Submitted:

16 July 2025

Posted:

17 July 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

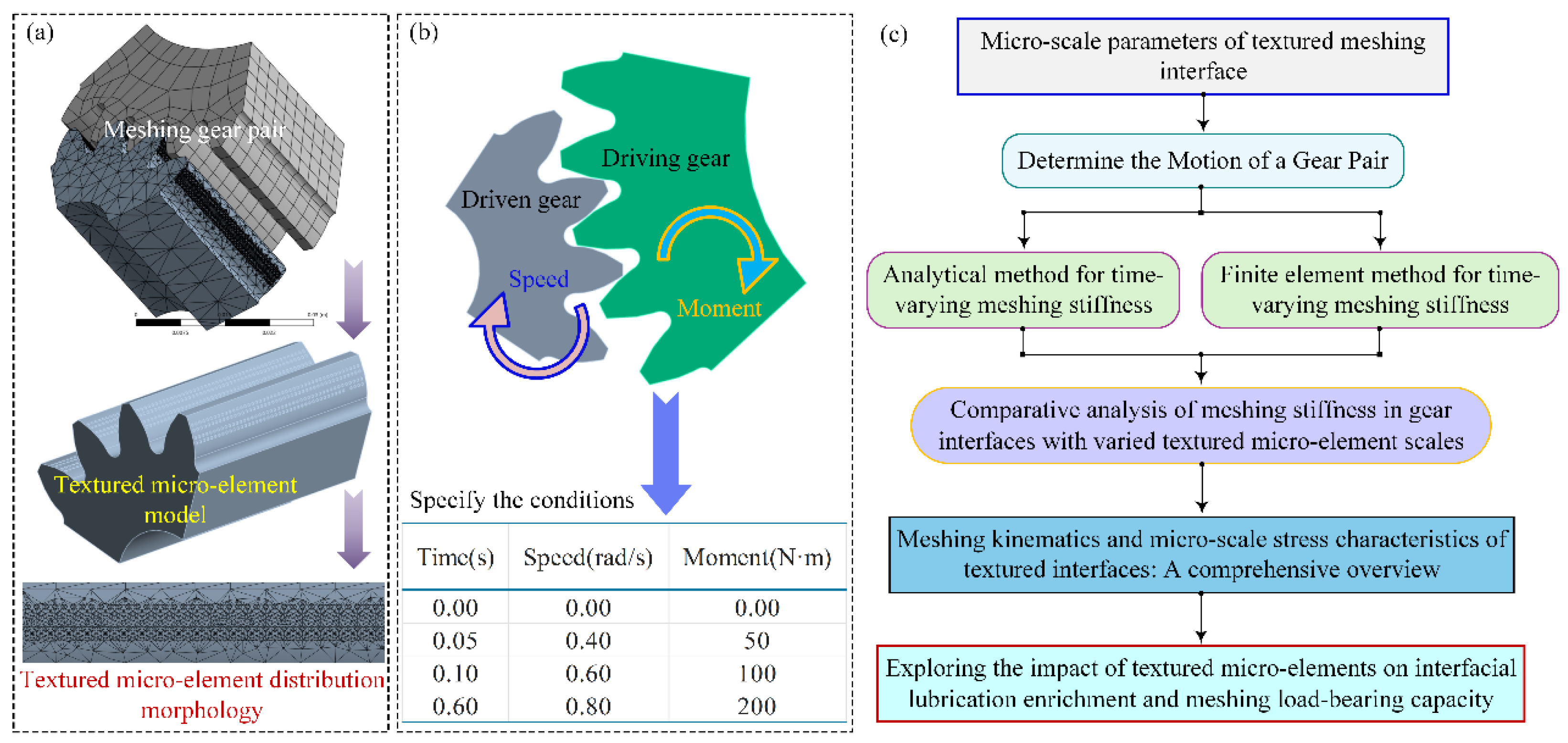

2. Theoretical Analysis of System Characteristics

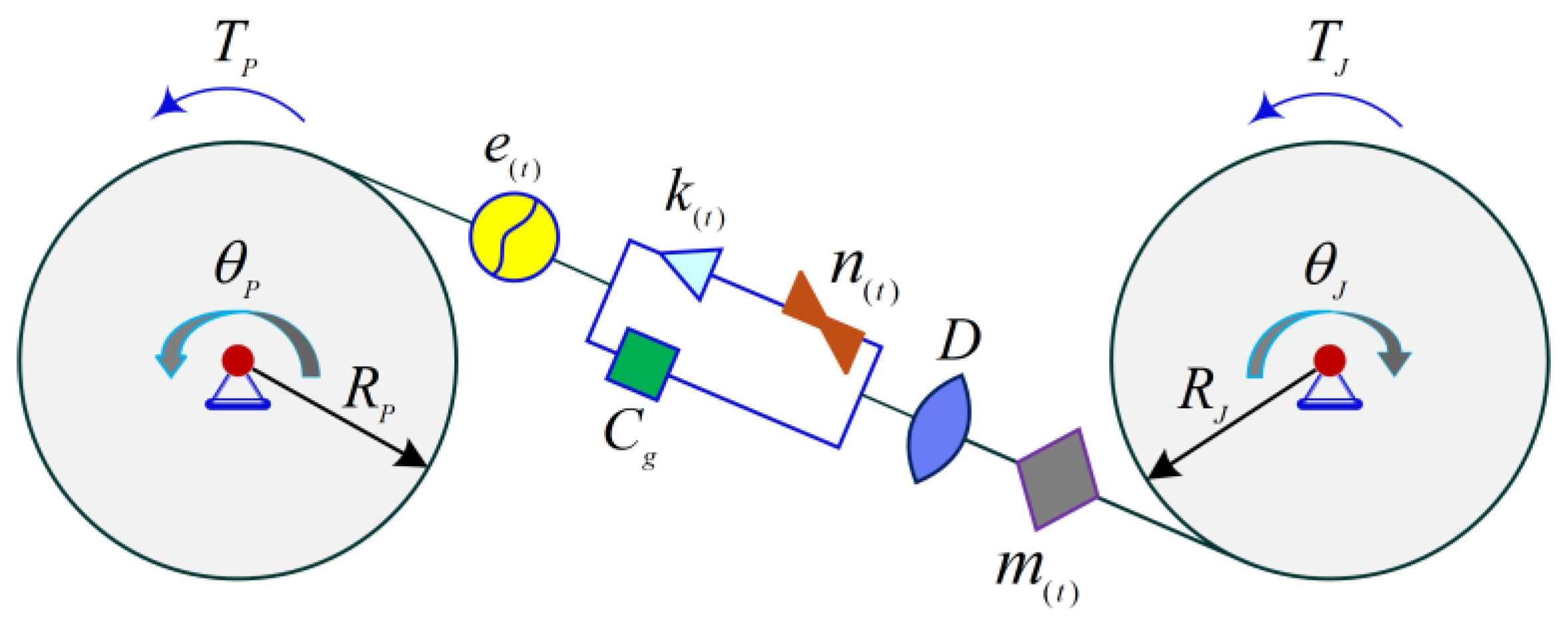

2.1. Dynamic Modeling of Deep-Sea Spatial Gear Transmission Systems

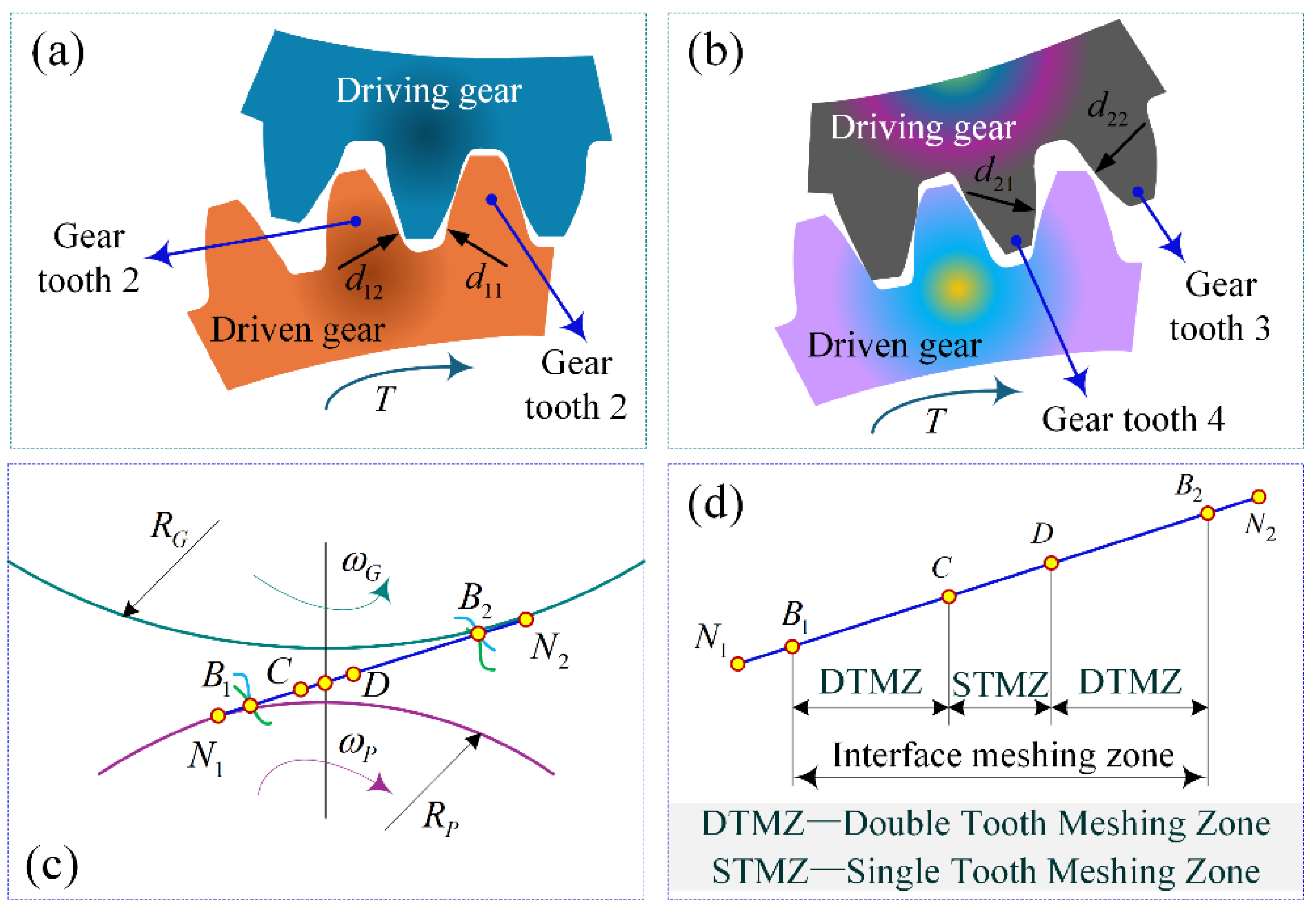

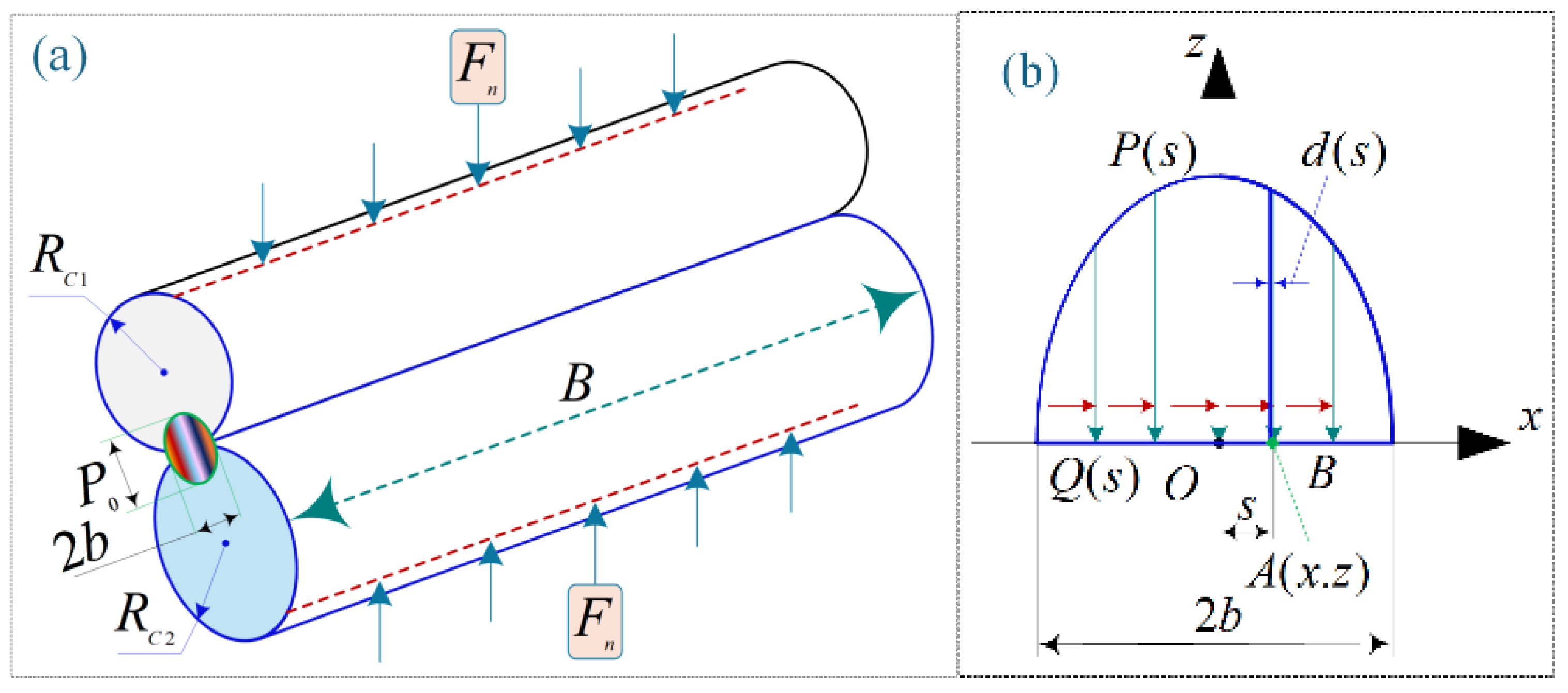

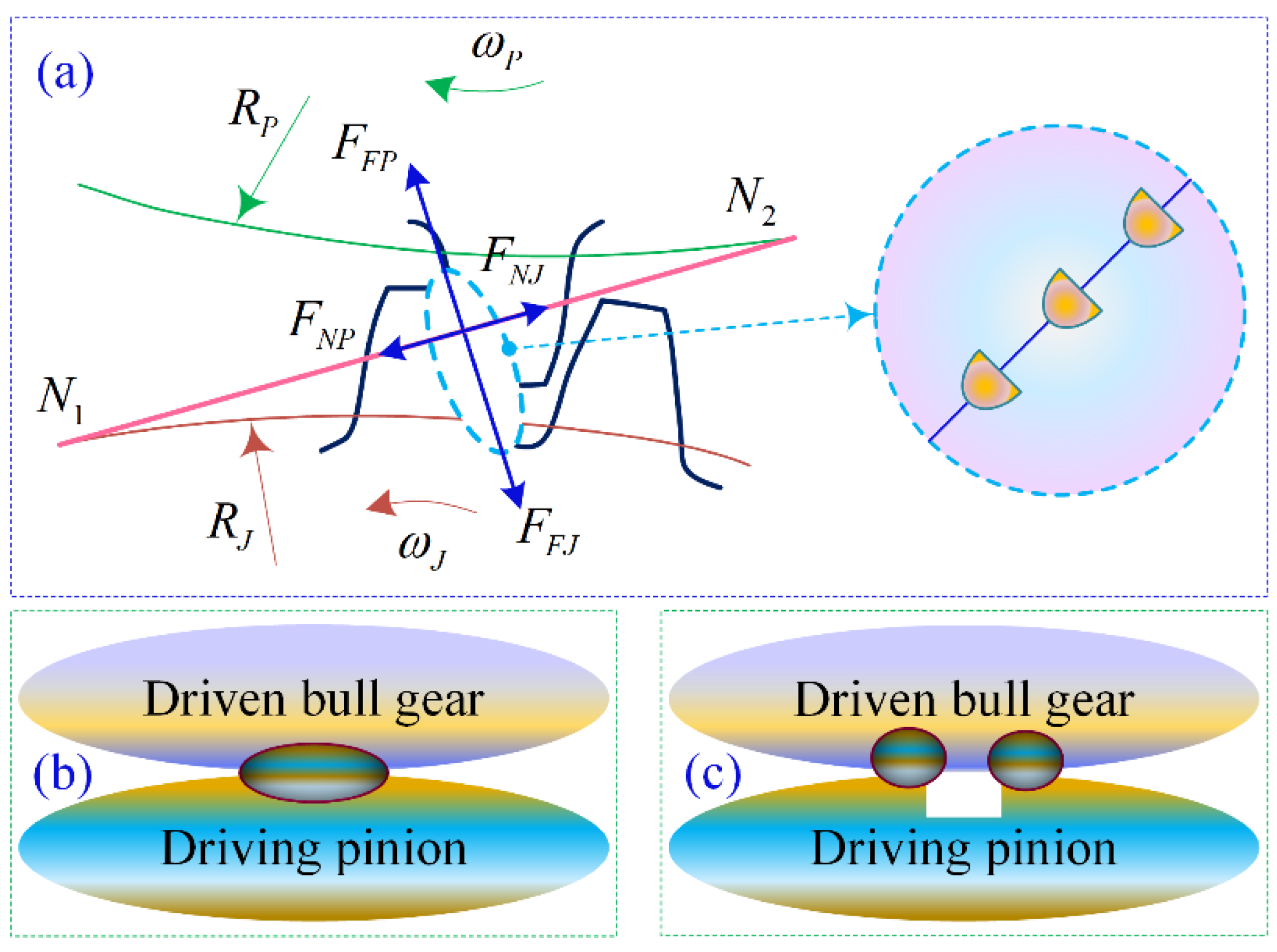

2.2. Meshing Pairs Contact Deformation Mechanism and Modeling Analysis

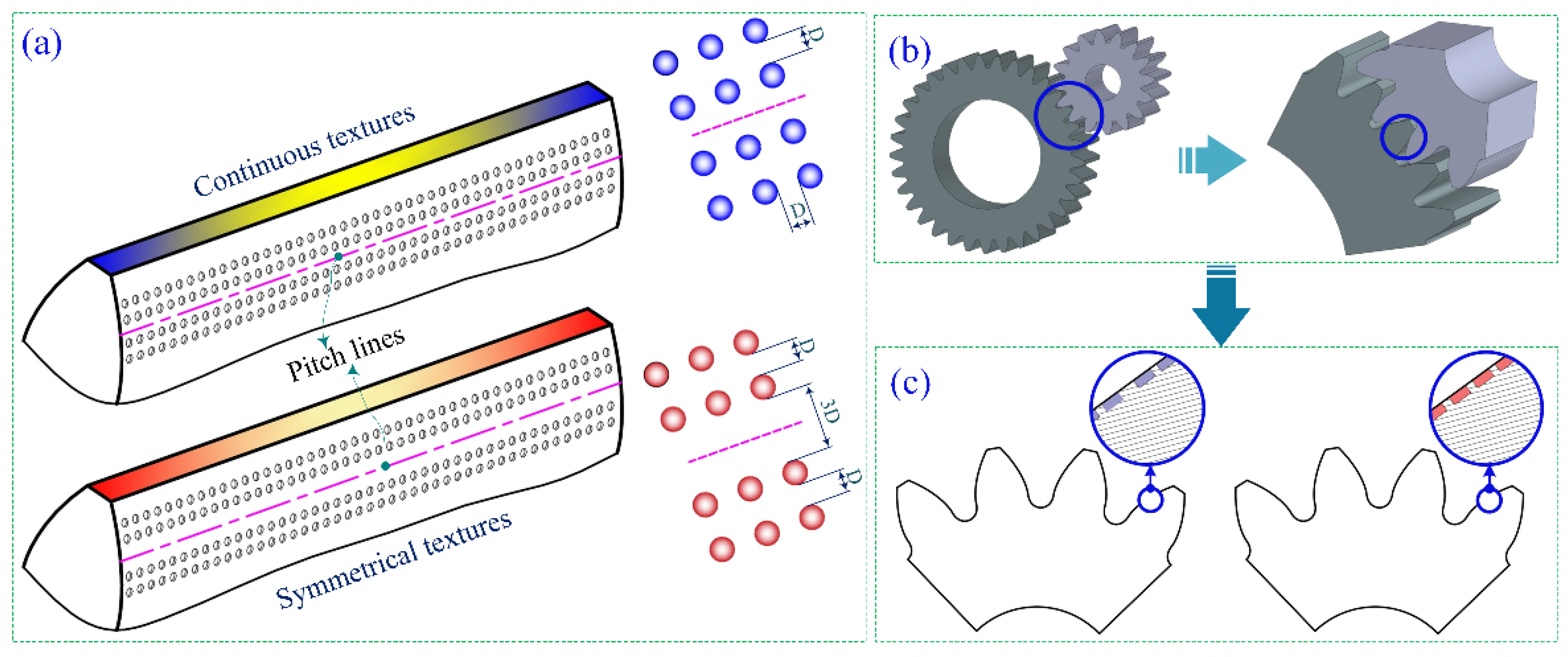

2.3. Contact Characteristics Analysis of Micro-Textured Meshing Interfaces

3. Finite Element Modeling Methodology and Validation for Micro-Textured Gears

3.1. Finite Element Modeling Methodology for Micro-Textured Meshing Interface

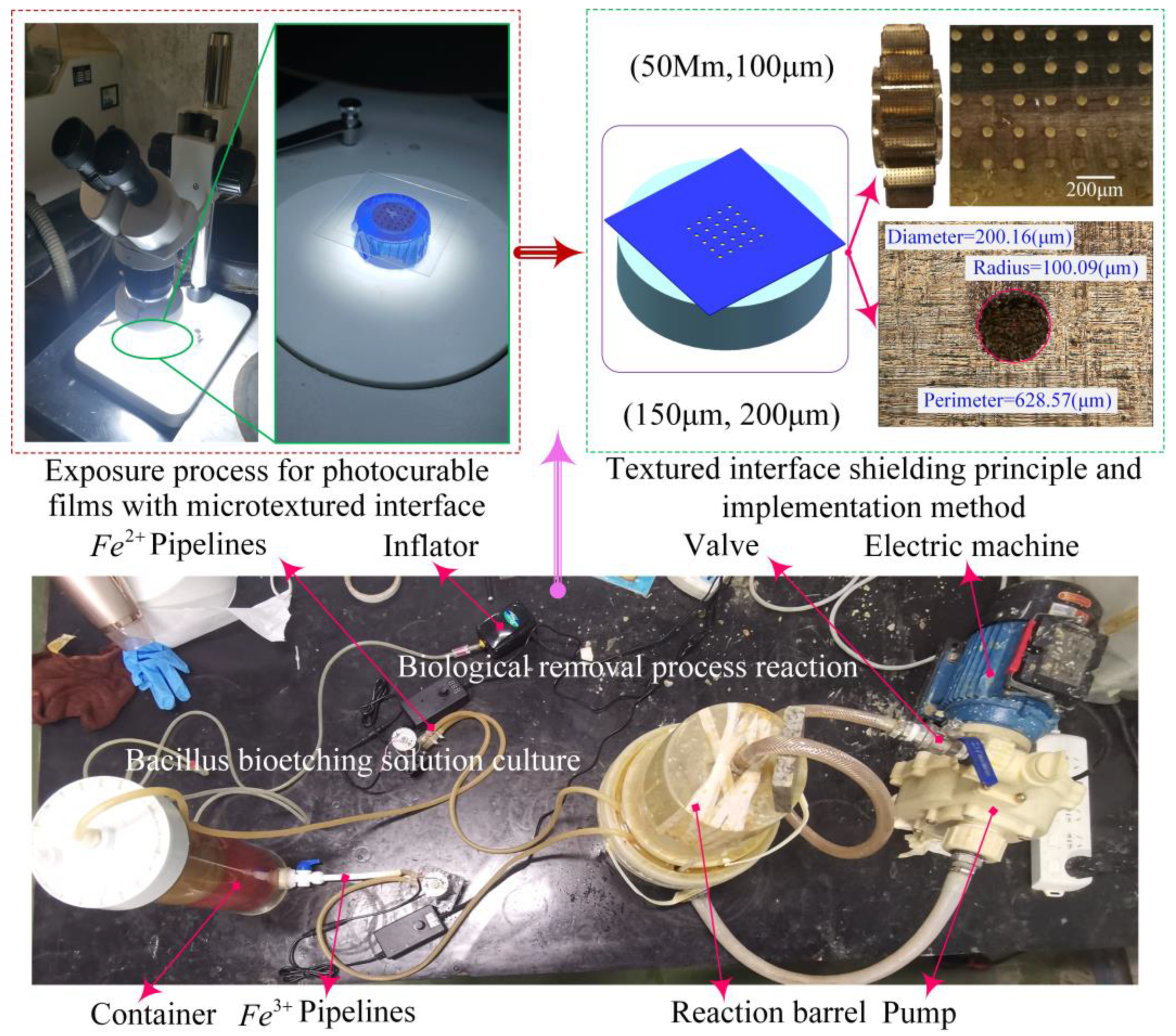

3.2. Optimized Experimental Details for Model Verification

4. Analysis of Simulation Results

4.1. Hypothesis of Dynamic Alternating Distribution of Contact Lines on Micro-Textured Gear Meshing Interfaces

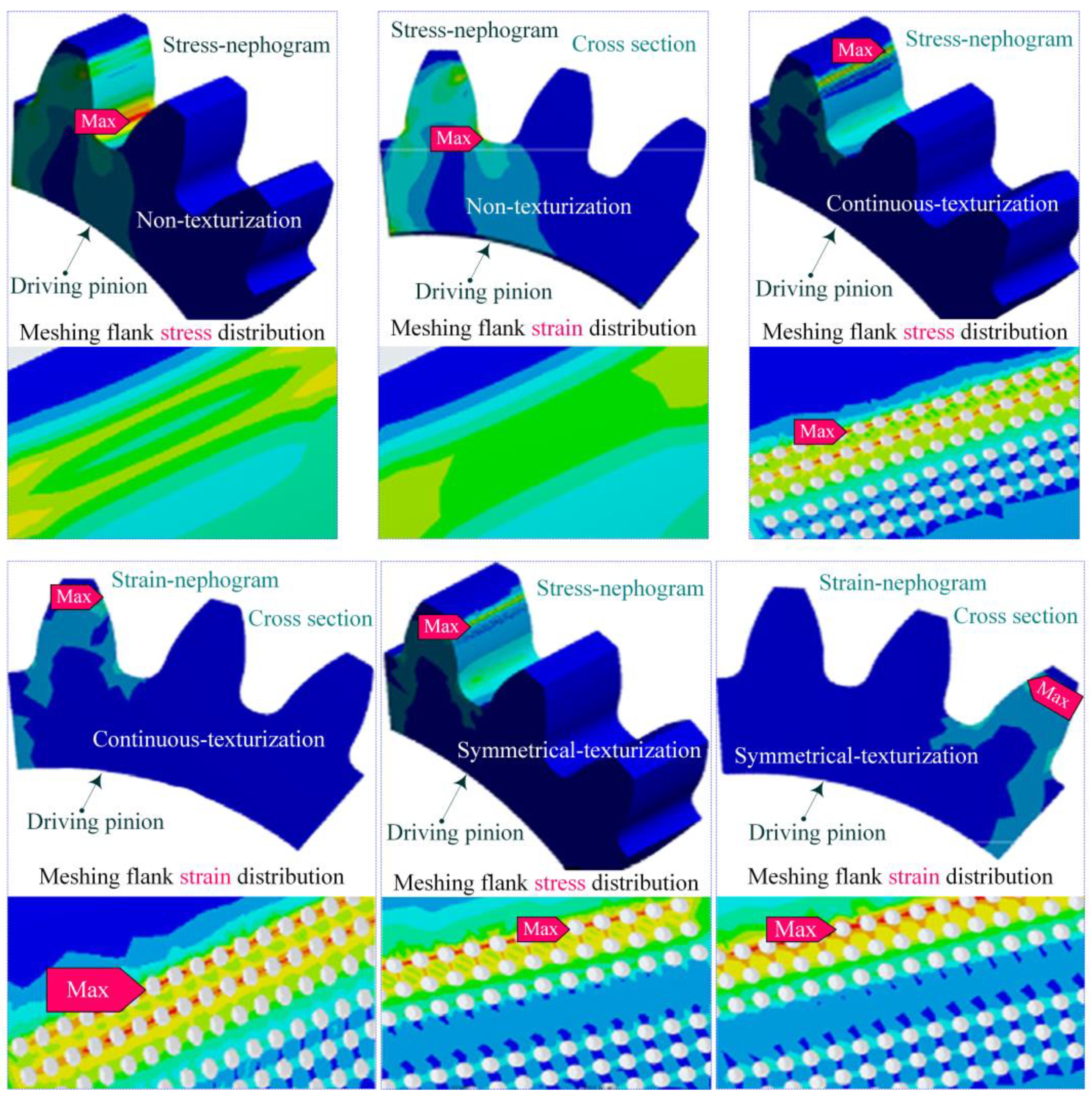

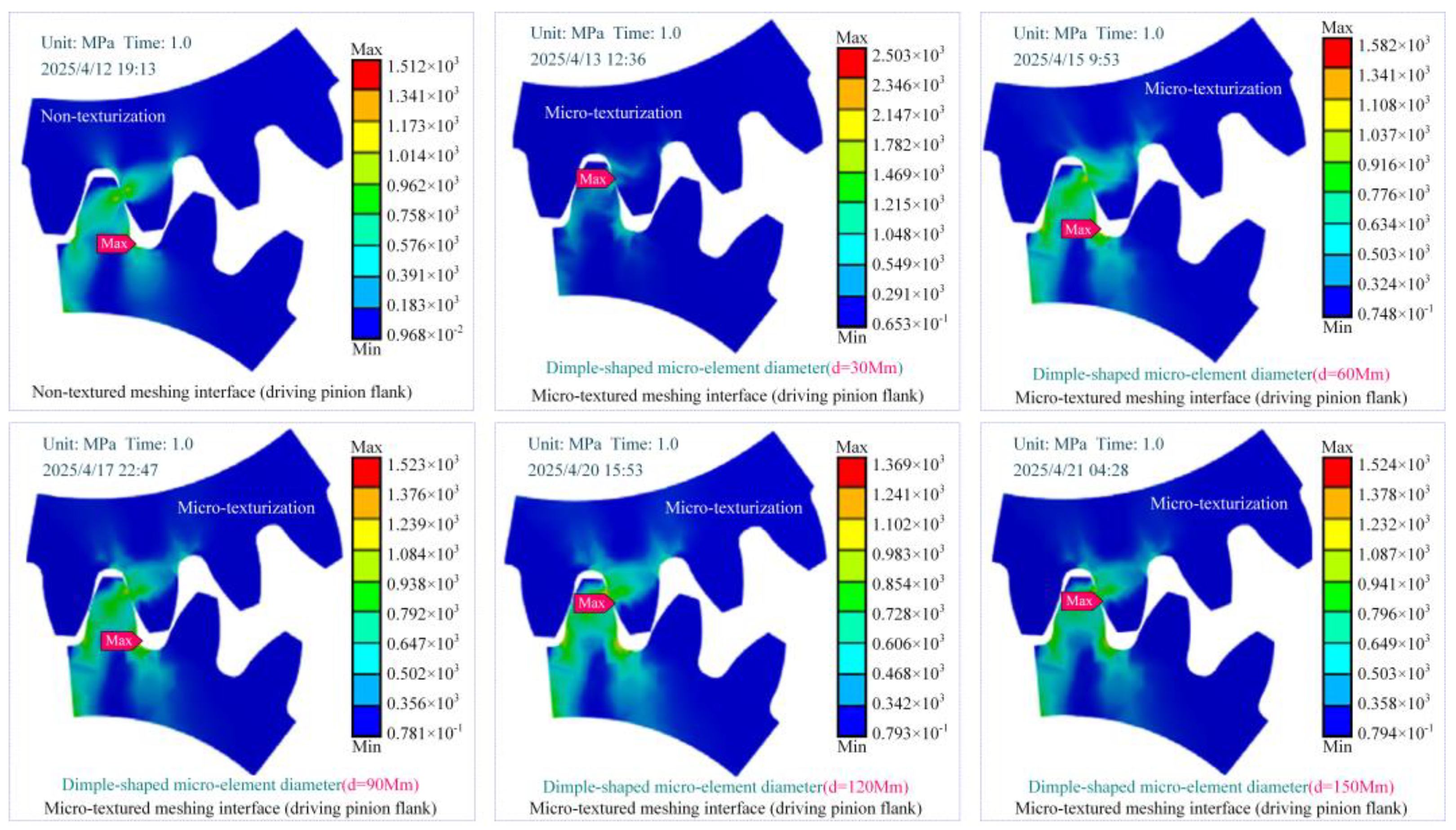

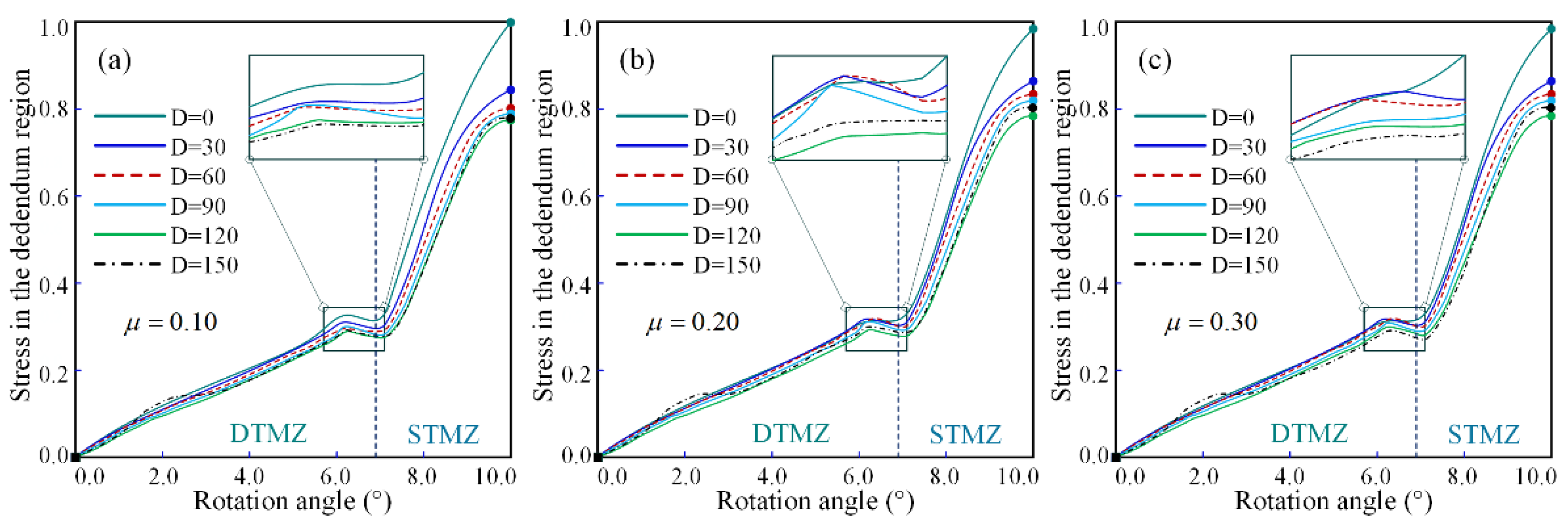

4.2. Transient Contact Stress/Strain Analysis of Interface Meshing Zones

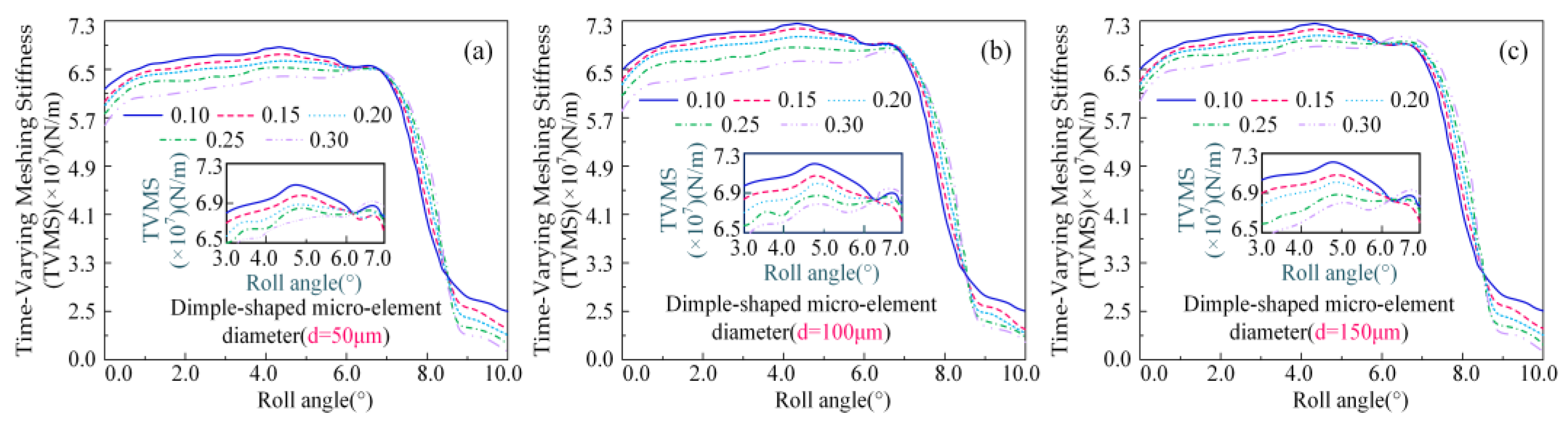

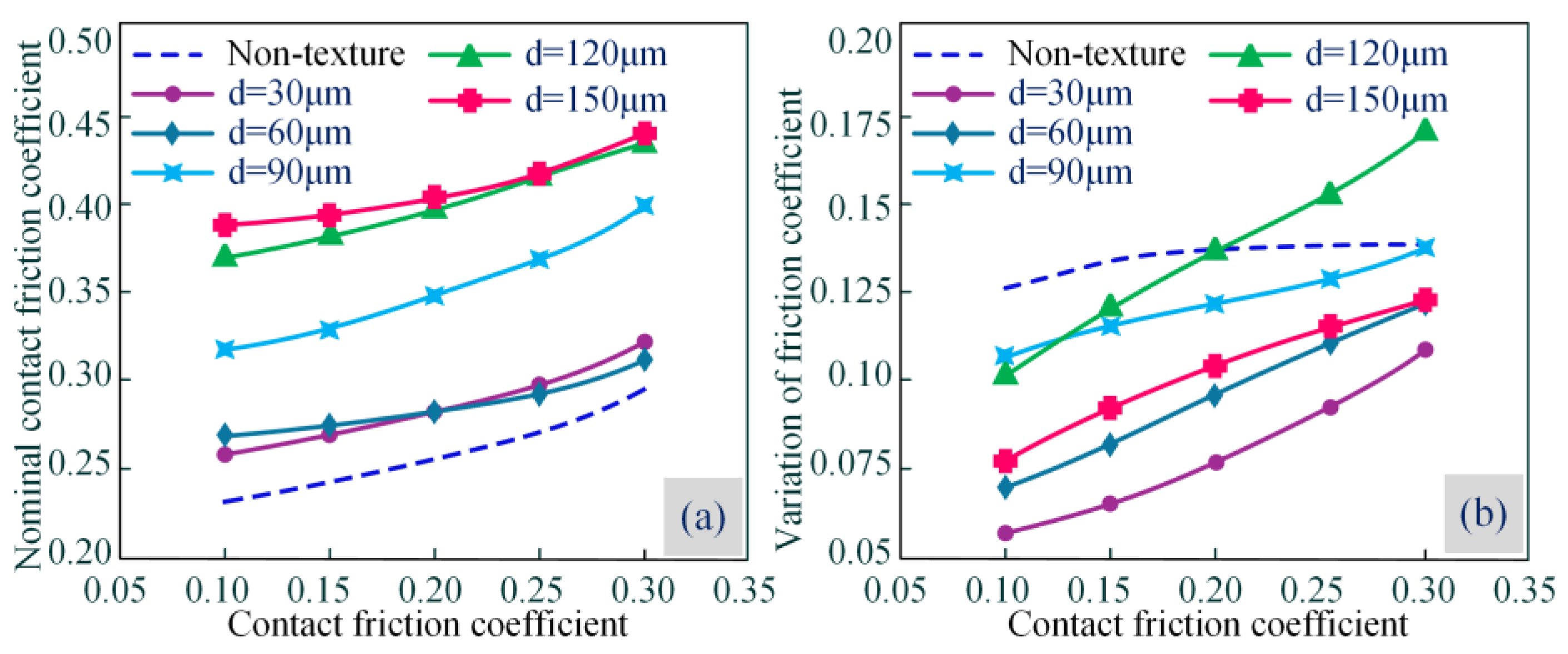

4.3. Synergistic Regulation of Meshing Stiffness and Load-Bearing Characteristics for Transient Contact Process of Micro-Textured Interfaces

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Galda, L.; Sep, J.; Olszewski, A.; Zochowski, T. Experimental investigation into surface texture effect on journal bearings performance. Tribol. Int. 2019, 136, 372–384. [Google Scholar] [CrossRef]

- Codrignani, A.; Savio, D.; Pastewka, L.; Frohnapfel, B.; Ostayen, R.V. Optimization of surface textures in hydrodynamic lubrication through the adjoint method. Tribol. Int. 2020, 148, 106352. [Google Scholar] [CrossRef]

- Xiao, Z.L.; Zhou, C.J.; Li, Z.D.; Zheng, M. Thermo-mechanical characteristics of high-speed and heavy-load modified gears with elasto-hydrodynamic contacts. Tribol. Int. 2019, 131, 406–414. [Google Scholar] [CrossRef]

- Chimanpure, A.S.; Kahraman, A.; Talbot, D. A transient hybrid elastohydrodynamic lubrication model for helical gear contacts. J. Tribol. 2021, 143, 061601. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, S.C. Textured conical hybrid journal bearing with ER lubricant behavior. Tribol. Int. 2019, 129, 363–376. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.J.; Zhu, C.C.; Parker, R.G. Effects of lubrication on gear performance: A review. Mech. Mach. Theory. 2020, 145, 103701. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H.L. Surface texturing in machine elements—A critical discussion for rolling and sliding contacts. Adv. Eng. Mater. 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Yue, H.Z.; Deng, J.X.; Zhang, Y.; Meng, Y.; Zou, X.Q. Characterization of the textured surfaces under boundary lubrication. Tribol. Int. 2020, 151, 106359. [Google Scholar] [CrossRef]

- Liu, W.L.; Ni, H.J.; Wang, P.; Chen, H.L. Investigation on the tribological performance of micro-dimples textured surface combined with longitudinal or transverse vibration under hydrodynamic lubrication. Int. J. Mech. Sci. 2020, 174, 105474. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Li, X.; Hu, R.Y.; Long, X.Y.; Wu, Z.; Liu, L. Numerical analyses of rectangular micro-textures in hydrodynamic lubrication regime for sliding contacts. Meccanica 2021, 56, 365–382. [Google Scholar] [CrossRef]

- Kaneta, M.; Matsuda, K.; Nishikawa, H. The causes of asymmetric deformation of surface contact micro kurtosis asperities in elastohydrodynamic lubrication contacts. J. Tribol. 2022, 144, 061601. [Google Scholar] [CrossRef]

- Huangfu, Y.F.; Dong, X.J.; Chen, K.K.; Peng, Z.K. Coupling mechanism between systematic elastic deformation and gear surface damage. Int. J. Mech. Sci. 2023, 238, 107850. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Li, B.T.; Hua, M.; Dong, G.N. Improving processing quality and tribological behavior of laser surface textures using oil layer method. Tribol. Int. 2020, 150, 106353. [Google Scholar] [CrossRef]

- Chen, Z.; Jiang, Y.; Li, S.; Tong, Z.; Tong, S.; Tang, N. Uncertainty propagation of correlated lubricant properties in gear tribodynamic system. Tribol. Int. 2023, 179, 107812. [Google Scholar] [CrossRef]

- Arasan, U.; Marchetti, F.; Chevillotte, F.; Tanner, G.; Chronopoulos, D.; Gourdon, E. On the accuracy limits of plate theories for vibro-acoustic predictions. J. Sound Vib. 2021, 493, 115848. [Google Scholar] [CrossRef]

- Wang, Y.; Azam, A.; Zhang, G.; Dorgham, A.; Liu, Y.; Wilson, M.C.T.; Neville, A. Understanding the Mechanism of Load-Carrying Capacity between Parallel Rough Surfaces through a Deterministic Mixed Lubrication Model. Lubricants. 2022, 10, 12. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhou, C.; Chen, S.; Li, Z. Effects of oil film stiffness and damping on spur gear dynamics. Nonlinear Dyn. 2019, 96, 145–159. [Google Scholar] [CrossRef]

- Rajput, H.; Atulkar, A.; Porwal, R. Optimization of the surface texture on piston ring in four-stroke IC engine. Mater. Today Proc. 2021, 44, 428–433. [Google Scholar] [CrossRef]

- Liu, S.; Qiu, L.; Wang, Z.; Chen, X. Influences of Iteration Details on Flow Continuities of Numerical Solutions to Isothermal Elastohydrodynamic Lubrication With Micro-Cavitations. J. Tribol. 2021, 143, 101601. [Google Scholar] [CrossRef]

- Lv, F.; Zhang, X.; Ji, C.; Rao, Z. Theoretical and experimental investigation on local turbulence effect on mixed-lubrication journal bearing during speeding up. Phys. Fluids. 2022, 34, 113104. [Google Scholar] [CrossRef]

- Torres, T.; Changenet, C.; Touret, T.; Guilbert, B. A New Experimental Methodology to Study Convective Heat Transfer in Oil Jet Lubricated Gear Units. Lubricants 2023, 11, 408. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C. A New Deterministic Model for Mixed Lubricated Point Contact With High Accuracy. J. Tribol. 2021, 143, 102201. [Google Scholar] [CrossRef]

- Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Investigation on the Wear Performance of Nano-Additives on Degraded Gear Lubricant. Lubricants. 2023, 11, 51. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Ma, L.; Jin, Z.; Prakash, B.; Ma, T.; Wang, W.J.F. A review of advances in tribology in 2020–2021. Friction 2022, 10, 1443–1595. [Google Scholar] [CrossRef]

- Yang, X.K.; Tofighi-Niaki, E.; Zuo, M.J.; Tian, Z.G.; Safizadeh, M.S.; Qin, D.L. Analysis of spur gearbox dynamics considering tooth lubrication and tooth crack severity progression. Tribol. Int. 2023, 178, 108027. [Google Scholar] [CrossRef]

- Wang, Y.C.; Dorgham, A.; Liu, Y.; Wang, C.; Wilson, M.C.T.; Neville, A.; Azam, A. An Assessment of Quantitative Predictions of Deterministic Mixed Lubrication Solvers. J. Tribol. 2021, 143, 011601. [Google Scholar] [CrossRef]

- Lu, R.; Tang, W.; Huang, Q.; Xie, J. An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication. Lubricants 2023, 11, 177. [Google Scholar] [CrossRef]

- Rohan, E.; Lukeš, V. Homogenization of the vibro–acoustic transmission on perforated plates. Appl. Math. Comput. 2019, 361, 821–845. [Google Scholar] [CrossRef]

- Patel, R.; Khan, Z.A.; Bakolas, V.; Saeed, A. Numerical Simulation of the Lubricant-Solid Interface Using the Multigrid Method. Lubricants 2023, 11, 233. [Google Scholar] [CrossRef]

- Singh, K.; Sadeghi, F.; Russell, T.; Lorenz, S.J.; Peterson, W.; Villarreal, J.; Jinmon, T. Fluid–Structure Interaction Modeling of Elastohydrodynamically Lubricated Line Contacts. J. Tribol. 2021, 143, 091602. [Google Scholar] [CrossRef]

- Zhou, W.G.; Zhu, R.P.; Liu, W.Z.; Shang, Y.W. An Improved Dynamic Transmission Error Model Applied on Coupling Analysis of Gear Dynamics and Elastohydrodynamic Lubrication. J. Tribol.-Trans. Asme. 2022, 144, 051601. [Google Scholar] [CrossRef]

- Tu Zh., R.; Meng, X.K.; Ma, Y.; Peng, X.D. Shape optimization of hydrodynamic textured surfaces for enhancing load-carrying capacity based on level set method. Tribol. Int. 2021, 162, 107136. [Google Scholar] [CrossRef]

- Chen, M.; Xiong, X.; Zhuang, W. Design and Simulation of Meshing Performance of Modified Straight Bevel Gears. Metals. 2021, 11, 33. [Google Scholar] [CrossRef]

- Meng, F.M.; Yu, H.Y.; Gui, C.; Chen, L. Experimental study of compound texture effect on acoustic performance for lubricated textured surfaces. Tribol. Int. 2019, 133, 47–54. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Comparing tribological effects of various chevron-based surface textures under lubricated unidirectional sliding. Tribol. Int. 2020, 146, 106205. [Google Scholar] [CrossRef]

- Patel, R.; Khan, Z.A.; Saeed, A.; Bakolas, V. A review of mixed lubrication modelling and simulation. Tribol. Ind. 2021, 44, 150–168. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q.J.; Chung, Y.-W.; Berkebile, S. Lubrication–Contact Interface Conditions and Novel Mixed/Boundary Lubrication Modeling Methodology. Tribol. Lett. 2021, 69, 164. [Google Scholar] [CrossRef]

- Shi, X.J.; Lu, X.Q.; He, T.; Sun,W. ; Tong, Q.S.; Ma, X.; Zhao, B.; Zhu, D. Predictions of friction and flash temperature in marine gears based on a 3D line contact mixed lubrication model considering measured surface roughness. J. Cent. South Univ. 2021, 28, 1570–1583. [Google Scholar] [CrossRef]

- Patel, R.; Khan, Z.A.; Saeed, A.; Bakolas, V. CFD Investigation of Reynolds Flow around a Solid Obstacle. Lubricants 2022, 10, 150. [Google Scholar] [CrossRef]

- Chang, X.; Renqing, D.; Liao, L.; Zhu, P.; Lin, B.; Huang, Y.; Luo, S. Study on hydrodynamic lubrication and friction reduction performance of spur gear with groove texture. Tribol. Int. 2023, 177, 107978. [Google Scholar] [CrossRef]

- Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants 2023, 11, 201. [Google Scholar] [CrossRef]

- Cheng, G.; Ma, J.; Li, J.; Sun, K.; Wang, K.; Wang, Y. Study on the Dynamic Characteristics of Gears Considering Surface Topography in a Mixed Lubrication State. Lubricants 2024, 12, 7. [Google Scholar] [CrossRef]

- Ruan, J.; Wang, X.; Wang, Y.; Li, C. Study on Anti-Scuffing Load-Bearing Thermoelastic Lubricating Properties of Meshing Gears With Contact Interface Micro-Texture Morphology. Journal of Tribology 2022, 144. [Google Scholar] [CrossRef]

- Wang, X.; Huang, H.; Song, J.; Wang, Y.; Ruan, J. Numerical Analysis of Friction Reduction and ATSLB Capacity of Lubricated MTS with Textured Micro-Elements. Lubricants 2023, 11, 78. [Google Scholar] [CrossRef]

- Wang, X.; Ruan, J.; Wang, Y.; Zou, W. Analytical and Experimental Research of Lubrication Load-Bearing Characteristics of Microtextured Meshing Interface. Materials 2025, 18, 845. [Google Scholar] [CrossRef] [PubMed]

| Geometric Parameter Definitions | Driving Pinion | Driven Bull Gear |

| Module m (mm) | 3.0 | 3.0 |

| Teeth number z | 48 | 60 |

| Tooth width b (mm) | 70 | 70 |

| Young’s modulus E (GPa) | ||

| Poisson’s ratio ν | 0.36 | 0.36 |

| Micro-scale textured element dimension of meshing interface (μm) | 30-200 | Non-texturization |

| Pressure angle α (°) | 20 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).