Submitted:

31 July 2025

Posted:

01 August 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Reducing waste by identifying and quickly correcting defects (e.g., a defective buckle detected and efficiently remedied);

- Implementing energy-efficient processes and using technologies that minimize resource consumption;

- Promoting sustainable design and green mobility (e.g., recyclable components, reducing emissions in manufacturing).

- ➢

- Identifying the role of quality in project success, analyzing how quality planning influences project outcomes, considering economic, technical, and organizational dimensions;

- ➢

- Analyzing relevant international standards, with ISO 9001 and PMBOK used as benchmarks for defining best practices in the field;

- ➢

- Studying a generic example by constructing a case study that reflects a real-world scenario, applicable to various industries, to illustrate the quality planning process;

- ➢

- Identifying common challenges—such as lack of resources, resistance to change, and poor communication—which are discussed and addressed from the perspective of the specialized literature.

2. Literature Review

Literature Review for the 8D Analysis Method

Structure of the 8D Method

- D0: Planning – Defining the plan of approach for the problem;

- D1: Team Formation – Selecting a multidisciplinary team with relevant expertise;

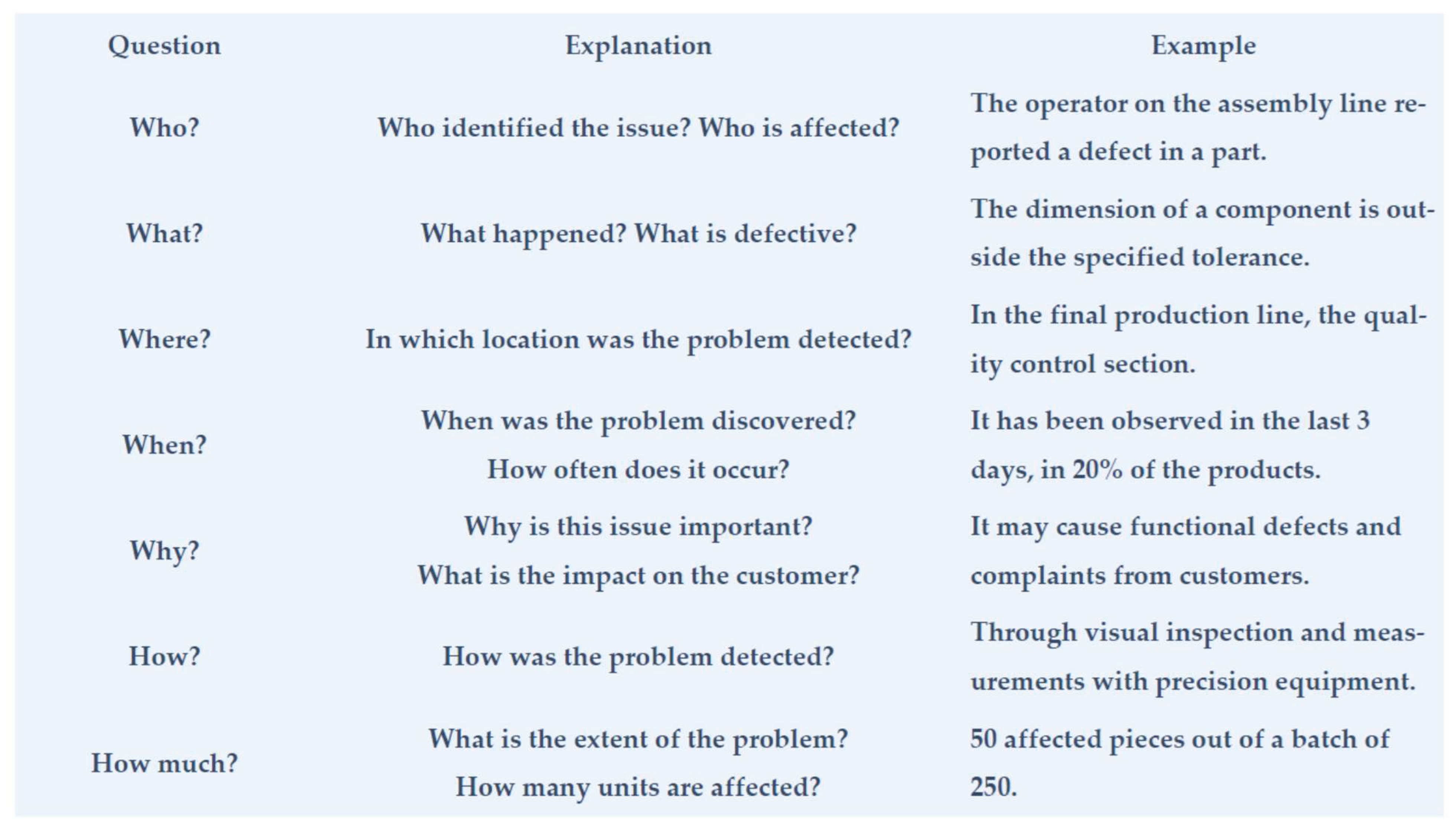

- D2: Problem Definition & Description – Detailed problem analysis using techniques such as 5W2H (who, what, where, when, why, how, how much);

- D3: Implementation of Containment Actions – Temporary measures to limit the impact of the problem;

- D4: Identification of Root Causes – Use of analysis tools such as “5 Whys” and the cause-effect (Ishikawa/Fishbone) diagram;

- D5: Selection and Verification of Permanent Corrections – Validation of the proposed solutions;

- D6: Implementation and Validation of Corrective Actions – Putting the solutions into practice and evaluating their effectiveness;

- D7: Prevention of Recurrence – Amending procedures to prevent recurrence of the issue;

- D8: Team Recognition – Formal acknowledgment of the collective effort [13].

Results and Demonstrated Benefits in the Literature

- Need for Training: The effectiveness of the method depends on the team’s training level and discipline in following the steps [21].

- Limited Applicability without Management Support: Long-term success requires active management involvement and the integration of 8D into the organizational culture [22].

- Empirical Evidence: Some of the literature highlights a lack of extensive empirical studies, with much of the body of work focusing on process description and less on statistical result analysis [23].

Literature Review: Quality Planning and 8D Analysis in the Automotive Industry

- Standardization and Systematic Approach: Quality planning processes are structured based on PDCA (Plan-Do-Check-Act) and SDCA (Standardize-Do-Check-Act) cycles, ensuring continuous improvement of product and service quality [27];

- Core Tools: Essential tools used in quality planning include APQP (Advanced Product Quality Planning), FMEA (Failure Mode and Effects Analysis), MSA (Measurement System Analysis), PPAP (Production Part Approval Process), and SPC (Statistical Process Control) [28];

- Integration of Strategic Objectives: The quality plan is aligned with organizational strategy, deployed at all operational levels and supported by cross-functional actions for continuous improvement [29];

- Management and Multidisciplinary Team Involvement: The success of quality planning depends on active management involvement and collaboration between departments, as well as the ongoing training and education of personnel [30].

8. D Analysis in the Automotive Industry

- Origin and Evolution: 8D was initially developed by Ford Motor Company and became a standard approach in the automotive industry for systematically addressing critical nonconformities [31];

- 8D Process Structure: The method involves eight disciplines, from initial planning and team formation to root cause identification, corrective action implementation, and prevention of recurrence. An additional stage, D0 (planning), is considered essential for process success [32];

- Demonstrated Benefits: Studies show that 8D implementation leads to reduced problem-solving times, fewer defects, higher customer satisfaction, and optimized internal processes [33];

- Complementary Tools: In practice, the 8D method is often used alongside other quality tools such as Six Sigma, FMEA, and statistical analysis to ensure a robust and efficient approach to technical and organizational issues [34];

- Challenges and Limitations: The literature points out the need for team training, management involvement, and integrating 8D into the organizational culture to achieve sustainable results [35].

Literature Synthesis and Current Trends

- Integration of Core Tools: The automotive industry uses an integrated set of tools for quality planning and management, and 8D is a key part of this ecosystem [36];

- Focus on Continuous Improvement: Both quality planning and 8D analysis are based on the principle of continuous improvement, aiming to prevent defect recurrence and increase competitiveness [37];

- Recent Case Studies and Research: Recent studies highlight the successful implementation of the 8D method for solving specific issues (e.g., automotive component defects, durability testing optimization) and its role in developing a quality- and innovation-oriented organizational culture [38].

3. The Concept and Methods

3.1. The Contribution of 8D Analysis to Quality Planning and Sustainability in the Automotive Industry

- ➢

- 8D Analysis and Quality Planning

- ➢

- 8D Analysis and Sustainability

- ➢

- Demonstrated Benefits in the Automotive Industry

- Reduced costs related to defects and warranties

- Increased customer satisfaction through more reliable products

- Creation of a lessons-learned database, useful for preventing future problems

- Enhanced team ability to efficiently manage nonconformities and make data-driven decisions

3.2. Methodology Used

- ✓

- Literature Review: A detailed analysis of relevant materials was conducted, including academic works, scientific articles, and internationally recognized standards such as ISO 9001 and PMBOK. This review provides a solid theoretical foundation and outlines the main concepts related to quality planning;

- ✓

- Hypothetical Case Study Approach: A generic scenario, representative of various fields, was created in order to analyze the quality planning process in a practical context. This case study covers all relevant stages, from requirements identification to performance evaluation;

- ✓

- Comparative Analysis: Within the study, best practices identified in the literature are discussed and compared to the challenges and solutions presented in the generic example. The proposed methodology enables a deep understanding of the addressed concepts, facilitating their applicability in real situations. At the same time, the work offers a generalized model that can be adapted according to the specific requirements of a project.

Choosing the Case Study Method

- -

- Testing Theoretical Models: The case study allows for the application of concepts from the literature in a practical context;

- -

- Identifying Problems and Solutions: By simulating a generic project, challenges encountered in quality planning can be analyzed and solutions can be proposed.

3.2.2. Description of the Tools Used

- ISO standards (e.g., ISO 9001): These provide a basis for defining and assessing quality requirements;

- Manuals and best practice guides (e.g., PMBOK): These were analyzed to identify relevant processes and tools.

- Previous studies: Published research offered perspectives on challenges and solutions applied in real projects.

- Project managers: to understand the practical perspective on challenges in quality planning.

- Quality control specialists: to identify preferred methods for quality monitoring and evaluation.

- Stakeholders: to assess how project deliverables’ quality and value are perceived.

3.2.3. Research Limitations

3.3. Example of a Gantt Chart for Quality Planning in an Automotive Project (Automotive Buckle)

- -

- Project Visibility: All team members clearly see the steps, responsibilities, and deadlines;

- -

- Identification of Dependencies: The chart makes it easy to observe activities that depend on each other and which may cause delays;

- -

- Progress Monitoring: Regular updates enable quick correction of deviations from the plan;

- -

- Improved Collaboration: Facilitates communication among design, quality, production, and management teams.

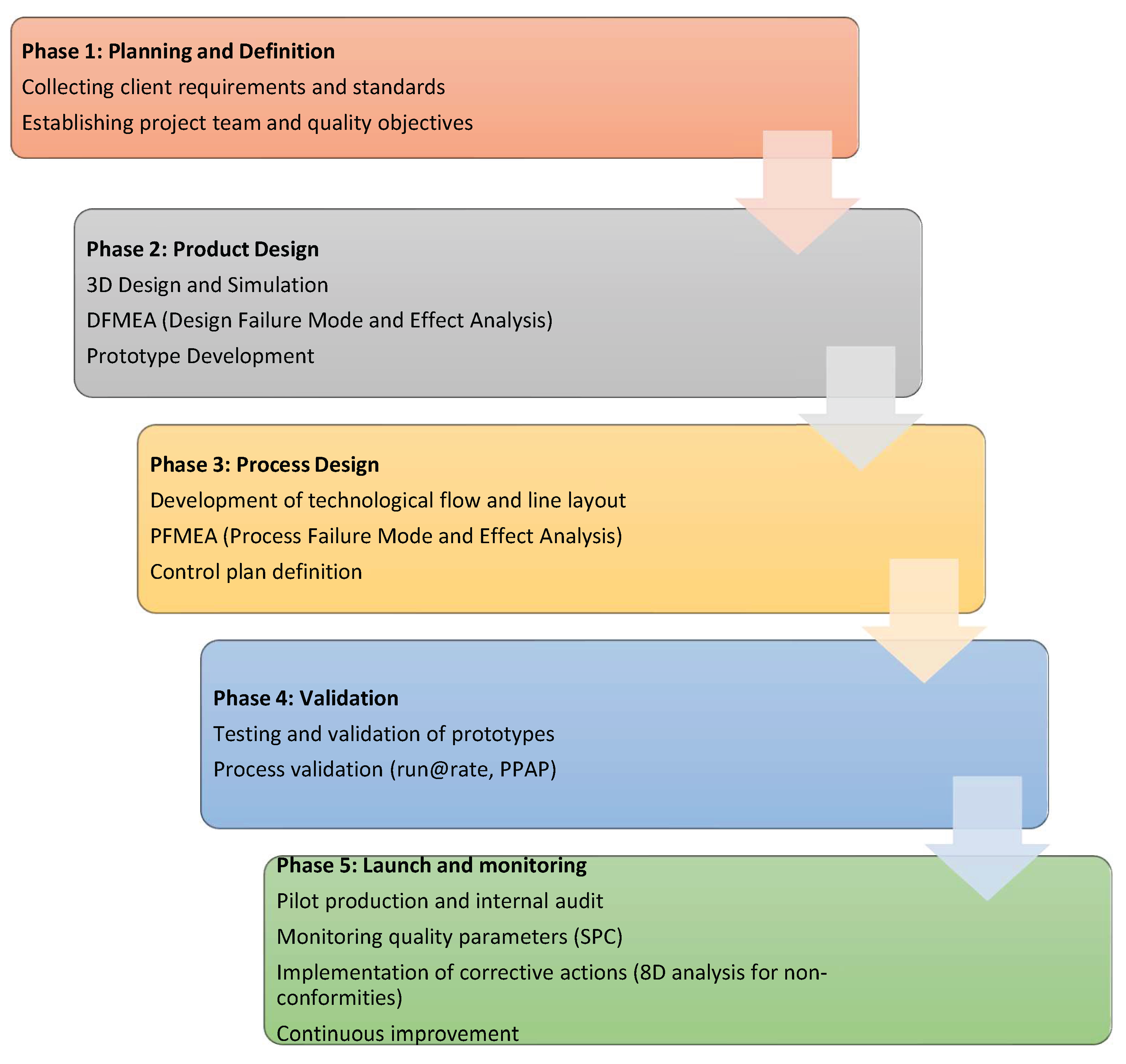

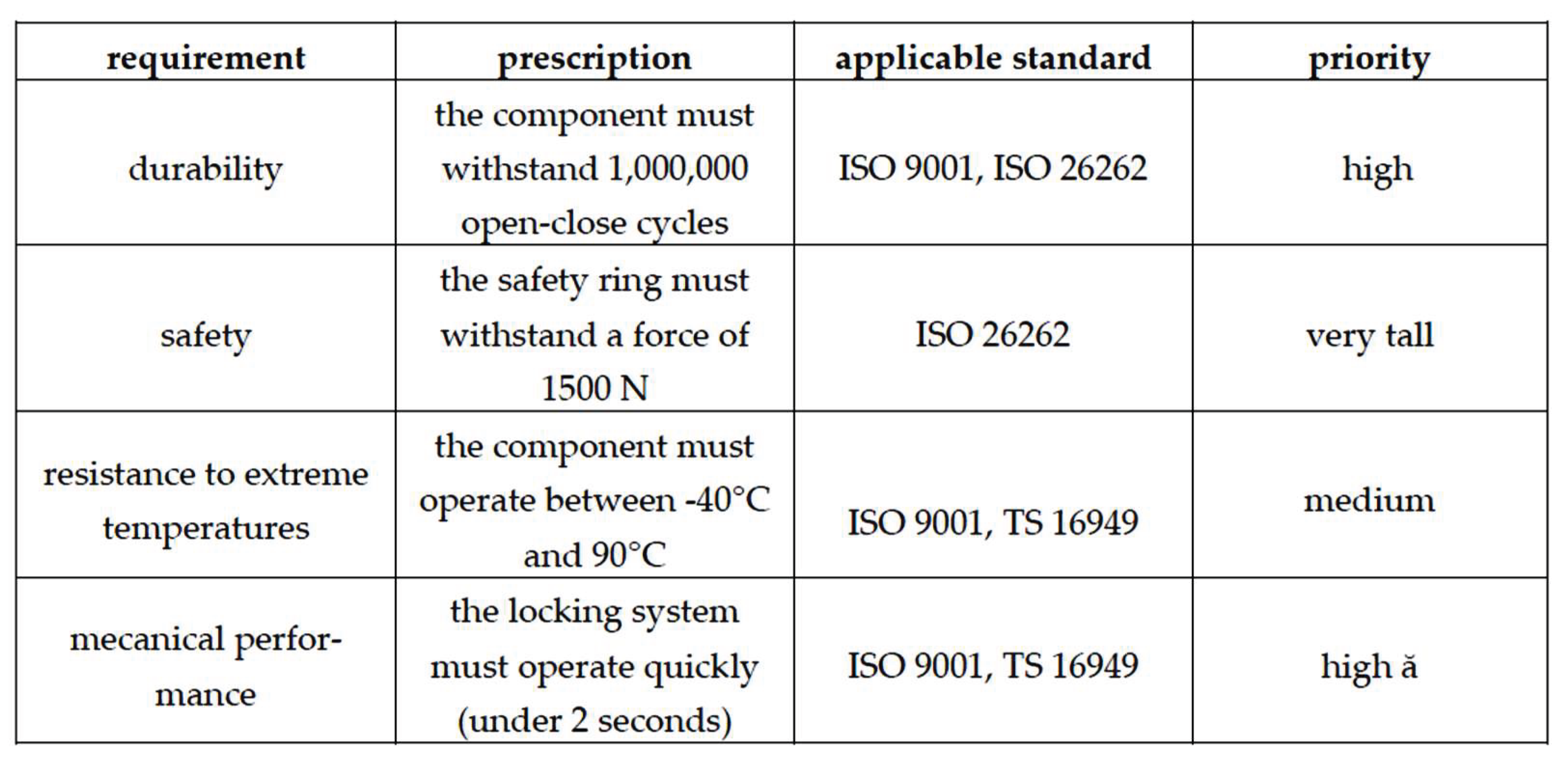

3.4. Example of a Quality Requirements Matrix

4. Case Study: Quality Planning in the Automotive Buckle Manufacturing Process - 8D Analysis

- A team of experts is formed who have the necessary knowledge about the product, process, and problem;

- The responsibilities of each member are defined;

- It is ensured that all team members have a common understanding of the 8D methodology.

- Quality manager – expert in defect analysis and quality requirements;

- Process engineer – understands the production flow and can identify potential causes;

- Product/design engineer – knows technical specifications and can verify if the problem is design-related;

- Operators and technicians – have practical experience with the product and can provide information about encountered problems;

- Supplier manager (if applicable) – analyzes if the problem comes from the supply chain;

- Manager or team leader – coordinates the process and ensures methodology compliance.

- A team leader is designated, responsible for managing the investigation and facilitating discussions;

- Clear communication channels are established between members;

- Necessary resources for investigation are defined (time, equipment, data access, etc.);

- Regular meetings are planned to monitor analysis progress.

- RACI Matrix (R (Responsible) – the person who actually performs the task or activity, A (Accountable) – the person who has final responsibility and approves the result, C (Consulted) – people who provide consultation or expertise, being consulted during the process, I (Informed) – people who need to be informed about the progress and results of the activity) – helps clarify the responsibilities of each member;

- Skills map – to ensure a well-balanced team;

- Communication plan – establishing meeting and reporting frequency.

- To describe the problem clearly and in detail;

- To eliminate assumptions and base the analysis on concrete data;

- To establish the impact of the problem on the product, process, and customer.

- Production data: Lots, serial numbers, involved suppliers;

- Process parameters: Temperature, pressure, operating time, etc.;

- Historical data: Previous similar problems, corrective actions applied;

- Customer complaints: Feedback and defect reports.

- Pareto Diagram: To identify the most frequent cause;

- Ishikawa (Fishbone) Diagram: To analyze possible causes;

- Check Sheet: For systematic data collection;

- Photos and samples: To clearly illustrate the defect.

- Report date: 16.05.2023

- Client: Fisker Inc.

- Supplier: Norma (an industrial supplier specialized in components for various industries)

- Problem: Insufficient riveting on the buckle, delivered by Autoliv Rovinari (Romania Rovinari Seatbelts – RRS), and Norma for seatbelt assembly.

- Part number: 63266666 E – rear buckle subassembly, exterior.

- Affected model: Fisker 2332

- Production date: 30.03.2023 (manufactured in the plant)

- Detection: The problem was discovered by Fisker

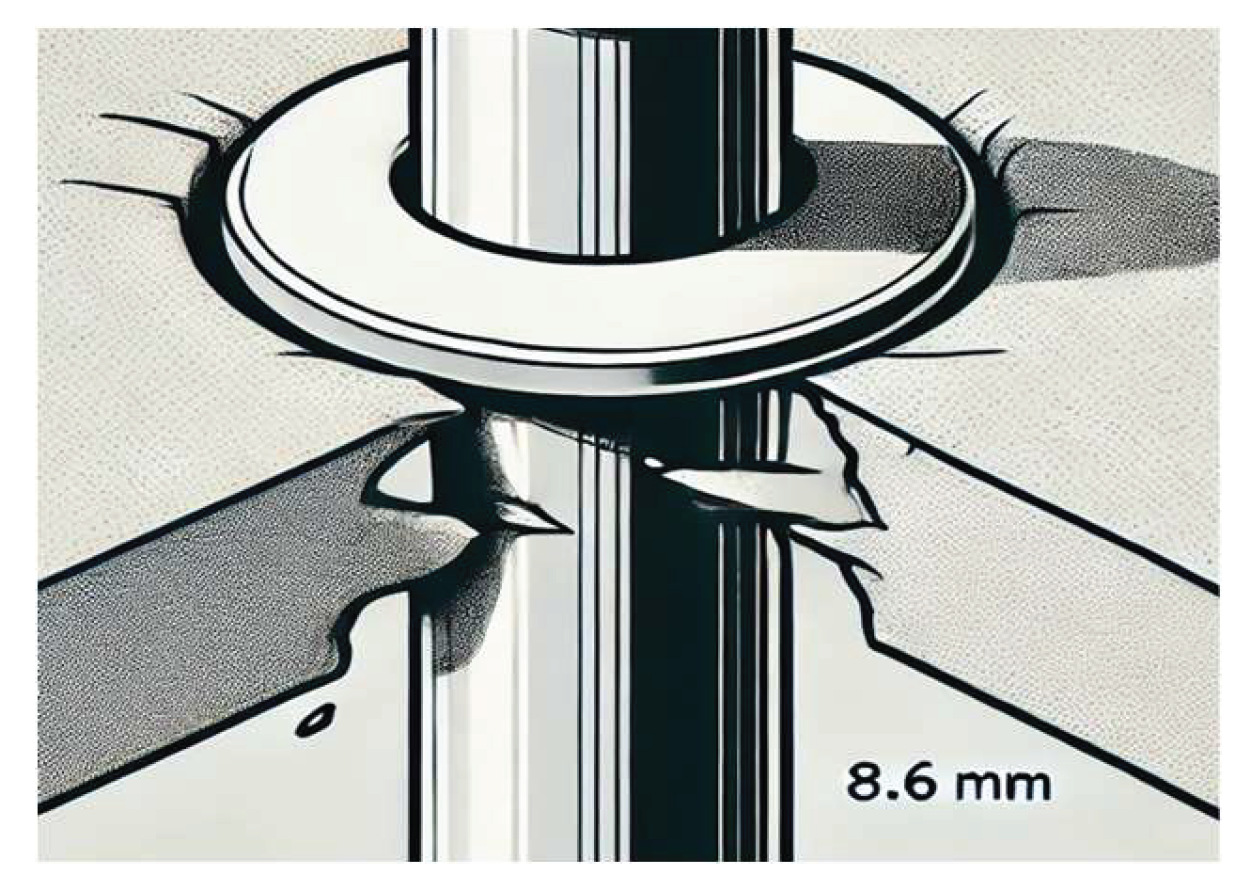

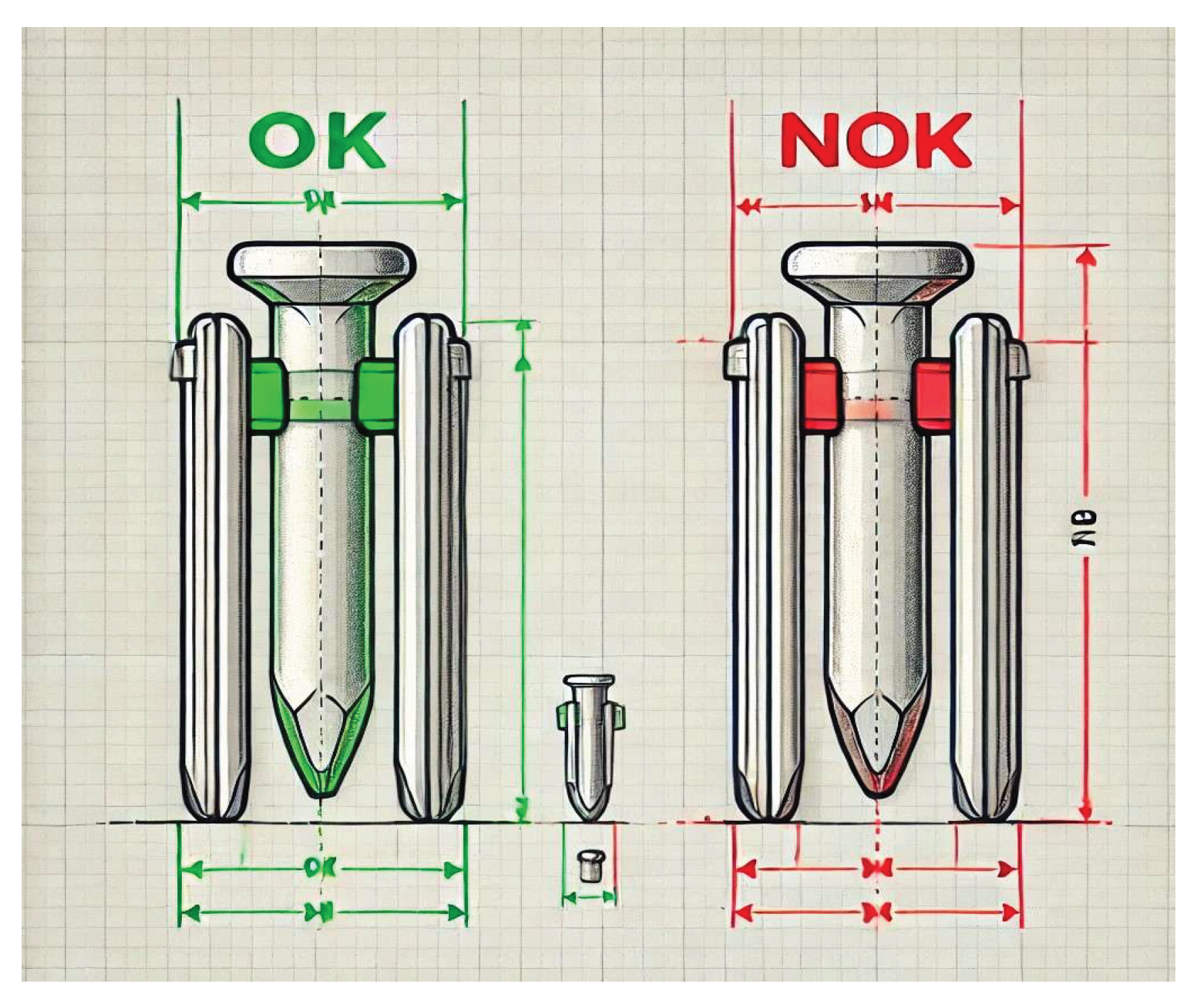

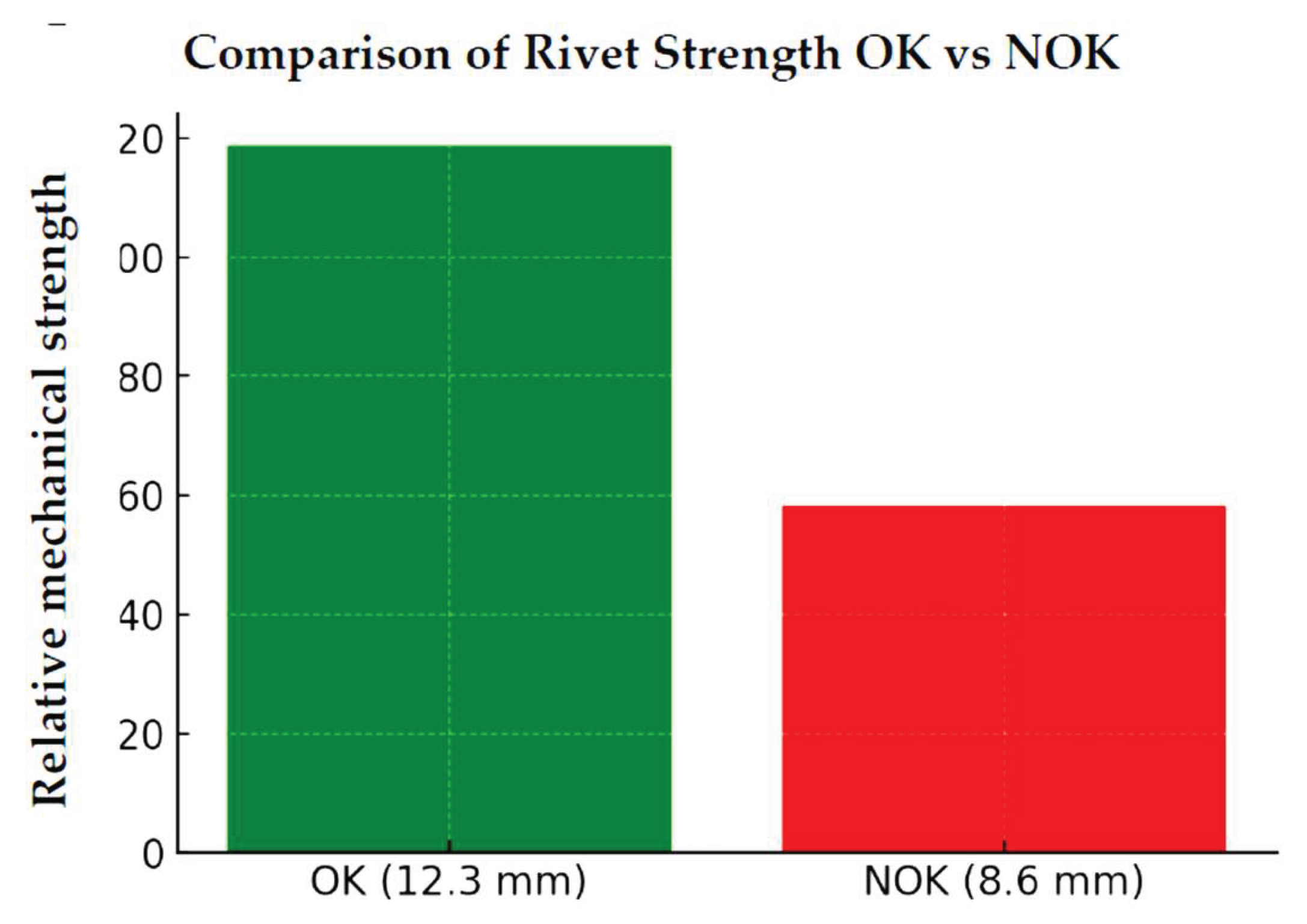

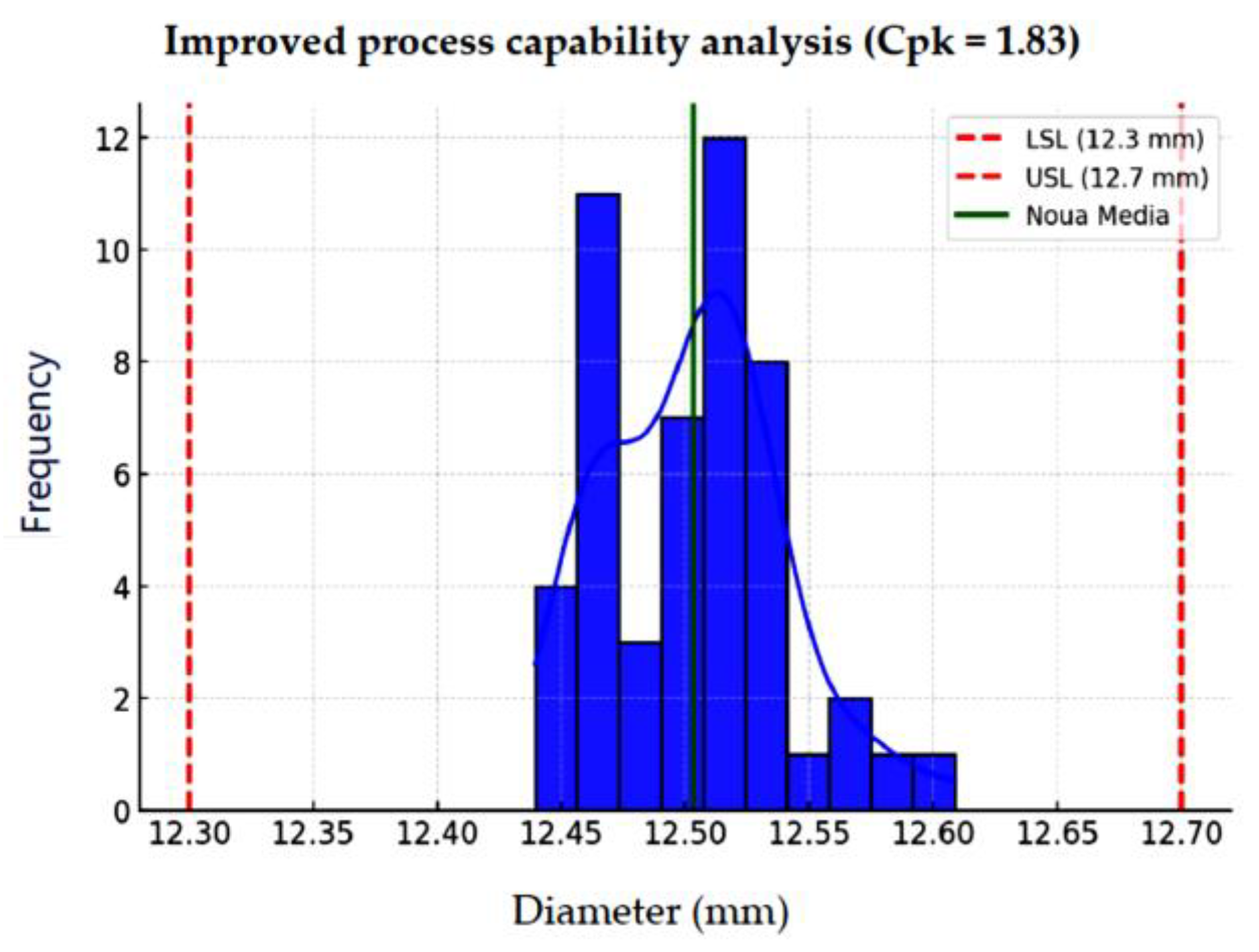

- Defect description: The rivet diameter was smaller than the standard specification, Figure 4.

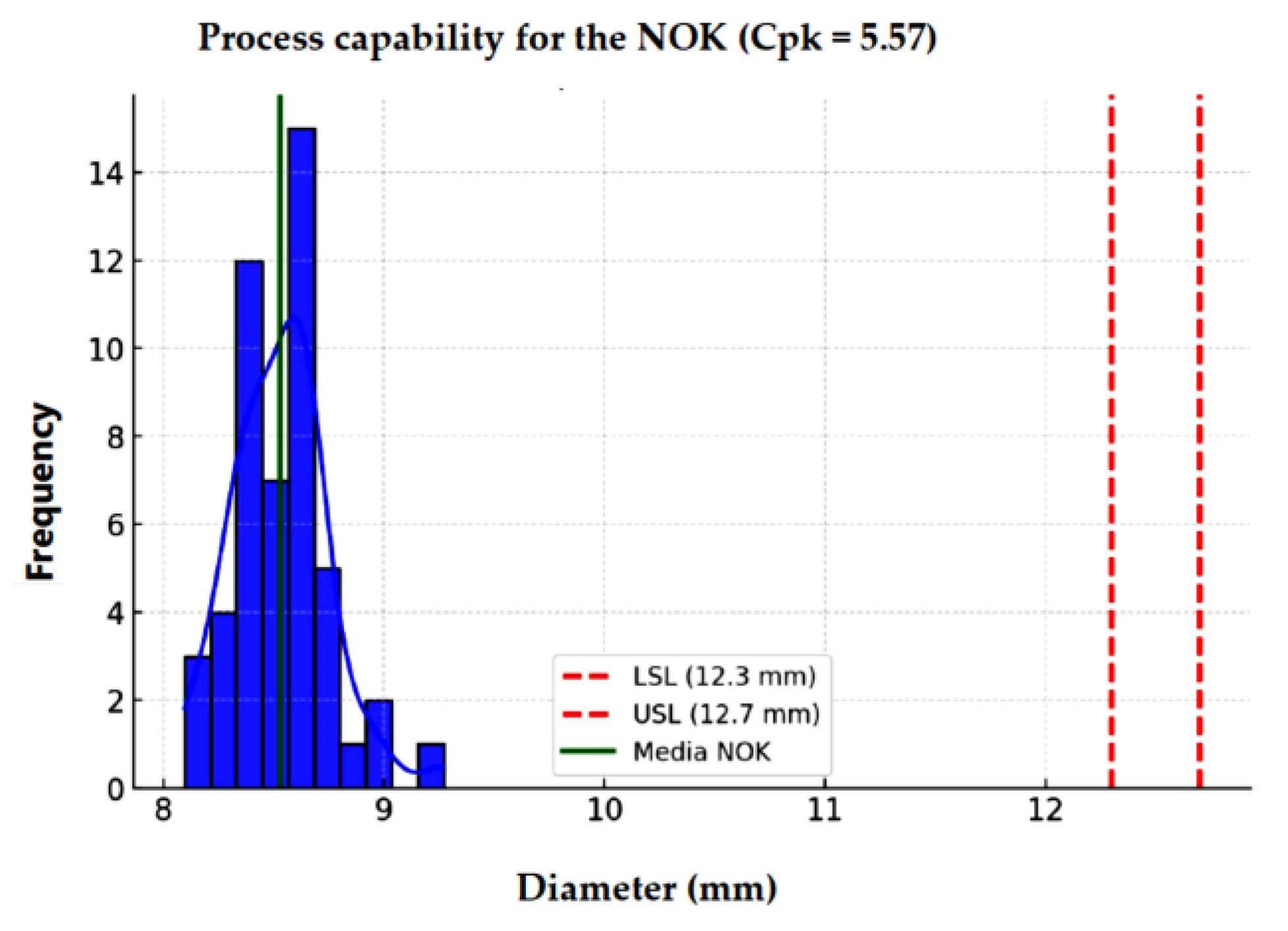

- NOK (nonconforming) dimension: 8.6 mm / OK (conforming) dimension: 12.3 mm

- Date of part receipt in the plant: 24.05.2023

- Confirmation of NOK dimension in the plant: 8.57 mm

- Parts produced on 30.03.2023 were isolated and blocked at the supplier;

- Visual and dimensional inspection was performed to separate NOK parts from OK parts;

- Previous and subsequent batches were checked to assess if the issue was widespread.

- Dimensional measurements on suspect parts:

- NOK dimension: 8.6 mm (confirmed 8.57 mm) / OK dimension: 12.3 mm;

- Implementation of a 100% filter for parts in stock;

- Additional checks in production to prevent new defect occurrences.

- Parts in stock and in transit were blocked until a solution was identified;

- Ford Saarlouis was notified to take action for parts already assembled.

- Adjustment of the riveting equipment parameters to improve pressure;

- Training operators to visually inspect the rivet before use;

- Use of a checking template for more precise measurements.

- Continuous monitoring of parts in production;

- 100% visual and dimensional inspection to prevent the delivery of nonconforming products;

- Customer confirmation that temporary actions are effective.

- Why does the rivet have a smaller diameter?

- Because the riveting process does not apply enough pressure.

- Why does the riveting process not apply enough pressure?

- Because the equipment settings are incorrect.

- Why are the equipment settings incorrect?

- Because proper calibration of the riveting force was not performed.

- Why was calibration of the riveting force not performed correctly?

- Because there is no clear standard for regular checks.

- Why is there no clear standard for regular checks?

- Because the preventive maintenance procedure is incomplete or not followed.

- It was confirmed that the riveting equipment settings were incorrect, which led to inadequately deformed rivets and thus a smaller final diameter;

- Additionally, the lack of regular inspections allowed this problem to go undetected for some time.

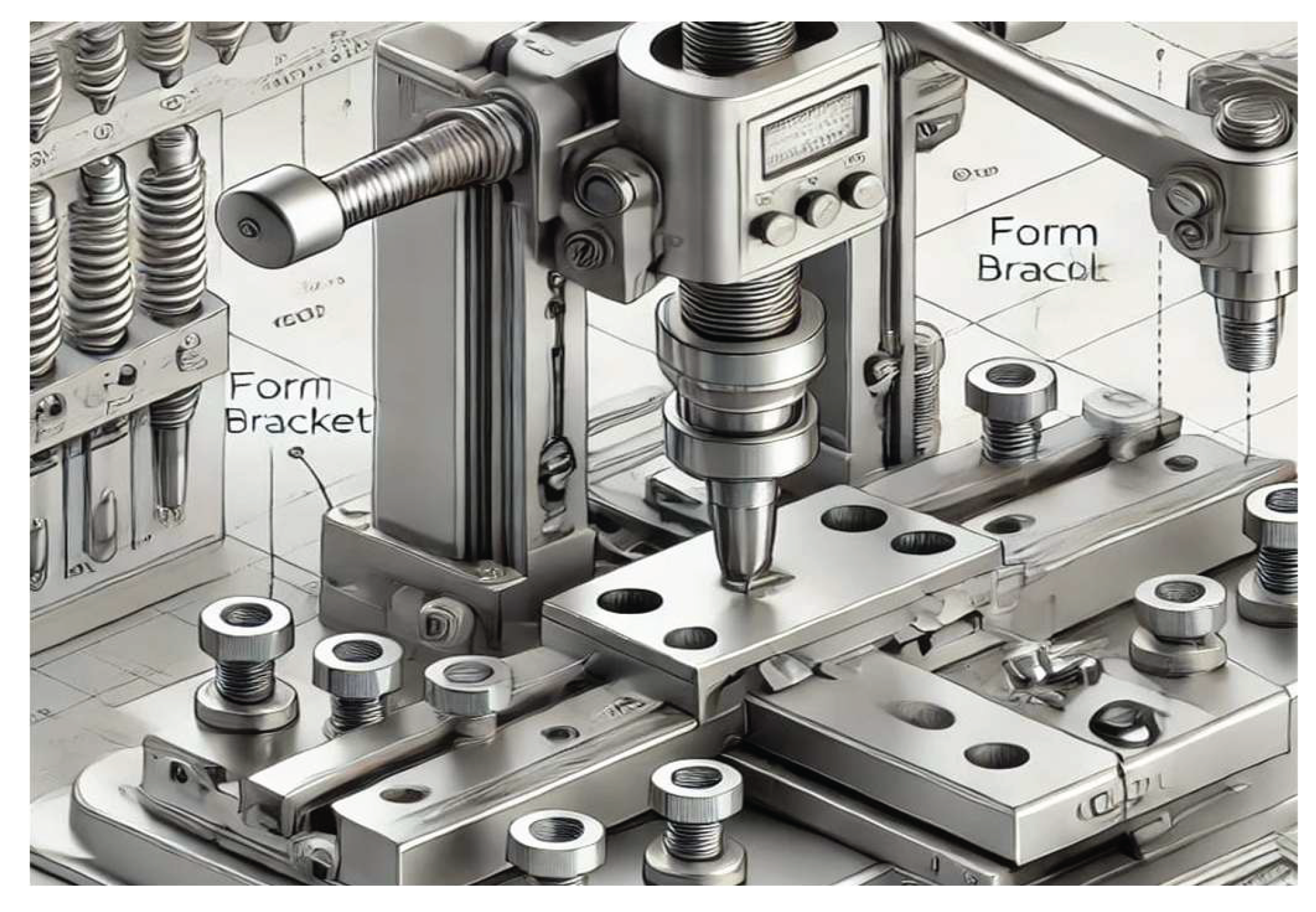

Description of the Riveting Process

- Evaluation of possible solutions – analyze various corrective action options, taking into account costs, required resources, and the impact on the process;

- Implementation of the corrective action – after selecting the solution, ensure that everyone involved in the process understands and follows the new procedure or practice;

- Monitoring the effectiveness of the corrective action – continuously assess whether the corrective measure has had the desired impact and if the problem has truly been resolved.

- The collected data is analyzed to understand the root cause of the problem;

- Effective solutions are chosen to eliminate or reduce the impact of the defect.

- Process parameters are defined and adjusted based on experimental analysis;

- Specifications are set according to clear objectives, such as stroke depth (S), process time (T), applied force (F), height after deformation (H), and total length before deformation (U).

- Verification of Corrective Action Implementation:

- Checking that work instructions have been updated;

- Evaluating implemented process changes (e.g., new quality control steps or changes in the production flow);

- Reviewing the training plan and assessing whether employees have been properly trained.

- 2.

- Measuring the Effectiveness of the Corrective Action

- Reduction in the number of similar incidents that occurred in the past;

- Decrease in the level of variability in the production process;

- Improvement in quality test results;

- Reduction in customer complaints.

- 3.

- Testing the Sustainability of the Corrective Measure

- Conducting periodic process audits to check ongoing compliance;

- Ongoing monitoring of process performance for any fluctuations or new issues;

- Collecting continuous feedback from operators or employees involved in implementing the corrective measure.

- 4.

- Documentation and Reporting of Results

- Details about the corrective measure implemented;

- Data and results of effectiveness measurements;

- Feedback from the teams involved in implementation;

- Analysis of sustainability and possible future adjustments.

- 5.

- Correcting or Adjusting the Corrective Measure, If Necessary

- 6.

- Communication with Stakeholders

- Problem: The diameter of a rivet does not meet specifications.

- Root cause: Die wear in the manufacturing process.

- Corrective action (D6): Replacement of the worn die.

- Preventive action (D7): Introduction of a predictive maintenance plan so that the die is replaced before defects occur.

- Report on actions implemented and their effectiveness;

- Records of data demonstrating process improvement;

- Revised control plans;

- Feedback from production and quality teams.

- Review of the P-FMEA (Process Failure Mode and Effects Analysis), taking into account the reported issues. Updating the PLM database to reflect the new revision. Responsible: process engineer, deadline: week 24.

- Updating the control plan to include the defined actions and updating the P-FMEA. Updating the PLM database with the new revision. Responsible: quality engineer, deadline: week 24.

- Issuing a Global Quality Alert for the rivet problem—a Global Quality Alert is created and recorded for the identified issue in the riveting process (item no. 237 / record no. 10922 in the QA database). Responsible: quality engineer, status: completed.

- Implementing a global Read Across for the review of the riveting process, ensuring extension of preventive measures at a global level to avoid recurrence in other locations or similar processes. Responsible: process engineer, deadline: week 23.

- -

- Updating process documentation (P-FMEA, Control Plan)

- -

- Distribution of information via a Global Quality Alert

- -

- Standardization and extension of measures at a global level (Read Across)

- Confirmation of Problem Elimination:

- Statistical data – Monitoring key indicators (e.g., defect rate, Cpk, number of complaints);

- Internal audits – Checking the implementation of procedures and process control;

- Feedback from the production and quality teams – Confirming the stability of the process;

- 2.

- Final Documentation and Standardization of Improvements

- The final 8D report, with a description of the problem, root cause, and implemented actions

- Updated P-FMEA and Control Plan, reflecting new risks and preventive measures

- Organizational learning by extending solutions to other processes (Read Across)

- 3.

- Team Recognition and Lessons Learned:

- Official acknowledgment at an internal meeting;

- Certificates of appreciation or symbolic awards;

- Communication within the organization via the internal newsletter, appreciation email, or internal platforms.

- 4.

- Official Closure of the 8D Analysis

- Identifies and eliminates the root cause of problems;

- Reduces costs associated with defects and repairs;

- Improves product and process quality;

- Increases customer satisfaction and organizational trust;

- Helps develop a culture based on continuous improvement.

5. Results and Discussion

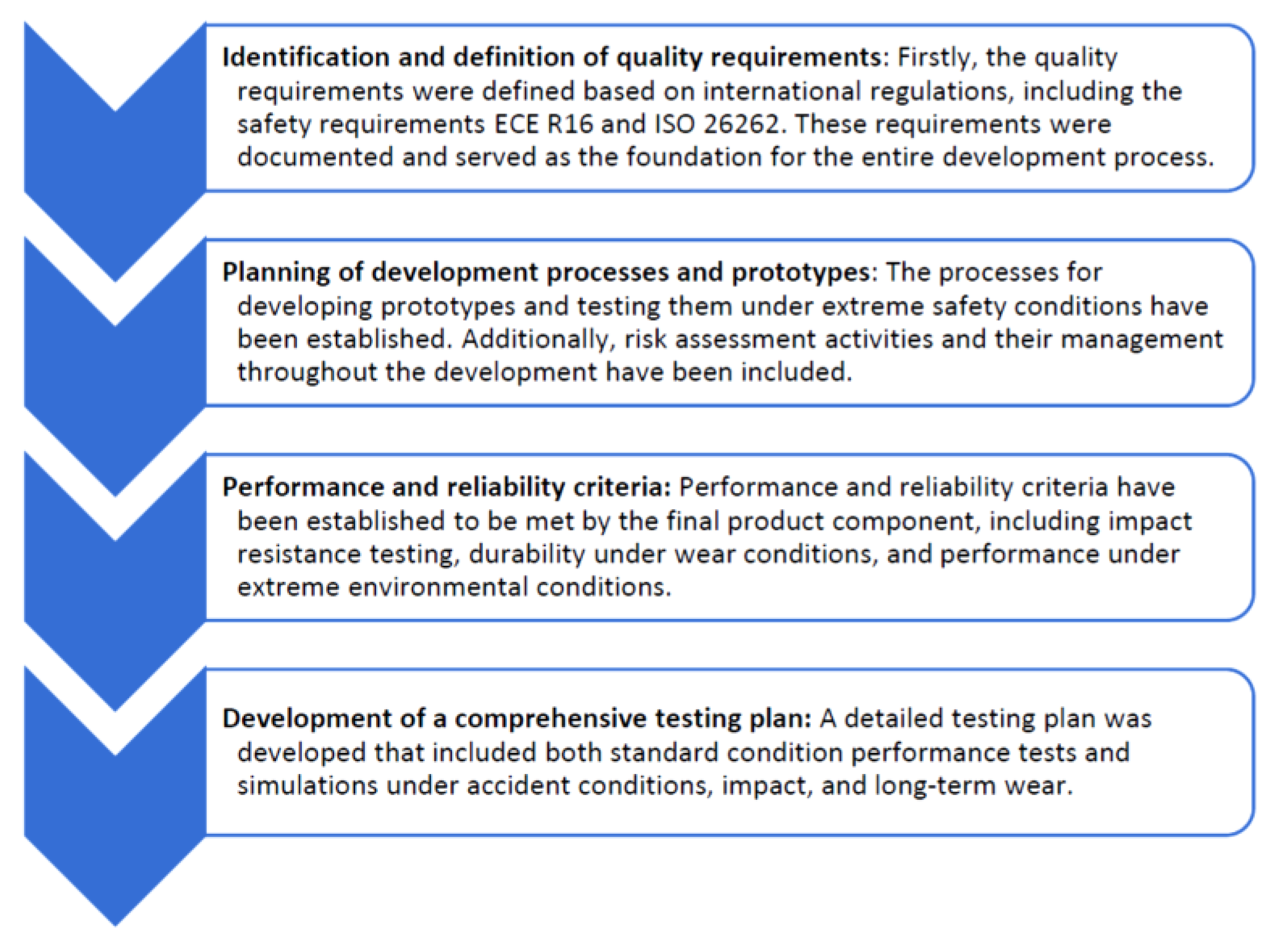

5.1. Analysis of the Implementation of Quality Planning

5.1.1. Initial Planning

5.1.2. Implementation and Monitoring

- Monitoring of impact and reliability tests: Impact tests with simulated vehicles were implemented to evaluate the behavior of the buckles under extreme conditions. All tests were recorded and analyzed to identify any deficiencies or areas needing improvement;

- Implementation of modern computer-aided manufacturing technologies (CAQ, SPC): These led to increased process capability for automotive components, including buckles, by reducing variation and optimizing process parameters;

- Virtual analysis and testing of the minimum functional force of automotive buckles: The use of multi-axial simulations and real operating conditions enabled the validation of improvements and rapid identification of potential weaknesses in the process.

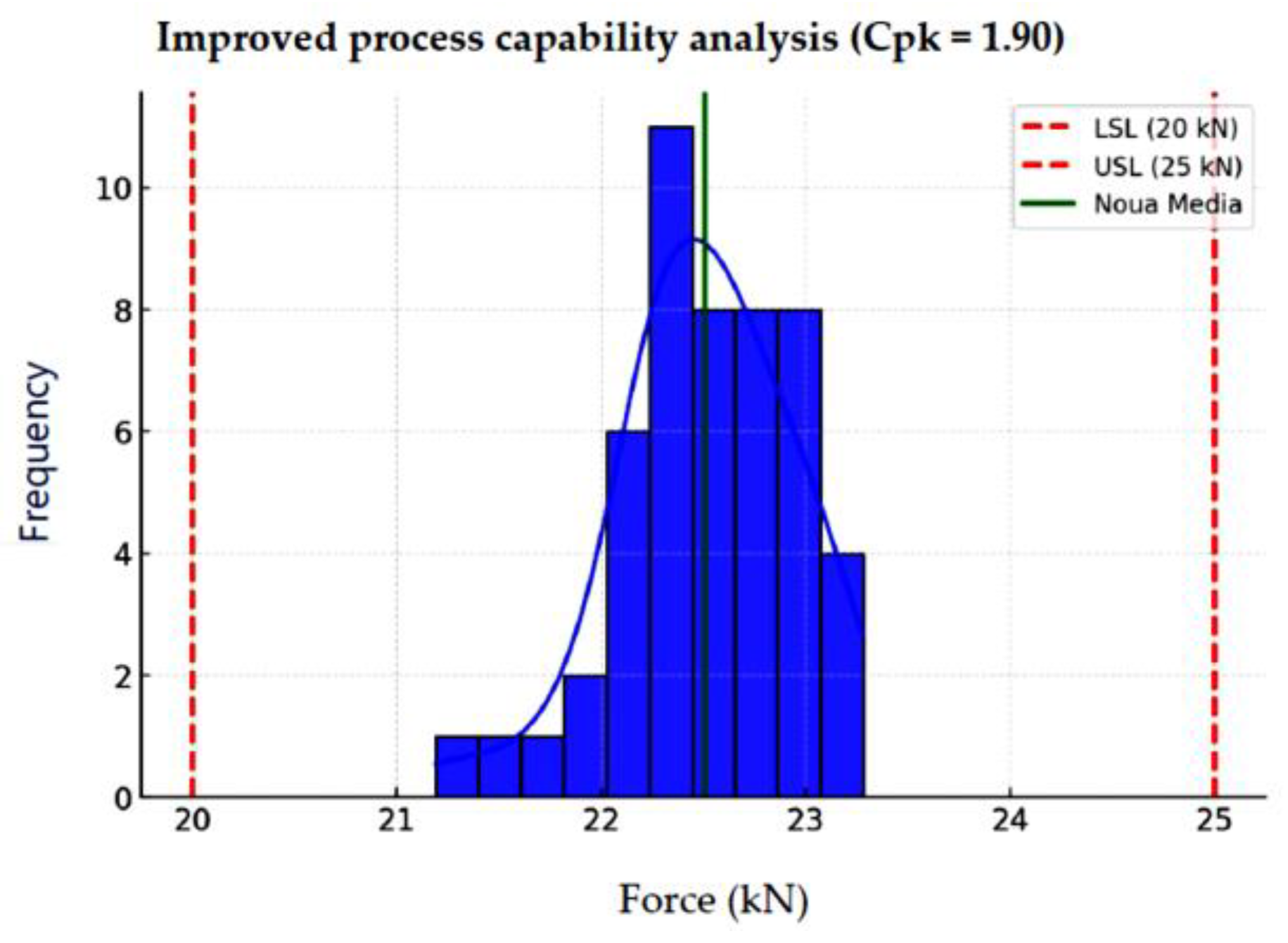

5.2. Benefits of Improved Process Capability Analysis

- Reduction of scrap/rejects and quality-related costs;

- Increased reliability and customer satisfaction;

- Continuous process improvement through monitoring and statistical feedback;

- Compliance with the strict requirements of the automotive industry and international standards (e.g., IATF 16949).

- The red line on the left (LSL - 20 kN) is the lower specification limit (LSL). The process must not produce values below this limit;

- The red line on the right (USL - 25 kN) is the upper specification limit (USL), representing the maximum acceptable value;

- The green line (the process mean) indicates the mean of the measured forces after optimization (approximately 22.5 kN), which is more centrally located with respect to the specification limits.

- Verification of electronic components: The team continuously monitored the reliability of the electronic components involved in the function of the buckle, performing periodic checks to ensure they meet safety and performance standards;

- Review and adjustment of processes: During implementation, some discrepancies arose between initial expectations and prototype performance. These differences led to a review of the manufacturing processes and adjustments to the design in order to achieve a more reliable product.

5.3. Impact of Quality Planning on Project Outcomes

5.3.1. Reduction of Risks and Defects

5.3.2. Increased Reliability and Durability

5.3.3. Cost Reduction

5.3.4. User Satisfaction

5.4. Lessons Learned and Best Practices

5.4.1. Importance of a Detailed Testing Plan

5.4.2. Close Collaboration Between Engineering and Quality Management Teams

5.4.3. Early Testing for Risk Identification

5.4.4. Adopting a Systematic Approach to Quality Management

6. Conclusions and Recommendations

6.1. Main Conclusions of the Study

- Quality Planning Ensures Long-term Project Success

- Continuous Quality Monitoring is Essential

- Integration of User Feedback is Critical

- Adopting a Global Regulatory Framework

6.2. Recommendations for Future Projects and Research

- Developing a More Adaptable Quality Planning Framework

- Encouraging Interdisciplinary Collaboration

- Investing in Continuous Staff Training

- Exploring New Technologies for Testing and Quality Validation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ciobanu M,ş,a, Ingineria Calităţii, Ed.Printech 1999.

- Tiuc, D., Drăghici, G., Pârvu, A., & Enache, B. (2015). Consideration about the Determination and Control of the Key Character-istics as Part of Planning Quality of the Product Development Process. Applied Mechanics and Materials Vols. 809-810, pg. 1269-1274. [CrossRef]

- Sanjuan, A. G., & Froese, T. (2012). The Application of Project Management Standards and Success Factors to the Development of a Project Management Assessment Tool. 26th IPMA World Congress, 91-100. [CrossRef]

- Tiuc D., & Drăghici G. (2015). Quality Project Plan Documentation Analysis in Automotive. Power Electronics and Energy Engi-neering (pg. 83-89). Lancaster: DESTECH PUBLICATIONS.

- Raţă V. Raţă D. Ciobanu M “Calitatea produselor industriale” Editura Bren Bucuresti 2002.

- Tiuc, D., & Drăghici, G. (2016). TRIZ Model Used for Complaint Management in the Automotive Product Development Process. 3th International Symposium in Management: Management During and After the Economic Crisis. 221, pg. 414–422. Procedia - Social and Behavioral Science. [CrossRef]

- C. Fragassa and A. Pavlocic (2014). Using a Total quality strategy in a new practical approach for improving the product reliabi-lity in automotive industry, International Journal for Quality Research, 8(3) 297-310, ISSN 1800-6450.

- C. A. Riesenberger and S. D. Sousa (2010). The 8D Methodology: An Effective Way to Reduce Recurrence of Customer Complaints? Proceedings of the World Congress on Engineering, Vol III, WCE 2010. iuc, D., & Drăghici, G. (2016). TRIZ Model Used for Complaint Management in the Automotive Product Development Process. 3th International Symposium in Management: Man-agement During and After the Economic Crisis. 221, pg. 414–422. Procedia - Social and Behavioral Science.

- Sharma, K.D.; Srivastava, S. Failure Mode and Effect Analysis (FMEA) Implementation: A Literature Review. Copyr. J. Adv. Res. Aeronaut. Sp. Sci. J. Adv. Res. Aero SpaceSci. 2018, 5, 2454–8669.

- https://asq.org/quality-resources/eight-disciplines-8d.

- https://www.mobile2b.com/blog/8d-methodology-guide-quality-management-eight-disciplines-problem-solving.

- https://sixsigmadsi.com/8d/.

- https://quality-one.com/8d.

- https://www.qip-journal.eu/index.php/QIP/article/download/1839/1371/8050.

- https://www.ijert.org/research/application-of-8d-methodology-for-minimizing- the-defects -in- manufacturing- process -a- case-study-IJERTV6IS090053.pdf.

- https://www.qipjournal.eu/index.php/QIP/article/view/1839/1371.

- https://www.fosunm.si/media/pdf/RUO_2012_15_Krajnc_Marjanca.pdf.

- https://automotive.upit.ro/index_files/2019/2019_5.pdf.

- https://www.sciencedirect.com/science/article/abs/pii/S2214785321038669.

- https://www.irjet.net/archives/V4/i4/IRJET-V4I4106.pdf.

- https://ca.indeed.com/career-advice/career-development/8d-problem-solving.

- https://www.ijsronline.org/issue/20230303-015555.647.pdf.

- https://www.ijsronline.org/issue/20230303-015555.647.pdf.

- www.ijirem.org/DOC/17- 8D Approach to Improve Productivity for Manufacturing Industry.

- https://www.mahle.com/media/global/purchasing/supplier-portal/8d-e-learning/manual_8d-process_en-ex.pdf.

- https://www.compliancequest.com/quality/8d-problem-solving.

- https://ro.scribd.com/document/463122686/09-L22Managementul Calitații in Industria de Automobile | PDF.

- https://bfk.ro/seminarii/automotive-core-tools-act-pentru-managementul-calitatii-in-industria-automotive/30.

- http://www.imst.pub.ro/Upload/Sesiune/ComunicariStiintifice/Lucrari_2015/06.09/09_L22.pdf.

- https://pt.scribd.com/presentation/397206139/Calitatea-Fabricatiei-Metoda-8D.

- https://ro.wikipedia.org/wiki/8D.

- https://virtualboard.ro/rezolvarea-problemelor/metoda-8d-rezolvarea-problemelor-organizationale/.

- https://docs.upb.ro/wpcontent/uploads/2022/03/TD_Rezumat-RO_DD.pdf.

- Baptista, A.; Silva, F.J.G.; Campilho, R.D.S.G.; Ferreira, S.; Pinto, G. Applying DMADV on the industrialization of updatedcom-ponents in the automotive sector: A case study. Procedia Manuf. 2020, 51, 1332–1339. [CrossRef]

- Jirasukprasert, P.; Garza-Reyes, J.A.; Kumar, M.K.; Lim, V. A Six Sigma and DMAIC Application for the Reduction of Defects in aRubber Gloves Manufacturing Process. Int. J. Lean Six Sigma 2014, 5, 2–21. [CrossRef]

- Telsang, M.T. Industrial Engineering and Production Management, 3rd ed.; S. Chand Publishing: New Delhi, India, 1998.

- Marin-Garcia, J.A.; Garcia-Sabater, J.J.; Bonavia, T. The impact of Kaizen Events on improving the performance of automotive components’ first-tier suppliers. Int. J. Automot. Technol. Manag. 2009, 9, 362–376. [CrossRef]

- E. Shevtshenko (2014). Quality improvement methodologies for continuous improvement of production processes and product quality and their evolution, 9th International DAAAM Baltic Conference Industrial Engineering 24-26 April.

- Olafsdottir, A.H.; Ingason, H.T.; Stefansson, G. Defining the variables for a dynamic model of quality management in the con-struction industry: Results from stakeholder group model-building sessions. Int. J.Prod. Qual. Manag. 2016, 19, 157. [CrossRef]

- Wu, X.; Zhao, W.; Ma, T. Improving the impact of green construction management on the quality of highway engineering projects. Sustainability 2019, 11, 1895. [CrossRef]

- Vukomanovic, M.; Radujkovic, M.; Nahod, M.M. EFQM excellence model as the TQM model of the construction industry of South-eastern Europe. J. Civ. Eng. Manag. 2014, 20, 50–81. [CrossRef]

- Watt, A. Project Management; BCampus: Victoria, BC, USA, 2014; ISBN 978-1-77420-013-1.

- C.V. Kifor (2006). Book: Quality engineering: 6 sigma improvement (Ingineria calităţii: îmbunătăţirea 6 sigma), University Lucian Blaga, ISBN 9737390350.

- Doskoˇcil, R.; Lacko, B. Risk Management and knowledge management as critical success factors of sustainability projects. Sus-tainability 2018, 10, 1438. [CrossRef]

- Kazaz, A., Birgonul, M.T. The evidence of poor quality in high rise and medium rise housing units: A case study of mass housing projects in Turkey. Building and Environment 2005, 40(11), 1548–1556. [CrossRef]

- Ljevo, Z.; Vukomanovi’c, M.; Rustempaši’c, N. Analysing significance of key quality factors for management of construction projects. Grad¯evinar 2017, 2017, 359–366. [CrossRef]

- https://careerromania.autoliv.com/locations/Romania Rovinari Seatbelts - RRS - Autoliv Romania.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).