Submitted:

18 September 2025

Posted:

19 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

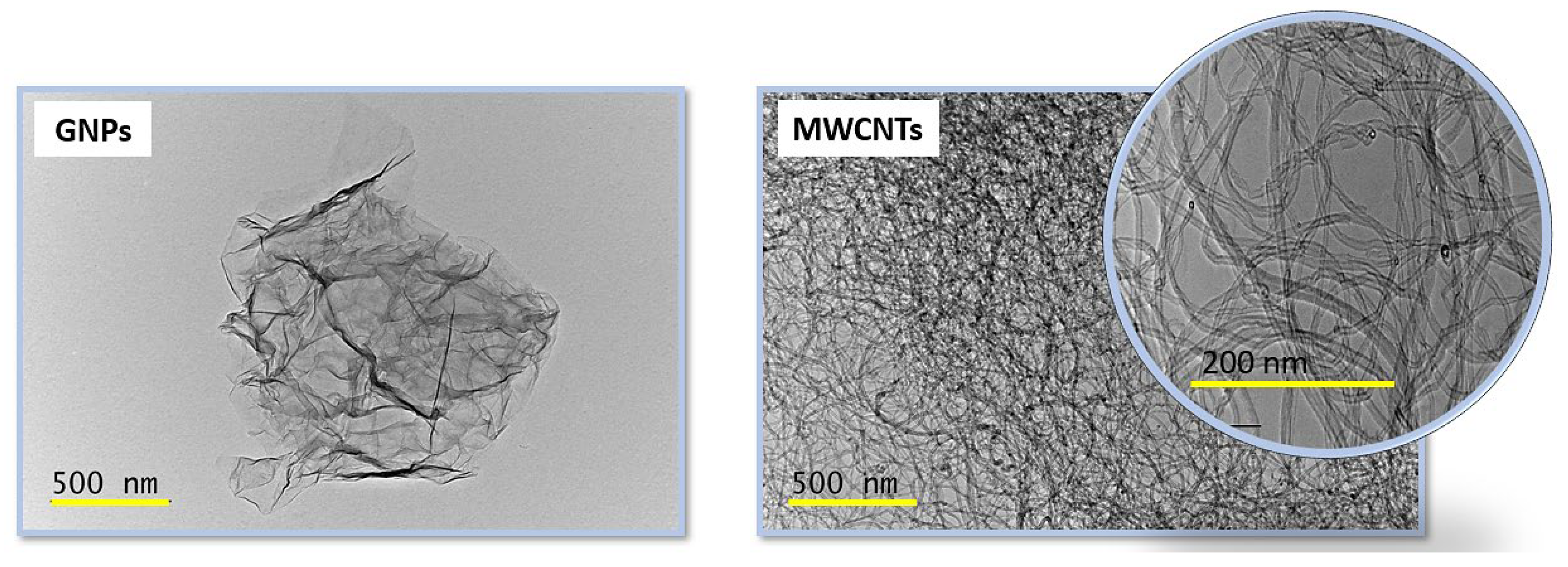

2.1. Materials

2.2. Preparation of Nanocomposites and Test Samples

2.3. Morphological Analysis

2.4. Thermal Analysis

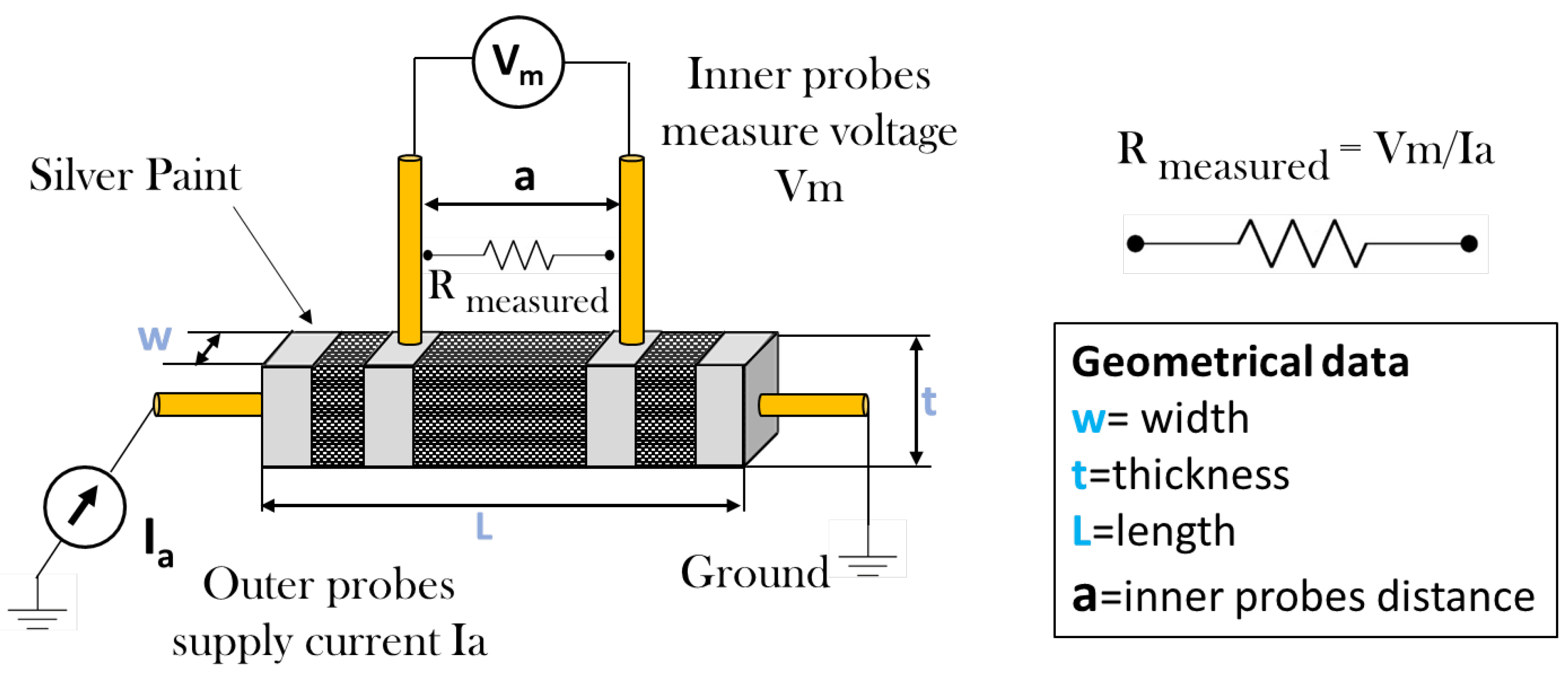

2.5. Electrical Characterization

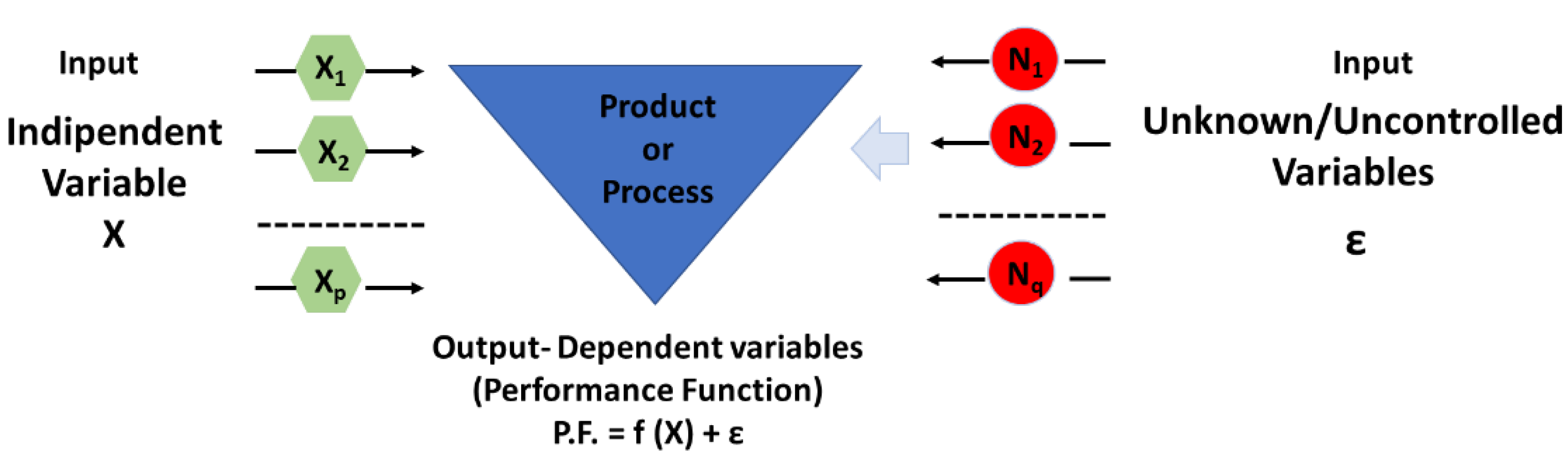

2.6. Design of Experiments

2.7. Response Surface Method (RSM)

2.8. Theoretical Model for the Electrical Heating

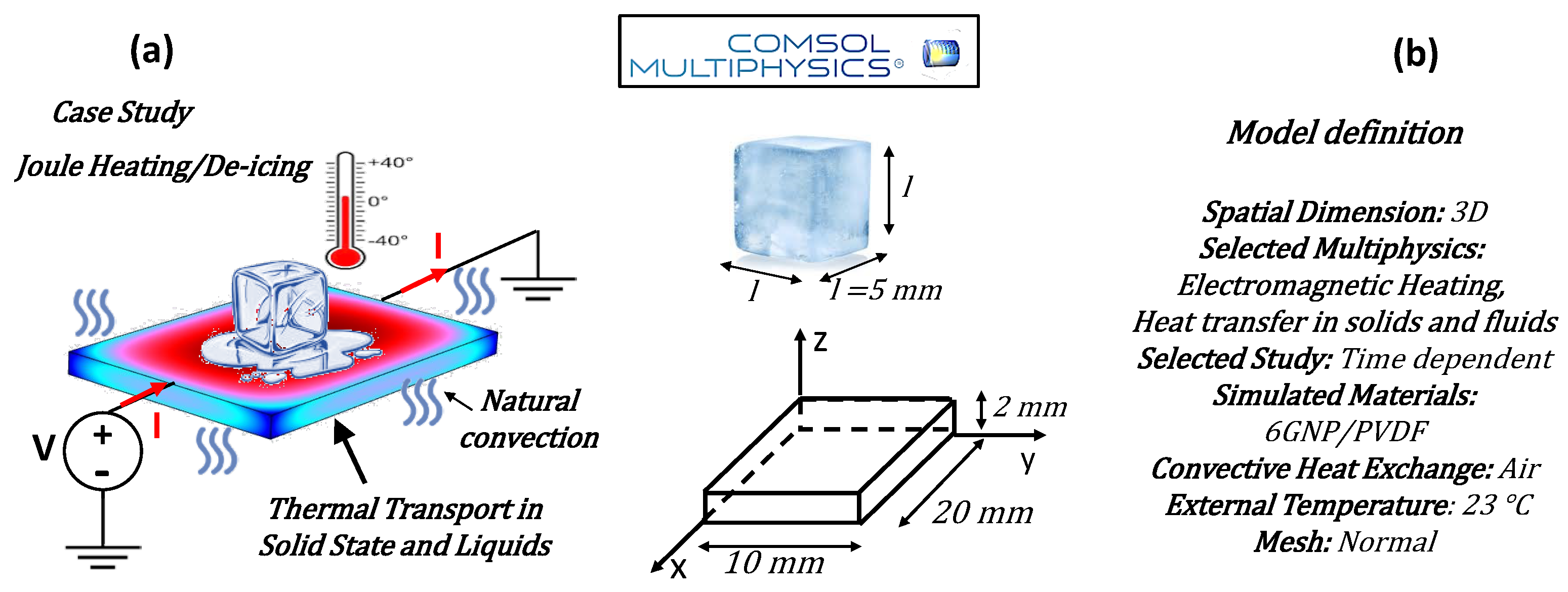

2.9. Simulation Study on the Electrical Heating and De-Icing Properties

3. Results and Discussions

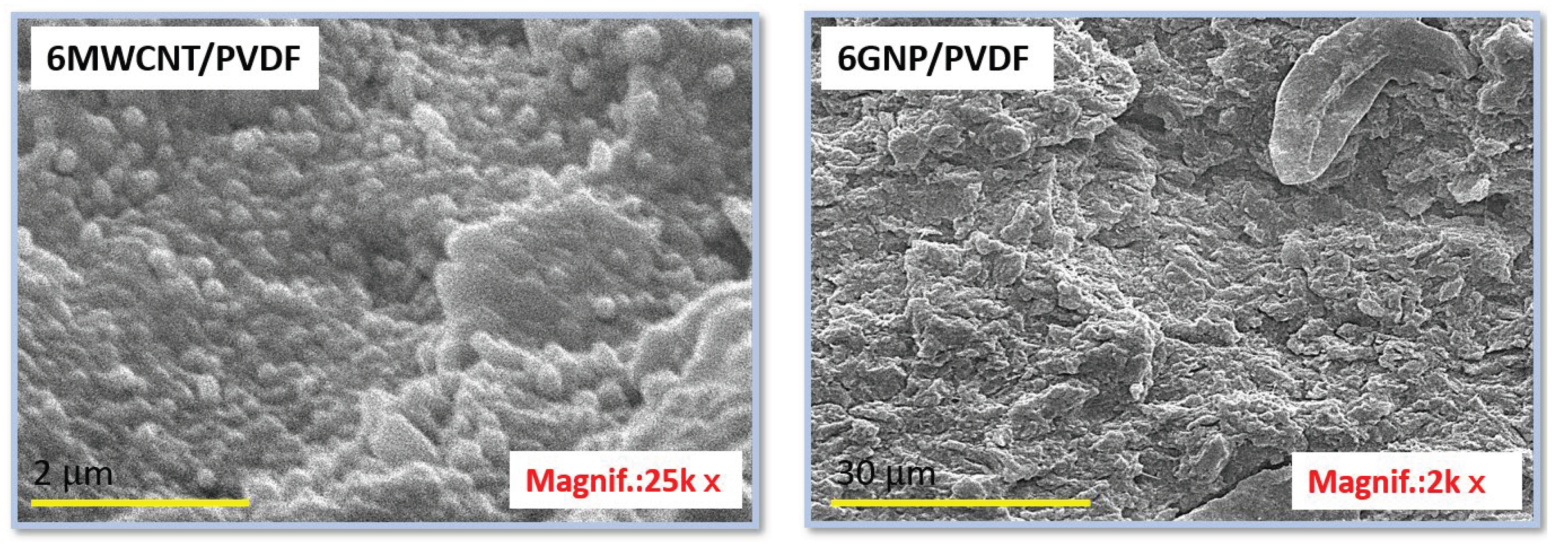

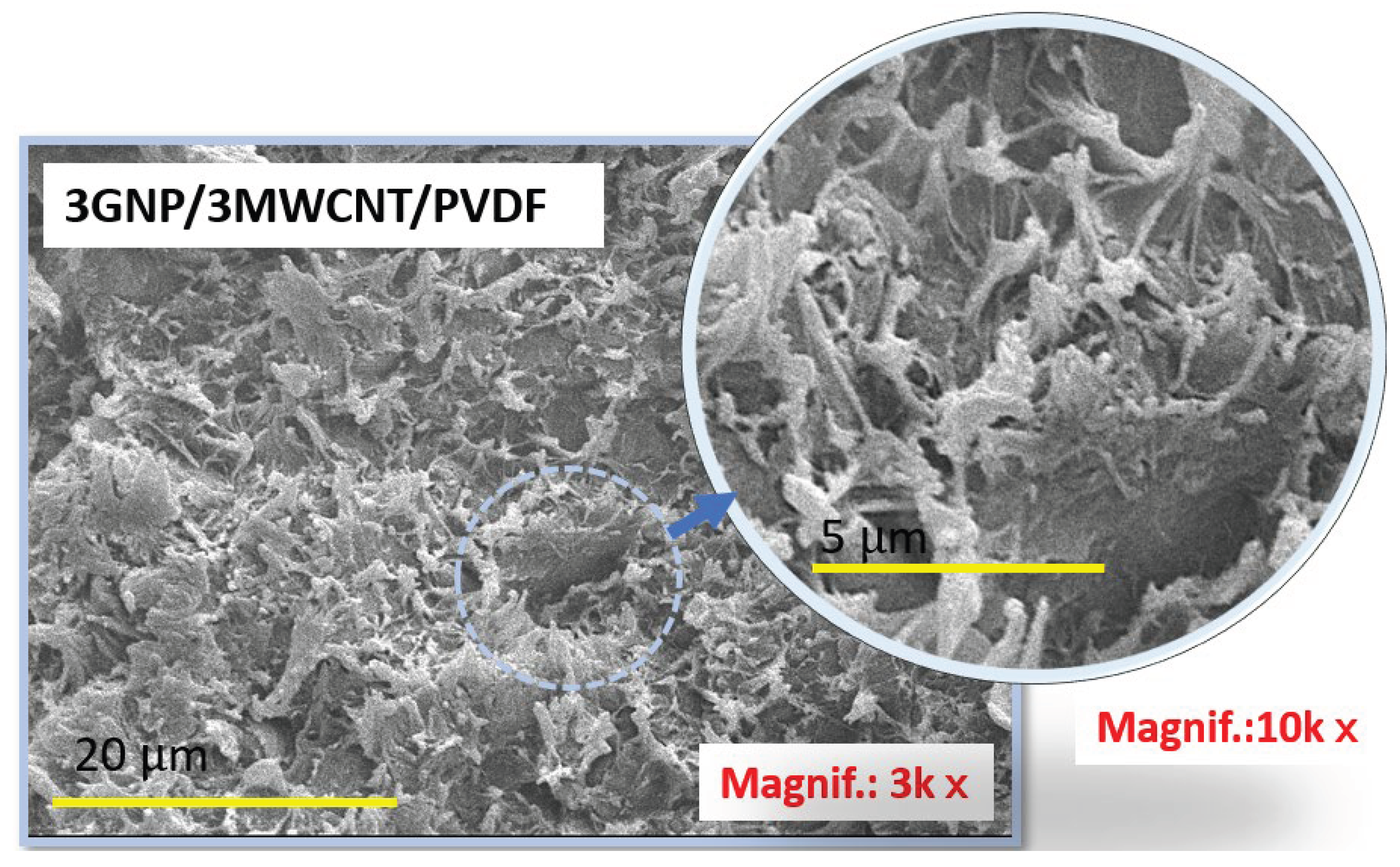

3.1. Morphological Investigation

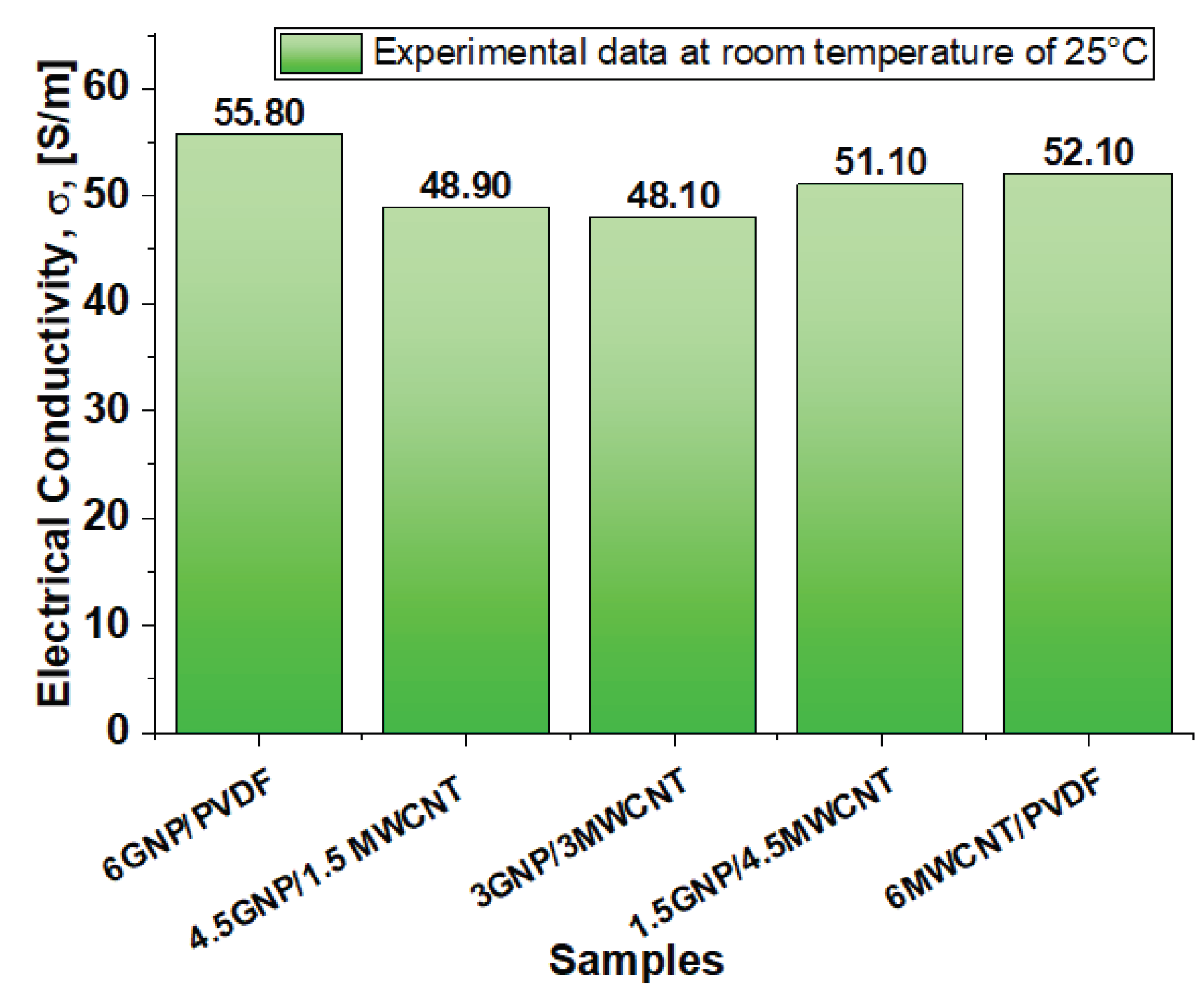

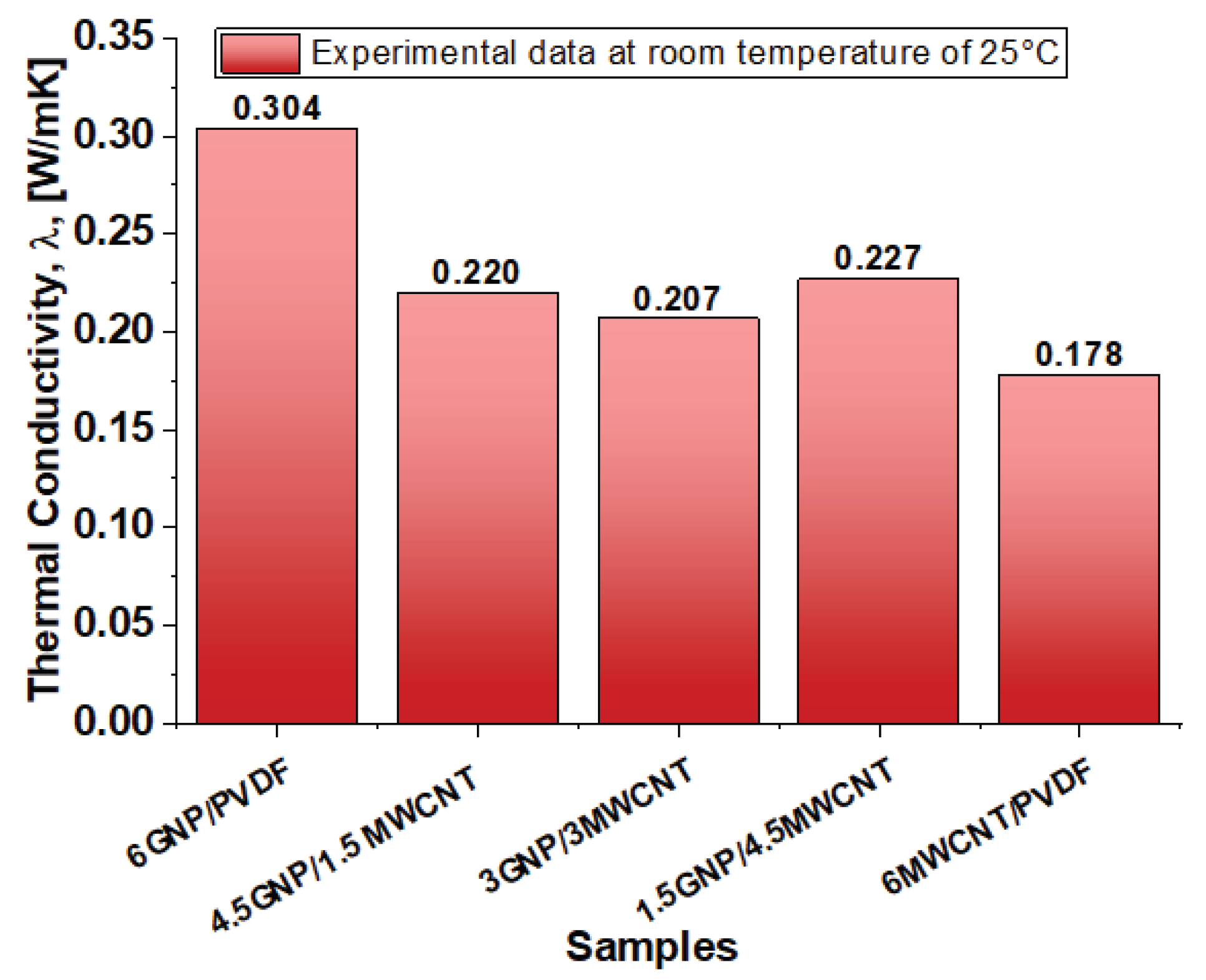

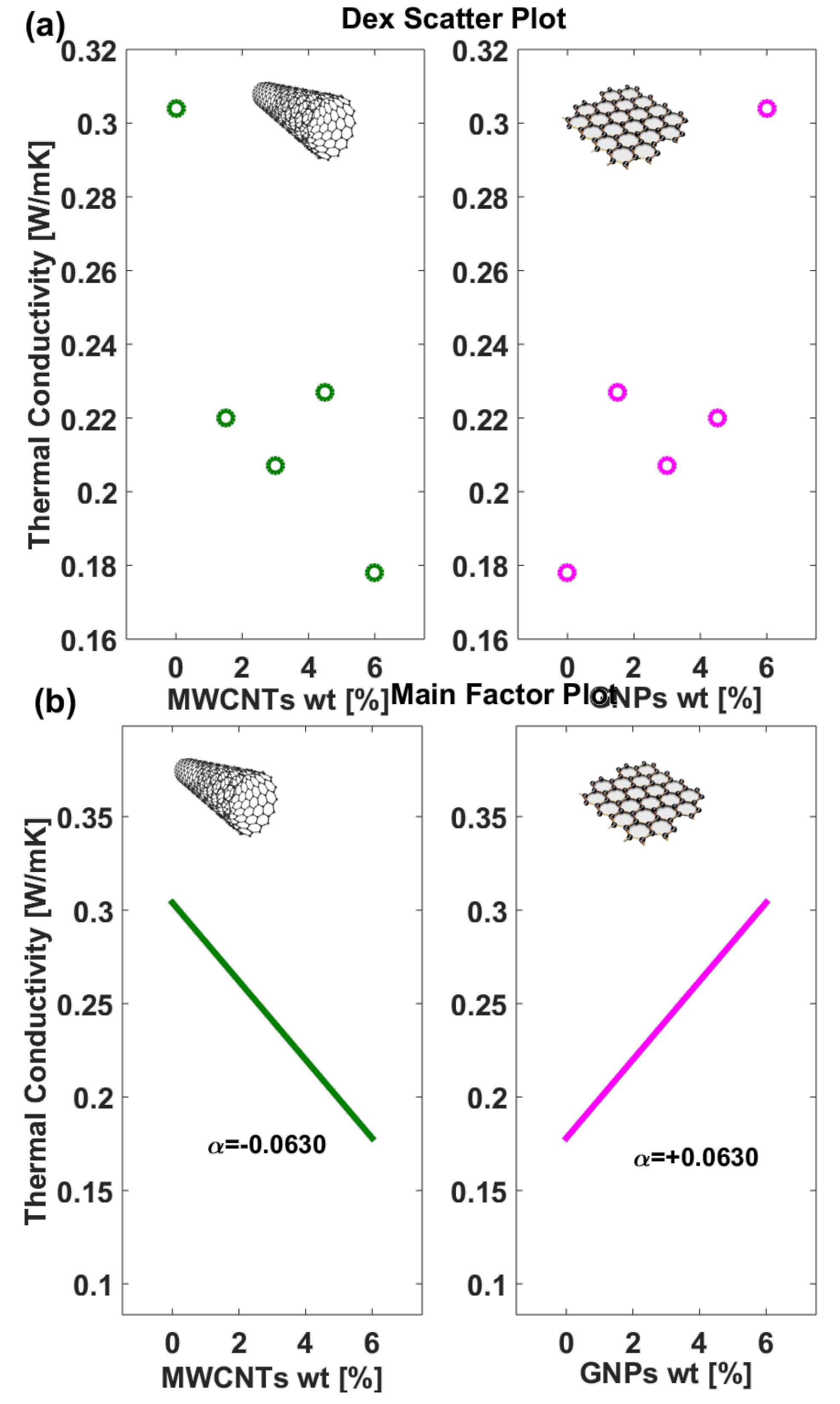

3.2. Experimental Electrical and Thermal Conductivity Evaluation

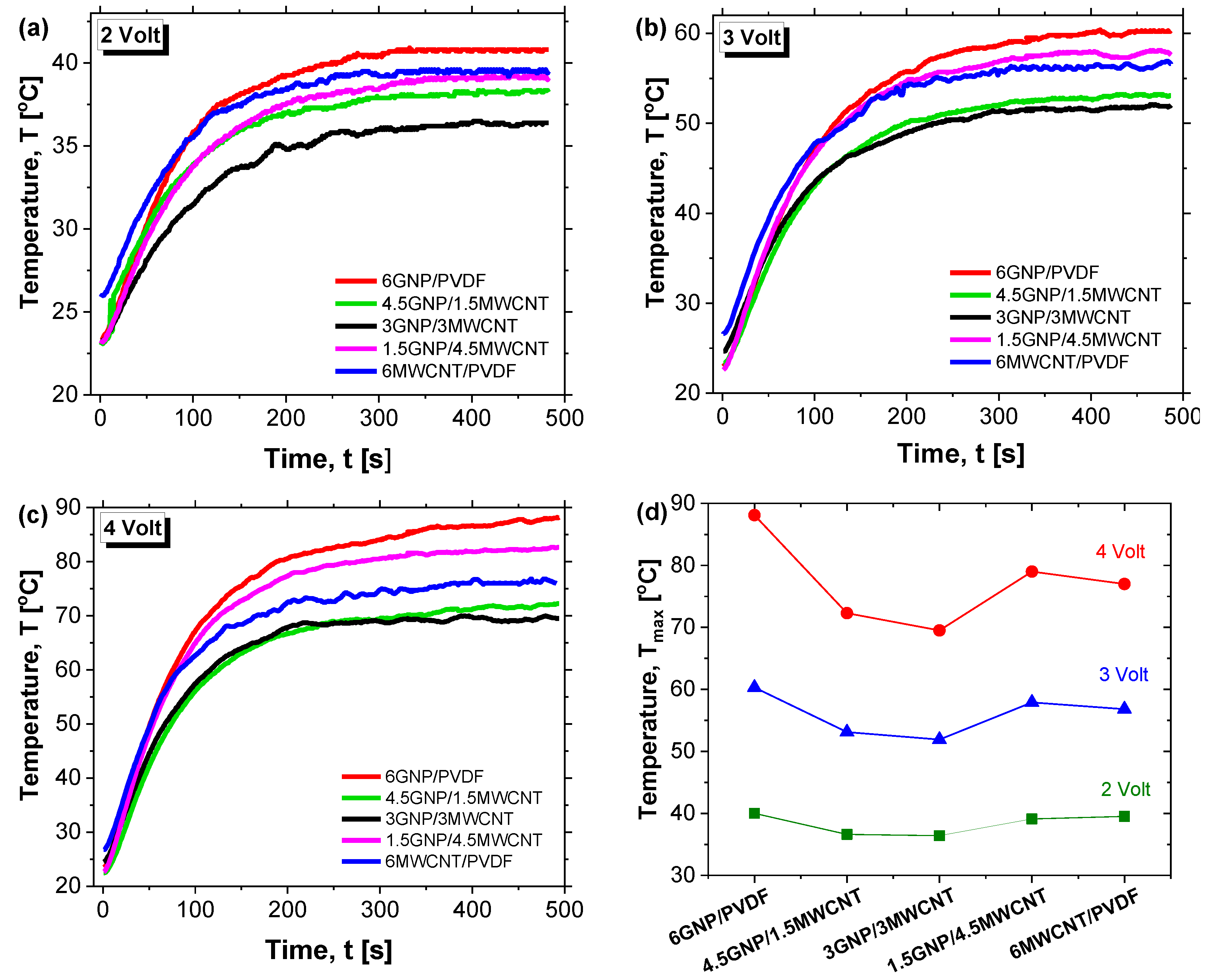

3.3. Joule Heating Characteristics

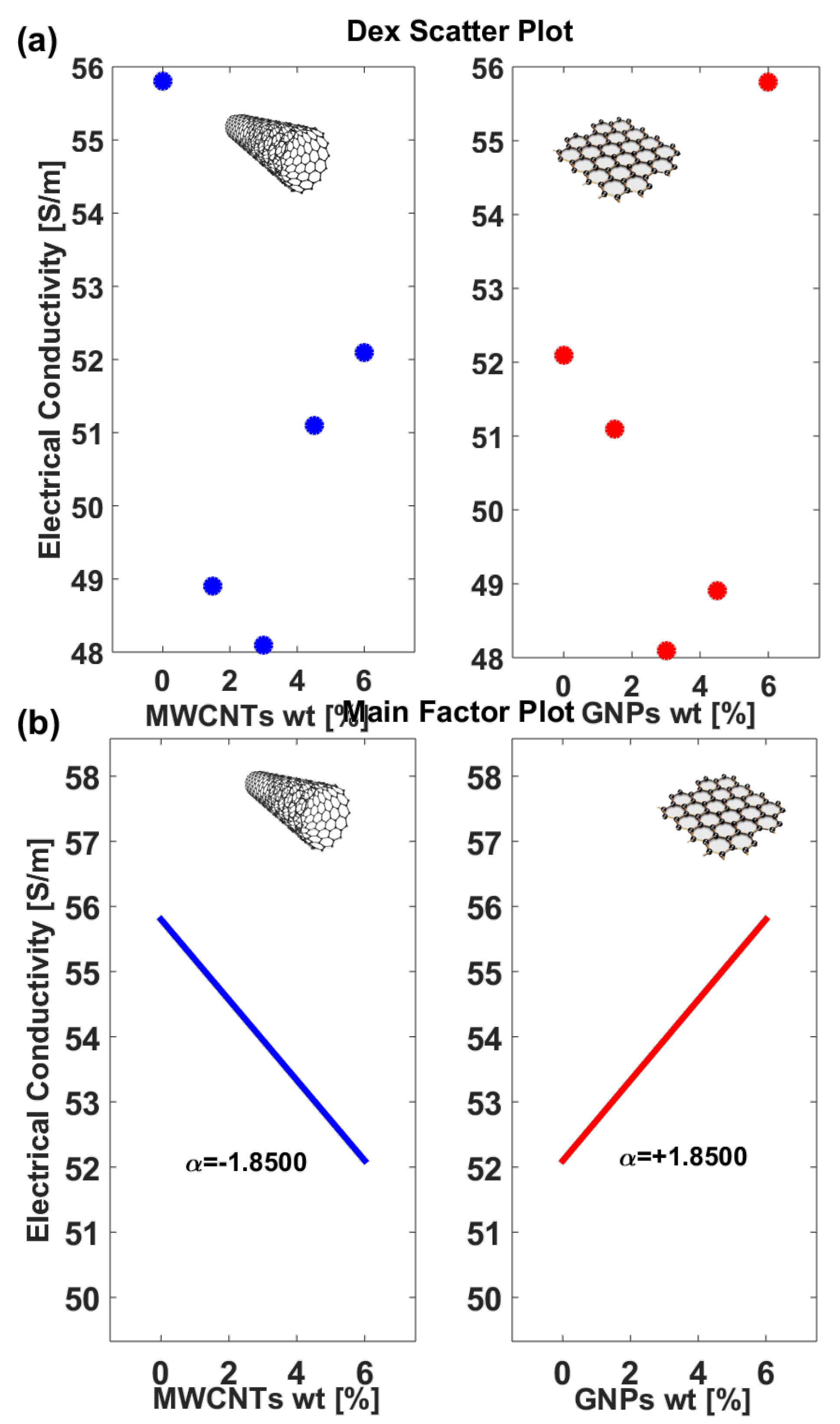

3.4. Design of Experiment: Dex Scatter Plot and Main Factor Plot

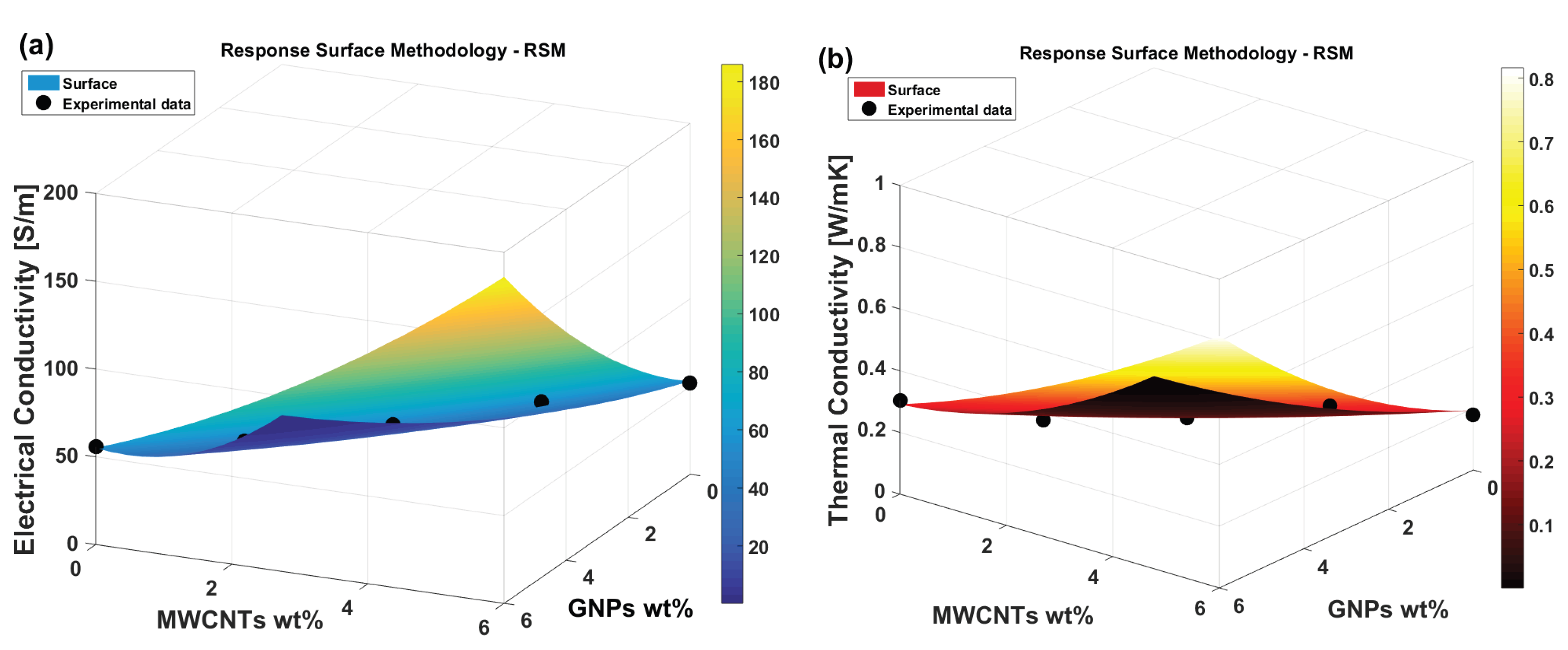

3.5. Response Surface Method

3.6. Simulation Results

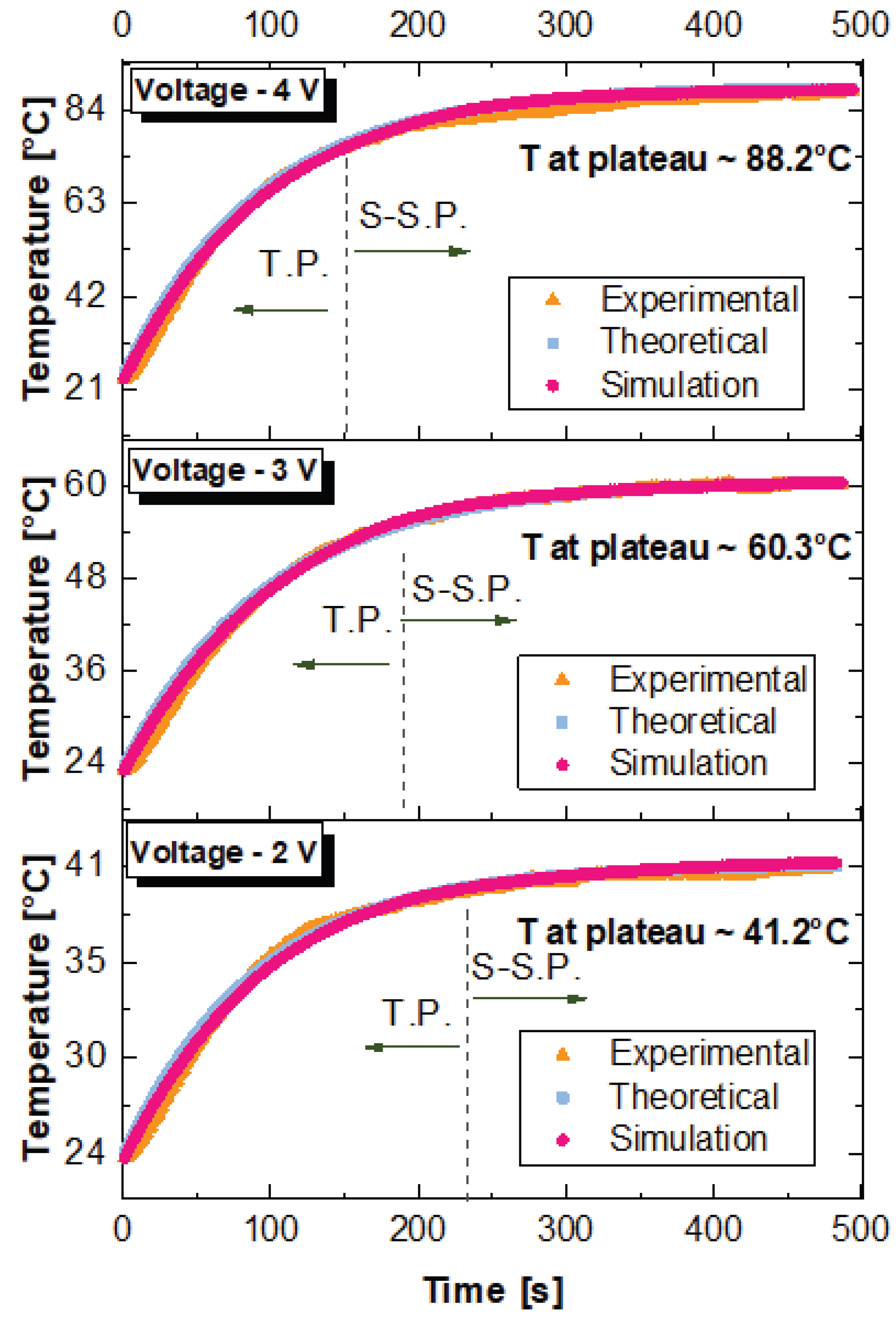

3.6.1. Model Validation

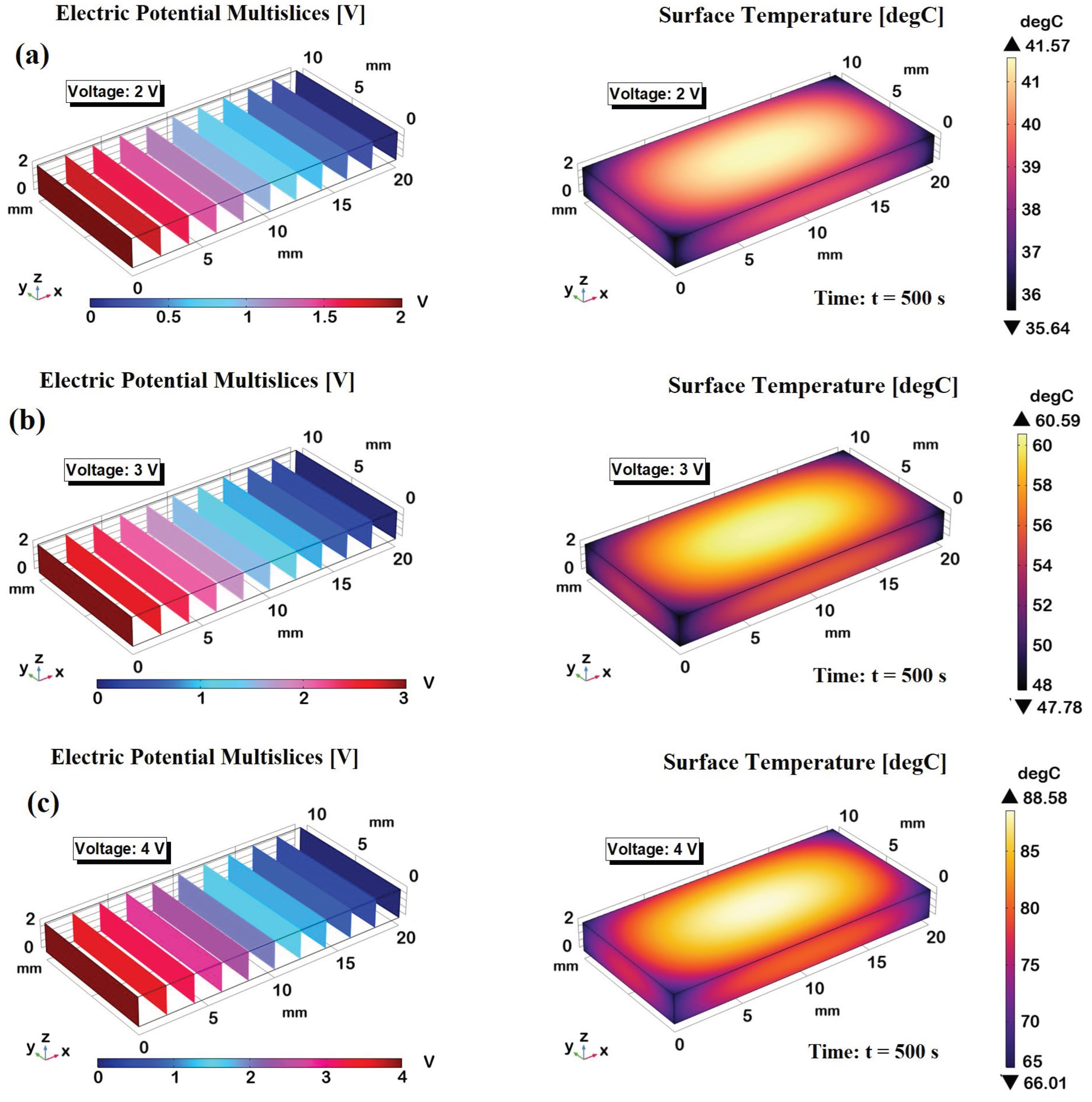

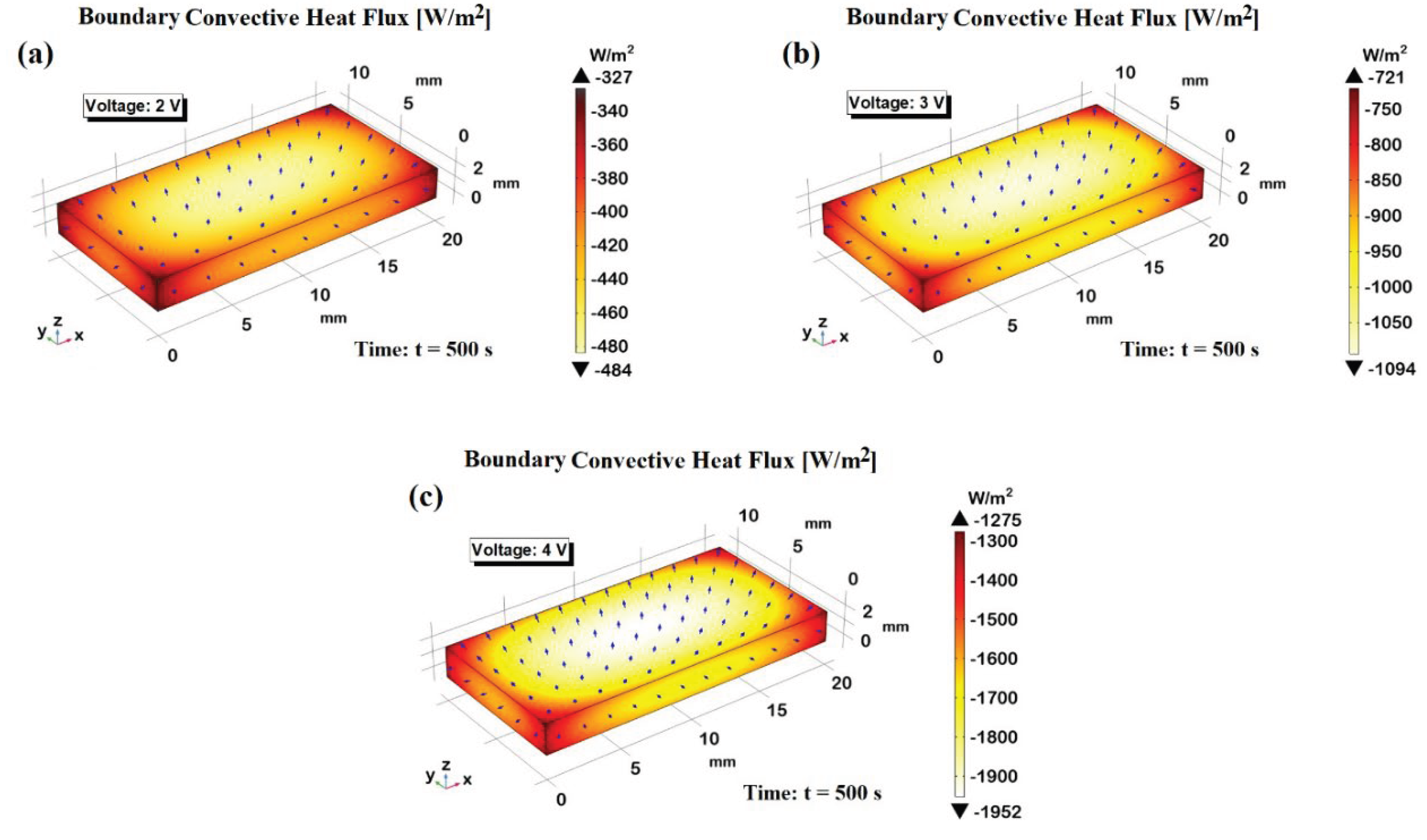

3.6.2. Temperature and Heat Flux Profiles Within the Sample

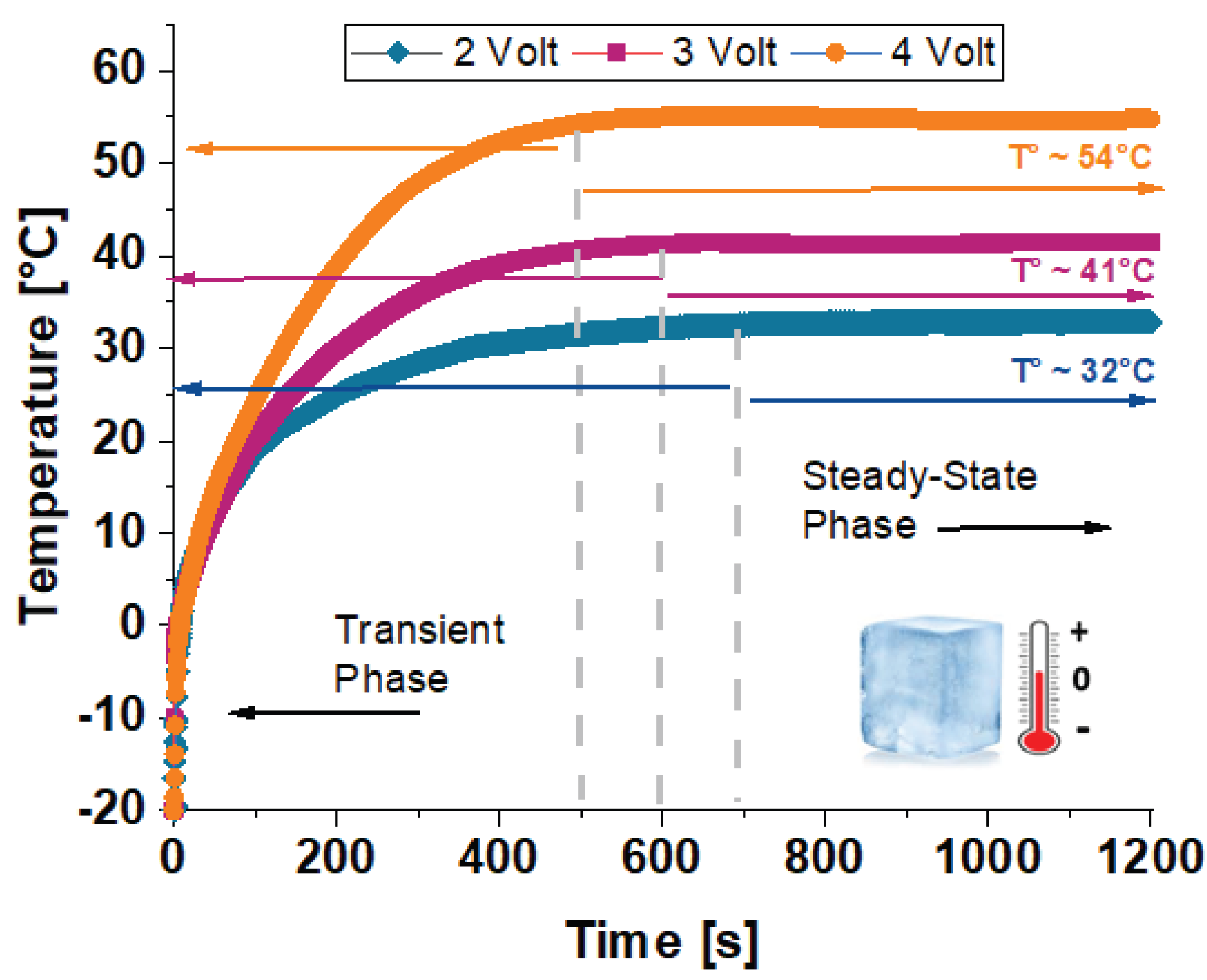

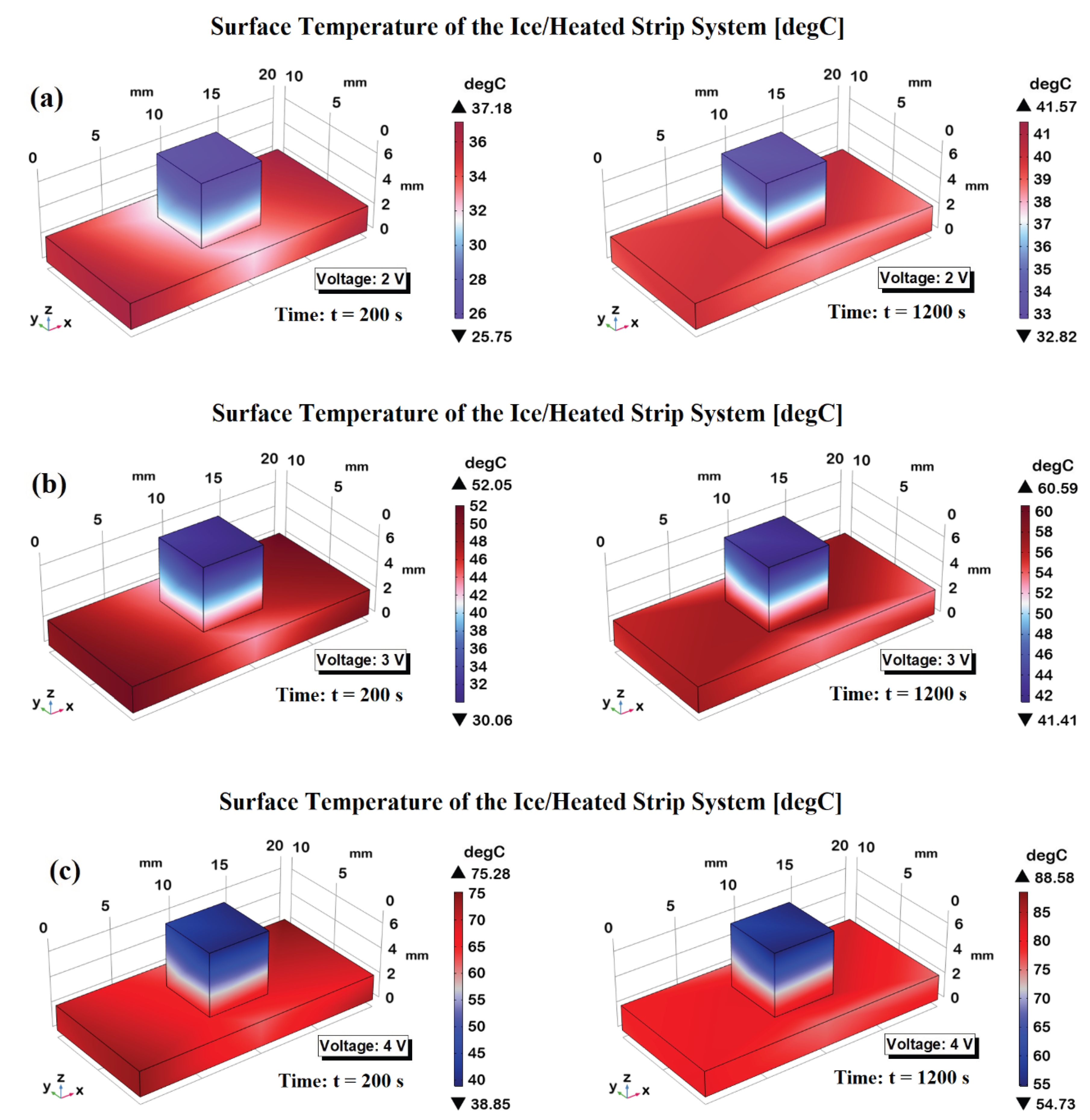

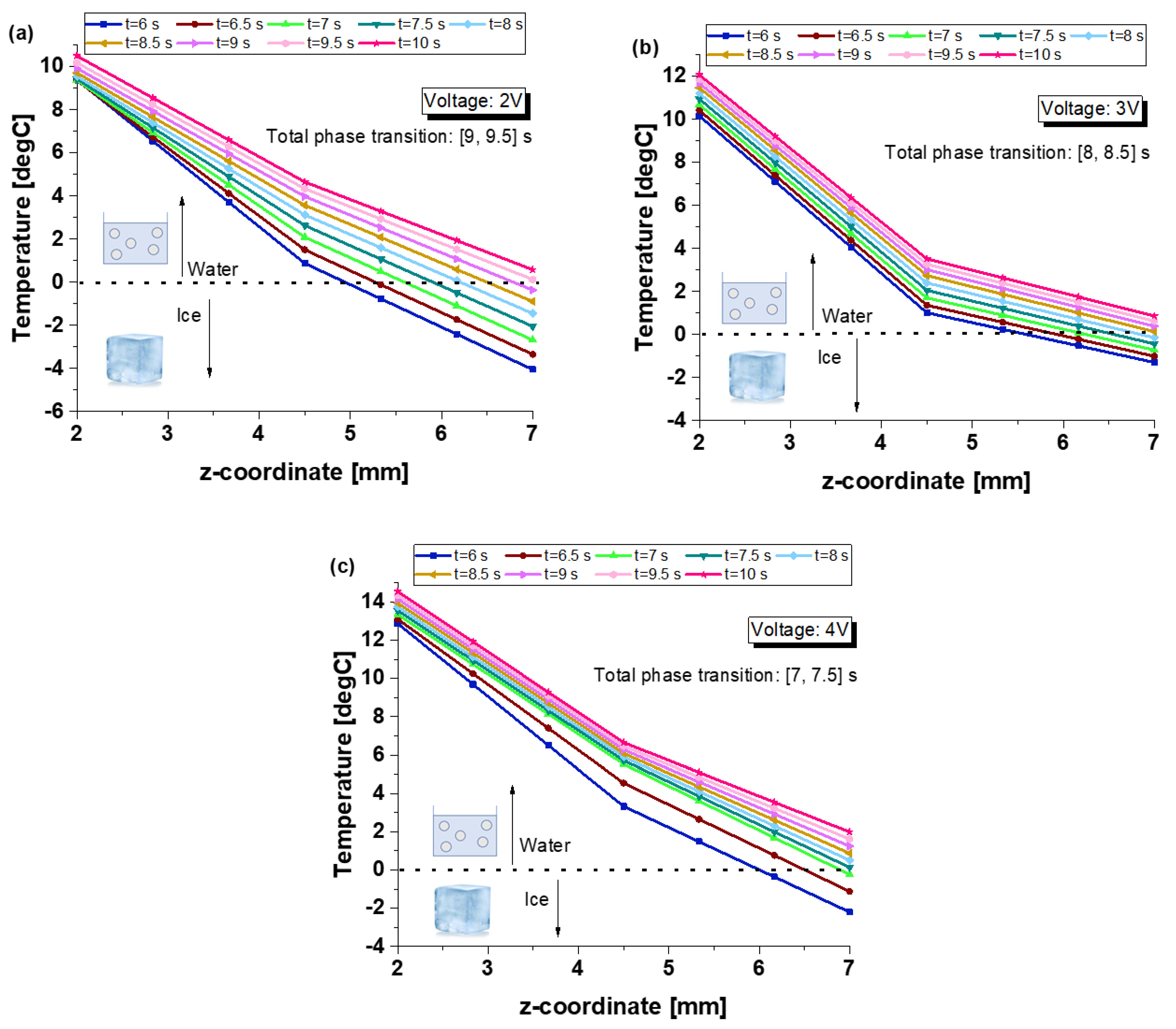

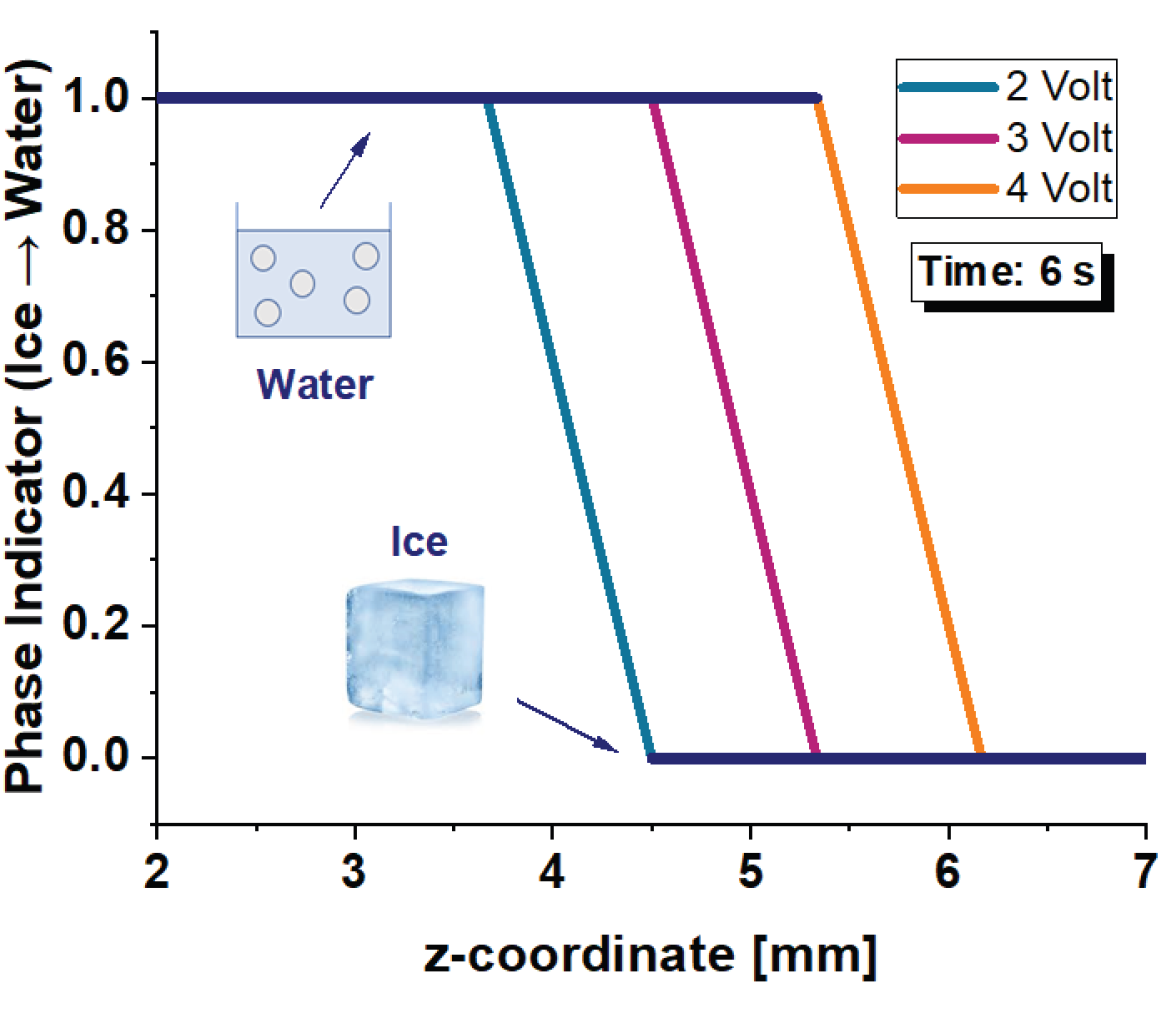

3.6.3. Simulation Study with COMSOL Multiphysics of Practical Applications: De-Icing Capability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guadagno, L.; Longo, R.; Aliberti, F.; Lamberti, P.; Tucci, V.; Pantani, R.; Vertuccio, L. Role of MWCNTs loading in designing self-sensing and self-heating structural elements. Nanomaterials 2023, 13, 495. [Google Scholar] [CrossRef]

- Tinti, A.; Carallo, G.A.; Greco, A.; Romero-Sánchez, M.D.; Vertuccio, L.; Guadagno, L. Effective practical solutions for de-icing of automotive component. Nanomaterials 2022, 12, 2979. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Aliberti, F.; Pantani, R.; Raimondo, M.; Catauro, M.; Longo, R. Development of de-icing/self-sensing structural composites via controlled Joule heating curing. Compos. Part B Eng. 2025, 292, 112079. [Google Scholar] [CrossRef]

- Chien, A. T.; Cho, S.; Joshi, Y.; Kumar, S. Electrical conductivity and Joule heating of polyacrylonitrile/carbon nanotube composite fibers. Polymer 2014, 55, 6896–6905. [Google Scholar] [CrossRef]

- Faruk, M. O., Ahmed, A., Jalil, M. A., Islam, M. T., Shamim, A. M., Adak, B., ...; Mukhopadhyay, S. Functional textiles and composite based wearable thermal devices for Joule heating: progress and perspectives. Applied Materials Today 2021, 23, 101025. [Google Scholar] [CrossRef]

- Farcas, C.; Galao, O.; Vertuccio, L.; Guadagno, L.; Romero-Sánchez, M. D.; Rodríguez-Pastor, I.; Garcés, P. Ice-prevention and de-icing capacity of epoxy resin filled with hybrid carbon-nanostructured forms: self-heating by joule effect. Nanomaterials 2021, 11, 2427. [Google Scholar]

- Schilde, C.; Schlömann, M.; Overbeck, A.; Linke, S.; Kwade, A. Thermal, mechanical and electrical properties of highly loaded CNT-epoxy composites–A model for the electric conductivity. Composites Science and Technology 2015, 117, 183–190. [Google Scholar] [CrossRef]

- Kulakov, V.; Aniskevich, A.; Ivanov, S.; Poltimae, T.; Starkova, O. Effective electrical conductivity of carbon nanotube–epoxy nanocomposites. Journal of Composite Materials, 2017, 51, 2979–2988. [Google Scholar] [CrossRef]

- Pilawka, R.; Paszkiewicz, S.; Rosłaniec, Z. Epoxy composites with carbon nanotubes. Advances in manufacturing science and technology 2012, 36, 67–79. [Google Scholar]

- Jang, Sung-Hwan, and Yong-Lae Park. Carbon nanotube-reinforced smart composites for sensing freezing temperature and deicing by self-heating. Nanomaterials and nanotechnology 2018, 8, 1847980418776473. [Google Scholar]

- Sánchez-Romate, X. F.; Sans, A.; Jiménez-Suárez, A.; Campo, M.; Ureña, A.; Prolongo, S. G. Highly multifunctional GNP/epoxy nanocomposites: from strain-sensing to joule heating applications. Nanomaterials 2020, 10, 2431. [Google Scholar] [CrossRef]

- Prolongo, S. G.; Redondo, O.; Campo, M.; Ureña, A. Heat dissipation on electrical conductor composites by combination of carbon nanotubes and graphene nanoplatelets. Journal of Coatings Technology and Research 2019, 16(2), 491–498. [Google Scholar] [CrossRef]

- Al-Saleh, M. H. Electrical and mechanical properties of graphene/carbon nanotube hybrid nanocomposites. Synthetic Metals 2015, 209, 41–46. [Google Scholar] [CrossRef]

- Ahbab, N.; Naz, S.; Xu, T. B.; Zhang, S. A Comprehensive Review of Piezoelectric PVDF Polymer Fabrications and Characteristics. Micromachines 2025, 16, 386. [Google Scholar] [CrossRef]

- C. Spitalsky, Z., Tasis, D., Papagelis, K.,; Galiotis, C. Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Tran, M. Q.; Shaffer, M. S.; Bismarck, A. Manufacturing carbon nanotube/PVDF nanocomposite powders. Macromolecular Materials and Engineering 2008, 293, 188–193. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer interfaces. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Navidfar, A.; Trabzon, L. Recent Advances in the Multifunctional Properties and Applications of Carbon Nanotube/Graphene Hybrid Polymer Nanocomposites. Polymer Composites 2025, 0, 1–23. [Google Scholar] [CrossRef]

- Li, Y., Huang, X., Zeng, L., Li, R., Tian, H., Fu, X., ...; Zhong, W. H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. Journal of Materials Science 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Charitos, I., Georgousis, G., Klonos, P. A., Kyritsis, A., Mouzakis, D., Raptis, Y., ...; Kontou, E. The synergistic effect on the thermomechanical and electrical properties of carbonaceous hybrid polymer nanocomposites. Polymer Testing 2021, 95, 107102. [Google Scholar] [CrossRef]

- Lu, L., Guo, H., Wang, Y., Liu, K. X., Martin-Fabiani, I., Peijs, T., ...; Liu, Y. Dual enhancement of Joule heating and positive temperature coefficient behaviour in biodegradable nanocomposites via hybrid carbon nanofiller networks. Composites Part A: Applied Science and Manufacturing 2025, 199, 109167. [Google Scholar] [CrossRef]

- Jin, F. L.; Park, S. J. Thermal properties of epoxy resin/filler hybrid composites. Polymer degradation and stability 2012, 97, 2148–2153. [Google Scholar] [CrossRef]

- Kotsilkova, R., Georgiev, V., Aleksandrova, M., Batakliev, T., Ivanov, E., Spinelli, G., ...; Tsanev, T. Improving Resistive Heating, Electrical and Thermal Properties of Graphene-Based Poly (Vinylidene Fluoride) Nanocomposites by Controlled 3D Printing. Nanomaterials 2024, 14, 1840. [Google Scholar] [CrossRef]

- Kausar, A.; Iqbal, K.; Muhammad, B. Polymer/graphene nanocomposites via 3D and 4D printing—design and technical potential. Processes 2023, 11, 868. [Google Scholar] [CrossRef]

- Elder, B.; Neupane, R.; Tokita, E.; Ghosh, U.; Hales, S.; Kong, Y.L. Nanomaterial patterning in 3D printing. Adv. Mater. 2020, 32, 1907142. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Sanchez-Romate, X.F.; Peregrina-Barreto, H.; Rodriguez-Resendiz, J. Conductive 3D printed PLA composites: on the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Guvendiren, M.; Molde, J.; Soares, R.M.D.; Kohn, J. Designing biomaterials for 3D printing. ACS Biomater. Sci. Eng. 2020, 6, 2843–2863. [Google Scholar] [CrossRef]

- Ribeiro, C., Costa, C. M., Correia, D. M., Nunes-Pereira, J., Oliveira, J., Martins, P., ...; Lanceros-Méndez, S. Electroactive poly (vinylidene fluoride)-based structures for advanced applications. Nature protocols 2018, 13, 681–704. [Google Scholar] [CrossRef]

- ASTM E1461-11. Standard test method for thermal diffusivity by the flash method. ASTM Int. 2011, 11. [CrossRef]

- Spinelli, G.; Guarini, R.; Kotsilkova, R.; Batakliev, T.; Ivanov, E.; Romano, V. Experimental and simulation studies of temperature effect on thermophysical properties of graphene-based polylactic acid. Materials 2022, 15, 986. [Google Scholar] [CrossRef]

- Spinelli, G.; Guarini, R.; Kotsilkova, R.; Ivanov, E.; Romano, V. Experimental, theoretical and numerical studies on thermal properties of lightweight 3D printed graphene-based discs with designed ad hoc air cavities. Nanomaterials 2023, 13, 1863. [Google Scholar] [CrossRef]

- Kuehl, R.O. Design of Experiment: Statistical Principles of Research Design and Analysis, 2nd ed.; Duxbury Press: Pacific Grove, CA, USA, 1999. [Google Scholar]

- Khuri, A.I. Multiresponse surface methodology. In Design and Analysis of Experiments; Handbook of Statistics 13; Ghosh, S., Rao, C.R., Eds.; Elsevier Science: Amsterdam, The Netherlands, 1996; pp. 377–406. [Google Scholar]

- Draper, N.R.; Lin, D.K.J. Response surface designs. In Design and Analysis of Experiments; Handbook of Statistics 13; Ghosh, S., Rao, C.R., Eds.; Elsevier Science: Amsterdam, The Netherlands, 1996; pp. 343–375. [Google Scholar]

| Filler | GNP | MWCNT |

|---|---|---|

| Trade name | SE1233 | NC7000 |

| Purity, C wt.% | > 97 | 90 |

| Average size, D50, μm Thickness, nm |

35- 50 < 10 |

- - |

| Length, μm Outer diameter, nm |

- | 1.5 9.5 |

| Aspect ratio | 3500-5000 | 150 |

| Shape | 2D | 1D |

| Volume Resistivity, Ω.cm | - | 10-4 |

| Samples |

PVDF wt.% |

GNP wt.% |

MWCNT wt.% |

|---|---|---|---|

| 6GNP/PVDF 4.5GNP/ 1.5MWCNT |

94.0 94.0 |

6.0 4.5 |

0 1.5 |

| 3GNP/3MWCNT 1.5GNP/4.5MWCNT 6MWCNT/PVDF |

94.0 94.0 94.0 |

3.0 1.5 0 |

3.0 4.5 6.0 |

| Initial (I.C.) and boundary (B.C.) conditions | Equations | Validity | ||

|---|---|---|---|---|

| I. C. | t=0 | T=Room Temperature (T0) | ||

| B. C. |

Topside and underside z=0 z=2 |

() | ||

| B. C. |

|

() | ||

| B. C. |

|

|||

| Phisical Property | Ice | Water |

|---|---|---|

| Density [kg/m3] | 918 | 997 |

| Heat capacity at constant pressure [J·kg⁻¹·K⁻¹] | 2052 | 4179 |

| Thermal conductivity [Wm⁻¹K⁻¹] | 2.31 | 0.613 |

| Phisical Property Sample |

Voltage [V] |

Max. Temp. [°C] |

Max. Curr. [A] |

Power [W] |

Gen. Heat [J] |

Heat Rate [°C/s] |

Heat Efficiency [%] |

|---|---|---|---|---|---|---|---|

| 6GNP/PVDF | 2 | 41.2 | 1.12x10-1 | 2.23x10-1 | 1.12x10+2 | 1.25x10-1 | 3.93x10+1 |

| 3 | 60.3 | 1.67 x10-1 | 5.02x10-1 | 2.51x10+2 | 2.19x10-1 | 5.85x10+1 | |

| 4 | 88.2 | 2.23 x10-1 | 8.93x10-1 | 4.46x10+2 | 4.38x10-1 | 7.17x10+1 | |

| 4.5GNP/1.5MWCNT | 2 | 38.23 | 9.78x10-2 | 1.96x10-1 | 9.78x10+1 | 8.00x10-2 | 3.46x10+1 |

| 3 | 53.1 | 1.47x10-1 | 4.40x10-1 | 2.20x10+2 | 1.71x10-1 | 5.29x10+1 | |

| 4 | 72.3 | 1.96x10-1 | 7.82x10-1 | 3.91x10+2 | 3.05x10-1 | 6.54x10+1 | |

| 3GNP/3MWCNT | 2 | 36.4 | 9.62x10-2 | 1.92x10-1 | 9.62x10+1 | 1.14x10-1 | 3.13x10+1 |

| 3 | 52.0 | 1.44x10-1 | 4.33x10-1 | 2.16x10+2 | 1.91x10-1 | 5.19x10+1 | |

| 4 | 70.0 | 1.92x10-1 | 7.70x10-1 | 3.85x10+2 | 3.24x10-1 | 6.43x10+1 | |

| 1.5GNP/4.5MWCNT | 2 | 39.1 | 1.02x10-1 | 2.04x10-1 | 1.02x10+2 | 1.14x10-1 | 3.61x10+1 |

| 3 | 57.6 | 1.53x10-1 | 4.60x10-1 | 2.30x10+2 | 2.21x10-1 | 5.66x10+1 | |

| 4 | 82.7 | 2.04x10-1 | 8.18x10-1 | 4.09x10+2 | 4.36x10-1 | 6.98x10+1 | |

| 6MWCNT/PVDF | 2 | 39.5 | 1.04x10-1 | 2.08x10-1 | 1.04x10+2 | 1.04x10-1 | 3.67x10+1 |

| 3 | 56.6 | 1.56x10-1 | 4.69x10-1 | 2.34x10+2 | 2.00x10-1 | 5.58x10+1 | |

| 4 | 76.8 | 2.08x10-1 | 8.34x10-1 | 4.17x10+2 | 4.09x10-1 | 6.74x10+1 |

| Property | β0 | Β1 | Β2 | Β11 | Β22 | Β12 |

| Electrical Conductivity (σ) | 0.19801 | 0.58936 | 0.59873 | 2.1688 | 1.3674 | 1.4236 |

| Thermal Conductivity (λ) | 0.00086245 | 0.0023666 | 0.0028081 | 0.0092595 | 0.0049403 | 0.007589 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).