Submitted:

04 January 2024

Posted:

04 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental testing program

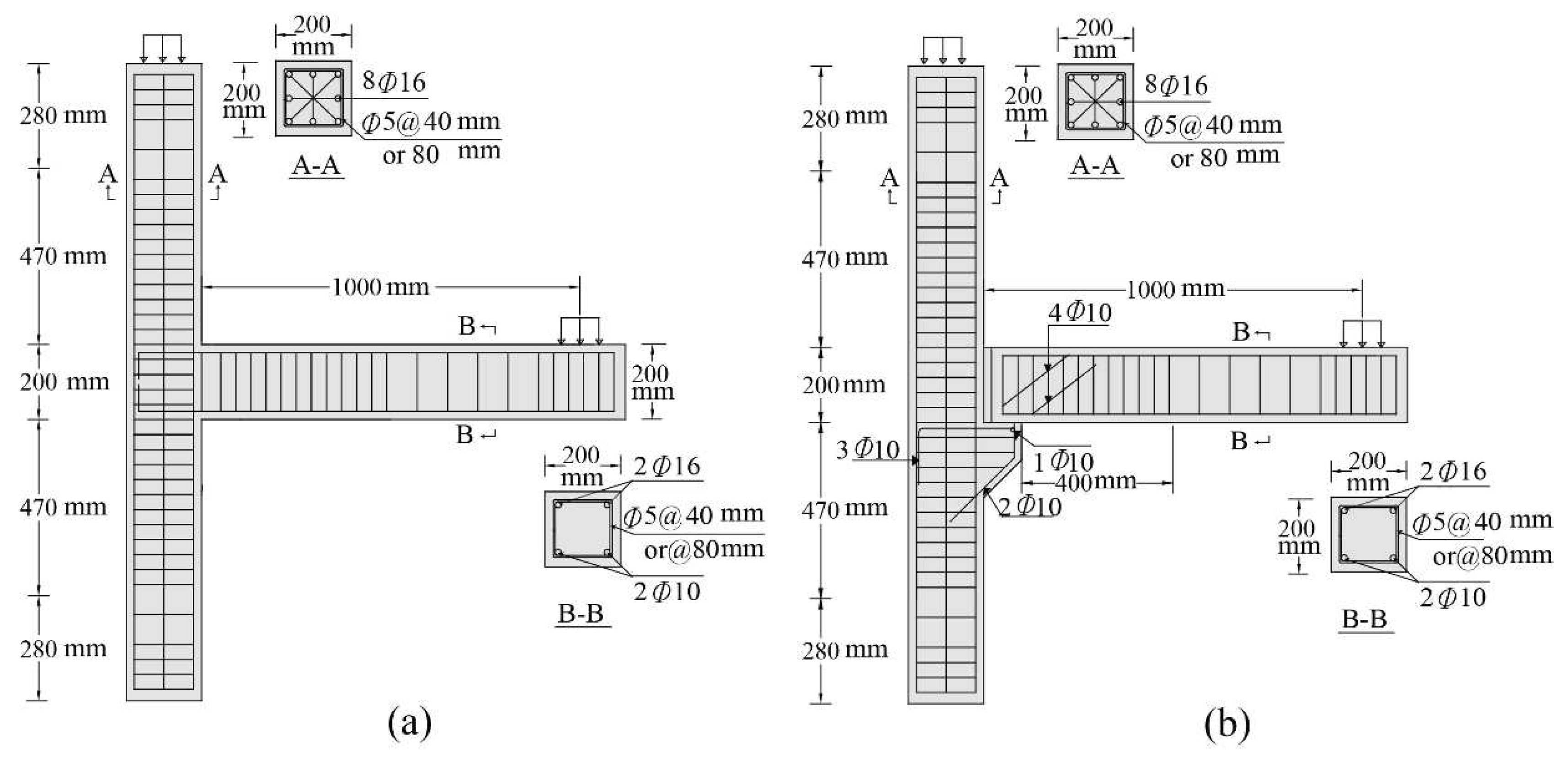

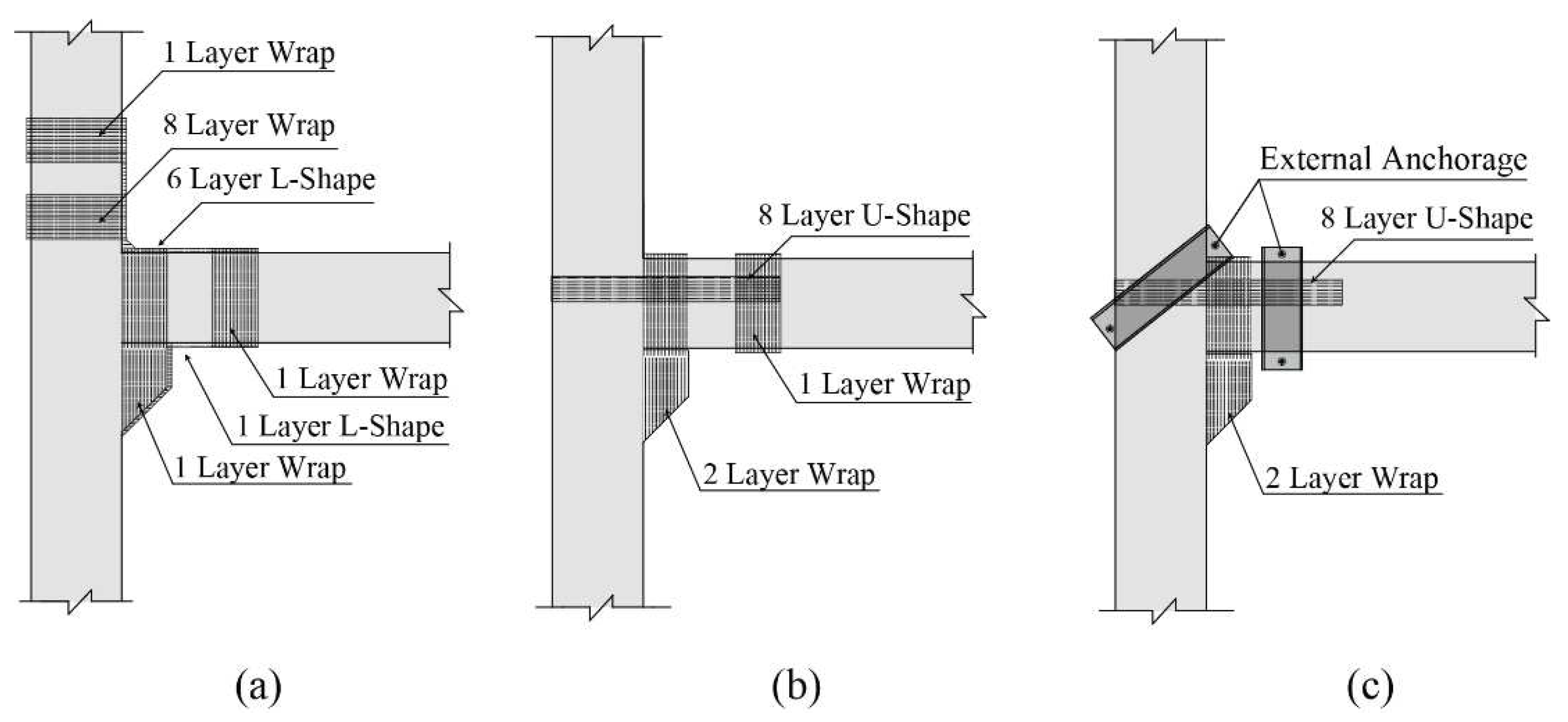

2.1. Description of test specimens

2.2. Preparation of test archetypes

2.3. Material properties

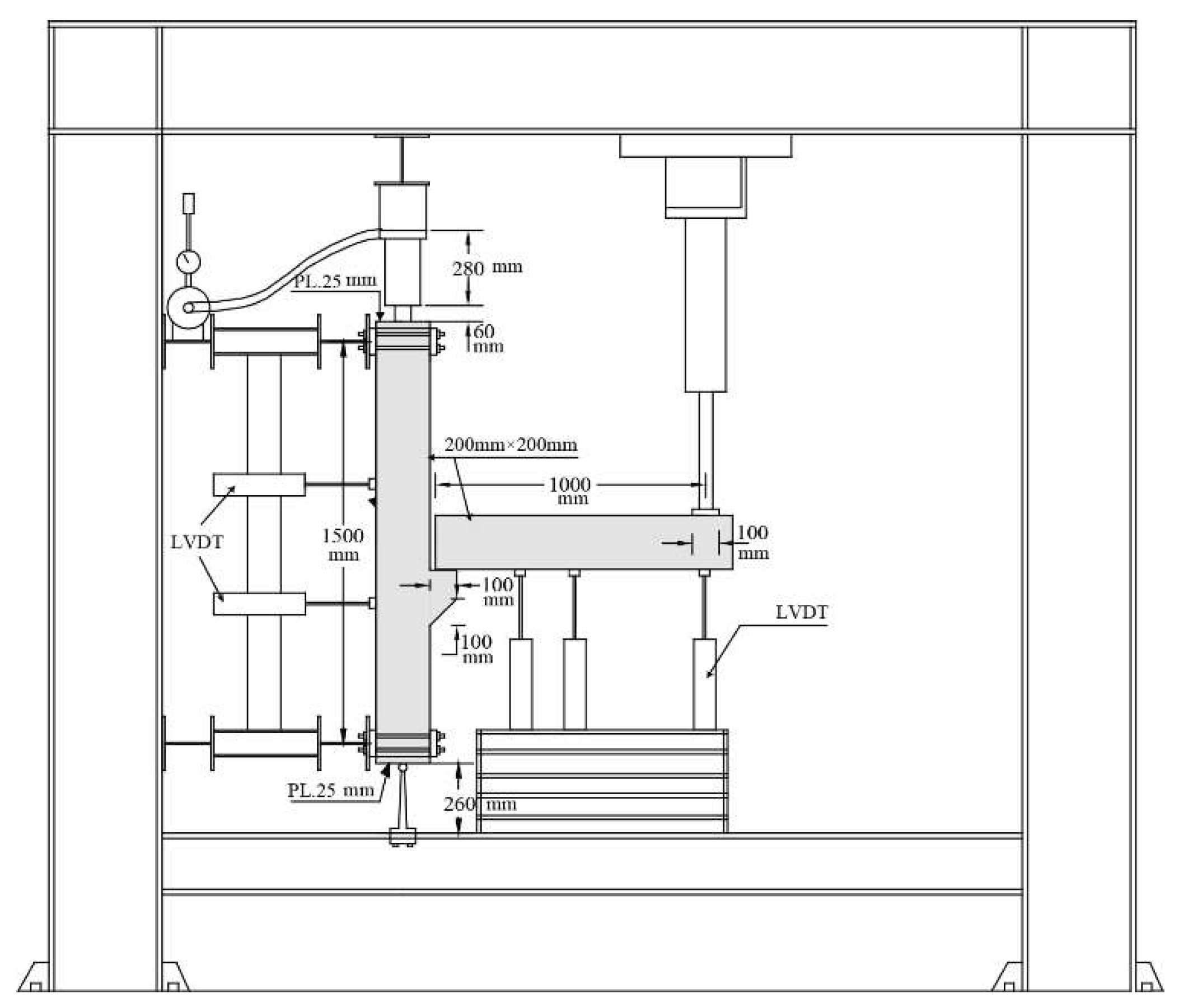

2.4. Test setup and instrumentation

3. Experimental results

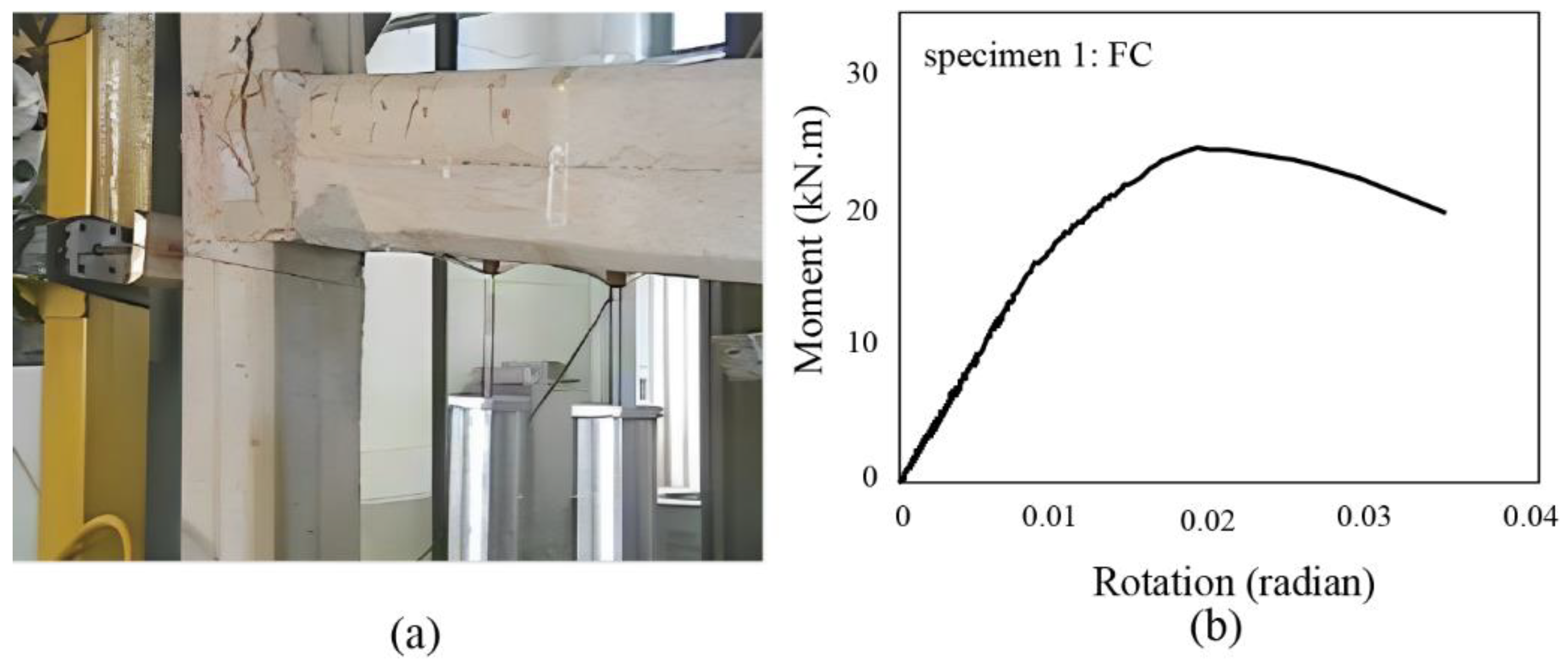

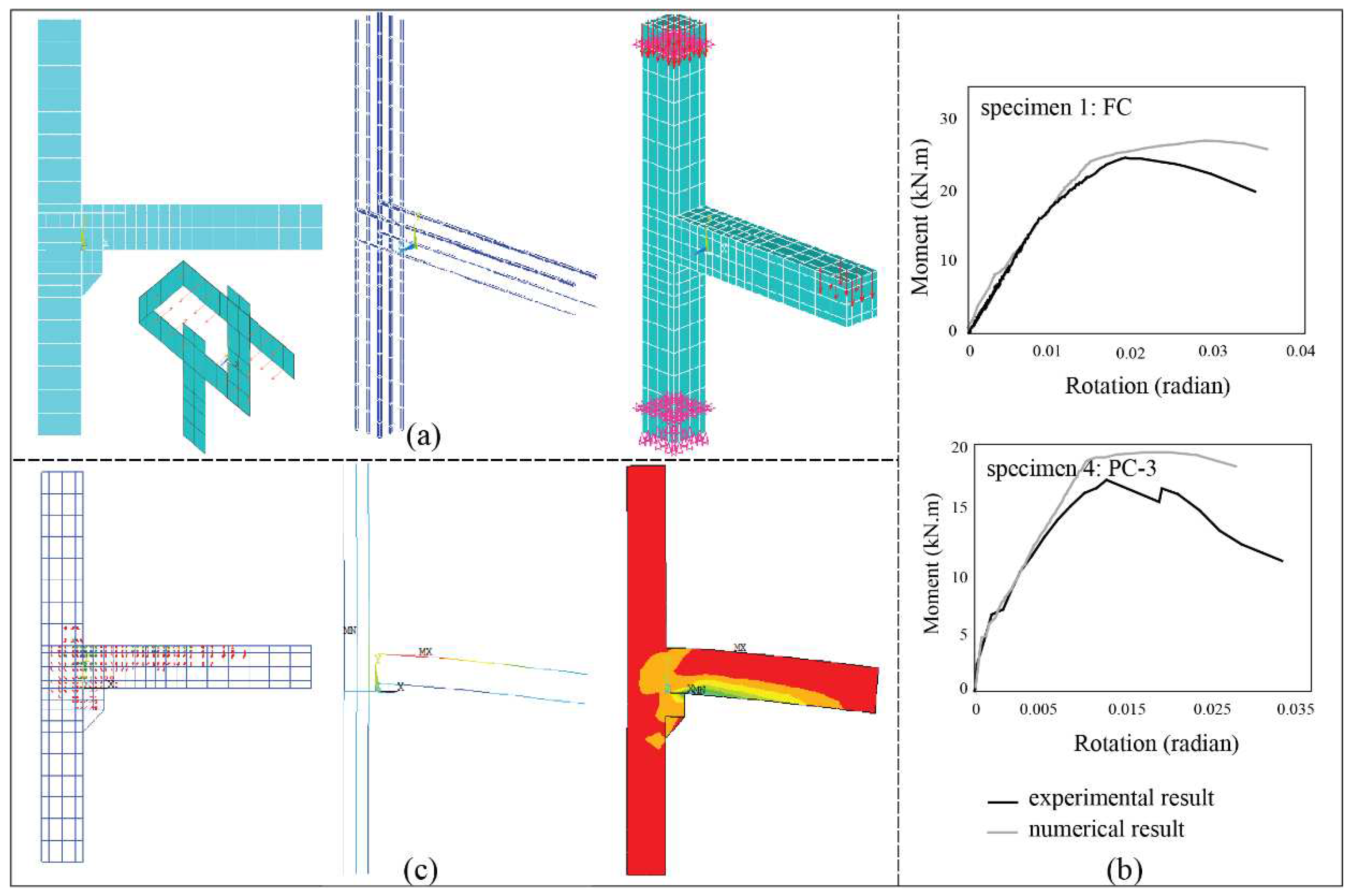

3.1. Specimen 1: FC archetype

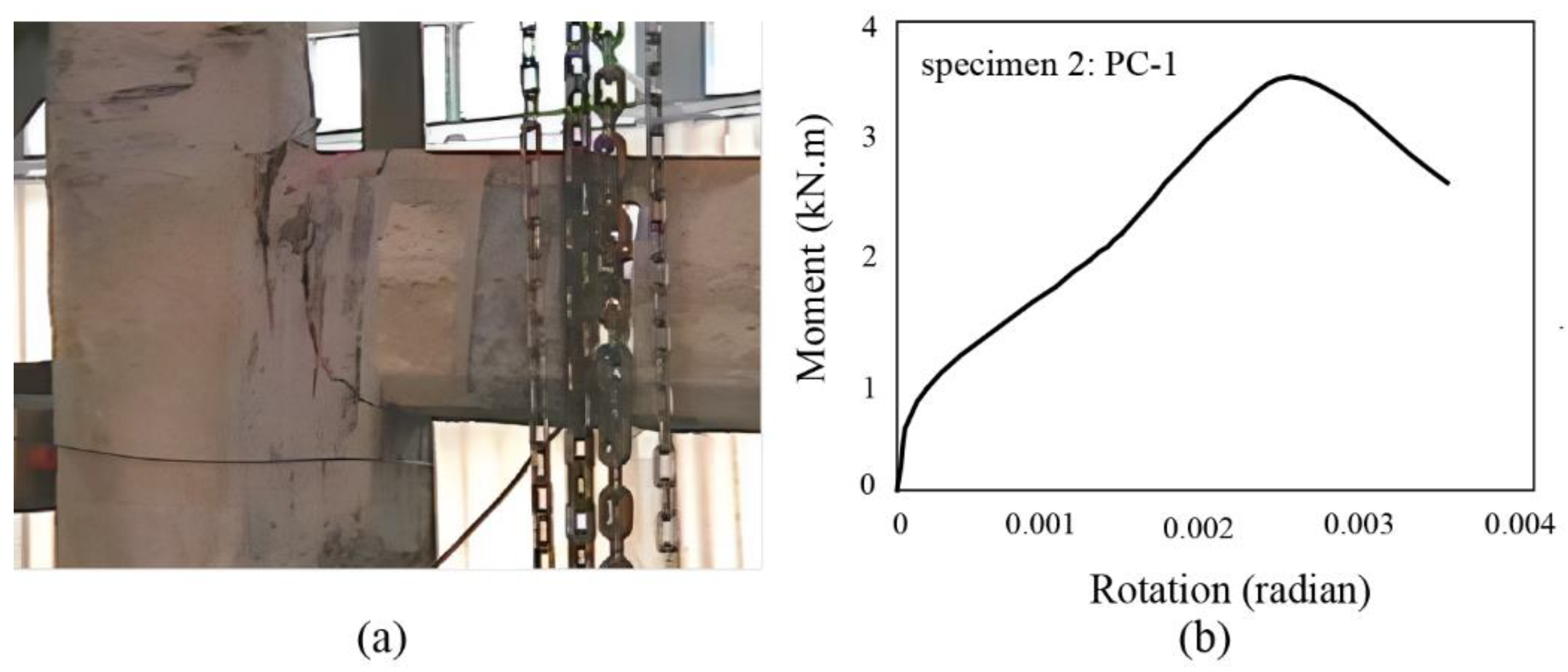

3.2. Specimen 2: PC-1 archetype

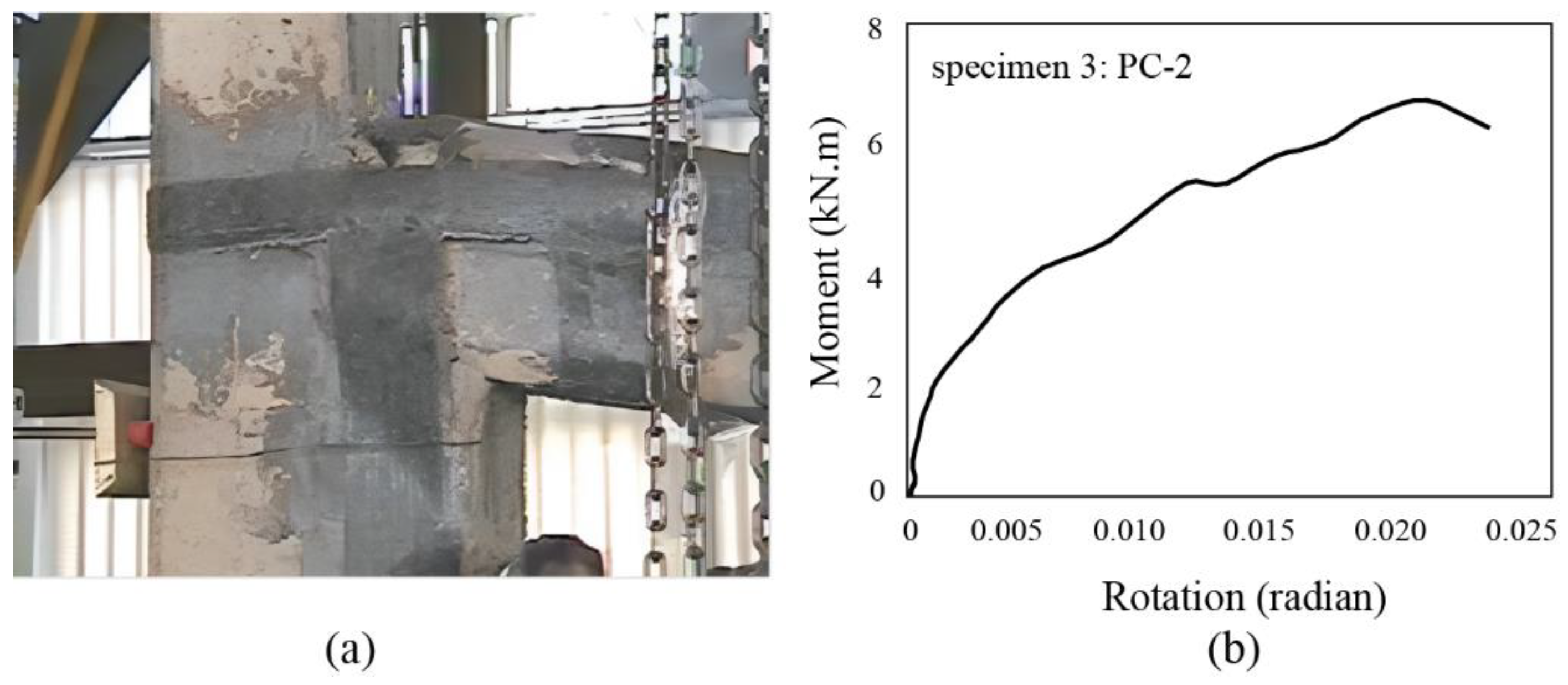

3.3. Specimen 3: PC-2 archetype

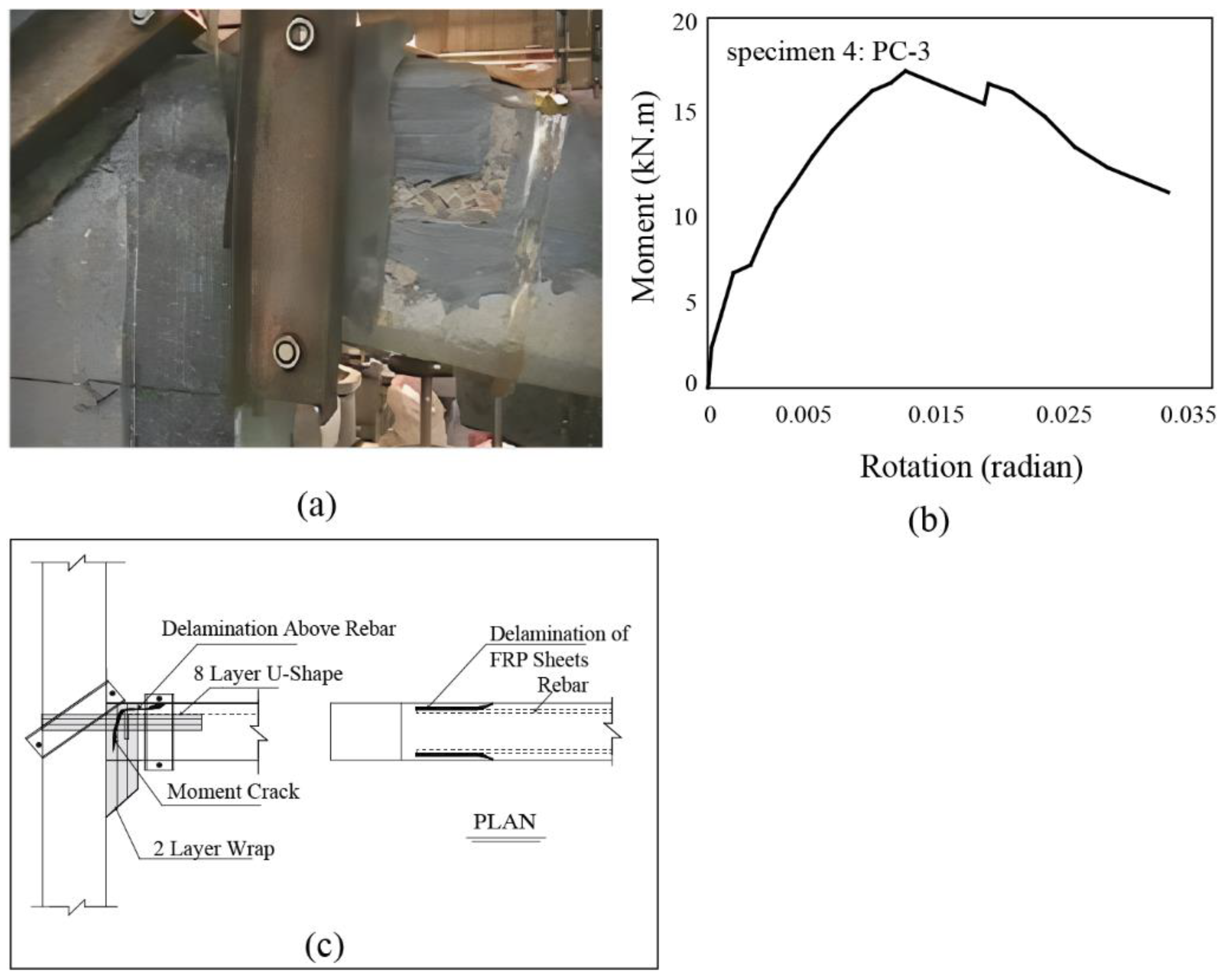

3.4. Specimen 4: PC-3 archetype

4. Numerical modeling and analysis

4.1. Simulation of archetypes

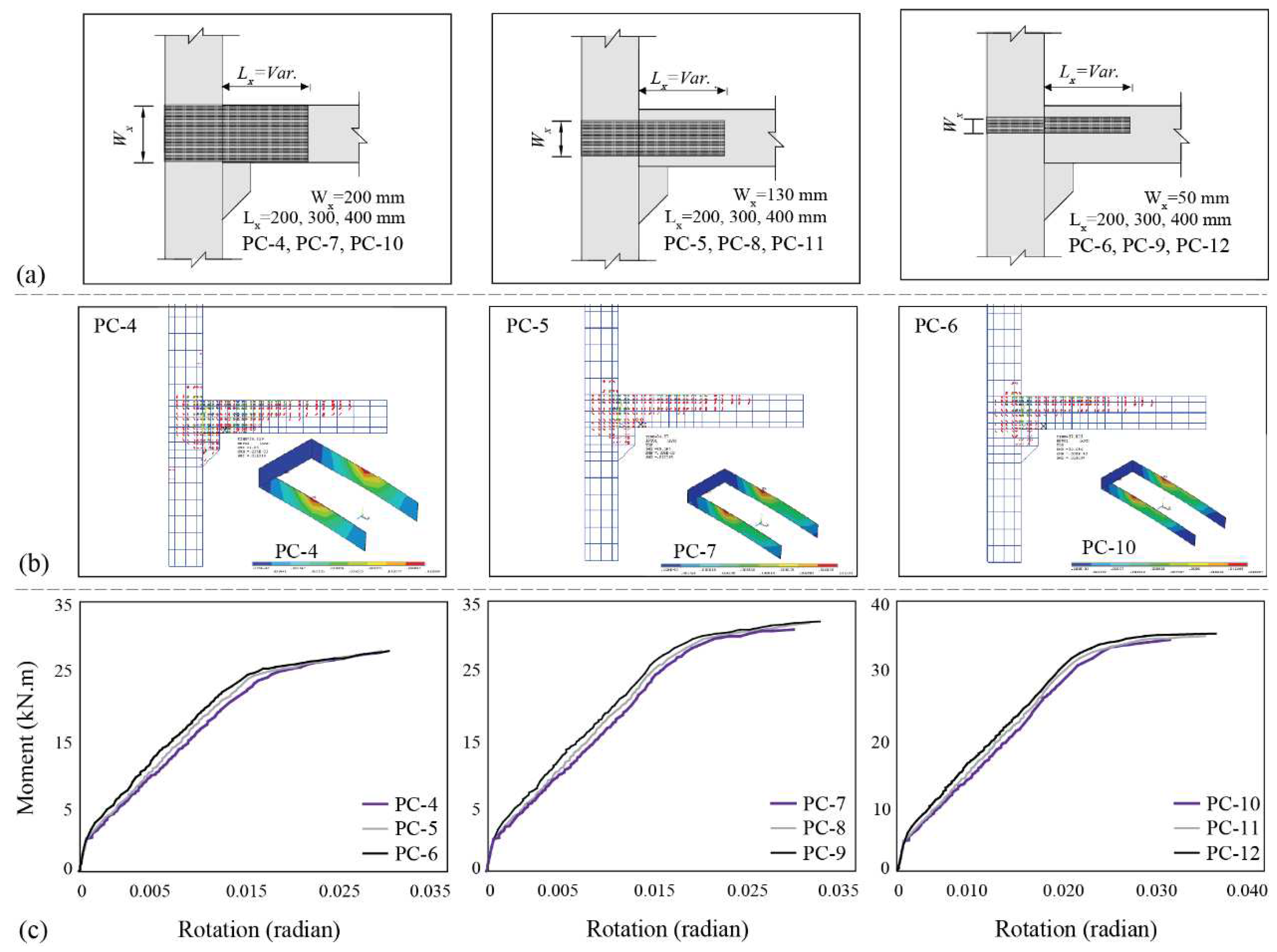

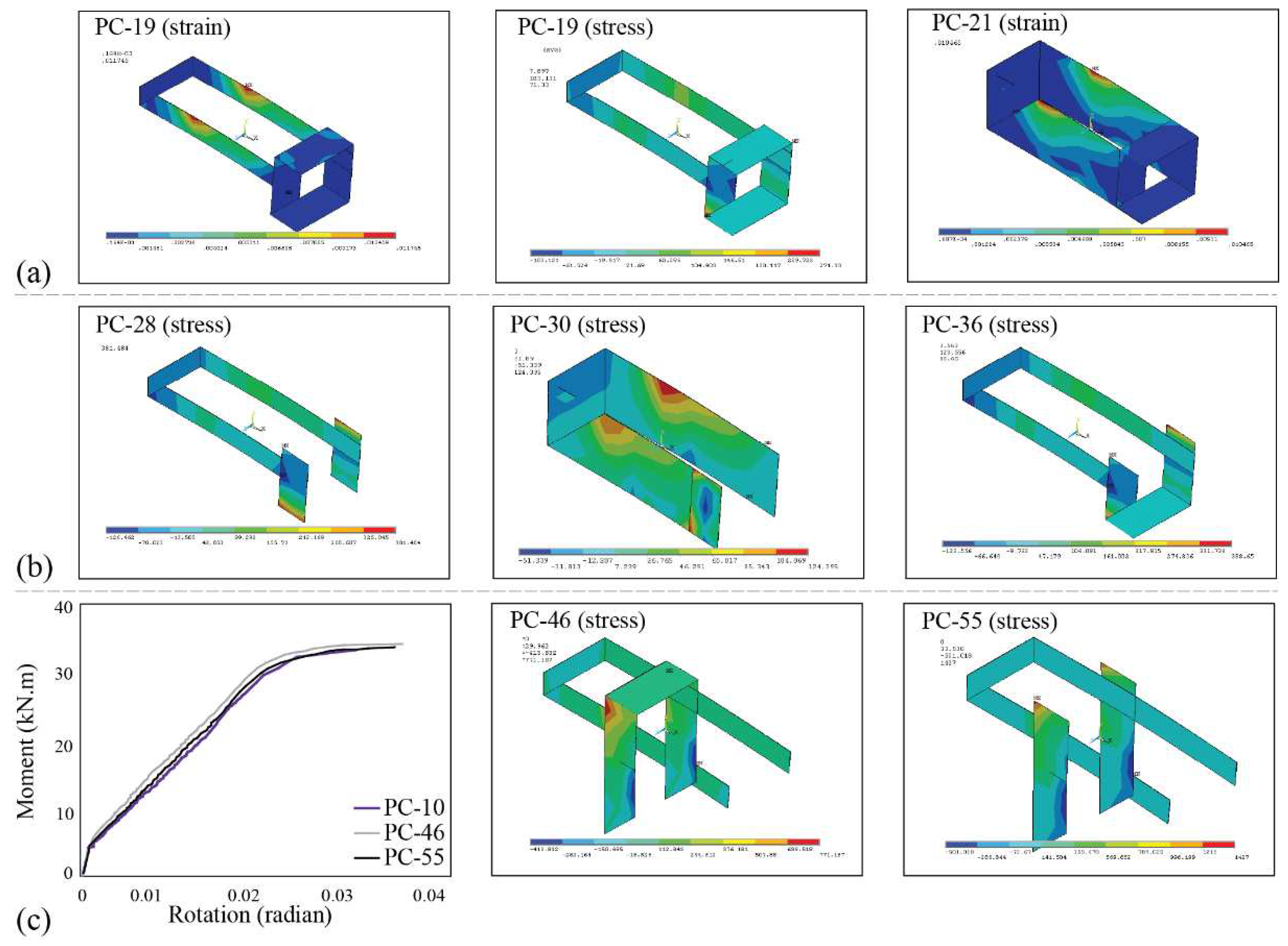

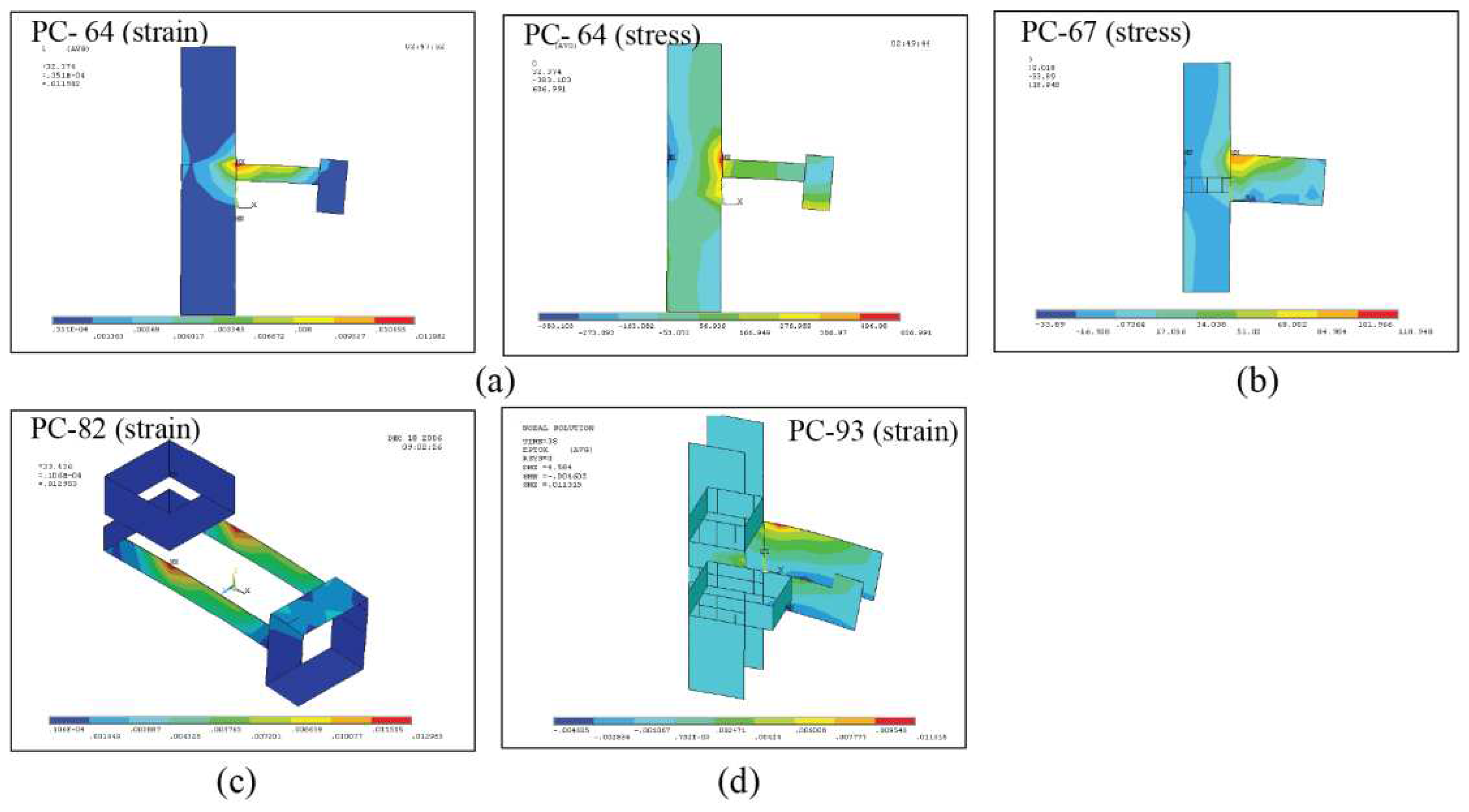

4.2. Analysis of illustrative examples

5. Results:

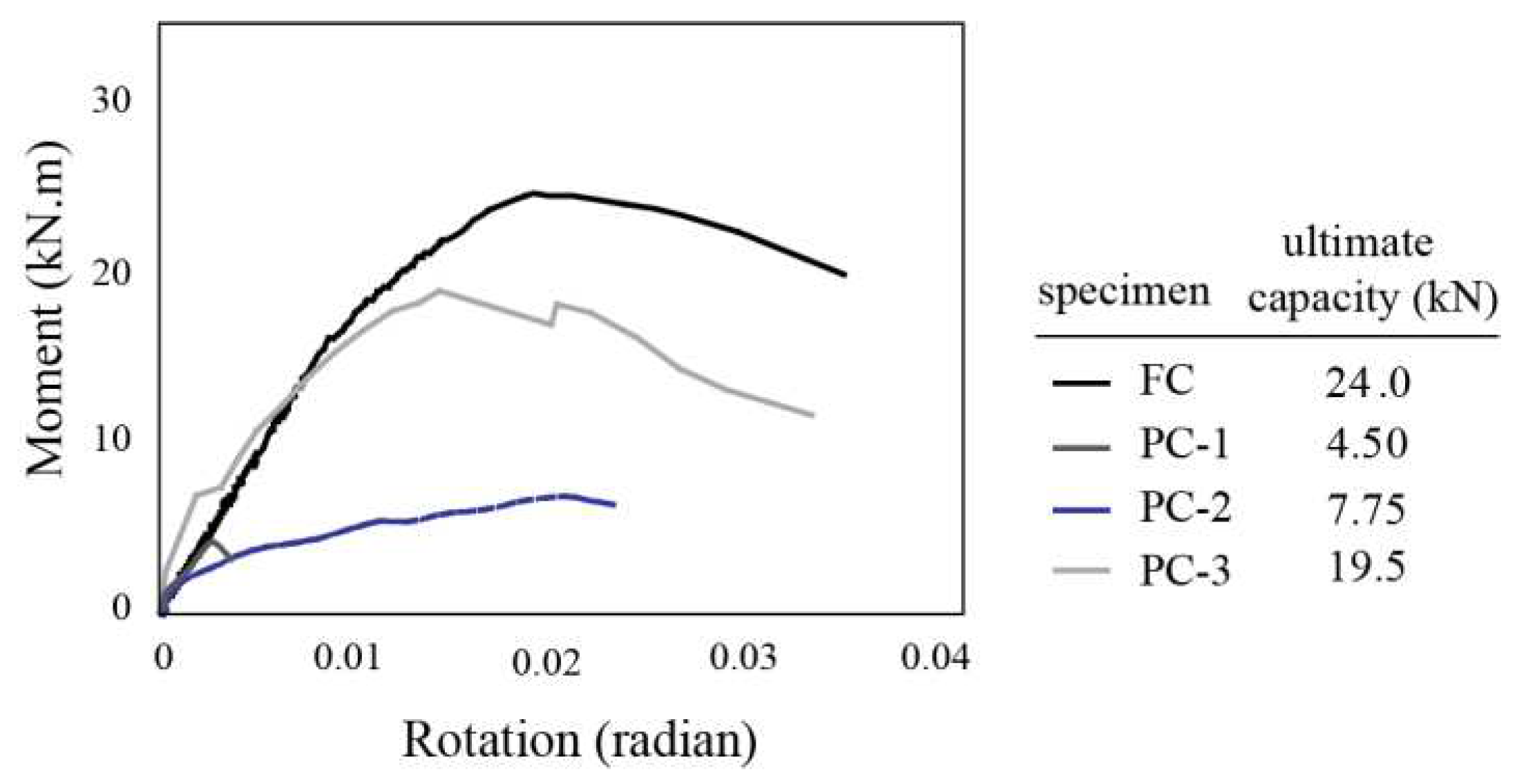

- Strengthening the PC-1 specimen's connection with L-shaped FRP sheets at the top and bottom minimally impacted the flexural capacity due to high shear-stress concentration. Similarly, relying solely on the spiral U-shaped FRP sheets without a mechanical anchorage for reinforcing the PC-2 connection did not result in significant bending capacity due to occurring debonding. With the incorporation of spiral sheets in PC-2, the debonding capacity of fibers improved by up to 100%, thereby extending the ultimate strain of the sheets from εu=0.001 to εu=0.002.

- The PC-3 connection managed to enhance the moment capacity to 81% of a fixed connection's flexural capacity. In this specimen, the debonding phenomenon was effectively controlled by employing an anchoring system. The mechanical anchors notably amplified the ultimate separation capacity of FRP sheets by 530%. Consequently, the ultimate separation strain of the FRP sheets increased from 0.001 to over 0.0053, accounting for 34% of the ultimate tensile strain of FRP.

- It was observed that the number and thickness of FRP layers influenced the ultimate debonding strain of FRP. Furthermore, the mechanical anchors over the U-shaped FRP sheet could postpone the reinforcement yielding.

- The theoretical analysis based on experimental findings of the PC-3 archetype revealed the mobilization of 35% of the ultimate capacity of FRP, while simulation results demonstrated a 41% contribution. This showcases a 6% difference between the numerical modeling and theoretical outcomes, affirming the accuracy of the numerical predictions. Moreover, the ultimate strain acquired from simulating the PC-3 corresponds to an 86% agreement with the strain derived from ACI-440 for simple beams.

- The implementation of U-shaped FRP sheets in the tensile region resulted in a shift of the critical cross-section, which was originally at the beam’s end. This modification has the potential to convert the pinned connection into a fully fixed one. As a result, the connection’s flexural strength is significantly enhanced, surpassing that of the cast-in-place FC specimen by approximately 1.19 to 1.5 times. This improvement underscores the potential of U-shaped FRP sheets in bolstering the structural integrity of precast concrete connections.

- The ultimate moment capacity of the connection is enhanced by increasing the bond length of the U-shaped sheet. This increase in bond length also elevates the tensile strength of the U-shaped sheet at the edge of the connections, thereby boosting the bearing capacity of the connection. Similarly, expanding the width of the U-shaped sheet augments the resisting moment of the connection to a certain degree. This expansion in sheet width also escalates the tensile strength of the U-shaped sheet at the edge of the connections, resulting in an increased bearing capacity of the connection.

- In neither of the archetypes did the FRP sheet strain reach beyond the ultimate strain at the peak load, thereby preventing any tearing. Consequently, there is potential to increase the number of sheet layers across all samples, if separation or buckling doesn't occur until the sheet's ultimate strain. Additionally, reducing the sheet thickness linearly decreased the stress within the sheet.

- Full wrap or side sheets at the end of the U-shaped sheet showed minimal impact on reducing stress or enhancing the connection's load-bearing capacity. However, the spirals over the beam and corbel side sheets significantly reduced stress in the U-shaped sheet. In contrast, the effect of column-side FRP sheets and full wrap on the column or corbel displayed negligible impact on stress reduction or moment resistance in the connection.

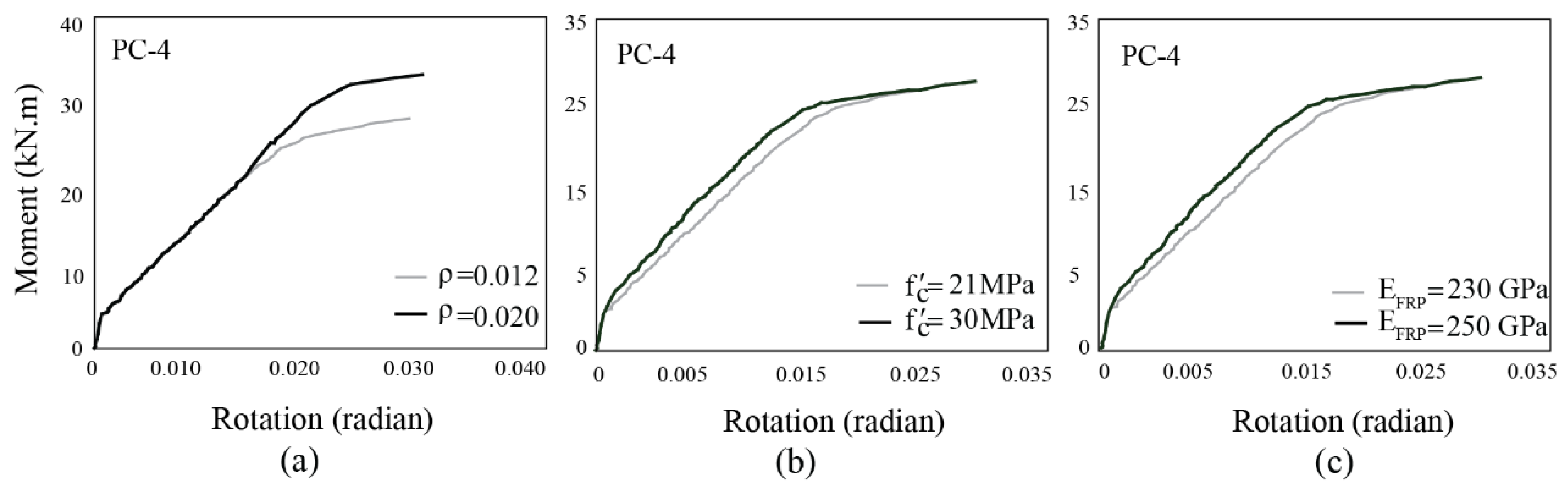

- Variations in longitudinal beam reinforcement ratios directly affect the connection's load-bearing capacity, altering it upon increase or decrease. Concrete strength impacted stiffness more than rotational moment capacity, while increased FRP fiber elastic modulus enhanced connection stiffness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Neuberger, Y. M.; de Lima Araújo, D. An improved analytical model for two-step corbels in a precast concrete system. Eng. Struct. 2023, 284, 115947. [Google Scholar] [CrossRef]

- Ghayeb, H. H., Razak, H. A.; Sulong, N. R. Performance of dowel beam-to-column connections for precast concrete systems under seismic loads: A review. Constr. Build. Mater. 2020, 237, 117582. [Google Scholar] [CrossRef]

- Akguzel, U.; Pampanin, S. Assessment and design procedure for the seismic retrofit of reinforced concrete beam-column joints using FRP composite materials. J. of Comp. for Constr. 2012, 16, 21–34. [Google Scholar] [CrossRef]

- Huang, C., Song, J., Zhang, N.; Lee, G. C. Seismic performance of precast prestressed concrete bridge girders using field-cast ultrahigh-performance concrete connections. J. Bridge Eng. 2019, 24, 04019046. [Google Scholar] [CrossRef]

- Sritharan, S., Aaleti, S., Henry, R. S., Liu, K. Y.; Tsai, K. C. Precast concrete wall with end columns (PreWEC) for earthquake resistant design. Earthquake Eng. Struct. Dyn. 2015; 44, 2075–2092. [Google Scholar]

- Singhal, S., Chourasia, A., Chellappa, S.; Parashar, J. Precast reinforced concrete shear walls: State of the art review. Struct. Concr. 2019; 20, 886–898. [Google Scholar]

- Abaev, Z., Valiev, A.; Kodzaev, M. Modeling of the precast concrete hollow-core floor diaphragm with tie beams under seismic action. AIP Conf. Proc. 2023; 2833. [Google Scholar]

- Kurama, Y. C., Sritharan, S., Fleischman, R. B., Restrepo, J. I., Henry, R. S., Cleland, N. M., et al. Seismic-resistant precast concrete structures: State of the art. J. Struct. Eng. 2018; 144, 03118001. [Google Scholar]

- Del Vecchio, C.; Di Ludovico, M.; Balsamo, A.; Prota, A.; Manfredi, G.; Dolce, M. Experimental investigation of exterior RC beam-column joints retrofitted with FRP systems. J of Comp. for Const. 2014, 18(4), 04014002. [Google Scholar] [CrossRef]

- Aninthaneni, P. K., Dhakal, R. P., Marshall, J.; Bothara, J. Experimental investigation of “dry” jointed precast concrete frame sub-assemblies with steel angle and tube connections. Bull. Earthquake Eng. 2020, 18, 3659–3681. [Google Scholar] [CrossRef]

- Li, H., Chen, W.; Hao, H. Dynamic response of precast concrete beam with wet connection subjected to impact loads. Eng. Struct. 2019, 191, 247–263. [Google Scholar] [CrossRef]

- Martins, R., Carmo, R. D., Costa, H.; Júlio, E. A review on precast structural concrete walls and connections. Adv. Struct. Eng. 2023, 26(14), 2600–2620. [CrossRef]

- Zhang, J., Ding, C., Rong, X., Yang, H., Wang, K.; Zhang, B. Experimental seismic study of precast hybrid SFC/RC beam–column connections with different connection details. Eng. Struct. 2020; 208, 110295. [Google Scholar]

- Psycharis, I. N.; Mouzakis, H. P. Shear resistance of pinned connections of precast members to monotonic and cyclic loading. Eng. Struct. 2012, 41, 413–427. [Google Scholar] [CrossRef]

- Holly, I.; Abrahoim, I. Connections and joints in precast concrete structures. Slovak J. Civil Eng. 2020, 28(1), 49–56. [Google Scholar] [CrossRef]

- Iverson, J. K.; Hawkins, N. M. Performance of Precast/Prestressed Concrete Building Structures During the Northridge Earthquake. PCI J. 1994, 65–76. [Google Scholar] [CrossRef]

- Wu, G., Feng, D. C.; Wang, C. L. Ductile Precast Concrete Frame with Dry-Connections. In Novel Precast Concrete Structure Systems; Springer Nature Singapore. 2023; 33–86. [Google Scholar]

- Xie, L., Wu, J., Zhang, J.; Liu, C. Experimental study on mechanical behaviour of replaceable energy dissipation connectors for precast concrete frames. Struct. 2021, 33, 3147–3162. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Arefian, B. Generic assessment of effective bond length of FRP-concrete joint based on the initiation of debonding: Experimental and analytical investigation. Compos. Struct. 2021, 277, 114625. [Google Scholar] [CrossRef]

- Aninthaneni, P. K., R. P. Dhakal, J. Marshall, and J. Bothara. Nonlinear cyclic behaviour of precast concrete frame sub-assemblies with “dry” end plate connection. Struct. 2018, 14, 124–136. [Google Scholar] [CrossRef]

- Li, Z. Y., Kang, S. B., He, H., Lu, W. Q., Liu, H. J.; Lu, C. J. Seismic behaviour of precast concrete beam-column connections with bolted end plates. Struct. 2023; 58, 105343. [Google Scholar]

- Rajeswari, M.; Jaya, K. P. Cyclic performance of emulative precast beam to column connection with corbel using dowel bar. Rev. de la construcción. 2022; 21, 354–367. [Google Scholar]

- Nimse, R. B., Joshi, D. D.; Patel, P. V. Experimental study on precast beam column connections constructed using RC corbel and steel billet under progressive collapse scenario. In Structures congress. 2015, 1101–1117. [Google Scholar]

- Bahrami, S., Madhkhan, M., Shirmohammadi, F.; Nazemi, N. Behavior of two new moment resisting precast beam to column connections subjected to lateral loading. Eng. Struct. 2017; 132, 808–821. [Google Scholar]

- Dasgupta, A. Retrofitting of concrete structure with fiber reinforced polymer. Int. J. 2018, 4(9), 42–49. [Google Scholar]

- Saadatmanesh, H.; Ehsani, M. Fiber composite plates can strengthen beams. Concrete Int. 1997, 12(3), 65–76. [Google Scholar]

- Granata, P.; Parvin, A. An Experimental Study on Kevlar Strengthening of Beam-Column Connections. Compos, 2001, 53, 163–171. [Google Scholar] [CrossRef]

- Huynh-Xuan, T., Do-Dai, T., Ngo-Huu, C., Pham, T. M.; Nguyen-Minh, L. Effect of corroded reinforcement on capacity of square reinforced concrete columns confined with FRP sheets under eccentric loads. Eng. Struct. 2023, 283, 115821. [Google Scholar] [CrossRef]

- Li, J., Bakoss, S. L., Samali, B.; Ye, L. Reinforcement of concrete beam–column connections with hybrid FRP sheet. Compos. Struct. 1999; 47, 805–812. [Google Scholar]

- Shrestha, R., Smith, S. T.; Samali, B. Strengthening RC beam–column connections with FRP strips. Proc. Instit. Civil Eng. Struct. Build. 2009; 162, 323–334. [Google Scholar]

- Allam, K., Mosallam, A. S.; Salama, M. A. Experimental evaluation of seismic performance of interior RC beam-column joints strengthened with FRP composites. Eng. Struct. 2019; 196, 109308. [Google Scholar]

- Antonopoluos, C. P.; Triantafillou, T. C. Analysis of FRP-Strengthened RC Beam-Column Joints. Compos. for Constr. 2002, 6(1), 41–51. [Google Scholar] [CrossRef]

- Gergely, I., Pantelides, C. P.; Reaveley, L. D. Shear Strengthening of RC T-joints Using CFRP Composites. Compos. for Constr. 2000; 4, 56–64. [Google Scholar]

- Parvin, A.; Granata, P. External Fiber Composite Reinforcement of Concrete Structural Members. Proc. of the Japan-U.S. Conference on Composite Materials, 1998; 942–948. [Google Scholar]

- Antonopoluos, C. P.; Triantafillou, T. C. Experimental Investigation of FRP-Strengthened RC Beam-Column Joints. Compos. for Constr. 2003, 6(1), 39–49. [Google Scholar] [CrossRef]

- Harmon, T. G., Kim, Y. J., Johnson, T.; Stark, A. Bond of Surface-Mounted Fiber-Reinforced Polymer Reinforcement for Concrete Structures. ACI Struct. J. 2003; 57, 557–564. [Google Scholar]

- ACI Committee. Building code requirements for structural concrete (ACI 318-08) and commentary. Am. Concrete Inst.

- Mass, G. R. Proportioning mass concrete incorporating Pozzolans using ACI 211.1. Concrete Int. 1982, 4(8), 48–55. [Google Scholar]

- Hernandez, D. A.; Orlandi, M. O. Mechanical properties of composites materials SIKACARBODURS512, SIKADUR 30 and SIKADUR 330. 22o CBECiMat–Congresso Brasileiro de Engenharia e Ciência dos Materiais, 2016.

- Holzenkampfer, O. Ingenieurmodelle des verbundes geklebter bewehrung fur betonbauteile. PHD Dissertation, TU Braunschweig (in German)., 1994.

- Sharif, A., Al-Sulaimani, G. J., Basunbul, I. A., Baluch, M. H., Ghaleb, B. N. Strengthening of Initially Loaded Reinforced Concrete Beams Using FRP Plates. ACI Struct. J. 1994; 91, 160–168. [Google Scholar]

- Arya, C., Farmer, N. Design guidelines for flexural strengthening of concrete members using FRP composites. FRPRCS-5: Fibre-reinforced plastics for reinforced concrete structures, 2001; 167–176. [Google Scholar]

- ACI Committee 440. Guide for the design and construction of externally bonded FRP systems for strengthened concrete structures, ACI 440.2R-02.

| Archetype | f’c (MPa) | ρfb (%) | ρfw (%) |

|---|---|---|---|

| FC | 21.3 | 0.00 | 0.00 |

| PC-1 | 23.2 | 0.25 | 0.11 |

| PC-2 | 23.1 | 0.22 | 0.22 |

| PC-3 | 21.1 | 0.22 | 0.22 |

| Type | E (GPa) | W(g/m2) | γ (g/m3) | Fu (MPa) | ɛu (%) | t (mm) |

|---|---|---|---|---|---|---|

| SikaWrap-200C | 230 | 200 ± 5% | 1.80 | 3900 | 1.55 | 0.11 |

| Archetype | Lx (mm) |

Wx (mm) |

Mu (kN.mm) |

Mu / Mu, FC | ɛu(U-Shap) | ɛ/ɛu |

|---|---|---|---|---|---|---|

| FC(1) | - | - | 24 | 1.00 | - | - |

| PC-3(1) | 300 | 50 | 19.5 | 0.81 | - | - |

| PC-4, PC-13, PC-22, PC-31 | 200 | 50 | 28.5 | 1.19 | 0.0111 | 0.72 |

| PC-5, PC-14, PC-23, PC-32 | 200 | 130 | 2. 95 | 1.21 | 0.0105 | 0.68 |

| PC-6, PC-15, PC-24, PC-33 | 200 | 200 | 29.2 | 1.22 | 0.0099 | 0.64 |

| PC-7, PC-16, PC-25, PC-34 | 300 | 50 | 31.2 | 1.30 | 0.0122 | 0.79 |

| PC-8, PC-17, PC-26, PC-35 | 300 | 130 | 32.3 | 1.35 | 0.0115 | 0.74 |

| PC-9, PC-18, PC-27, PC-36 | 300 | 200 | 32.5 | 1.35 | 0.0108 | 0.7 |

| PC-10, PC-19, PC-28, PC-37 | 400 | 50 | 34.1 | 1.42 | 0.0131 | 0.84 |

| PC-11, PC-20, PC-29, PC-38 | 400 | 130 | 35.0 | 1.46 | 0.0115 | 0.74 |

| PC-12, PC-21, PC-30, PC-39 | 400 | 200 | 35.4 | 1.47 | 0.0104 | 0.67 |

| PC-40(2) | 200 | 50 | 29.7 | 1.24 | 0.0074 | 0.48 |

| PC-41(2) | 200 | 130 | 29.4 | 1.23 | 0.0081 | 0.52 |

| PC-42(2) | 200 | 200 | 29.5 | 1.23 | 0.0089 | 0.57 |

| PC-43(2) | 300 | 50 | 32.2 | 1.34 | 0.0081 | 0.52 |

| PC-44(2) | 300 | 130 | 32.7 | 1.37 | 0.0092 | 0.59 |

| PC-45(2) | 300 | 200 | 32.8 | 1.37 | 0.0097 | 0.63 |

| PC-46(2) | 400 | 50 | 35.1 | 1.46 | 0.0087 | 0.56 |

| PC-47(2) | 400 | 130 | 35.7 | 1.49 | 0.0092 | 0.59 |

| PC-48(2) | 400 | 200 | 35.9 | 1.50 | 0.0093 | 0.6 |

| PC-49(2) | 200 | 50 | 29.6 | 1.23 | 0.0087 | 0.56 |

| PC-50(2) | 200 | 130 | 29.4 | 1.23 | 0.0088 | 0.57 |

| PC-51(2) | 200 | 200 | 29.3 | 1.22 | 0.0088 | 0.57 |

| PC-52(2) | 300 | 50 | 3.21 | 0.13 | 0.0097 | 0.62 |

| PC-53(2) | 300 | 130 | 32.7 | 1.36 | 0.0097 | 0.62 |

| PC-54(2) | 300 | 200 | 32.7 | 1.36 | 0.0097 | 0.62 |

| PC-55(2) | 400 | 50 | 35.0 | 0.15 | 0.0102 | 0.66 |

| PC-56(2) | 400 | 130 | 35.6 | 1.48 | 0.0104 | 0.67 |

| PC-57(2) | 400 | 200 | 35.8 | 1.49 | 0.0105 | 0.68 |

| PC-58(3) | 200 | 50 | 29.3 | 1.23 | 0.0111 | 0.72 |

| PC-59(3) | 200 | 130 | 29.8 | 1.25 | 0.0105 | 0.68 |

| PC-60(3) | 200 | 200 | 30.1 | 1.26 | 0.0099 | 0.64 |

| PC-61(3) | 300 | 50 | 32.1 | 1.34 | 0.0122 | 0.79 |

| PC-62(3) | 300 | 130 | 33.3 | 1.39 | 0.0115 | 0.74 |

| PC-63(3) | 300 | 200 | 33.4 | 1.39 | 0.0108 | 0.7 |

| PC-64(3) | 400 | 50 | 35.1 | 1.46 | 0.0131 | 0.84 |

| PC-65(3) | 400 | 130 | 36.0 | 1.50 | 0.0115 | 0.74 |

| PC-66(3) | 400 | 200 | 36.4 | 1.51 | 0.0104 | 0.67 |

| PC-67(2,3), PC-76(2,3) | 200 | 50 | 28.2 | 1.19 | 0.0107 | 0.69 |

| PC-68(2,3), PC-77(2,3) | 200 | 130 | 27.5 | 1.15 | 0.0097 | 0.62 |

| PC-69(2,3), PC-78(2,3) | 200 | 200 | 27.4 | 1.15 | 0.009 | 0.58 |

| PC-70(2,3), PC-79(2,3) | 300 | 50 | 32.1 | 1.34 | 0.0122 | 0.79 |

| PC-71(2,3), PC-80(2,3) | 300 | 130 | 31.3 | 1.31 | 0.0108 | 0.7 |

| PC-72(2,3), PC-81(2,3) | 300 | 200 | 30.9 | 1.29 | 0.01 | 0.64 |

| PC-73(2,3), PC-82(2,3) | 400 | 50 | 34.3 | 1.43 | 0.0128 | 0.82 |

| PC-74(2,3), PC-83(2,3) | 400 | 130 | 36.6 | 1.53 | 0.0117 | 0.75 |

| PC-75(2,3), PC-84(2,3) | 400 | 200 | 37.1 | 1.54 | 0.0106 | 0.68 |

| PC-85(2,3) | 200 | 50 | 32.2 | 1.36 | 0.0122 | 0.79 |

| PC-86(2,3) | 200 | 130 | 32.6 | 1.36 | 0.0115 | 0.74 |

| PC-87(2,3) | 200 | 200 | 32.9 | 1.38 | 0.0108 | 0.7 |

| PC-88(2,3) | 300 | 50 | 35.3 | 1.47 | 0.0134 | 0.93 |

| PC-89(2,3) | 300 | 130 | 36.5 | 1.53 | 0.0126 | 0.81 |

| PC-90(2,3) | 300 | 200 | 36.5 | 1.52 | 0.0118 | 0.76 |

| PC-91(2,3) | 400 | 50 | 38.6 | 1.61 | 0.0144 | 0.93 |

| PC-92(2,3) | 400 | 130 | 39.4 | 1.65 | 0.0126 | 0.81 |

| PC-93(2,3) | 400 | 200 | 39.9 | 1.66 | 0.0114 | 0.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).