1. Introduction

Natural dyes are sourced from plant extracts, minerals, or animal sources which make them biodegradable, renewable, and environmentally friendly [

1]. Natural dyes have a millennium-long history in textiles, which reflects the complex interrelationships between people, plants, and the environment [

2].

Based on their chemical composition, natural dyes are mainly divided into several groups such as tannins, carotenoids, quinoids, alkaloids, anthraquinones, flavonoids and indigonoids [

3]. Fruits and vegetables contain molecules with specific colours, which can be an environmentally attractive replacement for their synthetic counterparts in (non)food applications [

4]. Onion skins can be used to create beautiful shades of yellow and brown and can be a way of using kitchen waste for natural dyeing [

1].

The dyestuff, which is present in the onion skin, is called pelargonidin (3,5,7,4– tetrahydroxy anthocyanin). Four hydroxyl groups in a molecule act as the auxochrome groups, for the pelargonidin to communicate great dyeing properties.

The natural compound of the anthocyanin is a water-soluble natural pigment, which can be extracted from the red rose. There are more than 300 kinds of anthocyanins giving colours like pink, purple or magenta to the rose petal [

5]. Anthocyanins belong to the family of flavonoids, these consist of three cycles, two benzene rings and an oxygenated heterocycle, carrying hydroxyl groups in various positions [

6].

The colours obtained with eucalyptus dyeing varied between yellow and brown, depending on the dye concentration, dyeing process, and mordant chosen [

7]. The leaves contain up to 11 % of the major components of tannin (gallic acid [3,4,5–trihydroxy benzoic acid], with ellagic acid [2,3,7,8-tetrahydroxy (1) benzopyran (5,4,3-cde) (1) benzopyran-5,10-dione]) and flavonoids (quercetin [3,3’,4’,5,7-pentahydroxylflavone] and rutin 3,3’,4’,5,7-pentahydroxylflavone-3-rhamnoglucoside]) as the minor components. Tannins and flavonoids are useful substances during the dyeing process because of their ability to fix dyes within fabrics [

8].

Natural dyes have the potential to significantly impact on the future of sustainable textile production and promote a more socially and environmentally responsible sector with sustained improvements and industry-wide initiatives. Literature suggests that there is a major vacuum in research concerning the latest developments and potential applications of natural dyes in textiles materials is the lack of comprehensive studies that tackle the environmental sustainability and scalability of manufacturing and application procedures over the long run [

2].

Natural dyes often produce unique, softer, and earthly aesthetics but usually lack the intense brightness obtained with synthetic dyes. Additionally, natural dyes fade faster when exposed to sunlight or washing compared to synthetic dyes which offer excellent colour consistency and stability [

1]. To achieve successful and commercial use of natural dyes, appropriate and standardized dyeing techniques need to be adopted without decreasing the required quality of the dyeing fabrics.

The study of Hüseyin Benli emphasized the effect of pretreatment processes on the obtained colour with natural dyes. Bleached and mercerized cotton fabric were dyed by pigment printing method, with the use of extracts obtained from five different natural sources. These were pomegranate peel, nutshell, orange tree leaves, alkanet roots and dyer’s chamomile. Instead of mordanting agents, binder was used for fixing natural dye on the fabric and to make this process more environmentally friendly. The results showed that pretreatment processes had great importance in terms of colour efficiency and colour shades. Applying mercerization after bleaching prior to printing process caused a significant increase in colour efficiencies and darker shades, but the increase in colour saturation could be varied according to the natural dye source used. Natural dyes are usually applied to textiles by dyeing. For producing printed fabrics, a mordant must be applied because natural dyes are mostly non-substantive. Usually a metallic salt is used, having an affinity for both the fibre and the colouring matter [

9].

Chemical mordants, such as potassium alum, sodium chloride, ferrous sulphate, calcium chloride, and tannic acid, contribute to the enhancement or darkening of the hue by forming metallic dye complexes in the fabric [

10]. The study by Marquardt et al. showed that dyeing processes with annatto extract are enhanced by mordants such as alum and ferrous (II) sulphate and by polyelectrolyte agents such as PDDACl, which presented excellent colour yields [

11].

Another study researched the replacement of conventional mordants by using a natural mordant. Bio-waste chitosan was applied on wool fabric with natural dyes in fine powder form. The results were positive, showing deep and fast prints with chitosan. This natural mordant gave a higher colour value than alum mordant. All natural dyes exhibited good to excellent washing and light fastness, while the colour fastness properties improved with an increase in mordant concentration. This indicated that chitosan plays an important role as a mordant and was even superior to alum regarding efficacy as a mordant [

12].

In this study, two different ways of botanical printing are presented and are compared with the studies carried out so far on the application of natural dyes on textiles substrates. The aim was to investigate the suitability of using yellow onion skin, red rose petals and eucalyptus leaves as natural dyes in printing woven cotton and silk fabrics and knitted polyamide fabric. The aim of this work is to reduce the application of synthetic dyes and to help people using natural materials and apply these sustainable methods to the textile and dyeing industries. This study is a motivation to optimize current methods and development new techniques of natural dyeing and printing.

2. Materials and Methods

2.1. Materials

In the present work natural pigments from yellow onion skin (Allium cepa), red rose petals (Rosa gallica L.) and eucalyptus leaves (Eucalyptus grandis) were applied to fabrics composed of 100 % silk (woven fabric), 100 % polyamide (knitted fabric) and 98 % cotton and 2 % elastane (woven fabric). Copper sulphate (CuSO4) and iron oxide (Fe2O3) were applied as mordants. Distilled water and non-ionic detergent were also used.

2.2. Botanical Printing with Iron Oxide Mordant in Solution

Before printing, the fabrics and the mordant solution had to be prepared. Therefore, all samples were washed with water and detergent.

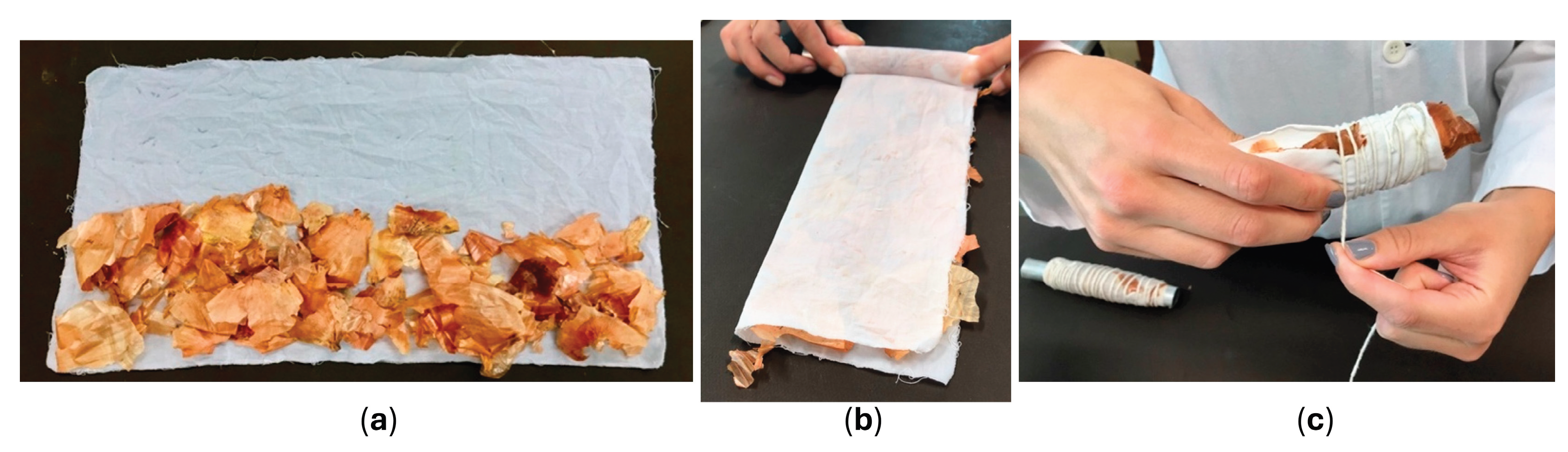

For the botanical printing process, the dried fabric sample was placed on a clean surface and the pigments (yellow onion skin, rose petals and eucalyptus leaves) were distributed over 50 % of the fabric´s surface (

Figure 1a). The fabric was then folded in half so that the dyes could dye the entire surface of the fabric. In the next step, the fabric was tightly rolled onto an aluminium cylinder, as shown in

Figure 1b. After being rolled into the cylinder, the samples were tied with a cotton thread, as shown in

Figure 1c.

To continue the printing process, a 2.5 % iron oxide mordant solution was prepared. Fabric samples were boiled for 60 minutes using water, with and without mordant in the solution, to evaluate and compare the effects of the printing on colour fastness. After this step, the fabrics were rinsed in clean water and dried at room temperature.

2.3. Botanical Printing with Copper Sulphate Mordant on Natural Elements

Initially, the fabrics were washed with water and detergent to promote better hydrophilicity. The mordant solution was prepared using a 2.5 % copper sulphate solution. Each natural element (yellow onion peel, eucalyptus leaves, and red rose petals) was immersed in the mordant solution for four hours, as shown in

Figure 2.

After the natural elements remained in the mordant solution, they were removed from the solution and immediately added to the fabric samples as described in

Section 2.2, as well as rolled and tied into cylinders. The samples were boiled for 60 minutes using water. After that, the fabrics were rinsed in clean water and dried at room temperature, to evaluate and compare the effects of the printing on colour fastness.

2.4. Determination of Colour Fastness to Washing

The ISO 105-C06 B2S method was used to determine the colour fastness to washing. The colour transfer is then compared with the grey scale for dyeing.

The grey scale for colour change was used to indicate the amount of transfer and colour change after washing. The samples printed with copper sulphate mordant were grouped into the following three categories: i) one wash cycle; ii) five wash cycles; iii) ten wash cycles.

2.5. Determination of Colour Crocking Fastness

For determination of colour fastness to dry rubbing, ISO method 105-X12:1993 (dry and wet) was followed. Samples were rubbed with a standard white fabric for ten complete cycles and evaluated using the gray scale for dyeing.

3. Results

3.1. Botanical Printing with Iron Oxide Mordant in Solution

In this method, the prints made with eucalyptus leaves and rose petals on the three fabric samples, with and without mordant, did not show satisfactory printing results. All samples lost colour, except for the polyamide fabric with the onion skins.

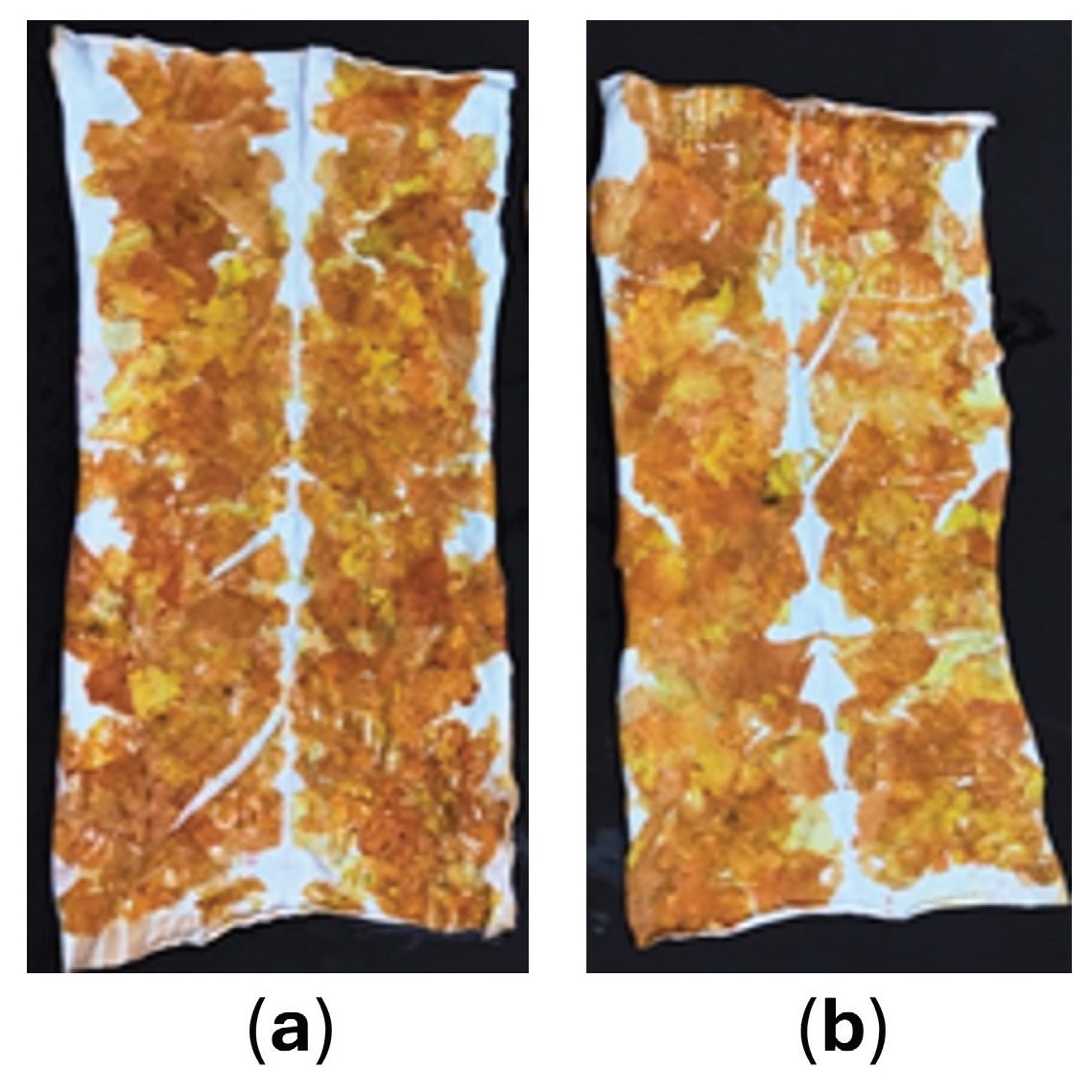

The yellow onion skin applied to polyamide knitted fabric, with and without mordant, showed very satisfactory results. The colours were bright and intense on the fabrics. There was no visual difference between the samples treated with and without mordant, as seen in

Figure 3, which leads us to believe, in this case, the iron oxide mordant did not need to be used to improve the interaction between the onion skin and the fabric.

Mohammad Raza Miah studied the dyeing of wool fabric using natural dye extracts from onion’s outer skin by using water and organic solvents. Alum mordant, copper mordant and chrome mordant were chosen for mordanting. The results showed that onion peel could be successfully used for dyeing wool with metallic mordants. The prints obtained a wide range of soft, pastel and light colours. Overall, it can be stated that wool fabric dyeing with extracted onion’s outer skin has a good prospect in the textile dyeing industry. This statement can be according to the results obtained in this research applied to polyamide and silk as well [

13]. The study of Ashish Debnath confirmed and expanded onion skin’s suitability as a natural dye in the textile dyeing sector. Red onion skin was applied on cotton fabric by the exhaust method then dried and cured for a proper fixation. The result was that red onion skin can dye cotton effectively [

4]. The dyes extracted from this type of waste material can be an attractive alternative for synthetic dyes.

3.2. Botanical Printing with Copper Sulphate Mordant on Natural Elements

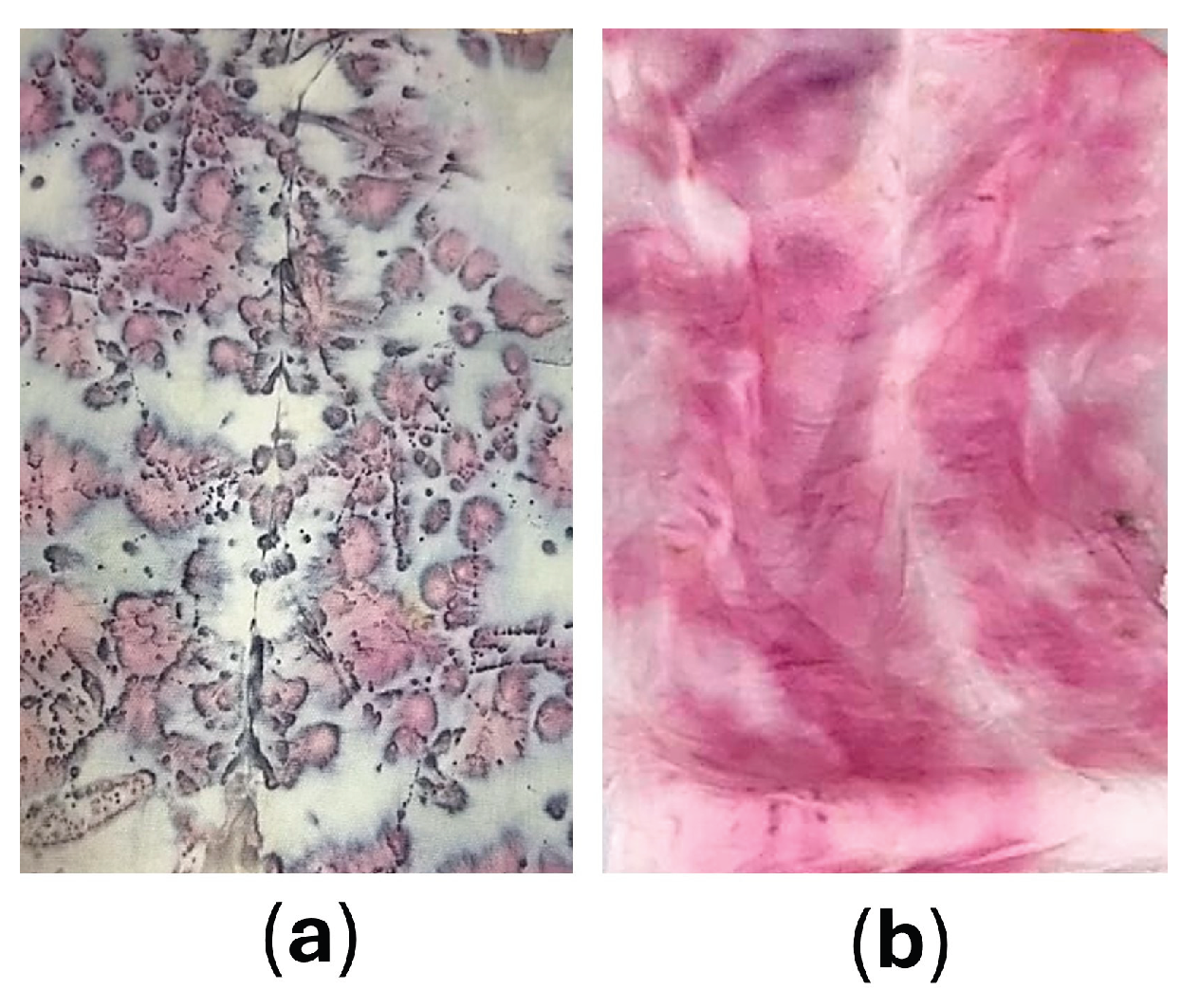

When printing was carried out without copper sulphate mordant, the cotton and silk prints were very light in tone and the plant structure was blurred on the textile substrate. However, when printed with pretreated natural dyes, the prints were deeper and sharper. The plant structure and contours were clearly visible and appeared in vibrant colours, especially on the cotton fabric, as can be seen in

Figure 4a. This indicated the positive role of the copper sulphate mordant in imparting affinity to the rose petal pigment on the cotton fabric.

Fabric samples printed with mordant eucalyptus leaves produced satisfactory results on silk fabric. The eucalyptus leaves left an intensified impression, with colours that highlighted the contour line structure of the plants, as shown in

Figure 5.

The study of Rattanaphol Mongkholrattanasit was concerned with dye extraction from the leaves of eucalyptus and the application of this natural dye for silk and wool fabric dyeing by the exhaustion method. This study confirms that silk and wool fabrics can be successfully dyed with eucalyptus leaf extract because of the tannin richness of the eucalyptus leaves. Tannin contains phenolic compounds who can form hydrogen bonds with the carboxyl group of protein fibres. Whereby, wool dyed with eucalyptus leaf extract undertook higher colour strength than silk, which is because wool contains more functional groups (NH

2) than silk fabric. The silk and wool fabrics dyed with the eucalyptus leaf extract, combined with a mordant compound, exhibited a yellowish-brown shade. Exceptions were the fabrics dyed with iron sulphate as mordant, resulting in a shade of dark greyish brown. This research proves that the usage of mordants does not only improve colour strength but also provides shade differences [

13].

Among the three fabrics used, polyamide produced the most intense printing result. The copper sulphate mordant improved the colour intensity and sharpness of the samples, as they appeared radiant with detailed printed structures. However, prints without mordant application also produced coloured prints, however, the colours were lighter in tone compared to those with copper sulphate mordant. This result demonstrates how mordants not only impart affinity to the pigment for polyamide, but in many cases also produce different colours.

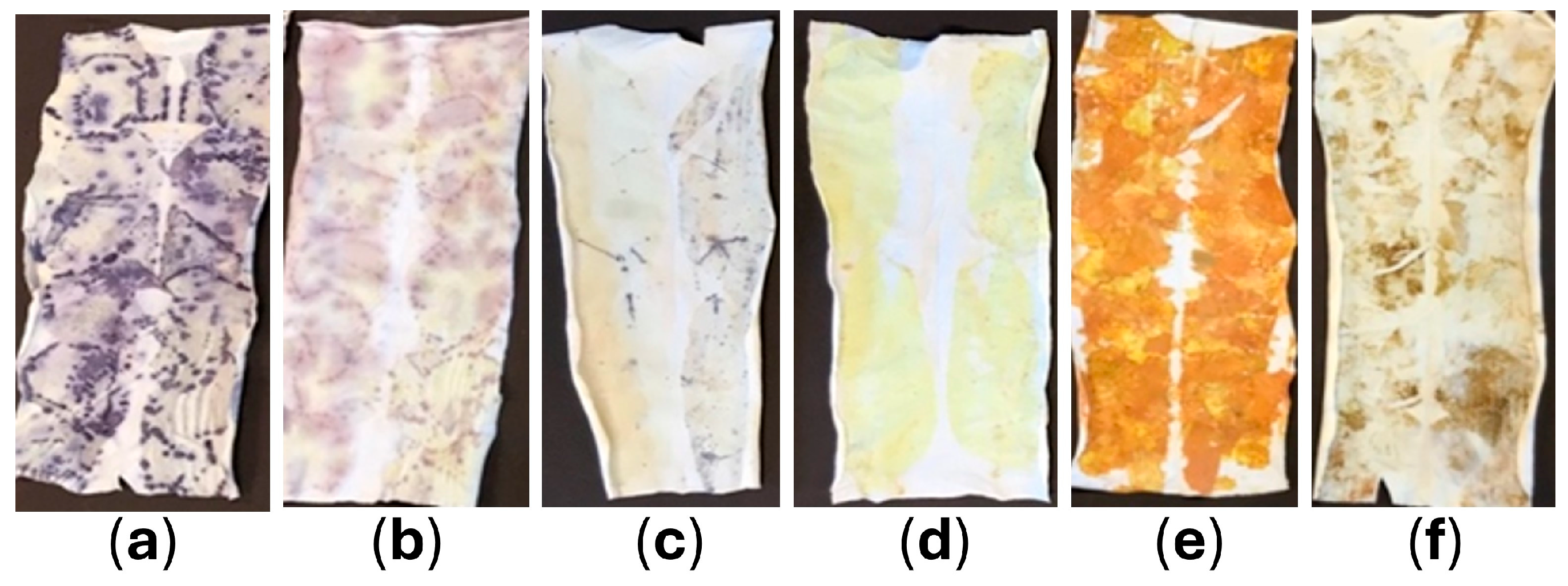

Figure 6 presents the colour differences between the polyamide samples using different natural pigments with and without the copper sulphate mordant.

Red rose petals and eucalyptus leaves without mordant (

Figure 6b and 6d, respectively) presented a less refined result, compared to the samples with mordant (

Figure 6a and 6c), due to faded colours, with blurred printed structures. However, the sample printed with rose petals with mordant presented colour intensity and sharpness. Exceptionally, the yellow onion skin (

Figure 6e and 6f) presented intense coloration, obtaining colours ranging from bright orange to greenish yellow, in the samples with and without mordant, respectively.

3.3. Fastness results of printed samples

3.3.1. Colour fastness to washing

The colour fastness to washing rating of the printed samples using the method presented in

Section 2.2 was evaluated and presented as shown in

Table 1.

The results of colour fastness to wash according to the gray scale for change and transfer were excellent, both scores 4/5. This indicated that the use of iron oxide mordant did not influence the fastness properties in printing with yellow onion skin as a natural pigment.

Ashish Debnath’s study on cotton-based samples dyed with pelargonidin extruded from red onion skin gave very satisfactory results of colour fastness to washing. Cotton and polyamide obtained the same score of 4/5 [

14]. The colour fastness to washing rating of the samples printed using the method presented in

Section 2.3 was evaluated and presented as shown in

Table 2. It is important to note that only the samples with satisfactory staining results were evaluated.

According to

Table 2, the colour fastness to washing considering transfer was excellent, indicating that the use of copper sulphate mordant had no effect on this property. However, most of the natural pigments changed their colour, i.e., faded or paled after one wash. The exception was the natural dye onion skin on polyamide, as the fastness to washing was excellent, therefore, the natural pigment did not lose its colour.

3.3.2. Colour fastness to washing after 1, 5 and 10 wash cycles

The samples were subjected to additional wash fastness tests to evaluate and compare the intensity of colour change after the first, fifth and tenth washes. The colour fastness to washing rating of the samples printed with natural pigments, with and without mordant applied to the pigment is presented in

Table 3.

The highest score was obtained using yellow onion skin on knitted polyamide fabric without copper sulphate mordant. The lowest score was obtained using eucalyptus leaves and mordant on woven cotton fabric. The more wash tests were carried out, the less intense the colour of the print became, resulting in a faded and pale appearance.

3.3.3. Colour fastness to dry rubbing

The classification of colour fastness to dry rubbing samples printed with natural onion skin pigment, with and without iron oxide mordant on polyamide fabric is presented in

Table 4.

The results observed in

Table 4 indicate that although the pigment transferred to the control fabric, this transfer was light and satisfactory for a natural pigment.

Table 4.

Evaluation of colour fastness to dry rubbing using natural onion skin pigment with and without iron oxide mordant.

Table 4.

Evaluation of colour fastness to dry rubbing using natural onion skin pigment with and without iron oxide mordant.

| Sample |

Mordant Fe2O3

|

Grayscale fastness |

| Polyamide |

with |

4 |

| without |

4 |

Table 5.

presents the results of colour fastness to dry rubbing for fabrics printed with natural pigments without copper sulphate mordant.

Table 5.

presents the results of colour fastness to dry rubbing for fabrics printed with natural pigments without copper sulphate mordant.

| Sample |

Natural dye |

Mordant CuSO4

|

Grayscale fastness |

| Cotton |

rose petals |

with |

5 |

| Cotton |

eucalyptus leaves |

with |

5 |

| Polyamide |

onion skin |

with |

4/5 |

| Polyamide |

onion skin |

without |

4 |

| Polyamide |

rose petals |

with |

4/5 |

| Polyamide |

rose petals |

without |

4/5 |

| Polyamide |

eucalyptus leaves |

with |

4/5 |

| Silk |

eucalyptus leaves |

with |

5 |

4. Conclusions

Botanical printing with mordant applied to the pigment was carried out using copper sulphate as mordant. Yellow onion skin, red rose petals and eucalyptus leaves were applied, achieving an expanded range of colour impressions. The mordant process provided deeper and sharper impressions. Polyamide knitted fabric reacted well with all natural pigments, obtaining prints with the greatest colour intensity with and without the mordant. Among the three natural pigments, the most promising was yellow onion skin. The outer skin of the plant, combined with polyamide knitted fabric, achieved the highest and brightest colour intensity. In conclusion, natural dyes represent a promising and sustainable alternative to reduce the environmental impact of synthetic dyes in the textile industry. Among them, yellow onion skin stands out as an affordable and environmentally friendly waste product with significant application potential. Although natural dyes do not yet offer the speed or scalability of their synthetic counterparts, they have considerable value in niche sectors such as fashion and handcrafted textiles. Looking ahead, the industry is expected to continue to refine current methods of applying natural dyes and invest in innovative technologies that promote more environmentally responsible dyeing and printing processes.

Author Contributions

Conceptualization, F.S., G.C.O.A and C.R.L.A.; methodology, C.R.L.A.; validation, A.E. and J.C.F.; formal analysis, F.S., G.C.O.A and C.R.L.A.; investigation, A.E. and J.C.F; resources, A.E. and C.R.L.A.; writing—original draft preparation, A.E.; writing—review and editing, F.S.; visualization, G.C.O.A.; supervision, C.R.L.A.; project administration, C.R.L.A.; funding acquisition, A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by PROMOS, scholarship program of DAAD (Deutscher Akademischer Austauschdienst e.V.).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

thanks to Niederrhein University of Applied Science in Germany and to Federal University of Santa Catarina, Brazil.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Algee, E.O.; Uthman, T.O. A review of history, properties, classification, applications and challenges of natural and synthetic dyes. Heliyon 2024, 10, 13. [Google Scholar] [CrossRef]

- Pranta, A.D.; Rahaman, Md. T. Extraction of eco-friendly natural dyes and biomordants for textile coloration: A critical review. Nano-Structures & Nano-Objects. 2024, 39. [Google Scholar] [CrossRef]

- Haji, A.; Naebe, M. Cleaner dyeing of textiles using plasma treatment and natural dyes: A review. Journal of Cleaner Production. 2020, 265. [Google Scholar] [CrossRef]

- 4Phan, K.; Raes, K.; Speybroeck, V.V.; Roosen, M.; De Clerck, K.; De Meester, S. Non-food applications of natural dyes extracted from agro-food residues: A critical review. Journal of Cleaner Production. 2021, 301. [Google Scholar] [CrossRef]

- Gokilamani, N.; Muthukumarasamy, N.; Thambidurai, M.; et al. Dye-sensitized solar cells with natural dyes extracted from rose petals. J Mater Sci: Mater Electron. 2013, 24, 3394–3402. [Google Scholar] [CrossRef]

- Eugster, C.H.; Märki-Fischer, E. The Chemistry of Rose Pigments. Angewandte Chemie International Edition in English. 1991, 30, 6, 613–622. [Google Scholar] [CrossRef]

- Santiago, D.; Cunha, J.; Cabral, I. Chromatic and medicinal properties of six natural textile dyes: A review of eucalyptus, weld, madder, annatto, indigo and woad, Heliyon. 2023, 9, 11. [CrossRef]

- Mongkholrattanasit, R.; Kryštůfek, J.; Wiener, J.; Studničková, J. Natural dyes from eucalyptus leaves and application for wool fabric dyeing by using padding techniques. In Natural dyes, IntechOpen, 2011, pp. 57-78.

- Bahtiyari, M. I.; Benli, H.; Yavas, A. Use of different natural dye sources for printing of cotton fabrics. Textile and Apparel. 2017, 27, 3, 259–265. [Google Scholar]

- Naqvi, S.A.R.; ul-Wara, K.; Adeel, S.; Mia, R.; Hosseinnezhad, M.; Rather, L.J.; Imran, M. Modern ecofriendly approach for extraction of luteolin natural dye from weld for silk fabric and wool yarn dyeing. Sustainable Chemistry and Pharmacy. 2024, 39. [Google Scholar] [CrossRef]

- Marquardt, A.L.; de Oliveira, C.R.S.; Volkmann, A.C.; Francisco, I.B.M.; da Silva Júnior, A.H. ; Aguiar, C.R.L. Exploring the dyeing potential of annatto dye on linen substrate: An inquiry into the effects of different mordants. Coloration Technology. 2025, 141, 3, 405–422. [CrossRef]

- Teli, M.D. Eco-friendly antibacterial printing of wool using natural dyes. Journal of Textile Science & Engineering. 2014, 4, 2. [Google Scholar] [CrossRef]

- Miah, M. R.; Telegin, F.; Rahman, Md. S. Eco-friendly dyeing of wool fabric using natural dye extracted from onion´s outer shell by using water and organic solvents. International Research Journal of Engineering and Technology. 2016, 3, 9, 450–467. [Google Scholar]

- Debnath, A. Natural dyeing of cotton fabric by extruded pelargonidin of red onion skin and finished it naturally with aloe vera. Int J Environ Sci Nat Res. 2018, 4, 2. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).