Submitted:

26 August 2025

Posted:

28 August 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Isolation of New Yeast Strains from Local Grape Varieties

2.2. Molecular Identification of the New Strains

2.3. Technological Characterization of the New Strains

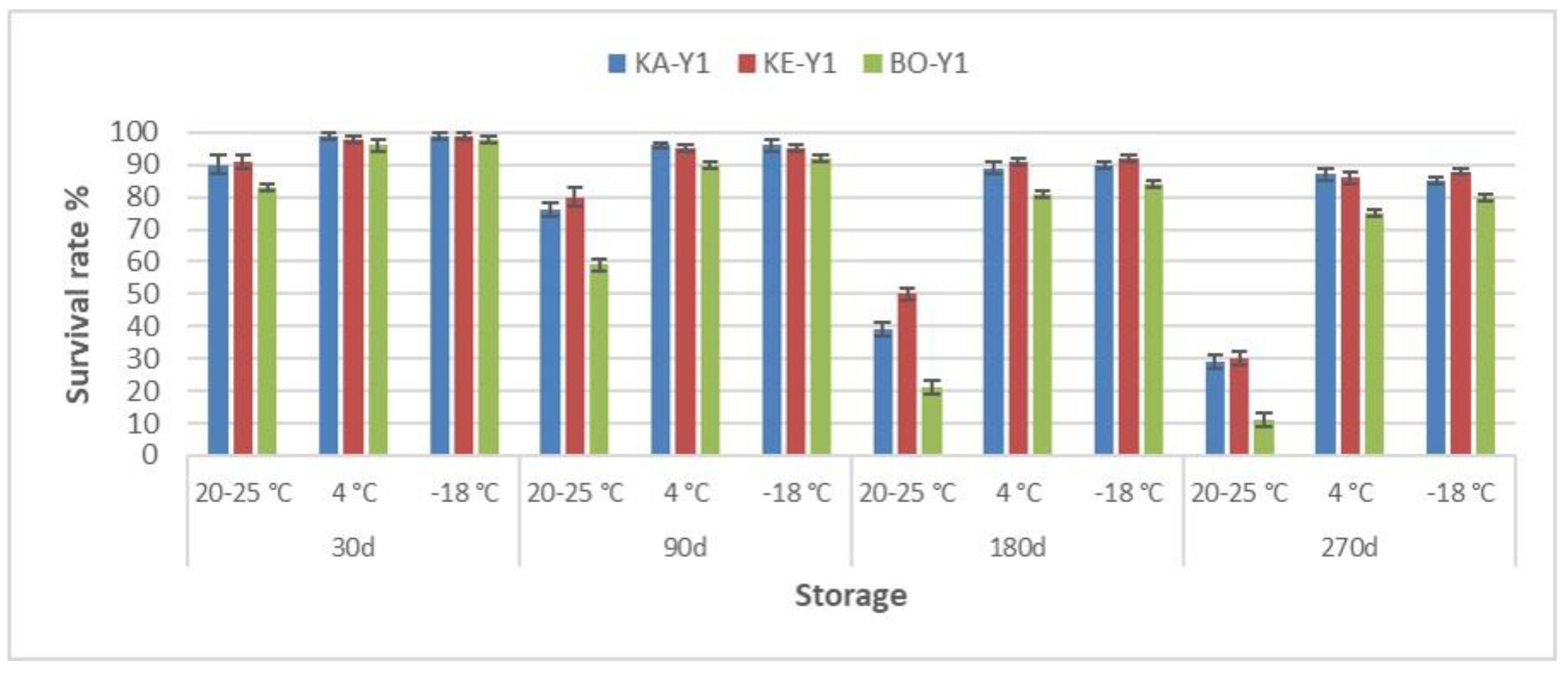

2.4. Freeze-Drying and Monitoring of Yeast Cell Viability During Storage

2.5. Fermentation Efficiency of the New Strains

2.6. Chemical and Sensory Analyses

2.6.1. pH, Total Acidity, and Volatile Acidity

2.6.2. Ε. thanol, Glycerol, Residual Sugars, and Organic Acid Content

2.6.3. Major Volatiles

2.6.4. Minor Volatiles

2.6.5. Preliminary Sensory Evaluation

2.7. Statistical Analysis

3. Results and Discussion

3.1. Yeast Strains Isolation and Characterization

3.2. Fermentations

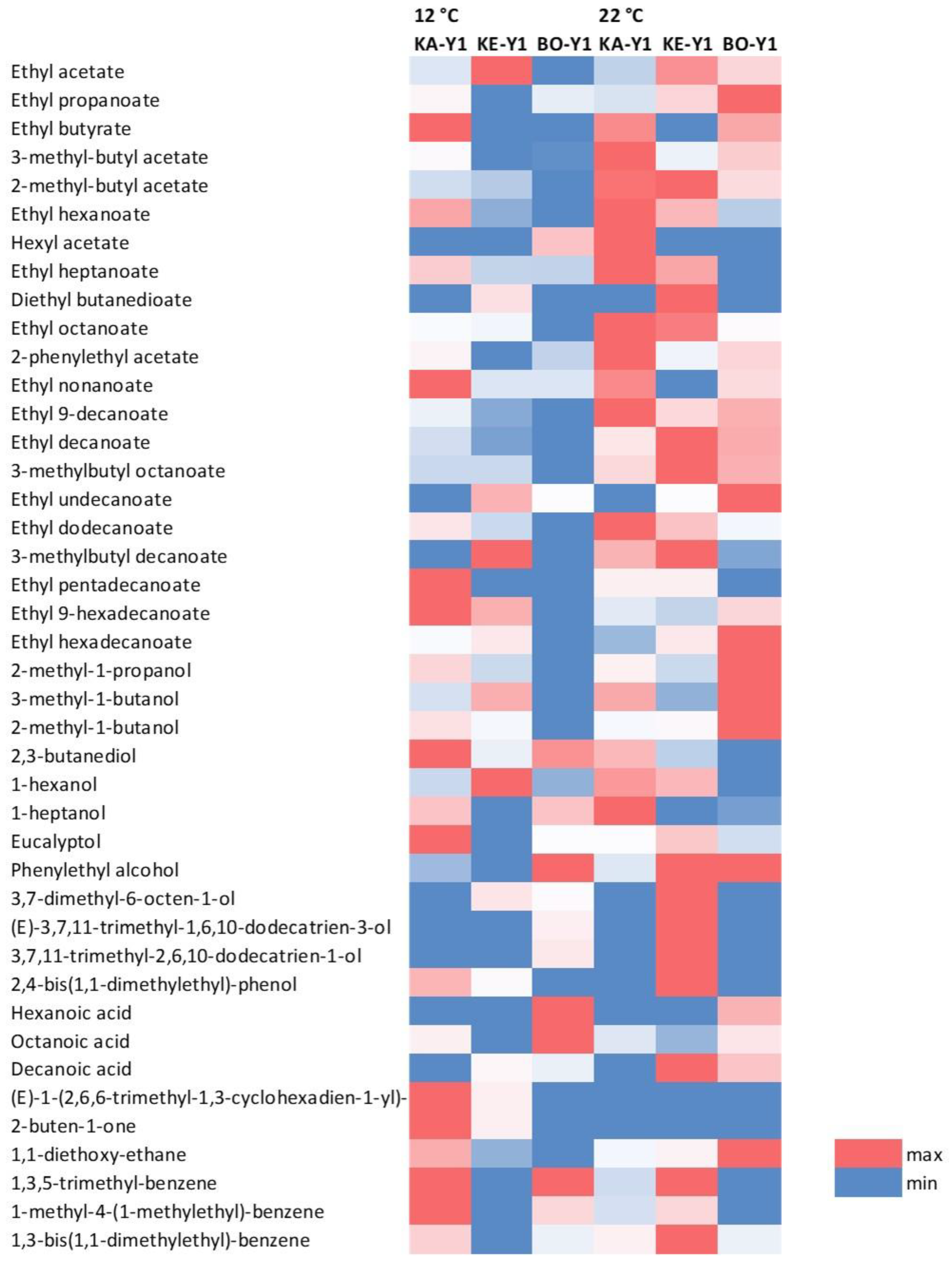

3.4.1. Major Wine Volatiles

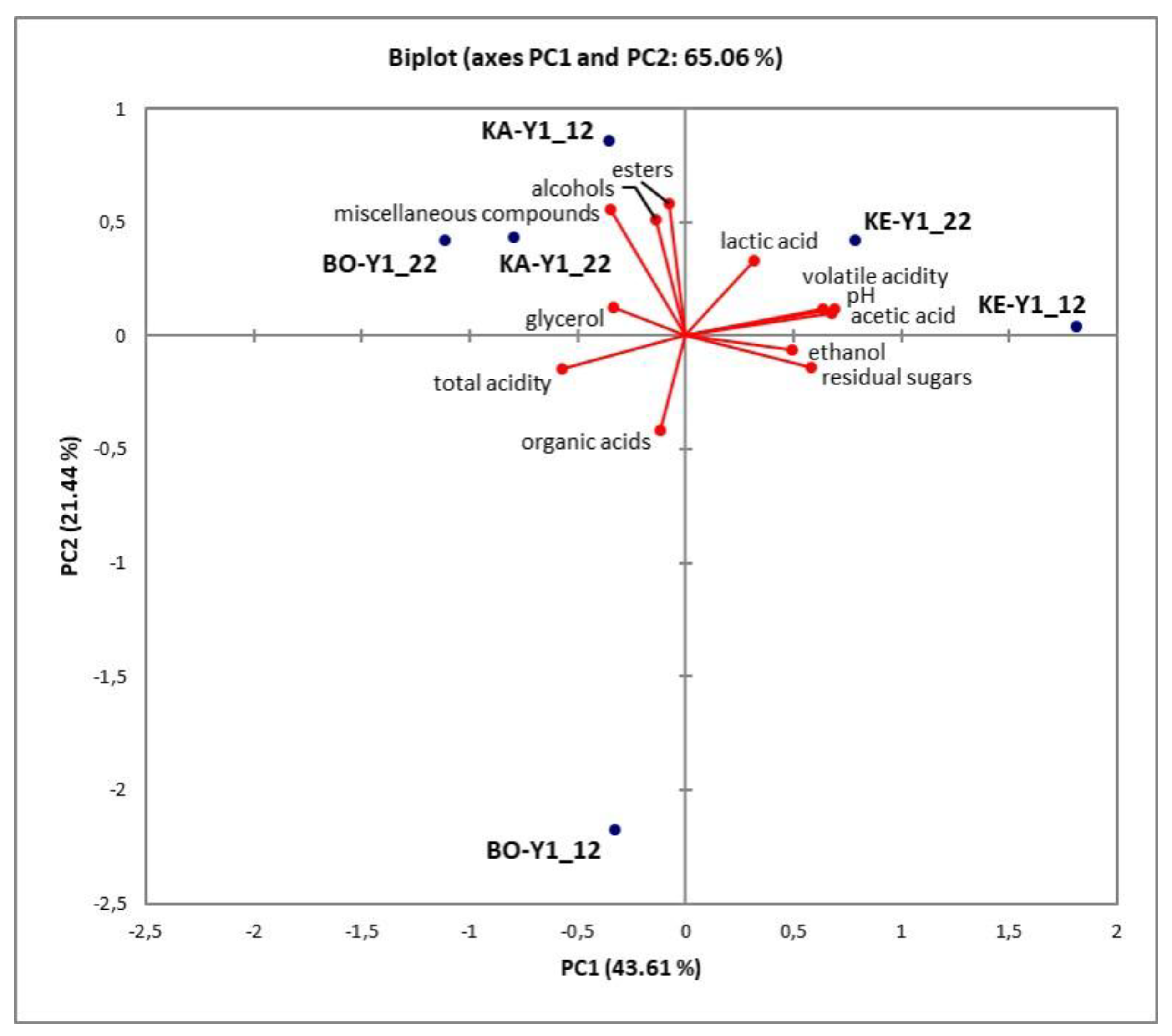

3.4.3. Chemometrics

3.5. Preliminary Sensory Evaluation

3.6. Technological Considerations and Current Limitations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fernández-Espinar, M.T.; López, V.; Ramón, D.; Bartra, E.; Querol, A. Study of the authenticity of commercial wine yeast strains by molecular techniques. Int. J. Food Microbiol. 2001, 70, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Vigentini, I.; Fracassetti, D.; Picozzi, C.; Foschino, R. Polymorphisms of Saccharomyces cerevisiae genes involved in wine production. Curr. Microbiol. 2009, 58, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Whiteley, L.E.; Rieckh, G.; Diggle, F.L.; Alaga, Z.M.; Nachbaur, E.H.; Nachbaur, W.T.; Whiteley, M. Use of commercial or indigenous yeast impacts the S. cerevisiae transcriptome during wine fermentation. Microbiol. Spectr. 2024, 12. [Google Scholar] [CrossRef] [PubMed]

- Csoma, H.; Zakany, N.; Capece, A.; Romano, P.; Sipiczki, M. Biological diversity of Saccharomyces yeasts of spontaneously fermenting wines in four wine regions: Comparative genotypic and phenotypic analysis. Int. J. Food Microbiol. 2010, 140, 239–248. [Google Scholar] [CrossRef]

- Di Maio, S.; Polizzotto, G.; Di Gangi, E.; Foresta, G.; Genna, G.; Verzera, A.; Scacco, A.; Amore, G.; Oliva, D. Biodiversity of Indigenous Saccharomyces Populations from Old Wineries of South-Eastern Sicily (Italy): Preservation and Economic Potential. PLoS ONE 2012, 7, e30428. [Google Scholar] [CrossRef]

- Kontogiannatos, D.; Troianou, V.; Dimopoulou, M.; Hatzopoulos, P.; Kotseridis, Y. Oenological Potential of Autochthonous Saccharomyces cerevisiae Yeast Strains from the Greek Varieties of Agiorgitiko and Moschofilero. Beverages 2021, 7, 27. [Google Scholar] [CrossRef]

- Capece, A.; Pietrafesa, R.; Siesto, G.; Romaniello, R.; Condelli, N.; Romano, P. Selected Indigenous Saccharomyces cerevisiae Strains as Profitable Strategy to Preserve Typical Traits of Primitivo Wine. Fermentation 2019, 5, 87. [Google Scholar] [CrossRef]

- Liu, J.; Li, R.; Li, Y.; Sun, Y. Selection of indigenous Saccharomyces cerevisiae strains with good oenological and aroma characteristics for winemaking in Ningxia China, Food Chem. : X. 2024, 23, 101693. [Google Scholar] [CrossRef]

- Berbegal, C.; Ferrer, S.; Polo, L.; Pardo, I.; García-Esparza, M.J.; Andrés, L.; Álvarez, I.; Lizama, V. Diversity of Indigenous Saccharomyces cerevisiae Yeast Strains in Cabernet Sauvignon Fermentations from Utiel-Requena Region (Spain) as a Resource to Improve Wine Distinctiveness. Fermentation 2023, 9, 654. [Google Scholar] [CrossRef]

- Costantini, A.; Cravero, M.C.; Panero, L.; Bonello, F.; Vaudano, E.; Pulcini, L.; Garcia-Moruno, E. Wine Fermentation Performance of Indigenous Saccharomyces cerevisiae and Saccharomyces paradoxus Strains Isolated in a Piedmont Vineyard. Beverages 2021, 7, 30. [Google Scholar] [CrossRef]

- Castellanos, E.; Pico, J.; Moore, J.; Dumayne, M.; Coletta, C.; Castellarin, S.; Measday, V. Suitability of indigenous Saccharomyces cerevisiae strains isolated from spontaneous fermentations as wine fermentation starter cultures in the Okanagan Valley wine region in Canada. OENO One 2025, 59. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, J.; Song, Y.; Zang, X.; Wang, G.; Pei, Y.; Song, Y.; Qin, Y.; Liu, Y. Yeast Diversity during Spontaneous Fermentations and Oenological Characterisation of Indigenous Saccharomyces cerevisiae for Potential as Wine Starter Cultures. Microorganisms 2022, 10, 1455. [Google Scholar] [CrossRef] [PubMed]

- Mas, A.; Padilla, B.; Esteve-Zarzoso, B.; Beltran, G.; Reguant, C.; Bordons, A. Taking advantage of natural biodiversity for wine making: The WILDWINE Project. Agric. Agric. Sci. Procedia 2016, 8, 4–9. [Google Scholar] [CrossRef]

- Aponte, M.; Romano, R.; Villano, C.; Blaiotta, G. Dominance of S. cerevisiae Commercial Starter Strains during Greco di Tufo and Aglianico Wine Fermentations and Evaluation of Oenological Performances of Some Indigenous/Residential Strains. Foods 2020, 9, 1549. [Google Scholar] [CrossRef]

- Zabukovec, P.; Cadez, N.; Cus, F. Isolation and Identification of Indigenous Wine Yeasts and Their Use in Alcoholic Fermentation. Food Technol. Biotechnol. 2020, 58(3), 337–347. [Google Scholar] [CrossRef]

- Biniari, K.; Stavrakaki, M. Genetic study of native grapevine varieties of Northern, Western and Central Greece with the use of ampelographic and molecular methods. Not. Bot. Horti Agrobot. 2019, 47, 46–53. [Google Scholar] [CrossRef]

- Miliordos, D.E.; Merkouropoulos, G.; Kogkou, C.; Arseniou, S.; Alatzas, A.; Proxenia, N.; Hatzopoulos, P.; Kotseridis, Y. Explore the Rare—Molecular Identification and Wine Evaluation of Two Autochthonous Greek Varieties: “Karnachalades” and “Bogialamades”. Plants 2021, 10, 1556. [Google Scholar] [CrossRef]

- Molinet, J.; Cubillos, F.A. Wild yeast for the future: Exploring the use of wild strains for wine and beer fermentation. Front. Genet. 2020, 11, 589350. [Google Scholar] [CrossRef]

- Mauriello, G.; Capece, A.; D’ Auria, M.; Garde-Cerdan, T.; Romano, P. SPME–GC method as a tool to differentiate VOC profiles in Saccharomyces cerevisiae wine yeasts. Food Microbiol. 2009, 26, 246–252. [Google Scholar] [CrossRef]

- Banilas, G.; Sgouros, G.; Nisiotou, A. Development of microsatellite markers for Lachancea thermotolerans typing and population structure of wine-associated isolates. Microbiol. Res. 2016, 193, 1–10. [Google Scholar] [CrossRef]

- Siesto, G.; Corbo, M.R.; Pietrafesa, R.; Sinigaglia, M.; Romano, P.; Bevilacqua, A. Screening of Saccharomyces and Non-Saccharomyces Wine Yeasts for Their Decarboxylase Activity of Amino Acids. Foods 2022, 11, 3587. [Google Scholar] [CrossRef] [PubMed]

- Nikolaou, A.; Sgouros, G.; Mitropoulou, G.; Santarmaki, V.; Kourkoutas, Y. Freeze-dried Immobilized Kefir Culture in Low Alcohol Wine-Making. Foods 2020, 9, 115. [Google Scholar] [CrossRef] [PubMed]

- Prapa, I.; Nikolaou, A.; Panas, P.; Tassou, C.; Kourkoutas, Y. Developing Stable Freeze-Dried Functional Ingredients Containing Wild-Type Presumptive Probiotic Strains for Food Systems. Appl. Sci. 2023, 13, 630. [Google Scholar] [CrossRef]

- Nikolaou, A.; Galanis, A.; Kanellaki, M.; Tassou, C.; Akrida-Demertzi, K.; Kourkoutas, Y. Assessment of free and immobilized kefir culture in simultaneous alcoholic and malolactic cider fermentations. LWT-Food Sci. Technol. 2017, 76, 67–78. [Google Scholar] [CrossRef]

- Nikolaou, A.; Tsakiris, A.; Kanellaki, M.; Bezirtzoglou, E.; Akrida-Demertzi, K.; Kourkoutas, Y. Wine production using free and immobilized kefir culture on natural supports. Food Chem. 2019, 272, 39–48. [Google Scholar] [CrossRef]

- Nikolaou, A.; Kourkoutas, Y. High-Temperature Semi-Dry and Sweet Low AlcoholWine-Making Using Immobilized Kefir Culture. Fermentation 2021, 7, 45. [Google Scholar] [CrossRef]

- Agarbati, A.; Comitini, F.; Ciani, M.; Canonico, L. Occurrence and Persistence of Saccharomyces cerevisiae Population in Spontaneous Fermentation and the Relation with “Winery Effect”. Microorganisms 2024, 12, 1494. [Google Scholar] [CrossRef]

- Suzuki, N.; Iwahashi, H.; Watanabe, D. Yeast diversity during the spontaneous fermentation of wine in a winery and in a laboratory. Int. J. Food Microbiol. 2024, 411, 110345. [Google Scholar] [CrossRef]

- Feng, L.; Jia, H.; Wang, J.M.; Qin, Y.; Liu, Y.L.; Song, Y.Y. Selection of indigenous Saccharomyces cerevisiae strains for winemaking in northwest China. Am. J. Enol. Vitic. 2019, 70, 115–126. [Google Scholar] [CrossRef]

- Suranská, H.; Vránová, D.; Omelková, J. Isolation, identification and characterization of regional indigenous Saccharomyces cerevisiae strains. Braz. J. Microbiol. 2016, 47, 181–190. [Google Scholar] [CrossRef]

- Swiegers, J.H.; Pretorius, I.S. Modulation of volatile sulfur compounds by wine yeast. Appl. Microbiol. Biotechnol. 2007, 74, 954–960. [Google Scholar] [CrossRef]

- Huang, C.-W.; Walker, M.E.; Fedrizzi, B.; Gardner, R.C.; Jiranek, V. Hydrogen sulfide and its roles in Saccharomyces cerevisiae in a winemaking context. FEMS Yeast Res. 2017, 17. [Google Scholar] [CrossRef]

- Hou, R.; Jelley, R.E.; van Leeuwen, K.A.; Pinu, F.R.; Fedrizzi, B.; Deed, R.C. Hydrogen Sulfide Production during Early Yeast Fermentation Correlates with Volatile Sulfur Compound Biogenesis but Not Thiol Release. FEMS Yeast Res. 2023, 23, foad031. [Google Scholar] [CrossRef]

- Sánchez-Gimeno, D.; Vela, E.; Ferreira, V.; Ontañón, I. Alternative strategies for eliminating hydrogen sulfide and methanethiol from wine: results and learnings. OENO One 2024, 58. [Google Scholar] [CrossRef]

- Bekker, M.Z.; Day, M.P.; Holt, H.; Wilkes, E.; Smith, P.A. Effect of oxygen exposure during fermentation on volatile sulfur compounds in Shiraz wine and a comparison of strategies for remediation of reductive character. Aust. J. Grape Wine Res. 2016, 22, 24–35. [Google Scholar] [CrossRef]

- Jastrzembski, J.A.; Allison, R. B.; Friedberg, E.; Sacks, G.L. Role of Elemental Sulfur in Forming Latent Precursors of H2S in Wine. J. Agric. Food Chem. 2017, 65, 10542–10549. [Google Scholar] [CrossRef] [PubMed]

- Speranza, B.; Campaniello, D.; Petruzzi, L.; Sinigaglia, M.; Corbo, M.R.; Bevilacqua, A. Preliminary characterization of yeasts from Bombino Bianco, a grape variety of Apulian Region, and selection of an isolate as a potential starter. Fermentation 2019, 5, 102. [Google Scholar] [CrossRef]

- Messenguy, F.; Dubois, E. Regulation of Arginine Metabolism in Saccharomyces cerevisiae: A Network of Specific and Pleiotropic Proteins in Response to Multiple Environmental Signals. Food Technol. Biotechnol. 2000, 38, 277–285. [Google Scholar]

- Ter Schure, E.G.; Flikweert, M.T.; van Dijken, J.P.; Pronk, J.T.; Verrips, C.T. Pyruvate decarboxylase catalyzes decarboxylation of branched-chain 2-oxo acids but is not essential for fusel alcohol production by Saccharomyces cerevisiae. Appl. Environ. Microbiol. 1998, 64, 1303–1307. [Google Scholar] [CrossRef]

- N'Guessan, F.K.; Coulibaly, H.W.; Alloue-Boraud, M.W.A.; Cot, M.; Djè, K.M. Production of freeze-dried yeast culture for the brewing of traditional sorghum beer, tchapalo. Food Sci. Nutr. 2016, 4, 34–41. [Google Scholar] [CrossRef]

- Miyamoto-Shinohara, Y.; Sukenobe, J.; Imaizumi, T.; Nakahara, T. Survival curves for microbial species stored by freeze-drying. Cryobiology 2006, 52, 27–32. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Giri, S.K. Probiotic functional foods: Survival of probiotics during processing and storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Jofré, A.; Aymerich, T.; Garriga, M. Impact of Different Cryoprotectants on the Survival of Freeze-Dried Lactobacillus Rhamnosus and Lactobacillus Casei/Paracasei during Long-Term Storage. Benef. Microbes 2015, 6, 381–386. [Google Scholar] [CrossRef] [PubMed]

- Nyanga, L.K.; Nout, M.J.; Smid, E.J.; Boekhout, T.; Zwietering, M.H. Yeasts preservation: alternatives for lyophilisation. World J. Microbiol. Biotechnol. 2012, 28, 3239–3244. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, A.S.; Silva, J.; Ho, P.; Teixeira, P.; Malcata, F.X.; Gibbs, P. Survival of freeze- dried Lactobacillus plantarum and Lactobacillus rhamnosus during storage in the presence of protectants. Biotechnol. Lett. 2002, 24, 1587–1591. [Google Scholar] [CrossRef]

- Morgan, C.A.; Herman, N.; White, P.A.; Vesey, G. Preservation of microorganisms by drying; a review. J. Microbiol. Methods 2006, 66, 183–193. [Google Scholar] [CrossRef]

- Hubalek, Z. Protectants used in the cryopreservation of microorganisms. Cryobiology 2003, 46, 205–229. [Google Scholar] [CrossRef]

- Nikolaou, A.; Nelios, G.; Kanellaki, M.; Kourkoutas, Y. Freeze-dried immobilized kefir culture in cider-making. J. Sci. Food Agric. 2020, 100, 3319–3327. [Google Scholar] [CrossRef]

- Nikolaou, A.; Mitropoulou, G.; Nelios, G.; Kourkoutas, Y. Novel Functional Grape Juices Fortified with Free or Immobilized Lacticaseibacillus rhamnosus OLXAL-1. Microorganisms 2023, 11, 646. [Google Scholar] [CrossRef]

- Hellenic National Meteorological Service. https://emy.gr/en/climatic-data?tab=statistics-tab (Accessed on July 2025).

- Jackson, R.S. Wine Science: Principles and Applications, 4th ed.; Academic Press Inc.: San Diego, CA, USA, 2014. [Google Scholar]

- Mallios, P.; Kourkoutas, Y.; Iconomopoulou, M.; Koutinas, A.A.; Psarianos, C.; Marchant, R.; Banat, I.M. Low-temperature wine-making using yeast immobilized on pear pieces. J. Sci. Food Agric. 2004, 84, 1615–1623. [Google Scholar] [CrossRef]

- Torija, M.J.; Rozès, N.; Poblet, M.; Guillamón, J.M.; Mas, A. Effects of fermentation temperature on the strain population of Saccharomyces cerevisiae. Int. J. Food Microbiol. 2003, 80, 47–53. [Google Scholar] [CrossRef]

- Gao, Y.-T.; Zhang, Y.-S.; Wen, X.; Song, X.-W.; Meng, D.; Li, B.-J.; Wang, M.-Y.; Tao, Y.-Q.; Zhao, H.; Guan, W.-Q.; Du, G. The glycerol and ethanol production kinetics in low-temperature wine fermentation using Saccharomyces cerevisiae yeast strains. Int. J. Food Sci. Technol. 2019, 54, 102–110. [Google Scholar] [CrossRef]

- Kopsahelis, N.; Bosnea, L.; Kanellaki, M.; Koutinas, A.A. Volatiles Formation from Grape Must Fermentation Using a Cryophilic and Thermotolerant Yeast. Appl. Biochem. Biotechnol. 2012, 167, 1183–1198. [Google Scholar] [CrossRef] [PubMed]

- Sipsas, V.; Kolokythas, G.; Kourkoutas, Y.; Plessas, S.; Nedovic, V.A.; Kanellaki, M. Comparative study of batch and continuous multi-stage fixed-bed tower (MFBT) bioreactor during wine-making using freeze-dried immobilized cells. J. Food Eng. 2009, 90, 495–503. [Google Scholar] [CrossRef]

- Scanes, K.T.; Hohrnann, S.; Prior, B.A. Glycerol Production by the Yeast Saccharomyces cerevisiae and its Relevance to Wine: A Review. S. Afr. J. Enol. Vitic. 1998, 19, 17–24. [Google Scholar] [CrossRef]

- Nurgel, C.; Pickering, G.J.; Inglis, D.L. Sensory and chemical characteristics of Canadian ice wines. J. Sci. Food Agric. 2004, 84, 1675–1684. [Google Scholar] [CrossRef]

- Rodicio, R.; Heinisch, J.J. Sugar metabolism in yeasts. In Biology of Microorganisms on Grapes, in Must and in Wine; König, H., Unden, G., Frölich, J., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017; pp. 189–213. [Google Scholar]

- Heras-Roger, J.; Díaz-Romero, C.; Darias-Rosales, J.; Darias-Martín, J. Organic Acids in Varietal Red Wines: Influence of Grape Cultivar, Geographical Origin, and Aging. Beverages 2025, 11, 102. [Google Scholar] [CrossRef]

- Volschenk, H.; Van Vuuren, H.; Viljoen-Bloom, M. Malic acid in wine: Origin, function and metabolism during vinification. S. Afr. J. Enol. Vitic. 2006, 27, 123–136. [Google Scholar] [CrossRef]

- Organisation International de la Vigneet du Vin. OIV-MA-AS4-01 Type IV. Microbiological Analysis of Wines and Musts Methodm, Compendium of International Methods of Analysis-OIV: Paris, France, 2010.

- Ribereau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. The microbiology of wine and vinifications. In Handbook of Enology; Wiley: Chichester, UK, 2006; Volume 1. [Google Scholar]

- Zoecklein, W.B.; Fugelsang, C.K.; Gump, H.B.; Nury, S.F. Wine analysis and production; Chapman and Hall Inc.: New York, USA, 1995. [Google Scholar]

- Cliff, M.A.; Pickering, G.J. Determination of odour detection thresholds for acetic acid and ethyl acetate in ice wine. J. Wine Res. 2006, 17, 45–52. [Google Scholar] [CrossRef]

- Arias-Pérez, I.; Sáenz-Navajas, M.P.; de-la-Fuente-Blanco, A.; Ferreira, V.; Escudero, A. Insights on the role of acetaldehyde and other aldehydes in the odour and tactile nasal perception of red wine. Food Chem. 2021, 361, 130081. [Google Scholar] [CrossRef]

- Noble, A.C.; Arnold, R.A.; Buechsenstein, J.; Leach, E.J.; Schmidt, J.O.; Stern, P.M. Modification of a standardized system of wine aroma terminology. Am. J. Enol. Vitic. 1987, 38, 143–146. [Google Scholar] [CrossRef]

- Grainger, K. Excessive Volatile Acidity and Ethyl Acetate. In Wine Faults and Flaws; John Wiley & Sons Ltd: Chichester, West Sussex, UK, 2021. [Google Scholar] [CrossRef]

- Rigou, P.; Mekoue, J.; Sieczkowski, N.; Doco, T.; Vernhet, A. Impact of industrial yeast derivative products on the modification of wine aroma compounds and sensorial profile. A review. Food Chem. 2021, 358, 129760. [Google Scholar] [CrossRef]

- Bartowsky, E.J.; Pretorius, I.S. Microbial formation and modification of flavor and off-flavor compounds in wine. In Biology of Microorganisms on Grapes, in Must and in Wine; König, H., Unden, G., Fröhlich, J., Eds.; Springer: Heidelberg/Berlin, Germany, 2009; pp. 209–231. [Google Scholar]

- Cameleyre, M.; Lytra, G.; Tempere, S.; Barbe, J.C. Olfactory Impact of Higher Alcohols on Red Wine Fruity Ester Aroma Expression in Model Solution. J. Agric. Food Chem. 2015, 63, 9777–9788. [Google Scholar] [CrossRef]

- de-la-Fuente-Blanco, A.; Sáenz-Navajas, M.P.; Ferreira, V. On the effects of higher alcohols on red wine aroma. Food Chem. 2016, 210, 107–114. [Google Scholar] [CrossRef]

- Jeromel, A.; Korenika, A.M.J.; Tomaz, I. 6—an influence of different yeast species on wine aroma composition. In Fermented Beverages; Grumezescu, A.M., Holban, A.M., Eds.; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Perestrelo, R.; Silva, C.; Gonçalves, C.; Castillo, M.; Câmara, J.S. An approach of the madeira wine chemistry. Beverages 2020, 6. [Google Scholar] [CrossRef]

- Lan, Y.B.; Xiang, X.F.; Qian, X.; Wang, J.M.; Ling, M.Q.; Zhu, B.Q.; Liu, T.; Sun, L.B.; Shi, Y. , Reynolds, A.G.; Duan, C.Q. Characterization and differentiation of key odor-active compounds of 'Beibinghong' icewine and dry wine by gas chromatography-olfactometry and aroma reconstitution. Food Chem. 2019, 287, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Sam, F.E.; Didi, D.A.; Atuna, R.A.; Amagloh, F.K.; Zhang, B. Contribution of edible flowers on the aroma profile of dealcoholized pinot noir rose wine. LWT-Food Sci. Technol. 2022, 170, 114034. [Google Scholar] [CrossRef]

- Waterhouse, A.L.; Sacks, G.L; Jeffery, D.W. Aldehydes, Ketones, and Related Compounds. In Understanding Wine Chemistry; John Wiley & Sons Ltd: Chichester, West Sussex, UK, 2016. [Google Scholar] [CrossRef]

- Januszek, M.; Satora, P.; Wajda, Ł.; Tarko, T. Saccharomyces bayanus Enhances Volatile Profile of Apple Brandies. Molecules 2020, 25, 3127. [Google Scholar] [CrossRef] [PubMed]

- Meilgaard, M.C. Effects on flavor of innovations in brewery equipment and processing: A review. J. Inst. Brew. 2001, 107, 271–286. [Google Scholar] [CrossRef]

- Rajoka, M.I.; Ferhan, M.; Khalid, A.M. Kinetics and thermodynamics of ethanol production by a thermotolerant mutant of Saccharomyces cerevisiae in a microprocessor-controlled bioreactor. Lett. Appl. Microbiol. 2005, 40, 316–321. [Google Scholar] [CrossRef]

- Etiévant, X.P. Wine. In Volatile Compounds in Foods and Beverages; Maarse, H., Ed.; Marcel Dekker: New York, NY, USA, 1991; pp. 483–533. [Google Scholar]

- Miranda-Lopez, R.; Libbey, L.M.; Watson, B.T.; McDaniel, M.R. Odor analysis of pinot noir wines from grapes of different maturities by a Gas chromatography-olfactometry technique (Osme). J. Food Sci. 1992, 57, 985–993. [Google Scholar] [CrossRef]

- Pena-Alvarez, A.; Capella, S.; Juarez, R.; Labastida, C. Determination of terpenes in tequila by solid phase microextraction-gas chromatography-mass spectrometry. J. Chromatogr. A 2006, 1134, 291–297. [Google Scholar] [CrossRef]

- Vilanova, M.; Sieiro, C. Determination of free and bound terpene compounds in Albarino wine. J. Food Compos. Anal. 2006, 19, 694–697. [Google Scholar] [CrossRef]

- Zhou, Y.; Chao, Y.; Huang, C.; Li, X.; Yi, Z.; Zhu, Z.; Yan, L.; Ding, Y.; Peng, Y.; Xie, C. Influence of Lactiplantibacillus plantarum and Saccharomyces cerevisiae Individual and Collaborative Inoculation on Flavor Characteristics of Rose Fermented Beverage. Foods 2025, 14, 1868. [Google Scholar] [CrossRef] [PubMed]

- Capone, D.L.; Van Leeuwen, K.; Taylor, D.K.; Jeffery, D.W.; Pardon, K.H.; Elsey, G.M.; Sefton, M.A. Evolution and occurrence of 1,8-cineole (eucalyptol) in Australian wine. J. Agric. Food Chem. 2011, 59, 953–959. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Arribas, M.V.; Polo, M.C. Wine Chemistry and Biochemistry; Springer: New York, NY, USA, 2009. [Google Scholar]

- Zhang, L.; Liu, Q.; Li, Y.; Liu, S.; Tu, Q.; Yuan, C. Characterization of wine volatile compounds from different regions and varieties by HS-SPME/GC-MS coupled with chemometrics. Curr. Res. Food Sci. 2022, 6, 100418. [Google Scholar] [CrossRef]

- Lopes, C.A.; Rodriguez, M.E.; Sangorrin, M.; Querol, A.; Caballero, A.C. Patagonian wines: The selection of an indigenous yeast starter. J. Ind. Microbiol. Biotechnol. 2007, 34, 539–546. [Google Scholar] [CrossRef]

- Suranska, H.; Vranova, D.; Omelkova, J. Isolation, identification and characterization of regional indigenous Saccharomyces cerevisiae strains. Braz. J. Microbiol. 2016, 47, 181–190. [Google Scholar] [CrossRef]

- Could Better Adapt to the Physicochemical Conditions and Natural Microbial Ecology of Prince Grape Must Compared with Commercial Saccharomyces cerevisiae FX10. Molecules 2022, 27, 6892. [CrossRef]

- OIV. Resolution OIV/VITI 333/2010, Definition of Vitivinicultural “TERROIR”, 2010. Available online: https://www.oiv.int/public/medias/379/viti-2010-1-en.pdf (accessed on July 2025).

- Ut, C.; Berbegal, C.; Lizama, V.; Polo, L.; García, M.J.; Andrés, L.; Pardo, I.; Álvarez, I. Isolation and characterisation of autochthonous Saccharomyces cerevisiae from ‘Pago’ Merlot wines of Utiel-Requena (Spain) Origin. Aust. J. Grape Wine Res. 2021, 28, 330–346. [Google Scholar] [CrossRef]

- Berbegal, C.; Polo, L.; Lizama, V.; Álvarez, I.; Ferrer, S.; Pardo, I.; García-Esparza, M.J. Influence of native S. cerevisiae strains on the final characteristics of “Pago” Garnacha wines from East Spain. Beverages 2023, 9, 17. [Google Scholar] [CrossRef]

- Zhou, Y.; Chao, Y.; Huang, C.; Li, X.; Yi, Z.; Zhu, Z.; Yan, L.; Ding, Y.; Peng, Y.; Xie, C. Influence of Lactiplantibacillus plantarum and Saccharomyces cerevisiae Individual and Collaborative Inoculation on Flavor Characteristics of Rose Fermented Beverage. Foods 2025, 14, 1868. [Google Scholar] [CrossRef] [PubMed]

- Nikolaou, A.; Sgouros, G.; Santarmaki, V.; Mitropoulou, G.; Kourkoutas, Y. Preliminary Evaluation of the Use of Thermally-Dried Immobilized Kefir Cells in Low Alcohol Winemaking. Appl. Sci. 2022, 12, 6176. [Google Scholar] [CrossRef]

| Grape variety | Yeast strain |

Ethanol resistance (14% vol) |

*SO2 resistance | H2S production | Decarboxylation of amino acids | |||

| Arginine | Tyrosine | Tryptophane | Leucine | |||||

| Karnachalas | ΚA-Y1 | High | 200 | High | + | + | - | - |

| ΚA-Υ3 | High | 300 | High | + | + | + | + | |

| ΚA-Υ4 | Low | 300 | High | + | + | + | + | |

| KA-YL2 | Medium | 300 | High | + | + | + | + | |

| KA-YL4 | Medium | 300 | High | + | + | + | + | |

| Keratsouda | KE-Y1 | Low | 200 | High | + | + | - | - |

| KE-Y2 | Low | 300 | High | + | + | - | + | |

| Bogialamas | BO-Y1 | Medium | 200 | Medium | + | + | + | + |

| BO-YL1 | Medium | 300 | High | + | + | + | + | |

| BO-YL2 | High | 250 | High | + | + | + | + | |

| Fermentation temperature | Yeast strain |

Fermentation time (d) |

Ethanol concentration (% vol) |

Residual sugars (g L-1) |

Ethanol productivity (g (L d)-1) | Ethanol production yield |

Conversion (%) |

Glycerol (g L-1) |

Lactic acid (g L-1) |

Acetic acid (g L-1) |

Total acidity (g tartaric L-1) |

Volatile acidity (g acetic L-1) |

pH |

| 12 °C | KA-Y1 | 21±2b | 11.9±0.5a | 17.9±1.0b | 4.5±0.1e | 0.49±0.02a,b | 91.5±0.6c | 11.0±0.8a | 2.3±0.2a | nd | 6.5±0.4b,c | 1.17±0.06c | 3.4±0.2a |

| KE-Y1 | 47±3a | 12.5±0.7a | 38.2±4.1a | 2.1±0.1f | 0.47±0.03a,b | 84.7±1.5d | 5.7±0.4c | 2.1±0.1a | 2.5±0.2a | 6.0±0.4c | 1.92±0.15b | 3.8±0.3a | |

| BO-Y1 | 19±1b,c | 12.0±0.8a | 18.4±0.9b | 5.0±0.1d | 0.49±0.02a | 91.2±0.4c | 6.8±0.5b,c | 0.3±0.1c | nd | 7.5±0.5a,b | 0.99±0.06c,d | 3.3±0.1a | |

| 22 °C | KA-Y1 | 9±0.5d | 12.0±0.5a | 4.9±0.5d | 10.5±0.1a | 0.46±0.03a,b | 97.7±0.2a | 6.8±0.6b,c | 0.3±0.1c | nd | 7.8±0.6a | 0.90±0.03d | 3.3±0.1a |

| KE-Y1 | 16±1c | 11.9±0.7a | 12.0±2.1c | 5.9±0.1c | 0.40±0.03b | 95.2±0.5b | 3.8±0.4d | 1.4±0.1b | 1.8±0.1b | 5.2±0.3c | 2.19±0.15a | 3.7±0.2a | |

| BO-Y1 | 10±0.5d | 12.0±0.5a | 7.3±06d | 9.5±0.1b | 0.47±0.03a,b | 96.5±0.2a,b | 7.0±0.5b | 0.3±0.1c | nd | 8.5±0.6a | 0.75±0.03d | 3.3±0.1a |

|

Fermentation temperature |

Yeast strain | Acetaldehyde (mg L-1) |

Ethyl acetate (mg L-1) |

1-Propanol (mg L-1) | Isobutanol (mg L-1) | 1-Hexanol (mg L-1) | Amyl alcohol (mg L-1) |

Isoamyl alcohol (mg L-1) |

Methanol (mg L-1) |

| 12 °C | KA-Y1 | 206±18a | 73±6c | 42±3c | 81±6c,d | 9±1c | 71±5c | 194±19b | 25±3a |

| KE-Y1 | 67±7d | 80±6c | 7±1d | 54±5e | 2±1d | 49±3d | 147±16c | 9±1d | |

| BO-Y1 | 121±12c | 71±8c | 75±8a | 112±10b | 8±1c | 102±9a | 251±18a | 19±2b | |

| 22 °C | KA-Y1 | 168±11b | 111±12b | 36±2c | 158±13a | 11±1b | 96±7a,b | 249±25a | 23±3a |

| KE-Y1 | 34±3e | 127±11a | 61±4b | 86±9c | 14±2a | 84±8b,c | 231±16a | 15±2c | |

| BO-Y1 | 62±4d | 31±2d | 35±4c | 64±4d,e | 2±1d | 50±5d | 104±11d | 6±1e |

|

Fermentation temperature |

Yeast strain |

Esters content (mg L-1) |

Alcohols content (mg L-1) |

Organic acids content (mg L-1) |

Carbonyl compounds content (mg L-1) |

Miscellaneous compounds content (mg L-1) |

Total volatiles (mg L-1) |

| 12 °C | KA-Y1 | 82.3b | 35.8c | 0.7c | 0.1a | 5.1a,b | 124.0b |

| KE-Y1 | 72.1b | 42.1b,c | 0.6c | <0.1b | 2.8d | 117.6b | |

| BO-Y1 | 39.2c | 12.8e | 2.1a | nd | 2.4d | 56.5c | |

| 22 °C | KA-Y1 | 106.0a | 43.7b | 0.5c | nd | 4.1c | 154.4a |

| KE-Y1 | 114.9a | 26.7d | 1.8b | nd | 4.5b,c | 147.9a | |

| BO-Y1 | 99.0a | 54.5a | 1.7b | nd | 5.4a | 160.6a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).