Submitted:

25 September 2025

Posted:

26 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. System Description

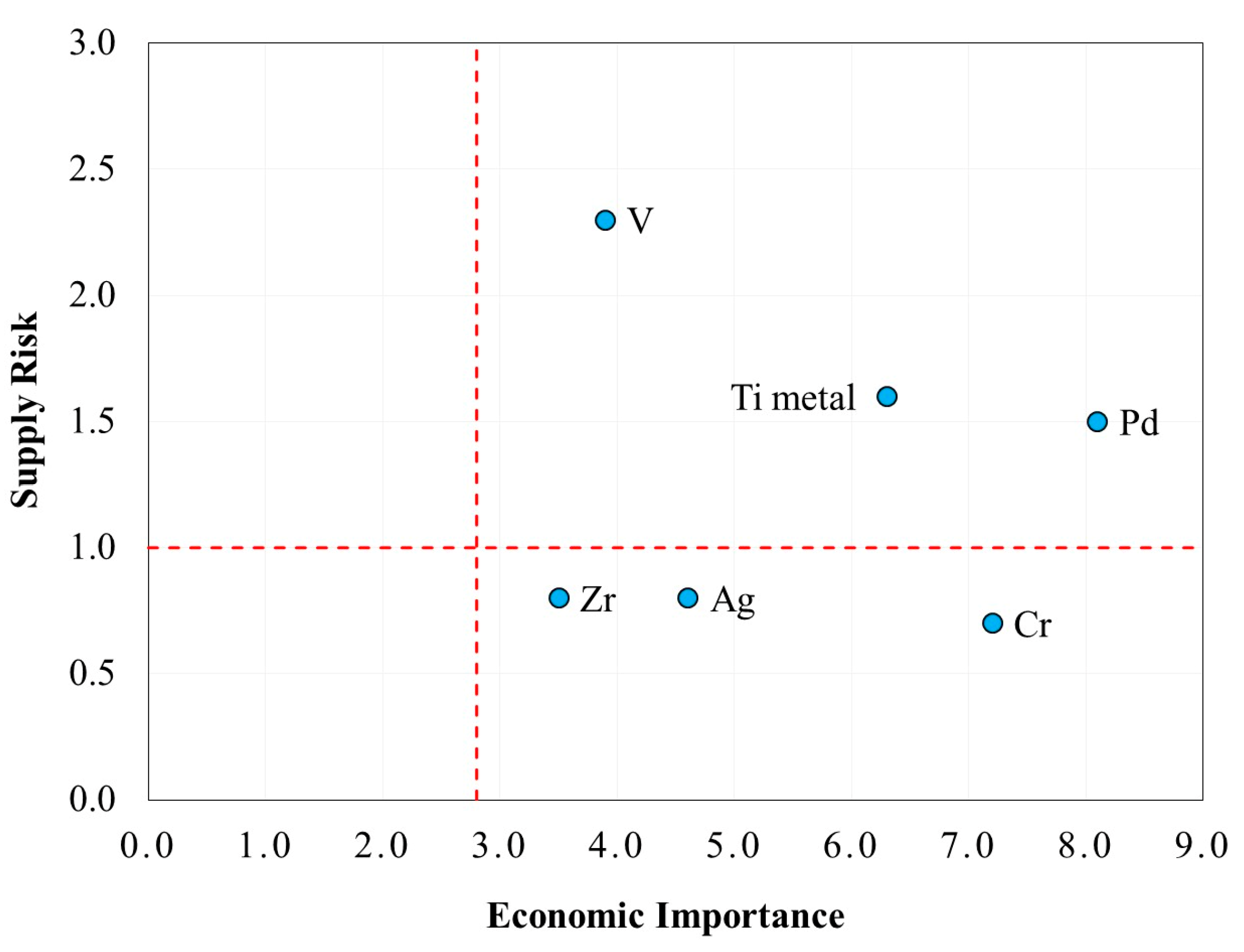

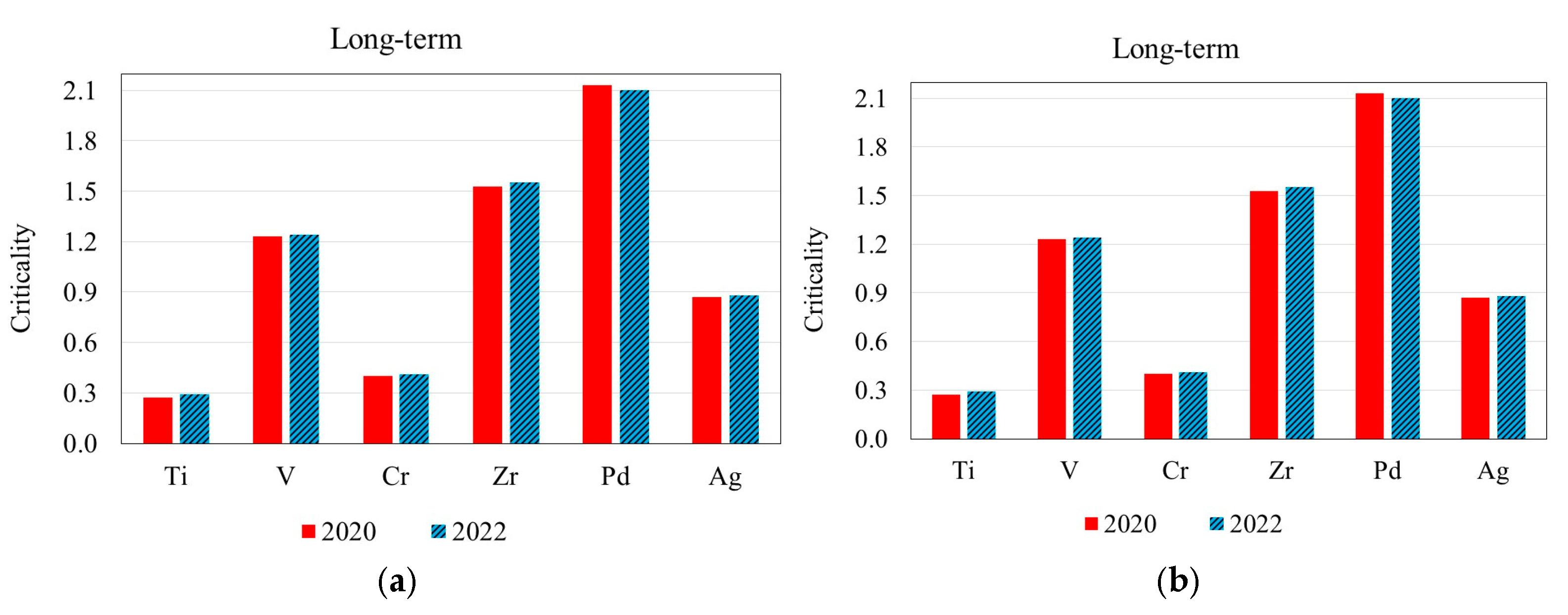

2.2. Critical Raw Materials

2.3. Life Cycle Assessment

2.3.1. Goal and Scope

2.3.2. Functional Unit

2.3.3. System Boundaries and Modeling Assumptions

2.3.4. Life Cycle Inventory and Data Sources

2.3.5. Uncertainty Analysis

- The mass of each membrane (deposited onto 2.56 cm2 alumina substrates) was calculated by considering the mean values of surface area (s), thickness (t), atomic mass (m), and unit cell volume (v). Measuring their respective uncertainty (GSDs, GSDt, GSDm, GSDv) allowed obtaining the uncertainty of membrane mass [41,42]. The equations regarding the GSD of a set of n values (xi) and error propagation considering the multiplication of parameters are reported below:

- 2.

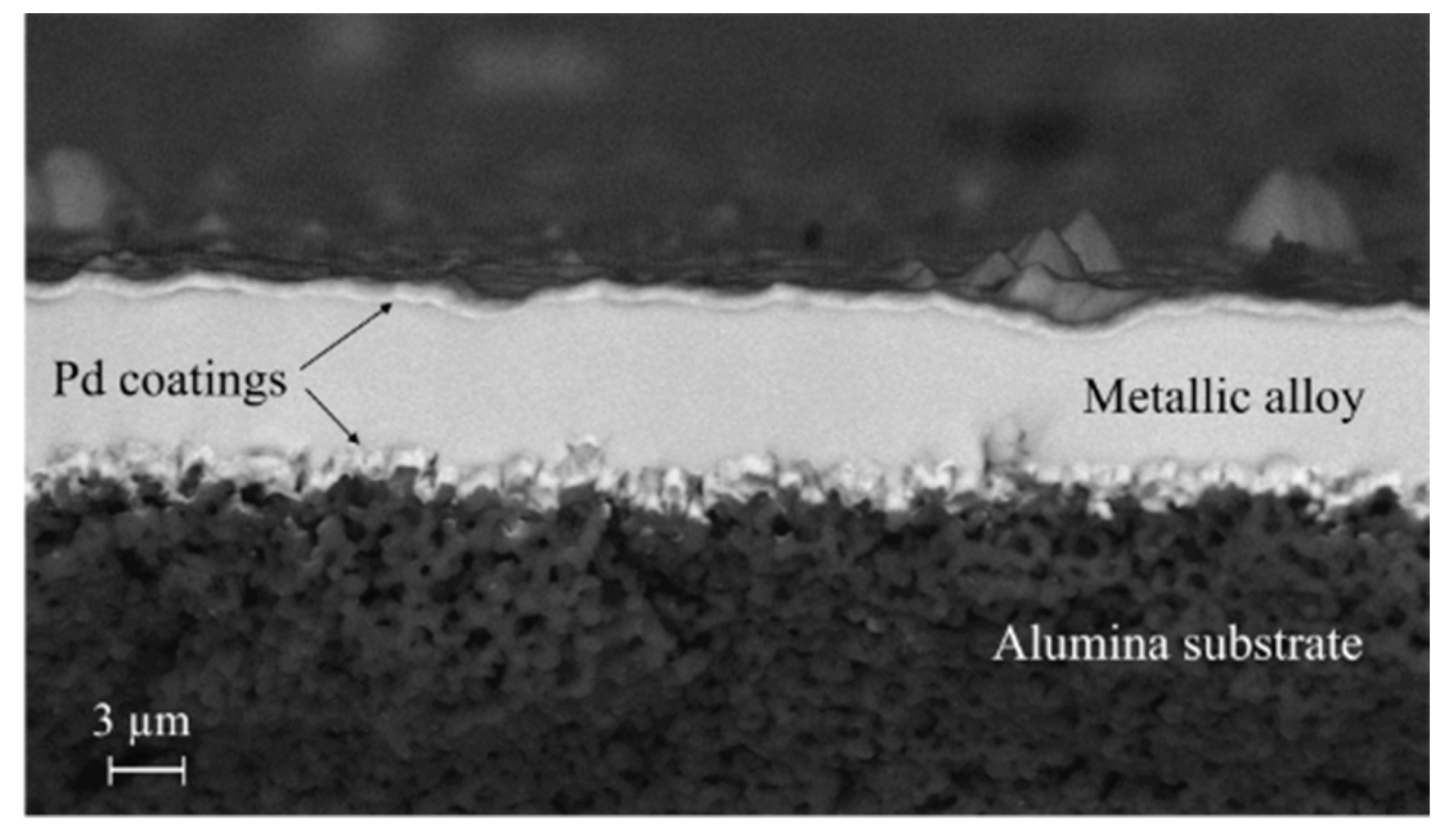

- The surface area of several alumina substrates was measured, and the mean and standard deviation were obtained. The contribution of thin film roughness was neglected being lower than the error on thickness estimation, measured using the FE-SEM cross-section images. To assess the coating thickness uniformity, the measurement was repeated in several regions to obtain a distribution of values and their GSD.

- 3.

- The composition evaluation of each membrane was carried out by EDS measurements, as reported in a previous work [42], and the corresponding mass GSDs were obtained.

- 4.

- The cell parameters of the crystalline phase of the membranes and their errors were acquired by Rietveld refinement of XRD patterns. Assuming an orthorhombic crystalline structure, the unit cell volume and its error were estimated for each membrane.

3. Results and Discussions

3.1. CRM Analysis

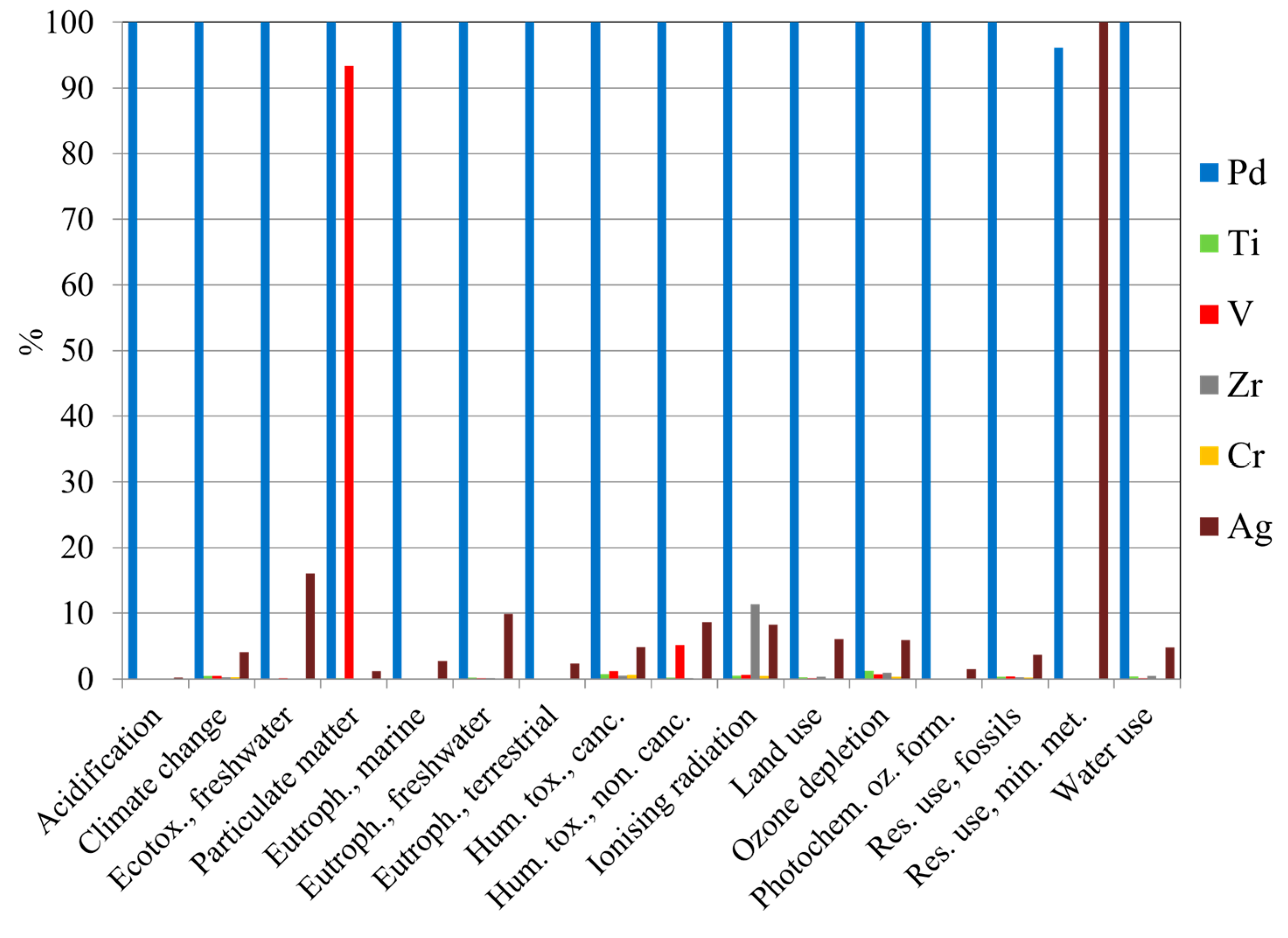

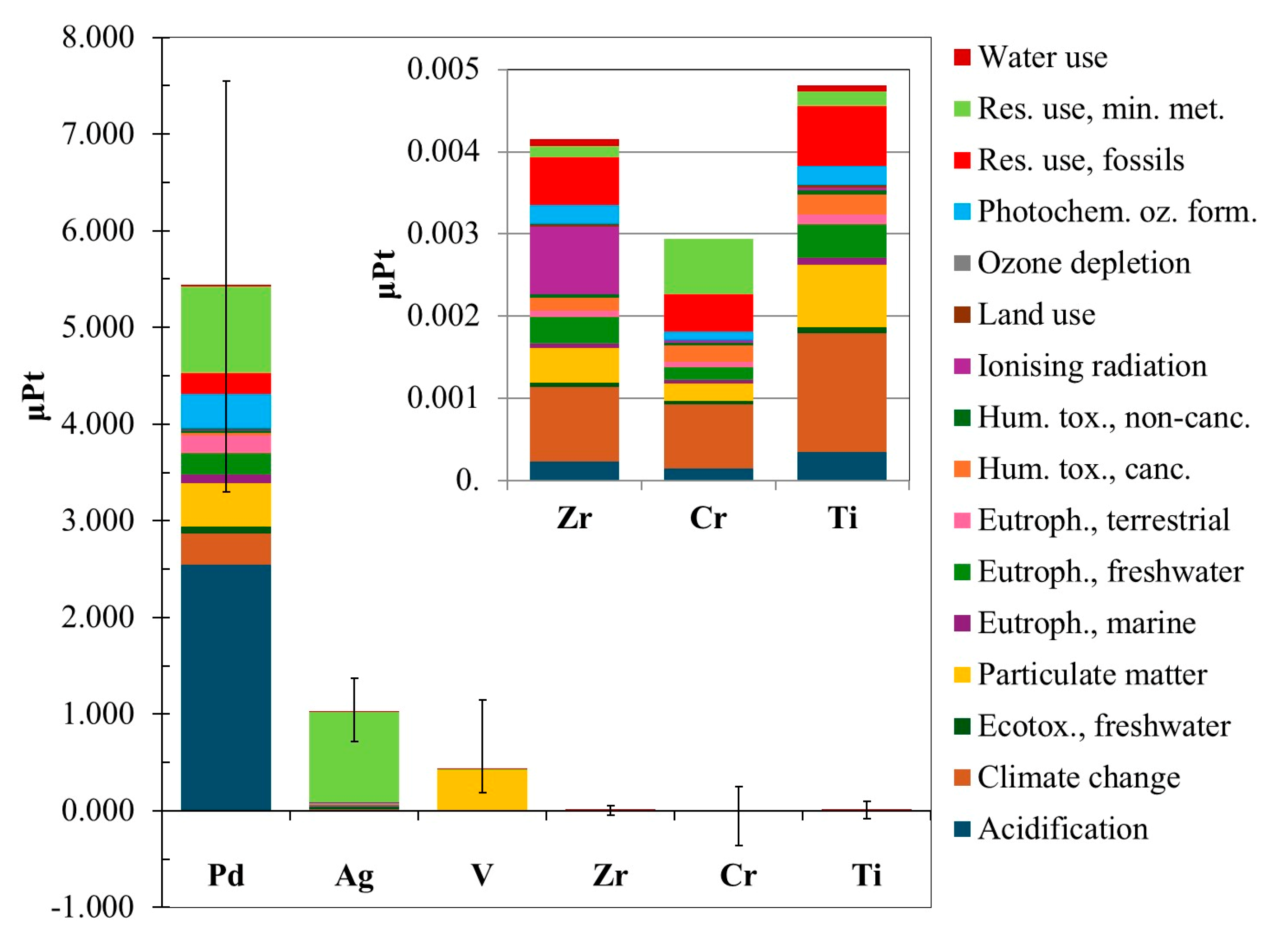

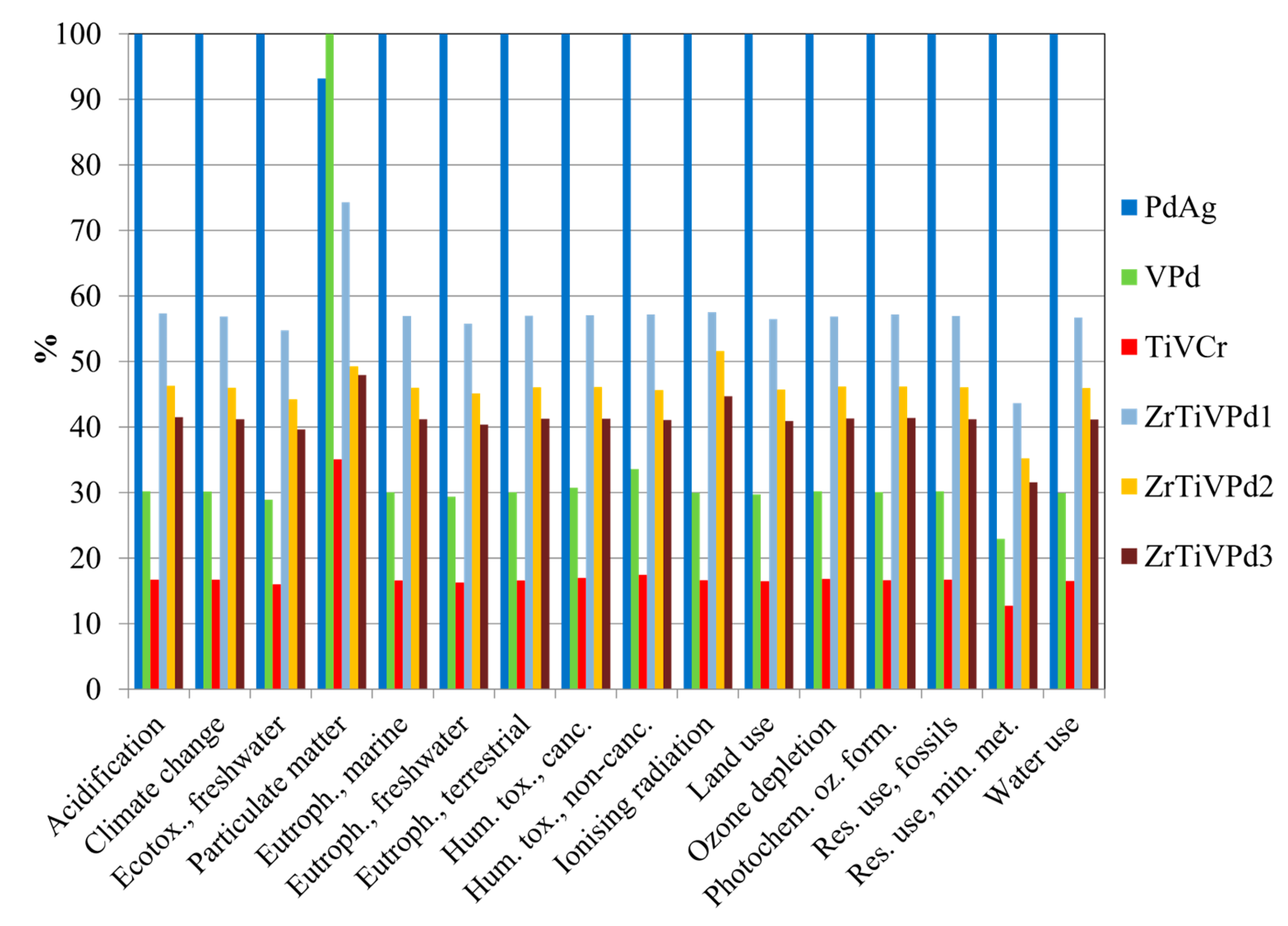

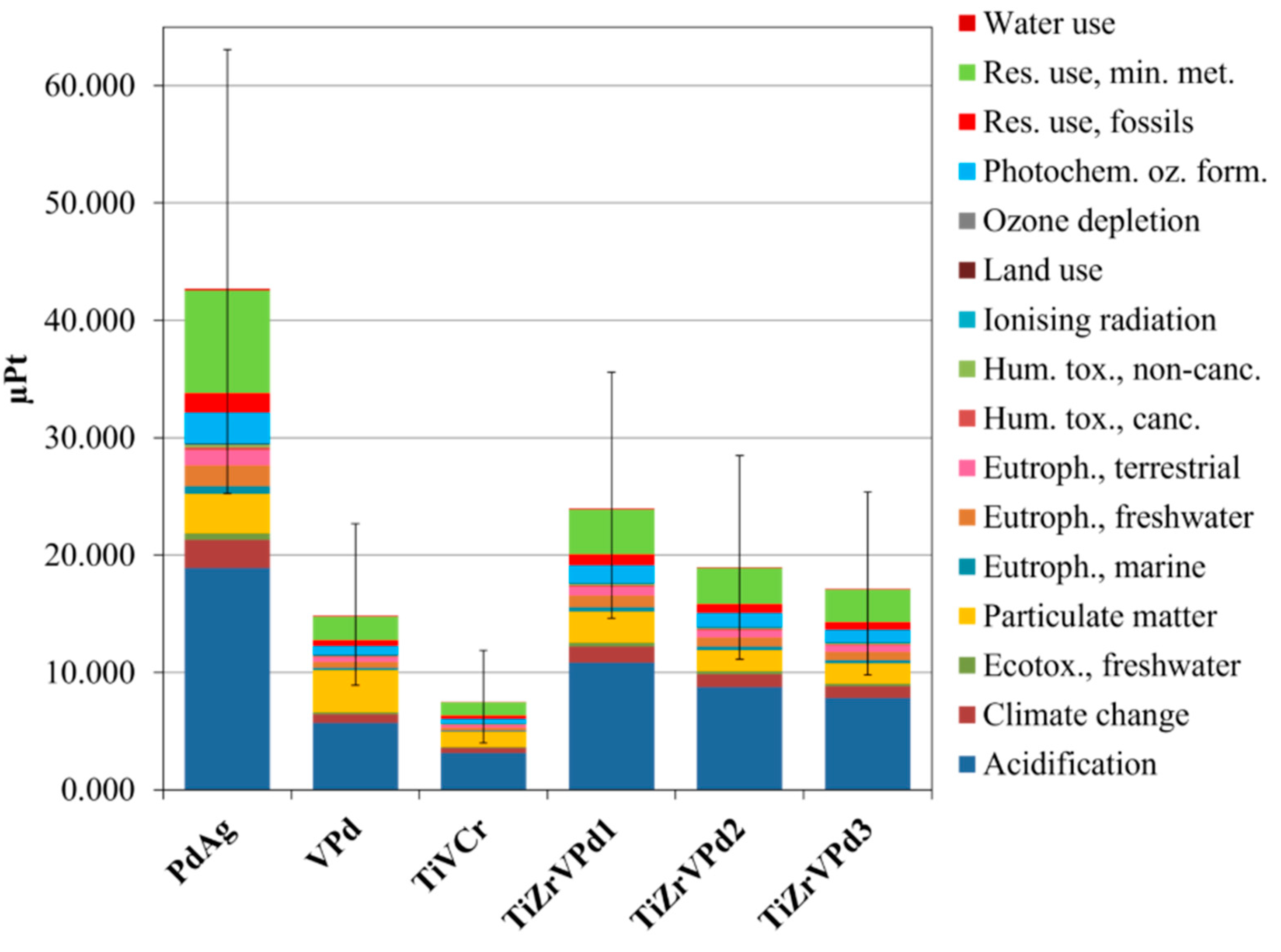

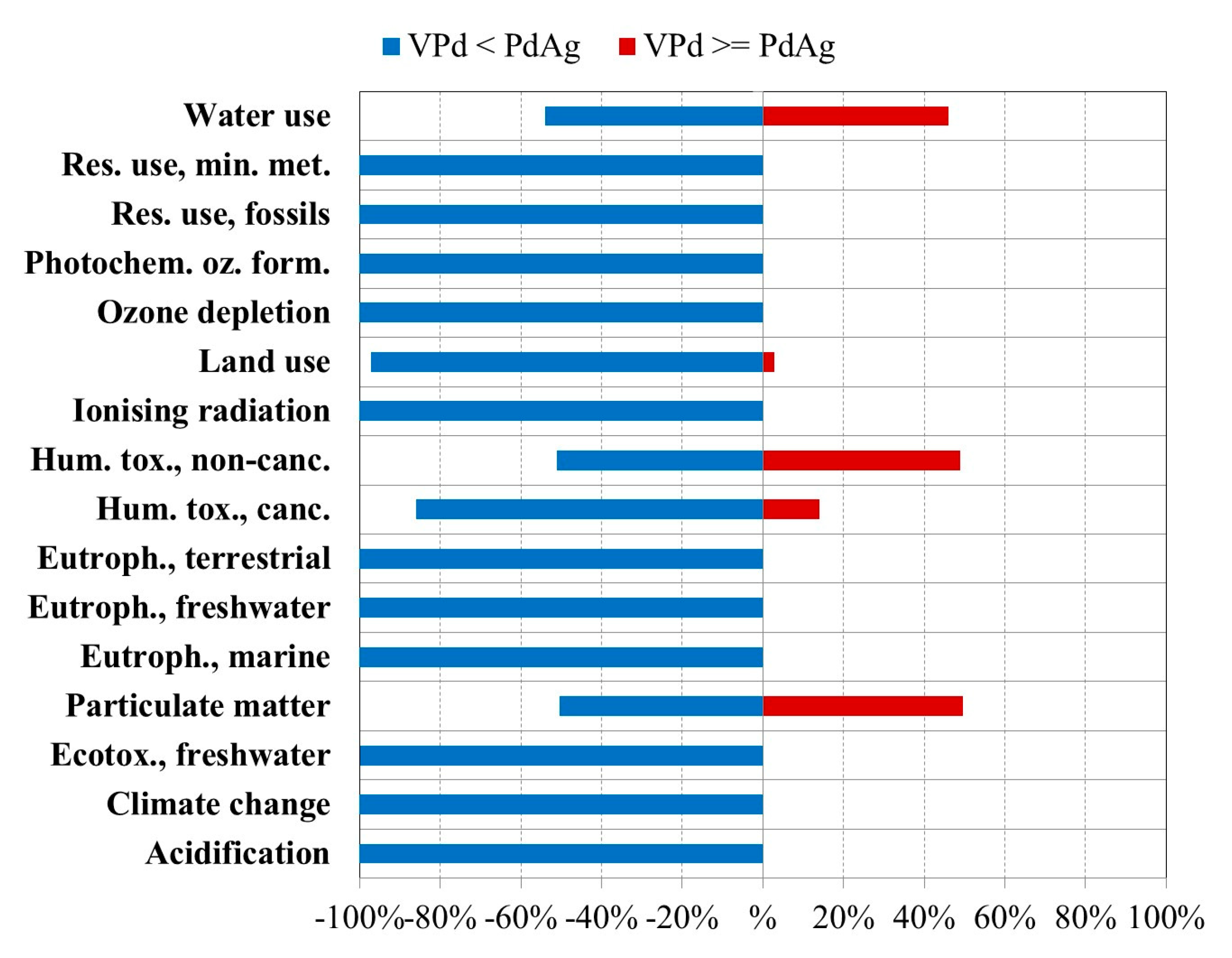

3.2. LCA Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CRM | Critical raw materials |

| SSbD | Safe and Sustainable by Design |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| XRD | X-ray Diffraction |

| EDS | Energy Dispersive X-ray Spectroscopy |

| FE-SEM | Field Emission Scanning Electron Microscopy |

| EI | Economic Importance |

| SR | Supply Risk |

| EF | Environmental Footprint |

| GLO | Global |

| GSD | Geometric Standard Deviation |

| HiPIMS | High-Power Impulse Magnetron Sputtering |

| PGM | Platinum Group Metals |

References

- Abas, N.; Kalair, A.; Khan, N. Review of Fossil Fuels and Future Energy Technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Saini, N.; Awasthi, K. Insights into the Progress of Polymeric Nano-Composite Membranes for Hydrogen Separation and Purification in the Direction of Sustainable Energy Resources. Sep Purif Technol 2022, 282, 120029. [Google Scholar] [CrossRef]

- Chuah, C. Y.; Jiang, X.; Goh, K.; Wang, R. Recent Progress in Mixed-Matrix Membranes for Hydrogen Separation. Membranes (Basel) 2021, 11. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Zhang, X.; Zhai, J.; Li, X.; Guo, X.; He, G. Research Progress and Prospects on Hydrogen Separation Membranes. Clean Energy 2023, 7, 217–241. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and Evaluation of Hydrogen Production Methods for Better Sustainability. Int J Hydrogen Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Al-Mufachi, N. A.; Rees, N. V; Steinberger-Wilkens, R. Hydrogen Selective Membranes: A Review of Palladium-Based Dense Metal Membranes. Renewable and Sustainable Energy Reviews 2015, 47, 540–551. [Google Scholar] [CrossRef]

- Amandusson, H.; Ekedahl, L.-G.; Dannetun, H. Hydrogen Permeation through Surface Modified Pd and PdAg Membranes. J Memb Sci 2001, 193, 35–47. [Google Scholar] [CrossRef]

- Dolan, M. D. Non-Pd BCC Alloy Membranes for Industrial Hydrogen Separation. J Memb Sci 2010, 362, 12–28. [Google Scholar] [CrossRef]

- Abdul Samat, N. A. S.; Goh, P. S.; Lau, W. J.; Guo, Q.; Ismail, A. F.; Wong, K. C. Green Hydrogen Revolution: Sustainable Hydrogen Separation Using Hydrogen-Selective Nanocomposite Membrane Technology. Int J Hydrogen Energy 2025, 99, 458–484. [Google Scholar] [CrossRef]

- Fasolin, S.; Barison, S.; Agresti, F.; Battiston, S.; Fiameni, S.; Isopi, J.; Armelao, L. New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification. 2022. [CrossRef]

- Grohol, M.; Veeh, C.; GROW, D. Study on the Critical Raw Materials for the EU 2023: Final Report; Brussels, 2023. [CrossRef]

- Commissione europea: Direzione generale del Mercato interno dell’imprenditoria e delle PMI, dell’industria; Blengini, G. A.; El Latunussa, C.; Eynard, U.; Torres De Matos, C.; Wittmer, D.; Georgitzikis, K.; Pavel, C.; Carrara, S.; Mancini, L.; et al. Study on the EU’s List of Critical Raw Materials (2020) : Final Report, Ufficio delle pubblicazioni dell’Unione europea. 2020. [CrossRef]

- Centre, E. C. J. R.; Caldeira, C.; Farcal, L.; Garmendia Aguirre, I.; Mancini, L.; Tosches, D.; Amelio, A.; Rasmussen, K.; Rauscher, H.; Riego Sintes, J.; et al. Safe and Sustainable by Design Chemicals and Materials – Framework for the Definition of Criteria and Evaluation Procedure for Chemicals and Materials; Publications Office of the European Union, 2022. [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int J Life Cycle Assess 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Abbate, E.; Ragas, A. M. J.; Caldeira, C.; Posthuma, L.; Garmendia Aguirre, I.; Devic, A. C.; Soeteman-Hernández, L. G.; Huijbregts, M. A. J.; Sala, S. Operationalization of the Safe and Sustainable by Design Framework for Chemicals and Materials: Challenges and Proposed Actions. Integr Environ Assess Manag 2025, vjae031. [Google Scholar] [CrossRef]

- Mankins, J. Technology Readiness Level – A White Paper. 1995.

- Waiyaki, P.; Thekkethil, R.; Ananthakumar, M.; Seshadri, S. How Green Is Green Hydrogen?─A Life-Cycle and Critical Raw Material Analysis of Green Hydrogen Production via PEMW Electrolysers in India. Energy & Fuels 2025, 39, 5534–5549. [Google Scholar] [CrossRef]

- Centre, E. C. J. R.; Caldeira, C.; Farcal, R.; Moretti, C.; Mancini, L.; Rauscher, H.; Riego Sintes, J.; Sala, S.; Rasmussen, K. Safe and Sustainable by Design Chemicals and Materials – Review of Safety and Sustainability Dimensions, Aspects, Methods, Indicators, and Tools; Publications Office of the European Union, 2022. [CrossRef]

- Cespi, D. Procedural Life Cycle Inventory of Chemical Products at Laboratory and Pilot Scale: A Compendium. Green Chemistry 2024, 26, 9554–9568. [Google Scholar] [CrossRef]

- Graedel, T. E.; Harper, E. M.; Nassar, N. T.; Nuss, P.; Reck, B. K. Criticality of Metals and Metalloids. Proceedings of the National Academy of Sciences 2015, 112, 4257–4262. [Google Scholar] [CrossRef]

- Zin, V.; Fiameni, S.; Mohtashamifar, A.; Battiston, S.; Montagner, F.; Deambrosis, S. M.; Losurdo, M. Environmental Sustainability of High-Power Impulse Magnetron Sputtering Nitriding Treatment of CoCrMo Alloys for Orthopedic Application: A Life Cycle Assessment Coupled with Critical Raw Material Analysis. Sustainability 2025, 17. [Google Scholar] [CrossRef]

- Schropp, E.; Campos-Carriedo, F.; Iribarren, D.; Naumann, G.; Bernäcker, C.; Gaderer, M.; Dufour, J. Environmental and Material Criticality Assessment of Hydrogen Production via Anion Exchange Membrane Electrolysis. Appl Energy 2024, 356, 122247. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Leo, P.; Sanz, R.; Carrero, A.; Calles, J. A.; Alique, D. Life Cycle Assessment of H2-Selective Pd Membranes Fabricated by Electroless Pore-Plating. J Clean Prod 2021, 316, 128229. [Google Scholar] [CrossRef]

- Sutar, P. R.; Yadav, G. D. Exploring the Environmental Performance of Electroless Plated Palladium Alloy Membranes for H2 Separation: A Cradle-to-Gate Life Cycle Study. Int J Hydrogen Energy 2024, 79, 1464–1471. [Google Scholar] [CrossRef]

- Barison, S.; Fasolin, S.; Boldrini, S.; Ferrario, A.; Romano, M.; Montagner, F.; Deambrosis, S. M.; Fabrizio, M.; Armelao, L. PdAg/Alumina Membranes Prepared by High Power Impulse Magnetron Sputtering for Hydrogen Separation. Int J Hydrogen Energy 2018, 43, 7982–7989. [Google Scholar] [CrossRef]

- Battiston, S.; Fiameni, S.; Fasolin, S.; Barison, S.; Armelao, L. Life Cycle Environmental Impact Assessment of Lab-Scale Preparation of Porous Alumina Pellets as Substrate for Hydrogen Separation Metal Layer-Based Membranes. Int J Life Cycle Assess 2023, 28, 1117–1131. [Google Scholar] [CrossRef]

- Fiameni, S.; Battiston, S.; Castellani, V.; Barison, S.; Armelao, L. Implementing Sustainability in Laboratory Activities: A Case Study on Aluminum Titanium Nitride Based Thin Film Magnetron Sputtering Deposition onto Commercial Laminated Steel. J Clean Prod 2021, 285, 124869. [Google Scholar] [CrossRef]

- Karakaya, I.; Thompson, W. The Ag−Pd (Silver-Palladium) System. Bulletin of Alloy Phase Diagrams 1988, 9, 237–243. [Google Scholar] [CrossRef]

- Fasolin, S.; Barison, S.; Boldrini, S.; Ferrario, A.; Romano, M.; Montagner, F.; Miorin, E.; Fabrizio, M.; Armelao, L. Hydrogen Separation by Thin Vanadium-Based Multi-Layered Membranes. Int J Hydrogen Energy, 2018. [Google Scholar] [CrossRef]

- LI, A.; Boyd, T.; Lim, J. C.; Grace, J. R. Development of Palladium-Alloy Membranes for Hydrogen Separation and Purification. Journal of Membrane Science and Research 2020, 6, 99–106. [Google Scholar] [CrossRef]

- Grondstoffenscanner www.grondstoffenscanner.nl (accessed Jun 19, 2025).

- Bastein, T.; Rietveld, E.; Zyl, S. Van. Materials in the Dutch Economy – a Vulnerability Assessment -, 2015. [Google Scholar]

- Official Journal of the European Union. Regulation (EU) 2024/1252 of the European Parliament and of the Council of 11 April 2024 Establishing a Framework for Ensuring a Secure and Sustainable Supply of Critical Raw Materials and Amending Regulations (EU) No 168/2013, (EU) 2018/858, (EU) 2018/1724 and (EU) 2019/1020 (Text with EEA Relevance), 2024.

- Kroll, W. The Production of Ductile Titanium. Transactions of The Electrochemical Society 1940, 78, 35. [Google Scholar] [CrossRef]

- da Silva Lima, L.; Quartier, M.; Buchmayr, A.; Sanjuan-Delmás, D.; Laget, H.; Corbisier, D.; Mertens, J.; Dewulf, J. Life Cycle Assessment of Lithium-Ion Batteries and Vanadium Redox Flow Batteries-Based Renewable Energy Storage Systems. Sustainable Energy Technologies and Assessments 2021, 46, 101286. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J Environ Manage 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro; 2016.

- Qin, Y.; Suh, S. What Distribution Function Do Life Cycle Inventories Follow? Int J Life Cycle Assess 2017, 22, 1138–1145. [Google Scholar] [CrossRef]

- Ciroth, A.; Muller, S.; Weidema, B.; Lesage, P. Empirically Based Uncertainty Factors for the Pedigree Matrix in Ecoinvent. Int J Life Cycle Assess 2016, 21, 1338–1348. [Google Scholar] [CrossRef]

- Endo, Y. Estimate of Confidence Intervals for Geometric Mean Diameter and Geometric Standard Deviation of Lognormal Size Distribution. Powder Technol 2009, 193, 154–161. [Google Scholar] [CrossRef]

- General Chemistry Laboratories. Uncertainties in Quantities and Error Propagation. 2019; https://chem.libretexts.org/@go/page/175486.

- Battiston, S.; Fanciulli, C.; Fiameni, S.; Famengo, A.; Fasolin, S.; Fabrizio, M. One Step Synthesis and Sintering of Ni and Zn Substituted Tetrahedrite as Thermoelectric Material. J Alloys Compd 2017, 702, 75–83. [Google Scholar] [CrossRef]

- Sun, S.; Ertz, M. Life Cycle Assessment and Monte Carlo Simulation to Evaluate the Environmental Impact of Promoting LNG Vehicles. MethodsX 2020, 7, 101046. [Google Scholar] [CrossRef] [PubMed]

- K, G.; U, E.; S, B.; F, P. C.; D, I.; E, D.; E, G. Palladium: Impact Assessment for Supply Security; European Commission, 2023.

- Ciotola, A.; Fuss, M.; Colombo, S.; Poganietz, W.-R. The Potential Supply Risk of Vanadium for the Renewable Energy Transition in Germany. J Energy Storage 2021, 33, 102094. [Google Scholar] [CrossRef]

- S, C.; S, B.; D, B.; P, A. D.; A, C.; K, G.; M, G.; A, I.; T, K.; C, L.; et al. Supply Chain Analysis and Material Demand Forecast in Strategic Technologies and Sectors in the EU – A Foresight Study; Publications Office of the European Union: Luxembourg (Luxembourg), 2023; 10.2760/386650 (online),10.2760/334074 (print). [Google Scholar]

- Alique, D.; Leo, P.; Martinez-Diaz, D.; Calles, J. A.; Sanz, R. Environmental and Cost Assessments Criteria for Selection of Promising Palladium Membranes Fabrication Strategies. Int J Hydrogen Energy 2024, 51, 302–319. [Google Scholar] [CrossRef]

- Heijungs, R.; Kleijn, R. Numerical Approaches towards Life Cycle Interpretation Five Examples. Int J Life Cycle Assess 2001, 6, 141–148. [Google Scholar] [CrossRef]

- Mancini, L.; Sala, S.; Recchioni, M.; Benini, L.; Goralczyk, M.; Pennington, D. Potential of Life Cycle Assessment for Supporting the Management of Critical Raw Materials. Int J Life Cycle Assess 2015, 20, 100–116. [Google Scholar] [CrossRef]

| Membrane | Composition | Thickness (μm) | Alloy Pd Content (wt%) | Selectivity |

| TiVCr | Ti20V33Cr47 | 2.0 ± 0.2 | - | 11 |

| VPd [29] | V93Pd7 | 3.5 ± 0.2 | 14% | 400 |

| PdAg [25] | Pd77Ag23 | 3.2 ± 0.2 | 65% | 222 |

| ZrVTiPd1 [10] | Zr9V34Ti30Pd27 | 4.7 ± 0.2 | 37% | 50 |

| ZrVTiPd2 [10] | Zr52V12Ti13Pd23 | 6.1 ± 0.2 | 36% | 100 |

| ZrVTiPd3 [10] | Zr39V20Ti19Pd22 | 6.4 ± 0.2 | 33% | 75 |

|

Element/ Ecoinvent process |

Pd77Ag23 | V93Pd7 | Ti20V33Cr47 | ZrVTiPd1 | ZrVTiPd2 | ZrVTiPd3 | |

| Pd | Palladium {GLO}| market for palladium | Cut-off, U | 0.768 | 0.136 | - | 0.419 | 0.291 | 0.299 |

| Ag | Silver {GLO}| market for silver | Cut-off, U | 0.232 | - | - | - | - | - |

| Cr | Chromium {GLO}| market for chromium | Cut-off, U | - | - | 0.481 | - | - | - |

| Zr | Zirconium triple-melt (modelled) | - | - | - | 0.120 | 0.563 | 0.455 |

| Ti | Titanium, triple-melt {GLO}| market for titanium, triple-melt | Cut-off, U | - | - | 0.188 | 0.209 | 0.073 | 0.116 |

| V | Vanadium triple-melt (modelled) | - | 0.864 | 0.331 | 0.252 | 0.073 | 0.130 |

| Element | P/R | Comp. | HHIres | Crit.LT | HHIprod | WGI | OECD | EOLRIR | Crit.ST |

| Pd | 0.16 | 0.97 | 0.97 | 2.100 | 0.34 | 0.2 | 0.00 | 0.22 | 0.053 |

| Ag | 0.02 | 0.72 | 0.14 | 0.880 | 0.1 | 0.08 | 0.00 | 0.75 | 0.002 |

| Cr | 0.15 | 0.02 | 0.24 | 0.410 | 0.22 | 0.18 | 0.02 | 1.00 | 0.000 |

| Zr | 0.03 | 1.00 | 0.52 | 1.550 | 0.21 | 0.28 | 0.00 | 0.06 | 0.055 |

| Ti | 0.10 | 0.00 | 0.19 | 0.290 | 0.11 | 0.16 | 0.00 | 0.33 | 0.012 |

| V | 0.18 | 0.74 | 0.32 | 1.240 | 0.36 | 0.28 | 0.53 | 0.01 | 0.289 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).