Submitted:

16 December 2024

Posted:

03 January 2025

You are already at the latest version

Abstract

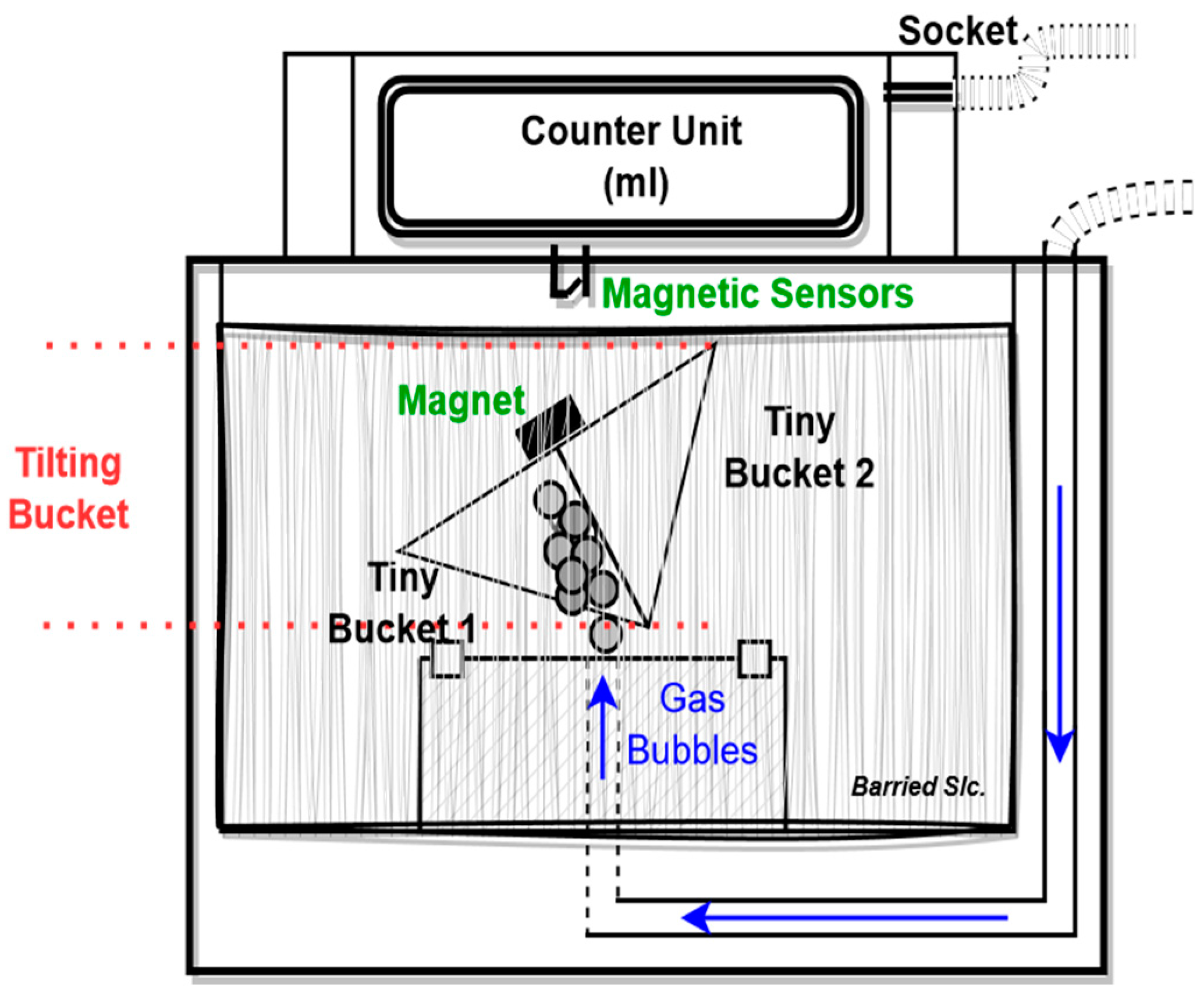

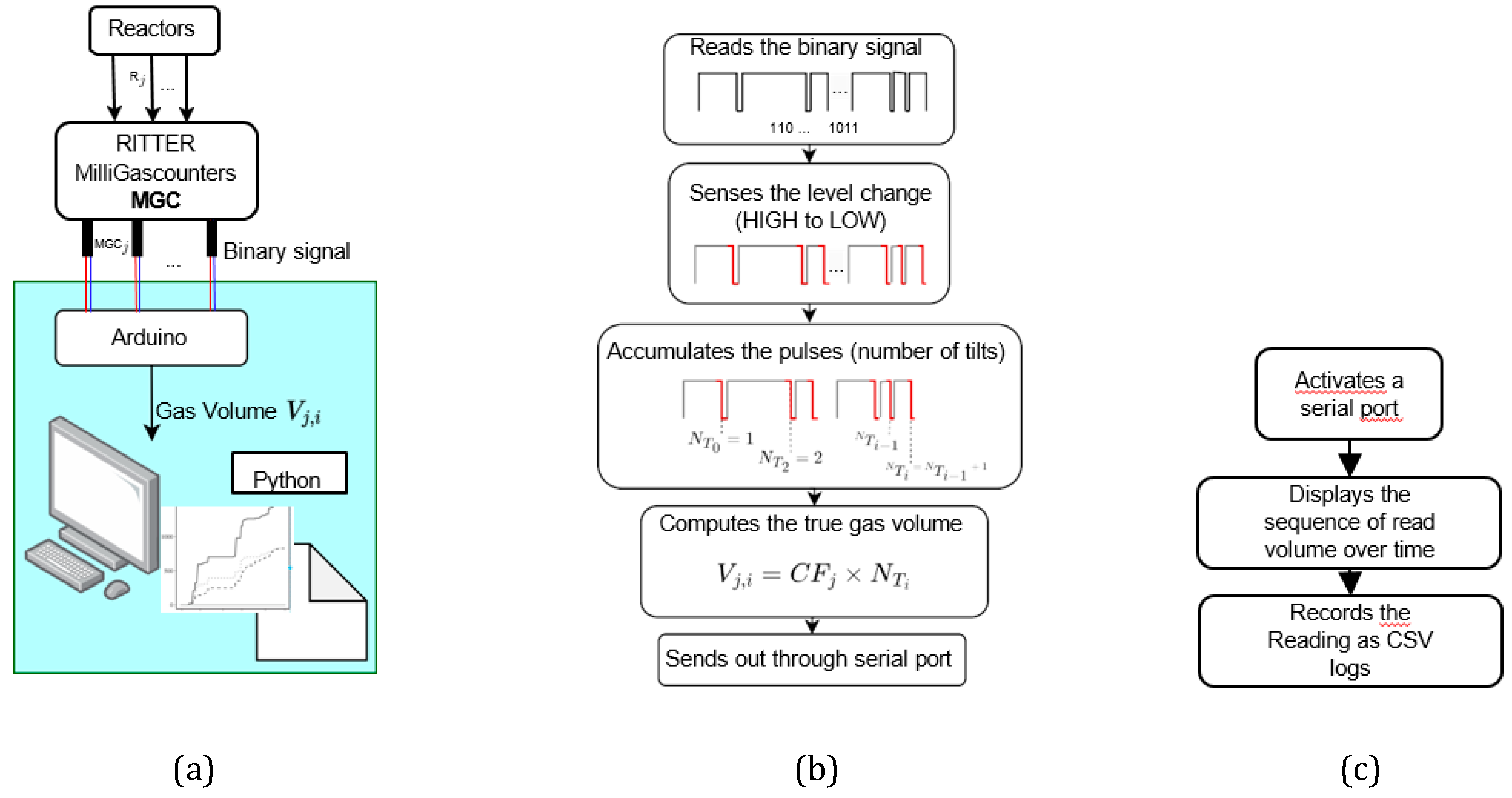

This paper presents the Arduino Gasometer Data Acquisition Control (AGDAC), a prototype interface offering a cost-effective and customizable alternative to pricey and restrictive commercial systems such as Rigamo, commonly paired with Ritter Milligas Counters. AGDAC, built on the Arduino Uno and a Python-based control application, enhances experimental flexibility by expanding data acquisition capabilities. It records and displays measurement data, supporting biogas production monitoring at the lab scale. User-friendly and based on open-source software, AGDAC lowers technical barriers, encourages interdisciplinary research, and reduces costs, democratizing data acquisition for scientific applications.

Keywords:

1. Hardware in Context

2. Hardware Description

- AGDAC’s affordability makes it a practical choice for biogas applications.

- The simplicity and accessibility of AGDAC components enable system customization and scalability to suit diverse experimental designs.

- AGDAC is user-friendly, making it accessible to researchers with limited instrument development or coding experience.

- Its foundation on free and open-source software empowers the development of advanced scientific applications.

3. Design Files

- AGDAC AR code 1: Arduino IDE code that sense and record tilts.

- AGDAC PY code 2: PYTHON code that records and saves Gas Volume production data in CSV file.

| Design file | File type | Open source | Location of the file |

|---|---|---|---|

| AGDAC AR code 1 | ARDUINO IDE | AGDAC | Reserved doi: here |

| AGDAC PY code 2 | PYTHON | AGDAC | Reserved doi: here |

4. Bill of Materials

| Designator | Component | Number | Cost per unit currency | Total cost | Source of materials |

|---|---|---|---|---|---|

| AR | Placa Arduino Uno Atmega 328 Smd Arduino Uno |

1 | $11 | $11 | CINESTEC electronics |

| UC | USB-B cable** | 1 | – | – | CINESTEC electronics |

| PWC | 12 V x 1 A AC-DC power con- verter, bivolt |

1 | $3,50 | $3,50 | CINESTEC electronics |

| PB | Black Waterproof Plastic Project Box ABS (41 x 73 x 99 mm) |

3 | $22 | $22 | Amazon |

| JP | PJ-392 Stereo Female Socket Jack with Screw |

3 | $7.4 | $22,2 | Amazon |

| AC | Aux Cord Male to Male 1m | 3 | $8 | $24 | Amazon |

| JC | 10 cm Male to Male Wire Jumper Cable for Arduino Breadboard* |

1 | $6.35 | $6.35 | Amazon |

| TS | Pocket Tube Solder Wire Tin 1.0 mm* |

1 | $4 | $4 | Amazon |

| LSc | QTEATAK 300Pcs Black Laptop Notebook Computer Replacement Screws Kit* | 1 | $6.49 | $6.49 | Amazon |

| TSc | Self Tapping Pan Head Screws M3x16 mm |

4 | $0.70 | $2.8 | Andorinha commercial |

| ASh | Genmitsu CNC Materials Acrylic Sheet, Transparent, 1Pcs 180 x 100 x 5 mm* |

1 | $4 | $4 | Amazon |

| BB | 20pcs 5x7cm Bakelite DIY Prototype Board PCB* |

20 | $6.99 | $6.99 | Amazon |

| Total cost ¬(3 channels AG- DAC) |

1 | $106.4 | $106.4 | ||

| Total cost ⊢ (> 3 channels AGDAC) |

1 | $113.33 | $113.33 |

5. Build Instructions

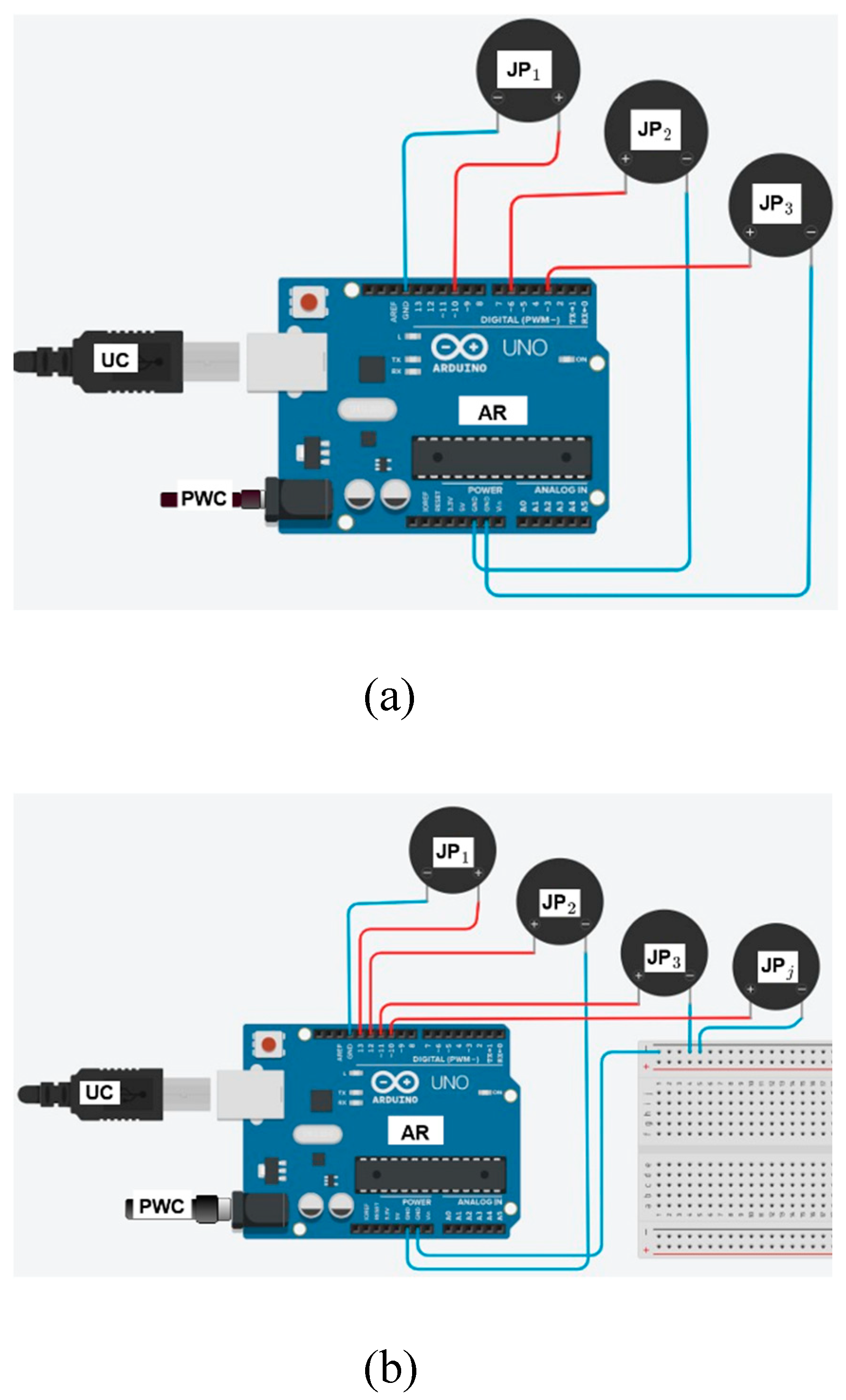

- Step 1. Arduino component

- Identify each JP’s signal and ground pins (JP1, JP2, and JP3). It can be easily found by identifying the configuration of the plug with a continuity mode of a multimeter.

- Select 3 digital pins on AR to read the binary signal from the 3 MGCs. Here, Pins 3, 6 and 10 were chosen.

- Prepare wires long enough to connect each JP’s signal and ground pins to the digital and ground pins on AR, respectively. In Figure 3a, red and blue lines correspond to the signal and ground wires.

-

Connect:

- -

- The signal (red) and ground (blue) wires of JP1 to the pin 3 and one GND pin on

AR, respectively.- -

- The signal (red) and ground (blue) wires of JP2 to the pin 6 and another GND pin on AR, respectively.

- -

- The signal (red) and ground (blue) wires of JP3 to the pin 10 and one GND pin on

AR, respectively. - Feed power to AR by using a PWC (optional).

- Connect the AR to the computer through UC.

- Follow the instructions as mentioned earlier only for two JPs. Signal wires of JPs can be systematically connected.

- Wire the last free GND pin to a mini breadboard. This extends the number of GND pins proportionally to the rest of the signal pins on AR. In Figure 3b, for example, the 3th and the others represented by the j-th JPs can be added.

- Step 2. Arduino IDE preparation

- Download and install Arduino IDE 1.8.19 ( available here).

- Open the code (refer to Design Files of Table 3).

- Step 3. Python IDE preparation

- Download and install PYTHON from here, or through Anaconda IDE 3, available here.

- Install Python-Serial package. This tutorial may help.

- Open the code (refer to Design Files of Table 3).

6. Operation Instructions

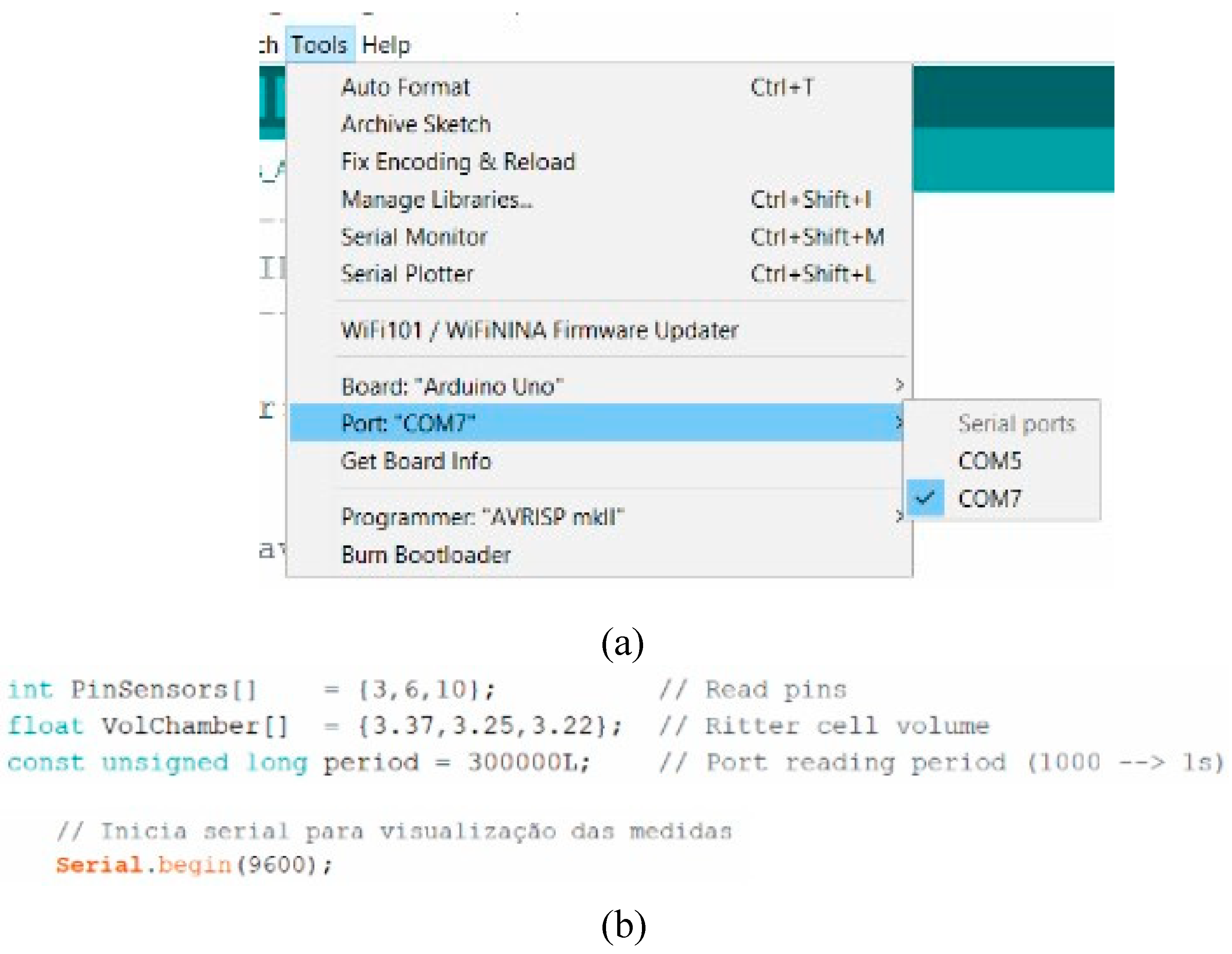

- Step 1. Arduino IDE inputs configuration

-

Within the Arduino IDE, in the Tools panel, select (see Figure 4a):

- -

- Board: “Arduino UNO”

- -

- Processor: “ATmega328P” – Port: select an available COM port.

-

Set the input parameters (see Figure 4b:

- -

- PinSensors for the selected pin number (e.g. 3, 6 and 10, as Figure 3a),

- -

- VolChamber for the corresponding cell volume of each MGC to which the pins refer and

- -

- period for the period of time in which a print will be performed (e.g., 5 minutes = 300000L)

- -

- Serial.Begin, the data rate in bits per second (baud) for serial data transmission is 9600.

- 3.

- Upload the sketch into AR.

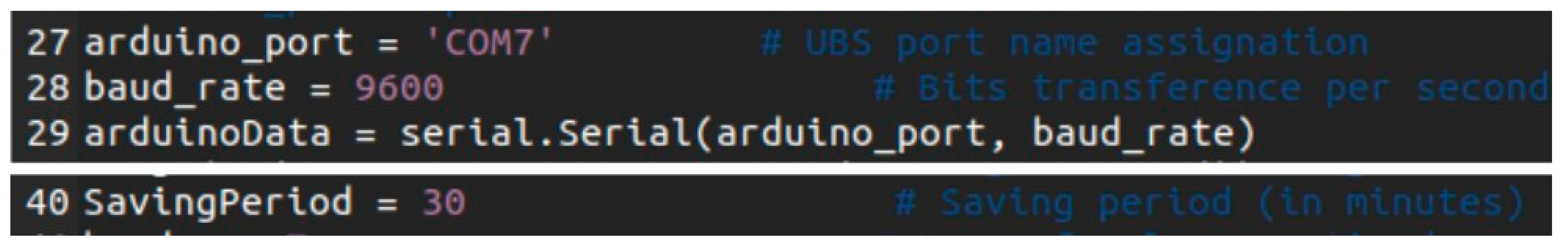

- Step 2. Python IDE inputs configuration

-

Set the input parameters as shown in Figure 4b. This consists of:

- -

- arduino port for the COM port identifier. Ensure that the selected COM port matches the physical port the board is plugged into.

- -

- baud rate for serial data transmission as the same it was defined in Arduino (Serial.begin of Step 1.)

- -

- SavingPeriod for the period in which a log file will be saved (e.g., 30 minute).

- Remove any CVS file from .../AGDAC/temporal

- Run the program

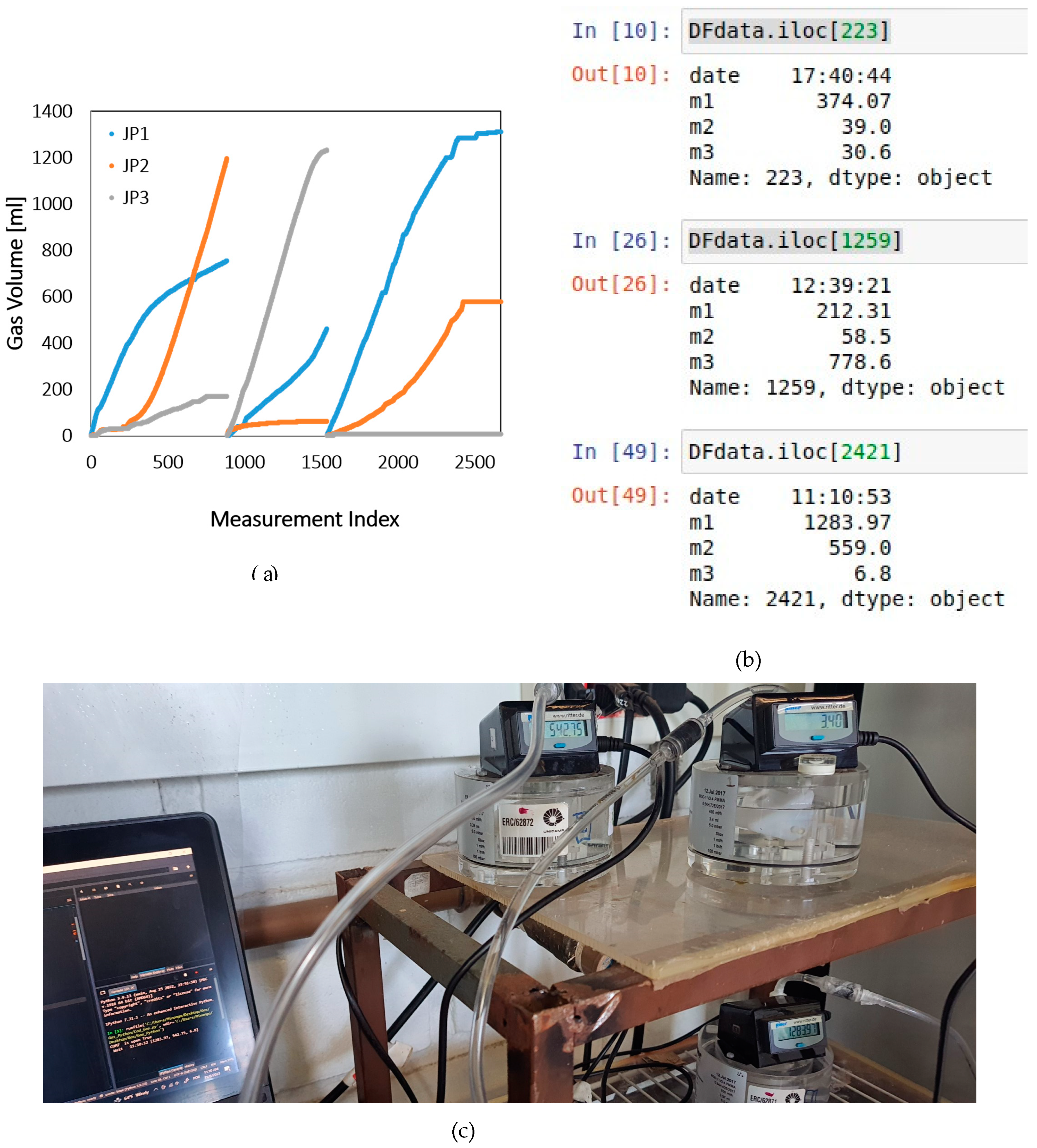

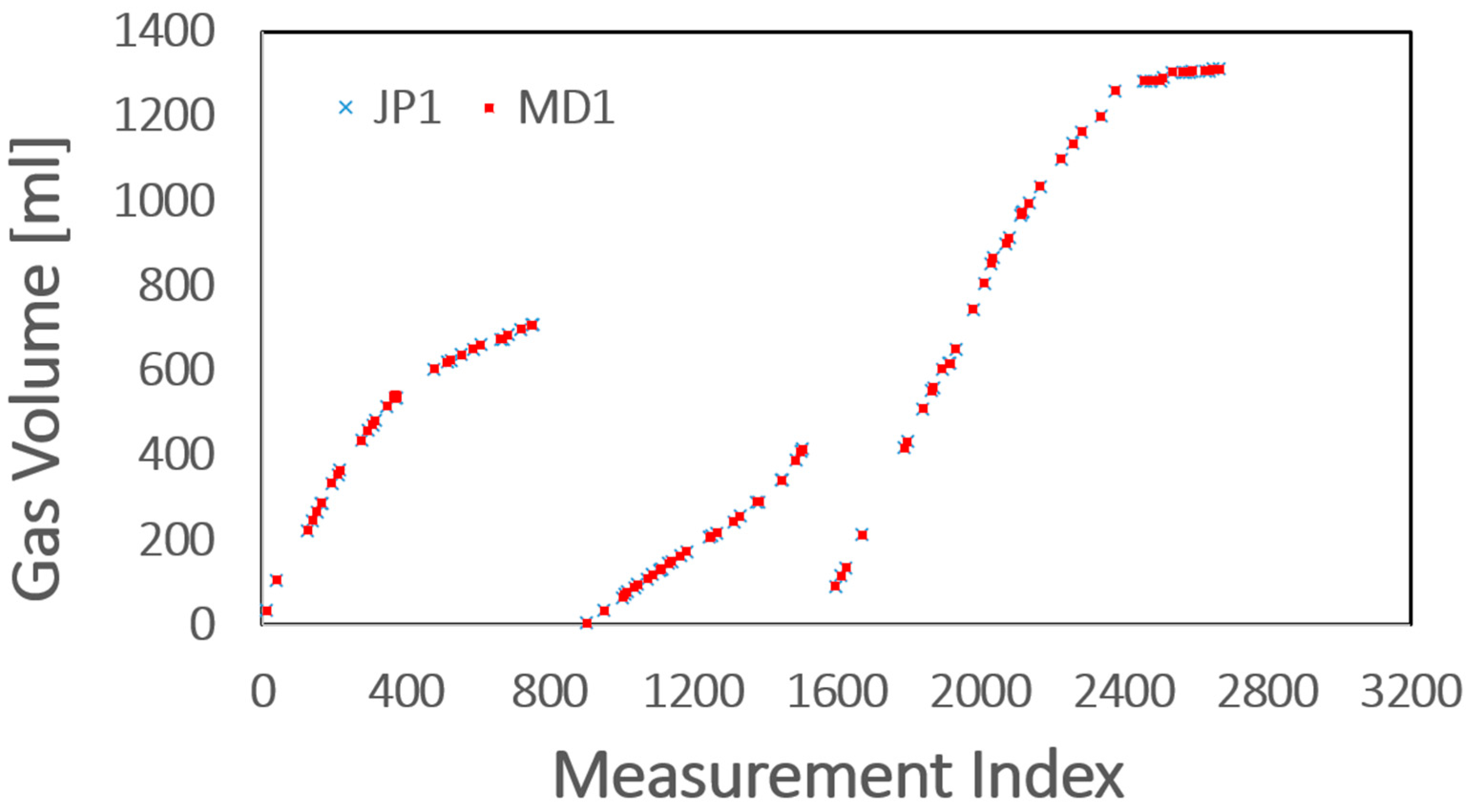

7. Validation and Characterization

8. Future Work

9. Conclusion

Declaration of Interest

Acknowledgements

Credit Author Statement

References

- C. Moreno, A. Gonz’alez, J. L. Olazagoitia, and J. Vinolas, “The acquisition rate and soundness of a low-cost data acquisition system (lc-daq) for high frequency applications,” Sensors, vol. 20, no. 2, 2020.

- C. Flores-Rodriguez, C. Nagendranatha Reddy, and B. Min, “Enhanced methane production from acetate intermediate by bioelectrochemical anaerobic digestion at optimal applied voltages,” Biomass and Bioenergy, vol. 127, p. 105261, 2019. [CrossRef]

- EPA, “Anaerobic digester/biogas system operator guidebook,” 2020.

- S. A. Kerstin Maurus, Nicola Kremmeter and M. Kazda, “High-resolution monitoring of vfa dynamics reveals process failure and exponential decrease of biogas production,” Biomass Conversion and Biorefinery, 2021. [CrossRef]

- T. Tikhomirova, M. Taraskevich, and O. Ponomarenko, “The role of laboratory-scale bioreactors at the semi-continuous and continuous microbiological and biotechnological processes,” Applied microbiology and biotechnology, vol. 102, p. 7293—7308, September 2018. [CrossRef]

- M. Walker, Y. Zhang, S. Heaven, and C. Banks, “Potential errors in the quantitative evaluation of biogas production in anaerobic digestion processes,” Bioresource Technology, vol. 100, no. 24, pp. 6339–6346, 2009. [CrossRef]

- B. R. Dhar, Y. Gao, H. Yeo, and H.-S. Lee, “Separation of competitive microorganisms using anaerobic membrane bioreactors as pretreatment to microbial electrochemical cells,” Bioresource Technology, vol. 148, pp. 208–214, 2013. [CrossRef]

- R. Ganesh, M. Torrijos, P. Sousbie, A. Lugardon, J. P. Steyer, and J. P. Delgenes, “Single-phase and two-phase anaerobic digestion of fruit and vegetable waste: Comparison of start-up, reactor stability and process performance,” Waste Management, vol. 34, no. 5, pp. 875–885, 2014. [CrossRef]

- C. Amodeo, S. Hattou, P. Buffiere, and H. Benbelkacem, “Temperature phased anaerobic digestion (tpad) of organic fraction of municipal solid waste (ofmsw) and digested sludge (ds): Effect of different hydrolysis conditions,” Waste Management, vol. 126, pp. 21–29, 2021. [CrossRef]

- L. T. Fuess, L. S. M. Kiyuna, A. D. N. Ferraz, G. F. Persinoti, F. M. Squina, M. L. Garcia, and M. Zaiat, “Thermophilic two-phase anaerobic digestion using an innovative fixed-bed reactor for enhanced organic matter removal and bioenergy recovery from sugarcane vinasse,” Applied Energy, vol. 189, pp. 480–491, 2017. [CrossRef]

- N. Wieczorek, M. A. Kucuker, and K. Kuchta, “Fermentative hydrogen and methane production from microalgal biomass (chlorella vulgaris) in a two-stage combined process,” Applied Energy, vol. 132, pp. 108–117, 2014. [CrossRef]

- A. Kovalev, E. R. Mikheeva, V. Panchenko, I. V. Katraeva, D. A. Kovalev, E. A. Zhuravleva, and Y. V. Litti, “Optimization of energy production from two-stage mesophilicndash;thermophilic anaerobic digestion of cheese whey using a response surface methodology approach,” Energies, vol. 15, no. 23, 2022. [CrossRef]

- Ritter, “Milligascounter,” 2022.

- Ritter, “Rigamo,” vol. V 3.1, 2017.

- K. M. McLean, A. L. Pasulka, and E. E. Bockmon, “A low-cost, accessible, and high-performing arduino-based seawater ph control system for biological applications,” HardwareX, vol. 10, p. e00247, 2021. [CrossRef]

- P. Reguera, D. Garc’ıa, M. Dom’ınguez, M. Prada, and S. Alonso, “A low-cost open source hardware in control education. case study: Arduino-feedback ms-150,” IFAC-PapersOnLine, vol. 48, no. 29, pp. 117–122, 2015. IFAC Workshop on Internet Based Control Education IBCE15.

- J. Sarik and I. Kymissis, “Lab kits using the arduino prototyping platform,” in 2010 IEEE Frontiers in Education Conference (FIE), pp. T3C–1–T3C–5, 2010.

- A. Vidal-Pardo and S. Pindado, “Design and development of a 5-channel arduino-based data acquisition system (abdas) for experimental aerodynamics research,” Sensors (Basel, Switzerland), vol. 18, 2018. [CrossRef]

- L. Loui, “Working principle of arduino and using it as a tool for study and research,” International Journal of Control, Automation, Communication and Systems, vol. 1, pp. 21–29, 2016.

- Naveenkumar and P. Krishna, “Low cost data acquisition and control using arduino prototyping platform and labview,” International Journal of Science and Research, vol. 2, pp. 366–369, 2013.

| Rigamo | AGDAC | |

|---|---|---|

| Total cost | $2,181.48 (One channel) | $10 |

| Interface component | National Instrument (NI6025) based Signal Interface Module (SIM) | Arduino UNO R3 |

| Cost: $1,336.66 | Cost: $10 | |

| Software | LabVIEW based RIGAMO | Arduino and PYTHON |

| Cost: $844,82 (1 channel); $1,157.52 (6 channel); $1,469.19 (9 channel); | Cost: Free | |

| Number of channels | Up 24 | Up 13 (digital pins) |

| Data storage type | Microsoft Excel | CSV |

| Operational System (OS) | Windows 7/8/10 | Window, Linux, Mac Os |

| Restriction | RIGAMO can only start once on a single PC. Other installed NI software may conflict with Rigamo software | Multiple PYTHON interfaces can operate simultaneously |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).