Metadata Overview

Main design files:

1. Introduction

Microbial electrolysis systems (MES) are electrochemical devices catalyzed by bacteria, utilizing pairs of electrodes (anode and cathode) for biofilm formation and adherence. MES technology is highly efficient for converting waste into valuable products such as hydrogen (H₂), methane (CH₄), and other by-products. The MES setup typically involves one or more pairs of electrodes (anode and cathode) that serve as the foundational support for biofilm development. Within MES, numerous organic compounds undergo oxidation at the anode through bioelectrochemical reactions driven by an applied voltage. The microbes in the anode, or bianode, act upon the biodegradable waste to generate electrons and protons. The electrons are then transferred to the cathode, where they reduce the protons for H

2 production. Thus, control, optimization, and performance monitoring are crucial for effective operation [

1,

2,

3].

MES requires a consistent external voltage to drive the electrochemical reactions and promote microbial metabolic processes. Power suppliers provide the necessary external voltage and current to optimize these reactions. Furthermore, multimeters help assess the efficiency of the electrolysis process and make necessary adjustments to the power supply. Multimeters equipped with data acquisition features allow continuous monitoring and recording of voltage and current data [

4,

5]. This real-time data is crucial for evaluating the performance of the MEC, identifying trends, and making informed decisions about process adjustments. However, commercial power suppliers, multimeters, and data acquisition systems are sold separately and are often expensive, featuring complex hardware and software, limiting broader investigations and experimental flexibility in MES research.

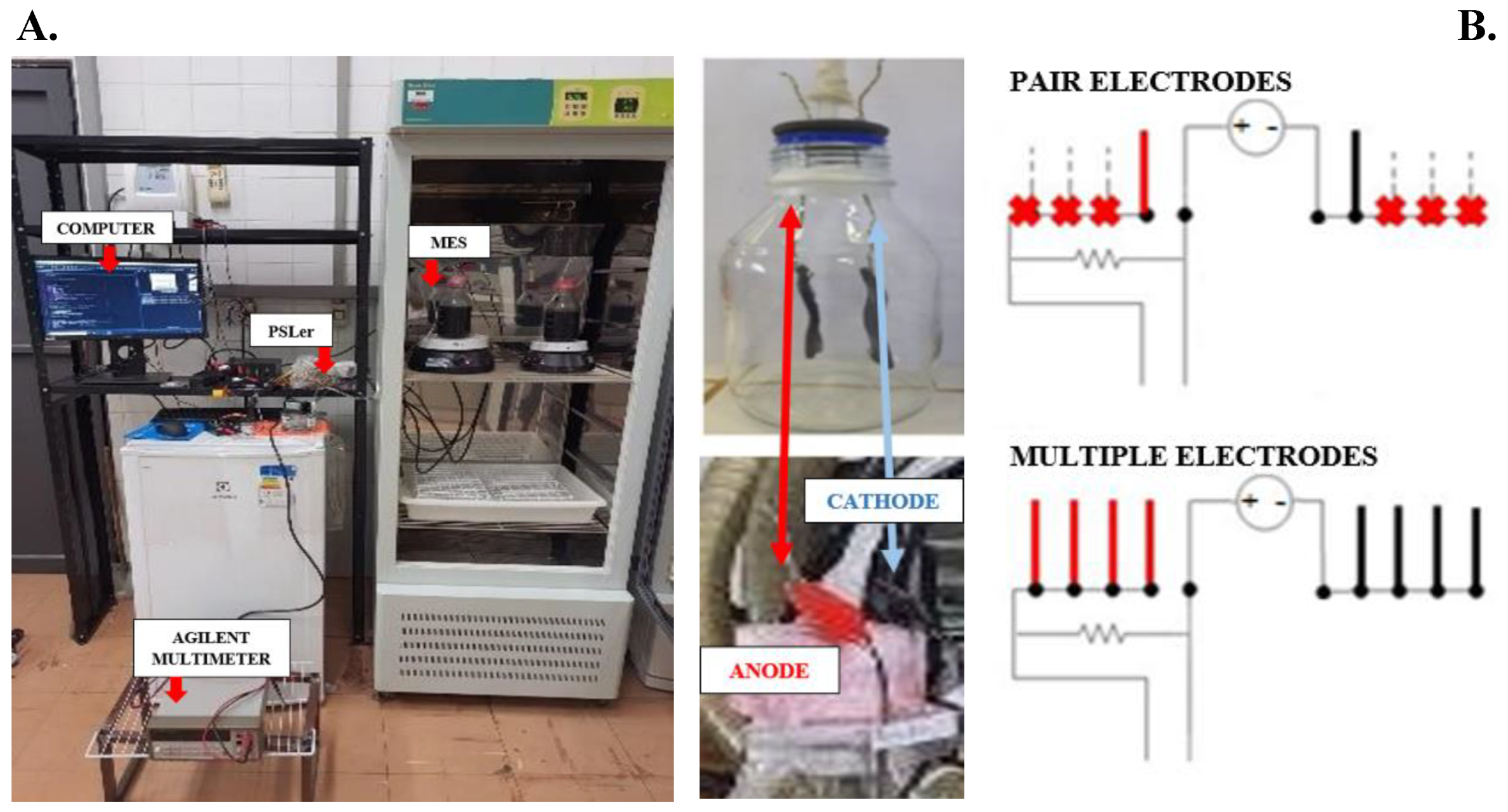

To provide a cost-effective and precise alternative to expensive commercial devices, we propose using a power supply unit, a customized circuit board, an adjustable voltage regulator, an Arduino Uno board, and a 24-bit ADS1256 board to build a customized prototype with a power supply and data logger (PSLer) (

Figure 1). This setup, including all necessary circuitry materials, can be constructed for less than

$300 USD. The 24-bit ADS1256 converter was chosen due to its high resolution, low noise, and affordability [

6]. Additionally, we chose the free software tools Arduino and Python due to their compatibility with Microsoft, Linux, and Mac OS X operating systems and their user-friendly nature[

7,

8]. This device is designed to be accessible and easy to use, making it an invaluable tool for process engineers, scientists, and anyone interested in monitoring bioelectrochemical dynamics at the laboratory scale. This approach promotes interdisciplinary research, helping to bridge gaps, save time, and reduce costs [

9].

2. Materials and Methods

2.1. Design Decision and Build Details

The PSLer system was designed to provide a low-cost, precise alternative to expensive commercial devices, making it accessible to a broader audience. When importing costly equipment is impractical, building a custom system using affordable boards, circuits, and open-source code offers a viable solution for experiments that rely on commercial tools. The system uses easily obtainable components, including a DC power supply, custom circuit board, adjustable voltage regulator, Arduino Uno, and the high-resolution ADS1256 converter. The programmability of the Arduino and ADS1256, combined with extensive online support, makes it user-friendly, while Python offers a versatile interface for data acquisition and analysis on any operating system.

Table 1 presents an overview of the components and materials, along with their affordability, highlighting the cost-effectiveness of building the PSLer system with readily available parts.

Table 2 outlines the essential operating software, hardware, and peripheral requirements for the PSLer system.

2.2. Design File Summary

Name: PSLer: Power Supplier and Logger for Microbial Electrolysis Systems >PSLer description method (Step-by-step build instructions)

Publisher: Carla Flores-Rodriguez

Name: PSLer: Power Supplier and Logger for Microbial Electrolysis Systems (All codes)

Date published: 2024-09-09

Name: PowerSupply-DataLoggerMES

Date published: 2024-11-09

2.3. Overall Implementation and Design

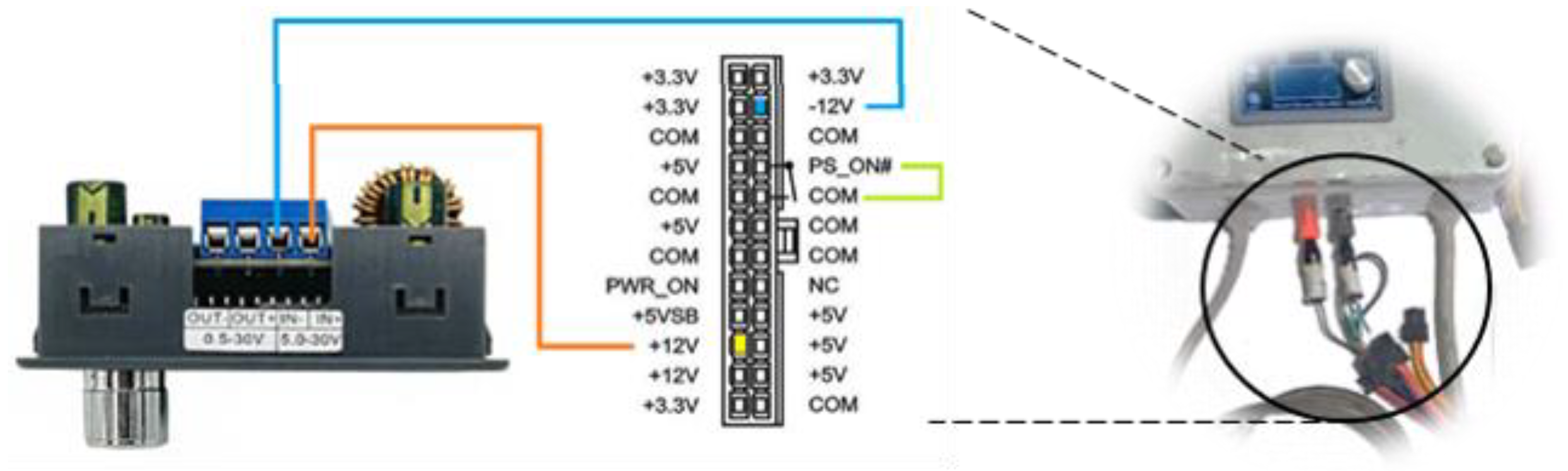

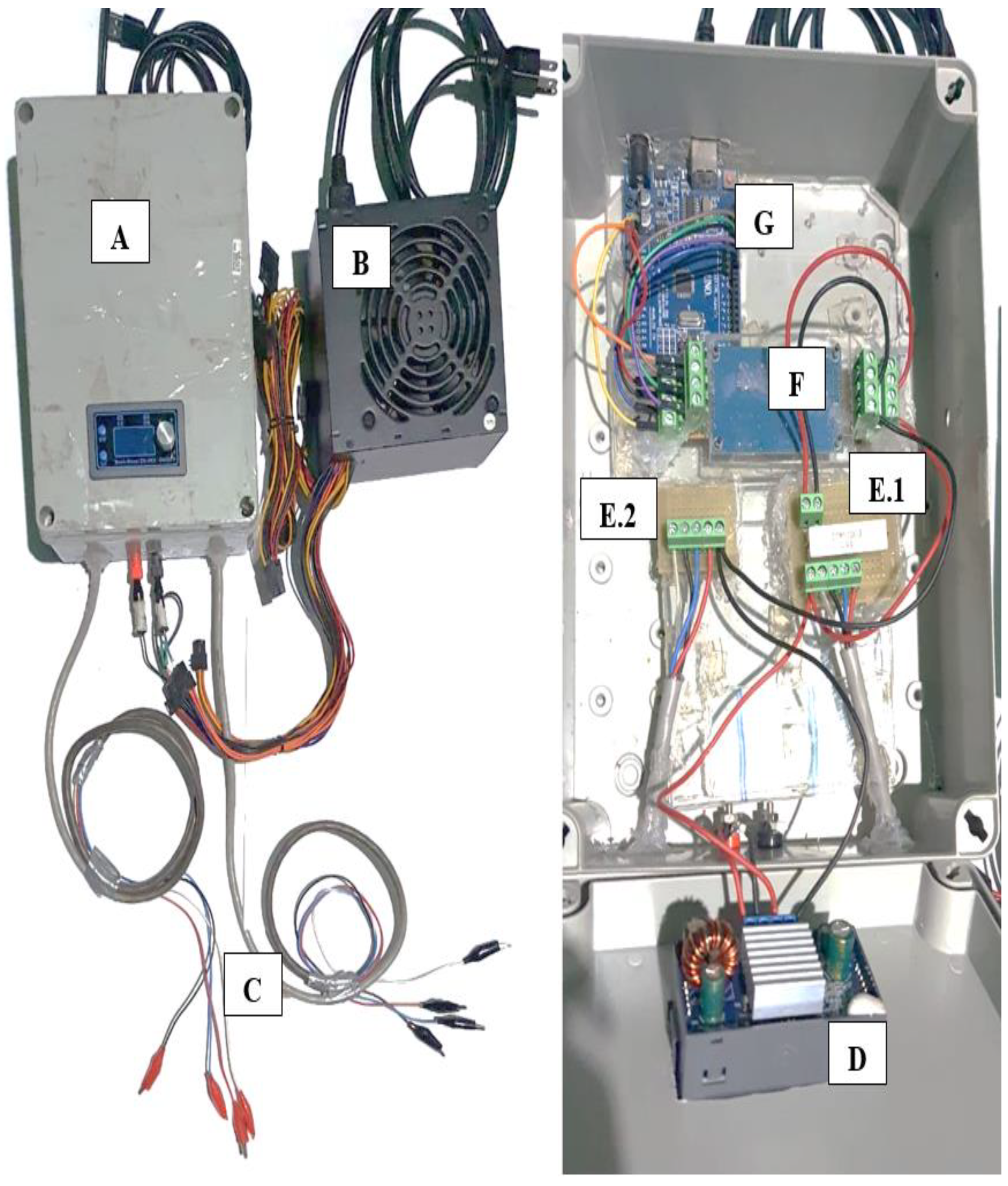

The +12 V and -12 V pins from the DC power supply unit were connected to the input and output pins of the adjustable power supply, respectively. The input voltage is then regulated using the potentiometer on the power supply, allowing precise adjustment of the resistor value to achieve output voltages up to 12 V.

Figure 2.

Power supply unit connection.

Figure 2.

Power supply unit connection.

- b.

Connecting the Adjustable Power Supply Unit to the Circuit

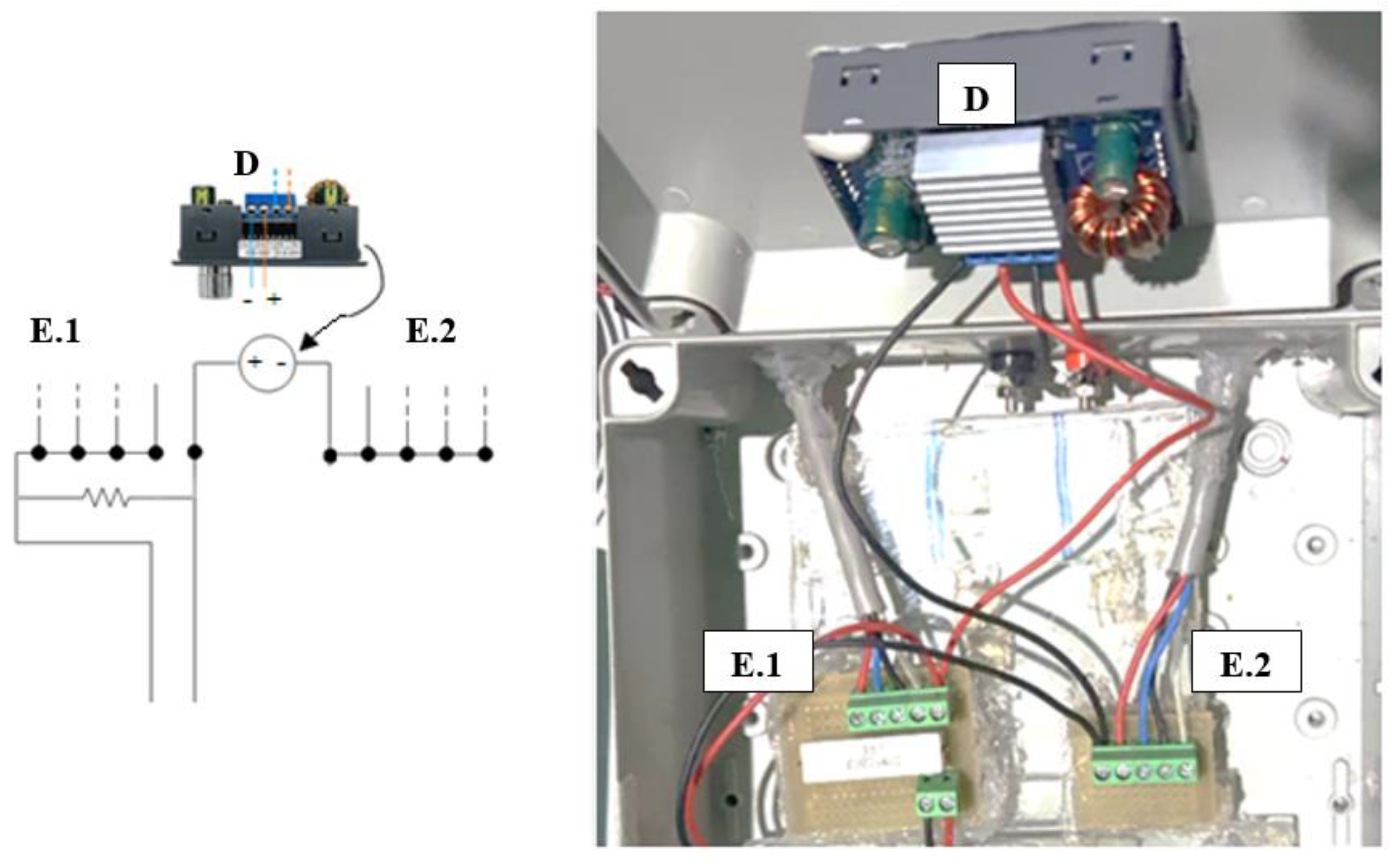

DC-DC converter or regulator module with an adjustable output is connected to the circuit. The positive terminal of the power supply connects to a central node for anodes, from which multiple branches extend in parallel. This connection ensures that the voltage across each branch is the same as the power supply voltage while the total current is distributed among the branches based on their resistance. Similarly, the negative terminal of the power supply connects to a central node for cathodes.

Figure 3.

Electronic modules and circuit diagram. (D) Adjustable power supply unit. (E1) Circuit for anodes. (E2) Circuit for cathodes.

Figure 3.

Electronic modules and circuit diagram. (D) Adjustable power supply unit. (E1) Circuit for anodes. (E2) Circuit for cathodes.

Depending on the configuration of the MES, the sensor circuit can accommodate up to 4 pairs of electrodes (4 anodes and 4 cathodes).

- c.

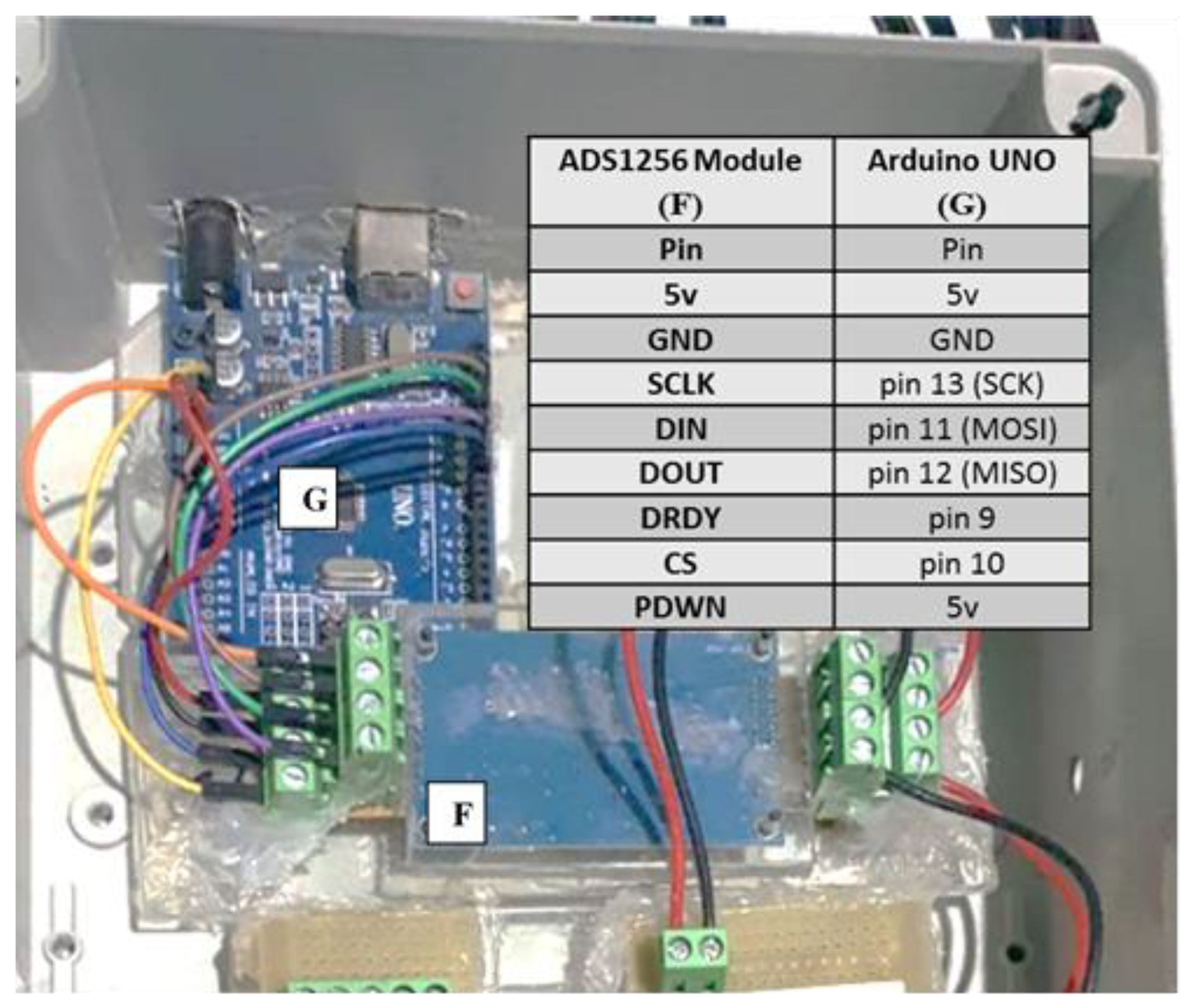

Connecting the Arduino UNO to the ADS1256

The ADS1256 is connected to the Arduino UNO board, as it is suggested in [

10,

11].

Figure 4.

Pin connection between the ADS1256 (F) and Arduino UNO boards (G).

Figure 4.

Pin connection between the ADS1256 (F) and Arduino UNO boards (G).

- d.

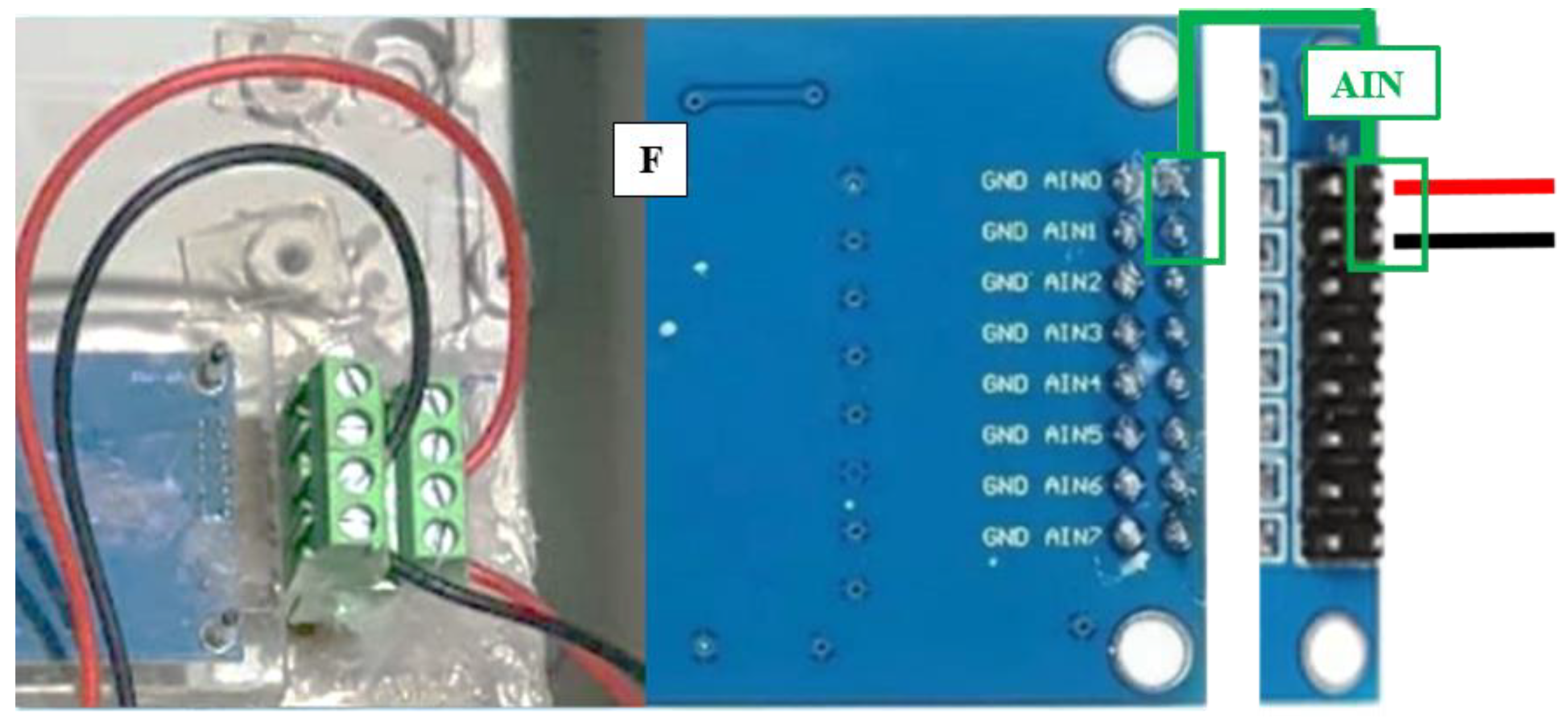

Connecting the Circuit to the ADS1256

The ADS1256 board was configured to support up to four 2-wire sensors. Each pair of ADC differential inputs (AIN0-AIN1, AIN2-AIN3, AIN4-AIN5, and AIN6-AIN7) is a sensor to measure voltage. For instance, in the PSLer prototype, the electrical signal from the metabolic reactions in the MES and the external input voltage could be detected and collected through the sensors simultaneously.

Figure 5.

Sensor identification in ADS1256 board (F).

Figure 5.

Sensor identification in ADS1256 board (F).

- e.

Setting Arduino UNO

The Arduino USB cable was connected to an available USB 2.0 port (typically black) on the computer, and the following settings were configured in the Tools panel:

It is recommended that the COM port number match the one found in the Device Manager under the Ports (COM & LPT) section on the computer.

Consequently, the Arduino code was implemented according to [

6,

10,

11]. The code considered a programmable gain amplifier (PGA) value of 4 and a sampling rate (Samples per second—SPS) of 2.5 to cover a full-scale input voltage ranging from ±1.25 V and 22.1 bits of free-noise resolution (Eq. 1).

Under these conditions, the theoretical voltage resolution was calculated as follows [

6]:

The resulting voltage resolution was 0.000000556131 V (or approximately 0.556 μV). This voltage resolution is notably high and is considered excellent for precision measurement in educational applications. Furthermore, the data collection was configured to collect multiple inputs every 5 minutes simultaneously with a maximum transfer rate of 9600 bits per second (

Table 3). Note that when the input voltage range is set to ±1.25 V on the ADS1256, the adjustable power supply should be configured to reach a maximum input voltage of 1.25 V. Maintaining an external voltage within this range is crucial for scaling up MES reactors, as they can harness energy from renewable sources like wind, solar, and biomass to maintain the sustainable cycle [

12].

- f.

Setting Python

The Python code was implemented according to [

13], and the input parameters are defined in

Table 4.

Before restarting, it is strongly suggested that you remove any CVS file from ... /temporary_measurements and run the code.

3. Quality Control

3.1. Experimental Setup

A 500 ml borosilicate glass was used to configure a single MES. The rubber top was provided with a port to connect a PVC hose (4 mm DO) for biogas collection and depressurization. Graphite-carbon felt electrodes (0.3× 2 × 6 cm

3) connected with stainless steel (SS) wires 24 ga (6 wires twisted together) were used as anodes and cathodes (

Figure 6C). SS wires were used to establish the electrical connections. Both electrodes were inserted through the rubber top. Voltage was supplied using the adjustable power supply from the PSLer prototype.

The single MES was inoculated with anaerobic digestion effluent sampled from the Barão Geraldo Wastewater Treatment Facility (Campinas, São Paulo-Brazil). The system was fed with 400 ml of a synthetic growth medium (GM) containing 50 mM phosphate buffer solution (pH 7), 1 mL of trace elements, 1 mL of vitamins, and 2 g/L of acetate as a carbon source. This mixture was combined with inoculum at a 1:1 volume ratio [

5,

14,

15]. The mixture was bubbled with nitrogen gas for approximately 10 minutes to remove dissolved oxygen. The entire single MES setup was placed on a magnetic stirrer set at 150 rpm (Fisatom 753, Brazil) for uniform mixing of the substrate and incubated at 35 ± 2 °C (BOD incubator, Nova Ética 411, Brazil).

3.2. First Test

Adding stable voltages is essential in microbial electrolysis systems. Thus, the input voltages (0.5, 0.8, 1.0, 1.2 V) were set and collected using the PSLer. Hundred eighty-eight data points were collected and analyzed for different statistic parameters.

Figure 6.

(A) PSLer and associated peripherals. (B) Single-cell MES setup. (C) Circuit configuration for a voltage sensor connected for a pair-electrode or multiple-electrode MES.

Figure 6.

(A) PSLer and associated peripherals. (B) Single-cell MES setup. (C) Circuit configuration for a voltage sensor connected for a pair-electrode or multiple-electrode MES.

The data presented in the table provides a comprehensive statistical summary for four different voltage levels: 0.5 V, 0.8 V, 1.0 V, and 1.2 V. The parameters include the standard deviation, mean, median, coefficient of variation, minimum, maximum, upper quantile (100%), and lower quartile (0%).

The

Table 5 shows the data set is consistent across all voltage levels, as evidenced by the small standard deviations, tight ranges, and the proximity of mean and median values to the nominal voltages. The consistent coefficient of variation, especially the decreasing trend with higher voltages, suggests that the measurement system is reliable and performs better at higher voltage levels.

3.3. Second Test:

The input voltage of 1.0 V was applied to induce electrical signals from metabolic reactions within the microbial electrolysis system (MES). These electrical signals (voltage) were measured across an external resistance of 10 Ω using the PSLer prototype. The system was programmed to sample the voltage every 5 minutes. Sixty data points were measured with the PSLer prototype and compared against the Agilent 34401A Multimeter. A Welch Two Sample t-test indicated a p-value of 0.9942, well above the 0.05 significance threshold. This suggests no statistically significant difference in the voltage measurements between the PSLer and the Agilent 34410A at the 0.05 significance level.

4. Results

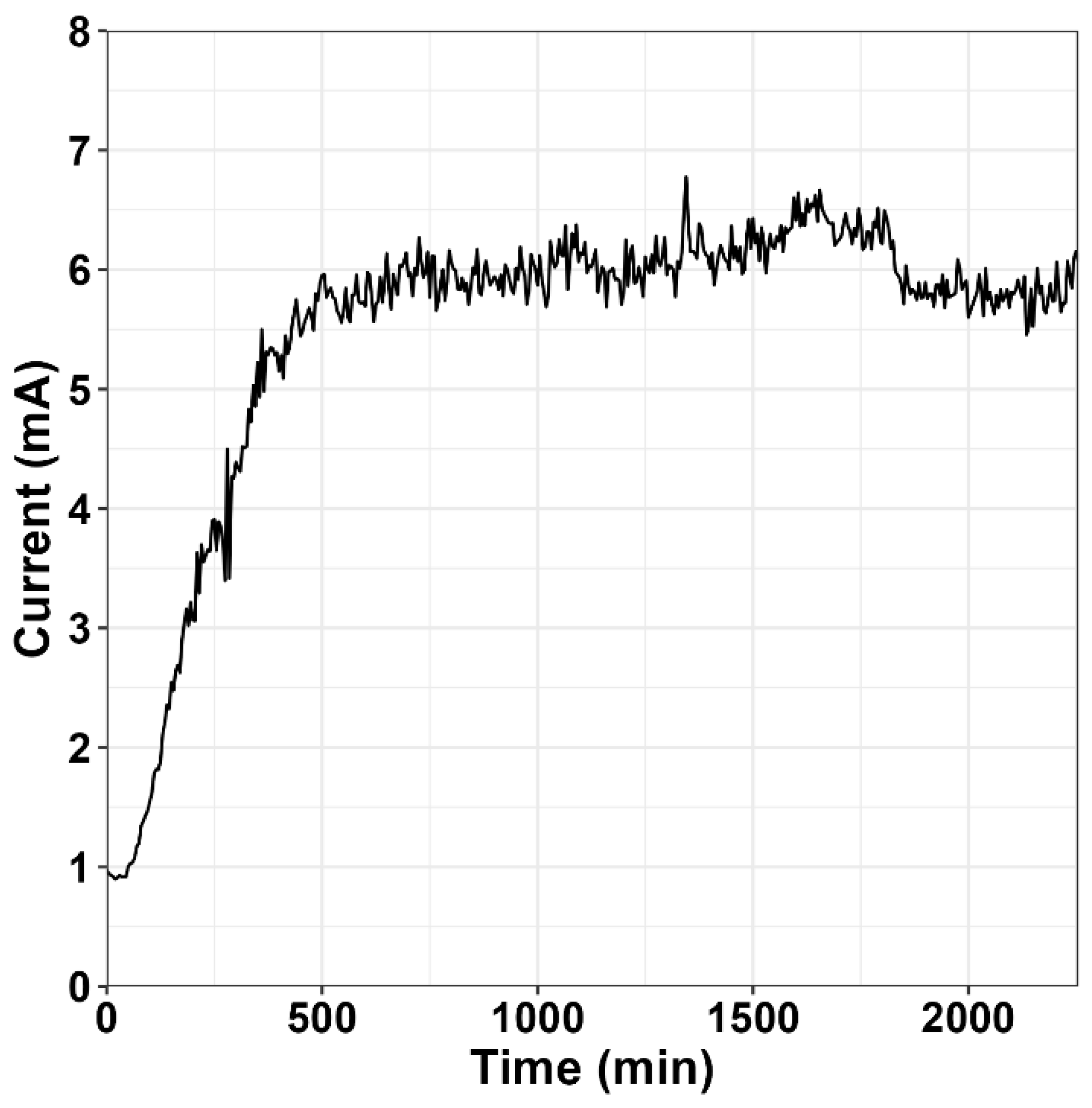

4.1. Application

In MES operations, the recorded voltage data is used to calculate the current generation according to Ohm's Law equation when the voltage and resistance are known (Eq. 2). Current generation in microbial electrolysis cells (MECs) is a crucial indicator of system performance, reflecting the efficiency of electroactive microorganisms in oxidizing substrates and transferring electrons. It directly correlates with converting organic matter into valuable products like hydrogen or methane, making it essential for optimizing MEC operation. Additionally, the current generation provides insights into the effectiveness of the cell's design, materials, and operating conditions, serving as both a measure of efficiency and a diagnostic tool for maintaining and improving MEC functionality in research and applied settings.

Where I(A) is the electric current in amperes (A), V is the voltage across the conductor in volts (V), and R is the resistance of the conductor in ohms (Ω).

To demonstrate the PSLer's application, voltage measurements were collected using the prototype and processed to calculate the current generation (

Figure 7). The results show a maximum current of 6.78 mA. These findings suggest that the externally applied voltage of 1.0 V effectively promoted the formation of exoelectroactive biofilms and the oxidation of organic matter (acetate) at the anode electrode.

Additional applications of the PSLer include:

The PSLer is equipped with 4 sensors (2 wire sensors each), allowing it to monitor 4 different experiments simultaneously.

In case a multiple-electrode MES is required, the circuit sensor can be adapted to accommodate up to 4 pairs of electrodes.

5. Discussion

The statistical analysis of the voltage levels demonstrates high accuracy, precision, and consistency in the measurements. The findings suggest that the system under test is stable and capable of providing reliable voltage readings across the 0.5 V to 1.2 V range. In Microbial Electrolysis Systems applications, an external voltage between 0.2 and 1.8 V is essential because it can be supplied by renewable energy sources like wind, solar, and biomass. Integrating these renewable sources aligns with the principles of a sustainable energy cycle. Furthermore, Based on this statistical analysis, the PSLer prototype demonstrates measurement accuracy comparable to the Agilent 34410A Multimeter. The high p-value (0.9942) indicates that the PSLer can reliably measure voltage in a manner consistent with established laboratory equipment. Given these results, the PSLer prototype using ADS1256 board shows strong potential for use in microbial electrolysis systems (MES) research at the laboratory, providing a cost-effective and accurate tool for voltage measurement in experimental setups. Its performance suggests it could be a valuable instrument for advancing MES studies, where precise and reliable data is crucial.

6. Future Work

Several enhancements can be made to improve the system's functionality and broaden its applications for future work. One potential upgrade involves incorporating a Raspberry Pi to enhance data processing capabilities, enabling real-time monitoring and control of the voltage sensor system. The Raspberry Pi could be programmed to interface with the ADS1256 board, providing a more robust computing platform for data acquisition, processing, and analysis. Additionally, upgrading the software to include graphical results in real-time would significantly enhance user experience. This could involve developing a custom interface using tools like Python (e.g., Matplotlib or Plotly) or integrating the system with platforms like Grafana to visualize voltage readings and trends. Another valuable improvement would be to enable online data uploading and storage. By integrating cloud-based platforms like ThingSpeak or Firebase, users could remotely access and monitor the voltage data, allowing for long-term tracking and the ability to analyze historical trends. These upgrades would significantly enhance the system's versatility, making it more suitable for laboratory and field applications in microbial electrolysis and other renewable energy research.

Paper author contributions (CRediT)

Carla Flores-Rodriguez: design, assembly, Data curation, Formal Analysis, Investigation, Methodology, Methodology, Validation, Writing - Original Draft, Writing - Review Editing. Gustavo Mockaitis: Project administration, Funding acquisition, Resources.

Funding statement

We want to acknowledge financial support from São Paulo Research Foundation (FAPESP, Portuguese: Fundação de Amparo à Pesquisa do Estado de São Paulo) – Research Grant No. 2019/03200-7.

Acknowledgments

We want to acknowledge financial support from São Paulo Research Foundation (FAPESP, Portuguese: Fundação de Amparo à Pesquisa do Estado de São Paulo) – Research Grant No. 2019/03200-7.

Competing interests

The authors declare that they have no competing interests.

Licenses

This is an open-access article distributed under the terms of the Creative Commons Attribution 4.0 International License (CC-BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. See

http://creativecommons.org/licenses/by/4.0/.

Copyright Notice

Authors who publish in this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

Authors can enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

By submitting this paper you agree to the terms of this Copyright Notice, which will apply to this submission if and when this journal publishes it.

References

- Flores-Rodriguez C, Min B. Enrichment of specific microbial communities by optimum applied voltages for enhanced methane production by microbial electrosynthesis in anaerobic digestion. Bioresour Technol [Internet]. 2020;300:122624. Available from: https://doi.org/10.1016/j.biortech.2019.122624. [CrossRef]

- Hasany M, Mardanpour MM, Yaghmaei S. Biocatalysts in microbial electrolysis cells: A review. Int J Hydrogen Energy [Internet]. 2016;41:1477–93. Available from: http://dx.doi.org/10.1016/j.ijhydene.2015.10.097. [CrossRef]

- Yu Z, Leng X, Zhao S, Ji J, Zhou T, Khan A, et al. A review on the applications of microbial electrolysis cells in anaerobic digestion. Bioresour Technol [Internet]. 2018;255:340–8. Available from: https://doi.org/10.1016/j.biortech.2018.02.003. [CrossRef]

- Guo H, Kim Y. Stacked multi-electrode design of microbial electrolysis cells for rapid and low-sludge treatment of municipal wastewater. Biotechnol Biofuels [Internet]. 2019;12:1–10. Available from: https://doi.org/10.1186/s13068-019-1368-0. [CrossRef]

- Flores-Rodriguez C, Nagendranatha Reddy C, Min B. Enhanced methane production from acetate intermediate by bioelectrochemical anaerobic digestion at optimal applied voltages. Biomass and Bioenergy [Internet]. 2019;127:105261. Available from: https://doi.org/10.1016/j.biombioe.2019.105261. [CrossRef]

- TI. Very Low Noise , 24-Bit Analog to Digital Converter. Texas Instruments [Internet]. 2013; Available from: https://www.alldatasheet.com/datasheet-pdf/pdf/336384/TI/ADS1256.html.

- Python Software Foundation. The Python Language Reference [Internet]. python.org. Available from: https://docs.python.org/3/reference/index.html.

- Massimo B, Cuartielles D, et al. About Arduino [Internet]. Arduino.cc. 2024 [cited 2024 Sep 11]. Available from: https://www.arduino.cc/education.

- V. Kyslitsyn, L. Shevchenko, V. Umanets, L. Sikoraka and YA. Python programming language and arduino robotics kits in the process of training future teachers of computer science. ETR. 2024;2:162–.

- Fernando K. Dá para criar uma empresa disso! [Internet]. Tutoriais Tecnol. Tendencias. 2020. Available from: https://www.fernandok.com/2020/10/da-para-criar-uma-empresa-disso.html.

- Akhmad A, Sepúlveda A, Axel. ADS1256 [Internet]. 2019. Available from: https://github.com/adienakhmad/ADS1256.git.

- Pawar AA, Karthic A, Lee S, Pandit S, Jung SP. Microbial electrolysis cells for electromethanogenesis: Materials, configurations and operations. Environ Eng Res [Internet]. 2022;27:0–2. Available from: https://doi.org/10.4491/eer.2020.484. [CrossRef]

- Flores-Rodriguez C. The AGDAC: An Innovative Market-Oriented, Open-Source Multiplexing System for Advanced Biogas Volume Measurements in Research Experiments. Zenodo [Internet]. Available from: . [CrossRef]

- Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, et al. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci Technol [Internet]. 2009;59:927–34. Available from: https://doi.org/10.2166/wst.2009.040. [CrossRef]

- Siegert I, Banks C. The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem [Internet]. 2005;40:3412–8. Available from: https://doi.org/10.1016/j.procbio.2005.01.025. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).