1. Introduction

1.1. Background and Motivation

Modern research laboratories operate in an increasingly dynamic environment, where experimental setups evolve rapidly to meet new challenges and opportunities[

1]. Recent advances in sensor technology and data processing have pushed the need for instrumentation systems that are not only high-performing but also flexible and affordable[

2,

3]. Traditional instrumentation platforms are often built with fixed architectures that require significant effort to modify when experimental needs change[

4]. In response to these limitations, a modular approach has emerged as a promising alternative that can adapt to diverse experimental conditions with minimal reconfiguration[

5,

6]. The motivation behind this work is to develop an integrated system that enables researchers to easily add, remove, or update sensor modules without overhauling the entire setup[

7,

8]. This approach is driven by several key objectives:

Adaptability: Enabling quick integration of new sensor types and data channels.

Cost-efficiency: Reducing overall expenditures by employing readily available components.

User-friendliness: Simplifying the process of system setup so that researchers can concentrate on scientific inquiry rather than technical integration.

By standardizing the connection interfaces and centralizing data acquisition, our system addresses the rigidity of traditional solutions while paving the way for future enhancements. This modular framework is essential in interdisciplinary research settings[

9], where the rapid reconfiguration of experiments can lead to new discoveries and increased research productivity[

10]. Overall, our approach strives to bridge the gap between high-performance instrumentation and practical, budget-conscious research environments.

1.2. Challenges in Traditional Instrumentation Systems

Conventional instrumentation systems are often burdened by inherent inflexibility and complex integration requirements[

11]. Many of these systems rely on dedicated hardware with fixed interfaces, which results in lengthy setup times and substantial manual calibration efforts[

12]. Researchers must frequently contend with a range of proprietary protocols and non-standardized connectors[

13], leading to compatibility issues and increased maintenance costs[

14]. In addition, the rigid design of traditional systems limits scalability; expanding an existing setup to incorporate additional sensors typically requires significant redesign or even a complete overhaul of the instrumentation platform[

15]. Such constraints are particularly problematic in dynamic laboratory settings where experimental conditions and measurement parameters can change rapidly[

16]. The challenges posed by traditional systems include:

Complex Configuration: The need for extensive manual intervention during setup and calibration[

17].

Limited Scalability: Difficulties in expanding the system to include new measurement devices[

18].

High Operational Costs: Increased expenses due to proprietary components and specialized interfaces[

19].

These issues hinder the efficiency of experimental workflows and restrict the potential for rapid prototyping. Addressing these challenges is vital for the advancement of flexible laboratory instrumentation, and our work is focused on developing a system that overcomes these limitations through a more adaptable[

20], modular design.

1.3. Modular Plug-and-Play Paradigm

The modular plug-and-play paradigm[

21] offers a robust solution to the challenges presented by conventional instrumentation systems. This approach is centered on the design of standardized interfaces that allow individual sensor modules to be easily connected or disconnected without the need for extensive reconfiguration[

22]. A major advantage of this paradigm is the reduction in system complexity; by relying on off-the-shelf components and uniform communication protocols, the integration process becomes straightforward and less prone to errors[

23]. The modular design supports scalability, meaning that the system can be expanded or upgraded as new technologies emerge. Key features of this approach include:

Standardized Interfaces: Uniform connectors and protocols that ensure compatibility across a wide range of devices.

Ease of Integration: Simplified assembly and disassembly processes that reduce setup time and minimize technical barriers.

Future-proofing: The ability to seamlessly incorporate emerging sensor technologies without overhauling the existing infrastructure.

This paradigm not only streamlines the integration of diverse sensor modules but also provides a cost-effective solution that enhances experimental efficiency. By minimizing wiring complexity and reducing manual configuration, the plug-and-play approach facilitates rapid prototyping and iterative experimentation. It allows researchers to focus on experimental outcomes rather than technical challenges, ultimately leading to more efficient and reliable data acquisition processes.

1.4. Leveraging the APP-All MCU 2023 Development Board

At the core of our proposed system lies the

Microchip Technology’s APP-All MCU 2023 development board[

24], which serves as the central hub for sensor integration and data management. This development board was selected for its versatility, robust performance, and comprehensive support for multiple communication protocols such as USB, I2C, and SPI. Its flexible architecture enables it to interface seamlessly with a wide range of sensor modules, ensuring high precision and rapid data processing. The APP-All MCU 2023 is designed for quick prototyping and customization, which allows for software configurations tailored to specific experimental needs. Advantages of incorporating this board include:

Integrating the APP-All MCU 2023 into our modular system enables a harmonized approach to data acquisition and sensor management. This board’s programmable nature permits rapid adjustments in response to evolving research needs. It also ensures that the system remains adaptable and scalable, allowing for seamless integration of future innovations. By capitalizing on the strengths of this development board, our design offers a compelling balance between technical performance and economic viability, thereby fostering more agile and efficient laboratory workflows.

1.5. Scope and Organization of This Work

This paper presents a detailed exploration of a modular, plug-and-play instrumentation system designed to advance laboratory research. The primary focus is on the development, implementation, and evaluation of a prototype that integrates multiple sensor modules through the APP-All MCU 2023 development board. The work addresses key challenges associated with traditional systems by providing a flexible, scalable, and cost-effective alternative. In the following sections, we outline the hardware architecture and software frameworks that underpin the proposed system. Specific attention is given to how standardized interfaces and modular components contribute to ease of integration and reduced setup times. The paper further details the experimental methods employed to assess the system’s performance in realistic laboratory settings, with discussions on reliability, scalability, and operational efficiency. By systematically comparing our approach with conventional instrumentation platforms, we highlight the improvements in adaptability and cost savings. This comprehensive evaluation not only validates the design choices made but also sets the stage for future enhancements. Ultimately, our work aims to provide a robust foundation for the development of next-generation laboratory instrumentation, promoting more effective research practices and fostering innovation in experimental methodologies.

2. Materials and Methods

2.1. Hardware Components and System Architecture

The backbone of our system is built around the Microchip Technology’s APP-All MCU 2023 development board, which has been deployed in an actual laboratory setting during our hands-on experiments. The board is interfaced with a suite of environmental sensors, including a pH sensor, light sensor, temperature sensor, and humidity sensor, all of which communicate via the I2C protocol. This communication standard was selected for its reliability and ease of implementation, ensuring that data from multiple sensors can be synchronized and processed concurrently. The hardware setup includes dedicated sensor conditioning circuits that convert raw analog signals into digital data, which is then communicated to the MCU. In addition, a power management module and signal buffering circuits are integrated to maintain stability and accuracy during prolonged operation. Our design emphasizes modularity by utilizing standardized connectors and interface protocols, allowing for rapid replacement or addition of sensor modules as experimental needs evolve. Key hardware features include:

Robust integration of multiple sensors through the I2C interface.

Dedicated conditioning circuits to enhance measurement precision.

A scalable architecture that supports easy expansion for future sensors.

Stable power and signal management to ensure consistent data acquisition.

This comprehensive hardware architecture not only meets the stringent requirements of real-time data acquisition in dynamic laboratory environments but also facilitates straightforward debugging and maintenance through modular design.

2.2. Software Implementation and Real-Time Data Acquisition

The software infrastructure is designed to complement the flexible hardware architecture, ensuring efficient, real-time data acquisition and visualization. Custom firmware, written in C/C++, runs on the APP-All MCU 2023 development board and is responsible for managing the I2C communication with the pH, light, temperature, and humidity sensors. Data captured by these sensors is transmitted to an external host computer where it is processed and logged in real time. On the host side, we leverage Python’s Bokeh library to create intuitive, interactive plots that provide immediate visual feedback on environmental conditions. The use of Bokeh allows for dynamic updating of plots, enabling users to monitor sensor outputs continuously and to quickly identify any deviations or anomalies. The software system is engineered to support detailed logging and debugging; all sensor data streams can be easily grepped for troubleshooting, ensuring that any issues in the data acquisition chain are promptly identified and resolved. The integration of these software components creates a robust, real-time monitoring system that is both user-friendly and adaptable, supporting rapid prototyping and iterative experimentation in a live lab environment.

2.3. Experimental Protocol and Debugging Strategies

Our experimental protocol was meticulously designed to validate the performance and reliability of the integrated modular system under real-world laboratory conditions. The hands-on experiment involved the installation of the sensor suite in a controlled lab environment, where variables such as pH, light intensity, temperature, and humidity were systematically varied. Prior to data acquisition, each sensor underwent a calibration process to ensure accuracy and consistency. During the experiment, the sensors continuously communicated environmental data to the APP-All MCU 2023 via I2C, and the acquired data was relayed to a computer for real-time processing. The following measures were implemented to ensure robust performance and facilitate effective debugging:

Calibration and Standardization: Each sensor was calibrated against known standards to minimize error margins.

Real-Time Monitoring: The Bokeh-based visualization system provided instantaneous graphical feedback, enabling immediate detection of any irregularities.

Data Logging and Grepping: Comprehensive logging allowed for the easy extraction and analysis of sensor data, which is critical for identifying and resolving communication or processing errors.

Modular Debugging: The modular design of both hardware and software permitted isolated testing of individual components, streamlining the troubleshooting process.

These strategies ensured that the system maintained high fidelity in data acquisition and processing, while also allowing for rapid iterative improvements. The experimental protocol demonstrates that our system is not only capable of real-time monitoring but is also resilient to potential issues, thereby providing a reliable platform for advanced laboratory instrumentation.

2.4. System Integration and Calibration Procedures

The integration of the sensor suite into the overall system required a systematic approach to ensure both hardware and software components worked harmoniously. Initially, each sensor module (pH, light, temperature, and humidity) was individually mounted onto custom-designed interface boards that facilitate secure connections to the APP-All MCU 2023 via I2C. Care was taken to shield sensitive components from electromagnetic interference by employing proper grounding techniques and signal buffering circuits. The integration process involved several stages: first, establishing a reliable physical connection through standardized connectors; second, verifying the electrical characteristics of each interface; and finally, testing the communication protocols to ensure data integrity. Calibration procedures were then conducted using controlled reference environments. For instance, the pH sensor was calibrated using buffer solutions with known pH values, while the temperature and humidity sensors were compared against certified instruments under controlled lab conditions. Specific calibration steps included:

Baseline Measurements: Recording initial sensor outputs under stable conditions.

Reference Comparison: Adjusting sensor readings based on discrepancies with known standards.

Iterative Tuning: Repeating the calibration process until the sensor outputs stabilized within acceptable error margins.

This systematic integration and calibration protocol ensured that each sensor provided accurate, consistent data, laying a robust foundation for subsequent real-time monitoring and analysis.

2.5. Data Analysis, Post-Processing, and Visualization

The data acquired from the sensor network undergoes extensive post-processing to transform raw measurements into actionable insights. Once transmitted from the APP-All MCU 2023 to the host computer, the data is first subjected to preprocessing routines that involve noise filtering, data smoothing, and outlier detection. Using Python, these routines leverage standard libraries for signal processing, ensuring that the sensor outputs are both reliable and interpretable. The preprocessed data is then analyzed using statistical techniques to determine trends and correlations among environmental parameters. For visualization, the Bokeh library is employed to generate interactive, real-time plots that update dynamically as new data is received. This visualization framework not only presents the current state of the laboratory environment but also allows users to:

Zoom into specific time intervals for detailed analysis.

Overlay historical data to identify long-term trends.

Configure alerts based on threshold violations in sensor readings.

Furthermore, automated scripts enable batch processing of logged data for comprehensive post-experiment analyses, including regression analysis and anomaly detection. These tools facilitate a deeper understanding of the sensor behavior and overall system performance. The detailed data analysis and visualization pipeline ensure that any deviations are promptly identified and addressed, thereby enhancing the reliability and effectiveness of the experimental system.

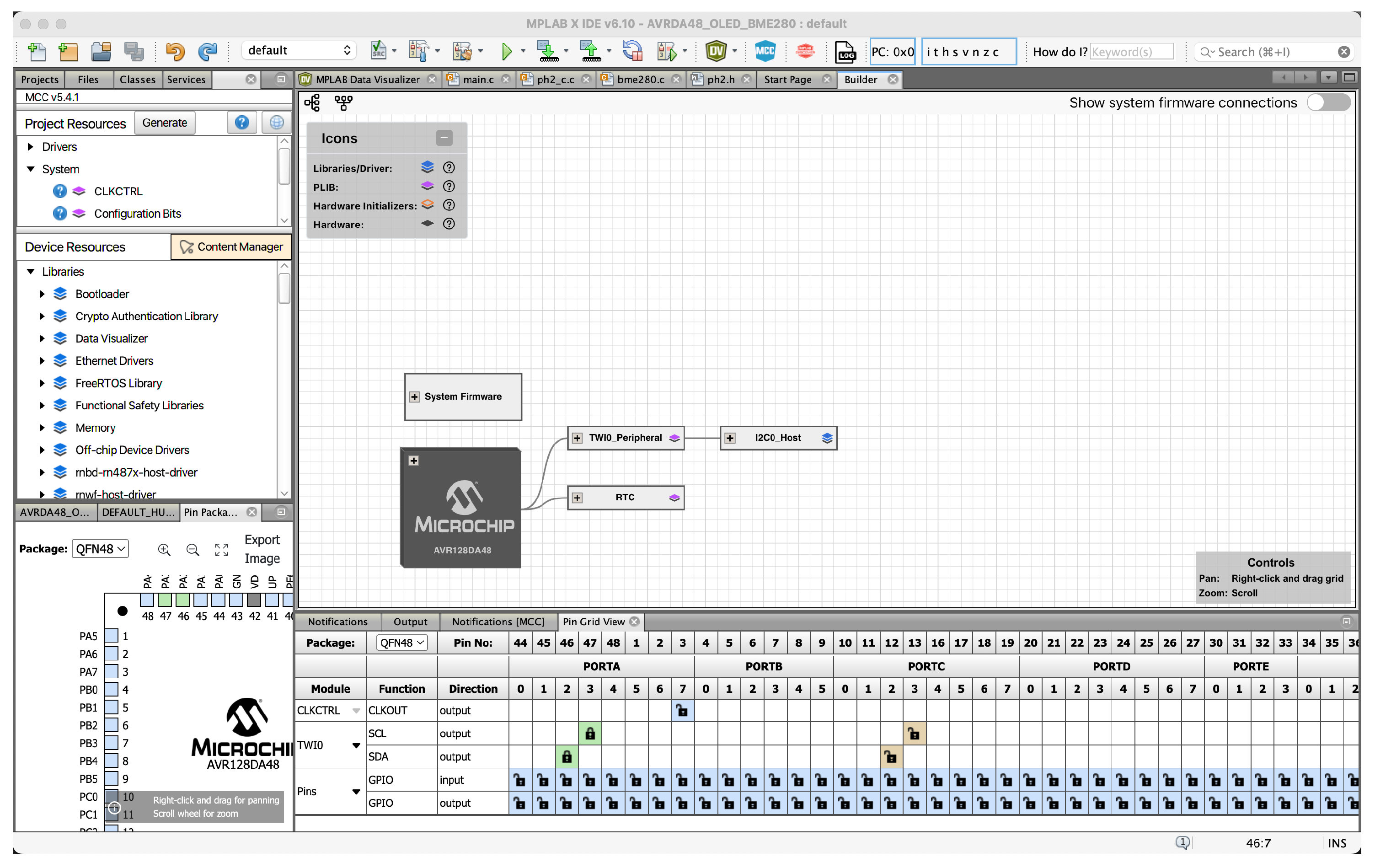

2.6. System Integration and Configuration Overview

Figure 1 presents an in-depth view of the configuration interface within the Microchip development framework. This section details how the hardware components are managed and interconnected using Microchip’s tools, providing a clear mapping of sensor modules, firmware settings, and peripheral pin assignments. The interface displayed in the figure exemplifies the streamlined process for assigning functionalities, ensuring efficient integration of sensors (such as temperature, humidity, pH, and light) with the central control unit. This visual overview is integral to understanding the systematic approach employed for achieving a low-cost, yet high-accuracy, plug-and-play laboratory setup.

3. Results

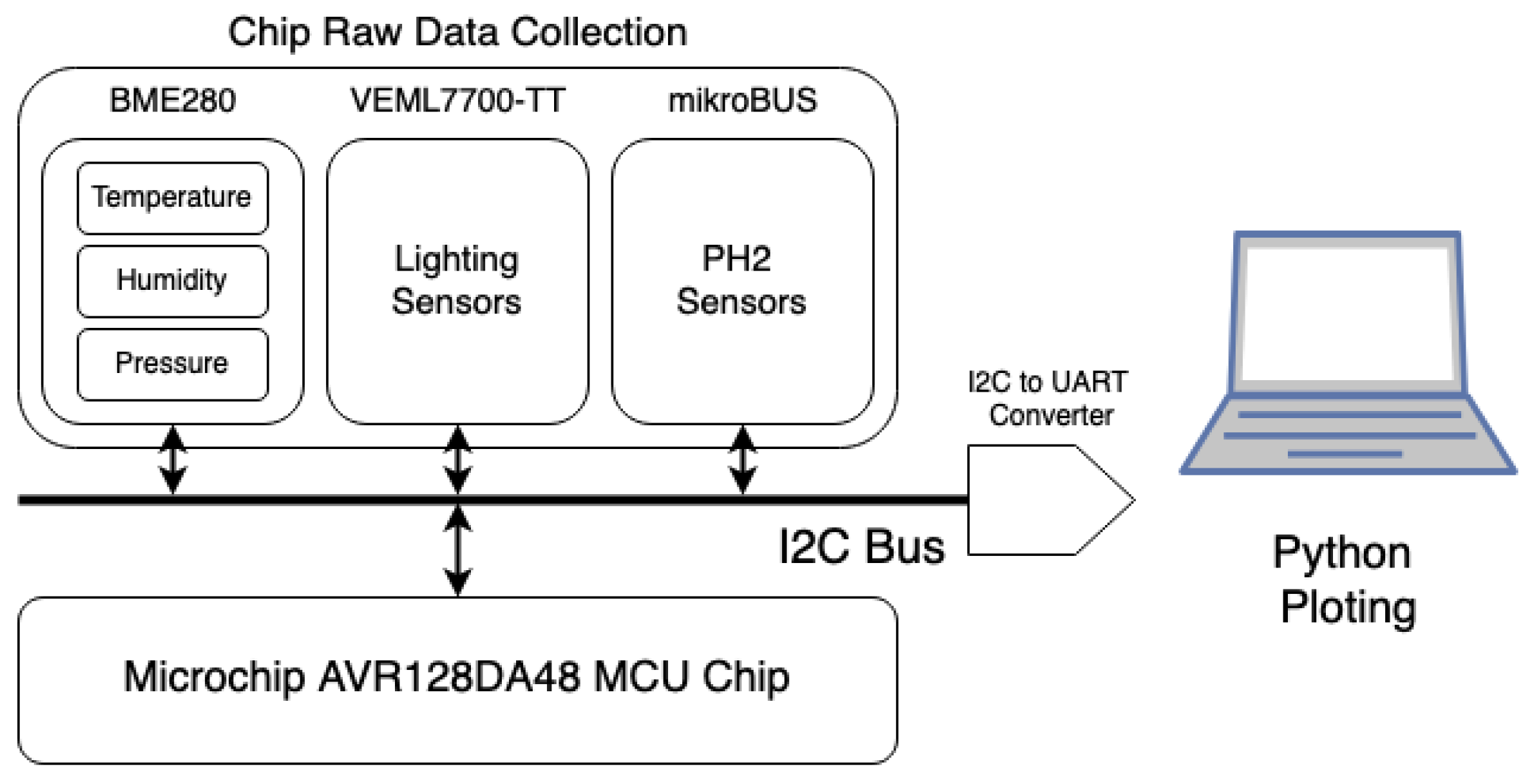

Before delving into the specific implementation details, we present a high-level overview of our experimental workflow and hardware connections as shown in

Figure 3. This flow chart illustrates how sensor data, collected by the

AVR128DA48 micro-controller on the Microchip Technology’s APP-All MCU 2023 development board, is routed through the I2C bus, processed by the onboard firmware, and ultimately transmitted to the host computer for real-time visualization and analysis. Each of the following subsections describes one or more key stages in this flow, from firmware-level data handling to the Python-based monitoring system.

3.1. Microchip APP-All MCU 2023 Code Implementation and Sensor Data Acquisition

This subsection focuses on the planning and execution of the firmware that runs on the

Microchip Technology’s APP-All MCU 2023 development board, specifically on the embedded

AVR128DA48 micro-controller. The firmware is developed in C/C++ and is structured around a main control loop with interrupt-driven routines for sensor data capture. All sensors—pH, light, temperature, and humidity—communicate via the I2C protocol, simplifying wiring and minimizing potential signal conflicts.

Figure 3 highlights the firmware flow, starting with sensor initialization, followed by periodic data sampling at user-defined intervals. A built-in calibration routine adjusts sensor readings based on predefined offsets or slope values to account for drift and manufacturing tolerances. Once the micro-controller gathers stable readings, it packages these values for transmission via the board’s serial interface. Error-checking mechanisms, such as CRC checks or simple checksums, are implemented to detect corrupted data frames. In the event of a sensor or communication failure, diagnostic flags are set, and the system logs the event for post-experiment debugging. This layered approach ensures high data fidelity and supports the rapid prototyping needs typical in dynamic laboratory settings.

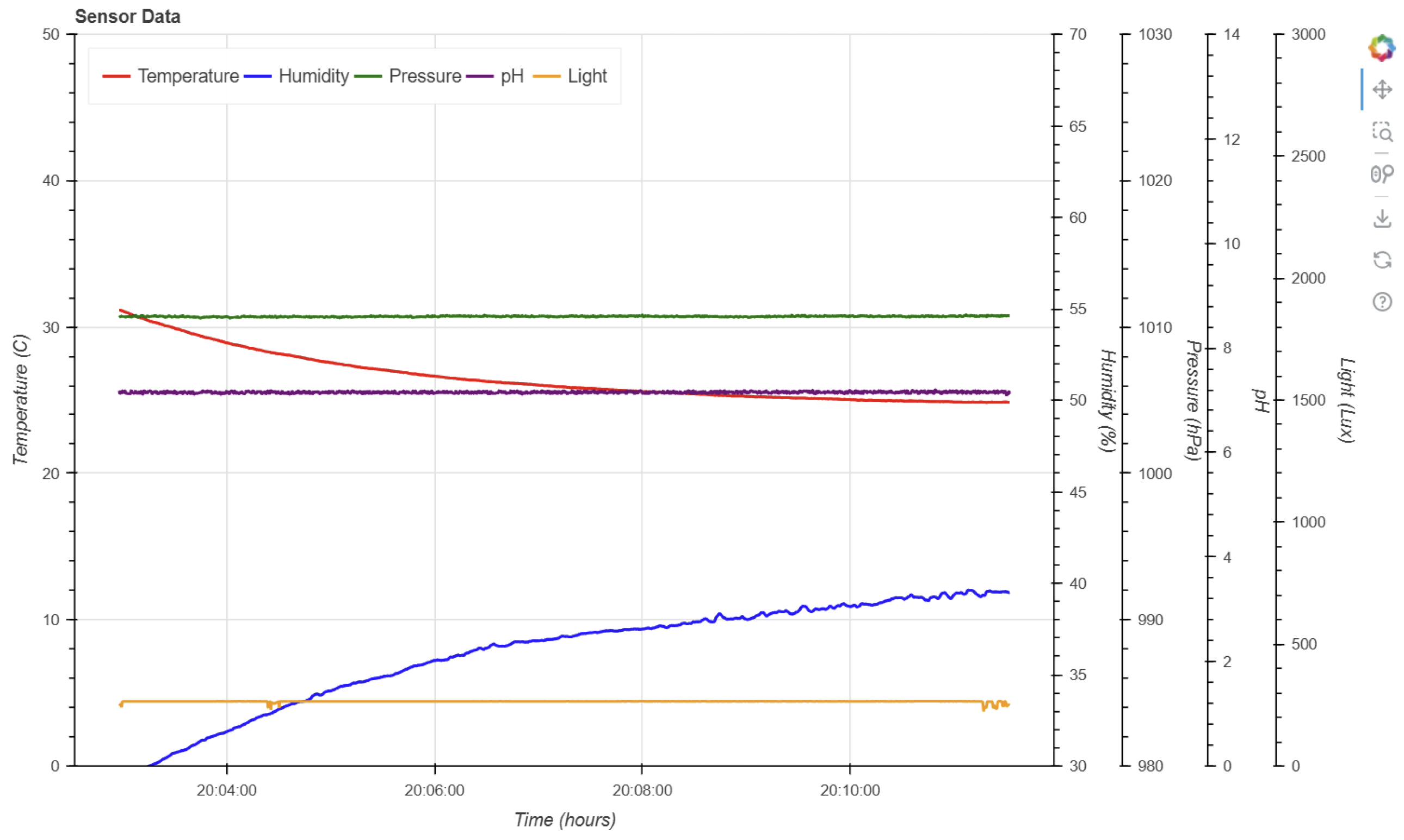

3.2. Python Real-Time Data Acquisition, Visualization, and Debugging

After the sensor data is packaged by the micro-controller, it is forwarded to a host computer for further analysis and display. In this subsection, we detail the planning behind the Python-based software stack, which leverages the

Bokeh library for real-time visualization(in

Figure 2). A dedicated Python module handles serial communication with the APP-All MCU 2023, parsing the incoming data packets and applying filtering or smoothing algorithms where needed. The processed data is then fed into interactive plots that update dynamically, providing lab administrators with immediate insight into environmental parameters such as pH, light intensity, temperature, and humidity. The real-time aspect is particularly valuable for catching anomalies or abrupt changes in experimental conditions. Additionally, the software includes a robust logging mechanism, allowing users to “grep” through historical data files to diagnose anomalies or sensor misbehavior. This modular design ensures that each component—data parsing, filtering, visualization—can be refined independently, thereby promoting maintainability and extensibility for future enhancements, such as automated alerts or cloud-based data storage.

Figure 2.

With an AVR128DA48 micro-controller and features an on-board debugger that provides a UART for serial communication with a host PC. This setup enables real-time data capture and visualization, facilitating efficient debugging and monitoring for laboratory administrators..

Figure 2.

With an AVR128DA48 micro-controller and features an on-board debugger that provides a UART for serial communication with a host PC. This setup enables real-time data capture and visualization, facilitating efficient debugging and monitoring for laboratory administrators..

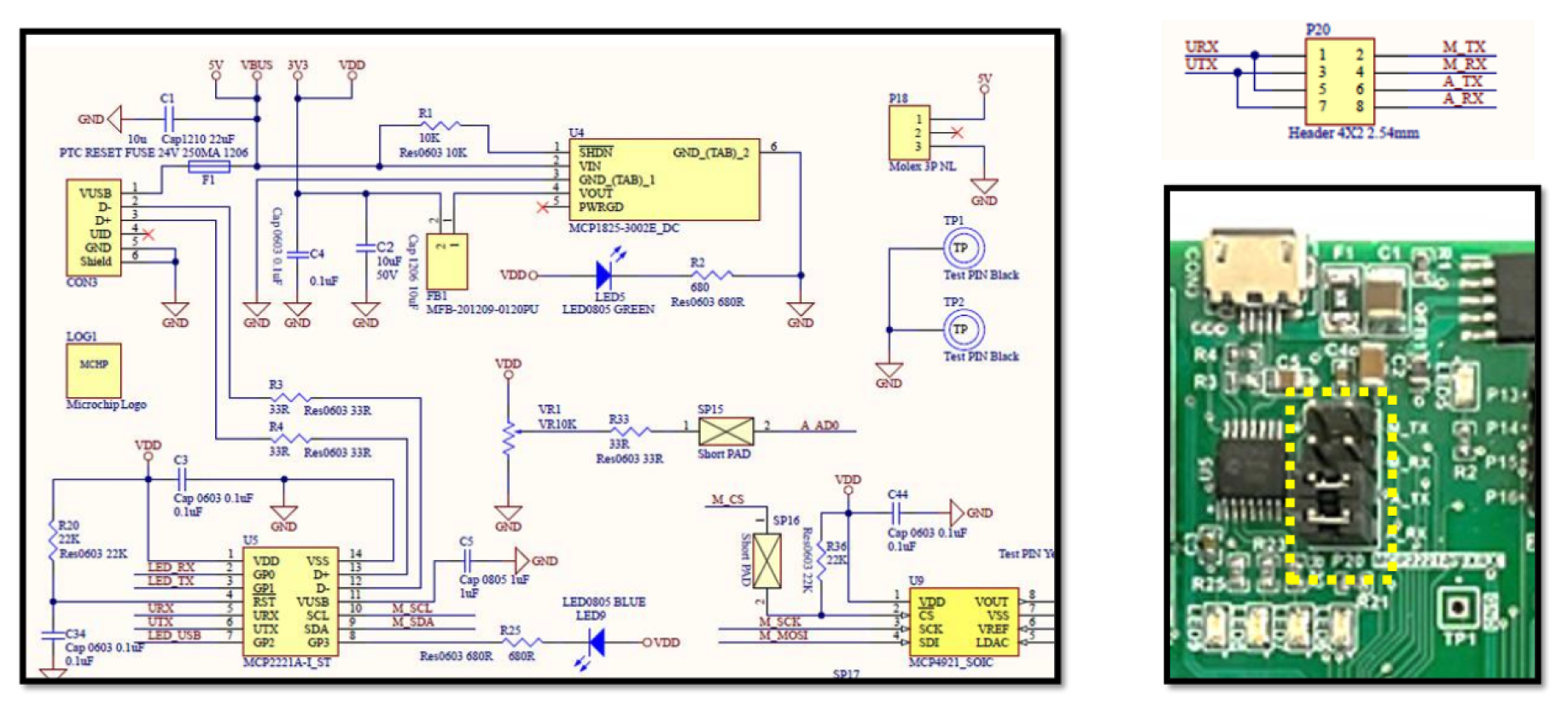

3.3. Host Interface – MCP2221A for UART and I2C Full LED Indicator

A critical component of our design is the

MCP2221A interface, which facilitates seamless communication between the micro-controller and the host computer via both UART and I2C. As shown in the schematic snippet (

Figure 4), the MCP2221A is connected to the

AVR128DA48 on the APP-All MCU 2023 board through dedicated signal lines. This interface provides:

USB-to-Serial Conversion: Enabling a straightforward bridge from the micro-controller’s UART to a USB COM port on the host PC.

I2C Pass-Through: Allowing direct I2C transactions for diagnostic or configuration tasks.

Full LED Indicator: Providing real-time feedback on data transmission, power status, and I2C activity.

In the highlighted

P20 jumper block (dashed yellow bracket in

Figure 4), users can select whether signals are routed to the

mikroBUS connector or the Arduino-style header, granting flexibility for various expansion modules. When configured for UART communication, the

AVR128DA48 bundles sensor readings into a serial data frame, which the MCP2221A then translates into USB packets recognizable by the operating system as a virtual COM port. On the host side, any standard serial terminal or Python-based script can open this COM port to read sensor data in real time. By providing a user-friendly interface layer, the MCP2221A significantly reduces the complexity of bridging between embedded hardware and PC-based data analysis, ensuring that the collected sensor data flows smoothly from the micro-controller to the host software environment.

Figure 3.

Illustrative flow chart of the overall data path. Sensor data is acquired by the AVR128DA48 micro-controller on the APP-All MCU 2023 board, passed through the MCP2221A interface for UART/I2C communication, and then visualized on the host computer via Python and the Bokeh library.

Figure 3.

Illustrative flow chart of the overall data path. Sensor data is acquired by the AVR128DA48 micro-controller on the APP-All MCU 2023 board, passed through the MCP2221A interface for UART/I2C communication, and then visualized on the host computer via Python and the Bokeh library.

Figure 4.

Partial schematic and PCB snippet illustrating the MCP2221A host interface, the P20 jumper selection (dashed yellow bracket), and the connections to the

AVR128DA48 micro-controller on the APP-All MCU 2023 board[

24].

Figure 4.

Partial schematic and PCB snippet illustrating the MCP2221A host interface, the P20 jumper selection (dashed yellow bracket), and the connections to the

AVR128DA48 micro-controller on the APP-All MCU 2023 board[

24].

In summary, the MCP2221A host interface not only offers a reliable, high-speed link between the micro-controller and the host PC, but also provides additional diagnostic capabilities through LED status indicators. This design choice simplifies troubleshooting, enabling researchers to quickly verify active data transfer or identify communication bottlenecks. By supporting both UART and I2C, the MCP2221A ensures maximum flexibility for future expansions or specialized sensor requirements, further solidifying the system’s modular and adaptable nature.

3.4. Final Device Setup and Sensor Configuration

To validate the complete workflow under real-world laboratory conditions, we assembled all hardware components into a single, integrated prototype. As shown in

Figure 5, the system centers around the

Microchip AVR128DA48 MCU on the APP-All MCU 2023 board, interfaced with multiple sensors through the shared I2C bus. Specifically, we employed a

BME280 sensor to monitor temperature, humidity, and pressure; a

VEML7700 sensor to measure ambient light intensity; and a dedicated

pH sensor module (often referred to as “PH2” on the mikroBUS interface) for real-time pH readings. The pH probe is attached via a standard BNC connector for ease of handling and maintenance. In this final setup, each sensor is mounted on its respective interface board or mikroBUS module, and their outputs are routed through the AVR128DA48 micro-controller’s I2C pins.

The device is powered via a regulated supply, with onboard conditioning circuits ensuring stable voltage levels for all sensor modules. Once collected, sensor data is passed through the MCP2221A interface, which bridges the micro-controller’s UART signals to a USB COM port on the host computer. The Python-based application then reads these values in real time, leveraging the Bokeh library for intuitive data visualization and rapid anomaly detection. This comprehensive setup—encompassing temperature, humidity, pressure, light intensity, and pH measurements—provides a versatile platform for a wide range of experiments. The modular design and standardized connectors further allow quick sensor swaps or system reconfigurations, thereby supporting ongoing research needs with minimal downtime.

4. Discussion

4.1. Hardware and Firmware Performance

The integration of Microchip Technology’s APP-All MCU 2023 development board and the AVR128DA48 micro-controller has demonstrated remarkable reliability and precision in environmental data acquisition. Utilizing the I2C protocol, the firmware efficiently initializes, calibrates, and samples from multiple sensors, including those measuring temperature, pH, light intensity, and humidity. The firmware architecture, built upon a robust, interrupt-driven data capture mechanism, ensures consistent performance and real-time responsiveness. The comprehensive implementation of error-checking algorithms, such as cyclic redundancy checks (CRC) and checksum validations, significantly enhances the integrity of data across prolonged experiments. Furthermore, calibration routines incorporated within the firmware mitigate sensor drift and manufacturing discrepancies, ensuring accuracy over extended operational periods. The system’s high fidelity is particularly valuable in laboratory scenarios where experimental conditions fluctuate dynamically. This setup successfully addresses key limitations of traditional rigid systems, highlighting the significant advantages of modular and flexible design methodologies in contemporary research environments. Overall, the hardware and firmware layers have proven to be robust, scalable, and highly effective in diverse experimental configurations.

4.2. Real-Time Data Visualization and Host Interface

The Python-based software stack leveraging the Bokeh visualization library significantly enhances the usability and operational efficiency of the ModuLab system. Real-time visualization provides researchers and laboratory administrators with immediate insights into the monitored environmental parameters, including temperature fluctuations, pH variations, light intensity changes, and humidity levels. The dynamic visualization capability is crucial for detecting anomalies and ensuring rapid intervention, thereby enhancing the reliability of experimental outcomes. The seamless integration of the MCP2221A interface bridges data flow between the micro-controller and the host computer, ensuring minimal latency and data loss. Additionally, the modular nature of the software architecture simplifies maintenance tasks, allowing isolated updates to the parsing, filtering, or visualization modules without extensive system downtime. The embedded logging mechanism further empowers users to retrospectively analyze historical data through comprehensive searching capabilities ("grepping"), crucial for diagnosing intermittent issues. These software features not only complement the hardware robustness but significantly advance the system’s practical utility, making real-time monitoring both accessible and effective for laboratory personnel.

4.3. Future Improvements and Research Opportunities

While the present ModuLab implementation exhibits robust performance, several potential enhancements remain. Optimizing the firmware to reduce data acquisition latency represents one critical area for development, potentially through integrating advanced processing algorithms or parallel computing techniques. Introducing wireless communication capabilities, such as Bluetooth or Wi-Fi integration, would significantly enhance the system’s flexibility and scalability. Additionally, further expansion of the software analytics framework, particularly through the incorporation of automated anomaly detection, predictive analytics, or AI-driven decision-making tools, would elevate the system’s diagnostic capabilities. Moreover, exploring cloud-based data management solutions could enhance collaborative research environments by facilitating easier data sharing and remote access. Extending sensor compatibility to encompass additional environmental variables or specialized analytical sensors could further broaden the applicability of the ModuLab platform. Addressing these opportunities would not only enhance overall system performance but also ensure continued relevance and adaptability to emerging research challenges and technological advancements.

4.4. Scalability and Adaptability of the System

The modular plug-and-play architecture of the ModuLab Interface System inherently supports extensive scalability and adaptability. By employing standardized connectors, communication protocols, and modular sensor configurations, the platform significantly simplifies the integration of new sensors or peripheral devices. This flexibility facilitates rapid prototyping and iterative experimentation, allowing researchers to quickly adapt setups according to evolving research requirements. The ability to seamlessly add or remove sensors without substantial system modifications underscores the long-term sustainability of the system, especially in interdisciplinary research scenarios. Furthermore, the standardized hardware and software interfaces ensure compatibility with emerging technologies, future-proofing laboratory investments. This modular approach contrasts markedly with traditional rigid instrumentation systems, providing researchers with a robust, versatile toolkit capable of adapting to diverse and evolving scientific inquiries.

4.5. System Robustness, Reliability, and Operational Efficiency

A critical aspect of laboratory instrumentation is the robustness and reliability under varying experimental conditions. ModuLab achieves these attributes through rigorous design and implementation practices. The embedded firmware’s extensive error-checking mechanisms, combined with real-time sensor diagnostics and calibration routines, ensure high data accuracy and system stability. Additionally, the dedicated power management and signal conditioning circuits contribute significantly to sustained operational reliability. By employing comprehensive data logging and debugging strategies, the system proactively identifies and mitigates potential issues, minimizing downtime and maintenance interventions. The modular hardware design further simplifies component-level troubleshooting, ensuring that individual sensors or modules can be independently tested and maintained without disrupting the entire experimental setup. Collectively, these design considerations enhance overall system efficiency, reduce operational costs, and ensure consistent performance, effectively meeting the stringent demands of modern laboratory environments.

4.6. Comparison to Traditional Instrumentation Systems

Compared to conventional, non-modular instrumentation, the ModuLab Interface System offers substantial benefits in terms of flexibility, ease of integration, and cost-effectiveness. Traditional laboratory instrumentation frequently relies on proprietary, rigid hardware solutions that restrict customization and scalability, often necessitating extensive and costly modifications when experimental parameters change. In contrast, ModuLab’s modular architecture facilitates easy and cost-efficient modifications, allowing laboratories to adapt rapidly to new research directions without substantial additional investments. The standardized communication protocols and interfaces employed by ModuLab significantly reduce complexity and compatibility issues, simplifying the integration process even for users with limited technical expertise. Furthermore, the overall operational costs, including initial setup and ongoing maintenance, are markedly reduced, making the ModuLab system particularly advantageous for resource-constrained research environments. This comparative analysis highlights the clear advantages of modular, flexible instrumentation over traditional fixed systems, emphasizing the value of adaptability in contemporary research infrastructure.

4.7. Impact on Laboratory Workflow and Research Productivity

The adoption of the ModuLab Interface System has demonstrated considerable positive impacts on laboratory workflow efficiency and overall research productivity. The streamlined setup process, facilitated by plug-and-play sensor integration and intuitive real-time monitoring capabilities, substantially reduces experiment preparation times. Researchers are able to rapidly prototype experimental setups, quickly iterate experimental conditions, and efficiently manage data acquisition processes. The availability of immediate data visualization through the Python-Bokeh interface further accelerates the experimental decision-making process, allowing for more informed, timely interventions. Consequently, laboratories employing the ModuLab system report enhanced throughput, reduced error rates, and improved resource utilization. By minimizing the technical burdens traditionally associated with instrumentation setup and maintenance, researchers can concentrate more fully on scientific inquiry, leading to higher productivity and potentially accelerating scientific discovery cycles.

5. Conclusions

5.1. Summary of Work and Contributions

This research introduced the ModuLab Interface System, an advanced modular hardware platform designed explicitly for modern laboratory instrumentation. Leveraging the capabilities of Microchip Technology’s APP-All MCU 2023 development board and its embedded AVR128DA48 micro-controller, the system achieves seamless integration and precise data acquisition from various environmental sensors, including temperature, pH, light intensity, and humidity, utilizing the robust I2C protocol. The firmware architecture, developed in C/C++, incorporates comprehensive initialization routines, meticulous calibration processes, and rigorous real-time data sampling methods to ensure data accuracy and reliability. Further enhancing its practical utility, the platform integrates a Python-based software solution using the Bokeh library for dynamic and interactive data visualization. This integrated approach, supported by the dedicated MCP2221A interface, significantly simplifies data handling and debugging tasks, thus addressing common limitations encountered with traditional, rigid instrumentation setups. The system’s modular design and standardized communication interfaces facilitate rapid adaptation and expansion to accommodate evolving research requirements, representing a meaningful advancement toward versatile, cost-effective laboratory solutions.

5.2. Implications and Benefits

The ModuLab Interface System offers numerous significant benefits to contemporary laboratory environments, markedly enhancing flexibility and operational efficiency. Its modular structure dramatically simplifies sensor replacement and system reconfiguration, enabling rapid adaptation to changing experimental conditions without extensive downtime or technical complications. The integration of the MCP2221A interface ensures robust and reliable data transfer between the micro-controller and host computer, enhancing data integrity and system responsiveness. Additionally, the real-time visualization capabilities provided by the Python-based Bokeh application offer immediate insight into environmental conditions, facilitating rapid anomaly detection and proactive intervention. Such immediate diagnostic feedback considerably reduces operational downtime and enhances laboratory workflow efficiency. Moreover, by employing readily available, cost-effective components and standardized communication protocols, the ModuLab system significantly lowers initial setup and ongoing maintenance costs, making advanced laboratory instrumentation accessible even to resource-limited research institutions. Consequently, the ModuLab Interface System not only bridges the gap between high-performance and practical usability but also sets a benchmark for future innovations in modular laboratory instrumentation.

5.3. Future Directions and Final Remarks

Although the current implementation of the ModuLab Interface System has demonstrated robust performance and substantial benefits in laboratory settings, several avenues for further optimization and improvement remain open. Future development efforts could explore reducing data acquisition latency through firmware optimization and the potential integration of additional communication protocols, such as wireless or cloud-based connectivity, to enhance flexibility and remote monitoring capabilities. Additionally, expanding the sensor suite to cover more environmental variables or specialized analytical functions could further broaden the platform’s applicability, enabling its use in more sophisticated and diverse research scenarios. Enhancing the existing Python-based analytics framework with advanced features such as automated anomaly detection, predictive analytics, and sophisticated data analysis algorithms would significantly increase the system’s utility and operational efficiency. Ultimately, continued development along these directions will not only refine system performance but also solidify its position as an essential tool for modern research laboratories, fostering innovation and enabling researchers to tackle increasingly complex scientific inquiries efficiently.

5.4. Integration with Emerging Technologies

Integrating emerging technologies such as Internet of Things (IoT), edge computing, and artificial intelligence (AI) presents significant opportunities for enhancing the ModuLab Interface System’s capabilities. By incorporating IoT connectivity, the system could provide seamless remote monitoring and control, enabling researchers to manage experiments and analyze data from anywhere, significantly enhancing accessibility and convenience. Edge computing integration could further optimize data processing and reduce latency by performing preliminary data analysis directly on the micro-controller, thus enhancing real-time responsiveness and decision-making capabilities. Additionally, integrating AI-driven algorithms could facilitate predictive maintenance, intelligent anomaly detection, and adaptive calibration routines, substantially improving system reliability and precision. Such technological advancements could transform the ModuLab Interface System into a more intelligent, adaptive, and self-sufficient instrumentation platform, empowering researchers to perform complex analyses and make informed decisions more rapidly and effectively.

5.5. Educational and Training Implications

The ModuLab Interface System holds considerable potential for educational and training applications, offering practical benefits beyond research environments. Its user-friendly, modular, and intuitive interface makes it an excellent educational tool for teaching complex instrumentation concepts, sensor integration, and data acquisition principles. Students and trainees can quickly grasp foundational concepts through hands-on experience, benefiting from immediate visual feedback provided by the real-time data visualization capabilities. Furthermore, the system’s cost-effectiveness and accessibility allow educational institutions, even those with limited resources, to adopt advanced laboratory instrumentation into their curricula. By simplifying the complexities associated with traditional laboratory setups, the ModuLab system fosters a deeper understanding of instrumentation principles among learners and promotes active learning experiences. This educational impact can enhance the skillsets of future researchers and engineers, ultimately contributing to a more competent and innovative workforce in science, technology, engineering, and mathematics (STEM) fields.