Submitted:

06 June 2025

Posted:

10 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Review of Literature

2.1. Climate Change and Operational Sustainability

2.2. Principles and Limitation of Lean

2.3. Green Operations: Scope and Strategy

2.4. Toward Green Lean: Converging Paradigms

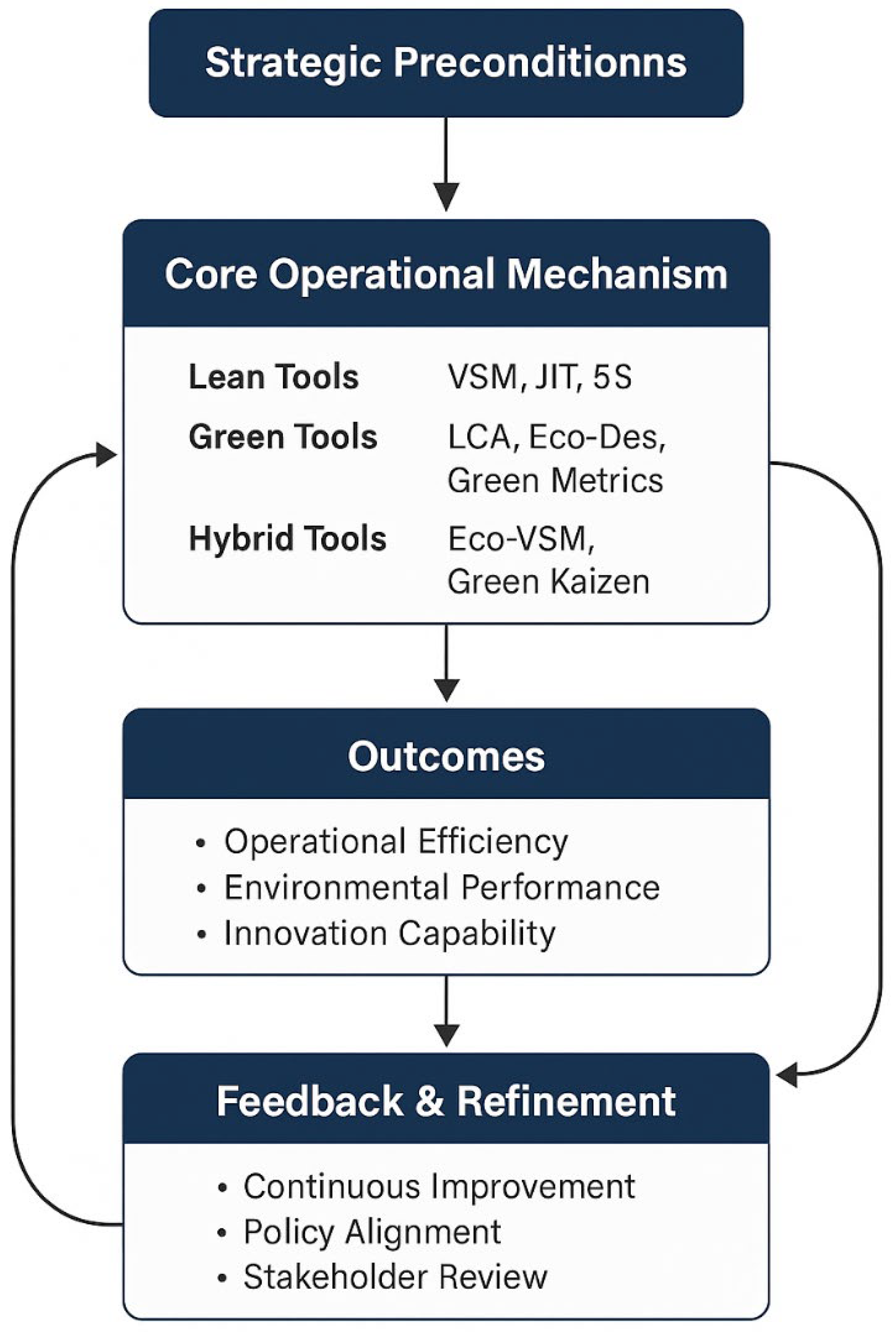

3. Conceptual Framework and Theorical Proposition

3.1. Strategic Preconditions

3.2. Core Operational Mechanism

- ■

- Eco-value stream mapping (Eco-VSM): Enhances traditional value stream mapping by incorporating energy flows, emissions data, and resource consumption metrics alongside time and cost [72].

- ■

- Green Kaizen initiatives: Empower employees to engage in continuous environmental improvement, fostering innovation in areas such as renewable resource utilization and circular production loops.

- ■

- Process redesign for sustainability: Involves reengineering production layouts, logistics flows, and packaging systems to reduce lifecycle emissions and align with circular economy principles.

- ■

3.3. Propositions

4. Discussion and Theorical Implications

4.1. Redefining Operational Excellence: From Cost-Efficiency to Sustainability Integration

4.2. Extending Lean Theory Toward Strategic Sustainability

4.3. Bridging Sustainability Science and Operation Management

4.4. Embedding Organizational Resilience in Operation Strategy

4.5. Implications for Theory-Building and Research Development

- ■

- How do trade-offs between cost-efficiency and sustainability evolve over time in different operational contexts?

- ■

- What organizational mechanisms mediate or moderate the effectiveness of green lean strategies across industries and cultures?

- ■

- Can green lean systems be extended to address social sustainability goals—such as worker well-being, inclusive innovation, and community resilience?

- ■

- Under what conditions do feedback loops enable genuine strategic adaptation rather than superficial compliance?

- ■

- How might digital technologies and AI tools interact with or disrupt the balance between lean discipline and environmental responsiveness?

4.6. Practical Relevance and Academic Significance

5. Managerial Implications

5.1. Implementation Requires ystemic Integration, Not Add-On Programs

5.2. Leadership Must Drive Strategic Alignment Cultural Adaptation

5.3. Rethinking Success Metrics and Operational Priorities

5.4. Transitioning from Control to Resilience in Operation Strategy

5.5. Summary for Practice

- ■

- Shift from siloed execution to integrated systems design: Sustainability cannot remain the remit of CSR or compliance departments. It must be embedded across operational processes, decision hierarchies, and performance architectures.

- ■

- Mobilize top leadership for strategic alignment: Cultural inertia is a key barrier. Without visible commitment from senior leaders—including the allocation of resources, redefinition of success, and narrative transformation—green lean initiatives will lack the traction needed to scale.

- ■

- Redefine success through multi-dimensional metrics: Traditional KPIs fail to capture system health. Managers must adopt indicators that account not only for throughput and cost, but also for carbon intensity, material circularity, employee well-being, and long-term adaptability.

- ■

- Transition from control to designed resilience: Rather than striving for operational perfection under ideal conditions, firms must be structured to bend without breaking—through redundancy, flexibility, modularity, and scenario-based planning.

- ■

- Foster adaptive learning and institutional reflexivity: GLOE demands a culture where routines are not sacred but provisional—constantly challenged and re-aligned based on sustainability feedback, stakeholder expectations, and contextual evolution.

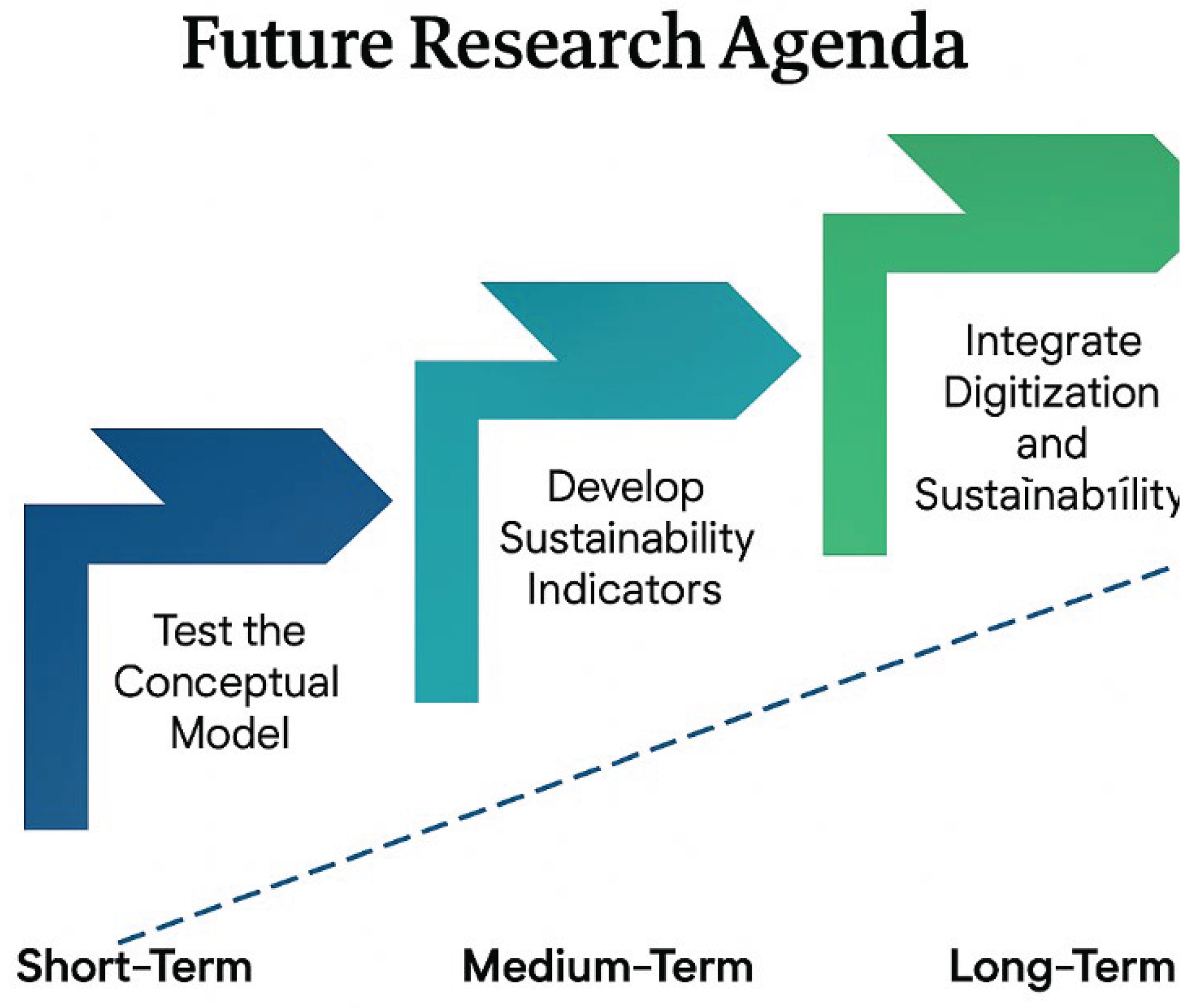

6. Future Research Agenda

6.1. Short-Term: Empirical Testing of the Conceptual Model

- ■

- Quantitative approaches such as structural equation modeling (SEM), partial least squares (PLS), or confirmatory factor analysis (CFA) can be deployed to assess the model’s internal logic, mediating structures, and predictive potential. These methods are particularly suited to validating the propositions outlined in Section 3.3, allowing researchers to evaluate the relationships between sustainability orientation, operational innovation, and performance outcomes.

- ■

- Qualitative methods such as embedded case studies, ethnographic fieldwork, or process-tracing can uncover implementation dynamics within organizations actively pursuing green lean strategies. These methods are vital for capturing the tacit logic, institutional constraints, and managerial interpretations that shape real-world adoption—elements that are often flattened in purely statistical models.

- ■

- Manufacturing (e.g., automotive, electronics), where operational efficiency is mature but environmental mandates are intensifying;

- ■

- Logistics and distribution, where green transport and low-carbon logistics are emerging performance differentiators;

- ■

- Energy utilities and infrastructure, where resilience, carbon reduction, and stakeholder legitimacy are deeply intertwined with operational models.

6.1. Medium-Term: Indicator Development and Contextual Adaptation

- ■

- Industry-specific sensitivity: Each sector faces unique environmental pressures and operational structures. In logistics, indicators might focus on carbon intensity per transport unit; in packaging and consumer goods, material circularity ratios may be more salient; in energy utilities, a resilience index combining grid flexibility, renewable integration, and climate adaptation may be most relevant.

- ■

- Strategic alignment with global frameworks: Indicators should not only serve operational goals but also reflect alignment with the UN Sustainable Development Goals (SDGs), particularly SDG 9 (Industry, Innovation, Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). This alignment supports reporting legitimacy and stakeholder engagement.

- ■

- Cultural and institutional adaptability: Successful adoption of GLOE metrics depends on their fit with the regulatory landscapes, stakeholder expectations, and institutional maturity of different regions. Metrics that work well in highly regulated, data-rich environments may require adaptation in emerging markets where infrastructure or reporting standards vary.

- ■

- A validated set of multi-dimensional indicators capable of capturing the operational essence of GLOE;

- ■

- A typology of GLOE configurations, outlining how firms adapt and prioritize different components of the framework based on sectoral, institutional, and strategic contexts;

- ■

- And potentially, the foundations for diagnostic tools or sustainability maturity models that organizations can use to self-assess their progress along the GLOE continuum.

6.3. Long-Term: Integration With Digitalization and Broader Systems Innovation

- ■

- Automating green performance monitoring through IoT-enabled sensors, which allow real-time measurement of energy use, emissions, water intensity, and material flows across the value stream;

- ■

- Enhancing adaptive capacity via AI-driven predictive analytics, enabling scenario modeling for supply chain disruptions, climate-related risks, and stakeholder shifts;

- ■

- Operationalizing reflexivity through dynamic dashboards and closed-loop feedback systems that translate sustainability metrics into real-time operational adjustments—thus making continuous improvement ecologically intelligent.

- ■

- How does GLOE shape sustainability governance across supply networks? Can the model foster synchronized green lean practices among suppliers, partners, and logistics providers?

- ■

- What is the potential for sectoral or industry-wide transformation, especially in industries with high environmental intensity such as energy, construction, and heavy manufacturing?

- ■

- Can GLOE principles inform policy frameworks, standard-setting bodies, and transnational sustainability benchmarks?

6.4. Closing Remarks and Research Potential

- ■

- Bridges theory and practice by translating abstract sustainability principles into actionable operational systems;

- ■

- Spans multiple industries and geographies, allowing comparative insights across varied regulatory, institutional, and cultural contexts;

- ■

- Adapts to evolving technological and environmental conditions, enabling integration with digital transformation, climate imperatives, and stakeholder-driven sustainability governance.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Description |

| GLOE | Green Lean Operational Excellence |

| SDG | Sustainable Development Goals |

| KPI | Key Performance Indicator |

| VSM | Value Stream Mapping |

| Eco-VSM | Ecological Value Stream Mapping |

| SEM | Structural Equation Modeling |

| PLS | Partial Least Squares |

| CFA | Confirmatory Factor Analysis |

| CSR | Corporate Social Responsibility |

| TBL | Triple Bottom Line |

| ESG | Environmental, Social, and Governance |

| AI | Artificial Intelligence |

| SCM | Supply Chain Management |

References

- G. M. Silva, A. S. Patrucco, and P. J. Gomes, “Advancing green supply chains through downstream digitalization: An information processing theory perspective,” Journal of Purchasing and Supply Management, 2025. [CrossRef]

- A. Ahenkan, E. Nordjo, E. Boon, and S. Akalibey, “Corporate Environmentalism and Business Sustainability in Ghana: Prospects and Challenges,” Business Strategy and Development, vol. 8, no. 1, 2025. [CrossRef]

- M. Dieste, R. Panizzolo, and J. A. Garza-Reyes, “Evaluating the impact of lean practices on environmental performance: evidences from five manufacturing companies,” Production Planning and Control, vol. 31, no. 9, pp. 739–756, 2020. [CrossRef]

- L. Gutierrez, G. Anand, B. A. Lameijer, J. Antony, and V. Sunder M, “Beyond efficiency: the role of lean practices and cultures in developing dynamic capabilities microfoundations,” International Journal of Operations and Production Management, vol. 42, no. 13, pp. 506–536, 2022. [CrossRef]

- C. Moreno-Silva, L. Pagliero, and N. McIntyre, “Environmental and social impacts from desalinated water supply projects,” Environ Impact Assess Rev, vol. 115, 2025. [CrossRef]

- L. Mazzoni and S. R. Sedita, “Unpacking the drivers of the socio-environmental sustainability of new ventures: insights from innovative digital start-ups in Italy,” International Entrepreneurship and Management Journal, vol. 21, no. 1, 2025. [CrossRef]

- J. Shurrab, M. Hussain, and M. Khan, “Green and sustainable practices in the construction industry: A confirmatory factor analysis approach,” Engineering Construction and Architectural Management, vol. 26, no. 6, pp. 1063–1086, 2019. [CrossRef]

- A. A. Mamun, N. Hayat, N. R. B. Zainol, and C. A. N. Malarvizhi, “Economic and environmental sustainability through green composting: A study among low-income households,” Sustainability Switzerland, vol. 12, no. 16, 2020. [CrossRef]

- J. A. Garza-Reyes, “Green lean and the need for Six Sigma,” International Journal of Lean Six Sigma, vol. 6, no. 3, pp. 226–248, 2015. [CrossRef]

- L. M. S. Campos and D. A. Vazquez-Brust, “Lean and green synergies in supply chain management,” Supply Chain Management, vol. 21, no. 5, pp. 627–641, 2016. [CrossRef]

- M. Kanan et al., “An Empirical Study of the Implementation of an Integrated Ergo-Green-Lean Framework: A Case Study,” Sustainability Switzerland, vol. 15, no. 13, 2023. [CrossRef]

- M. S. Kaswan, R. Rathi, J. Cross, J. A. Garza-Reyes, J. Antony, and V. Yadav, “Integrating Green Lean Six Sigma and industry 4.0: a conceptual framework,” Journal of Manufacturing Technology Management, vol. 34, no. 1, pp. 87–121, 2023. [CrossRef]

- Anshima, D. Sharma, and B. Bhardwaj, “Green human resource management practices and sustainable development in India: A systematic literature review and future research agenda,” Social Sciences and Humanities Open, vol. 11, 2025. [CrossRef]

- S. Taneja, A. Siraj, Y. Zhu, L. Ali, A. Kumar, and S. Luthra, “Is FinTech Implementation a Strategic Step for Sustainability in Today’s Changing Landscape? An Empirical Investigation,” IEEE Trans Eng Manag, vol. 71, pp. 7553–7565, 2024. [CrossRef]

- K. G. Steinhäuser, A. Von Gleich, M. Große Ophoff, and W. Körner, “The Necessity of a Global Binding Framework for Sustainable Management of Chemicals and Materials—Interactions with Climate and Biodiversity,” Sustainable Chemistry, vol. 3, no. 2, pp. 205–237, 2022. [CrossRef]

- Z. T. Beyene, M. E. Jaleta, S. P. Nadeem, and A. Kreie, “Research Trends in Dry Port Sustainability: A Bibliometric Analysis,” Sustainability Switzerland, vol. 16, no. 1, 2024. [CrossRef]

- K. A. Akkemik, J. T. Borges, and P. T. Dang, “Assessing carbon tax using a CGE model with firm heterogeneity: An application to Vietnam,” J Environ Manage, vol. 365, 2024. [CrossRef]

- N. Çömez-Dolgan, B. Tanyeri-Günsür, F. Mai, X. Zhao, and S. Devaraj, “Lean operations and firm resilience - contrasting effects of COVID-19 and economic recession,” Omega United Kingdom, vol. 135, 2025. [CrossRef]

- J. D. Gandhi and S. Thanki, “Sustainability index development by integrating lean green and Six Sigma tools: a case study of the Indian manufacturing industry,” International Journal of Productivity and Performance Management, vol. 74, no. 3, pp. 793–818, 2025. [CrossRef]

- H. Feleafel, M. Leseure, and J. Radulovic, “Shifting Towards Greener and More Collaborative Microgrids by Applying Lean-Heijunka Strategy,” Eng, vol. 6, no. 4, 2025. [CrossRef]

- J. R. Díaz-Reza, J. L. García-Alcaraz, C. Sánchez-Ramírez, and A. R. Vargas, “Assessing the impact of Lean manufacturing on the Social Sustainability through Structural Equation Modeling and System Dynamics,” Jordan Journal of Mechanical and Industrial Engineering, vol. 18, no. 1, pp. 113–130, 2024. [CrossRef]

- G. Tortorella et al., “Soft lean practices and organizational resilience in the service sector,” Management Decision, vol. 62, no. 4, pp. 1424–1452, 2024. [CrossRef]

- M. M. C. Fritz, “A supply chain view of sustainability management,” Cleaner Production Letters, vol. 3, 2022. [CrossRef]

- Y. Liu, P. Hasdell, Y. Pan, C. Gao, B. Wang, and I. Y. Jian, “Connection, deviation, patterns, and trends: Visualizing the interplay of sustainability science and social–ecological system research,” J Clean Prod, vol. 504, 2025. [CrossRef]

- C. A. Craig and I. Karabas, “Sustainability science in management education: Cognitive and affective sustainability learning in an MBA course,” International Journal of Management Education, vol. 23, no. 2, 2025. [CrossRef]

- N. Sundararajan and R. Terkar, “Improving productivity in fastener manufacturing through the application of Lean-Kaizen principles,” in Materials Today Proceedings, 2022, pp. 1169–1178. [CrossRef]

- A. Mofolasayo, S. Young, P. Martinez, and R. Ahmad, “How to adapt lean practices in SMEs to support Industry 4.0 in manufacturing,” in Procedia Computer Science, 2022, pp. 934–943. [CrossRef]

- N. T. Nguyen, T. T. B. C. Vo, C.-N. Wang, and P. H. Le, “Improvıng Inventory Tıme in Productıon Lıne through Value Stream Mappıng: A Case Study,” Journal of Engineering Science and Technology Review, vol. 16, no. 1, pp. 33–43, 2023. [CrossRef]

- P. Trebuna, M. Pekarcikova, M. Kliment, J. Kopec, and T. Svantner, “ONLINE E-KANBAN SYSTEM IMPLEMENTATION IN A MANUFACTURING COMPANY,” International Journal of Simulation Modelling, vol. 22, no. 1, pp. 5–16, 2023. [CrossRef]

- A. Zaytsev, N. Dmitriev, and D. Bunkovsky, “ASSESSING THE ECONOMIC EFFICIENCY OF LEAN TECHNOLOGIES IMPLEMENTATION IN AN INDUSTRIAL ENTERPRISE,” Academy of Strategic Management Journal, vol. 19, no. 5, pp. 1–14, 2020.

- K. Piętka and P. Bogacz, “Lean Green ‒ Integration of Lean Manufacturing and Sustainable Development in the Light of the Pursuit of Economically and Environmentally Efficient Operations | Lean Green – integracja Lean Manufacturing i zrównoważonego rozwoju w świetle dążenia do prow,” Inzynieria Mineralna, vol. 53, no. 2, pp. 211–218, 2024. [CrossRef]

- S. Choudhary, R. Nayak, M. Dora, N. Mishra, and A. Ghadge, “An integrated lean and green approach for improving sustainability performance: a case study of a packaging manufacturing SME in the U.K.,” Production Planning and Control, vol. 30, no. 5–6, pp. 353–368, 2019. [CrossRef]

- S. A. Salah and A. Mustafa, “Integration of energy saving with lean production in a food processing company,” Journal of Machine Engineering, vol. 21, no. 4, pp. 118–133, 2021. [CrossRef]

- A. Bilancia, F. Costa, and A. P. Staudacher, Sustainable Lean Practices in the Luxury Fashion Industry: A Case Study, vol. 730 IFIP. 2024. [CrossRef]

- Ö. F. Yılmaz, F. B. Yeni, B. Gürsoy Yılmaz, and G. Özçelik, “An optimization-based methodology equipped with lean tools to strengthen medical supply chain resilience during a pandemic: A case study from Turkey,” Transp Res E Logist Transp Rev, vol. 173, 2023. [CrossRef]

- N. Alemsan, G. Tortorella, F. Hui, A. Portioli Staudacher, J. Antony, and A. Trianni, “Integrating lean and resilience: a healthcare supply chain perspective,” International Journal of Industrial Engineering and Operations Management, 2025. [CrossRef]

- V. E. Forbes, “The need for standardization in ecological modeling for decision support: Lessons from ecological risk assessment,” Ecol Modell, vol. 492, 2024. [CrossRef]

- H.-A. Grypma, B. Sparrow, and D. K. Bardsley, “The Critical Social Processes for Standardising the Ecological Monitoring of Australian Landscapes,” Environ Manage, vol. 74, no. 6, pp. 1145–1159, 2024. [CrossRef]

- M. Elrayah and A. Zakariya, “INFLUENCE OF WORKPLACE GREEN PRACTICES ON ENVIRONMENTAL SUSTAINABLE PRODUCT SERVICE SYSTEM: MEDIATING ROLE OF GREEN INNOVATIONS,” Journal of Modern Project Management, vol. 12, no. 1, pp. 52–67, 2024.

- Y. A. Alarabiat, H. M. Alayed, and F. T. Awamleh, “Green Innovation Strategies in Achieving Corporate Sustainable Performance Through Big Data Analytics,” International Journal of Sustainable Development and Planning, vol. 20, no. 2, pp. 751–759, 2025. [CrossRef]

- N. Khanna et al., “Comparison of dry and liquid carbon dioxide cutting conditions based on machining performance and life cycle assessment for end milling GFRP,” International Journal of Advanced Manufacturing Technology, vol. 122, no. 2, pp. 821–833, 2022. [CrossRef]

- A. Kluczek and B. Gladysz, Energy LCA-Oriented Sustainability Analysis Assessment Approach for Visualization of Energy-Efficient Manufacturing. 2020. [CrossRef]

- S. Mehedi, S. Nahar, and D. Jalaludin, “Determinants of corporate climate change disclosure: Is the mediating role of corporate strategic response to environmental governance and policy matter? Evidence from emerging market,” Sustainable Development, vol. 32, no. 1, pp. 195–210, 2024. [CrossRef]

- L. N. Van Wassenhove, “Sustainable Innovation: Pushing the Boundaries of Traditional Operations Management,” Prod Oper Manag, vol. 28, no. 12, pp. 2930–2945, 2019. [CrossRef]

- H. Liao, L. Su, T. Tang, and Z. Shang, “Green initiatives and stakeholder engagement: Unveiling the impact of green strategies and CSR on financial performance from descriptive-normative perspectives of stakeholder theory,” Sustainable Development, vol. 32, no. 5, pp. 4800–4811, 2024. [CrossRef]

- A. Sulich and L. M. Sołoducho-Pelc, “Sustainable development in production companies: integrating environmental strategy and green management style,” Discover Sustainability, vol. 6, no. 1, 2025. [CrossRef]

- Q. Mao, M. Zhao, and Q. Sun, “How supply chain enterprises achieve coordination between green transition and profitability under the carbon trading framework,” J Environ Manage, vol. 377, 2025. [CrossRef]

- J. Wang, Y. Deng, Z. Liu, H. Peng, and X. Yang, “Optimal strategy for enterprises’ green technology innovation considering individual disappointment avoidance and altruistic reference based on differential game theory,” Clean Technol Environ Policy, vol. 27, no. 3, pp. 1311–1332, 2025. [CrossRef]

- J. Sahni, P. Darda, and S. S. Gaur, “Integration of principles for responsible management education principles (PRME) in Saudi Arabian universities: a thematic analysis of claims on university websites,” Society and Business Review, 2025. [CrossRef]

- K.-C. Ho, C. Yan, Z. Mao, and F. An, “Corporate sustainability policies and corporate investment efficiency: Evidence from the quasi-natural experiment in China,” Energy Econ, vol. 127, 2023. [CrossRef]

- S. Ali Saeed Alameri, S. J. M. AL-Barazanchi, N. K. I. Al-Obaidi, and R. Salman, “ADVANCEMENTS IN CORPORATE SUSTAINABILITY PRACTICES: A SYSTEMATIC REVIEW OF STRATEGIES ALIGNED WITH SUSTAINABLE DEVELOPMENT GOALS,” Journal of Modern Project Management, vol. 12, no. 2, pp. 68–81, 2024.

- Y. Kazancoglu, E. Ekinci, Y. D. O. Ozen, and M. O. Pala, “Reducing Food Waste Through Lean And Sustainable Operations: A Case Study From The Poultry Industry | Redução do desperdício de alimentos por meio de operações sustentáveis e enxutas: Estudo de caso do setor avícola | Reducción del desperdicio de alimento,” RAE Revista De Administracao De Empresas, vol. 61, no. 5, pp. 1–18, 2021. [CrossRef]

- K. Mathiyazhagan, V. Agarwal, A. Appolloni, T. Saikouk, and A. Gnanavelbabu, “Integrating lean and agile practices for achieving global sustainability goals in Indian manufacturing industries,” Technol Forecast Soc Change, vol. 171, 2021. [CrossRef]

- V. V. Muthuswamy and B. Sudhakar, “MEDIATING ROLE OF SUPPLY CHAIN INTEGRATION AMONG INTERNAL LEAN PRACTICES, ENTERPRISE RESOURCE PRACTICES, GREEN OPERATIONS PRACTICES AND OPERATIONAL PERFORMANCE,” Operational Research in Engineering Sciences Theory and Applications, vol. 6, no. 3, pp. 104–123, 2023.

- S. Boopathi, Minimization of Manufacturing Industry Wastes Through the Green Lean Sigma Principle. 2024. [CrossRef]

- J. Calderon, M. Cuellar, D. Aranda, J. C. Alvarez, and O. Yildiz, “Business Process Model Re-Design with A Data-Based Green Lean Management Approach with OEEM: A Case of Plastic Product Manufacturing Firm,” International Journal of Engineering Trends and Technology, vol. 73, no. 3, pp. 289–314, 2025. [CrossRef]

- C. Singh, D. Singh, and J. S. Khamba, “Developing a conceptual model to implement green lean practices in Indian manufacturing industries using ISM-MICMAC approach,” Journal of Science and Technology Policy Management, vol. 12, no. 4, pp. 587–608, 2020. [CrossRef]

- C. Castillo, “The workers’ perspective: emotional consequences during a lean manufacturing change based on VSM analysis,” Journal of Manufacturing Technology Management, vol. 33, no. 9, pp. 19–39, 2022. [CrossRef]

- I. Salifu Osumanu, C. O. Aigbavboa, and D. W. Thwala, “THE IMPACT OF LEAN THINKING ON ORGANIZATIONAL LEARNING,” African Journal of Applied Research, vol. 8, no. 2, pp. 315–321, 2022. [CrossRef]

- M. Rafiq and D. Xiuqing, “Green inclusive leadership at the helm: pro-environmental behavior and environmental strategy in steering environmental performance,” Leadership and Organization Development Journal, vol. 46, no. 3, pp. 416–431, 2025. [CrossRef]

- S. Suieubayeva, A. Sadenova, E. Sánchez-García, J. Martínez-Falcó, B. Marco-Lajara, and J. V. Montalvo-Falcón, “Green leaders and global change: Uncovering the drivers of corporate environmental sustainability,” Environ Dev, vol. 54, 2025. [CrossRef]

- M. Sultan and S. Hussain, “Towards a sustainable workforce: integrating workplace spirituality, green leadership, and employee adaptability for green creativity,” Discover Sustainability, vol. 6, no. 1, 2025. [CrossRef]

- P. B. Le and N. T. Tuyen, “Fostering organizational learning capability through leadership practices and knowledge sharing: the moderating role of knowledge-centered culture,” Journal of Knowledge Management, 2025. [CrossRef]

- N. A. Jan, A. K. Subramani, C. Ramkumar, and S. Chandrasekaran, “Transformational leadership’s impact on organisational citizenship: mediating roles of organisational learning and affective commitment,” International Journal of Management and Enterprise Development, vol. 24, no. 1, pp. 23–41, 2025. [CrossRef]

- A. Harkat, R. A. Sularso, D. Yulisetiarini, and P. Titisari, “The role of Organizational Learning as a Mediating Influence Between Transformational Leadership and Information Technology on Job Satisfaction,” Quality Access to Success, vol. 26, no. 205, pp. 89–98, 2025. [CrossRef]

- J. K. Akuma, E. A. Kwaning, D. N. Akude, and K. A. Asiama, “Green marketing practices and financial performance of manufacturing firms: The moderating role of organizational culture,” Multidisciplinary Reviews, vol. 8, no. 1, 2025. [CrossRef]

- A. Kakouris, E. Sfakianaki, and M. Kapaj, “Lean readiness factors for higher education,” International Journal of Lean Six Sigma, vol. 16, no. 3, pp. 752–777, 2025. [CrossRef]

- Y. Bhatt, K. Ghuman, and A. Dhir, “Sustainable manufacturing. Bibliometrics and content analysis,” J Clean Prod, vol. 260, 2020. [CrossRef]

- L. Sundermann and V. Maier-Speredelozzi, “Measuring the Effects of Lean and Green Manufacturing Practices on the Triple Bottom Line,” in Proceedings of the Iise Annual Conference and Expo 2024, 2024.

- R. Rathi, M. S. Kaswan, J. Antony, J. Cross, J. A. Garza-Reyes, and S. L. Furterer, “Success factors for the adoption of green lean six sigma in healthcare facility: an ISM-MICMAC study,” International Journal of Lean Six Sigma, vol. 14, no. 4, pp. 864–897, 2023. [CrossRef]

- V. Tripathi et al., “Lean, green, and smart manufacturing: An ingenious framework for enhancing the sustainability of operations management on the shop floor in industry 4.0,” Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering, vol. 238, no. 4, pp. 1976–1990, 2024. [CrossRef]

- M. J. Mohamadi, M. Tolou Askari, V. Ghods, and M. Samiei Moghaddam, “Optimizing energy flow in advanced microgrids: a prediction-independent two-stage hybrid system approach,” Energy Informatics, vol. 8, no. 1, 2025. [CrossRef]

- E. Afum, Y. Agyabeng-Mensah, Z. Sun, and R. Zhang, “Sustainability excellence: the interactions of lean production, internal green practices and green product innovation,” International Journal of Lean Six Sigma, vol. 12, no. 6, pp. 1089–1114, 2021. [CrossRef]

- M. Zokaei Ashtiani and S. T. Muench, “Using construction data and whole life cycle assessment to establish sustainable roadway performance benchmarks,” J Clean Prod, vol. 380, 2022. [CrossRef]

- C. Clark and G. P. Nyaupane, “Rewilding as a destination development phenomenon: Examining community resilience through a systems thinking lens,” Tour Manag, vol. 111, 2025. [CrossRef]

- N. Stylos, F. Okumus, and I. Onder, “Beauty or the Borg: Agentic artificial intelligence organizational socialization in synergistic Hybrid Transformative Dynamic Flows,” Tour Manag, vol. 111, 2025. [CrossRef]

- Y. Song, Z. Song, J. Yang, L. Wei, and J. Tang, “Enhancing energy efficiency and sustainability in offshore drilling through real-time multi-objective optimization: Considering lag effects and formation variability,” Reliab Eng Syst Saf, vol. 261, 2025. [CrossRef]

- C. Zhou, W. Song, H. Wang, and L. Wang, “Resilience Assessment of Supply Chain Networks Considering Continuously Varying Sates of Firms in Ripple Effect: A Comprehensive and Dynamic Operational-Structural Analysis,” Omega United Kingdom, vol. 135, 2025. [CrossRef]

- G. Hoxha, I. Simeli, D. Theocharis, A. Vasileiou, and G. Tsekouropoulos, “Sustainable Healthcare Quality and Job Satisfaction through Organizational Culture: Approaches and Outcomes,” Sustainability Switzerland, vol. 16, no. 9, 2024. [CrossRef]

- V. Yadav et al., “Exploration and mitigation of green lean six sigma barriers: a higher education institutions perspective,” TQM Journal, vol. 36, no. 7, pp. 2132–2153, 2024. [CrossRef]

- M. Shamsi, M. R. Zareifard, and M. Zakerinejad, “Optimal, reliable, and sustainable technology selection for mining overburden waste utilization using green & climate-smart mining (GCSM): A hybrid fuzzy multi-criteria decision-making tool,” J Environ Chem Eng, vol. 13, no. 3, 2025. [CrossRef]

- A. Di Vaio, A. Zaffar, and D. Balsalobre-Lorente, Carbon and Decarbonization Disclosure: Role of Responsible Innovation in Adoption of Artificial Intelligence of Things Towards SDGs, vol. 192. 2024. [CrossRef]

- M. Laimon, T. Yusaf, T. Mai, S. Goh, and W. Alrefae, “A systems thinking approach to address sustainability challenges to the energy sector,” International Journal of Thermofluids, vol. 15, 2022. [CrossRef]

- X. Hu, C. Wang, and A. Elshkaki, “Material-energy Nexus: A systematic literature review,” Renewable and Sustainable Energy Reviews, vol. 192, 2024. [CrossRef]

- J. A. Dueñas Santana, A. Di Benedetto, O. González Gómez, and E. Salzano, “Towards sustainable hydrogen production: An integrated approach for Sustainability, Complexity, and Systems Thinking in the energy sector,” J Clean Prod, vol. 449, 2024. [CrossRef]

- H. L. Bhaskar, “Optimizing Manufacturing Sector through Business Process Reengineering and Lean Integration: A B2Lean Methodology Approach,” Operations Research Forum, vol. 6, no. 1, 2025. [CrossRef]

- A. Dabbous, K. Aoun Barakat, and A. G. Woodside, “How do configurations of the sharing economy, renewable energy, and financial development support/dampen nations’ sustainable competitiveness?,” J Clean Prod, vol. 511, 2025. [CrossRef]

- B. Salgin, A. Akgün, R. Ulucak, B. Akdemir, K. Agyekum, and J. Amudjie, “Awareness, perceived importance, and implementation of circular economy principles: Insights from Turkish construction sector,” J Environ Manage, vol. 387, 2025. [CrossRef]

- D. Hariyani, P. Hariyani, S. Mishra, and M. K. Sharma, “A literature review on lean tools for enhancing the quality in the outcome-based education system,” Think Skills Creat, vol. 57, 2025. [CrossRef]

- D. Hariyani, P. Hariyani, S. Mishra, and M. K. Sharma, “Drivers for the adoption of integrated sustainable green lean six sigma agile service system (ISGLSASS) in the service organizations,” Sustainable Futures, vol. 9, 2025. [CrossRef]

- A. Kakouris, E. Sfakianaki, and V. Athanasiadis, “Industry 4.0 and lean thinking: the critical success factors perspective,” International Journal of Quality and Reliability Management, vol. 42, no. 6, pp. 1625–1671, 2025. [CrossRef]

- H. Ayoubi, Y. Tabaa, and M. El Kharrim, “Artificial Intelligence in Green Management and the Rise of Digital Lean for Sustainable Efficiency,” in E3s Web of Conferences, 2023. [CrossRef]

- A. A. Osman, A. N. N. Kamar, and S. R. Rahamadulla, Towards achieving a sustainable lean transformation: Measuring tangible and intangible gains. 2023. [CrossRef]

- M. Gianni and K. Gotzamani, “Lean Digital Culture as an Enabler of Corporate Sustainability Performance: The Mediating Role of Intention to Use Industry 4.0 Technologies,” in Springer Proceedings in Business and Economics, 2024, pp. 58–74. [CrossRef]

- J. Llach, F. J. León-Mateos, N. Depino-Besada, and A. Sartal, “Do green practices and technologies mediate lean manufacturing’s impact on industrial performance? Evidence from the European manufacturing survey,” International Journal of Lean Six Sigma, vol. 16, no. 3, pp. 723–751, 2025. [CrossRef]

- M. Ferrazzi, F. Costa, A. Portioli-Staudacher, G. L. Tortorella, and W. Li, “From People to Performance: Leveraging Soft Lean Practices for Environmental Sustainability in Large-Scale Production,” Sustainability Switzerland, vol. 17, no. 9, 2025. [CrossRef]

- M. Ferrazzi, F. Costa, S. Frecassetti, and A. Portioli-Staudacher, “Unlocking synergies in lean manufacturing for enhanced environmental performance: a cross-sector investigation through fuzzy DEMATEL,” Cleaner Logistics and Supply Chain, vol. 15, 2025. [CrossRef]

- H. A. Kellner, M. Spreeuwenberg, E. R. Edelman, N. van Eldik, and P. Hunen, “The evaluation of a lean healthcare concept to improve the implementation of Digital Health innovations in secondary health care: a qualitative study within a Dutch hospital setting,” BMC Health Serv Res, vol. 24, no. 1, 2024. [CrossRef]

- A. Baker-Shelley, A. Van Zeijl-Rozema, and P. Martens, “Pathways of organisational transformation for sustainability: a university case-study synthesis presenting competencies for systemic change & rubrics of transformation,” International Journal of Sustainable Development and World Ecology, pp. 687–708, 2020. [CrossRef]

- D. Hestad, J. D. Tàbara, and T. F. Thornton, “Transcending unsustainable dichotomies in management: Lessons from Sustainability-Oriented Hybrid Organisations in Barcelona,” J Clean Prod, vol. 244, 2020. [CrossRef]

- C. M. Raymond, R. Kaaronen, M. Giusti, N. Linder, and S. Barthel, “Engaging with the pragmatics of relational thinking, leverage points and transformations–Reply to West et al.,” Ecosystems and People, vol. 17, no. 1, pp. 1–5, 2021. [CrossRef]

- A. Kliskey et al., “Transforming sustainability science for practice: a social–ecological systems framework for training sustainability professionals,” Sustain Sci, vol. 16, no. 1, pp. 283–294, 2021. [CrossRef]

- J. Delgado-Ceballos, N. Ortiz-De-Mandojana, R. Antolín-López, and I. Montiel, “Connecting the Sustainable Development Goals to firm-level sustainability and ESG factors: The need for double materiality,” Brq Business Research Quarterly, vol. 26, no. 1, pp. 2–10, 2023. [CrossRef]

- J.-P. Schöggl, L. Stumpf, and R. J. Baumgartner, “The role of interorganizational collaboration and digital technologies in the implementation of circular economy practices—Empirical evidence from manufacturing firms,” Bus Strategy Environ, vol. 33, no. 3, pp. 2225–2249, 2024. [CrossRef]

- A. Osei, A. O. Agyemang, and J. Cobbinah, “Strategic Sustainability Initiatives and the Circular Economy: Insights From Firm-Level Targets, Board Dynamics, Stakeholder Pressure, and Digital Transformation,” Business Ethics the Environment and Responsibility, 2025. [CrossRef]

- Y. Qian, Z. Xu, Y. Qin, and X. Gou, “A critical review on the multidimensional complexity of sustainable energy development,” Appl Energy, vol. 394, 2025. [CrossRef]

- D. Ivanov and Y. Tu, “Supply chain viability in the post-COVID era,” Omega United Kingdom, vol. 137, 2025. [CrossRef]

- A. Käsbohrer, H.-M. Zademach, and K. S. Rogge, “Regulatory state capacity for accelerating net-zero transitions: Lessons learned from governing electricity storage in Germany,” Energy Policy, vol. 205, 2025. [CrossRef]

- P. Mguni et al., “Scaling deep at the margins: coproduction of nature-based solutions as decolonial research praxis in Cape Town,” Npj Urban Sustainability, vol. 5, no. 1, 2025. [CrossRef]

- D. López-García, T. Zerbian, S. Cuevas, and A. M. Moragues-Faus, “Blurred powers, multiple agencies, and discontinuous temporalities. A multi-level perspective on bottom-up innovation in agri-food policies,” Environ Innov Soc Transit, vol. 57, 2025. [CrossRef]

- A. G. Frank, G. B. Benitez, T. J. Sturgeon, G. A. Marodin, and S. Ferreira e Cunha, “How lean and industry 4.0 affect worker outcomes and operational performance: A quantitative assessment of competing models,” Int J Prod Econ, vol. 279, 2025. [CrossRef]

- H. Mamoojee-Khatib et al., “A systematic review of lean implementation frameworks and roadmaps: lessons learned and the way forward,” TQM Journal, vol. 37, no. 1, pp. 264–287, 2025. [CrossRef]

- F. Jia, T. Pan, T. Zhang, Q. He, and L. Chen, “Supply chain design: implications for sustainability,” International Journal of Logistics Research and Applications, 2024. [CrossRef]

- Y. Xue, J. Zhang, X. Wang, Y. Hong, S. Guo, and X. Zeng, “A Sustainable Supply Chain Design for Personalized Customization in Industry 5.0 Era,” IEEE Trans Industr Inform, vol. 20, no. 6, pp. 8786–8797, 2024. [CrossRef]

- L. Safari, F. M. Sobhani, and S. J. Sadjadi, “Resilient and sustainable supply chain design and planning under supply disruption risk using a multi-objective scenario-based robust optimization model,” Environ Dev Sustain, vol. 26, no. 11, pp. 27485–27527, 2024. [CrossRef]

- M. Montefalcone, C. Morri, and C. N. Bianchi, “Scientists’ warning on sustainability: the ecologist point of view, with examples from marine ecosystems,” Discover Sustainability, vol. 6, no. 1, 2025. [CrossRef]

- M. Atienza-Barba, J. del Brío-González, M. Mitre-Aranda, and V. Barba-Sánchez, “Gender differences in the impact of ecological awareness on entrepreneurial intent,” International Entrepreneurship and Management Journal, vol. 21, no. 1, 2025. [CrossRef]

- A. T. T. Phuong, N. B. Ngoc, N. T. Nhat, N. H. Ngu, N. C. Dinh, and N. Q. Tan, “Land, livelihoods, and legacies: How tenure security shapes drought responses in central Vietnam,” Environmental and Sustainability Indicators, vol. 27, 2025. [CrossRef]

- H. Ladio, “Transformative governance based on local ecological knowledge is impossible without genuine inclusion of indigenous peoples and local communities in NW Patagonia,” J Ethnobiol Ethnomed, vol. 21, no. 1, 2025. [CrossRef]

- R. Datta, C. Charles, J. Chapola, C. E. Haque, and S. Subroto, “Rethinking environmental sustainability education through land-based learning and practice with Woodland Cree First Nation, Lac La Ronge, Saskatchewan, Canada,” Discover Sustainability, vol. 6, no. 1, 2025. [CrossRef]

- W. Ma et al., “A physics-based and data-aided transient prediction framework for sustainable operation of pumped-storage hydropower systems,” Appl Energy, vol. 384, 2025. [CrossRef]

- A. M. Geske, S. Kummer, and D. M. Herold, “Using sustainable technology to drive efficiency: Artificial intelligence as an information broker for advancing airline operations management,” Sustainable Technology and Entrepreneurship, vol. 4, no. 3, 2025. [CrossRef]

- R. Chaudhuri, B. Singh, S. Chatterjee, A. K. Agrawal, S. Gupta, and S. K. Mangla, “A TOE-DCV approach to green supply chain adoption for sustainable operations in the semiconductor industry,” Int J Prod Econ, vol. 275, 2024. [CrossRef]

- Z. A. Saqib, G. Xu, and Q. Luo, “Green Manufacturing for a Green Environment from Manufacturing Sector in Guangdong Province: Mediating Role of Sustainable Operations and Operational Transparency,” Applied Sciences Switzerland, vol. 14, no. 22, 2024. [CrossRef]

- F. Bhuiyan, D. Adu, H. Ullah, and N. Islam, “Employee Organisational Commitment and Corporate Environmental Sustainability Practices: Mediating Role of Organisation Innovation Culture,” Bus Strategy Environ, vol. 34, no. 4, pp. 4485–4506, 2025. [CrossRef]

- A. Kinder et al., “Effects of adaptive feedback generated by a large language model: A case study in teacher education,” Computers and Education Artificial Intelligence, vol. 8, 2025. [CrossRef]

- H. M. Qadir, R. A. Khan, M. Rasool, M. Sohaib, M. A. Shah, and M. J. Hasan, “An adaptive feedback system for the improvement of learners,” Sci Rep, vol. 15, no. 1, 2025. [CrossRef]

- Z. Karparvar, G. Salimi, and M. Mirzabeigi, “Exploring the experiences of researchers in the interdisciplinary humanities research teams on knowledge creation: a qualitative study,” Aslib Journal of Information Management, vol. 76, no. 6, pp. 914–937, 2024. [CrossRef]

- J. Zhang, R. Zhuang, Y. Zhao, and Y. Zhai, “Overview of Interdisciplinary Knowledge Diffusion Research: Measurement, Process, and Influencing Factors | 跨学科知识扩散研究综述: 测度、 过程与影响因素,” Information Studies Theory and Application, vol. 47, no. 12, pp. 194–195, 2024. [CrossRef]

| Dimension | Lean Operations | Green Operations | Green Lean (Integrated) |

| Primary Goal | Maximize efficiency and eliminate non-value-adding activities | Minimize environmental impact and support resource regeneration | Simultaneously improve efficiency and environmental performance |

| Core Tools | Value Stream Mapping, Kanban, 5S, JIT, Kaizen | Life Cycle Assessment, Environmental Audits, ISO 14001 | Eco-VSM, Green Kaizen, Sustainable JIT |

| Underlying Principles | Cost-based value creation, standardization, flow optimization | Ecological stewardship, pollution prevention, circularity | Integrated thinking, balanced value creation |

| Success Metrics | Cycle time, defect rate, inventory turnover, cost savings | Carbon emissions, energy use, waste reduction, resource intensity | Combined metrics: cost, emissions, energy efficiency, eco-efficiency |

| Organizational Values | Efficiency, discipline, problem-solving culture | Responsibility, ethics, long-term thinking |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).