4. Test Results and Hysteretic Responses

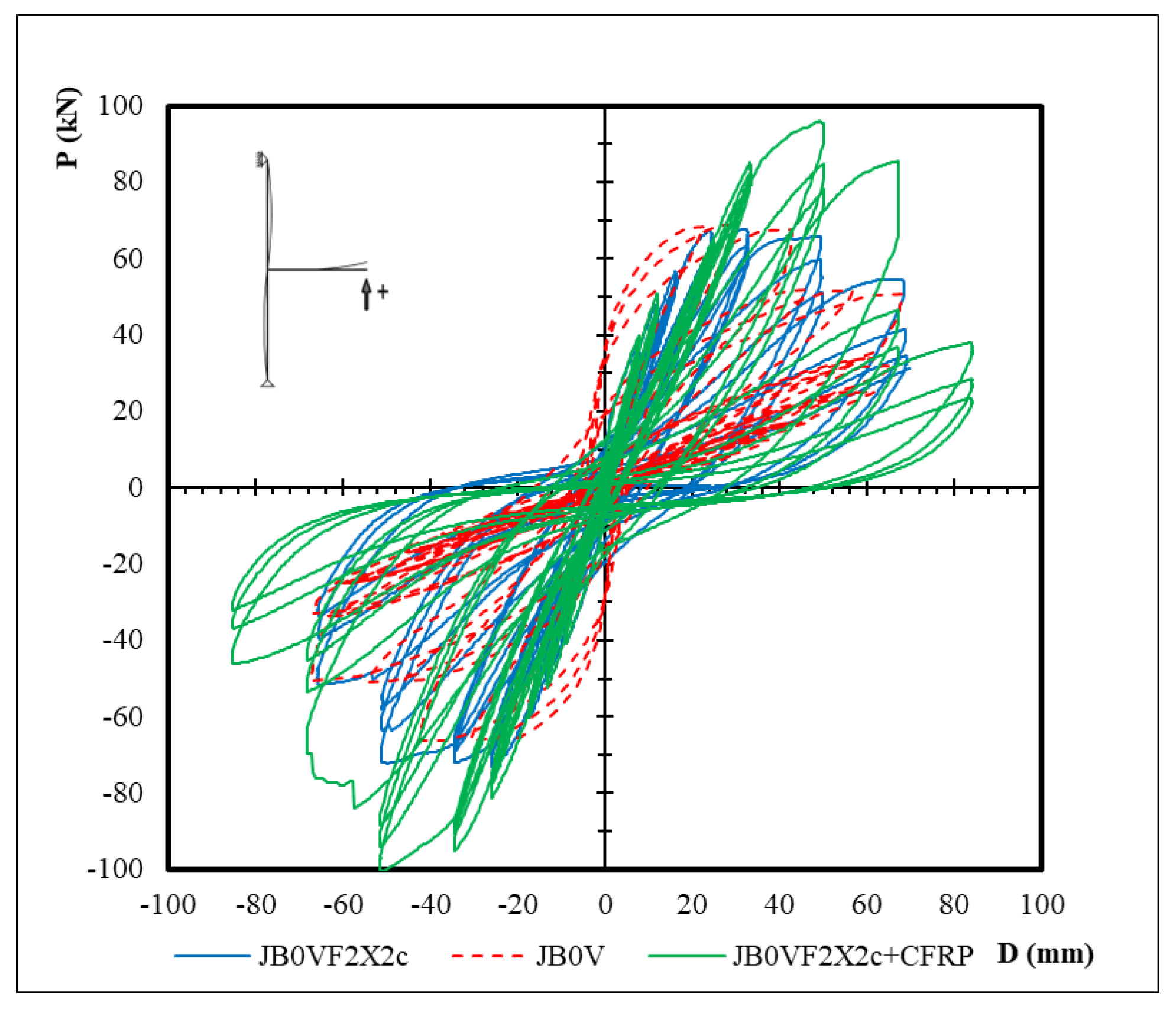

The analysis of the hysteresis curves (P–D) [

10,

18,

24], of specimens JB0V, JB0VF2X2c, and JB0VF2X2c+CFRP highlights clear distinctions in their mechanical behavior under cyclic loading, with respect to load-bearing capacity, deformability, and stiffness. A comparative assessment of the results follows:

Figure 4.

Hysteretic responses of the specimens. Comparative depiction of the pilot specimen with the corresponding retrofitted ones.

Figure 4.

Hysteretic responses of the specimens. Comparative depiction of the pilot specimen with the corresponding retrofitted ones.

The JB0V specimen, serving as the control specimen, demonstrated significantly lower load-bearing capacity, with reduced peak load (P) values in both positive and negative directions. The hysteresis loops appear narrow, indicating limited energy dissipation capability and low ductility. Furthermore, early degradation of load resistance was observed as the loading cycles progressed.

In the JB0VF2X2c specimen, which was retrofitted with X-type C-FRP ropes embedded within the joint and anchored along the column edges (one rope per corner), a significantly enhanced mechanical response was observed. The load-bearing capacity was notably higher compared to the JB0V specimen, while the hysteresis loops were wider and more effective in dissipating energy [

9]. The specimen exhibited improved deformability without abrupt strength degradation, and the resistance distribution remained consistent throughout the deformation range [

25].

The JB0VF2X2c + C-FRP specimen incorporated combined strengthening, with both X-type C-FRP ropes at the joint and vertical ropes along the column, in addition to externally bonded C-FRP sheets along the beam. This configuration resulted in optimal overall performance [

2,

19]. The highest peak loads were recorded, reaching up to ±90 kN, and the hysteresis loops were broader and denser, indicating superior energy dissipation capacity. The structural system exhibited high ductility and retained mechanical integrity under repeated seismic-type loading. Moreover, the delay in stiffness degradation further confirmed the effectiveness of the applied retrofitting scheme [

20,

23,

26].

In summary, the use of X-type C-FRP ropes (JB0VF2X2c) improved by over 40% the shear behavior compared to the unstrengthened specimen. The additional beam strengthening with externally bonded C-FRP sheets (JB0VF2X2c+CFRP) further enhanced the system’s overall capacity and deformability. The general shape of the hysteresis loops suggests that the retrofitted specimens are better suited to withstand repeated seismic actions, offering increased safety margins and reduced mechanical deterioration over time.

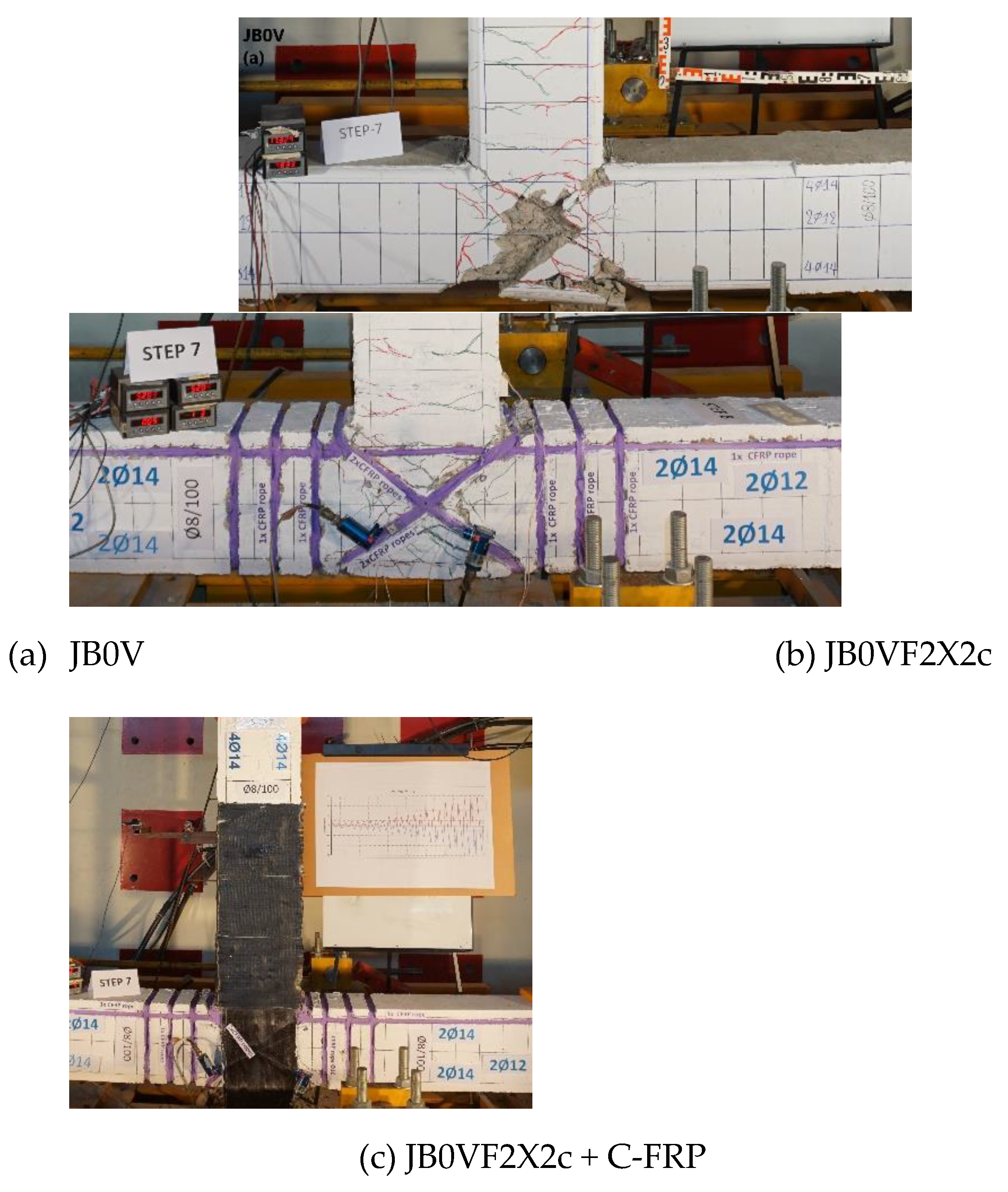

At the final loading stage (Step 7), the observed damage patterns revealed significant differences in the structural performance of the three specimens. For the reference specimen JB0V (

Figure 5a), severe material degradation was evident in the joint core, with pronounced concrete crushing and spalling. The specimen experienced complete shear failure, as indicated by irregular and discontinuous diagonal cracking across the joint region. The cracks were widespread and dense in both the beam and the joint body, signifying severe to extensive structural damage. The absence of any confinement or reinforcement mechanism led to low energy dissipation and poor ductility.

Specimen JB0VF2X2c, which was strengthened with internal X-shaped C-FRP ropes within the joint and vertical ropes along the column edges (

Figure 5b), exhibited a notably improved damage profile. Cracking was reduced and more uniformly distributed. The reinforcement configuration appeared effective in controlling the progression of shear failure. No signs of concrete crushing, material loss, or delamination were recorded. The joint maintained its integrity, and the damage level was assessed as minor to moderate.

In specimen JB0VF2X2c + C-FRP, where a combined retrofit strategy was applied—including internal C-FRP X-ropes and vertical ropes along the column, as well as externally bonded C-FRP sheets on the beam (

Figure 5c)—the structure remained largely undamaged. The surface showed no visible diagonal cracks or distress, and the element preserved its cohesion. The combined retrofit ensured excellent confinement and integrity, with the C-FRP sheet on the column significantly contributing to stiffness retention and damage suppression. The overall damage level was classified as negligible.

In conclusion, the progressive application of retrofit techniques from specimen JB0V to JB0VF2X2c + C-FRP resulted in a clear enhancement in mechanical behavior and substantial reduction in joint and beam damage. The use of X-shaped C-FRP ropes in JB0VF2X2c provided significant improvement over the unretrofitted control specimen, while the additional application of bonded C-FRP sheets on the beam in JB0VF2X2c + C-FRP led to optimum seismic performance, preserving the structural integrity even under the most demanding cyclic loading conditions. The fully retrofitted system demonstrated enhanced resilience, superior energy dissipation, and increased seismic reliability.

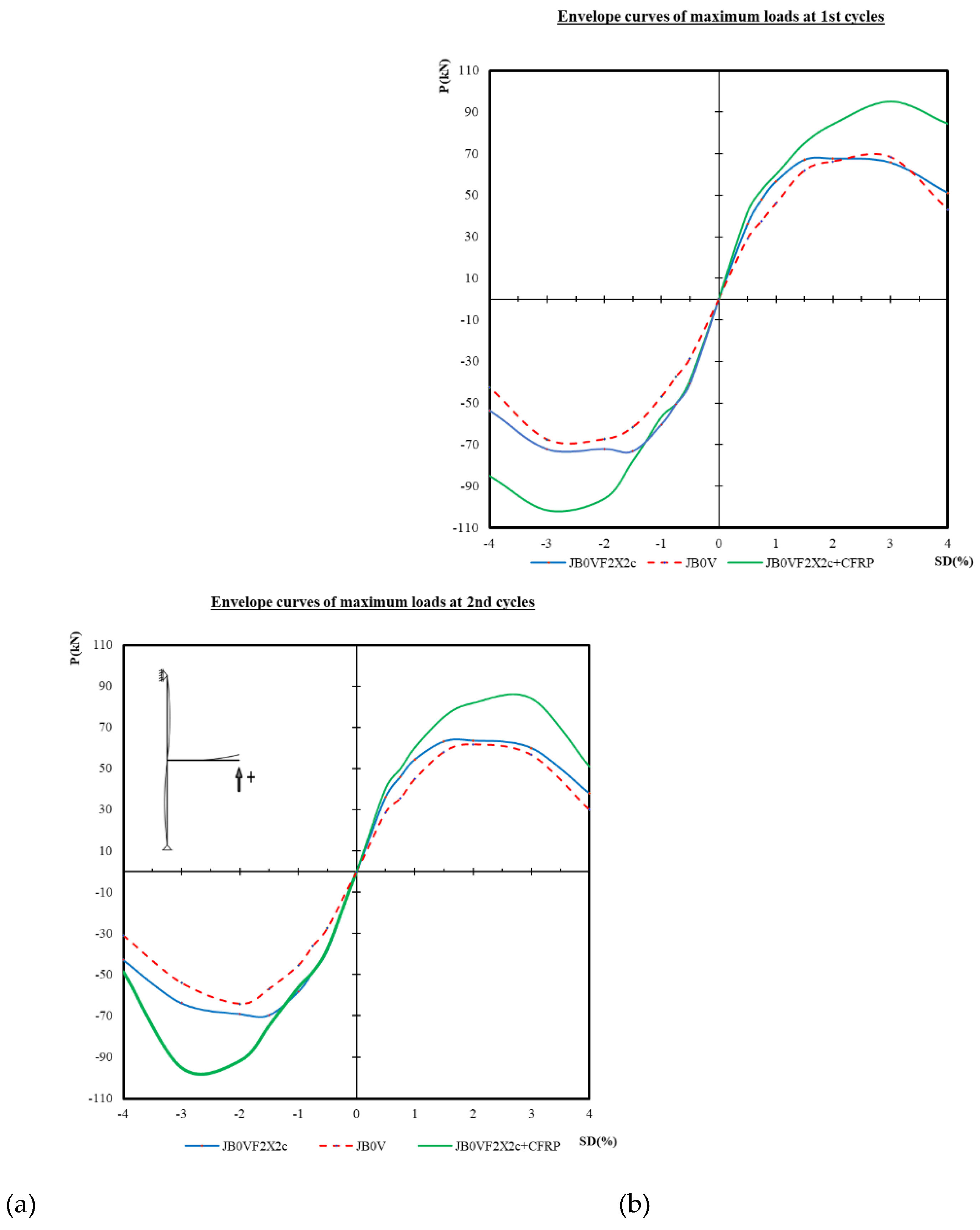

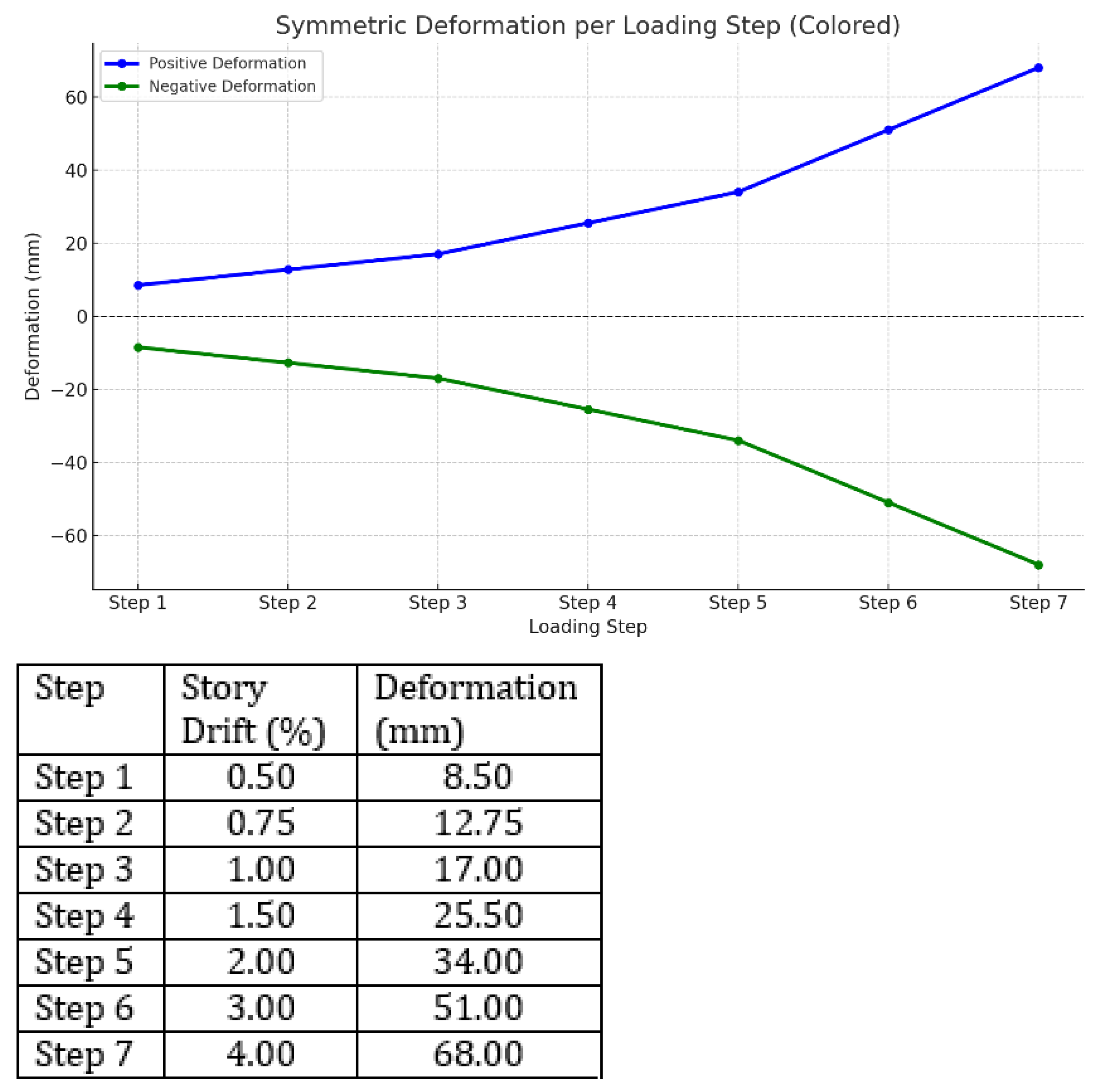

The following four diagrams illustrate the cyclic loading behavior of the specimens, presenting the maximum applied force (P) as a function of the relative displacement (Story Drift—SD). The assessment at each loading stage is summarized below:

Figure 6.

Envelope curves of the hysteretic responses. Specify: First (a), second (b), third (c), and cumulative (d) cycles, showing load vs. story drift (%) for each specimen (JB0V, JB0VF2X2c, JB0VF2X2c + C-FRP).

Figure 6.

Envelope curves of the hysteretic responses. Specify: First (a), second (b), third (c), and cumulative (d) cycles, showing load vs. story drift (%) for each specimen (JB0V, JB0VF2X2c, JB0VF2X2c + C-FRP).

The cyclic load-displacement response of the three tested specimens reveals distinct differences in structural performance, as illustrated by the evolution of their envelope curves. The fully strengthened specimen JB0VF2X2c + C-FRP consistently demonstrates the highest load-bearing capacity, achieving peak forces of approximately ±90 kN in both tension and compression, already from the first loading cycle (

Figure 6a). This highlights the substantial improvement in strength and ductility due to the combined use of X-type C-FRP rope reinforcement within the joint and external C-FRP sheets along the beam.

The JB0VF2X2c specimen, reinforced with X-type ropes only, also displays a markedly improved response compared to the unstrengthened reference specimen JB0V, particularly for story drift values exceeding 1%. In contrast, JB0V exhibits lower strength, with a premature reduction in force capacity as deformation increases, indicating limited energy dissipation and early stiffness degradation.

As the cyclic loading progresses, these trends become even more evident. In the second cycle (

Figure 6b), JB0VF2X2c+CFRP continues to perform without noticeable degradation, maintaining high resistance across the full drift range. The divergence between the envelope curves of the strengthened and unstrengthened specimens increases significantly. JB0V shows a progressive decline, particularly under negative displacements, consistent with cumulative internal damage.

During the third loading cycle (

Figure 6c), JB0VF2X2c + C-FRP preserves its dominant performance, demonstrating a high tolerance to repeated loading and effective confinement of structural deterioration. JB0VF2X2c maintains a stable load-displacement profile, while JB0V further deteriorates, with clear evidence of stiffness loss and reduced residual strength.

When examining the overall cumulative response across all cycles (

Figure 6d), the envelope curve of JB0VF2X2c + C-FRP is clearly separated from the other two, indicating superior seismic behavior. This specimen not only achieves higher peak forces but also retains its strength at large displacements, reflecting enhanced ductility and energy dissipation capacity. JB0VF2X2c also maintains consistent performance throughout the loading history. Conversely, JB0V exhibits a significantly narrower force range, rapid strength degradation, and poor hysteretic performance, confirming its unsuitability for seismic applications.

Finally, the comparative envelope analysis highlights the clear benefits of progressive strengthening. The unstrengthened specimen JB0V suffered early degradation, limited deformation capacity, and poor energy dissipation under cyclic demands, rendering it structurally vulnerable in seismic conditions.

The implementation of X-type C-FRP rope reinforcement in JB0VF2X2c led to significant gains in both load-bearing capacity and deformation tolerance.

The JB0VF2X2c + C-FRP specimen, incorporating combined strengthening of both joint and beam, delivered the most robust performance across all metrics — strength, ductility, stiffness retention, and cyclic energy dissipation.

Overall, the results confirm that C-FRP-based strengthening techniques, especially when combining internal ropes and external sheets, offer a highly effective retrofit strategy for critical RC beam-column joints, significantly improving their seismic resilience and ensuring enhanced safety for existing structures subjected to earthquake loading.

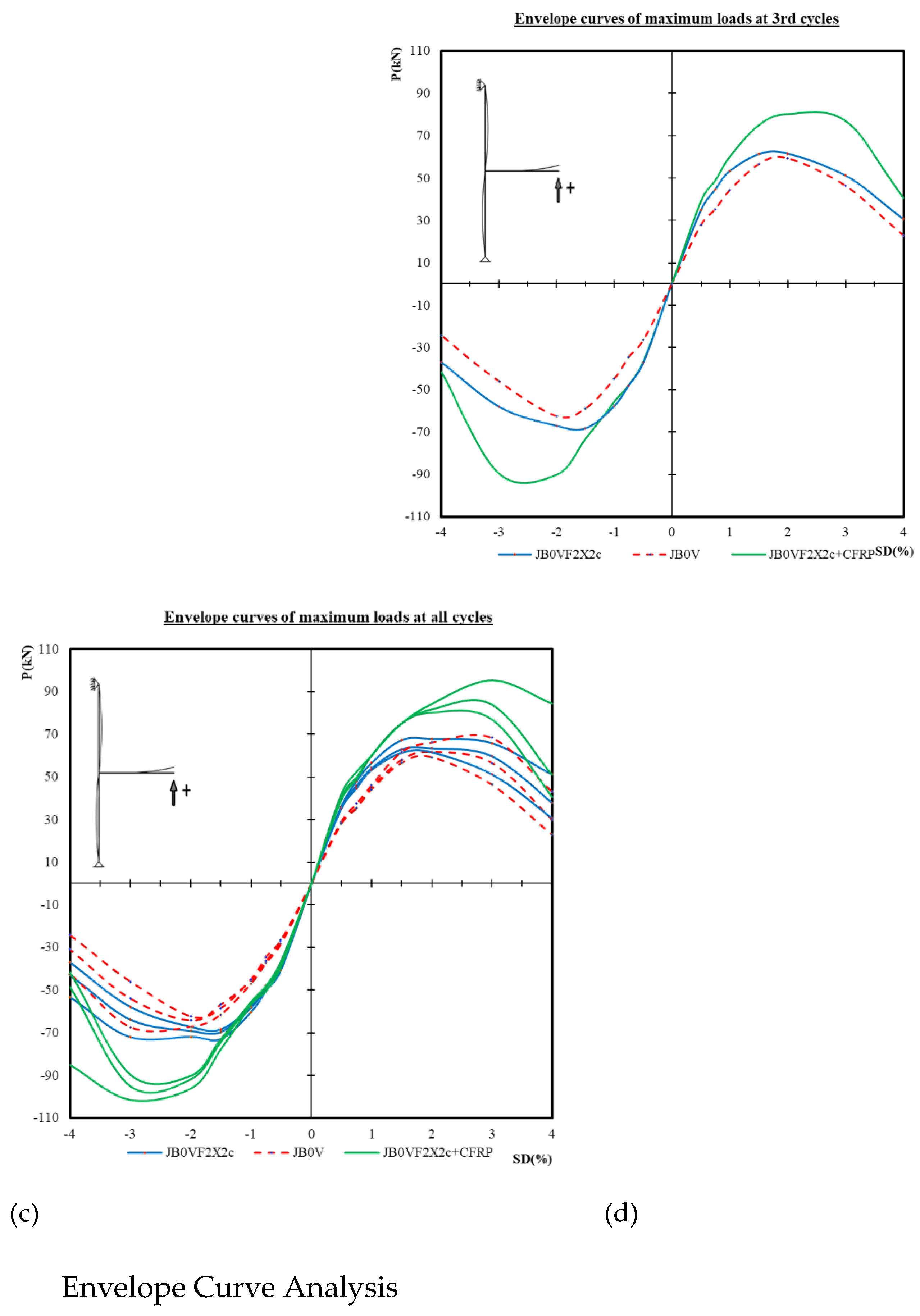

The following diagrams present the dissipated energy [

28] per loading cycle (1st, 2nd, and 3rd) as a function of the story drift ratio (SD (%)) for three specimens: JB0V, JB0VF2X2c, and JB0VF2X2c + C-FRP.

Figure 7.

Comparative dissipated energy per cycle (1st, 2nd, 3rd) as a function of story drift for each specimen.

Figure 7.

Comparative dissipated energy per cycle (1st, 2nd, 3rd) as a function of story drift for each specimen.

The analysis of the dissipated energy (E) diagrams for the first three loading cycles clearly highlights the positive effect of strengthening techniques on the energy absorption capacity of the specimens under cyclic loading. In the first cycle, specimen JB0VF2X2c + C-FRP, strengthened with C-FRP ropes on the column and C-FRP sheets on the beam, exhibits significantly superior performance, achieving the highest values of dissipated energy, particularly for deformations (SD) exceeding 2%. This specimen outperforms both the pilot specimen JB0V and JB0VF2X2c, which includes only limited reinforcement with C-FRP ropes on the column, thus demonstrating the contribution of C-FRP to the enhancement of the energy dissipation capacity [

28].

During the second cycle, an overall reduction in dissipated energy is observed, indicating the effects of cyclic loading and the gradual degradation of the mechanical properties of the specimens. Nevertheless, JB0VF2X2c + C-FRP continues to maintain a comparative advantage, especially at higher SD levels, confirming the improved durability of the strengthened section [

28].

In the third cycle, the deterioration of the specimens becomes more evident, with a further decrease in dissipated energy across all cases. Specimen JB0V shows a significant loss of energy dissipation capacity, whereas the strengthened specimens particularly JB0VF2X2c + C-FRP still absorb higher levels of energy, underscoring the role of the applied reinforcements in delaying degradation.

Overall, the use of C-FRP ropes and C-FRP sheets offers significant advantages in managing dissipated energy under seismic loading, enhancing both the stiffness and long-term durability of the section under repeated load cycles.

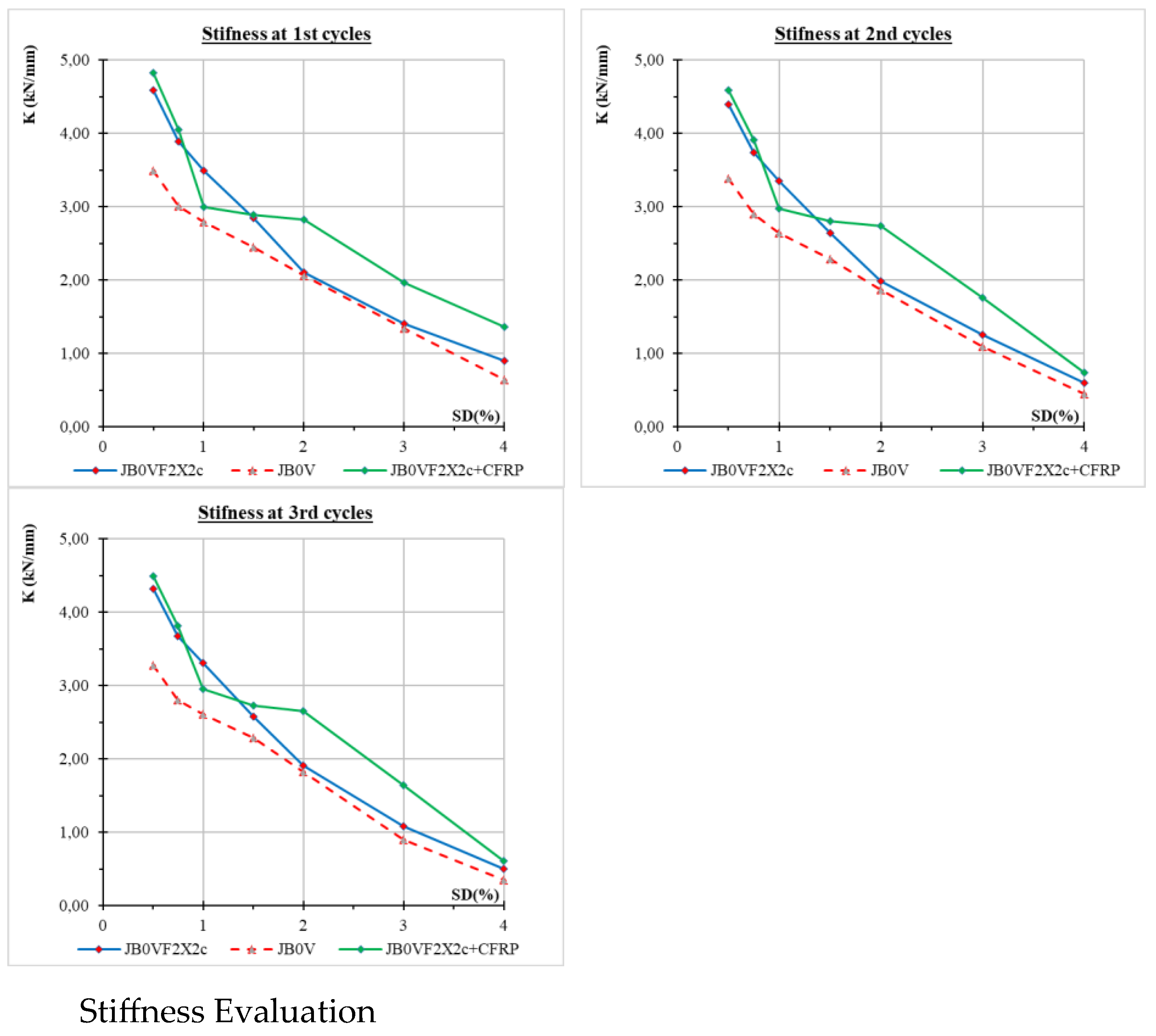

The following diagrams illustrate the variation of stiffness (K) of the specimens per loading cycle as a function of the story drift ratio (SD(%)).

Figure 8.

Stiffness (K) as a function of story drift per cycle. Comparison between pilot and strengthened specimens during 1st, 2nd, and 3rd loading cycles.

Figure 8.

Stiffness (K) as a function of story drift per cycle. Comparison between pilot and strengthened specimens during 1st, 2nd, and 3rd loading cycles.

The analysis of the stiffness (K) diagrams for the first three loading cycles reveals the gradual reduction in the stiffness of the specimens with increasing story drift ratio (SD%), a trend that is expected due to the development of cracking and the progressive degradation of mechanical properties under cyclic loading. In the first cycle, the strengthened specimen JB0VF2X2c + C-FRP, which is reinforced with C-FRP ropes on the column and C-FRP sheets on the beam, exhibits the highest initial stiffness, exceeding 4.5 kN/mm, and maintains higher values throughout the deformation range [

30]. The specimen JB0VF2X2c, which is reinforced only with C-FRP ropes on the column, shows slightly lower stiffness, while the pilot specimen JB0V consistently exhibits the lowest values, confirming the beneficial effect of the strengthening on the overall stiffness of the system.

During the second loading cycle, a further reduction in stiffness is observed across all three specimens. However, JB0VF2X2c + C-FRP retains its advantage, particularly at higher SD values. The specimen JB0VF2X2c follows with intermediate values, while JB0V continues to lag behind, recording lower stiffness values at all deformation levels. In the third cycle, degradation becomes more pronounced. The stiffness of all specimens drops significantly; nevertheless, the strengthened specimen JB0VF2X2c + C-FRP continues to demonstrate an increased ability to retain stiffness compared to the others. In contrast, JB0V exhibits nearly zero stiffness at 4% SD, indicating a complete loss of load-bearing capacity.

Overall, the use of composite C-FRP strengthening materials whether in the form of ropes or sheets contributes significantly to the increase and retention of stiffness in structural elements under cyclic loading. The application of such strengthening techniques proves particularly effective in enhancing the seismic performance and overall resilience of structures subjected to repeated loading.

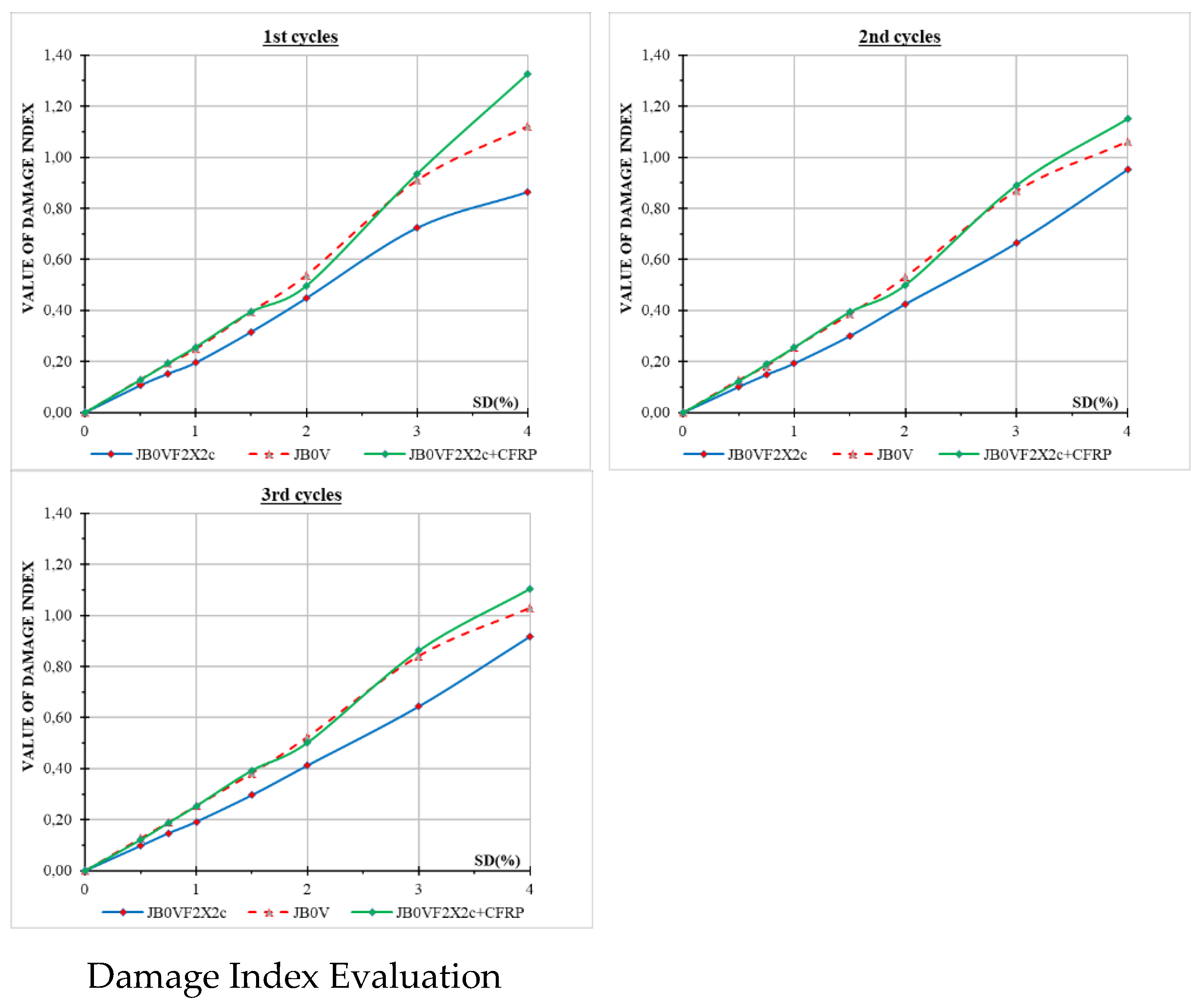

Below are the diagrams illustrating the evolution of the damage index as a function of the story drift ratio (SD%) for the first three loading cycles.

Figure 9.

Damage index evolution per cycle and per drift step for all specimens. Highlight first, second, and third loading cycles.

Figure 9.

Damage index evolution per cycle and per drift step for all specimens. Highlight first, second, and third loading cycles.

The analysis of the diagrams illustrating the evolution of the damage index in relation to the story drift ratio (SD%) over the first three loading cycles reveals the progressive deterioration of the specimens under cyclic loading. As expected, the damage index increases gradually with increasing SD across all specimens, reflecting the ongoing accumulation of damage [

27] within the cross-section.

During the first cycle, the strengthened specimen JB0VF2X2c + C-FRP exhibits the highest damage index values, particularly for drift levels exceeding 2.5%. This behavior does not indicate inferior performance, but rather corresponds to the specimen’s enhanced energy dissipation capacity, which is accompanied by more pronounced local deformations. JB0V follows with slightly lower values, while JB0VF2X2c maintains the lowest rate of increase, indicating a more uniform and controlled damage progression at this stage.

In the second cycle, damage index values rise significantly for all specimens. JB0VF2X2c + C-FRP continues to record the highest values, following the same trend as in the first cycle. JB0V approaches the CFRP-strengthened specimen, suggesting an accelerated degradation rate of its cross-section, whereas JB0VF2X2c shows a relatively more restrained increase.

By the third cycle, deterioration becomes more pronounced. The damage index for all specimens reaches values between 1.0 and 1.2, indicating severe damage. JB0VF2X2c + C-FRP continues to exhibit the highest values, possibly due to concentrated damage in localized areas, despite its superior energy dissipation and retained stiffness. JB0V follows, having reached critical damage levels, confirming the more rapid exhaustion of its load-bearing capacity. JB0VF2X2c appears to be the most “resilient” in terms of overall damage, maintaining the lowest values.

In summary, the increased damage index observed in JB0VF2X2c + C-FRP does not necessarily indicate structural failure, but rather as a consequence of the higher stress levels associated with its improved energy performance. In contrast, JB0V deteriorates more rapidly and reaches critical states earlier, emphasizing the importance of strengthening techniques in delaying damage progression.

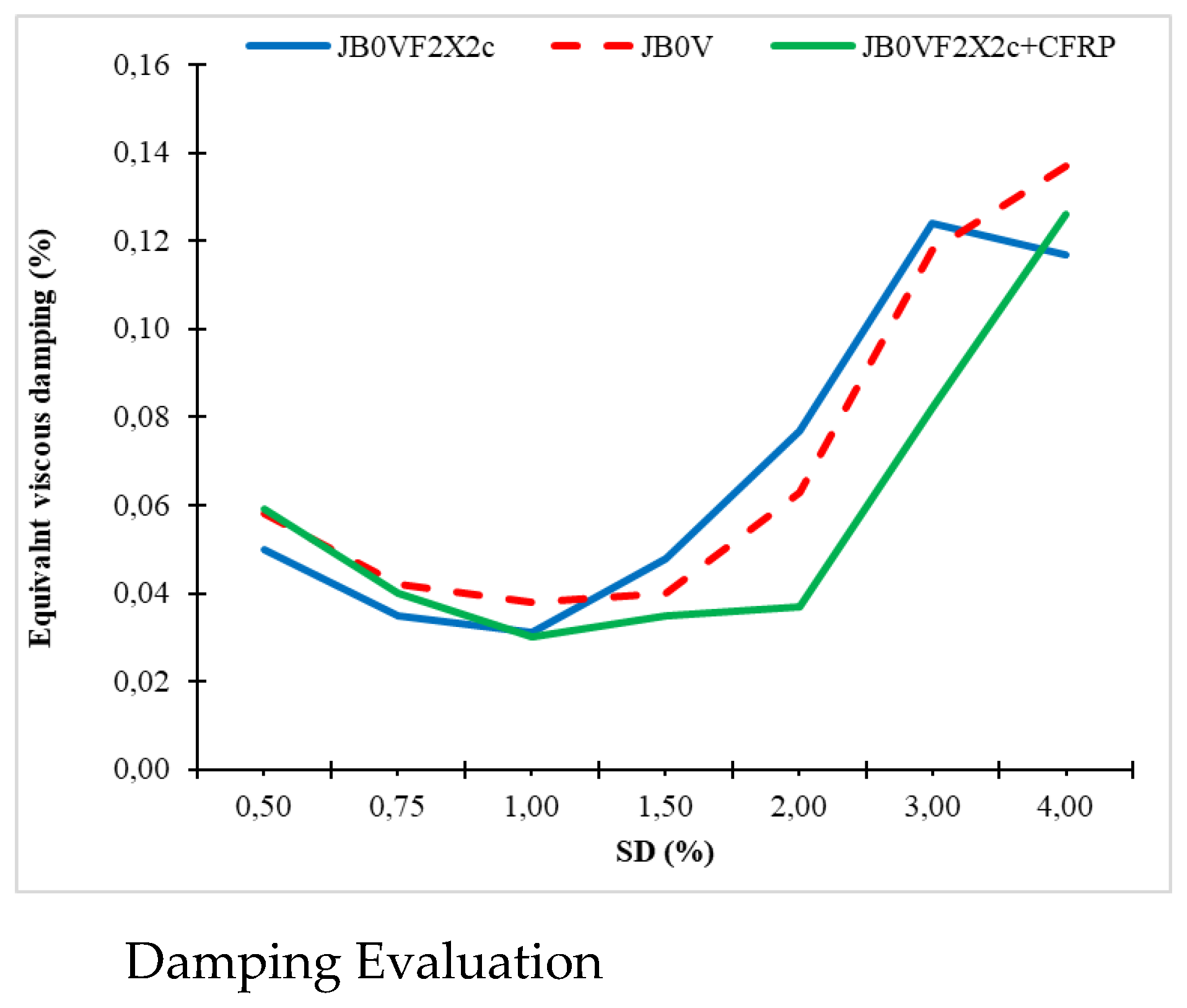

Below is the interpretation of the results from the diagram that illustrates the variation of equivalent viscous damping (%) as a function of story drift ratio (SD%) for specimens JB0V, JB0VF2X2c, and JB0VF2X2c + C-FRP.

Figure 10.

Equivalent viscous damping vs. story drift (%) for pilot and strengthened specimens (JB0V, JB0VF2X2c, JB0VF2X2c + C-FRP).

Figure 10.

Equivalent viscous damping vs. story drift (%) for pilot and strengthened specimens (JB0V, JB0VF2X2c, JB0VF2X2c + C-FRP).

The analysis of the diagram illustrating equivalent viscous damping (%) as a function of the story drift ratio (SD%) reveals the evolving behavior of the specimens in terms of their energy dissipation capacity under cyclic loading [

29]. As observed, all specimens exhibit an initial decrease in damping up to approximately 1% SD, followed by a gradual and significant increase at higher deformation levels. This phenomenon is attributed to the transition from elastic to inelastic behavior, with the progressive activation of mechanisms such as cracking, debonding, localized failures, and material friction.

The pilot specimen JB0V shows the highest equivalent damping for SD values greater than 3%, reaching up to 0.15. This is attributed to intense inelastic deformation and the early activation of failure mechanisms compared to the strengthened specimens. JB0VF2X2c, which includes strengthening only at the column, displays slightly lower damping within the same deformation range, maintaining higher stiffness and therefore exhibiting more limited inelasticity.

In contrast, the fully strengthened specimen JB0VF2X2c + C-FRP, which is reinforced both at the column and the beam, presents the lowest damping values up to 2.5% SD. This behavior suggests a delayed activation of inelastic mechanisms due to its increased initial stiffness. However, beyond this threshold, damping rises sharply, reaching levels comparable to those of the other specimens at 4% SD. This indicates the specimen’s ability to sustain elastic behavior over a broader loading range before entering into significant nonlinearity.

In summary, the diagram highlights the differentiated response of the specimens in terms of energy dissipation. JB0V absorbs more energy through uncontrolled damage, whereas JB0VF2X2c + C-FRP achieves high damping at larger deformation levels in a more controlled manner. The use of C-FRP ropes and sheets appears to delay the onset of severe inelastic phenomena, preserving the structural integrity of the section during the early stages of loading an outcome that significantly enhances both the seismic response and the overall resilience of the structure.