1. Introduction

Biogas, like any energy fuel, requires compliance with certain conditions for efficient production and use. It is known that the stability of biogas plants and the energy output largely depend on the quality of the gas produced. However, among the many challenges facing the development of the biogas industry, on of the highest priorities is the organization of effective monitoring and management of biogas quality [

1]. Key characteristics such as methane levels, humidity, temperature and the presence of impurities have a direct impact on the energy value and safety of plant operations.

Quality control of biogas is a rather difficult task, especially for small and medium-sized producers, as it requires certain technical knowledge and understanding of the physico-chemical processors occurring in biogas reactors. Most farmers and plant operators, especially in developing countries, do not have the ability to perform regular laboratory analysis or use sophisticated measurement tools [

2].

Existing methods for assessing gas quality often do not allow for the rapid detection of parameter deviations, as they are based either on subjective observations or on manual samples, the analysis of which takes considerable time. Such approaches do not ensure accurate and timely decision-making on adjusting the operating mode of the installation, which can lead to reduced efficiency and increased costs [

5]. Therefore, the task of implementing intelligent systems capable of automating the process of monitoring and analyzing the quality of biogas in real time is becoming especially urgent.

In cases where more accurate and scientifically based control methods are needed, biogas producers are forced to resort to periodic sampling of gas and then sending them to a laboratory for analysis. However, this approach is time-consuming, requires significant time and human resources, and significantly slows down the decision-making process when deviations in quality parameters are detected [

3]. The use of portable analyzers and hand-held kits to assess the composition of biogas, although it represents a step forward, does not completely solve the problem, as it continues to rely on manual labor and does not provide continuous monitoring.

As a result of such restrictions, problems with the quality of biogas are usually discovered too lately – after the negative consequences begin to affect the operation of the equipment or the energy efficiency of the system. This leads to a decrease in plant productivity, a decrease in the overall profitability of production and direct losses for manufactures [

4]. In a broader context, such disruptions can have a negative impact on energy security, the sustainability of local farms, and the development of renewable energy in the region.

The emergence of modern technologies, including the development of high — precision electronic sensors, embedded systems, intelligent devices with Internet support, automation and artificial intelligence, has opened up broad prospects for the introduction of innovative solutions in various fields, including renewable energy and biogas production. Currently, scientific research is actively underway worldwide aimed at adapting these technologies to solve key problems related to sustainable energy production and efficient processing of organic waste [

6]. This contributed to the formation of the concept of “smart” biogas production based on the use of sensors, the Internet of Things (IoT), machine learning, real-time data analysis and intelligent algorithms, which allows solving a number of significant tasks and improving the productivity and reliability of biogas plants [

8].

The following key research questions were identified in this study. To effectively use the Internet of Things and intelligent automation technologies to measure, monitor and control biogas quality parameters. An IoT-based biogas quality management system can be effective in improving the stability of the plant and increasing energy production. An IoT sensor network and control module for continuous monitoring of critical biogas parameters such as methane levels, temperature and humidity have been developed and implemented, followed by data transfer to a cloud platform for storage and processing [ 9]. An intelligent algorithm for analyzing the obtained data has been developed with the ability to automatically interpret the results and control actuators to maintain optimal operating conditions for the plant. Testing and evaluation of the effectiveness of the proposed system under real operating conditions have been carried out..

The quality of biogas encompasses the totality of the physical and chemical characteristics of the gas that determine its suitability for efficient use in power plants. The quality parameters of biogas include all those properties that somehow affect caloric content, burning stability, safety of equipment operation and overall energy efficiency [

10]. Many studies have been conducted to study the key components of biogas and the factors affecting its quality. Insufficient understanding of these factors can lead to low energy output, unstable operation of installations and even damage to equipment [

1].

Among the many parameters that determine the quality of biogas, the following are of the greatest importance: the concentration of methane, the content of hydrogen sulfide and other harmful impurities, humidity, gas temperature, carbon dioxide and oxygen content. These parameters are critical, as they directly affect the possibility of using biogas in cogeneration plants or for heating, as well as the service life of equipment. Nevertheless, special attention in monitoring systems should be paid precisely to those indicators that determine the energy value and safety of biogas use to the greatest extent, since they are the ones that can be controlled and regulated using modern intelligent management methods [

11].

Review of relevant research papers on the use of the Internet of Things in biogas quality management

A number of researchers have explored the possibilities of using Internet of Things (IoT) technologies to monitor and manage parameters in various industries, including agriculture and aquaculture. These approaches have formed the basis of modern intelligent systems that can be adapted for quality control of biogas.

For example, Agossu and Toshiro [

27] developed an IoT system combined with artificial intelligence to control water parameters in fish farming. In their work, electronic sensors were used to measure nine indicators, including pH, temperature, turbidity, dissolved oxygen level, electrical conductivity, total dissolved substances, carbon dioxide, ammonia and water level. Data was collected using an Arduino microcontroller and data was transferred to the cloud via an ESP32 module and Wi-Fi. To analyze the data, they used an algorithm based on a convolutional neural network (CNN) designed to predict diseases in fish.

Jan and co-authors [

14] proposed a simplified IoT model for monitoring water quality, including sensors for monitoring pH, temperature, turbidity and water level, as well as a fish motion detector. Data from the sensors was collected by an Arduino Uno microcontroller and transmitted via a GSM module to a desktop server, from where the user could track information in real time. Unlike cloud solutions, a local database was used for data storage. The authors focused on reducing the cost of development, which affected the functionality of the system, limiting the use of the some key advantages of the IoT.

Khairol and co-authors have developed an automated control system for pond fish farming based on the Arduino Mega microcontroller [

15]. The system controlled only two parameters — the water temperature and its level — but at the same time included the functions of automatic feed supply and water replacement. A Wi-Fi module was used to transfer data, thanks to which information was sent to an Android application accessible to the user. However, the capabilities of the Internet of Things in this system were partially implemented: the user could view only data, but could not control the system remotely. In addition, the system’s actions were performed on a timer, without the use of intelligent algorithms for data analysis or decision-making.

Flores-Iwasaki and co-authors have implemented a more advanced monitoring system for water quality in aquaculture, with the ability to track parameters such as temperature, pH, electrical conductivity and color [

16]. Data collection was carried out using Arduino and information processing and data transmission were implemented on the basis of a Raspberry Pi mini-computer. A smartphone camera connected to a Raspberry Pi was used to analyze the color of the water. The system provided the user with access to information both via local Wi-Fi and via Internet using an Android application. The program could perform basis parameter analysis and assess the overall condition of the water, offering recommendations on necessary actions. However, automatic decision-making and management based on intelligent algorithms have not been implemented.

The described examples demonstrate the potential of using IoT in monitoring systems and also indicate the importance of further development towards the intellectualization of such solutions. These developments can be adapted to create a biogas quality management system in which sensors will monitor parameters.

Both approaches demonstrate the practical application of the Internet of Things for real-time monitoring and management. When the values exceed the set limits, the intelligent controller can initiate automatic corrective actions, such as changing the feed mode, activating filtration systems, adjusting the temperature or giving a command to start ventilation. This solution significantly increases the reliability, safety and efficiency of biogas production.

Company Flowvy has introduced a solution based on a Raspberry Pi single-board computer with an integrated solar-powered Wi-Fi module, which makes the system non-volatile and convenient for installation in remote locations [

17]. Sensors were connected to the device, data from which was transmitted to the operator via the Internet of Things network. However, the system only allowed parameter monitoring: the user could view the data, but could not remotely control the actuators. In addition, there was no automatic parameter adjustment.

In another study, an IoT system was introduced that can automatically adjust key parameters. The system was built on the basis of the ESP8266 microcontroller and used a serverless architecture using the Firebase cloud database for real-time data exchange [

18].

Srikar Meka and colleagues have developed an intelligent IoT system based on a wireless sensor network with Zigbee architecture. The main focus of their work was on increasing energy efficiency and flexibility of the network structure, which is important for industrial environments with limited power supply or, if necessary, system scaling [

19].

From the analysis of existing solutions, it can be seen that considerable attention was paid to the collection and transfer of technological data to web platforms or mobile applications. However, most systems are limited only to parameter monitoring, without full support for remote control or intelligent automatic process correction. This highlights the need to develop an integrated IoT system for biogas plants that not only provides continuous monitoring of parameters, but is also capable of autonomously controlling these parameters by performing corrective actions without operator involvement. This solution will improve the sustainability, safety and efficiency of biogas production.

2. Materials and Methods

We have built our own bio-installation based at the Institute of Information and Computing Technologies, including 8 full-fledged bioreactors of 30 cubic meters, combined into a single technological chain. Each bioreactor is equipped with a heating, mixing and automatic control system for environmental parameters. Bioreactors operate in anaerobic mode, converting organic waste into biomethane, carbon dioxide and high-quality biofertilizers. To protect against climatic influences, a hangar protective dome with an area of 240 m² was built over the reactor block. A pressure tower and homogenizer were installed for efficient preparation and dosing of the substrate into the bioreactors. All eight bioreactors are integrated into a digital control system with the ability to monitor via a mobile application. The installation includes automated bottling and packaging lines for biofertilizers, as well as a biogas compression system. We used modern 3D modeling and simulation methods to optimize the design of each bioreactor. The technological process is fully automated and allows for the installation to be controlled in real time from the operator’s workstation.

The developed intelligent biogas quality management system is an integrated solution for automated monitoring and control of biogas production parameters. The system includes the following key functions:

Collecting data on biogas quality parameters;

Data transmission over the Internet using wireless networks;

Processing incoming sensor data in real time;

Record and store information in a cloud database;

Display of system parameters via the web interface for a remote user;

Generating emergency notifications and sending alerts when indicators exceed acceptable limits;

Receiving commands from the user for remote control of the system;

Automatic implementation of corrective actions without operator involvement.

Such a system provides not only monitoring, but also intelligent control of the technological process, increasing the stability, safety and efficiency of the biogas plant.

Description of the system

The developed biogas quality monitoring system uses sensors designed to measure key process parameters. These sensors continuously collect data on the condition inside the biogas plant and transmit it to the control module. The control module performs primary data processing and transfers them to a cloud database via a Wi-Fi network connection. The cloud database stores incoming information in real time and provides an opportunity for its subsequent analysis and visualization.

The user gets access to the data through a web application that connects to the cloud and displays system performance on an interactive dashboard. The system supports two-way communication between the user and the installation, allowing not only to control the parameters, but also to remotely control the system components. If the controlled parameters exceed the set permissible limits, the system automatically activates the correction mechanisms. This can be, for example, the inclusion of pumps for supplying neutralizing additives, removing gas, or regulating temperature [

20].

In addition, the management module is integrated with the WhatsApp API, which allows the system to send alarm notifications directly to the user’s mobile device. Thus, if critical deviations are detected, the user immediately receives a message in WhatsApp with the relevant information and can promptly take action either manually or allow the system to act automatically.

The developed intelligent biogas quality management system supports two-way communication and can operate in both automatic and manual mode. In automatic mode, the built-in intelligent algorithm implemented in the control module independently controls the process — the system automatically reacts to the deviations of parameters form the set values. In this case, the corresponding actuators, such as pumps or ventilation units, are activated without the need for user intervention. The user receives notifications and has access to an event log that records all automatic system actions.

In manual mode, the system performs monitoring functions: collects transmits and displays data on the current installation parameters. In this case, the control of the actuators is completely carried out by the user through the web interface. The user can manually start or turn off the equipment depending on the current situation and the data received. This approach provides flexibility in the operation of the system, allowing control to be adapted both for fully autonomous conditions and for scenarios involving the operator.

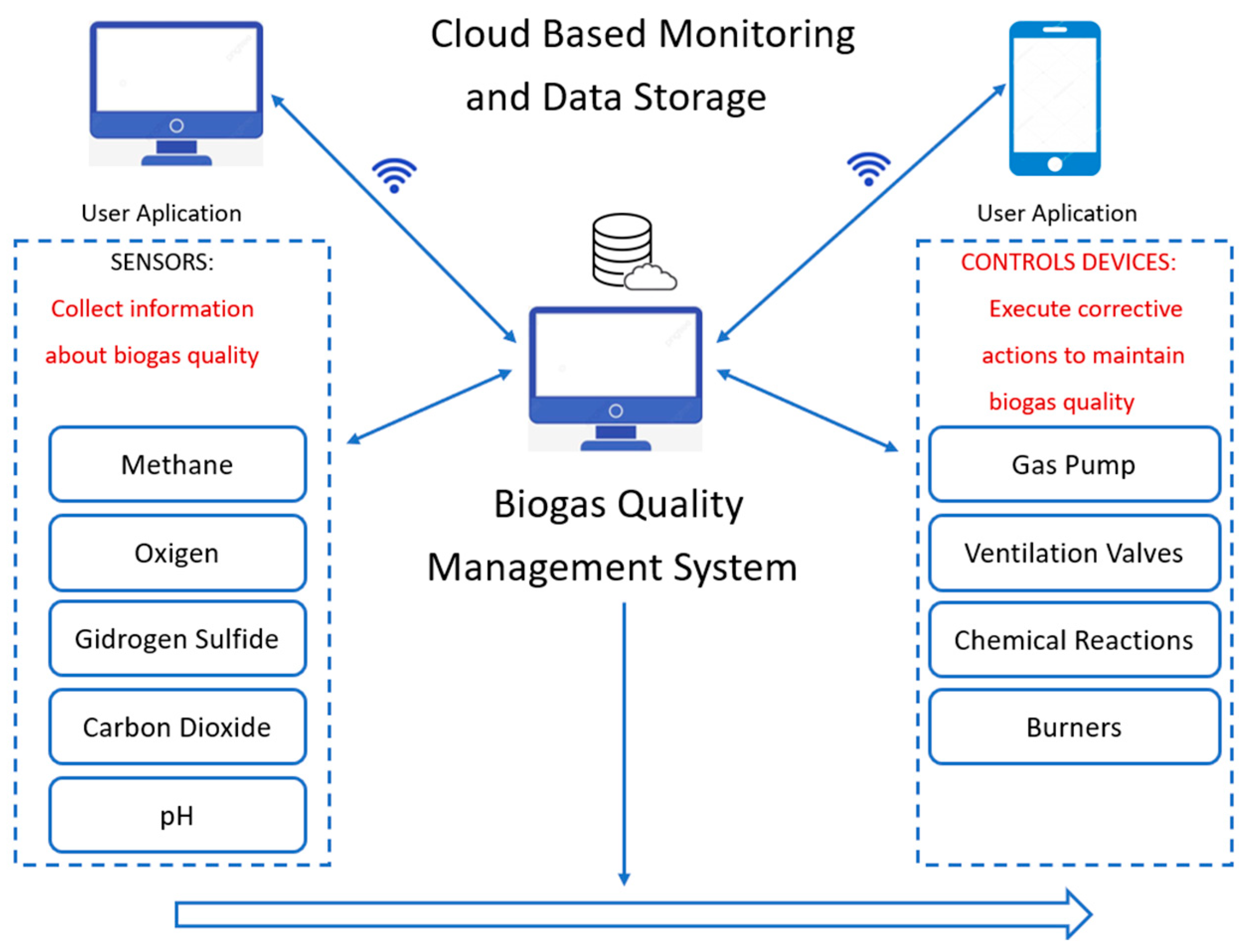

The image in

Figure 1 shows a block diagram of an intelligent biogas quality management system based on the Internet of Things (IoT) technologies. On the left side of the circuit there are sensors that collect real-time data on key parameters of biogas. All this data is fed into the central module, the Biogas Quality Management System, which analyzes the information, transfers it to the cloud storage and, if necessary, initiates control actions to maintain stable parameters.

Above the management system, there is a cloud data storage and a monitoring module, which provides centralized information storage and access to data for remote users. There is a computer in the upper-left corner of the diagram, and a smartphone in the upper-right corner symbolizing that the user can control and operate the system form both a personal computer and a mobile device.

On the right side of the circuit there are actuating devices. These devices perform corrective actions in automatic when the system detects a deviation of the parameters from the set values, thereby maintaining stable biogas quality [

22]. The lower part of the diagram shows the flow of the biogas, which highlights the maintain direction of gas movement and demonstrates that the entire system is built around its monitoring and management. This architecture illustrates the modern approach to managing technological process of biogas production based on IoT, ensuring high efficiency, responsiveness and remote quality of biogas. Selection of hardware components. To build an intelligent monitoring system for the parameters of a biogas plant, reliable and proven sensors were selected to ensure accurate measurements in an industrial environment.

The DS18B20 in a waterproof design was used as a temperature sensor. This sensor is highly accurate and stable, does not require additional external components, and can be used in the temperature range from –55 °C to +125 °C with an accuracy of ±0,5 °C, which makes it particularly suitable for monitoring the temperature regime inside a bioreactor [

21].

An analog pH sensor SEN0161 was used to measure the acidity level of the medium. It is easy to connect and specially adapted for industrial applications. The sensor is equipped with a standard BNC connector connected to an analog-to-digital conversion (ADC) module, which allows efficient interaction with the microcontroller.

The degree of contamination of the medium was monitored using the SEN0189 concentration density sensor, which determines the amount of suspended particles using the measurement of the luminous flux and its scattering angle. This allows you to estimate the total suspended solids (TSS), which is important for the stable operation of the installation.

In the system, the sensors were configured to operate in analog mode. The signals from the analog output connected to pin A0 of the microcontroller are read as a floating voltage value. The digital signal is converted according to the formula:

where Vcc is the supply voltage. This allows you to convert an analog signal into a voltage within acceptable limits of the value corresponding to the concentration of the monitored indicator.

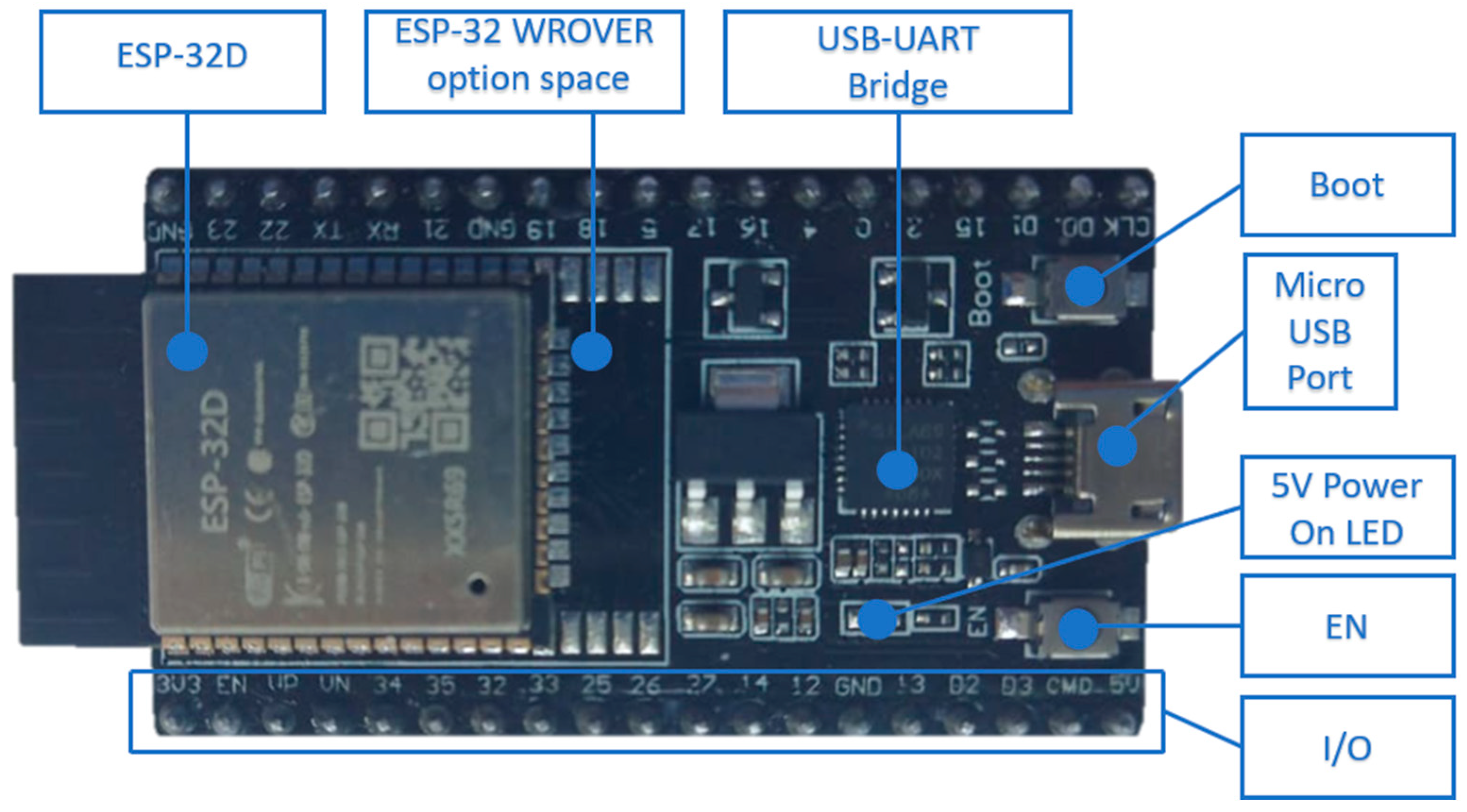

The ESP32 microcontroller shown in

Figure 2 was chosen as the central element of the control system.

This device has built-in Wi-Fi modules and dual-mode Bluetooth. The ESP32 is ideal for IoT tasks, as it supports real-time data acquisition, processing, storage and transmission. Thanks to the built-in communication facilities, there is no need to connect additional GSM or LTE modules. Support for TCP/IP, HTTP, HTTPS and other network standards allows the microcontroller to easily interact with external web servers or function as its own server accessible to remote devices [

23].

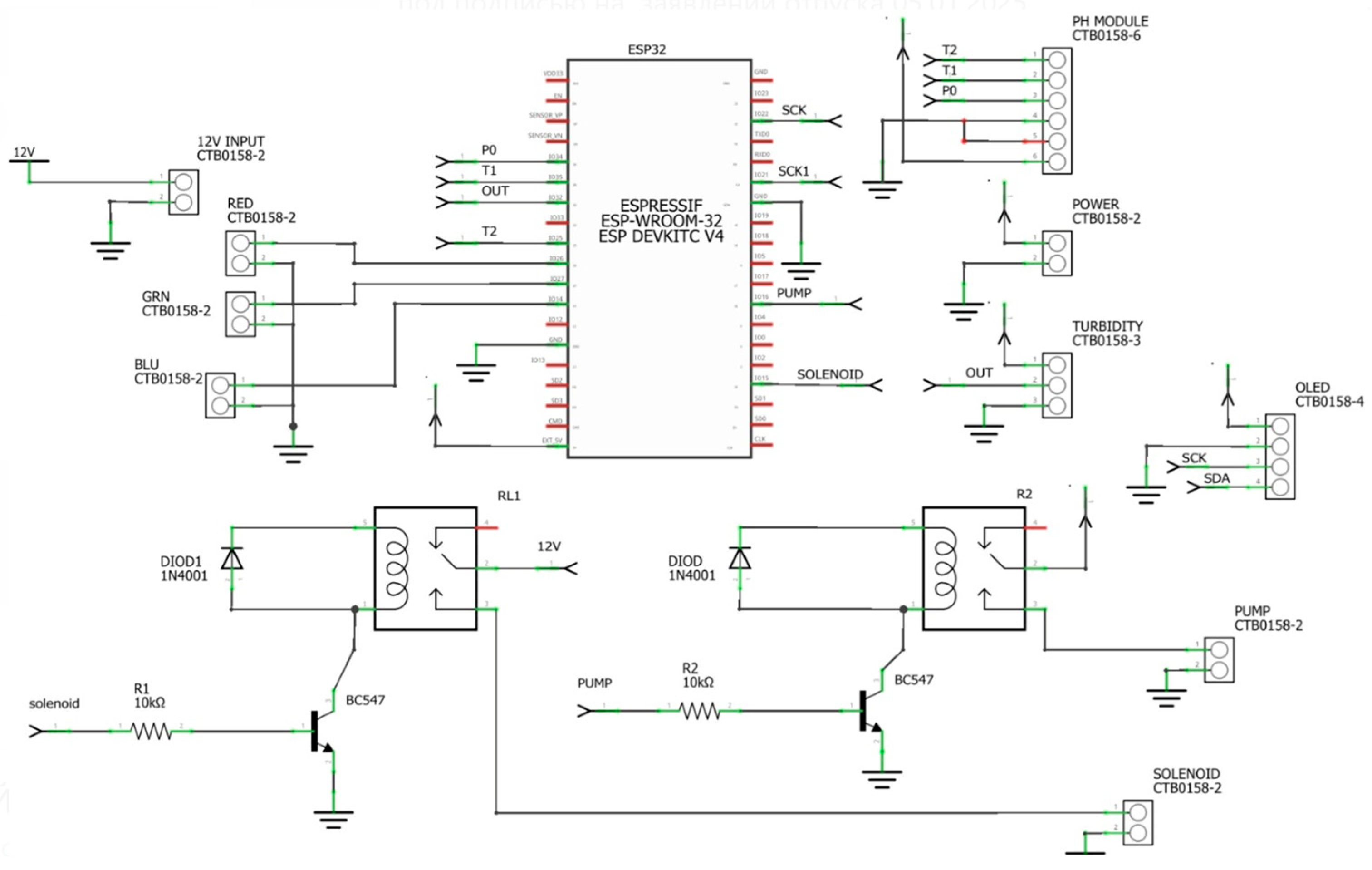

The schematic diagram of the control system was developed and modeled in the Proteus 8.0 software. A visual representation of the scheme of the IoT module adapted for process control in a biogas plant is shown in . 2.

After completing the circuit design, a printed circuit board (PCB) layout was created to implement the control circuit in hardware form. The PCB design was also made using the Proteus environment, which ensured accurate implementation and reliable assembly of the electronic part of the device.

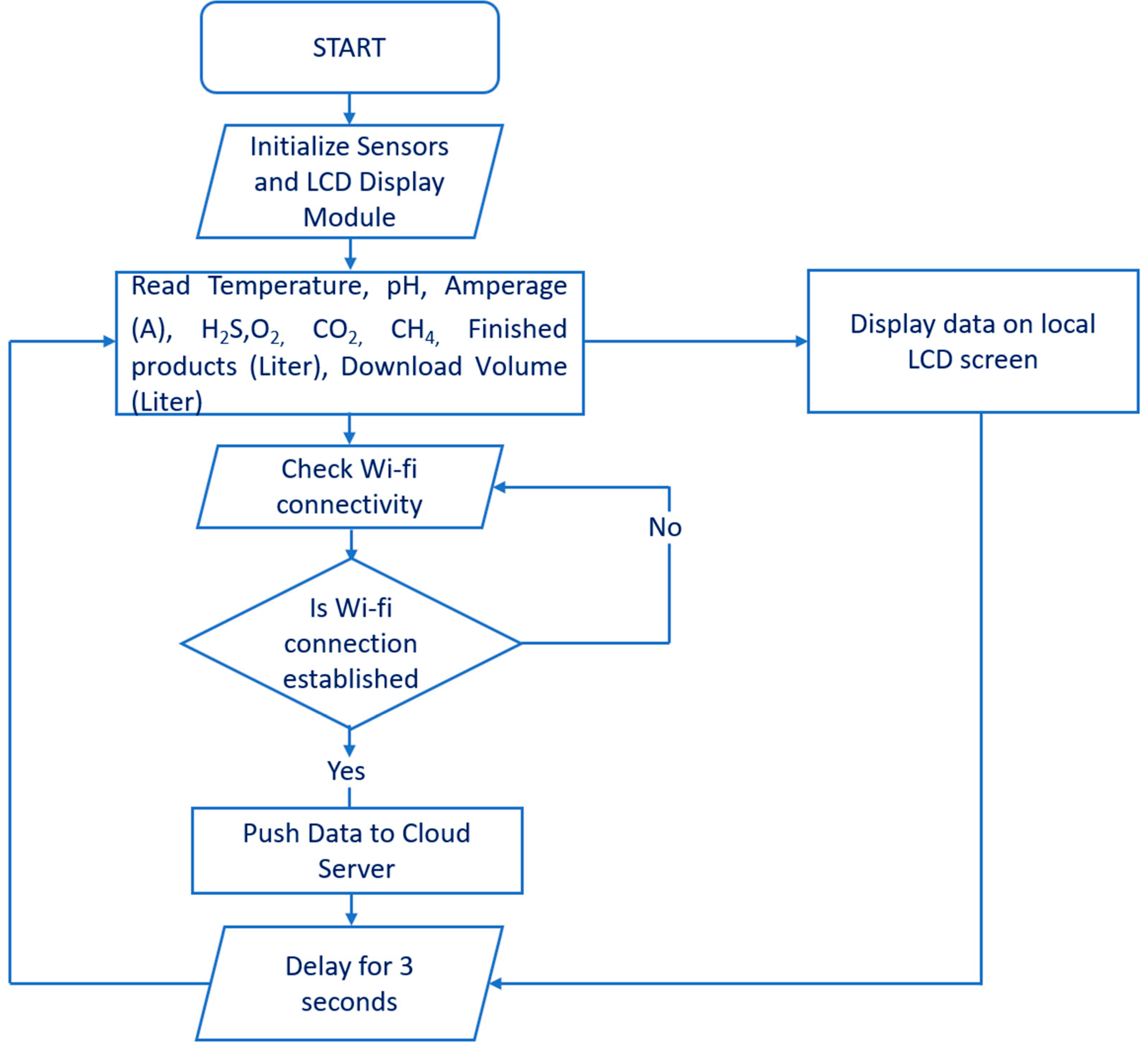

Microcontroller software: data reading and transmission

The software for the microcontroller control module was developed in C programming language. After startup, the device initializes the connected sensors and begins reading their current values. In parallel, the search for available Wi-Fi networks is performed. If the device detects the network to which it is configured, the module automatically connects to it and establishes a secure connection to a cloud server hosting the database and user interface [

24].

After the connection is established, the system immediately starts transmitting data from the sensors to the cloud server. In case of loss of Internet connection or inability to connect, the microcontroller temporarily stores data in the built-in memory and displays current parameters on the local LCD screen. As soon as the connection is restored, the accumulated data is automatically uploaded to the server.

The software algorithm is designed as a continuous cycle that ensures round-the-clock operation of the system without restarting while the device’s power supple remain active.

Database and user interface: receiving, storing and displaying data

To implement data storage and visualization in the system under development, the Firebase cloud platform was used, which provides a database and a web interface user interaction.

Firebase is a modern cloud-based Backend-as-a-Service (BaaS), solution that provides a wide range of functions, including a real-time database, cloud storage, authentication system, failure monitoring, machine learning tools, remote configuration and static content hosting. All data coming from the microcontroller is automatically recorded in a cloud database [

25].

In addition to the raw values coming from sensors, additional information is also stored in the database: timestamps, parameter status, the current state of actuators, and also, the selected operating mode of the system is manual or automatic, set by the user.

A web application linked to the database provides the operator with access to a visual real-time dashboard. Through this interface, the user can view the current state of the installation, the log of parameter changes, and control the devices with the intelligent circuit system in

Figure 3.

The web application with user interface was developed using HTML5, CSS and JavaScript. It provides a graphical representation of all the information received from the Internet of Things management module stored in the database. A block diagram receiving and displaying data from an Internet of Things device is shown in

Figure 4

Implementation of control actions. The intelligent control system based on Internet of Things technologies includes an automatic control function that allows the system to independently activate or disable actuators (for example, pumps vales, ventilation) when the controlled parameters deviate from the set permissible values. The control module not only collects and transmits data, but also performs their analysis, interpretation and decision — making without operator involvement in order to maintain stable conditions inside the biogas plant [

26].

The system operates in two modes: manual and automatic. In manual mode, the IoT module monitors and evaluates the values of parameters, but does not take any action. The user makes decisions and manages the system manually via the web interface.

In automatic mode, the system independently analyzes the current data and, if deviations are detected, automatically initiates control actions. All actions are recorded in the log and displayed to the user in the web application in real time.

3. Results

This study confirmed the high applicability of IoT technologies for automation of biogas production control, and also identified areas for further improvement of the system in order to increase its intelligence, energy efficiency and scalability, taking into account the thresholds of key parameters (

Table 1) for system management.

Table 1 provides a summary of the set thresholds for key biogas quality parameters and the algorithms of the intelligent control system when these parameters deviate from acceptable standards.

Table 1 shows the following for each controlled parameter:

Threshold values. The established minimum and maximum permissible limits, within which the parameters must be in order to ensure a stable and safe biogas production process. For example, the optimal range is set for pH, beyond which there is a risk of inhibiting fermentation.

Critical deviations. Describes the conditions under which the parameter exceed the set thresholds. Such deviations may indicate a violation of anaerobic conditions, deterioration of gas quality, or a threat to equipment.

Control actions of the system. The programmed reactions of the system in response to the identified critical deviations are given. Depending on the type of deviation, the intelligent system initiates appropriate actions, such as:

Activating or disabling ventilation,

Starting or stopping supply/discharge pumps,

Activating chemical treatment modules,

Sending an alarm notification to the user via the IoT interface.

The structure of table 1provides a quick comparison between the parameter deviation and the required and corrective action of the system without the need for operator intervention.

Thanks the system,

Table 1 is the basis for the autonomous operation of the entire biogas plant, minimizing the risks of the human factor and speeding up the reaction to changing conditions inside the reactor.

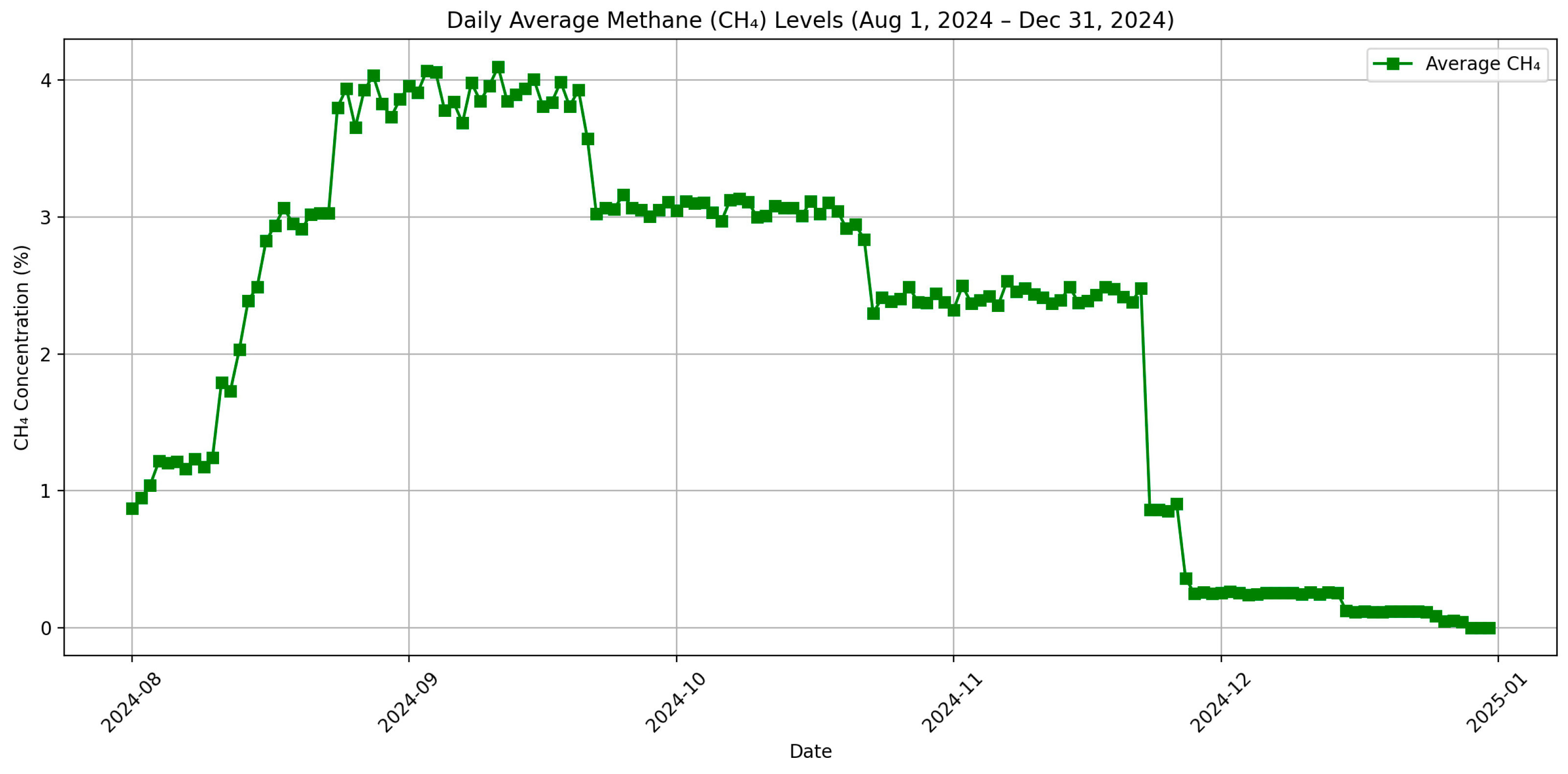

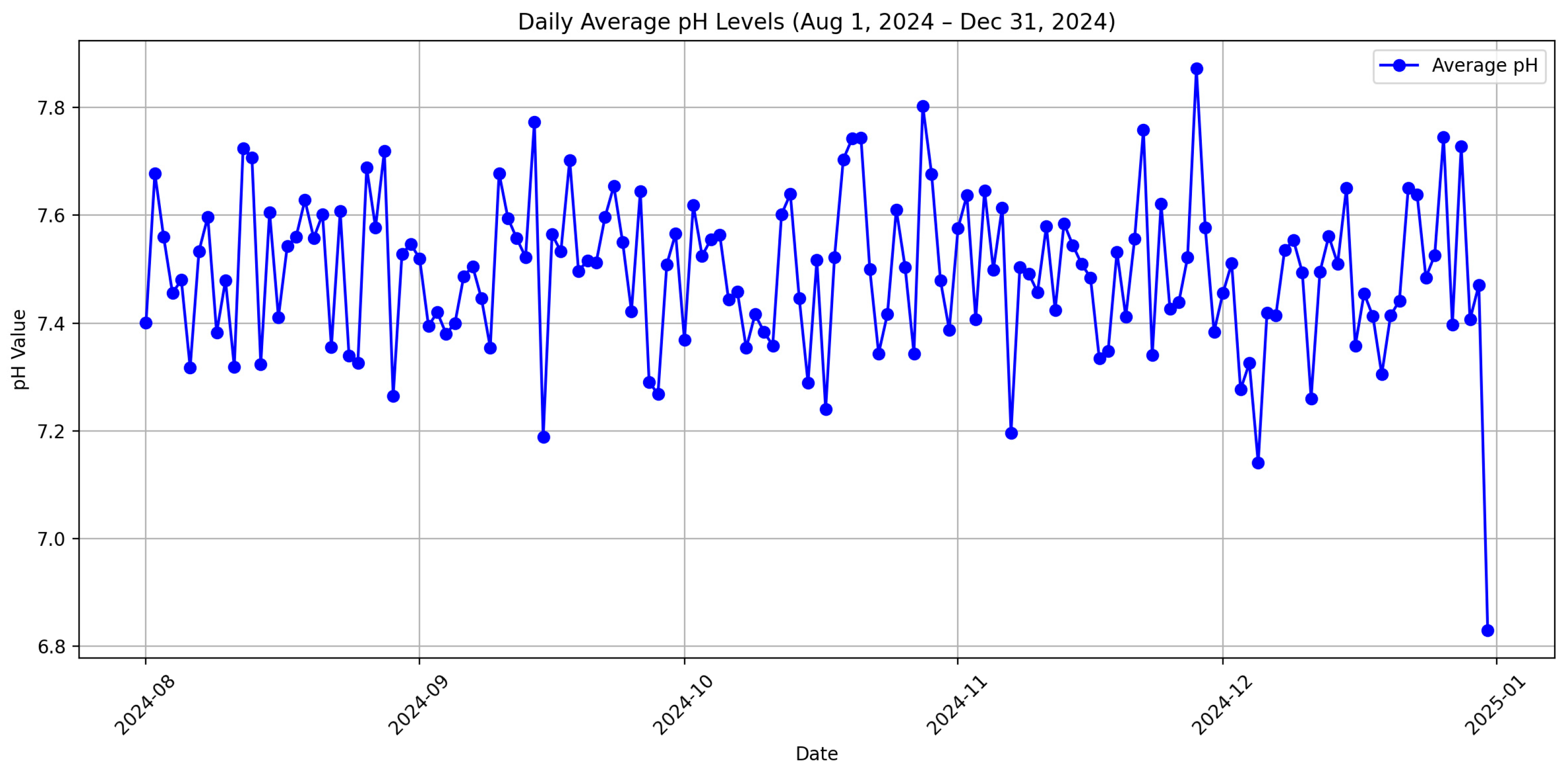

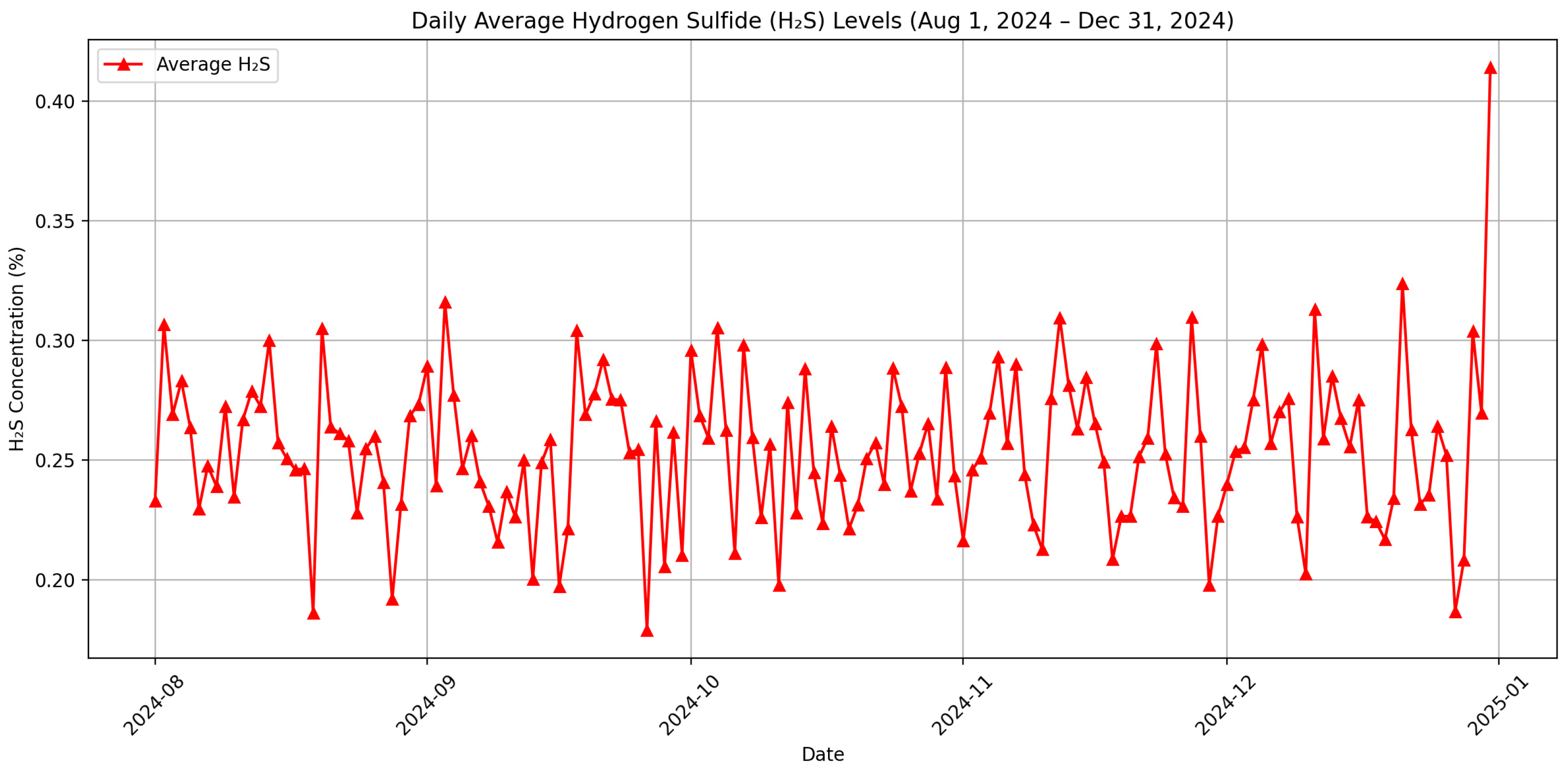

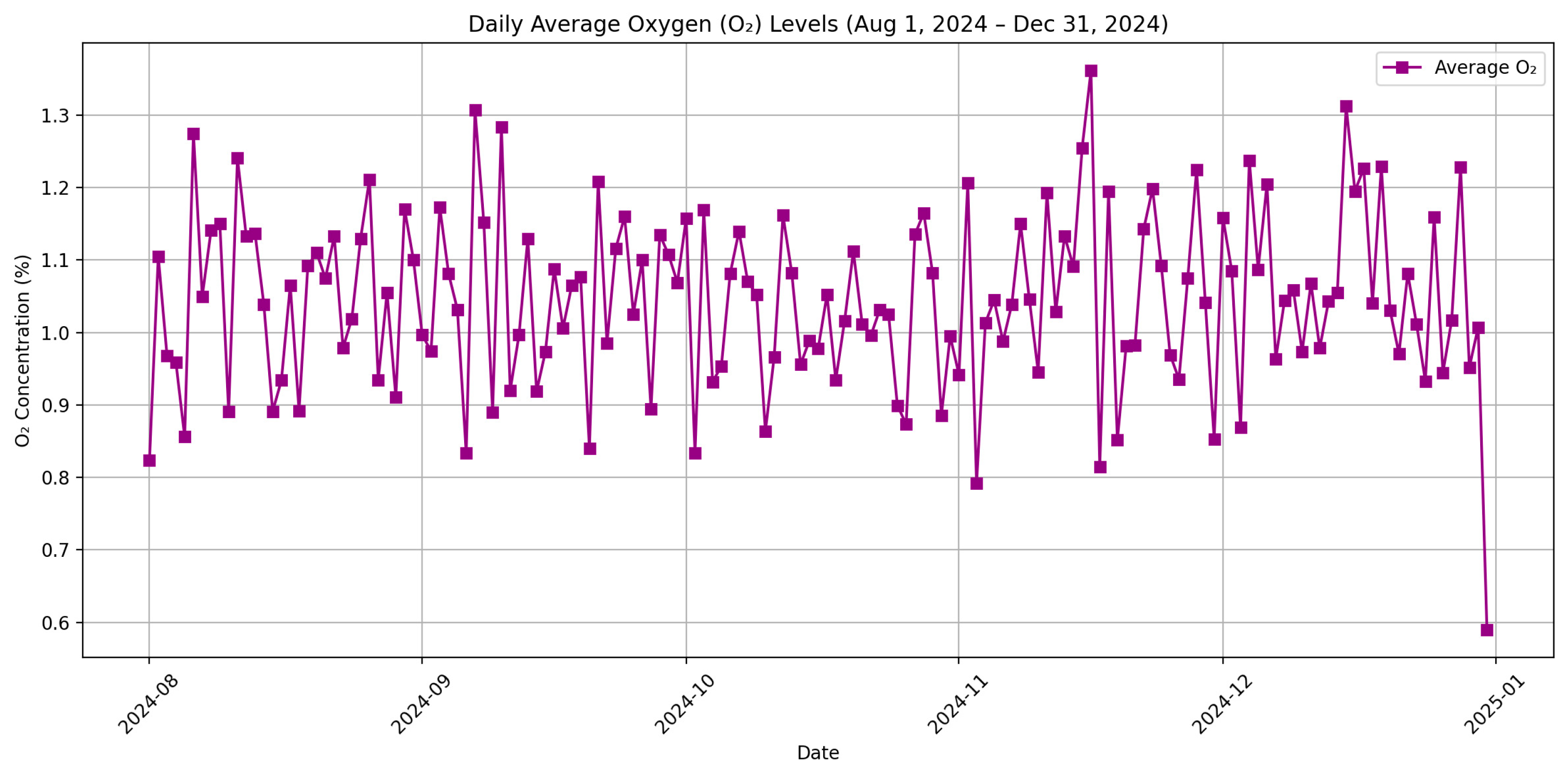

The data collected using an intelligent IoT system for monitoring biogas quality parameters is presented in

Table 2. The data aggregation interval is 6 hours, which allows you to tack the dynamics of changes within the day in more detail. In each 6-hour interval, the first measured value is recorded without averaging or changing the initial data.

Table 2 includes the following key parameters:

Date and time of measurements (Datetime_6h) — the beginning of the corresponding 6-hour interval.

pH — an indicator of the acidity of the medium, which is important for optimizing the fermentation process.

CH₄ (%) — the concentration of methane, the main indicator of the energy value of biogas.

H₂S (%) — the concentration of hydrogen sulfide, which is critical due to its toxicity and corrosive effects.

O₂ (%) — the oxygen content, the excess of which indicates the violation of anaerobic conditions.

CO₂ (%) — the proportion of carbon dioxide accompanying the process of methanogenesis.

Temperature (if present in data) — key factor affecting the activity of anaerobic microorganisms.

The data is sorted by time in ascending order. The table format allows you to build time series and analyze trends on a semi-daily scale. The data is used to plot deviations, predict the quality of biogas, and configure automatic control actions in an intelligent system. All values are saved in their original form without mathematical processing.

As a result of the project, an intelligent biogas quality management system based on Internet of Things technologies was successfully developed, assembled and tested. The system provides collection, processing, storage, visualization and control of the parameters of the biogas process in real time.

The main results achived:

A hardware platform has developed that includes ESP32 microcontroller, temperature, pH sensors, as well as ammonia, methane, and hydrogen sulfide concentration sensors. The system operates offline and is powered by a stable DC power source.

Two-way data transfer is implemented between the microcontroller and the Firebase cloud database via Wi-Fi. Sensor data is transmitted with minimal delay and displayed in a custom web application.

A control module has been designed and programmed, capable of operating both manually and automatically, In automatic mode, the system analyzes incoming data without human intervention and takes the necessary corrective actions when the parameters deviate from the set thresholds.

Integration with the WhatsApp API has been provided, allowing the user send alarm notifications about critical changes in the installation status.

A web interface has been developed that provides display of the current parameter values, event logs, status of actuators and operating mode. The user can remotely control the system and switch between control modes.

Tests of the prototype have been carried out, confirming its operability. The system reacted correctly to parameter changes, recorded events, saved data in the cloud and initiated appropriate control actions.

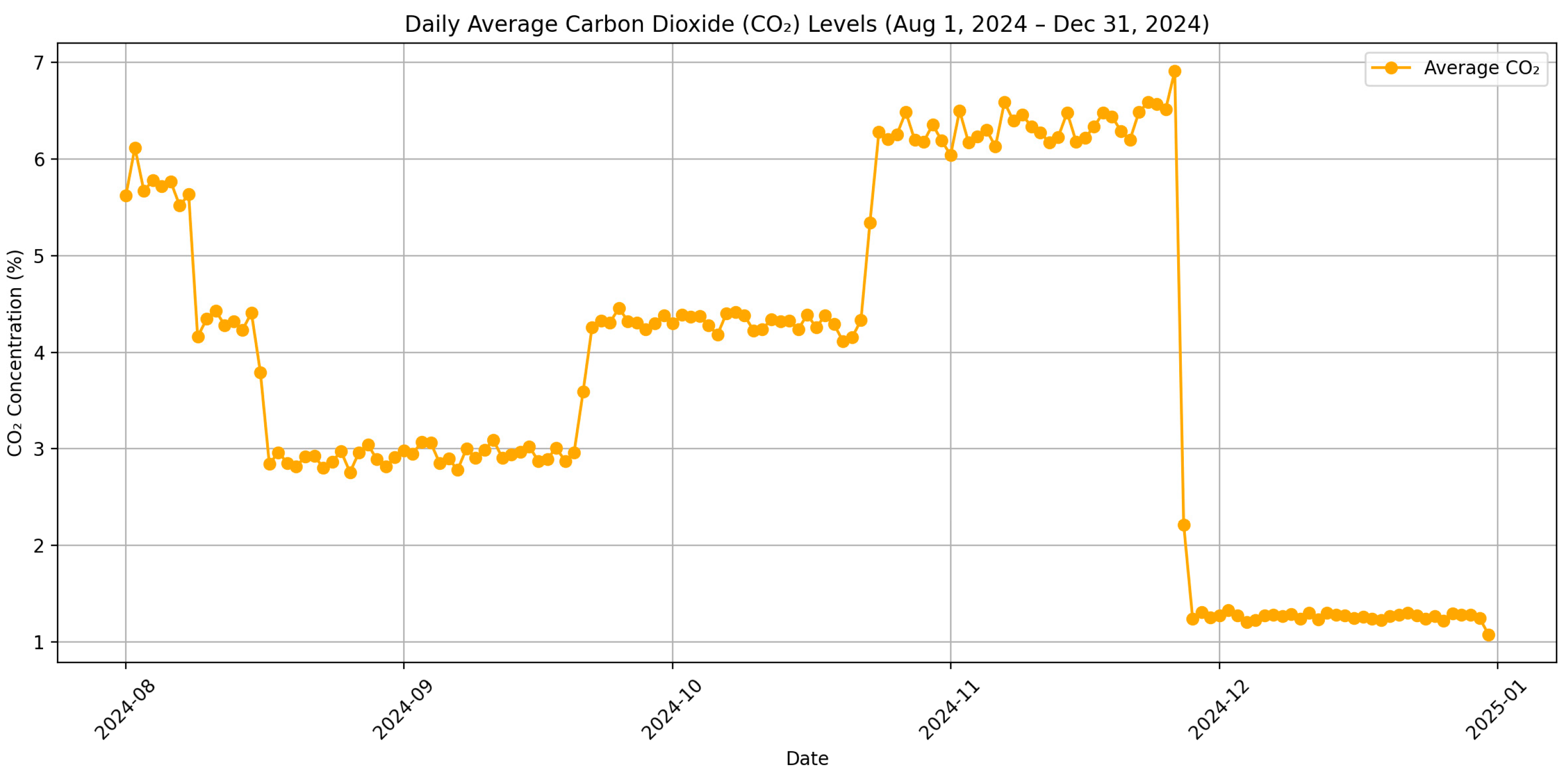

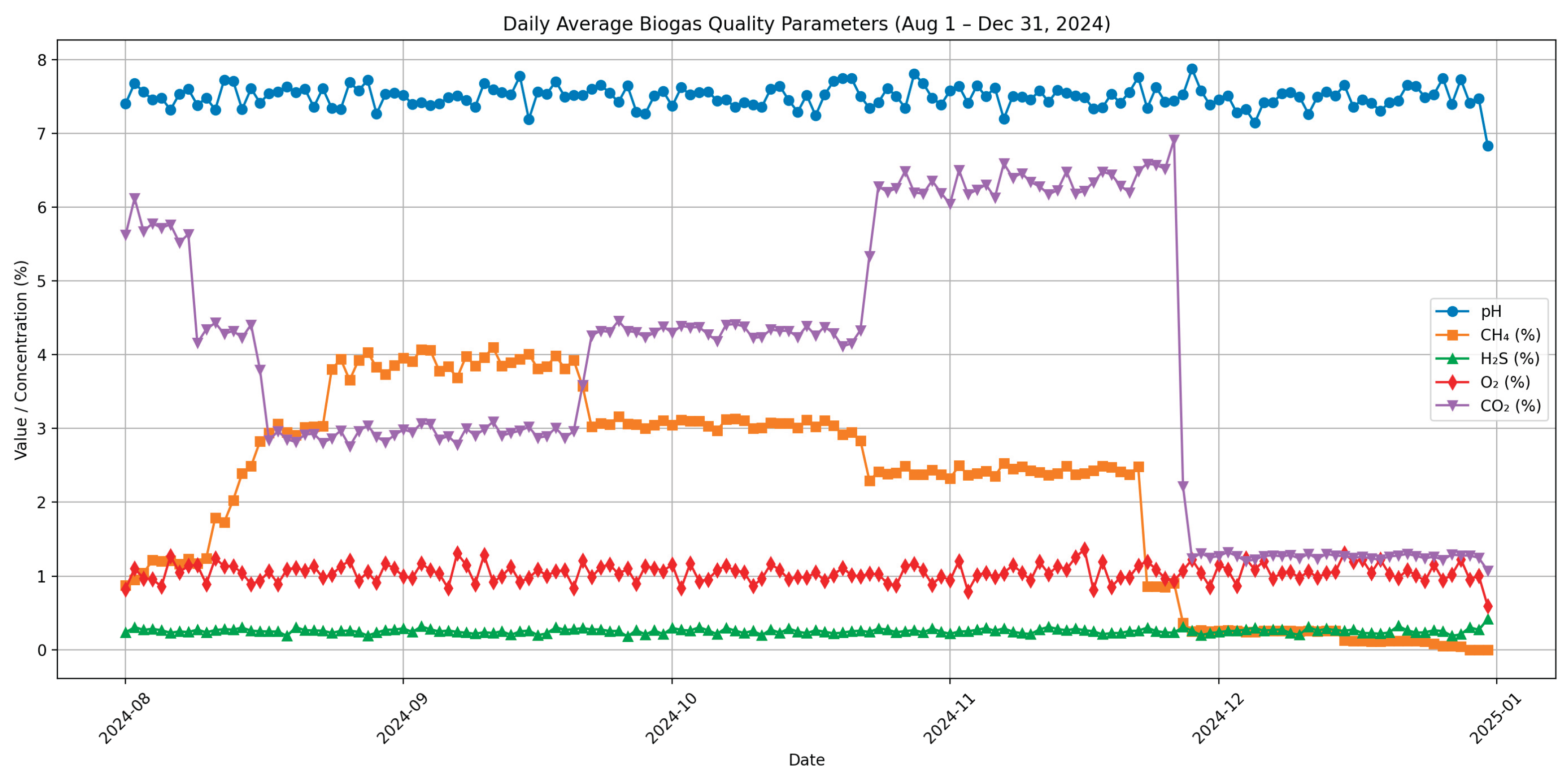

The created system has demonstrated high efficiency, flexibility and potential applicability for automation of biogas quality control processes in small and medium-sized installations. In the study and monitoring using the intelligent IoT system, the results were obtained in the form of graphs of

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10 which confirms the viability of proposed approach and laid the foundation for further development, including the introduction of predictive algorithms and machine learning [

28].

The graph shows the average daily change in the concentration of methane (CH₄) in biogas for the period from August 1 to December 31, 2024.

The graph clearly shows how the level of methane, which is the main energy component of biogas, varied. Using an IoT Web-application allows you to:

Monitor decrease or increase in concentration CH₄,

Evaluate the effectiveness of fermentation,

Respond to system instability in a timely manner.

The graph shows the average daily pH value in biogas plant from August 1 to December 31, 2024.

The graph was built on the basis of data collected by the IoT system and displayed in a Web-application. It allows to:

Track pH deviations from the norm over time,

Identify periods of environmental instability,

Decide on corrective actions (e.g. buffering or dilution).

The graph shows the average daily change in the level of hydrogen sulfide (H₂S) in biogas from August 1 to December 31, 2024.

Hydrogen sulfide — toxic and corrosive component. Monitoring its concentration in an IoT Web-application allows you to:

Promptly identify safe level exceedances,

Prevent damage to equipment,

Run filtration and neutralization systems in automatic mode.

The graph shows the average daily change in oxygen (O₂) concentration in a biogas plant for the period from August 1 to December 31, 2024.

Oxygen in aerobic processes is an undesirable component, as it can inhibit the activity of methanogenic bacteria. Thanks to data visualization in the IoT Web-application, it is possible to:

Promptly monitor air leaks into the system,

Control the tightness of the bioreactor,

Automatically launch measures to stabilize the process (for example, to eliminate sealing violations).

The graph shows the average daily change in the concentration of carbon dioxide (CO₂) in biogas for the period from August 1 to December 31, 2024.

CO₂ — unavoidable byproduct of anaerobic digestion. Monitoring its level allows you to:

Evaluate the quality of biogas (high CO₂ content reduces the calorific value),

Monitor the effectiveness of methanogenesis,

Make decisions about gas purification or adjusting the composition of raw materials.

The combined graph shows the average daily values of the main parameters of biogas quality for the period from August 1 to December 31, 2024:

pH — reflects the acid-base balance of the environment.

CH₄ (methane) — main energy component of biogas.

H₂S (hydrogen sulfide) — toxic and corrosive component.

O₂ (oxygen) — undesirable under anaerobic conditions.

CO₂ (carbon dioxide) — secondary fermentation product.

The graph allows you to compare the behavior of parameters over time, identify correlations between them, and make informed management decisions using an IoT system.

4. Discussion

The developed intelligent biogas quality management system using Internet o Things technologies has demonstrated a high degree of reliability and adaptability in controlling key technological parameters of the biogas process. The results obtained during the testing confirmed the possibility of using IoT technologies to create an automated system capable of operating both offline and remotely controlled.

One of the significant advantages of the proposed system is the ability continuously monitor and analyze parameters, followed by corrective actions in case of deviations from acceptable values. This minimizes the risks associated with disrupting the technological process, reducing gas production, or damaging equipment [

27].

The system has demonstrated efficiency in both manual and automatic operation modes. In automatic mode, an algorithm is implemented that allows the system to make decisions without human intervention, which increases the autonomy of the installation and reduces the need for constant monitoring by the operator. In manual mode, the user retains full control over the actuators via the web interface, which is convenient for spot tuning or parameter testing.

Integration with the Firebase cloud database and support for remote access via a web application ensured transparency and availability of information about the installation status in real time. This allows the user to control the process from anywhere in the world. Notifications via the WhatsApp API increase responsiveness in case of critical situations.

However, the system has certain limitations that requires further development. The current version implements basic control algorithms based on threshold values. To increase the intelligence of the system, in the future it is planned to introduce machine learning modules capable of predicting changes in parameters and making more accurate management decisions. The sensor suite can also be expanded to take into account additional factors such as substrate humidity, pressure level, gas release rate, etc.

5. Conclusions

As part of this work, an intelligent biogas quality management system based on Internet of Things technologies was developed and implemented. The system is an integrated solution that provides continuous monitoring, analysis and automatic regulation of key parameters that determine the stability and efficiency of biogas production, such as temperature, pH, concentrations of methane, ammonia and hydrogen sulfide [

29].

The ESP32 microcontroller with built-in wireless communication facilities was used as the hardware platform, which made it possible to organize two-way data transfer between the system and the cloud infrastructure without using additional communication modules. Data is collected and processed using reliable sensors connected to the control module, and the results are displayed in a web0based user interface implemented using the Firebase platform.

The system supports two operating modes — manual and automatic. In manual mode, the user exercises full control over the actuators through a web application, whereas in automatic mode, the control module independently makes decisions and performs corrective actions without operator intervention [

30]. This allows you to respond to deviations in a timely manner and maintain stable operation of the installation. There is a also function for notifying the user about critical parameter changes via WhatsApp notifications.

The proposed IoT system demonstrates high potential for use in biogas plants, providing more precise control, rapid response and improved overall process efficiency and safety. A promising area of further research is to expand the capabilities of the system through the introduction of predictive analytics and integration with machine learning algorithms for forecasting and optimizing the production cycle [

31]

Scientific novelty and difference from existing world studies. The present study has a scientific and applied novelty, consisting in an integrated approach to monitoring and automatic management of biogas quality parameters using Internet of Things technologies, cloud computing and intelligent control algorithms. Unlike most existing solutions focused primarily om monitoring and displaying data, the proposed system implements full-sledged two-way communication and automatic execution of control actions without human intervention.

Key differences and novelty elements:

The integration of IoT with the Firebase cloud platform allows not only to collect and store data in real time, but also to instantly initiate actions to adjust parameters (temperature, pH, CH₄, NH₃, H₂S) through actuators.

Support for hybrid control mode (automatic and manual) with the ability to switch via the web interface make the system universal for both autonomous and controlled operation scenarios.

For the first time in the context of small and medium-sized biogas plants, the integration of the control module with the WhatsApp API has been implemented, which expands the operational capabilities of notification and user interaction in real time.

Unlike a number of foreign studies in which the system is limited to transmitting readings to a web platform without reacting to exceeding thresholds, the presented system is able to automatically initiate actions (turning on pumps, ventilation, adjusting composition) based on an analysis of current data.

A modular architecture has been applied, which provides extensibility: the system can be adapted for other parameters (for example, pressure, substrate humidity) and supplemented with predictive models based on machine learning.

The development is focused on accessibility and cost-effectiveness, which is especially important for developing countries and agricultural enterprises, where previously there was limited use of digital solutions in the biogas industry.

The presented solution goes beyond traditional monitoring systems and demonstrates the potential for building autonomous, adaptive and intelligent biogas quality management platforms, which contributes to the development of smart energy solutions based on renewable sources.

Author Contributions

“Conceptualization A. Kozbakova, O. Auelbekov and K. Yessentaev; methodology, A. Kozbakova, O. Auelbekov.; software, K. Yessentaev and K. Igibayev; formal analysis, A. Kozbakova, O. Auelbekov; visualization, K. Yessentaev and K. Igibayev; supervision, A. Kozbakova and O. Auelbekov. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by a grant and funding from the Ministry of Science and Higher Education of the Republic of Kazakhstan within the framework of the Project №AP23490744, Institute Information and Computational Technologies CS MSHE RK.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The work was supported by grant funding from the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (AP23490744).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- P. Sakiewicz, K. Piotrowski, J. Ober, J. Karwot, Innovative artificial neural network approach for integrated biogas – wastewater treatment system modelling: Effect of plant operating parameters on process intensification, Renewable and Sustainable Energy Reviews, volume 124, 2020. [CrossRef]

- Yesen Sun, Hong-liang Dai, Hossein Moayedi, Binh Nguyen Le, Rana Muhammad Adnan, Predicting steady-state biogas production from waste using advanced machine learning-metaheuristic approaches, Fuel, volume 355, 2024. [CrossRef]

- João Gonçalves Neto, Leticia Vidal Ozorio, Thais Cristina Campos de Abreu, Brunno Ferreira dos Santos, Florian Pradelle, Modeling of biogas production from food, fruits and vegetables wastes using artificial neural network (ANN), Fuel, volume 285, 2021. [CrossRef]

- Obileke, K., Makaka, G., Tangwe, S. et al. Improvement of biogas yields in an anaerobic digestion process via optimization technique. Environ Dev Sustain (2024). [CrossRef]

- Hale Dogan, Fulya Aydın Temel, Ozge Cagcag Yolcu, Nurdan Gamze Turan, Modelling and optimization of sewage sludge composting using biomass ash via deep neural network and genetic algorithm, Bioresource Technology, Volume 370, 2023. [CrossRef]

- Hale Dogan, Fulya Aydın Temel, Ozge Cagcag Yolcu, Nurdan Gamze Turan, Modelling and optimization of sewage sludge composting using biomass ash via deep neural network and genetic algorithm, Bioresource Technology, Volume 370, 2023. [CrossRef]

- Franklin Oliveira, Daniel G. Costa, Flavio Asis, Ivanovitch Silva, Internet of Intelligent Things: A convergence of embedded systems, edge computing and machine learning,Internet of Things, vol 26,2024. [CrossRef]

- S. Swami, S. Suthar, S. R. Addula, V. Kumar Saini, Komal and A. Lande, "IoT-Based Smart Solution for Biogas Plant Operation," 2023 International Conference on Smart Devices (ICSD), Dehradun, India, 2024, pp. 1-5. [CrossRef]

- Mohanakrishnan Logan, Masihullah Safi, Piet Lens, Chettiyappan Visvanathan, Investigating the performance of internet of things based anaerobic digestion of food waste, Process Safety and Environmental Protection, vol 127, 2019, Pages 277-287. [CrossRef]

- Mohammed Khaleel Jameel, Mohammed Ahmed Mustafa, Hassan Safi Ahmed, Samira jassim Mohammed, Hameed Ghazy, Maha Noori Shakir, Amran Mezher Lawas, Saad khudhur Mohammed, Ameer Hassan Idan, Zaid H. Mahmoud, Hamidreza Sayadi, Ehsan Kianfar, Biogas: Production, properties, applications, economic and challenges: A review, Results in Chemistry, Vol 7, 2024. [CrossRef]

- Carmona-Martínez, A.A.; Bartolomé, C.; Jarauta-Córdoba, C.A. The Role of Biogas and Biomethane as Renewable Gases in the Decarbonization Pathway to Zero Emissions. Energies 2023, 16, 6164. [CrossRef]

- Wang, S.; Ma, F.; Ma, W.; Wang, P.; Zhao, G.; Lu, X. Influence of Temperature on Biogas Production Efficiency and Microbial Community in a Two-Phase Anaerobic Digestion System. Water 2019, 11, 133. [CrossRef]

- Agossou, B.Emmanuel and Takahara Toshiro. “IoT & AI Based System for Fish Farming: Case study of Benin.” Proceedings of the Conference on Information Technology for Social Good (2021): n. pag.

- Jan, F.; Min-Allah, N.; Düştegör, D. IoT Based Smart Water Quality Monitoring: Recent Techniques, Trends and Challenges for Domestic Applications. Water 2021, 13, 1729. [CrossRef]

- K. N. Hairol, R. Adnan, A. M. Samad and F. Ahmat Ruslan, "Aquaculture Monitoring System using Arduino Mega for Automated Fish Pond System Application," 2018 IEEE Conference on Systems, Process and Control (ICSPC), Melaka, Malaysia, 2018, pp. 218-223. [CrossRef]

- Flores-Iwasaki, M.; Guadalupe, G.A.; Pachas-Caycho, M.; Chapa-Gonza, S.; Mori-Zabarburú, R.C.; Guerrero-Abad, J.C. Internet of Things (IoT) Sensors for Water Quality Monitoring in Aquaculture Systems: A Systematic Review and Bibliometric Analysis. AgriEngineering 2025, 7, 78. [CrossRef]

- Bhagyalakshmi, P S, G. Divya and N. L. Aravinda. “Raspberry PI And Wifi Based Home Automation.”.

- Nilanjan and Chatterjee. “Low Cost, Easy-to-Use, IoT and Cloud-Based Real-Time Environment Monitoring System Using ESP8266 Microcontroller.” (2021).

- Meka, S.; Fonseca, B., Jr. Improving Route Selections in ZigBee Wireless Sensor Networks. Sensors 2020, 20, 164. [CrossRef]

- J. Mabrouki, M. Azrour, G. Fattah, D. Dhiba and S. E. Hajjaji, "Intelligent monitoring system for biogas detection based on the Internet of Things: Mohammedia, Morocco city landfill case," in Big Data Mining and Analytics, vol. 4, no. 1, pp. 10-17, March 2021. [CrossRef]

- Dedgaonkar, S., Kaalay, A., Biyani, N., Mohite, M. (2018). Biogas Monitoring System Using DS18B20 Temperature Sensor and MQTT Protocol. In: Bhalla, S., Bhateja, V., Chandavale, A., Hiwale, A., Satapathy, S. (eds) Intelligent Computing and Information and Communication. Advances in Intelligent Systems and Computing, vol 673. Springer, Singapore. [CrossRef]

- Nsair, A.; Onen Cinar, S.; Alassali, A.; Abu Qdais, H.; Kuchta, K. Operational Parameters of Biogas Plants: A Review and Evaluation Study. Energies 2020, 13, 3761. [CrossRef]

- Hercog, D.; Lerher, T.; Truntič, M.; Težak, O. Design and Implementation of ESP32-Based IoT Devices. Sensors 2023, 23, 6739. [CrossRef]

- Mijailović, Đ.; Đorđević, A.; Stefanovic, M.; Vidojević, D.; Gazizulina, A.; Projović, D. A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm. Sustainability 2021, 13, 12396. [CrossRef]

- Wen-Tsai Sung, Indra Griha Tofik Isa, Sung-Jung Hsiao, An IoT-Based Aquaculture Monitoring System Using Firebase, Computers, Materials and Continua, Volume 76, Issue 2, 2023, Pages 2179-2200. [CrossRef]

- T. R. Wanasinghe, R. G. Gosine, L. A. James, G. K. I. Mann, O. de Silva and P. J. Warrian, "The Internet of Things in the Oil and Gas Industry: A Systematic Review," in IEEE Internet of Things Journal, vol. 7, no. 9, pp. 8654-8673, Sept. 2020. [CrossRef]

- Mazhar, T.; Irfan, H.M.; Haq, I.; Ullah, I.; Ashraf, M.; Shloul, T.A.; Ghadi, Y.Y.; Imran; Elkamchouchi, D.H. Analysis of Challenges and Solutions of IoT in Smart Grids Using AI and Machine Learning Techniques: A Review. Electronics 2023, 12, 242. [CrossRef]

- Ianny Andrade Cruz, Luciano de Melo, Ariadne Nunes Leite, João Victor Melquiades Sátiro, Larissa Renata Santos Andrade, Nádia Hortense Torres, Rebeca Yndira Cabrera Padilla, Ram N. Bharagava, Renan Figueiredo Tavares, Luiz Fernando Romanholo Ferreira, A new approach using an open-source low cost system for monitoring and controlling biogas production from dairy wastewater,Journal of Cleaner Production, Volume 241, 2019. [CrossRef]

- Kalamaras, S.D.; Tsitsimpikou, M.-A.; Tzenos, C.A.; Lithourgidis, A.A.; Pitsikoglou, D.S.; Kotsopoulos, T.A. A Low-Cost IoT System Based on the ESP32 Microcontroller for Efficient Monitoring of a Pilot Anaerobic Biogas Reactor. Appl. Sci. 2025, 15, 34. [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85. [CrossRef]

- Mohamed Anis Aguida, Samir Ouchani, and Mourad Benmalek. 2022. An IoT-based Framework for an Optimal Monitoring and Control of Cyber-Physical Systems: Application on Biogas Production System. In Proceedings of the 11th International Conference on the Internet of Things (IoT '21). Association for Computing Machinery, New York, NY, USA, 143–149. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).