al. Proliferation and Differentiation of Rat Bone Marrow Stromal Cells on Poly(Glycolic Acid)–Collagen Sponge. Tissue Engineering 2005, 11, 1346–1355. [Google Scholar] [CrossRef]

- Jayabalan, M.; Shalumon, K.T.; Mitha, M.K.; Ganesan, K.; Epple, M. Effect of Hydroxyapatite on the Biodegradation and Biomechanical Stability of Polyester Nanocomposites for Orthopaedic Applications. Acta Biomaterialia 2010, 6, 763–775. [Google Scholar] [CrossRef]

- Zamora, I.; Alfonso Morales, G.; Castro, J.I.; Ruiz Rojas, L.M.; Valencia-Llano, C.H.; Mina Hernandez, J.H.; Valencia Zapata, M.E.; Grande-Tovar, C.D. Chitosan (CS)/Hydroxyapatite (HA)/Tricalcium Phosphate (β-TCP)-Based Composites as a Potential Material for Pulp Tissue Regeneration. Polymers 2023, 15, 3213. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Yan, J.; Zhang, K.; Lin, F.; Xiang, L.; Deng, L.; Guan, Z.; Cui, W.; Zhang, H. Pharmaceutical Electrospinning and 3D Printing Scaffold Design for Bone Regeneration. Advanced Drug Delivery Reviews 2021, 174, 504–534. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.S. Mechanical Relation for Porous Metal Foams under Complex Loads of Triaxial Tension and Compression. Materials & Design 2010, 31, 2264–2269. [Google Scholar] [CrossRef]

- Jiang, N.; Qi, B.; Fan, X.; Yao, L.; Wang, Y.; Zhao, Z.; Xu, Y.; Razali, M.H. Fabrication of Biocompatible and Biodegradable Polyvinyl Alcohol/Sodium Alginate Blend Polymers Incorporating Ca2+ Doped TiO2 Nanocomposite 3D Scaffold for Biomedical Applications. Journal of Saudi Chemical Society 2023, 27, 101758. [Google Scholar] [CrossRef]

- Sadowska, J.M.; Power Rachael, N.; Genoud, K.J.; Matheson, A.; González-Vázquez, A.; Costard, L.; Eichholz, K.; Pitacco, P.; Hallegouet, T.; Chen, G.; et al. A Multifunctional Scaffold for Bone Infection Treatment by Delivery of microRNA Therapeutics Combined With Antimicrobial Nanoparticles. Advanced Materials 2024, 36, 2307639. [Google Scholar] [CrossRef] [PubMed]

- Müller, W.E.; Neufurth, M.; Wang, S.; Tolba, E.; Schröder, H.C.; Wang, X. Morphogenetically Active Scaffold for Osteochondral Repair (Polyphosphate/Alginate/N,O-Carboxymethyl Chitosan). Eur Cell Mater 2016, 31, 174–190. [Google Scholar] [CrossRef]

- Mahapatra, C.; Jin, G.-Z.; Kim, H.-W. Alginate-Hyaluronic Acid-Collagen Composite Hydrogel Favorable for the Culture of Chondrocytes and Their Phenotype Maintenance. Tissue Eng Regen Med 2016, 13, 538–546. [Google Scholar] [CrossRef]

- González-González, A.M.; Cruz, R.; Rosales-Ibáñez, R.; Hernández-Sánchez, F.; Carrillo-Escalante, H.J.; Rodríguez-Martínez, J.J.; Velasquillo, C.; Talamás-Lara, D.; Ludert, J.E. In Vitro and In Vivo Evaluation of a Polycaprolactone (PCL)/Polylactic-Co-Glycolic Acid (PLGA) (80:20) Scaffold for Improved Treatment of Chondral (Cartilage) Injuries. Polymers 2023, 15, 2324. [Google Scholar] [CrossRef]

- Jm, P.; Jp, K.; Hg, B.; Ak, K.; U, F.; M, S.; M, N.; M, E.; C, K. Polyglycolic Acid-Hyaluronan Scaffolds Loaded with Bone Marrow-Derived Mesenchymal Stem Cells Show Chondrogenic Differentiation in Vitro and Cartilage Repair in the Rabbit Model. Journal of biomedical materials research. Part B, Applied biomaterials 2013, 101. [Google Scholar] [CrossRef]

- Sd, M.; H, A.; A, C.; E, G.; Mm, S. Anisotropic Fibrous Scaffolds for Articular Cartilage Regeneration. Tissue engineering. Part A 2012, 18. [Google Scholar] [CrossRef]

- Pulat, G.; Gökmen, O.; Özcan, Ş.; Karaman, O. Collagen Binding and Mimetic Peptide-Functionalized Self-Assembled Peptide Hydrogel Enhance Chondrogenic Differentiation of Human Mesenchymal Stem Cells. Journal of Biomedical Materials Research Part A 2025, 113, e37786. [Google Scholar] [CrossRef] [PubMed]

- Biomaterials and Neural Regeneration: Neural Regeneration Research. Available online: https://journals.lww.com/nrronline/fulltext/2020/15070/biomaterials_and_neural_regeneration.8.aspx (accessed on 25 September 2025).

- Durgam, H.; Sapp, S.; Deister, C.; Khaing, Z.; Chang, E.; Luebben, S.; Schmidt, C.E. Novel Degradable Co-Polymers of Polypyrrole Support Cell Proliferation and Enhance Neurite Out-Growth with Electrical Stimulation. Journal of Biomaterials Science, Polymer Edition 2010. [Google Scholar] [CrossRef]

- Lee, J.Y.; Bashur, C.A.; Goldstein, A.S.; Schmidt, C.E. Polypyrrole-Coated Electrospun PLGA Nanofibers for Neural Tissue Applications. Biomaterials 2009, 30, 4325–4335. [Google Scholar] [CrossRef] [PubMed]

- Tarus, D.; Hamard, L.; Caraguel, F.; Wion, D.; Szarpak-Jankowska, A.; Van Der Sanden, B.; Auzély-Velty, R. Design of Hyaluronic Acid Hydrogels to Promote Neurite Outgrowth in Three Dimensions. ACS Appl. Mater. Interfaces 2016, 8, 25051–25059. [Google Scholar] [CrossRef]

- Pinho, T.S.; Cunha, C.B.; Lanceros-Méndez, S.; Salgado, A.J. Electroactive Smart Materials for Neural Tissue Regeneration. ACS Appl. Bio Mater. 2021, 4, 6604–6618. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Sun, C.; Hu, W.; Zhao, J.; Li, G.; Zhang, L.; Liu, M.; Liu, Y.; Ding, F.; et al. Chitosan Degradation Products Promote Nerve Regeneration by Stimulating Schwann Cell Proliferation via miR-27a/FOXO1 Axis. Mol Neurobiol 2016, 53, 28–39. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M.; Cheng, Q.; Su, W.; Wang, C.; Yang, Y.; Cao, Z.; Ding, F. The Beneficial Effect of Chitooligosaccharides on Cell Behavior and Function of Primary Schwann Cells Is Accompanied by Up-Regulation of Adhesion Proteins and Neurotrophins. Neurochem Res 2014, 39, 2047–2057. [Google Scholar] [CrossRef]

- Jin, J.; Ji, Z.; Xu, M.; Liu, C.; Ye, X.; Zhang, W.; Li, S.; Wang, D.; Zhang, W.; Chen, J.; et al. Microspheres of Carboxymethyl Chitosan, Sodium Alginate, and Collagen as a Hemostatic Agent in Vivo. ACS Biomater. Sci. Eng. 2018, 4, 2541–2551. [Google Scholar] [CrossRef]

- Sr, B.; N, B.; P, V.; Hk, Y.; Ph, H.; Hy, K. Hydrophilic Nanofibrous Structure of Polylactide; Fabrication and Cell Affinity. Journal of biomedical materials research. Part A 2006, 78. [Google Scholar] [CrossRef]

- Sharifi, F.; Irani, S.; Zandi, M.; Soleimani, M.; Atyabi, S.M. Comparative of Fibroblast and Osteoblast Cells Adhesion on Surface Modified Nanofibrous Substrates Based on Polycaprolactone. Prog Biomater 2016, 5, 213–222. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, J.; Peng, C.; Huang, T.; Zhou, H.; Ou, B.; Chen, J.; Liu, Q.; He, S.; Cao, D.; et al. Fabrication and Physical Properties of Gelatin/Sodium Alginate/Hyaluronic Acid Composite Wound Dressing Hydrogel. Journal of Macromolecular Science, Part A 2014. [Google Scholar] [CrossRef]

- Haidari, H.; Vasilev, K.; Cowin, A.J.; Kopecki, Z. Bacteria-Activated Dual pH- and Temperature-Responsive Hydrogel for Targeted Elimination of Infection and Improved Wound Healing. ACS Applied Materials & Interfaces 2022. [Google Scholar] [CrossRef]

- Soletti, L.; Hong, Y.; Guan, J.; Stankus, J.J.; El-Kurdi, M.S.; Wagner, W.R.; Vorp, D.A. A Bilayered Elastomeric Scaffold for Tissue Engineering of Small Diameter Vascular Grafts. Acta Biomaterialia 2010, 6, 110–122. [Google Scholar] [CrossRef]

- Electrospun Poly(l-Lactic Acid-Co-ɛ-Caprolactone) Fibers Loaded with Heparin and Vascular Endothelial Growth Factor to Improve Blood Compatibility and Endothelial Progenitor Cell Proliferation. Colloids and Surfaces B: Biointerfaces 2015, 128, 106–114. [CrossRef]

- Radisic, M. Biomaterials for Cardiac Tissue Engineering. Biomed. Mater. 2015, 10, 030301. [Google Scholar] [CrossRef] [PubMed]

- Mihic, A.; Cui, Z.; Wu, J.; Vlacic, G.; Miyagi, Y.; Li, S.-H.; Lu, S.; Sung, H.-W.; Weisel, R.D.; Li, R.-K. A Conductive Polymer Hydrogel Supports Cell Electrical Signaling and Improves Cardiac Function After Implantation into Myocardial Infarct. Circulation 2015. [Google Scholar] [CrossRef] [PubMed]

- Navaei, A.; Moore, N.; Sullivan, R.; Truong, D.; Migrino, R.; Nikkhah, M. Electrically Conductive Hydrogel-Based Micro-Topographies for the Development of Organized Cardiac Tissues. RSC Advances 2017. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, W.M. Heating/Solvent Responsive Shape-Memory Polymers for Implant Biomedical Devices in Minimally Invasive Surgery: Current Status and Challenge. Macromolecular Bioscience 2020, 20, 2000108. [Google Scholar] [CrossRef] [PubMed]

- Sivaraman, S.; Amoroso, N.; Gu, X.; Purves, J.T.; Hughes, F.M.; Wagner, W.R.; Nagatomi, J. Evaluation of Poly (Carbonate-Urethane) Urea (PCUU) Scaffolds for Urinary Bladder Tissue Engineering. Ann Biomed Eng 2019, 47, 891–901. [Google Scholar] [CrossRef]

- Sl, L.; Wd, C.; Ga, T.; Qz, C. The Mechanical Characteristics and in Vitro Biocompatibility of Poly(Glycerol Sebacate)-Bioglass Elastomeric Composites. Biomaterials 2010, 31. [Google Scholar] [CrossRef]

- Full, S.M.; Delman, C.; Gluck, J.M.; Abdmaulen, R.; Shemin, R.J.; Heydarkhan-Hagvall, S. Effect of Fiber Orientation of Collagen-Based Electrospun Meshes on Human Fibroblasts for Ligament Tissue Engineering Applications. Journal of biomedical materials research. Part B, Applied biomaterials 2014, 103, 39. [Google Scholar] [CrossRef] [PubMed]

- Sensini, A.; Gualandi, C.; Focarete, M.L.; Belcari, J.; Zucchelli, A.; Boyle, L.; Reilly, G.C.; Kao, A.P.; Tozzi, G.; Cristofolini, L. Multiscale Hierarchical Bioresorbable Scaffolds for the Regeneration of Tendons and Ligaments. Biofabrication 2019, 11, 035026. [Google Scholar] [CrossRef]

- Khosravimelal, S.; Mobaraki, M.; Eftekhari, S.; Ahearne, M.; Seifalian, A.M.; Gholipourmalekabadi, M. Hydrogels as Emerging Materials for Cornea Wound Healing. Small 2021, 17, 2006335. [Google Scholar] [CrossRef]

- Ahadian, S.; Khademhosseini, A. Smart Scaffolds in Tissue Regeneration. Regenerative Biomaterials 2018, 5, 125–128. [Google Scholar] [CrossRef]

- Municoy, S.; Álvarez Echazú, M.I.; Antezana, P.E.; Galdopórpora, J.M.; Olivetti, C.; Mebert, A.M.; Foglia, M.L.; Tuttolomondo, M.V.; Alvarez, G.S.; Hardy, J.G.; et al. Stimuli-Responsive Materials for Tissue Engineering and Drug Delivery. IJMS 2020, 21, 4724. [Google Scholar] [CrossRef]

- Biodegradable- Versus Durable-Polymer Drug-Eluting Stents for STEMI: Final 2-Year Outcomes of the BIOSTEMI Trial. JACC: Cardiovascular Interventions 2021, 14, 639–648. [CrossRef]

- Kurowiak, J.; Klekiel, T.; Będziński, R. Biodegradable Polymers in Biomedical Applications: A Review—Developments, Perspectives and Future Challenges. IJMS 2023, 24, 16952. [Google Scholar] [CrossRef] [PubMed]

- The Development of Polymeric Biomaterials Inspired by the Extracellular Matrix. Available online: https://www.tandfonline.com/doi/epdf/10.1080/09205063.2017.1297285?needAccess=true (accessed on 25 September 2025).

- Patel, B.B.; Chakraborty, S. Biodegradable Polymers: Emerging Excipients for the Pharmaceutical and Medical Device Industries. Journal of Excipients and Food Chemicals 2013. [Google Scholar]

- Adeosun, S.O.; Lawal, G.I.; Gbenebor, O.P. Characteristics of Biodegradable Implants. Journal of Minerals and Materials Characterization and Engineering 2014, 2, 88–106. [Google Scholar] [CrossRef]

- Charles, L.F.; Shaw, M.T.; Olson, J.R.; Wei, M. Fabrication and Mechanical Properties of PLLA/PCL/HA Composites via a Biomimetic, Dip Coating, and Hot Compression Procedure. J Mater Sci: Mater Med 2010, 21, 1845–1854. [Google Scholar] [CrossRef]

- Russias, J.; Saiz, E.; Nalla, R.K.; Gryn, K.; Ritchie, R.O.; Tomsia, A.P. Fabrication and Mechanical Properties of PLA/HA Composites: A Study of in Vitro Degradation. Materials science & engineering. C, Biomimetic and supramolecular systems 2006, 26, 1289. [Google Scholar] [CrossRef]

- Kumar, A.; Mir, M.; Aldulijan, I.; Mahajan, A.; Anwar, A.; Leon, C.H.; Terracciano, A.; Zhao, X.; Su, T.-L.; Kalyon, D.M.; et al. Load-Bearing Biodegradable PCL-PGA-Beta TCP Scaffolds for Bone Tissue Regeneration. Journal of Biomedical Materials Research Part B: Applied Biomaterials 2021, 109, 193–200. [Google Scholar] [CrossRef] [PubMed]

- Silva, D. da; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Roitman, J.; Schroeder, A. Biocompatibility, Biodegradation and Excretion of Polylactic Acid (PLA) in Medical Implants and Theranostic Systems. Chemical engineering journal (Lausanne, Switzerland: 1996) 2018, 340, 9. [Google Scholar] [CrossRef]

- Elmowafy, E.M.; Tiboni, M.; Soliman, M.E. Biocompatibility, Biodegradation and Biomedical Applications of Poly(Lactic Acid)/Poly(Lactic-Co-Glycolic Acid) Micro and Nanoparticles. J. Pharm. Investig. 2019, 49, 347–380. [Google Scholar] [CrossRef]

- Pérez-Davila, S.; Garrido-Gulías, N.; González-Rodríguez, L.; López-Álvarez, M.; Serra, J.; López-Periago, J.E.; González, P. Physicochemical Properties of 3D-Printed Polylactic Acid/Hydroxyapatite Scaffolds. Polymers 2023, 15, 2849. [Google Scholar] [CrossRef]

- Peng, W.; Zheng, W.; Shi, K.; Wang, W.; Shao, Y.; Zhang, D. An in Vivo Evaluation of PLLA/PLLA-gHA Nano-Composite for Internal Fixation of Mandibular Bone Fractures. Biomed. Mater. 2015, 10, 065007. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Singh, J. Biodegradable and Biocompatible Thermosensitive Polymer Based Injectable Implant for Controlled Release of Protein. International Journal of Pharmaceutics 2009, 365, 34–43. [Google Scholar] [CrossRef]

- Koutserimpas, C.; Alpantaki, K.; Chatzinikolaidou, M.; Chlouverakis, G.; Dohm, M.; Hadjipavlou, A.G. The Effectiveness of Biodegradable Instrumentation in the Treatment of Spinal Fractures. Injury 2018, 49, 2111–2120. [Google Scholar] [CrossRef]

- Kukk, A.; Nurmi, J.T. A Retrospective Follow-up of Ankle Fracture Patients Treated with a Biodegradable Plate and Screws. Foot and Ankle Surgery 2009, 15, 192–197. [Google Scholar] [CrossRef]

- Amini, A.R.; Wallace, J.S.; Nukavarapu, S.P. Short-Term and Long-Term Effects of Orthopedic Biodegradable Implants. Journal of long-term effects of medical implants 2011, 21, 93. [Google Scholar] [CrossRef] [PubMed]

- Grayson, A.C.R.; Voskerician, G.; Lynn, A.; Anderson, J.M.; Cima, M.J.; Langer, R. Differential Degradation Rates in Vivo and in Vitro of Biocompatible Poly(Lactic Acid) and Poly(Glycolic Acid) Homo- and Co-Polymers for a Polymeric Drug-Delivery Microchip. Journal of Biomaterials Science, Polymer Edition 2004. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, L.; Chen, J.; Wang, L.; Gui, X.; Ran, J.; Xu, G.; Zhao, H.; Zeng, M.; Ji, J.; et al. Silk Fibroin Biomaterial Shows Safe and Effective Wound Healing in Animal Models and a Randomized Controlled Clinical Trial | Semantic Scholar.

- Gore, M. Evaluation of Safety and Efficacy of Barrier Foam Dressing in Patients with Exuding Wounds. Biomedical Journal of Scientific & Technical Research 2021. [Google Scholar]

- Haik, J.; Ullman, Y.; Gur, E.; Ad-El, D.; Egozi, D.; Kruchevsky, D.; Zissman, S.; Biros, E.; Nir, R.; Kornhaber, R.; et al. Advances in the Use of Electrospun Nanofibrous Polymeric Matrix for Dermal Healing at the Donor Site after the Split-Thickness Skin Graft Excision: A Prospective, Randomized, Controlled, Open-Label, Multicenter Study. Journal of Burn Care & Research 2021. [Google Scholar]

- Jamlang, J.; Marañon, M.T.; Rigor, G.J.; Tumolva, T. Developing a Physically Cross-Linked Hydroxyethyl Cellulose Hydrogel for Wound Dressing Applications. Materials Science Forum 2019. [Google Scholar] [CrossRef]

- Abulayzied, D.; Alturki, A.; Alatawi, A.; Bousbih, R.; Alamlah, R.; Abomostafa, H.; El Komy, G.; Abdel Aziz Taha, M.; A. Youness, R. Production of Polyvinyl Alcohol/Natural Hydroxyapatite/Magnesia/Silicon Carbide Hybrid Composites for Use in Orthopedic Applications: Optical, Electrical, and Mechanical Propertie. Egypt. J. Chem. 2024, 0, 0–0. [Google Scholar] [CrossRef]

- Hong, Y.; Huber, A.; Takanari, K.; Amoroso, N.J.; Hashizume, R.; Badylak, S.F.; Wagner, W.R. Mechanical Properties and in Vivo Behavior of a Biodegradable Synthetic Polymer Microfiber–Extracellular Matrix Hydrogel Biohybrid Scaffold. Biomaterials 2011, 32, 3387–3394. [Google Scholar] [CrossRef]

- Tripathi, S.; Dixit, P. COMPARATIVE EVALUATION OF EFFICACY OF CYANOACRYLATE AND SUTURE MATERIAL IN THE MANAGEMENT OF OPERATIVE SKIN WOUNDS. Asian J Pharm Clin Res 2022, 59–61. [Google Scholar] [CrossRef]

- Acharjee, S.A.; Bharali, P.; Gogoi, B.; Sorhie, V.; Walling, B. ; Alemtoshi PHA-Based Bioplastic: A Potential Alternative to Address Microplastic Pollution. Water Air Soil Pollut 2023, 234, 1–31. [Google Scholar] [CrossRef] [PubMed]

- Kubowicz, S.; Booth, A.M. Biodegradability of Plastics: Challenges and Misconceptions. Environ. Sci. Technol. 2017, 51, 12058–12060. [Google Scholar] [CrossRef]

- Cheng, J.; Gao, R.; Zhu, Y.; Lin, Q. Applications of Biodegradable Materials in Food Packaging: A Review. Alexandria Engineering Journal 2024. [Google Scholar] [CrossRef]

- Gupta, R.; Guha, P.; Srivastav, P. Natural Polymers in Bio-Degradable/Edible Film: A Review on Environmental Concerns, Cold Plasma Technology and Nanotechnology Application on Food Packaging- A Recent Trends. Food Chemistry Advances 2022. [Google Scholar] [CrossRef]

- Łupina, K.; Kowalczyk, D.; Drozłowska, E. Polysaccharide/Gelatin Blend Films as Carriers of Ascorbyl Palmitate - A Comparative Study. Food Chemistry 2020. [Google Scholar] [CrossRef]

- Mirza, Z.S.; Chatta, A.M.; Shafi, J.; Waheed, K.N.; Saleem, S.; Hanif, M.M. The Effect of Natural Edible Coatings on Chemical, Microbial, and Sensory Quality of Tilapia during Frozen Storage. Journal of Food Quality and Hazards Control 2023. [Google Scholar] [CrossRef]

- Uzundağ, D.; Can, Ö.P.; Saraç, M.G. Extending the Shelf Life of Unsalted White Cheese Produced for Special Dietary Preferences: Role of Essential Oils and Coating. Harran Tarım ve Gıda Bilimleri Dergisi 2025, 29, 191–204. [Google Scholar] [CrossRef]

- Esmaeili, M.; Pircheraghi, G.; Bagheri, R. Optimizing the Mechanical and Physical Properties of Thermoplastic Starch via Tuning the Molecular Microstructure through Co-plasticization by Sorbitol and Glycerol. Polymer International 2017, 66, 809–819. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Oprea, O.-C.; Sonmez, M.; Ficai, A.; Motelica, L.; Ficai, D.; Georgescu, M.; Gurau, D.F. Structural and Thermal Characterization of Some Thermoplastic Starch Mixtures. Polysaccharides 2024, 5, 504–522. [Google Scholar] [CrossRef]

- González Carmona, E.; Schlapp-Hackl, I.; Jääskeläinen, S.; Järvinen, M.; Nieminen, K.; Sawada, D.; Hummel, M.; Sixta, H. Development of Cellulose Films by Means of the Ioncell® Technology, as an Alternative to Commercial Films. Cellulose 2023, 30, 11633–11648. [Google Scholar] [CrossRef]

- Yang, Q.; Saito, T.; Isogai, A. Transparent, Flexible, and High-strength Regenerated Cellulose/Saponite Nanocomposite Films with High Gas Barrier Properties. J of Applied Polymer Sci 2013, 130, 3168–3174. [Google Scholar] [CrossRef]

- Zhao, S.; Bian, Y.; Zhang, G.; Yang, G.; Hou, X.; Gui, J.; Mu, S.; Liu, S.; Fang, Y. Shelf-life Extension of Pacific White Shrimp ( Litopenaeus Vannamei ) Using Sodium Alginate/Chitosan Incorporated with Cell-free Supernatant of Streptococcus Thermophilus FUA 329 during Cold Storage. Journal of Food Science 2024, 89, 1976–1987. [Google Scholar] [CrossRef]

- Putranti, L.N.; Nugraheni, P.S. Effect of Carboxymethyl Cellulose Addition on the Characteristic of Chitosan-Based Bioplastic. IOP Conf. Ser.: Earth Environ. Sci. 2023, 1289, 012038. [Google Scholar] [CrossRef]

- Zhao, S.; Bian, Y.; Zhang, G.; Yang, G.; Hou, X.; Gui, J.; Mu, S.; Liu, S.; Fang, Y. Shelf-Life Extension of Pacific White Shrimp (Litopenaeus Vannamei) Using Sodium Alginate/Chitosan Incorporated with Cell-Free Supernatant of Streptococcus Thermophilus FUA 329 during Cold Storage. Journal of Food Science 2024. [Google Scholar] [CrossRef]

- Raghav, P.T.; Narayanapurapu; Bellevue, S.A. de EFFECT OF COMPOSITE EDIBLE COATINGS AND ABIOTIC STRESS ON POST HARVEST QUALITY OF FRUITS. Available online: https://www.semanticscholar.org/paper/EFFECT-OF-COMPOSITE-EDIBLE-COATINGS-AND-ABIOTIC-ON-Raghav-Narayanapurapu/5badccb98be6ef0c40ca4309c1d21df125943eeb (accessed on 25 September 2025).

- Tullo, A. A Biodegradable Polymer Hits the Big Time. C&EN Global Enterprise 2021. [Google Scholar]

- Aversa, C.; Barletta, M.; Cappiello, G.; Gisario, A. Compatibilization Strategies and Analysis of Morphological Features of Poly(Butylene Adipate-Co-Terephthalate) (PBAT)/Poly(Lactic Acid) PLA Blends: A State-of-Art Review. European Polymer Journal 2022. [Google Scholar] [CrossRef]

- Chen, H.; Chen, F.; Chen, H.; Liu, H.; Chen, L.; Yu, L. Thermal Degradation and Combustion Properties of Most Popular Synthetic Biodegradable Polymers. Waste Manag Res 2023, 41, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Singh, S.; Singh, J. Performance Evaluation of PLA against Existing PET and PS Containers. Journal of Testing and Evaluation 2006. [Google Scholar] [CrossRef]

- Ali, N. Effect of Polyethylene Terphalet (PET) On Mechanical and Optical Properties of Polylactic Acid (PLA) for Packaging Application. Available online: https://www.semanticscholar.org/paper/Effect-of-Polyethylene-Terphalet- (accessed on day month year).

- Qi, Y.; Zhai, H.; Sun, Y.; Xu, H.; Wu, S.; Chen, S. Electrospun Hybrid Nanofibrous Meshes with Adjustable Performance for Potential Use in Soft Tissue Engineering. Textile research journal 2021. [Google Scholar] [CrossRef]

- Klabukov, I.; Tenchurin, T.; Shepelev, A.; Baranovskii, D.; Mamagulashvili, V.; Dyuzheva, T.; Krasilnikova, O.; Balyasin, M.; Lyundup, A.; Krasheninnikov, M.; et al. Biomechanical Behaviors and Degradation Properties of Multilayered Polymer Scaffolds: The Phase Space Method for Bile Duct Design and Bioengineering. Biomedicines 2023, 11, 745. [Google Scholar] [CrossRef]

- Nagy, B.; Miskolczi, N.; Eller, Z. Evaluation of the Effect of Castor Oil-Based Experimental Additives on Pla/Starch Foils. Hung. J. Ind. Chem. 2023, 51, 35–41. [Google Scholar] [CrossRef]

- Wang, M.; Li, Z.; Zhao, W.; Huang, Z.; Liu, H.; Ma, L.; Yang, L. Preparation and Properties of Poly (Butylene-adipate-co-terephthalate) /Thermoplastic Hydroxypropyl Starch Films. Polymer international 2024. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Shaikh, H.M.; Alshammari, B.A. Structural, Morphological and Thermal Properties of Nano Ller Produced from Date Palm-Based Micro Fibers (Phoenix Dactylifera L.).

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable Biodegradable Coffee Grounds Filler and Its Effect on the Hydrophobicity, Mechanical and Thermal Properties of Biodegradable PBAT Composites. J of Applied Polymer Sci 2017, 134, app.44498. [Google Scholar] [CrossRef]

- Khan, A.; Asiri, A.M.; Jawaid, M.; Saba, N. ; Inamuddin Effect of Cellulose Nano Fibers and Nano Clays on the Mechanical, Morphological, Thermal and Dynamic Mechanical Performance of Kenaf/Epoxy Composites. Carbohydrate Polymers 2020. [Google Scholar] [CrossRef]

- Mandal, A.; Chakrabarty, D. Studies on Mechanical, Thermal, and Barrier Properties of Carboxymethyl Cellulose Film Highly Filled with Nanocellulose. Journal of Thermoplastic Composite Materials 2019, 32, 995–1014. [Google Scholar] [CrossRef]

- Ma, F.; Chen, S.; Liu, P.; Geng, F.; Li, W.; Liu, X.; He, D.; Pan, D. Improvement of β-TCP/PLLA Biodegradable Material by Surface Modification with Stearic Acid. Materials Science and Engineering C: Materials for Biological Applications 2016. [Google Scholar] [CrossRef]

- De La Rosa-Ramírez, H.; Aldas, M.; Ferri, J.M.; Pawlak, F.; López-Martínez, J.; Samper, M.D. Control of Biodegradability Under Composting Conditions and Physical Performance of Poly (Lactic Acid) Based Materials Modified with Phenolic-Free Rosin Resin. J Polym Environ 2023, 31, 5462–5476. [Google Scholar] [CrossRef]

- Samorì, P.; Kinloch, I.A.; Feng, X.; Palermo, V. Graphene-Based Nanocomposites for Structural and Functional Applications: Using 2-Dimensional Materials in a 3-Dimensional World. 2D Mater. 2015, 2, 030205. [Google Scholar] [CrossRef]

- Drozdov, A.; Christiansen, J.; Klitkou, R. Volume Growth and Viscoplasticity of Polymer/Clay Nanocomposites. Available online: https://www.semanticscholar.org/paper/Volume-growth-and-viscoplasticity-of-polymer-clay-Drozdov-Christiansen/04a32ceebb37d07312ef4221fb2d24dae53776ad (accessed on 25 September 2025).

- Rezvani, M.B.; Atai, M.; Hamze, F.; Hajrezai, R. The Effect of Silica Nanoparticles on the Mechanical Properties of Fiber-Reinforced Composite Resins. J Dent Res Dent Clin Dent Prospects 2016, 10, 112–117. [Google Scholar] [CrossRef]

- El-Shafai, N.; El-Khouly, M.E.; El-Kemary, M.; Ramadan, M.; Eldesoukey, I.; Masoud, M. Graphene Oxide Decorated with Zinc Oxide Nanoflower, Silver and Titanium Dioxide Nanoparticles: Fabrication, Characterization, DNA Interaction, and Antibacterial Activity. RSC Adv. 2019, 9, 3704–3714. [Google Scholar] [CrossRef] [PubMed]

- Mandal, D.; Mualchin, M. Effects of Essential Oils on Post Harvest Quality and Shelf Life of Mango (Mangifera Indica L.). Bangladesh J. Bot. 2021, 50, 1143–1149. [Google Scholar] [CrossRef]

- Branciari, R.; Galarini, R.; Trabalza-Marinucci, M.; Miraglia, D.; Roila, R.; Acuti, G.; Giusepponi, D.; Dal Bosco, A.; Ranucci, D. Effects of Olive Mill Vegetation Water Phenol Metabolites Transferred to Muscle through Animal Diet on Rabbit Meat Microbial Quality. Sustainability 2021, 13, 4522. [Google Scholar] [CrossRef]

- Miraglia, D.; Castrica, M.; Esposto, S.; Roila, R.; Selvaggini, R.; Urbani, S.; Taticchi, A.; Sordini, B.; Veneziani, G.; Servili, M. Quality Evaluation of Shrimp (Parapenaeus Longirostris) Treated with Phenolic Extract from Olive Vegetation Water during Shelf-Life, before and after Cooking. Foods 2021, 10, 2116. [Google Scholar] [CrossRef] [PubMed]

- Martinelli, M.; Bruner, M. The Effect of Cinnamon Extract on the Prevention of Fruit Spoilage via Delay in Microbial Growth. 2024, 13. [Google Scholar] [CrossRef]

- Fiorentini, C.; Leni, G.; De Apodaca, E.D.; Fernández-de-Castro, L.; Rocchetti, G.; Cortimiglia, C.; Spigno, G.; Bassani, A. Development of Coated PLA Films Containing a Commercial Olive Leaf Extract for the Food Packaging Sector. Antioxidants 2024, 13, 519. [Google Scholar] [CrossRef]

- Grabska-Zielińska, S.; Gierszewska, M.; Olewnik-Kruszkowska, E.; Bouaziz, M. Polylactide Films with the Addition of Olive Leaf Extract—Physico-Chemical Characterization. Materials 2021, 14, 7623. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh-Sani, M.; Mohammadian, E.; Rhim, J.; Jafari, S. pH-Sensitive (Halochromic) Smart Packaging Films Based on Natural Food Colorants for the Monitoring of Food Quality and Safety. Trends in Food Science and Technology 2020. [Google Scholar] [CrossRef]

- Ma, L.; Long, T.; Yuan, S.; Qi, P.; Han, L.; Hao, J. A pH-Indicating Smart Tag Based on Porous Hydrogel as Food Freshness Sensors. Journal of Colloid and Interface Science 2023. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Y.; Zhao, L.; Wang, Y. Anthocyanin-Based pH-Sensitive Smart Packaging Films for Monitoring Food Freshness. Journal of Agriculture and Food Research 2022. [Google Scholar] [CrossRef]

- Biological Degradation of Plastics: A Comprehensive Review. Biotechnology Advances 2008, 26, 246–265. [CrossRef] [PubMed]

- Arora, A.; Padua, G.W. Review: Nanocomposites in Food Packaging. Journal of Food Science 2010, 75, R43–R49. [Google Scholar] [CrossRef]