1. Introduction

Phosphorus has a crucial function in the national economy and social development. [

1,

2,

3]. Phosphorus plays a very important role in the business and social progress of the country. Phosphorus concentrate is made by processing phosphorus ore. For every tonne of phosphorus concentrate made, about 0.44 tonnes of phosphorus tailings are made [

4]. The large amount of phosphorus tailings that has built up in China is bad for the environment, so the techniques for using phosphorus tailings need to be improved quickly. [

5,

6,

7,

8].

Phosphorus tailings are extensively utilized in industrial applications, and owing to their favorable mechanical qualities, they can be processed into foamed filling materials for mine site backfilling [

9]. Phosphorus tailings, owing to their skeleton and cementing properties, have been utilized as modified clay in construction materials [

10,

11,

12,

13], roadbed fillers [

14,

15,

16], and in the manufacture of ceramics [

17,

18]. Phosphate tailings possess a high concentration of CaMg(CO₃)₂ and exhibit effective adsorption and desulfurization properties, leading numerous researchers to utilize phosphorus tailings as desulfurization adsorbents [

19,

20]. The aforementioned recovery methods primarily exploit the physical characteristics of phosphorus tailings; nonetheless, the elemental utilization rate remains suboptimal, and a significant quantity of Ca2+ in phosphorus tailings remains ineffectively employed.

Numerous researchers have focused on the extraction of valuable elements, such as magnesium and phosphorus, from phosphorus tailings for high-value-added applications [

21,

22,

23]. Several studies have utilized calcium sulfate whiskers (CSW), anhydrous calcium sulfate whiskers (ACSW), and modified whiskers as alternatives to wood pulp fibers in papermaking, resulting in enhanced mechanical properties of the paper [

24,

25,

26,

27]. All the aforementioned studies utilized calcium sulfate whiskers as paper fillers; however, these whiskers are costly, and their production conditions are stringent. Consequently, the expense associated with enhancing mechanical properties as paper fillers is prohibitively high for large-scale industrial applications.

This study aims to investigate a novel method for utilizing phosphorus tailings resources by extracting Ca²⁺ from phosphorus tailings to produce gypsum fibers, which will be employed as a filler in paper manufacturing. The enhanced value-added application of phosphorus tailings can be achieved concurrently with the improvement of the paper’s mechanical qualities. Systematic study on the preparation process of gypsum fiber and its papermaking performance offers innovative concepts and technical assistance for the comprehensive utilization of phosphorus tailings, along with cost-effective, high-performance paper filler alternatives for the paper industry.

2. Materials and Methods

2.1. Materials and Equipment

Phosphorus tailings from Hubei Liuguo Chemical Industry Co., Ltd., classified as a new batch of 50 mesh, were analyzed for component content using XRF detection. The test findings are as follows.

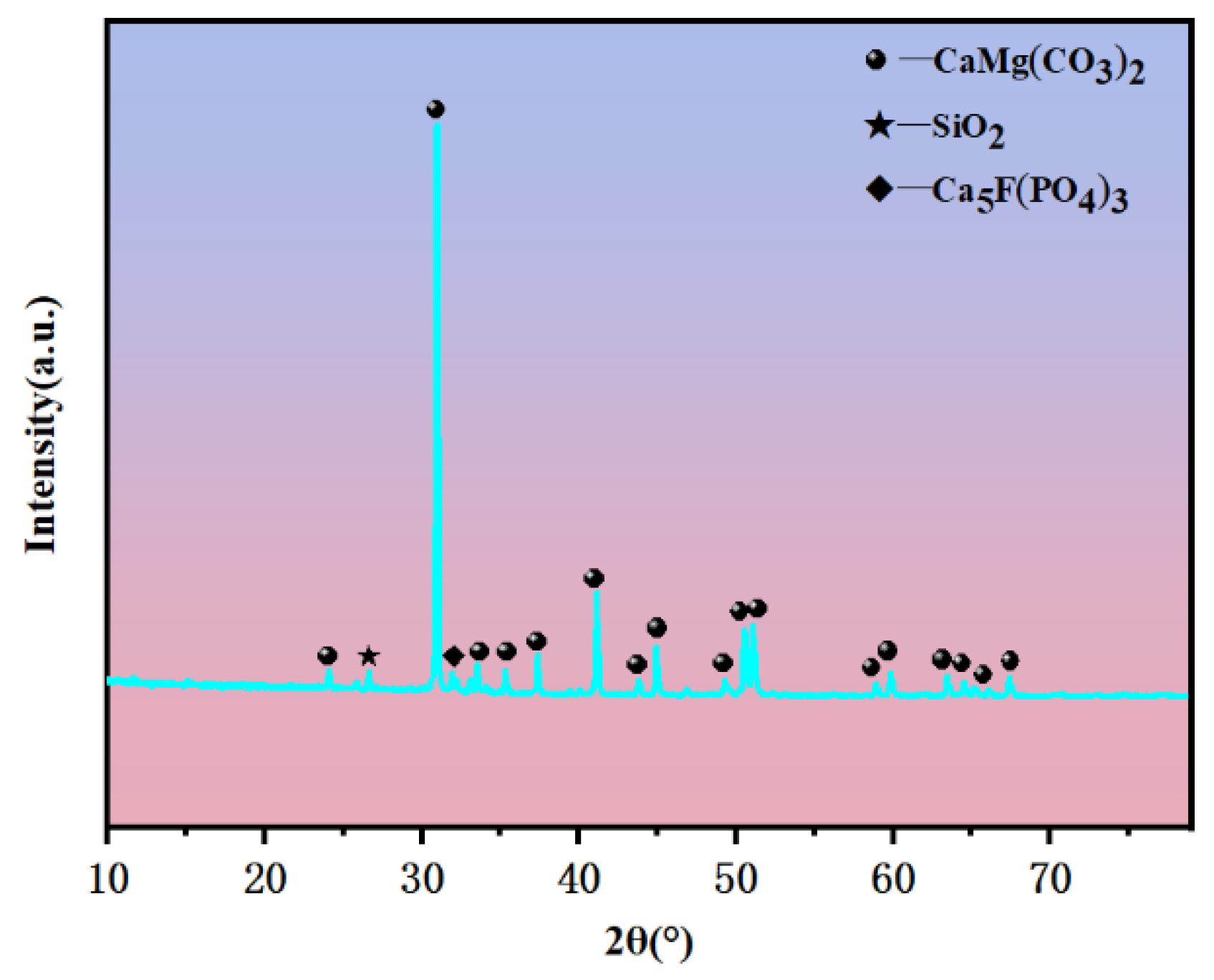

Table 1 presents the results of the XRD physical phase analysis.

Figure 1. Sulfuric acid (H₂SO₄), utilized as the analytically pure acidolytic reagent, was acquired from Shanghai Taitan Science and Technology Co. The paper fiber is classified. A waste paper shell (corrugated paper) derived from recycled cartons or cardboard, devoid of discernible oil or chemical treatment residues.

The primary equipment utilized in this investigation includes an X-Ray Diffractometer (XRD) for analyzing the material’s composition; the specific instrument model is D8ADCANCE. The tungsten filament scanning electron microscope (JSM5510LV) is mostly utilized to examine the microscopic morphology of crystal surfaces and flaws. The super depth of field microscope (VHX-5000) was employed to examine the morphology of gypsum fibers and to quantify their length, aspect ratio, and other pertinent data.

2.2. Experimental Methods

Phosphorus tailings primarily consist of dolomite (CaMg(CO₃)₂), fluorapatite (Ca₅F(PO₄)₃), and silicon dioxide (SiO₂). To prepare gypsum fibers, it is necessary to extract Ca2+ and calcium sulfate from the phosphorus tailings, resulting in the generation of CaSO₄ from the reaction with SO₄²⁻. The reaction equation is illustrated below.

Phosphate tailings particles were milled to a size of less than 300 μm, a 20% sulfuric acid solution was made and concentrated by 10%, and the reaction was conducted using a peristaltic pump at a low flow rate, introducing the solution into the phosphate tailings for 2 hours to ensure complete reaction. The reaction products were sieved, retaining the calcium sulfate solids on the sieve. Subsequently, the prepared gypsum fibers were examined under an ultra-deep field microscope to analyze their morphology, and 100 samples of gypsum fibers were randomly selected and measured for length and diameter.

Gypsum fibers produced in the aforementioned tests were integrated into the pulp of corrugated paper as a filler. The reclaimed Class A waste paper shells were initially shredded and subjected to heat soaking, after which the processed paper fragments were introduced into a Vallee pulper for pulping, adhering to the Canadian norm for free degree of determination in pulping standards. Fibers of CaSO₄·2H₂O with varying mass fractions were measured and combined with pulp fibers, which were subsequently placed into a sheet for paper production. The moisture in the paper was initially extracted using a hydraulic sheet press and subsequently dried in a vacuum drier until a constant weight was achieved, resulting in the finished corrugated paper for physical property testing.

3. Results

This experiment examined the impact of several experimental circumstances (slurry content, stirring speed, and temperature) on the synthesis of gypsum fiber from flotation phosphorus tailings. The varying lengths of gypsum fibers acquired from the experiment were included in corrugated paper as a filler to examine the effects of the content of gypsum fibers, retention, and length on paper strength, and to understand the underlying principles.

3.1. Factors Affecting the Length of Gypsum Fibers

3.1.1. Slurry Concentration

Slurry concentration denotes the ratio of the total mass (solid + liquid) represented by the mass or volume of solid particles within the slurry (a fluid created by combining crushed ore particles with water) in mineral processing. The primary way to express slurry concentration is through mass concentration, with the calculation formula as follows:

where C is the slurry concentration, m1 is the mass of the solid, and m2 is the mass of the liquid.

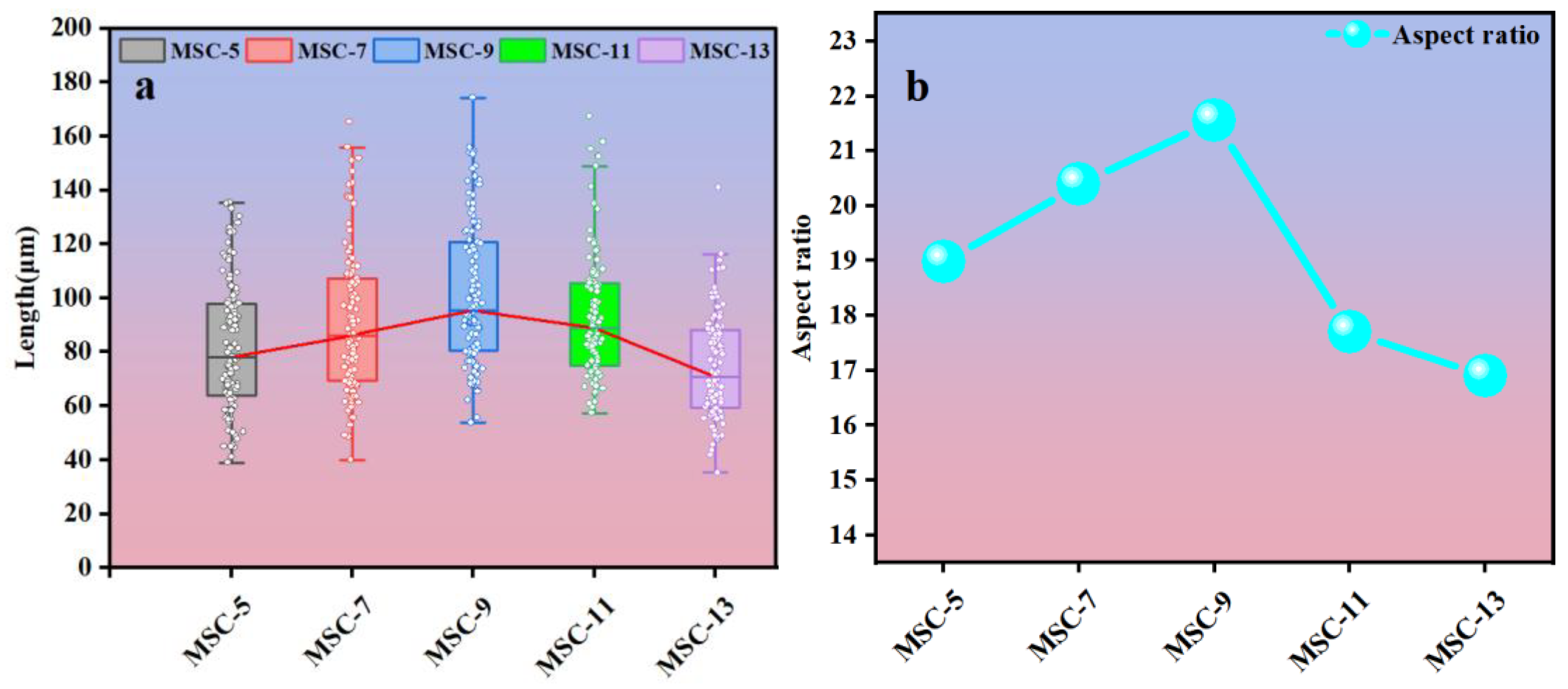

This experiment examined the influence of slurry concentration on fiber length at a stirring speed of 50 rpm and a reaction temperature of 50°C. Five slurry concentrations were evaluated: 5% (MSC-5), 7% (MSC-7), 9% (MSC-9), 11% (MSC-11), and 13% (MSC-13). The resulting fiber lengths from the various reactions are depicted in

Figure 3. The fiber lengths created by different reaction settings are shown in

Figure 2 below. The median length-to-aspect ratio of gypsum fibers first went up and then down as the slurry concentration rose, reaching its highest point at 9%. When the slurry concentration is lower, the solution’s supersaturation isn’t high enough, which slows down the nucleation rate, shortens the fiber length, and lowers the aspect ratio throughout the reaction period. This makes fiber growth more likely to be stopped by fracture or refinement. On the other hand, when the slurry concentration is high, the solution’s viscosity rises, which makes it harder for fibers to grow since there isn’t enough space for them to do so. This slows down growth and makes it harder for long fibers to form and stay in place. Ion diffusion is limited, but the number of nucleation sites increases. This stops fiber growth and lowers the average length-to-aspect ratio. Higher concentrations speed up the pace at which crystals form, but they also make more fibers and shorten them. The slurry concentration significantly influences the length of gypsum fibers; both elevated and diminished concentrations impede fiber growth. The optimal slurry concentration (9%) yields the maximum average length and aspect ratio of gypsum fibers.

Figure 2.

Gypsum fibers prepared with different slurry concentrations: (a) length distribution (b) average aspect ratio.

Figure 2.

Gypsum fibers prepared with different slurry concentrations: (a) length distribution (b) average aspect ratio.

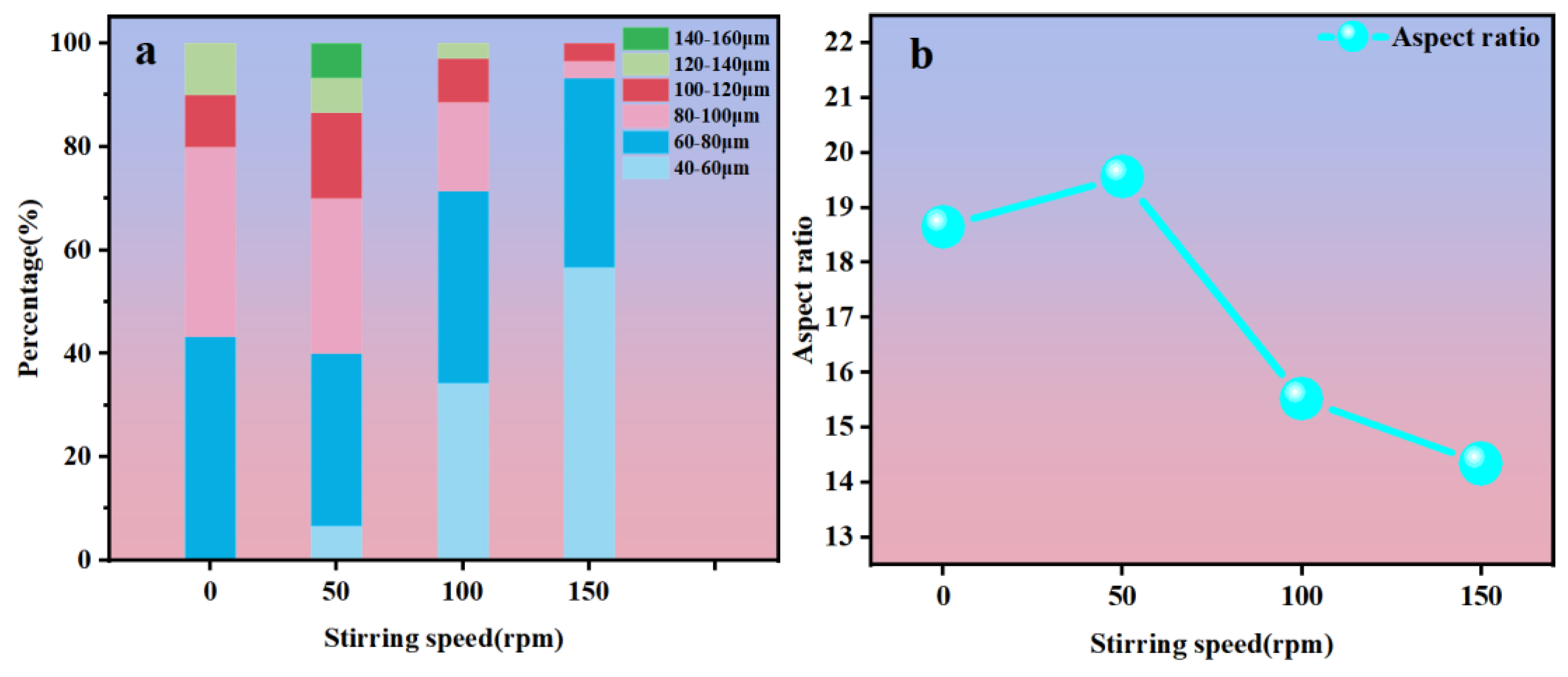

Figure 3.

Fibers obtained with different mixing speeds: (a) length distribution (b) average aspect ratio.

Figure 3.

Fibers obtained with different mixing speeds: (a) length distribution (b) average aspect ratio.

3.1.2. Stirring Speed

Different stirring speeds have a big effect on how long gypsum fibers are. This experiment examined the impact of stirring speed on fiber length at a slurry concentration of 9% and a reaction temperature of 50°C, utilizing four stirring speeds: no stirring, 50 rpm, 100 rpm, and 150 rpm.

Figure 3 illustrates the length and aspect ratio distribution of fibers produced at several stirring speeds, revealing that the fiber length distribution is comparable between the absence of stirring and a stirring speed of 50 rpm. The aspect ratio of the 50 rpm group exceeds that of the non-stirring group. The non-stirring group is devoid of shear force effects, resulting in sluggish ion diffusion within the reaction system, uneven local concentrations of reactants, and a comparatively slow radial growth rate of crystals. This culminates in larger diameters of gypsum fibers and a reduced aspect ratio. As the stirring speed goes up, the length of the gypsum fibers goes down, which makes the average aspect ratio go down a lot. This is because the high-speed mixing creates a lot of shear stress, which breaks up long fibers and speeds up the formation of nuclei and the development of more short fibers. In conclusion, optimal conditions for gypsum fiber formation occur at a stirring speed of 50 rpm, with homogenous reactant concentration and the absence of significant shear forces that could disrupt the gypsum fibers.

3.1.3. Reaction Temperature

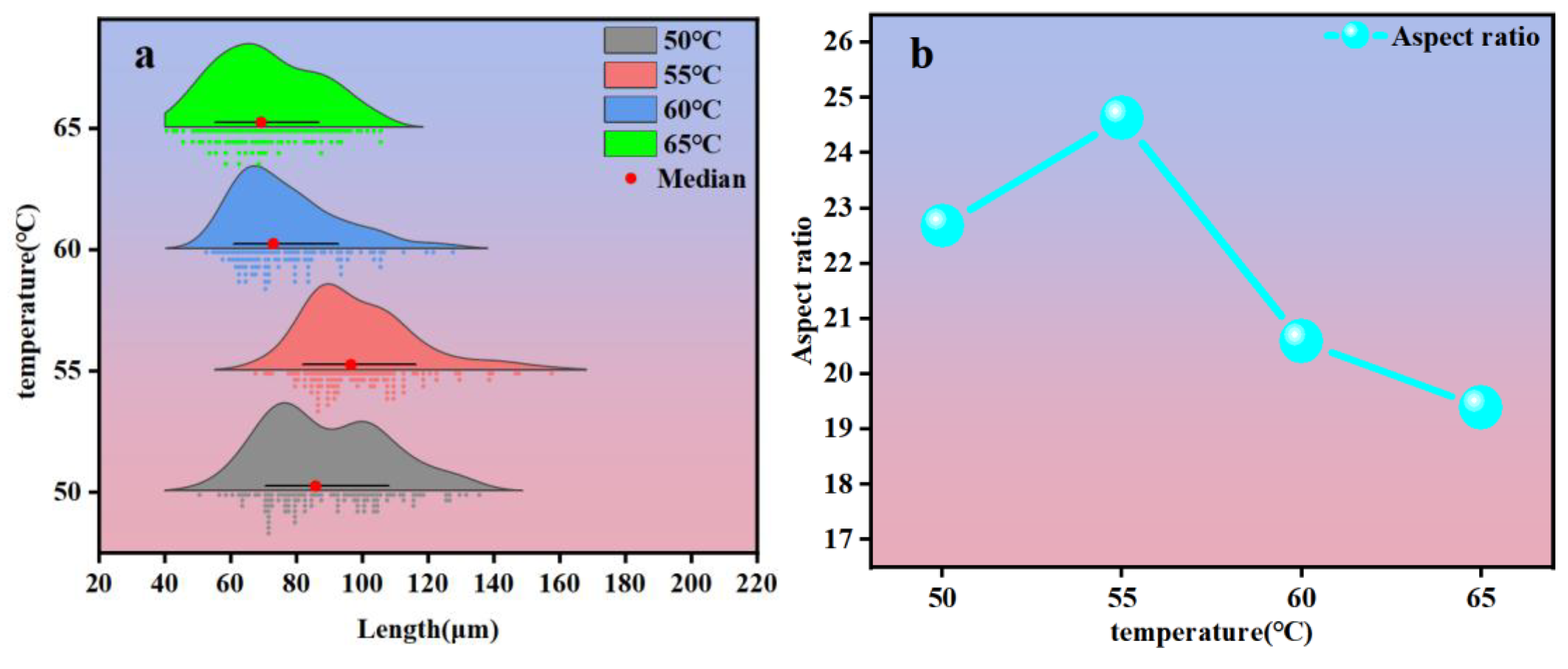

Alongside slurry concentration and stirring speed, temperature significantly influences the length of gypsum fibers during the acid digestion of phosphorus tailings. Consequently, at a slurry concentration of less than 9% and a stirring speed of 50 rpm, the system temperature was established at 50 °C, 55 °C, 60 °C, and 65 °C to empirically examine the influence of varying temperatures on the length of gypsum fibers.

Figure 4 illustrates the length distribution of fibers produced at various reaction temperatures, revealing that the length of gypsum fibers initially increases and subsequently declines with rising temperature. The median length of gypsum fibers at 55 °C reached 96.5 μm, and the average length was 102.45 μm, whereas the aspect ratio exhibited a comparable trend, initially increasing and subsequently decreasing, peaking at 24.63 at 55 °C before declining with rising temperature. The length and aspect ratios of the produced fibers were lowered at 50°C due to the lower reaction temperature, dropped molecular activity, and heightened activation energy required for the reaction; at 55 °C, the elevated temperature improved molecular mobility and expedited the reaction rate. Elevated temperatures supply sufficient energy to substantially enhance fiber length. The ion migration rate in the system is enhanced, facilitating the rapid development of fibers on the crystal nucleus. The rate of crystal nucleation equilibrates with the rate of crystal growth; as the temperature rises to 60 °C and 65 °C, the fiber length significantly diminishes. The elevated temperature results in a reduction of the solution’s supersaturation, hence inhibiting the fiber development rate and diminishing the trend of length increase. At elevated temperatures, the crystal nucleation rate surpasses the growth rate, leading to the continuous formation of crystal nuclei without subsequent growth, resulting in predominantly short gypsum fibers. Consequently, 55 °C is the ideal reaction temperature for the acid digestion of phosphorus tailings to produce calcium sulfate fibers, during which the reaction yields gypsum fibers of increased length and superior aspect ratio.

This experiment examined the influence of reaction conditions on the length and aspect ratio of gypsum fibers. The results indicated that the average length and aspect ratio of the fibers attained maximum values of 102.45 μm and 21.68, respectively, at a slurry concentration of 9%, a stirring speed of 50 rpm, and a reaction temperature of 55°C. The mean length of gypsum fibers and the mean aspect ratio of gypsum fibers attained maximum values of 102.45 μm and 21.68, respectively.

3.2. Effect of Fiber Mixing Ratio on Retention Rate

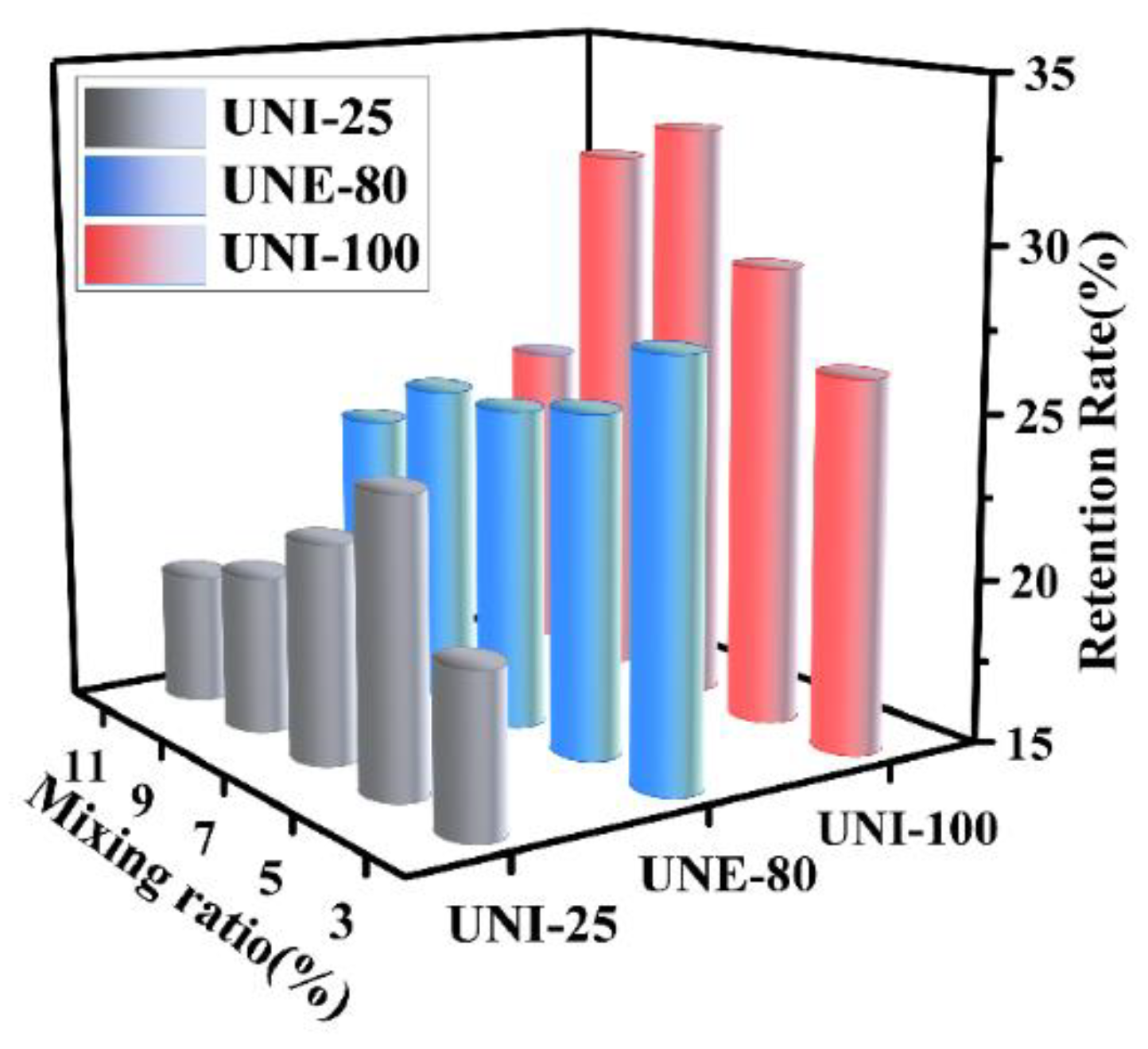

In this experiment, gypsum fibers were incorporated into paper as a filler material. Experiments were performed utilizing CaSO₄·2H₂O fibers synthesized in the preceding phase and combined with pulp fibers. CaSO₄·2H₂O fibers were categorized into three classifications based on fiber length and uniformity: homogeneous gypsum fibers averaging 25 μm (UNI-25), homogeneous gypsum fibers averaging 100 μm (UNI-100), and inhomogeneous gypsum fibers averaging 80 μm (UNE-80). The results were derived from varying lengths and inhomogeneous gypsum fibers (UNE-80). The study examined uniform gypsum fibers averaging 80 μm in length (UNE-80) and their function as paper fillers through tests varying in fiber lengths, doses, and retention rates.

The quantity of gypsum fibers incorporated does not solely indicate the retention rate, as some fibers will be lost throughout the sheet formation process; the retention rate serves as a specific metric to assess the effective amount of fibers integrated into the paper. This experiment involved the addition of three distinct fiber lengths to the sheet forming at varying dosages, which were subsequently mixed with pulp fibers for paper production, followed by drying and weighing the resultant paper. The ash mass that resulted from heating the dry paper to 800°C was measured. X-ray diffraction was used to evaluate the ash’s composition. The mass percentage of calcium sulfate in the paper was quantitatively assessed to determine the retention rate M of integrated gypsum fibers:

where M denotes the retention rate of gypsum fibers; k represents the conversion coefficient between gypsum dihydrate and anhydrous gypsum, set at 1.265; w indicates the percentage of calcium sulfate mass in the ash of paper after the incorporation of gypsum fibers; w₀ signifies the percentage of calcium sulfate mass in the ash of paper without the addition of gypsum fibers; “v” refers to the quality of paper ash, “u” is the percentage of gypsum fibers integrated into the paper, and “m” denotes the mass of the paper.

Figure 5 illustrates the correlation among varying lengths of gypsum fibers, doping levels, and retention rates. In the uniform group of gypsum fiber lengths (UNI-25, UNI-100), the retention rates initially increase with rising doping levels before subsequently declining. The UNI-25 group achieved a peak retention rate of 23.94% at a doping rate of 5%, while the UNI-100 group reached a maximum retention rate of 32.79% at a doping rate of 7%. The uniform long fibers of the UNI-100 group facilitate the formation of a fiber mesh structure, and the retention rate of the fibers may be efficiently maintained above the mesh structure at low dosages. However, when the dosage increases, gypsum fibers occupy excessive volume, leading to agglomeration that disrupts the initial interwoven fiber network, resulting in a loose structure where fibers are prone to detachment, hence diminishing the retention rate. The UNE-80 group exhibits erratic fluctuations in retention rate with increasing dosage, ranging from 3% to a maximum of 27.75%. The cause is that the length of unequal fiber mixing readily leads to localized clumping or irregular dispersion, making the formation of a fiber mesh structure challenging, resulting in a low and unpredictable retention rate without a discernible pattern. The fiber length of the UNI-25 group is shorter, making it more likely to be overlooked during the sheet formation process, resulting in the lowest blending retention rate.

In conclusion, elongated and uniform gypsum fibers are more inclined to integrate with paper fibers, hence improving paper performance, whereas the UNI-100 group is more predisposed to create an organic-inorganic fiber mesh structure with a superior retention rate upon incorporation into the paper.

3.3. Effect of Fiber Retention on Paper Properties

Gypsum fiber, used as a paper filler, takes the place of some of the wood pulp fiber, which changes the paper’s mechanical strength. This experiment looks at how varied amounts of gypsum fibers that are kept in place effect the paper’s burst index and ring crush index. Due to the fibers being lost during the sheet formation process post-blending, the quantity of gypsum fiber blended does not accurately reflect the retention amount; therefore, the paper retention amount of gypsum fibers is recalibrated as N:

In this context, N denotes gypsum fiber paper retention, k represents the conversion coefficient of gypsum dihydrate and anhydrous gypsum (assumed to be 1.265), w indicates the percentage of calcium sulfate mass in paper ash, v signifies the mass of paper ash, and m refers to the mass of paper.

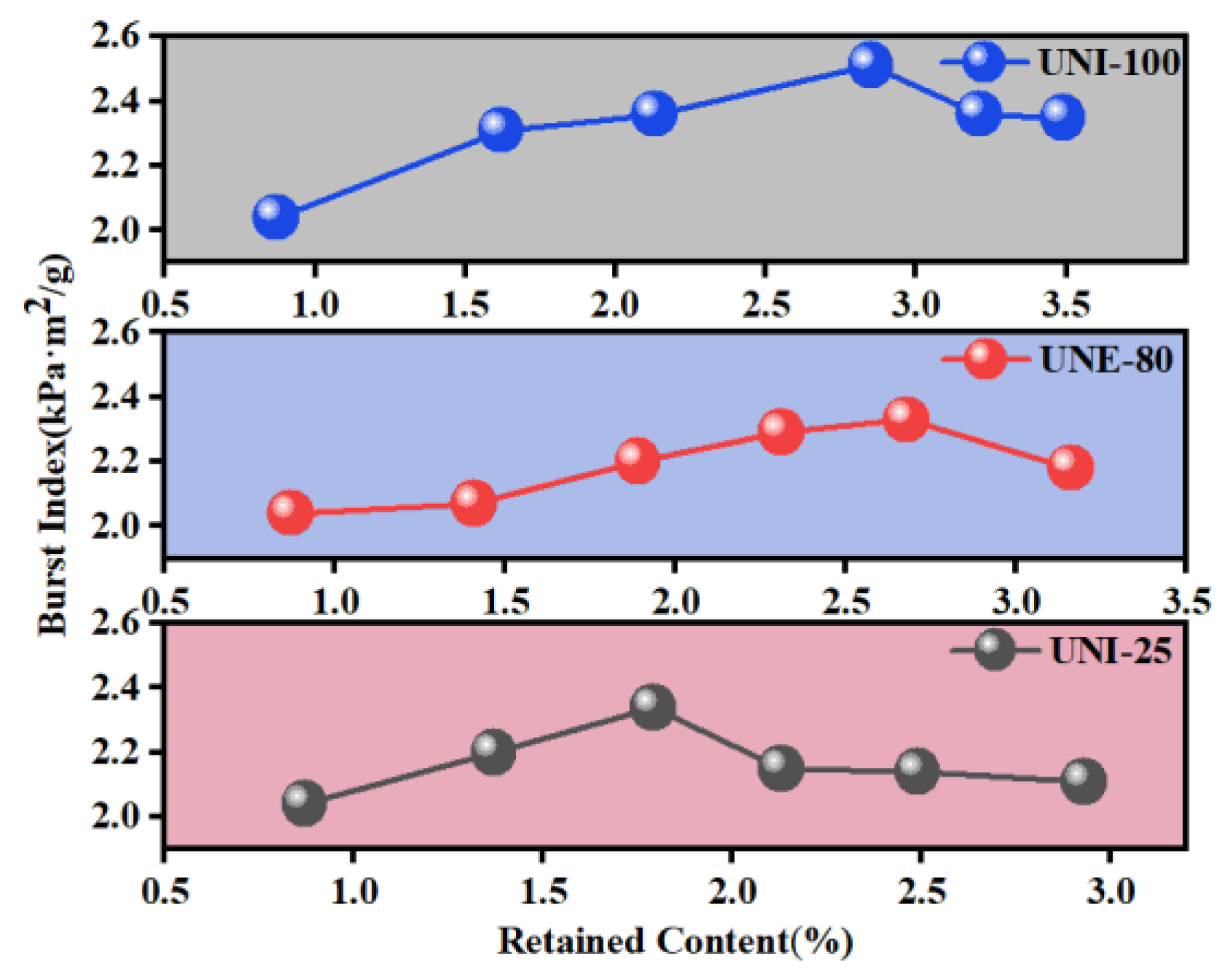

3.3.1. Burst Index

The burst index of paper quantifies its capacity to withstand rupture under uniform vertical pressure. It comprehensively represents the tensile strength and elongation of paper and is intricately linked to the bond strength among fibers, the inherent strength of the fibers, and the uniformity of the fiber network.

Figure 6 illustrates the correlation between gypsum fiber retention and burst index following the incorporation of varying lengths of gypsum fibers into paper. The retention of unblended gypsum fibers was 0.87%, while the burst index of the paper measured 2.04 kPa·m²/g. Following the incorporation of gypsum fibers, the burst index first rose before subsequently declining as the retention of gypsum fibers increased. In the UNI-100 group, the peak burst index was 2.44 kPa-m²/g when the fiber retention rate was 2.85%, and the burst index increased by 19.61% compared with the paper without gypsum fiber. Due to their high aspect ratio, gypsum fibers can be mechanically interlocked inside the inorganic fiber network, creating an organic-inorganic fiber mesh structure that distributes and transfers stresses, hence enhancing overall breakage resistance strength. The UNE-80 group possesses longer fibers; however, the length distribution is non-uniform, leading to an uneven dispersion in the pulp, which may create comparatively weak regions in certain areas, thereby affecting its burst index. The UNI-25 group has the lowest efficacy in augmenting the breakage resistance of paper due to the challenges posed by short fibers in establishing a robust network structure, which predisposes them to slippage or detachment from the matrix; its maximal burst index is 2.34 kPa·m²/g. The tensile strength of gypsum fibers is much inferior to that of plant fibers, resulting in excessive fiber retention, which consequently diminishes the overall strength of the paper. The inferior strength of gypsum fiber compared to plant fiber results in excessive fiber retention, leading to the substitution of high-intensity plant fibers with low-strength gypsum, hence causing a deterioration in the overall mechanical characteristics. Gypsum fiber is inorganic and cannot create hydrogen bonds with plant fibers. As retention increases, a significant quantity of gypsum fibers will isolate the contact area between the plant fibers, resulting in a loss in the internal bonding strength of the paper and a reduction in the burst index. Only the requisite quantity of gypsum fiber can occupy the interstices between the plant fibers, enhance the fiber gradation, and augment the strength of the paper. If fiber retention is excessively high, it will conversely lead to a reduction in the paper’s burst index. In conclusion, the UNI-100 group demonstrates the most significant enhancement in the burst index at a retention level of 2.85%.

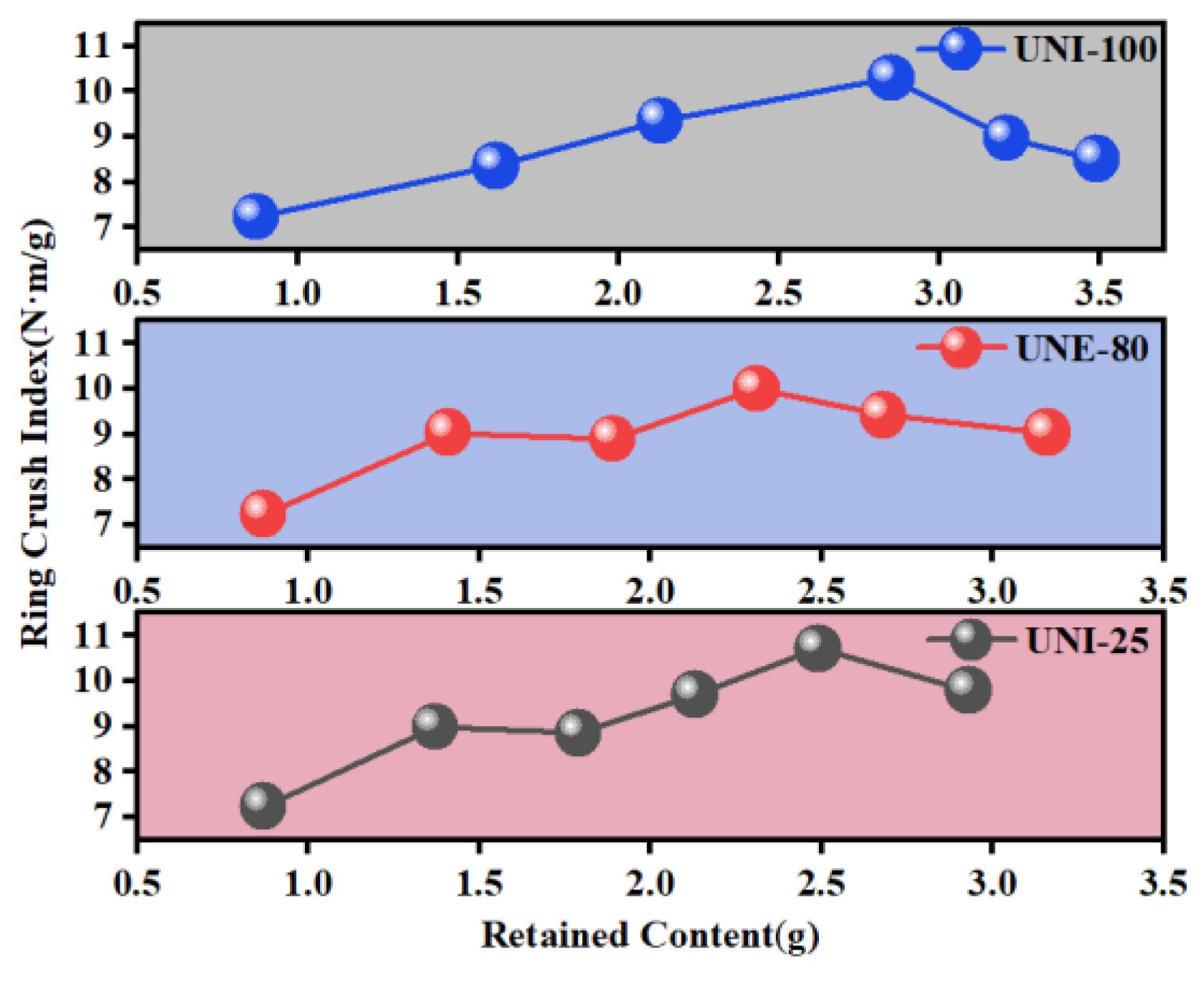

3.3.2. Ring Crush Index

The ring crush index is essential for measuring paper and cardboard compressive strength. Fillers usually affect the stacking strength and compression resistance of packaging materials like cartons and cardboard.

Figure 7 illustrates the correlation between the ring crush index and the retention of gypsum fiber. In the absence of gypsum fiber, the retention is 0.87% and the ring crush index measures 7.23 N·m/g. Following the incorporation of gypsum fiber, the ring crush index initially rises and subsequently declines with an increase in gypsum fiber retention. In the UNI-25 group, a fiber retention of 2.68% results in a maximum ring crush value of 10.89 N·m/g, representing a 50.62% increase compared to unadulterated gypsum fibers, optimized performance. The paper undergoes vertical compressive stress during the ring compression test. Because the 25 μm fibers are finer and shorter than the longer 100 μm fibers, they can fill the spaces between the plant fibers and improve the consistency of the paper’s structure. As a result, there is less chance of localized buckling since the stress distribution during compression is more uniform. The filling effect strengthens the paper structure’s resistance to vertical deformation pressure by increasing its density under pressure. Because of the elongated fibers that contribute to the gap-filling effect, the UNI-100 group shows slightly less strength than the UNI-25 group. The elongated fibers in the UNI-100 group have a somewhat lower strength than the UNI-25 group because they can’t fold as well and break into shorter fibers when they rupture, which weakens the link between the fibers. The ring crush index is 10.78 N·m/g, which is 49.1% higher than that of unadulterated gypsum fibers paper. Conversely, the UNE-80 group demonstrates the lowest bond strength, resulting from the irregular fiber lengths and suboptimal filling effect, with a ring crush index of 9.96 N·m/g. In the ring pressure test, the UNI-25 and UNI-100 groups exhibit greater compactness under pressure, hence demonstrating substantial resistance to vertical deformation pressure. The 25 group and UNI-100 group exhibit comparable effects on enhancing the ring crush index of the paper.

Evaluating the three metrics of gypsum fiber retention rate, paper burst index, and ring crush index, the elongated and more uniform gypsum fibers of the UNI-100 group are superior in enhancing the physical qualities of paper.

4. Conclusions

This work rigorously analyzed the effects of slurry content, stirring velocity, and reaction temperature on gypsum fiber length by a controlled variable methodology, and subsequently investigated the influence of gypsum fiber mixing ratio and retention on paper properties. The primary conclusions of the inquiry are as follows:

1. Gypsum fiber derived from flotation phosphorus tailings can serve as a paper filler, significantly enhancing the mechanical qualities of paper. With this method, phosphorus tailings can be exploited as a high-value resource in a novel way.

2. The optimal parameters for gypsum fiber preparation include a slurry concentration of 9%, a stirring speed of 50 rpm, and a reaction temperature of 55 °C. Under these conditions, the average length and length-to-diameter ratio of the resultant gypsum fiber were 102.45 μm and 21.68, respectively.

3. Gypsum fibers exhibiting greater length and elevated aspect ratio can enhance the mechanical properties of paper more efficiently. The mechanical strength of paper infused with UNI-100 gypsum fibers can be augmented, resulting in a 19.61% increase in the burst index and a 49.1% increase in the ring crush index compared to paper devoid of gypsum fibers. Utilizing whiskers as a filler in paper production results in lower costs and represents a high-value-added application.

References

- Geissler B, Hermann L, Mew MC, et al. Striving Toward a Circular Economy for Phosphorus: The Role of Phosphate Rock Mining [J]. Minerals, 2018, 8(359). [CrossRef]

- Yu Y H, Du CM. Leaching of phosphorus from phosphate tailings and extraction of calcium phosphates: Toward comprehensive utilization of tailing resources [J]. Journal of Environmental Management, 2023, 347(000):10. [CrossRef]

- Taha Y, Elghali A, Hakkou R, et al. Towards Zero Solid Waste in the Sedimentary Phosphate Industry: Challenges and Opportunities [J]. Minerals, 2021. [CrossRef]

- Li X, Shu J, Zhao H, et al. A Critical Review on Approaches for Phosphorus Ore Flotation Tailings Treatment and Disposal Technology: Environment Properties, Comprehensive Utilization, and Resource Utilization [J]. Industrial & Engineering Chemistry Research, 2024, 63(3):9. [CrossRef]

- Wang L, Ji B, Hu Y, et al. A review on in situ phytoremediation of mine tailings [J]. Chemosphere, 2017, 184(Oct.):594-600. [CrossRef]

- Adiansyah J S, Rosano M, Vink S, et al. A framework for a sustainable approach to mine tailings management: disposal strategies [J]. Journal of Cleaner Production, 2015, 108(DEC.1PT.A):1050-1062. [CrossRef]

- Edraki M, Baumgartl T, Manlapig E, et al. Designing mine tailings for better environmental, social and economic outcomes: a review of alternative approaches [J]. Journal of Cleaner Production, 2014, 84(Dec. 1):411-420. [CrossRef]

- Wang C, Harbottle D, Liu Q, et al. Current state of fine mineral tailings treatment: A critical review on theory and practice [J]. Minerals Engineering, 2014, 58(4):113-131. [CrossRef]

- Qi, C. F. A. Cemented paste backfill for mineral tailings management: Review and future perspectives [J]. Minerals Engineering, 2019, 144. [CrossRef]

- Chen Q, Zhang Q, Fourie A, et al. Utilization of phosphogypsum and phosphate tailings for cemented paste backfill [J]. Journal of Environmental Management, 2017, 201(Oct. 1):19-27. [CrossRef]

- Liu G, Liao Y, Sha X, et al. Application of Calcium Sulfate Whiskers to Cement-Based Materials: A Review [J]. Materials (1996-1944), 2024, 17(5). [CrossRef]

- Zheng K, Zhou J, Gbozee M. Influences of phosphate tailings on hydration and properties of Portland cement [J]. Construction and Building Materials, 2015. [CrossRef]

- Moukannaa S, Loutou M, Benzaazoua M, et al. Recycling of phosphate mine tailings for the production of geopolymers [J]. Journal of Cleaner Production, 2018, 185(JUN.1):891-903. [CrossRef]

- Zhao X, Yang T, Zong Z, et al. Study on mechanical properties of phosphate tailings modified clay as subgrade filler [J]. Geomechanics And Engineering, 2024, 36(6):11. [CrossRef]

- Liu Z, Li J, Zhao Q, et al. Gradation Design of Phosphorus Tailing–Graded Waste Rock Subgrade Filling Using Discrete Element Method [J]. Minerals (2075-163X), 2022, 12(5). [CrossRef]

- Liu Y, Yang Z, Luo H, et al. Preparation, characterization, and properties of asphalt modified by surface-treated anhydrous calcium sulfate whiskers [J]. Construction and Building Materials, 2023, 384(000):16. [CrossRef]

- Yang Y, Wei Z, Chen YL, et al. Utilizing phosphate mine tailings to produce ceramisite [J]. Construction and Building Materials, 2017, 155 (Nov. 30): 1081-1090. [CrossRef]

- Loutou M, Taha Y, Benzaazoua M, et al. Valorization of clay by-product from moroccan phosphate mines for the production of fired bricks [J]. Journal of Cleaner Production, 2019, 229(AUG.20):169-179. [CrossRef]

- C Y N A B, C J D A B, C Y H A B, et al. An efficient and environmentally friendly process for the reduction of SO₂ by using waste phosphate mine tailings as adsorbent [J]. Journal of Hazardous Materials, 2025, 6(30):388. [CrossRef]

- Jiang W, Jiang Y, Li P, et al. Reuse of phosphogypsum and phosphorus ore flotation tailings as adsorbent: The adsorption performance and mechanism of phosphate [J]. The journal of physics and chemistry of solids, 2023. [CrossRef]

- Li B, Shu J, Yang L, et al. An innovative method for simultaneous stabilization/solidification of PO₄³⁻ and F- from phosphogypsum using phosphorus ore flotation tailings [J]. Journal of Cleaner Production, 2019, 235(OCT.20):308-316. [CrossRef]

- Oliveira M S, Santana R C, Carlos H. Ataíde, et al. Recovery of apatite from flotation tailings [J]. Separation and Purification Technology, 2011, 79(1):79-84. [CrossRef]

- Gu H, Zhou G, Wen H, et al. Using of phosphoric acid to dissolve phosphate ore flotation tailings for stepwise separation of calcium and magnesium values [J]. Chemical Engineering Science, 2025, 307. [CrossRef]

- Feng X, Zhang Y, Wang G, et al. Dual-surface modification of calcium sulfate whisker with sodium hexametaphosphate/silica and use as new water-resistant reinforcing fillers in papermaking [J]. Powder Technology, 2015, 271:1-6. [CrossRef]

- Tian Zeshan, et al. Synthesis of high-length calcium sulfate whisker, an ideal substitute of the plant-based pulp fiber for papermaking [J]. Environmental Technology, 2024, 45(2):360-368. [CrossRef]

- Sheng X, Peng X, Yuting D, et al. A research on the application of industrial by-product calcium sulfate whiskers in paper filling [J]. Wood Research, 2022(3):67. [CrossRef]

- Liu J, Jin X, Liu H, et al. Research on the physical properties of calcium sulfate whisker and the effects of its addition on paper and its printing performance [J]. Nordic Pulp & Paper Research Journal, 2022, 37(1):66-77. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).