Submitted:

28 June 2025

Posted:

30 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

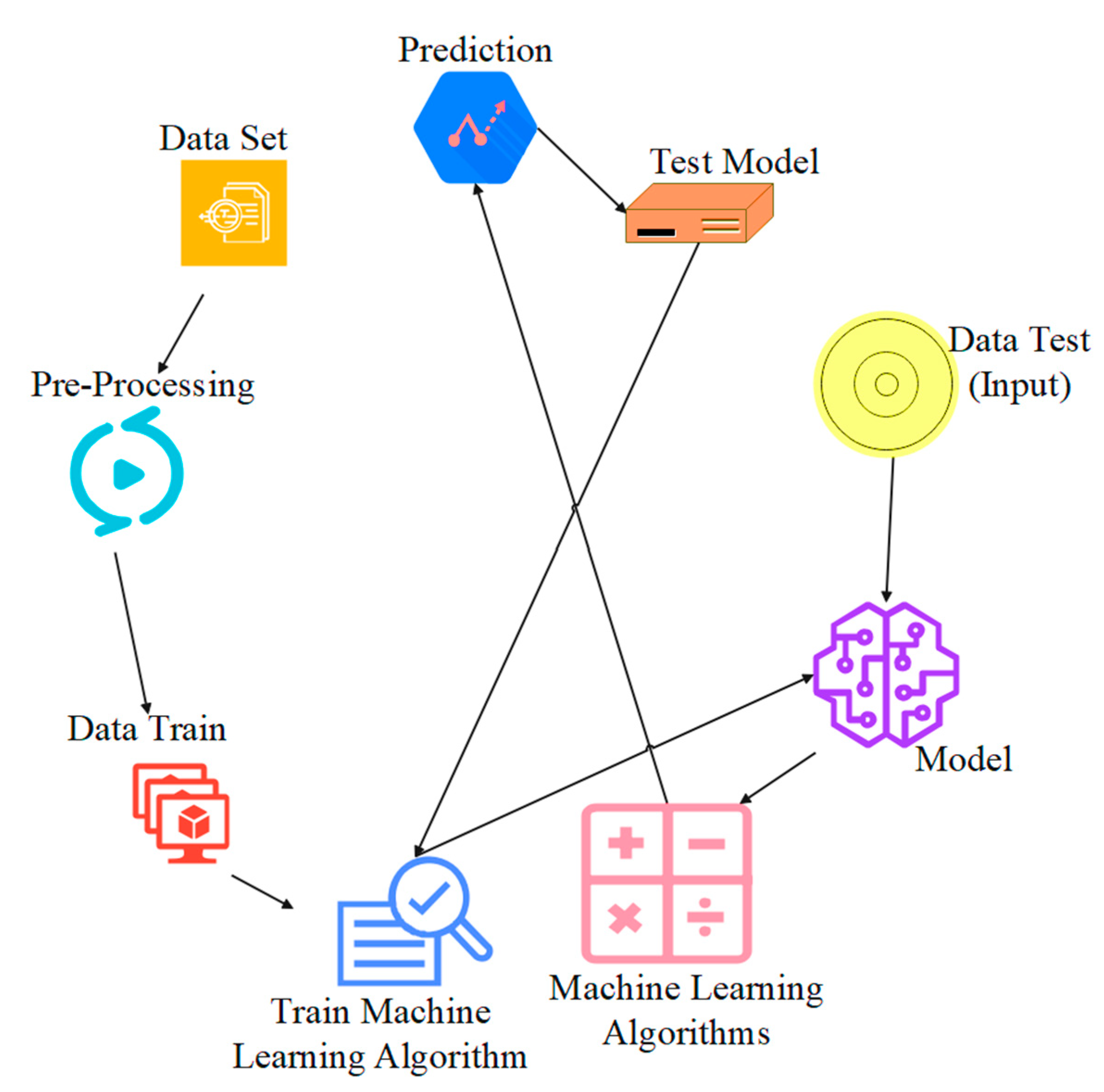

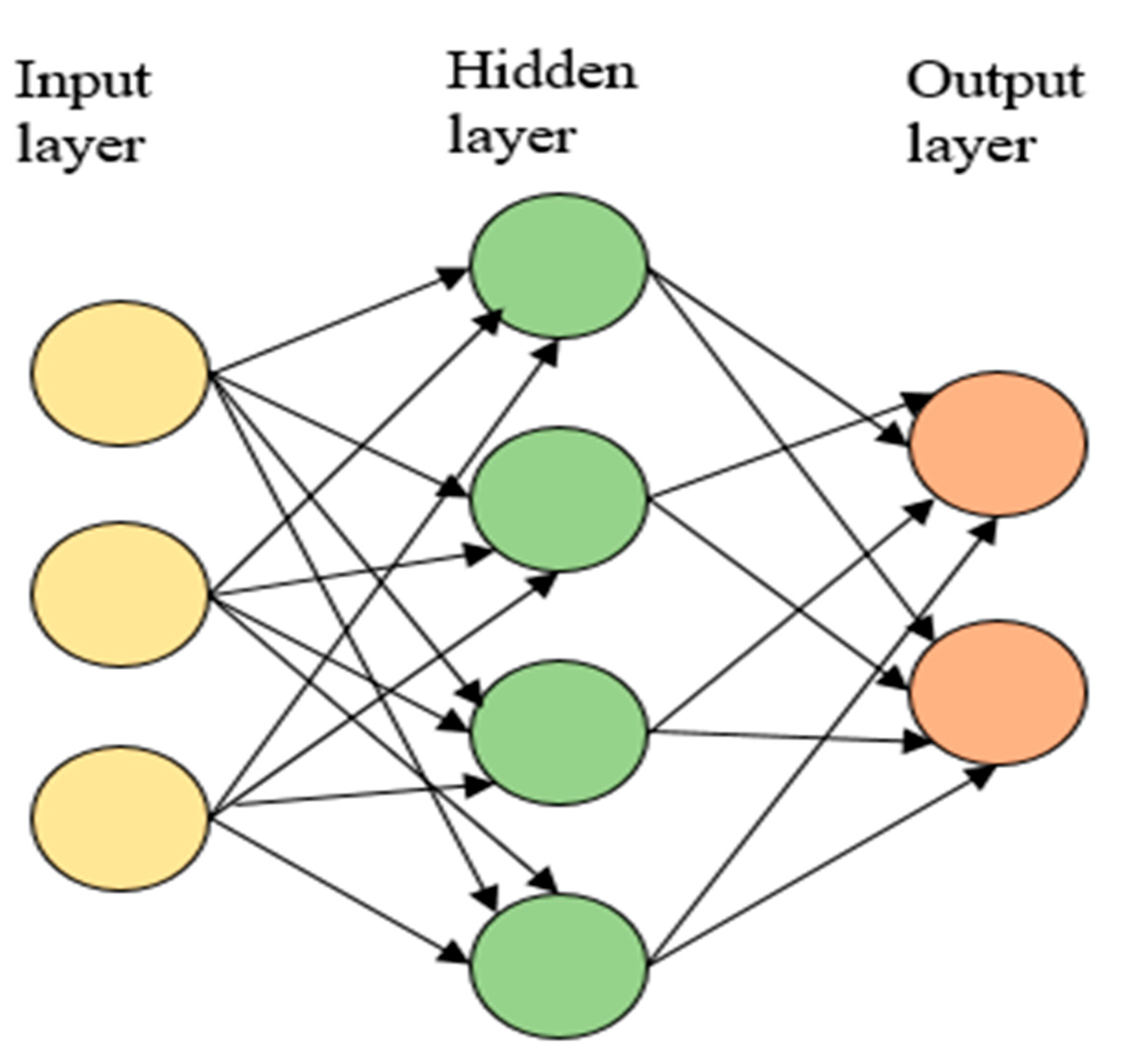

2. Machine Learning Principles in Coatings

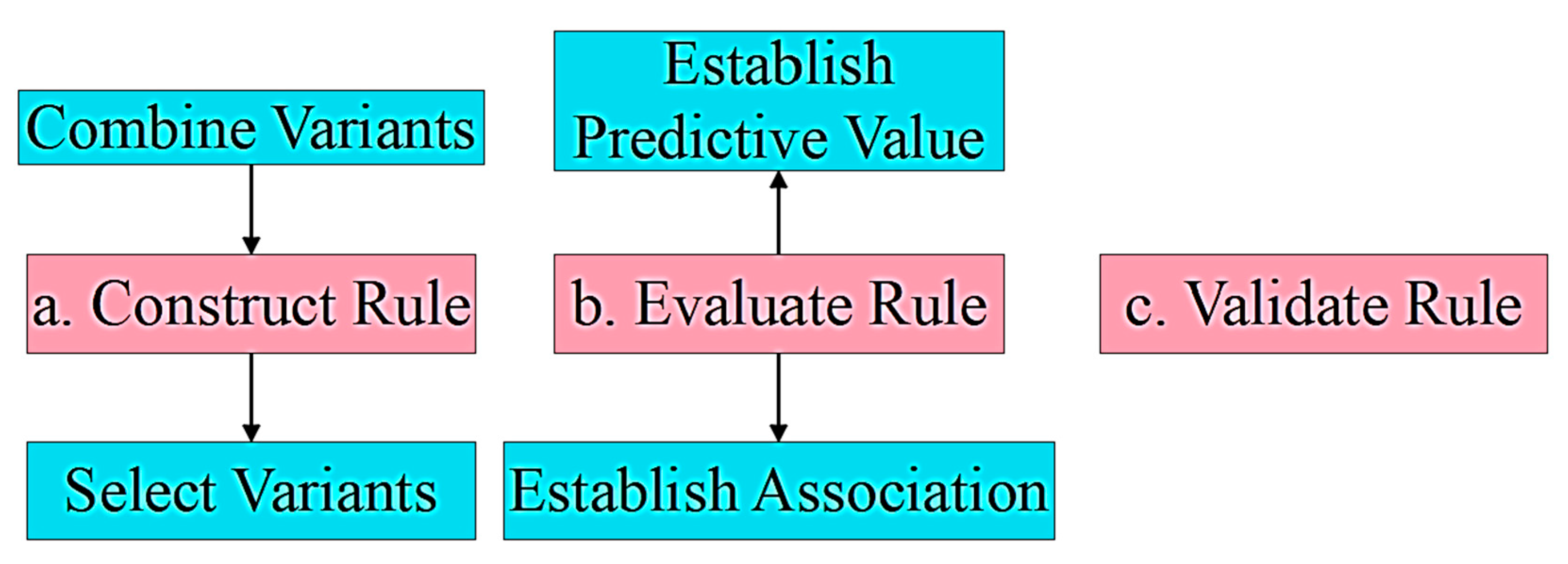

3. Predictive Design and Estimation Methods

4. Protein-Resistant Surface Coatings

5. Free Layer Damping Coatings

6. Ferroalloy and Advanced Coating Systems

7. Green and Sustainable Coating Production

8. Conclusion

References

- Bajari, P. Nekipelov, D., Ryan, S. P., & Yang, M. (2015). Machine Learning Methods for Demand Estimation. American Economic Review 2015, 105(5), 481–485. [Google Scholar] [CrossRef]

- Boriratrit, S. , Fuangfoo, P., Srithapon, C., & Chatthaworn, R. (2023). Adaptive meta-learning extreme learning machine with golden eagle optimization and logistic map for forecasting the incomplete data of solar irradiance. Energy and AI 2023, 13, 100243. [Google Scholar] [CrossRef]

- Bowen, D. Ungar, L. (2020). Generalized SHAP: Generating multiple types of explanations in machine learning. Arxiv 2020. [Google Scholar]

- Brunton, S. L. (2021). Applying machine learning to study fluid mechanics. In Acta Mechanica Sinica/Lixue Xuebao (Vol. 37, Issue 12, pp. 1718–1726). Springer Verlag. [CrossRef]

- Candanedo, I. S., Nieves, E. H., González, S. R., Martín, M. T. S., & Briones, A. G. (2018). Machine Learning Predictive Model for Industry 4.0 (pp. 501–510). [CrossRef]

- Deepanshu, Garg, K., Mittal, H., Yadav, V., & Kushwaha, O. S. (2025). Solar Panel Degradation Prediction using Machine Learning: A Comprehensive Approach. [CrossRef]

- Garg, K. , Mittal, H., Yadav, V., Sehrawat, A., Shah, V., & Kushwaha, O. (2025). Municipal Solid Waste (MSW) Management Prediction Through Machine Learning Models: An Ensemble Tree Regressor Analysis. [CrossRef]

- Hossain, E., & Fredj, F. (2021). Editorial Energy Efficiency of Machine-Learning-Based Designs for Future Wireless Systems and Networks. IEEE Transactions on Green Communications and Networking, 5(3), 1005–1010. [CrossRef]

- Jonayat, A. S. M., van Duin, A. C. T., & Janik, M. J. (2018). Discovery of Descriptors for Stable Monolayer Oxide Coatings through Machine Learning. ACS Applied Energy Materials 2018, 1, 6217–6226. [CrossRef]

- Kruppa, J. , Ziegler, A., & König, I. R. (2012). Risk estimation and risk prediction using machine-learning methods. Human Genetics 2012, 131, 1639–1654. [Google Scholar] [CrossRef] [PubMed]

- Liu, H. , Chan, V. K. H., Tantikhajorngosol, P., Li, T., Dong, S., Chan, C., & Tontiwachwuthikul, P. (2022). Novel Machine Learning Model Correlating CO2Equilibrium Solubility in Three Tertiary Amines. Industrial and Engineering Chemistry Research 2022, 61, 14020–14032. [Google Scholar] [CrossRef]

- Magadum, T. , Garg, K., Murgod, S., Yadav, V., Mittal, H., & Kushwaha, O. (2025). Geospatial Analysis in Machine Learning for CO2 Emissions Prediction Analysis in 2100: A Continent-Wise Analysis. [CrossRef]

- Magadum, T. , Murgod, S., Garg, K., Yadav, V., Mittal, H. N., & Kushwaha, O. (2025). Africa Renewable Energy Development to 2050: Forecast Analysis through a Machine Learning Perspective. [CrossRef]

- Magadum, T. , Murgod, S., Mittal, H., Anshu, D., & Kushwaha, O. (2025). <span style="mso-fareast-language: EN-IN;">Global Wind Energy Generation Trends and Projections: A Comprehensive Analysis to 2050. [CrossRef]

- Mittal, H. , & Kushwaha, O. S. (2024). Machine Learning in Commercialized Coatings. In Functional Coatings (pp. 450–474). Wiley. [CrossRef]

- Murgod, S. , Garg, K., Magadum, T., Yadav, V., Mittal, H., & Kushwaha, O. (2025). AI Powered Renewable Energy Balancing, Forecasting and Global Trend Analysis using ANN-LSTM Integration. [CrossRef]

- Ramsundar, B. (2018). Molecular machine learning with DeepChem. Doctoral Dissertation Stanford University.

- Rodriguez-Galiano, V. , Sanchez-Castillo, M., Chica-Olmo, M., & Chica-Rivas, M. (2015). Machine learning predictive models for mineral prospectivity: An evaluation of neural networks, random forest, regression trees and support vector machines. Ore Geology Reviews 2015, 71, 804–818. [Google Scholar] [CrossRef]

- Rout, D. , Shyamsukha, N., Mittal, H., & Kushwaha, O. S. (2025). Solar energy generation and power prediction through computer vision and machine intelligence. In Computer Vision and Machine Intelligence for Renewable Energy Systems (pp. 103–123). Elsevier. [CrossRef]

- Saraswat, V. , Magadum, T., Mittal, H., & Kushwaha, O. (2025). AI-Driven Modeling of Microbial Carbon Capture Systems for ESG-Linked Carbon Accounting and Disclosures. [CrossRef]

- Schmitz, M. , Kim, J.-Y., & Jacobs, L. J. (2023). Machine and deep learning for coating thickness prediction using Lamb waves. Wave Motion 2023, 120, 103137. [Google Scholar] [CrossRef]

- Sehrawat, A. , Bhatnagar, R. M., Magadum, T., Mittal, H., & Kushwaha, O. (2025). Comparative Analysis of Bio-Based and Traditional Plastics: Life Cycle Assessment, Cost-Benefit Analysis, and Health Impact Evaluation. [CrossRef]

- Tehrani, A. M. , Oliynyk, A. O., Parry, M., Rizvi, Z., Couper, S., Lin, F., Miyagi, L., Sparks, T. D., & Brgoch, J. (2018). Machine Learning Directed Search for Ultraincompressible, Superhard Materials. Journal of the American Chemical Society 2018, 140, 9844–9853. [Google Scholar] [CrossRef]

- Thomare, C. , Magadum, T., & Mittal, H. (2025). Conversion of Cow Dung to Electricity: Process Analysis and Energy Yield Assessment. [CrossRef]

- Thomare, C. , Nagappagol, A., Magadum, T., Mittal, H., & Kushwaha, O. (2025). Simulation and Parametric Analysis of Microbial Fuel Cells Using MATLAB-Based Mathematical Modelling. [CrossRef]

- Varoquaux, G. , Varoquaux, G., Buitinck, L., Buitinck, L., Buitinck, L., Louppe, G., Louppe, G., Grisel, O., Grisel, O., Pedregosa, F., Pedregosa, F., Mueller, A., & Mueller, A. (2015). Scikit-learn: Machine Learning Without Learning the Machinery. [CrossRef]

- Yadav, V. , Deepanshu, Mittal, H., Shah, V., & Kushwaha, O. S. (2025). Fuel Cell Degradation Prediction Using Machine Learning Models: A Study on Proton Exchange Membrane (PEM) Fuel Cell Dataset. [CrossRef]

- Yadav, V. , S, K., Sehrawat, A., Magadum, T., Mittal, H., Shah, V., & Kushwaha, O. (2025). Sustainable Development and Advanced Technologies: Properties, Perspectives, and Applications of Synthetic Aerogels. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).