3.1. Chemical Composition

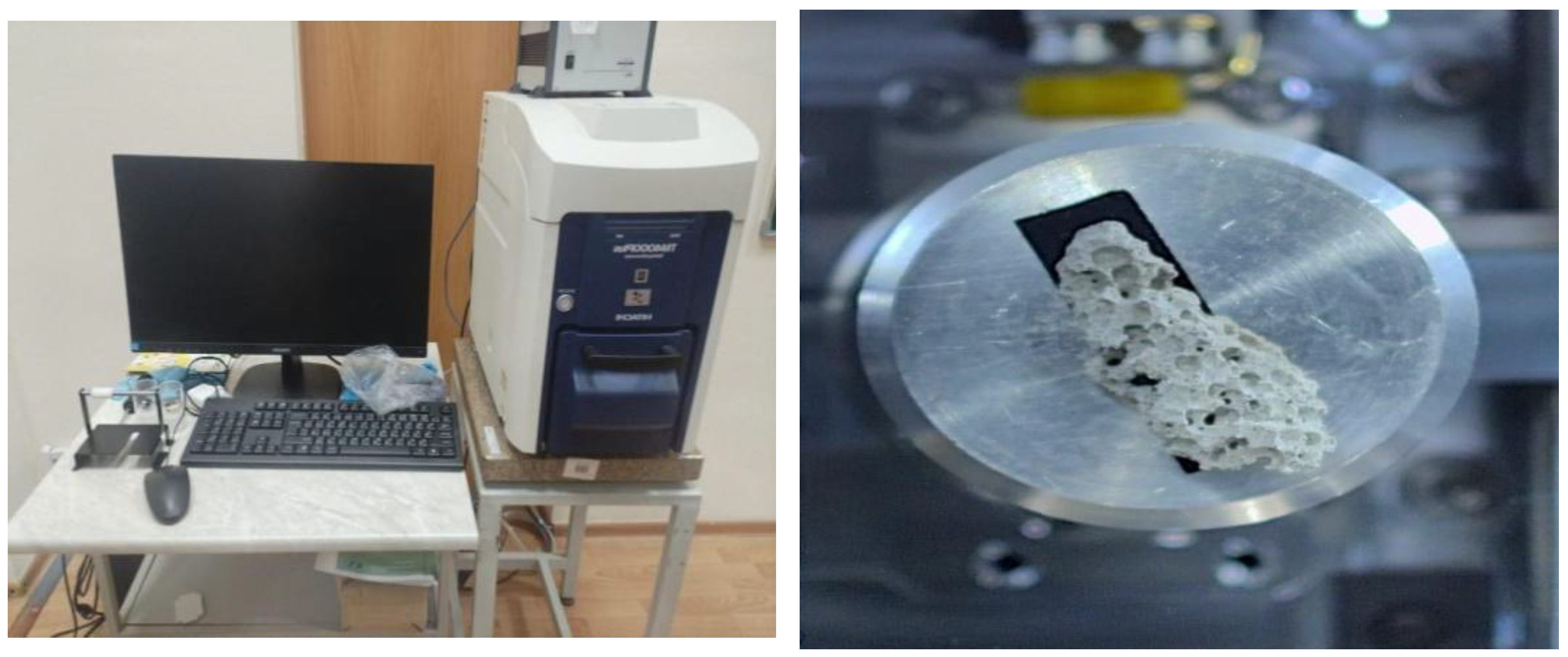

To investigate the structure formation of modified foam concrete using mineral fiber and complex modifiers to determine its structural and phase composition. In the process of studying the quality of foam concrete using mineral fiber and complex modifiers, the results of an energy dispersive X-ray spectroscope were obtained. These studies are necessary to ensure the stability and quality of foam concrete, taking into account the structural features of foam concrete and its changes during structure formation, which will eliminate all possible risks in the technological process of manufacturing the material.

Figure 6.

- Control sample of foam concrete D 400.

Figure 6.

- Control sample of foam concrete D 400.

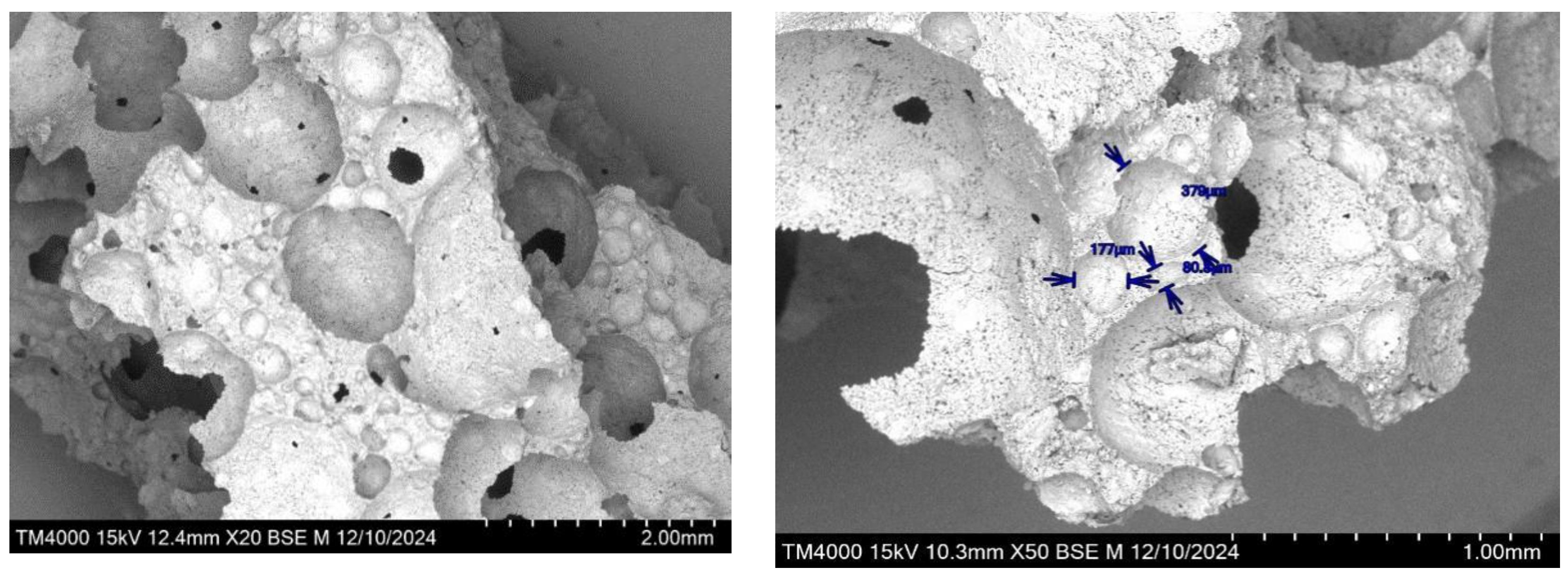

The results of the scanning electron microscope allowed us to determine the structure of the cell skeleton, its integrity and quality.

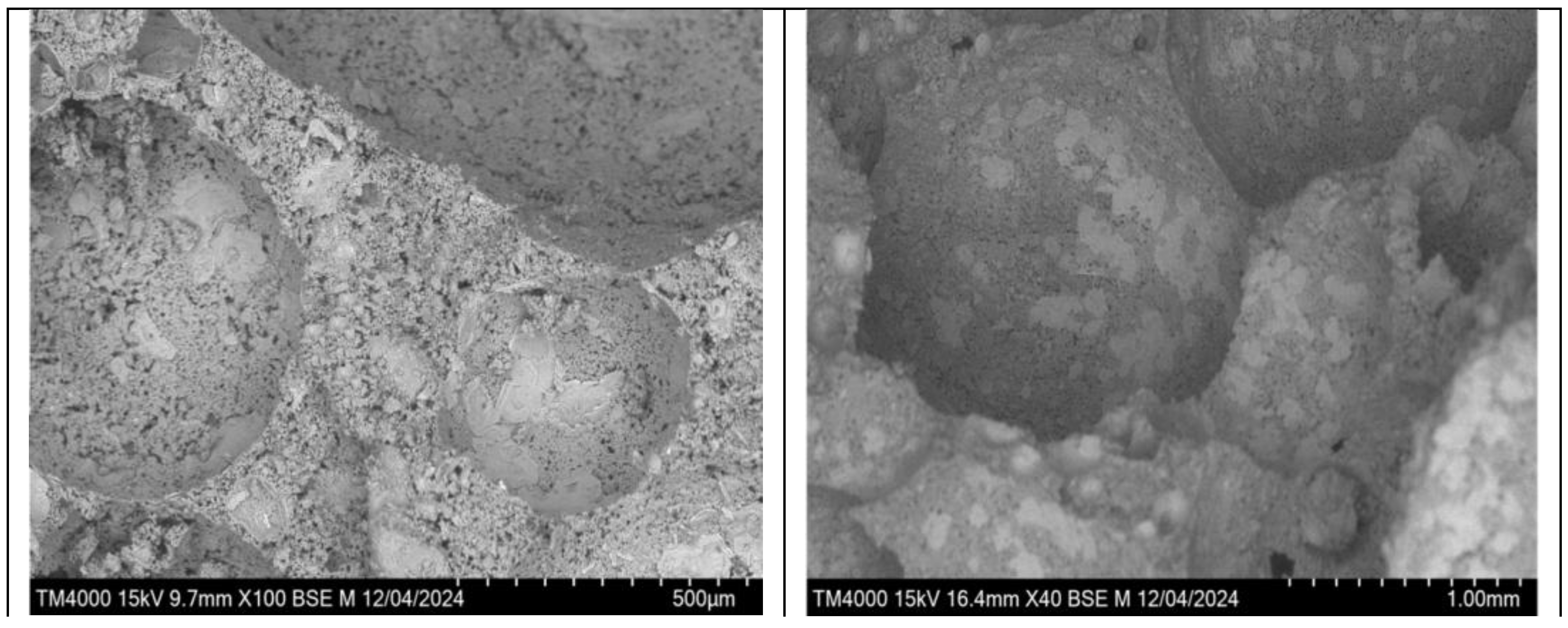

To study the structure of foam concrete, a sample with a density of 400 kg/m3 was taken. In

Figure 4, we see an uneven pore structure of foam concrete, as well as defects and cracks in larger cells that violate the integrity of the pores. These results of the scanning microscope show that during the preparation of the foam concrete solution.

-firstly, the foam is unstable and its delamination leads to the formation of uneven pores, and an increase in pores leads to an increase in the surface area of the pore walls, and as a result, the foam is unable to maintain its structure since the solution has a high load on the foam due to the large area;

-secondly, the internal stress of concrete is created after the beginning of setting and hardening, and the reason is large pores, a large area and a thin structure of the pore wall contribute to the formation of microcracks.

Thus, in order to obtain low-density thermal insulation foam concrete, it is necessary to use polymer components to reduce internal stress. The polymer component creates a film on the crack areas and thereby ensures the integrity of the pore structure. One of the important factors is the stability of the foam, and it is difficult to achieve its stability because as the foam bubble increases, its area increases and the solution affects it, thereby forming defects in the pore or destroying the pores. To reduce the pore structure and density of foam concrete, a reinforcing component is needed, since the created frame will reduce the load on the foam despite its multiplicity, thereby allowing the solution to take shape and harden.

The obtained results of modified foam concrete showed that the presence of a polymer reduces the internal stress of concrete due to an additional polymer shell on the walls and in the open spaces of the pore structure. However, the use of a polymer provides only a reduction in high blood pressure.

Figure 7.

Type 4 cell structure, foam concrete sample D 400.

Figure 7.

Type 4 cell structure, foam concrete sample D 400.

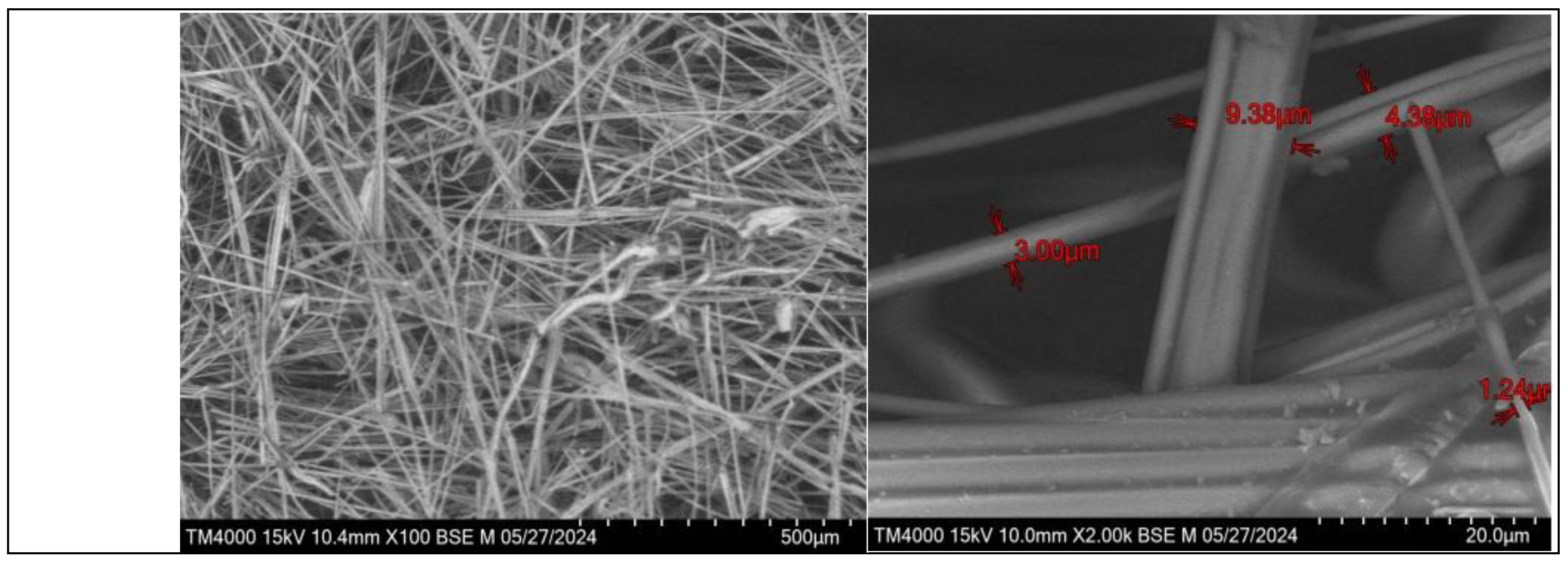

Figure 7 shows a Type 4 sample using mineral fiber and a complex modifier. According to the results of the scanning electron microscope, a cell skeleton was obtained, which had a structure without microcracks and chips, and there are no large fiber fibers in the image that violate the integrity of the cell. This study confirms that during the mixing process, the mineral fiber is destroyed, but into smaller fibers that allow the cell walls to be structured, reinforcing only them and not creating their own frame, thereby allowing the surface of the finished product to be polished after laying, eliminating the release of fibers on the surface that violate the aesthetics of the surface. Given the thickness and length of the fibers, it can be concluded that the fibers are destroyed by mixing the mixture, but during the formation of the structure, the destroyed fibers, although small, reinforce the cell structure.

Figure 6 shows mineral fiber fibers and their dimensions. The maximum fiber size is 9.38µm per minute.

Figure 8.

- Microstructure of mineral fiber.

Figure 8.

- Microstructure of mineral fiber.

Thus, the results obtained confirm that mineral fiber can significantly strengthen the walls of cells, creating the effect of their micro-reinforcement, and when using a complex modifier based on polymer components, a protective film is formed that ensures the formation of cracks and chips on the surface of the cell, thereby allowing high-quality material to be obtained.

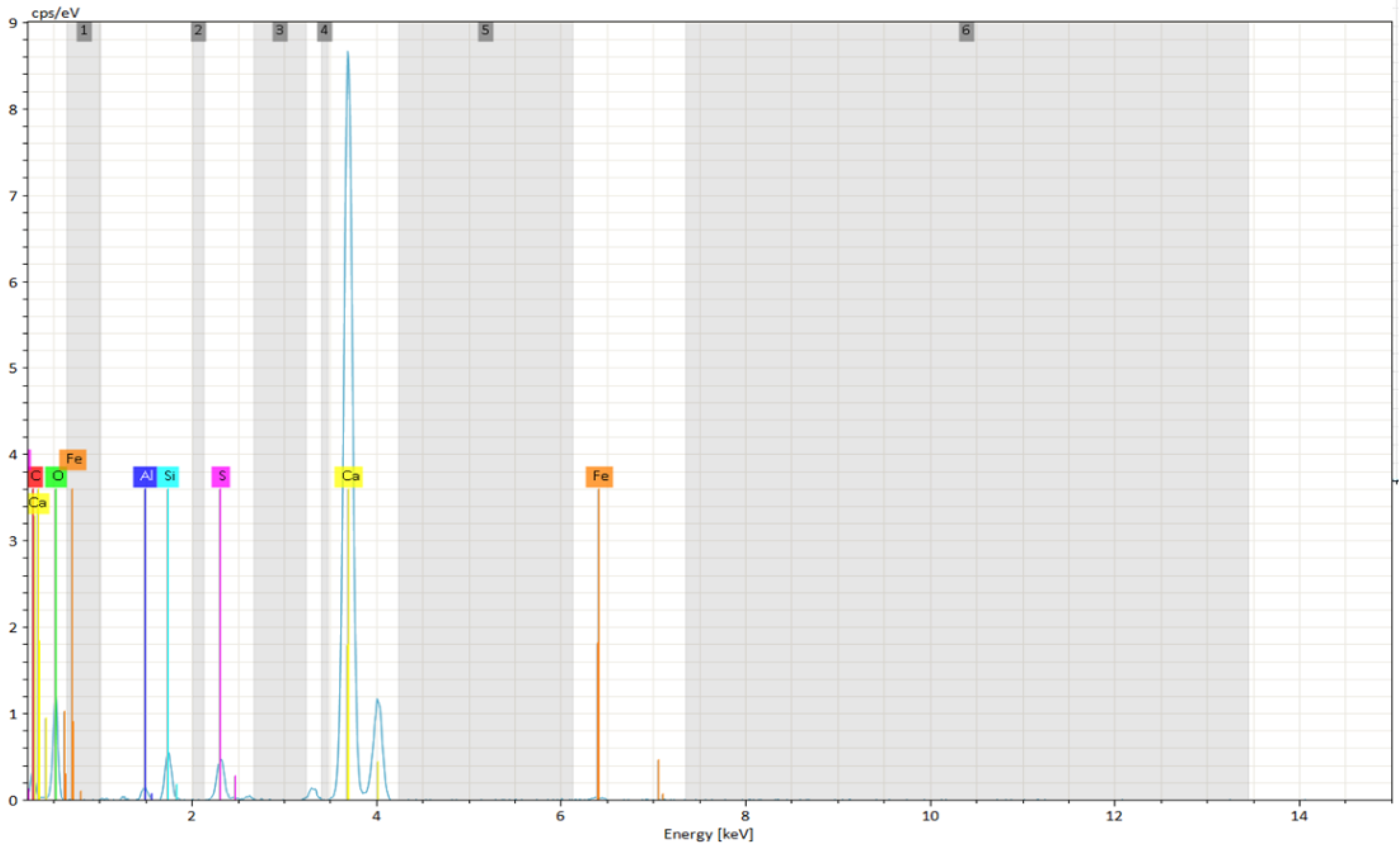

Having studied the changes in the chemical processes of hydration, we see that there are not significant changes in the quantitative parameters of the active oxides involved in the hydration process. These studies show that reinforcement of the cellular concrete wall structure with mineral fiber, as well as a complex modifier consisting of polymer components.

The presented studies show an increase in the activity of portlandite, as well as an increase in silicon in the composition of foam concrete with mineral fiber, as well as with a complex modifier.

Figure 9.

- Studies of the chemical composition of a control sample of foam concrete.

Figure 9.

- Studies of the chemical composition of a control sample of foam concrete.

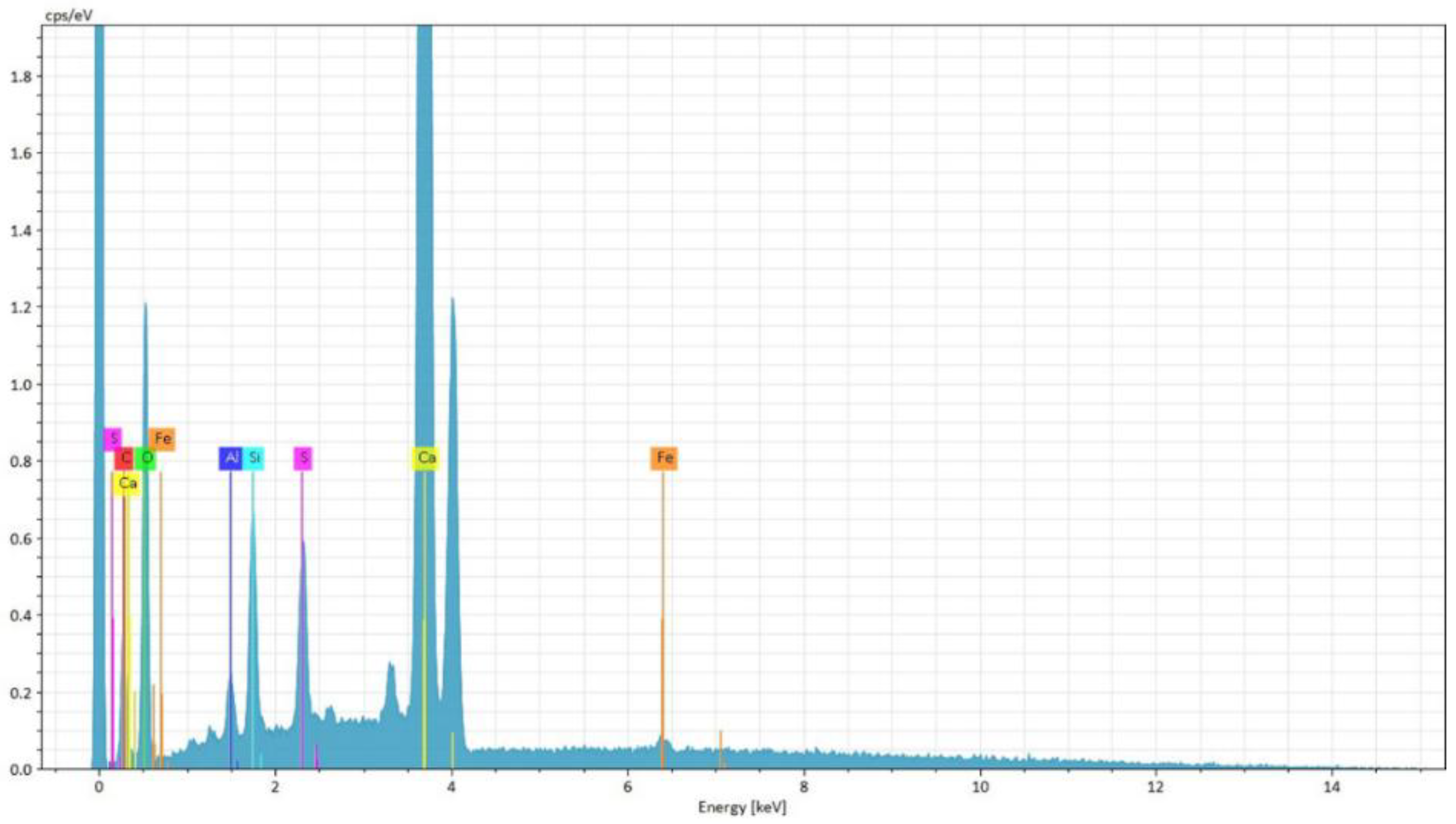

Figure 9 shows a control sample where we observe a large amount of portlandite. According to chemical analysis, the composition of calcium oxide was 93.64%, which indicates a high activity of the cement binder. However, there is also a negative side to the high activity of cement, which is the risk of high alkalinity and as a result of corrosion of the material (Peeling and cracks and chips) peeling occurs due to the migration of free lime, which promotes the movement of salts through the structure of the material, creating locations for its maximum accumulation, thereby causing corrosion processes.

Table 7.

Results of the chemical and mineralogical composition of the control sample of foam concrete.

Table 7.

Results of the chemical and mineralogical composition of the control sample of foam concrete.

| Element |

Atom [%] |

Comp. |

Sto.Norm. [%] |

| O |

52,31 |

|

|

| Si |

1,63 |

SiO2

|

3,62 |

| S |

1,33 |

SO3

|

3,92 |

| Ca |

44,05 |

CaO |

91,19 |

| Al |

0,68 |

Al2O3

|

1,28 |

Figure 10.

- Studies of the chemical composition of a control sample of foam concrete with mineral fiber, as well as with a complex modifier

Figure 10.

- Studies of the chemical composition of a control sample of foam concrete with mineral fiber, as well as with a complex modifier

Table 8.

Results of the chemical and mineralogical composition of a sample of foam concrete with mineral fiber, as well as with a complex modifier.

Table 8.

Results of the chemical and mineralogical composition of a sample of foam concrete with mineral fiber, as well as with a complex modifier.

| Element |

Atom [%] |

Comp. |

Sto.Norm. [%] |

| O |

54,12 |

|

|

| Si |

3,21 |

SiO2

|

7,31 |

| S |

2,24 |

SO3

|

6,79 |

| Ca |

38,95 |

CaO |

82,74 |

| Al |

1,11 |

Al2O3

|

2,15 |

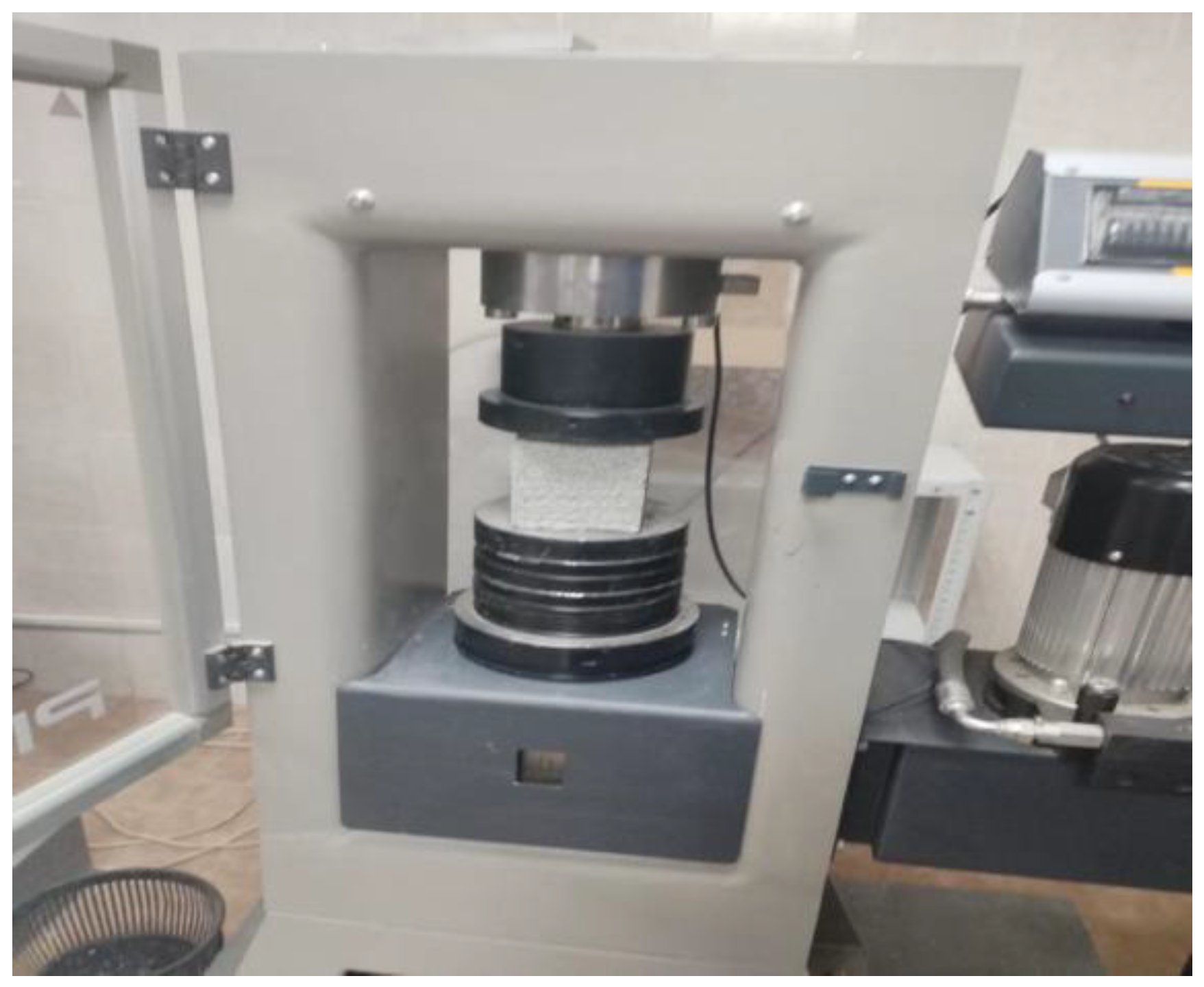

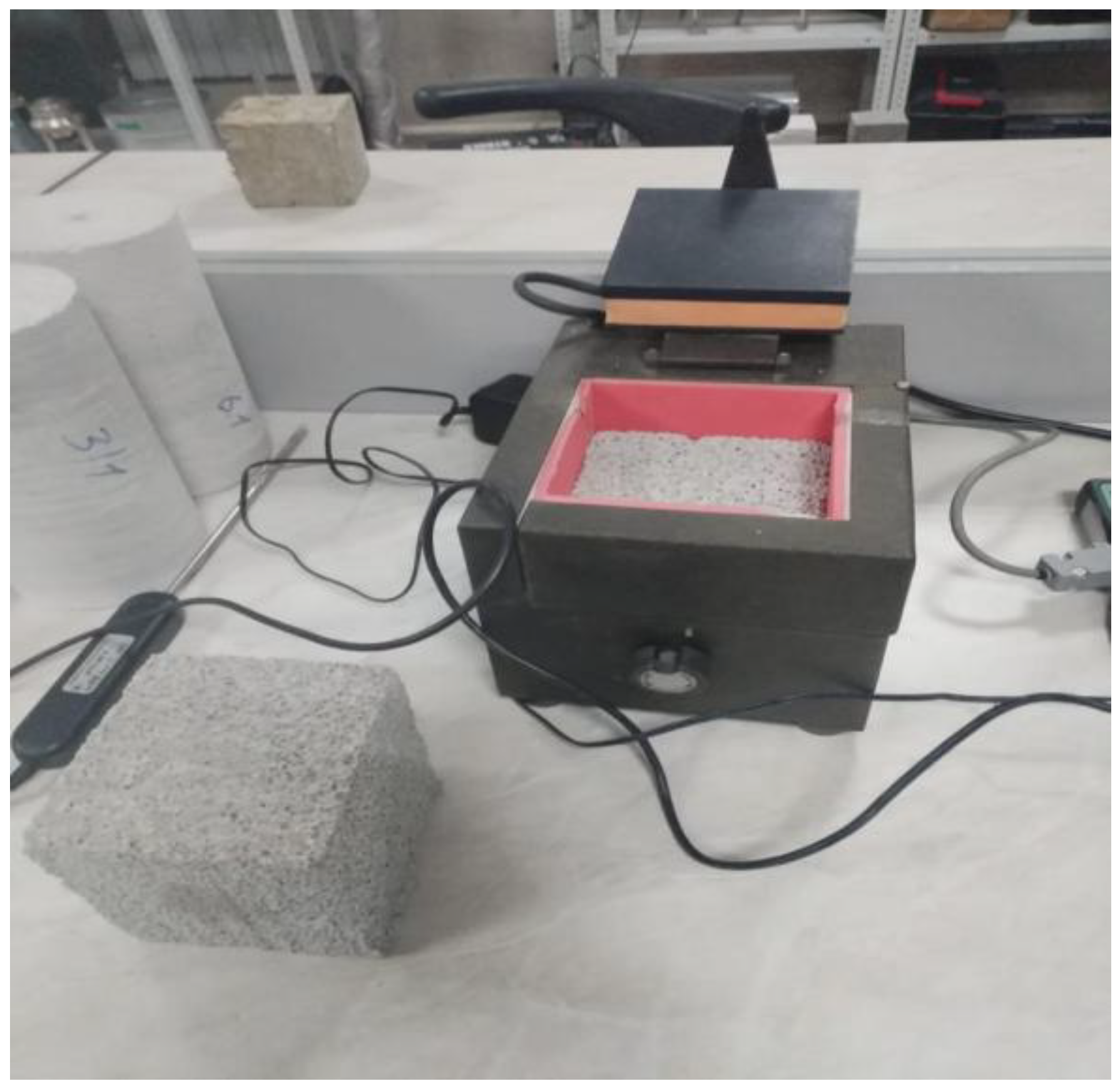

The conducted studies showed the effectiveness of the applied additives, taking into account the microstructure images, as well as the chemical and mineralogical composition can be concluded on the improvement of the structure of foam concrete. The research of physical-mechanical and construction-technical properties of foam concrete with the use of mineral fiber and complex modifiers in comparison with the control sample showed a significant difference in the improvement of foam concrete with additives and mineral fiber.

To fully analyze the effect of polymer components and mineral fiber on the property of foam concrete, thermal insulating foam concrete D 400, thermal insulating and structural foam concrete D 800 and structural foam concrete D 1100 were taken.

Table 9 shows the quality indicators of D 400 insulating foam concrete.

Table 9.

Optimal compositions of the studied structural foam concrete D 400.

Table 9.

Optimal compositions of the studied structural foam concrete D 400.

| № |

Composition |

Physical and mechanical properties of foam concrete |

| Strength MPa |

Water absorption % |

Thermal conductivity (λ), W/m °C |

Density, kg/m3 |

| 1 |

Type 1 |

1,1 |

15,5 |

0,10 |

489 |

| 2 |

Type 2 |

1,3 |

12,3 |

0,10 |

468 |

| 3 |

Type 3 |

1,8 |

13,8 |

0,09 |

405 |

| 4 |

Type 4 |

2 |

11,2 |

0,09 |

411 |

Based on the results of qualitative indicators of strength we can conclude that the greatest strength effect is achieved when using Type 4. This is due to the fact that the composition of Type 4 contains both polymeric component and mineral fiber strengthening the structure of foam concrete, which provides a framework at the time of setting and hardening of foam concrete, and the polymeric component having in its composition surfactant provides effective wetting and plasticity of the mixture and as a result of quality cell walls of foam concrete. As a result of the obtained data we see an increase in the strength of foam concrete from the control sample of type 1 by 82%. Type 3 showed an increase in strength by 64% while type 2 showed an increase in strength by 19% obtained. The results are explained by the fact that because of the instability of the frame during setting and curing caused by the presence of surfactants type 2 has not gained high strength this fact confirms and not stable density, presented in

Table 9 high density indicates the uneven distribution of density in the structure of foam concrete as there was shrinkage of the material. Similar result we see in type 1 control sample.

Low water absorption of foam concrete was also shown by the sample of type 4 by 28% lower than the control sample. This effect is explained by the fact that the integrity of the closed cell walls and the polymeric component contained in the additive provides a protective framework of the cell.

Low thermal conductivity was obtained in the samples of type 3 and 4. This result was obtained due to the stable density of the material as the main indicator of thermal conductivity is the stable density of the material over the entire tested surface according to the results of the study can be seen a decrease in thermal conductivity in the samples of type 3 and 4 by 10%.

Table 10 shows the quality indicators of D 800 insulating foam concrete.

Table 10.

Optimal compositions of the studied structural foam concrete D 800.

Table 10.

Optimal compositions of the studied structural foam concrete D 800.

| № |

Composition |

Physical and mechanical properties of foam concrete |

| Strength MPa |

Water absorption % |

Thermal conductivity (λ), W/m °C |

Density, kg/m3 |

| 1 |

Type 1 |

4,3 |

11,1 |

0,21 |

895 |

| 2 |

Type 2 |

6,1 |

8,2 |

0,21 |

836 |

| 3 |

Type 3 |

7,5 |

9,7 |

0,18 |

807 |

| 4 |

Type 4 |

7,9 |

8 |

0,18 |

802 |

Studies of physical-mechanical and construction-technical properties of heat-insulating-constructive foam concrete D 800 with the use of mineral fiber and complex modifiers in comparison with the control sample showed the following results Type 4 showed the highest quality indicators in

Table 9 shows an increase in the strength of type 4 by 85%, while type 3 showed 74%, and type 2 showed an increase in strength by 42%. The obtained results of thermal insulating and structural foam concrete in percentage ratio is higher than the results of thermal insulating foam concrete this fact is explained by the fact that the density is higher and in the process of setting and curing, by reducing the size of the cells reduces the internal stress on the walls of the cells thereby allowing effective hydration.

Water absorption of insulating and structural foam concrete showed the following result type 2 showed a 29% reduction in water absorption sample type 3 showed a result of 14% and type 4 showed a 28% reduction in water absorption.

Thermal conductivity also showed improvement in type 3 and 4 samples. The reduction of thermal conductivity from the control sample of type 1 in relation to type 3 and 4 showed 14% while the thermal conductivity of type 2 showed the same results as type 1. Also according to the results of the study we can conclude that the compliance of the actual density with the design density provides high quality of all physical and mechanical characteristics.

Table 11 shows the quality indicators of D 1100 insulating foam concrete.

Table 11.

Optimal compositions of the studied structural foam concrete D 1100.

Table 11.

Optimal compositions of the studied structural foam concrete D 1100.

| № |

Composition |

Physical and mechanical properties of foam concrete |

| Strength MPa |

Water absorption % |

Thermal conductivity (λ), W/m °C |

Density, kg/m3 |

| 1 |

Type 1 |

10 |

9,8 |

0,33 |

1170 |

| 2 |

Type 2 |

13,6 |

7,5 |

0,33 |

1138 |

| 3 |

Type 3 |

14,3 |

9 |

0,25 |

1101 |

| 4 |

Type 4 |

15,4 |

7,1 |

0,24 |

1092 |

The study of structural foam concrete D 1100 as well as heat-insulating and heat-insulating-constructive showed similar results of physical and mechanical properties maximum strength was achieved in the sample type 4 from type 1 (control) 64% strength of the sample type 3 was 43% and type 2 was 36% strength of structural foam concrete increased not significantly from the control sample this fact is due to the fact that because of the high density of cells in foam concrete is much smaller, and their walls are much thicker in contrast to the foam concrete with low density.

Water absorption of foam concrete with density 1100 type 2 with the use of complex modifier significantly decreased, because the composition contains a polymer component and amounted to 23.5%. Type 4 showed the lowest water absorption of 27.6% as the composition contained not only complex modifier, but also mineral fiber, which improved the structure of foam concrete. Type 3 showed a decrease in water absorption of only 8.2%, which is explained by the lack of complex modifier.

Thermal conductivity of the studied structural foam concrete D 1100 showed the highest results in the samples of type 4, which amounted to a decrease in thermal conductivity by 27%. Also the thermal conductivity reduction showed the sample of type 3 by 24%. The sample of type 2 showed the same results as type 1.