1. Introduction

Textile industry faces an increasing pressure from consumers and European Commission to adopt more sustainable raw materials and practices [

1,

2]. The intensive exploitation of natural resources, the contamination of effluents, greenhouse gas emissions, microplastics release, low biodegradability of textiles and the low recycling rates are highlighted as the main environmental concerns [

3,

4,

5]. Emerging strategies to address these challenges are primarily focused on the implementation of circular economy models. In addition to promoting reuse, repair, eco-design, and recycling practices, the textile industry is also striving to implement the use of renewable raw materials [

6,

7,

8]. Biopolymers like chitosan, alginates, poly(lactic acid) [

9], bacterial cellulose [

10], starch [

11] and polyhydroxyalkanoates (PHA) [

12] are already used in textile applications. In this paper starch was selected for the high abundance, thermoplastic properties and possibility to develop biodegradable and flexible bio-composites [

13,

14]. Starch is one of the most abundant biopolymers and can be obtained from renewable sources. It is produced by plants as well as certain strains of fungi and algae [

15,

16]. Due to its high absorbency, biodegradability, biocompatibility, and non-toxicity, starch is widely utilized by various industries, including agriculture [

16,

17,

18], cosmetics and personal care products [

19,

20,

21], pharmaceutical [

15,

22,

23], food industry [

24,

25,

26], packaging [

27,

28,

29] and paper industry [

30,

31,

32].

Starch has also known applications related to textile field. Several studies focused on exploring starch as flocculant or absorbent of dyes/pigments from wastewaters derived from wet-finishing processes like dying and printing [

33,

34,

35,

36]. Admase et al. (2024), used cassava starch as an eco-friendly alternative to petroleum-based adhesives to join materials together by hot melt [

37]. An antibacterial and hydrophobic polyester woven textile was developed using a ZnO/Zn(OH)₂/starch/stearic acid composite applied via dip-coating. The textile material demonstrated antibacterial activity against

Staphylococcus aureus and exhibited washing durability for up to 20 cycles (antibacterial) and 5 cycles (water repellence) [

38]. Starch is widely used in the textile industry as a thickening agent in printing formulations [

39,

40,

41]. A patented process involved the use of quaternary ammonium-type cationic starch for cotton pre-treatment. The inventor claims that this modification, applied prior to dyeing, shortens processing steps, enhances colour fastness, and improves anti-wrinkling performance [

42]. Cationic starch was used as a coating pre-treatment for reactive dyeing. With increasing degrees of substitution, both dye absorption and colour intensity improved. These results suggest the potential for salt-free reactive dyeing [

43]. Fernandes et al. (2025) applied cationic starch to develop functional textiles exhibiting water repellence with washing durability.[

44].

The company

®ANGEL provides starch-based solutions for different industries, including textile sector. According to the company, starch can be applied to warp threads (sizing) before weaving to enhance their strength, stiffness, and smoothness, making them less susceptible to abrasion and breakage during the weaving process. Moreover, starch-treated yarns exhibit reduced airiness and a smoother surface, which helps minimize tangling and breakage and ultimately enhance production efficiency, fabric quality and durability [

45]. Besides yarns sizing, BlueCraftAgro

® which is specialized in starch processing, also mention the use of starch-based finishings to improve a fabric’s shine, resistance to wrinkling and as a thickener for printing formulations [

46]. The Laundress New York sells starch-based sprays to be applied during ironing to achieve a crisp, professional finishing. Starch adds body to cotton and linen garments, making ironing easier while enhancing resistance to wrinkling and soiling [

47]. AGRANA provide starch- based products as sizing agents, adhesives for textile webs, printing thickeners, including digital printing applications. These products are compatible with other finishing agents such as optical bleaching agents, filling agents, synthetic resins and dispersion agents [

48]. Starch-based films are already intensively explored for sustainable food packaging and preservation offering protection against mold and humidity while extending product shelf life [

49,

50]. Based on our literature review, the use of starch-based films to develop functional textiles has not been previously reported.

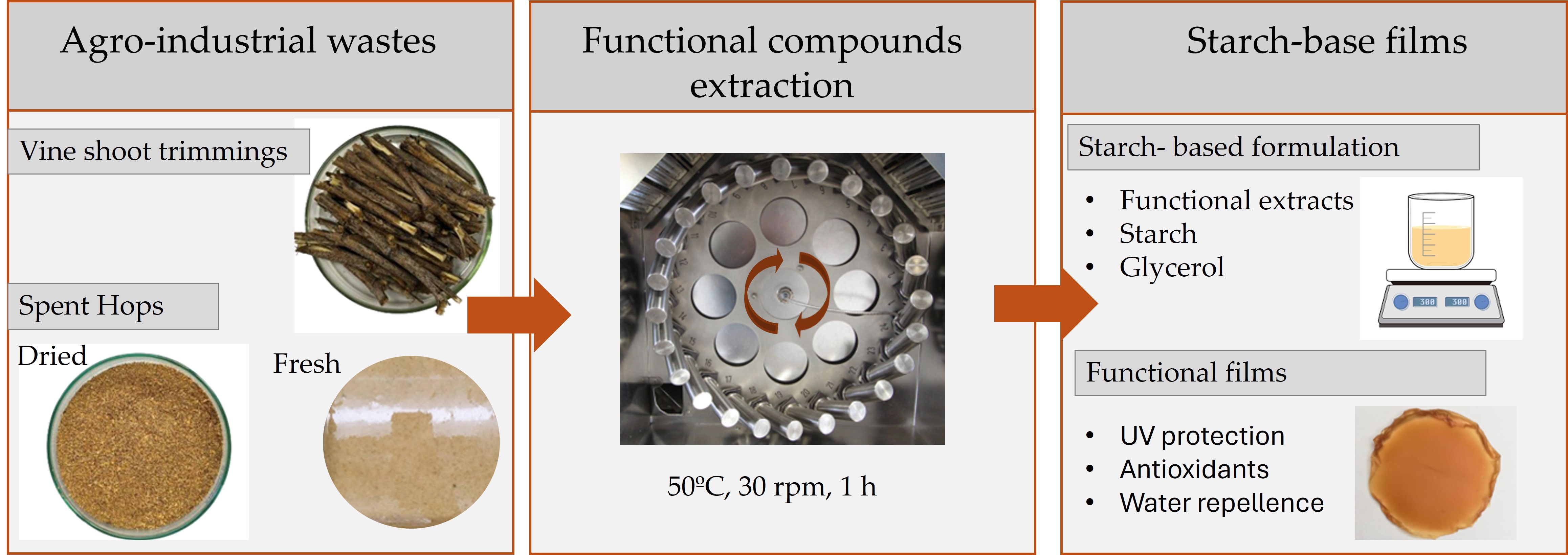

In our work, cationic-starch and extracts from vine shooting trimmings (VST) and spent hops (SH) were used to develop functional textiles with UV protection, antioxidant and water repellence properties. Those findings are relevant for outdoor garments such as leisurewear or sports applications.

2. Materials and Methods

2.1. Raw Materials

VST and SH were supplied by Quinta de Amares (Amares, Portugal) and LETRA (Vila Verde, Portugal) respectively. Both wastes were dried at 60 °C until a constant weight and <20% moisture were obtained. VSTs were ground at 0.25 mm using a Retsch SM 300 cutting mill (Retsch GmbH, Haan, Germany). The SH was tested in the dried and fresh form. The fresh SH was frozen (-18°C) until use.

The cationic starch was donated by COPAM (Loures, Portugal). Glycerol was purchased to Himedia.

2.2. Functional Extracts Preparation

Aqueous extraction was performed at 3 %, 5 %, and 10 % wastes biomass, for a final volume of 200 mL. The extraction was performed in a laboratory machine that simulates exhaustion dyeing, Mathis Labomat (BFA/8), at 50 ºC, 30 rpm for 1 hour. The extracts were filtered using a vacuum pump and stored in the fridge (6 °C) until use.

2.3. Preparation of Starch-Based Films

The formulations consisted in cationized starch (6.25 % w/w) and glycerol (30 wt. % on the dry starch basis) combined with the functional extracts. As a control, water was used instead of the functional extracts (referred as control). The formulation was stirred for 10 minutes at room temperature. After, the temperature was increased to 80 ºC to start starch gelatinization. The mixture was maintained for 45 minutes at continuous stirring. Subsequently, 20 mL of the hot suspension was poured into a silicone mold and remained at room temperature for 3 hours. Then, the formulations were dried in an oven Venticell 111 eco line (MMM) at 65 ºC and 10 % ventilation.

2.4. Starch Films Characterization

Attenuated total reflectance–Fourier transform infrared spectroscopy (ATR-FTIR) analysis was performed to characterize the functional groups of the starch-based films (control and with functional extracts). The spectra of the samples was recorded in the range of 680–4000 cm−1 with a spectral resolution of 2 cm−1.

Colour analysis was conducted in a colorimeter (datacolor, Spectro 750), using the standard illuminant CIE D65 and an observer angle of 10°. Colour coordinates from CIEL*a*b* colour space, where L* corresponds to lightness (value of 100 and 0 corresponds to white and perfect black, respectively); a* corresponds to the transition from green (−a*) to red (+a*); and b* corresponds to the transition from blue (−b*) to yellow (+b*). Three films (replicates) were measured for each concentration and 3 readings were performed for each film.

The measurement of ultraviolet protection factor (UPF) of the starch-based films was performed following the standard in Australia/New Zealand A(S/NZ) 4399. For that, transmittance measurements (290 nm and 400 nm) were performed in UV–Vis spectrometer (UV−2600i, Shimadzu, Duisburg, Germany). Three films (replicates) were measured for each concentration and 6 readings were performed for each film.

The antioxidant properties were determined by the 2,2-diphenyl-1-picrylhydrazyl (DPPH) method. For that analysis, a film with 100 mg was immersed in 6 mL DPPH solution (0.024 mg/mL in ethanol). After 30 min in darkness at room temperature, the absorbance of the solution was recorded at 517 nm using a spectrophotometer (Shimadzu UV-2600i ISR-2600Plus). Two replicates of each biomass concentration were used. The antioxidant activity was determined as its capacity to scavenge the DPPH free radicals, according to the following equation:

Abscontrol corresponds to the absorbance of the control film and Abssample to the absorbance of the film with the functional extracts incorporated.

Hydrophobic and oleophobic properties of the starch-based films were evaluated by measuring the contact angles of distilled water (3 µL) and diiodomethane (1 µL), referred to as WCA and DCA, respectively. These measurements were performed using a tensiometer (Biolin Scientific Attension Theta Flex). For each analysis, contact angle measurements were taken at three different locations on each sample.

2.5. Statistical Analysis

For statistical analysis, Microsoft Excel 365, and GraphPad Prism (version 10.4.1) were utilized. Analysis of variance (ANOVA) and Tukey’s multiple comparisons (α = 0.05) were used to calculate the statistically significant differences in the results between groups, and it was considered a confidence level of 95 % (p < 0.05) for the experimental results.

3. Results

This section presents the characterization of the developed starch-based films.

3.1. Colorimetric Characterization

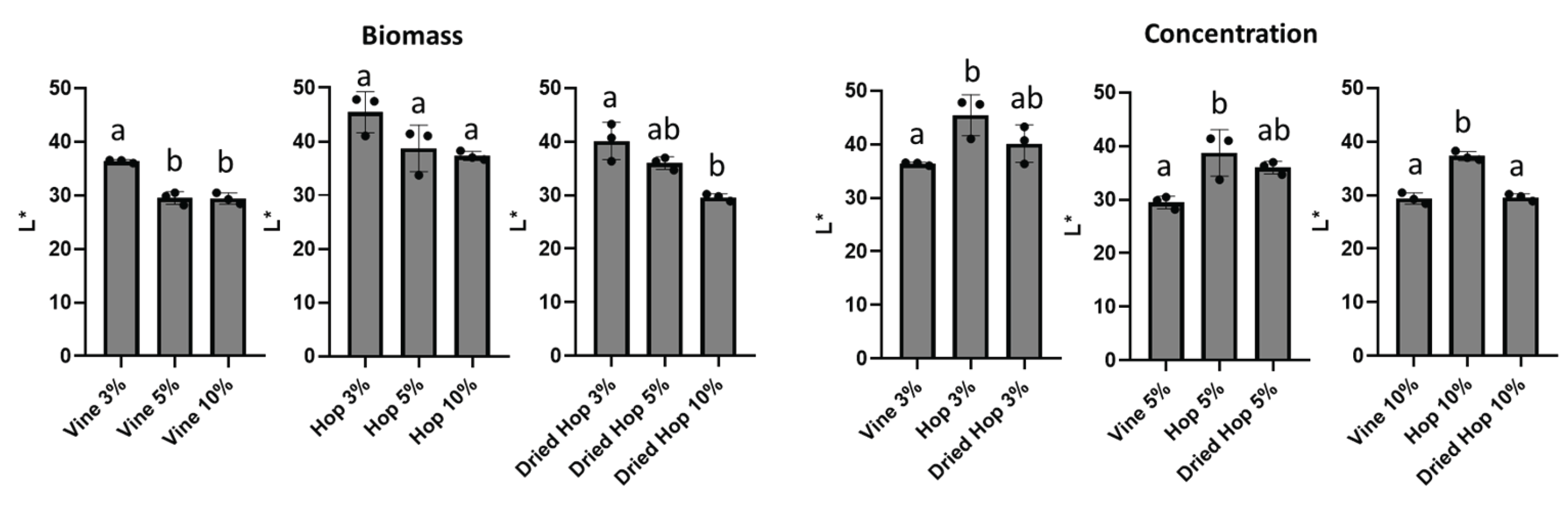

Colour is an essential characteristic for textiles. For that the colour coordinates from CIEL*a*b* colour space were accessed and presented in the following figures (

Figure 1,

Figure 2 and

Figure 3). The control film was not considered since it was white and transparent.

As shown in

Figure 1, the L* coordinate values decrease with increasing concentrations of waste biomass, indicating that higher biomass content results in darker film coloration.VST films presented an inferior L* value compared to the SH films at the same, demonstrating darker coloration. Dried SH films presented a lower L* coordinate values and, consecutively, a darker colour then fresh SH. Statistical analysis reveals that the L* values of VST films differ significantly (p < 0.05) when the biomass concentration is increased up to 5% and 10%. For fresh SH, no significant differences were observed with changes in biomass concentration. However, in the case of dried SH, using 10% biomass led to a significant difference in film lightness compared to 3%.

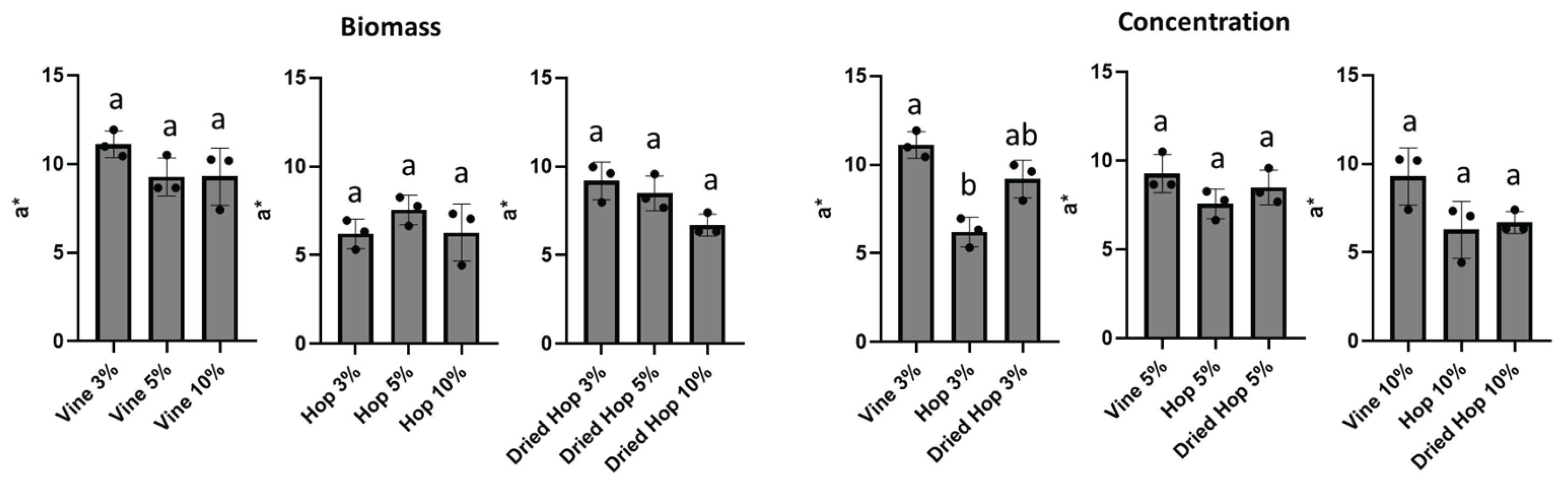

As shown in

Figure 2, the positive values of the

a* coordinate for all films indicate a predominant red hue. Both VST and dried SH films showed a decrease in

a* values with increasing concentration, although these differences were not statistically significant (p < 0.05). VST present higher a* coordinate values, indicating a reddish coloration compared to SH films. When comparing the three waste sources, statistically significant differences were observed at 3% concentration between VST and fresh SH films.

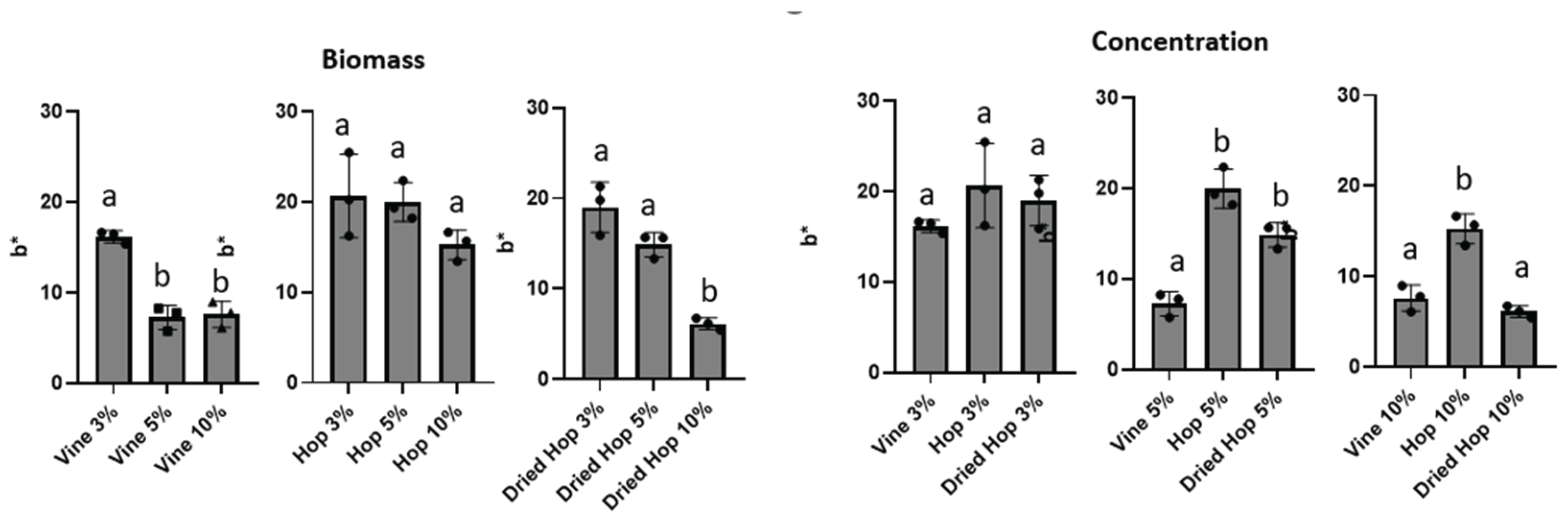

For all the films, b* coordinate showed only positive values indicating a dominant yellow coloration. A general decrease in b* values was observed with increasing biomass concentration. These differences were statistically significant (p < 0.05) when the concentration of VSH increased up to 3% and of dried SH to 10%. Comparing VST and SH, significant differences were observed at the 5% biomass concentration. At 10%, significant differences between VSG and fresh SH. Fresh SH films have a yellowish colour compared to the dried SH and VST.

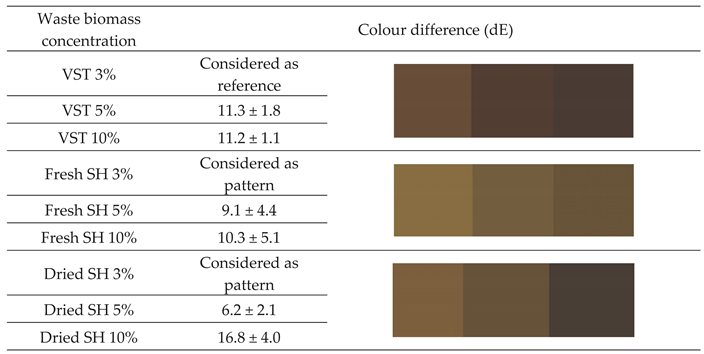

In

Table 1 are presented the colour differences (dE) between starch-based films developed with extracts containing 5% and 10% waste biomass, compared to the film incorporating the lowest biomass concentration of 3% (reference).

Analysing the dE values in

Table 1, for both VST and SH, increasing the biomass concentration up to 3% led to noticeable colour changes but minimal differences were observed between the 5% and 10% concentrations for VST and fresh SH. This is an indication of saturation beyond 5%. For dried SH, the dE between 3% and 5% is less pronounced compared to VST and fresh SH. However, when the concentration increases to 10%, dE reaches the highest value among all the films.

3.2. FTIR Spectra

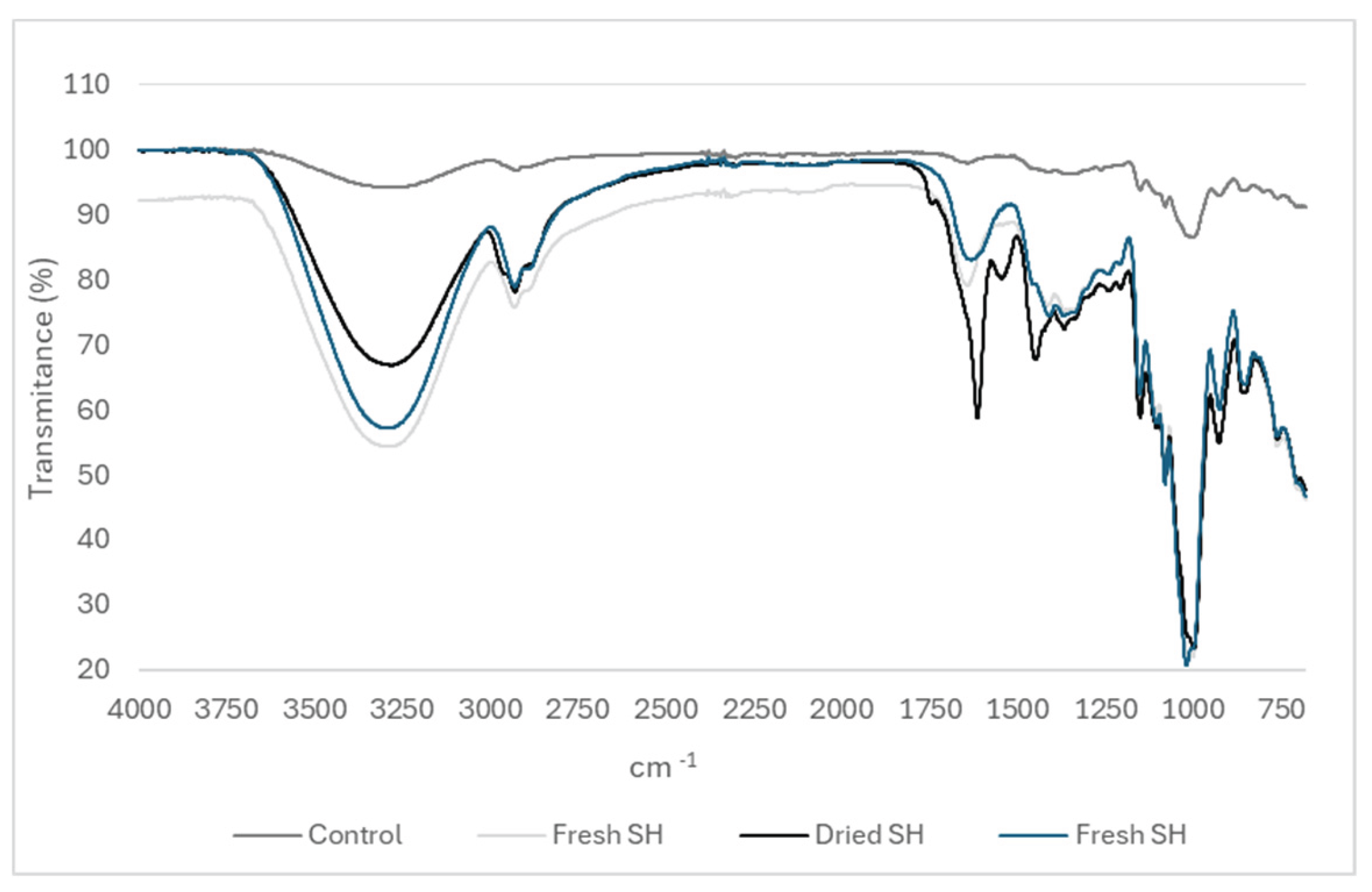

For chemical composition analysis of the starch-based films, the FTIR spectra was recorded (

Figure 4).

In

Figure 4 is shown common absorption bands at around 3400-3200 cm

-1 (O- H); 3000-2900 cm

-1 (C-H), 1600 cm

-1 (C-O bending associated with OH group) and 1000 cm

-1 (C-O) for SH and VST starch-based films. The board peak at 3400-3200 cm

-1 and the peak at 1000 cm

-1 are also found in the control (starch-film). However, these peaks are more intense in the films that incorporated the functional extracts.

3.3. UV Protection

The UV protection conferred by the starch-based films is presented in

Table 2.

All starch-based films incorporating the functional extracts have maximum UV protection (50+), classified as “Excellent”, according to Australia/New Zealand A(S/NZ) 4399. The incorporation of the functional extracts is responsible for conferring UV protection, since the control film, only made with water and starch, exhibited an UPF of 2.19 (UPF < 15).

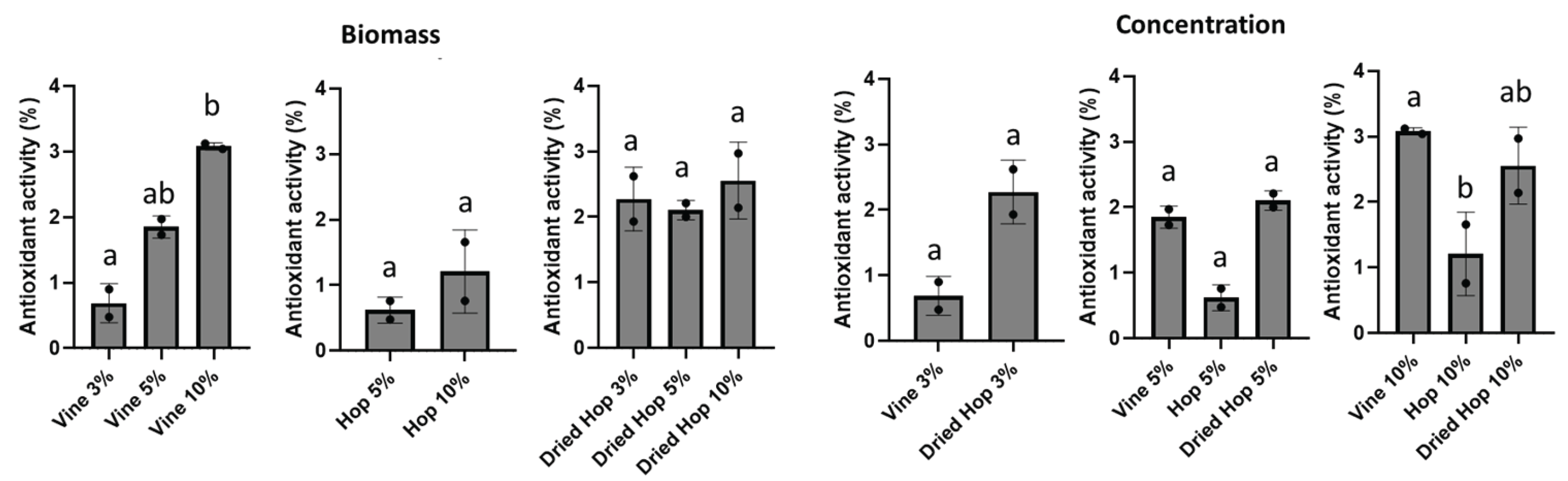

3.4. Antioxidant Properties

The antioxidant potential of the starch-based films was accessed by DPPH method and expressed as percentage of antioxidant activity (

Figure 5)

From the analysis of

Figure 5, it can be observed that the antioxidant activity generally increases with the biomass concentration in the extracts incorporated into the films. Statistically significant differences (p < 0.05) were only observed in VST films comparing the 3% and 10% biomass concentrations. When comparing the different wastes, significant differences were only observed between VST and fresh SH films at the 10% biomass concentration. However, the films present lower antioxidant properties, corresponding the higher values to VST films at 10% biomass.

3.5. Watter Repellence

The characterization of static contact angles of water and diiodomethane for the starch-based films are summarized in

Table 3.

Theoretically, hydrophobic/oleophobic surfaces have WCA/DCA superior to 90°. Superhydrophobic/oleophobic surfaces exhibit a WCA/DCA exceeding 150° [

30,

51]. Starch-based films incorporated VST (3%, 5%, 10%) extracts presented the higher WCA (~120°), indicating excellent water repellence and hydrophobic behaviour. Little variation is observed between the different waste biomass concentrations. The water repellence properties cannot be only attributed to the plasticizing effect of cationized starch and glycerol, as films incorporating residue extracts exhibited higher WCA values compared to the control. All starch-based films show DCA values below 90°, meaning they do not exhibit oil repellence. However, some improvements were observed with the incorporation of the functional extracts, particularly for VST and SH at 10% when compared to the control.

4. Discussion

Agro-industrial wastes are known for being rich in colouring components and functional ingredients [

52,

53,

54]. In this study VSH and SH (dried and fresh) were explored for their functional properties to develop 100% bio-based films with interesting properties for textile applications.

All the films exhibited a brown coloration, with noticeable variations in shade intensity ranging from lighter to darker colours. As the concentration of waste biomass increased, the colour intensity of the films also intensified, as visually demonstrated in the last column of

Table 1 and supported by the dE values presented in the same table. This colour difference is attributed to variations in the L* and b* coordinates. Despite dE values around 10 when comparing fresh SH films at 3% to 5% and 10% biomass, not statistically significant differences (p < 0.05) were observed in the L*, a*, and b* colour coordinates. In the case of VST and SH, the difference is significant increasing biomass concentration up to 3% and at 10%, respectively. In contrast, increasing the concentration of fresh SH significant changes in the colour coordinates L*a*b*did not occur. Drying SH leaded to the production of films with a higher colour intensity (see images in

Table 1), with statistic significant differences for L* and b* coordinates at 10% biomass concentration (p < 0.05). It is also important to note that the standard deviations in the colour coordinates are related to the heterogeneity among the replicated films. For that improvements in the drying step are needed.

FTIR spectra of VST films detected intense bands at around 1000 cm

-1, 1500 cm

-1 and 1600 cm

-1, typical peaks found at VST and attributed to the presence of polyphenolic compounds [

55]. Those peaks are also found in SH films. A broad and intense peak at 3400-3200 cm

-1 is also common for the control film and VST and SH films and is reported to be related to OH and NH groups. Those peaks were also found by other authors in VST [

55] and SH [

56].The FTIR spectra of the control films (not included functional extracts) revelled board peaks at 3400-3200 cm

-1 and 1000 cm

-1 also reported in literature [

57]. The main differences detected due to the drying of SH was the higher intensity of the bands at 1600 cm

-1 and 1450 cm

-1, attributed to C -C group of aliphatic and/or unsaturated aromatic compounds and C-H bonds of hydrocarbons [

58,

59].

Despite the brown colour, the developed films were not opaque and even semi-transparent. For that, the Excellent UV protection (50+) presented by all the films is not exclusively related to coloration properties but may be attributed to the functional compounds present in the functional extracts. An early patent from 1976 reported the use of hops (

Humulus lupulus) as a UV absorber in skincare applications [

61]. However, Kurzawa et al. (2022) evaluated the sun protection factor (SPF) of aqueous extracts from hops and recorded a low to moderate UVA/UVB protection, with SPF increasing alongside extract concentration [

62]. In our study, starch-based films containing SH extracts demonstrated a UV protection of 50+, even at the lowest SH concentration. Regarding wine industry wastes, grape seed extracts have been reported to protect fibroblasts from UV-induced damage [

63]. For VST no information is available in the literature about the UV protection potential. Our findings are very relevant, as the use of SH and VST, as waste materials, allowed the development of films with a maximum UV protection.

The antioxidant potential of SH is documented in the literature, primarily due to the presence of the phenolic compound xanthohumol in its composition [

64,

65,

66]. Petrón et al., (2021) quantify an antioxidant activity in SH aqueous extracts superior to 70% [

67]. VST are also a known source of antioxidants and in phenolic compounds such as flavonoids, stilbenes and condensed polyphenols [

55,

60,

68]. However, in our study, the VST and SH films showed a low antioxidant activity. Although the drying temperature of the films was below 80 °C—the threshold commonly associated with antioxidant degradation [

69,

70]—the low antioxidant activity may be attributed to the extended drying duration (approximately 20 hours), which could have led to the degradation of bioactive compounds. No statistically significant differences (p < 0.05) were observed between dried and fresh SH in terms of antioxidant activity.

The incorporation of VST and dried SH extracts at 10% biomass, allowed the development of hydrophobic starch-based films. Hydrophobic textiles represent a significant market due to their association with self-cleaning, antimicrobial, and water-repellent properties [

51].

VST are the main waste generated by the wine industry during pruning. Unlike grape pomace, which is considered a by-product and valorised in various industrial applications, VST remain unexploited considering the large quantity of its production [

55,

71]. Moreover, the typical disposal of VST by open-air burning or composted in the field is associated with negative environmental impacts [

72,

73]. SH (mixture of beer and hop plant) are generated in significant amounts after beer fermentation. Some studies report the valorisation of SH as fertilizer, but others mention its disposal, contributing to wastewaters contamination [

64,

65,

74]. In fact, the companies that supplied the VST and SH confirmed having no existing valorisation routes for these wastes. Our findings are very relevant not only considering the development of functional 100% bio-based films but also for the valorisation of VST and SH wastes and as a solution for the negative environmental impacts associated with linear industrial process.

5. Conclusions

Starch-based films with colouring and functional properties were developed by the incorporation of aqueous extracts of VST and SH (dried and fresh). 100% bio-based films with UV protection of 50+ and water repellent properties were obtained following sustainable and easily scalable process for industrial applications. These functionalities are highly valued across various sectors, including sportswear, outdoor apparel, medical textiles, furniture upholstery, and footwear. Moreover, the use of water-based extracts and starch in the production of the films—without harmful chemicals—is significant not only for the manufacturing process but also for the films’ end-of-life. If landfilling is considered as the final disposal route, the faster biodegradation of these starch-based films, without releasing microplastics like those from PVC, polyurethane, or other petroleum-derived materials, further highlights the relevance of this work. The valorisation of VST and SH, which would otherwise be burned or discarded, aligns with bioeconomy principles and represents a pathway for improving sustainability for industry.

Author Contributions

Conceptualization, A.M.F.; methodology, MM.; WCA and DWC measurements, VC; validation, A.M.F.; investigation, A.M.F. and MM; resources, C.J.S; data curation, A.M.F and MM; writing—original draft preparation, A.M.F and MM; writing—review and editing, A.M.F; supervision, C.J.S.; project administration, C.J.S.; funding acquisition, C.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support from integrated project be@t – Textile Bioeconomy (TC-C12-i01, Sustainable Bioeconomy No. 02/C12- i01.01/2022), promoted by the Recovery and Resilience Plan (RRP), Next Generation EU, for the period 2021 – 2026.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors kindly thank Cervejaria Letra, Quinta de Amares and COPAM for the supply of materials.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| VST |

Vine shoot trimmings |

| SH |

Spent hops |

| UPF |

Ultraviolet protection factor |

| ATR-FTIR |

Attenuated total reflectance–Fourier transform infrared spectroscopy |

| dE |

Colour difference |

| WCA |

Water contact angle |

| DCA |

Diiodomethane contact angle |

| SPF |

Sun protective factor |

References

- Siliņa, L.; Dāboliņa, I.; Lapkovska, E. Sustainable Textile Industry – Wishful Thinking or the New Norm: A Review. J Eng Fiber Fabr 2024, 19. [Google Scholar] [CrossRef]

- European Commission. EU Strategy for Sustainable and Circular Textiles 2022.

- Sadhna; Greeshma, S.; Kumar, R. Introduction to Climate Action, Waste Management, and Eco-Textiles. In Climate Action Through Eco-Friendly Textiles, 1st ed.; Sadhna; Greeshma, S.; Kumar, R, Eds.; SDGs and Textiles. Springer: Singapore, 2024; pp. 1–10. [CrossRef]

- Alex, R.K.; Muhammed, T.M.; Kannankai, M.P.; Radhakrishnan, A.; Borah, A.; Reghuvaran, A.; Devipriya, S.P. Microfiber Pollution: Assessment, Emission Estimation, and Time-Series-Based Forecast of Microfibers from Domestic Washing Machine Laundering and Mitigation Measures. Integr Environ Assess Manag 2024, 20, 2116–2127. [Google Scholar] [CrossRef] [PubMed]

- Espinoza-Pérez, L.A.; Espinoza-Pérez, A.T.; Vásquez, Ó.C. Life Cycle Assessment of Alternatives for Industrial Textile Recycling. Science of The Total Environment 2024, 927, 172161. [Google Scholar] [CrossRef]

- Ramírez-Escamilla, H.G.; Martínez-Rodríguez, M.C.; Padilla-Rivera, A.; Domínguez-Solís, D.; Campos-Villegas, L.E. Advancing Toward Sustainability: A Systematic Review of Circular Economy Strategies in the Textile Industry. Recycling 2024, 9, 95. [Google Scholar] [CrossRef]

- Daget, T.M.; kassie, B.B.; Tassew, D.F. A Shift from Synthetic to Bio-Based Polymer for Functionalization of Textile Materials: A Review. Int J Biol Macromol 2025, 306, 141637. [Google Scholar] [CrossRef]

- Abagnato, S.; Rigamonti, L.; Grosso, M. Life Cycle Assessment Applications to Reuse, Recycling and Circular Practices for Textiles: A Review. Waste Management 2024, 182, 74–90. [Google Scholar] [CrossRef]

- Abdellatif, F.H.H.; Abdellatif, M.M. Utilization of Sustainable Biopolymers in Textile Processing. In Green Chemistry for Sustainable Textiles; Ibrahim, N, Mustansar, C., Hussain, *!!! REPLACE !!!*, Eds.; Woodhead Publishing, Springer: United Kingdom, 2021; pp. 453–469. [Google Scholar] [CrossRef]

- Absharina, D.; Padri, M.; Veres, C.; Vágvölgyi, C. Bacterial Cellulose: From Biofabrication to Applications in Sustainable Fashion and Vegan Leather. Fermentation 2025, 11, 23. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Piłczyńska, K.; Murawski, T.; Jeznach, A.; Niczyporuk, K. Study on the Printability of Starch-Based Films Using Ink-Jet Printing. Materials 2024, 17, 455. [Google Scholar] [CrossRef]

- Shahi, Z.; Mehrizi, M.K.; Firoozabad, M.S.M. Introduction of Polyhydroxyalkanoates (PHAs) and Their Application in the Textile Industry. In Biopolymers in the Textile Industry. In Biopolymers in the Textile Industry; Shahi, Z., Mehrizi, M.K., Firoozabad, M.S.M., Eds.; Springer Nature Singapore: Singapore, 2024; pp. 29–40. [Google Scholar] [CrossRef]

- Shuprajhaa, T.; Paramasivam, S.K.; Pushpavalli, S.; Anandakumar, Su.; Naik, R. Influence of Additives on the Development, Mechanical, Functional Characteristics and Biodegradability of Banana Starch-Based Bio Plastic Films. Int J Biol Macromol 2025, 295, 139544. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Basak, S.; Baite, H.; Bhowmick, M.; Debnath, S.; Roy, A.N. Jute Fibre Reinforced Biodegradable Composites Using Starch as a Biological Macromolecule: Fabrication and Performance Evaluation. Int J Biol Macromol 2024, 273, 132641. [Google Scholar] [CrossRef] [PubMed]

- Grafia, A.L.; González, N.; López, O.V.; Ramírez Rigo, M.V.; Pacheco, C.; Razuc, M.F. Starch-Based Antioxidant Formulations for Pharmaceutical Purposes. In Studies in Natural Products Chemistry; Attaur-Rahman, *!!! REPLACE !!!*, Ed.; Elsevier: Amsterdam, Netherlands, 2025; Volume 84, pp. 279–345. [Google Scholar] [CrossRef]

- Gamage, A.; Liyanapathiranage, A.; Manamperi, A.; Gunathilake, C.; Mani, S.; Merah, O.; Madhujith, T. Applications of Starch Biopolymers for a Sustainable Modern Agriculture. Sustainability 2022, 14, 6085. [Google Scholar] [CrossRef]

- Lopes, M.M.; Lodi, L.A.; Oliveira-Paiva, C.A. de; Farinas, C.S. Emulsion/Cross-Linking Encapsulation of Bacillus in Starch/PVA-Based Microparticles for Agricultural Applications. ACS Agricultural Science & Technology 2024, 4, 490–499. [Google Scholar] [CrossRef]

- Lv, Q.; Xiao, T.; Dong, G.; Tan, X.; Zhang, Z.; Zhao, M.; Zhu, M.; Li, J.; Zhang, W. Preparation and Characterization of Starch Carbamate Modified Natural Sodium Alginate Composite Hydrogel Blend Formulation and Its Application for Slow-Release Fertilizer. Int J Biol Macromol 2024, 278, 134713. [Google Scholar] [CrossRef]

- Biyimba, B.N.; Ekaette, I.; Cobbinah-Sam, E. Starch Functionality in Cosmetics and Personal Care Products. Carbohydr Polym 2025, 123597. [Google Scholar] [CrossRef] [PubMed]

- Olivato, J.B. Starch: A Natural, Safe, and Multifunctional Ingredient for Cosmetic Formulations. In Starch Industries: Processes and Innovative Products in Food and Non-Food Uses; Cereda, M.P, Vilpoux O.P., Ed.; Academic Press, Elsevier: Massachusetts, USA, 2024; pp. 255–269. [Google Scholar] [CrossRef]

- Klosowski, A.B.; Riccio, B.V.F.; Pereira, K. de C.; Balado, M.G.P.; Lopes, A.C.; Cordeiro, L.R.G.; Campos, P.M.; Olivato, J.B. Starch Nanoparticles with Brewers’ Spent Grain Extract as Stabilizers for Pickering Emulsions: A Biodegradable and Sustainable Alternative for Natural Cosmetics. Observatório de la economía latinoamericana 2025, 23, e9711. [Google Scholar] [CrossRef]

- Bhatt, P.; Kumar, V.; Singh, S.; Garg, S.; Kumar, M.; Wong, L.S.; Kumarasamy, V.; Pahwa, S.; Subramaniyan, V. Enzymatic Debranching of Starch: Techniques for Improving Drug Delivery and Industrial Applications. Starch 2025, 77. [Google Scholar] [CrossRef]

- Kapoor, D.U.; Pareek, A.; Sharma, M.; Prajapati, B.G.; Suttiruengwong, S.; Sriamornsak, P. Exploring Starch-Based Excipients in Pharmaceutical Formulations: Versatile Applications and Future Perspectives. European Journal of Pharmaceutics and Biopharmaceutics 2025, 212, 114727. [Google Scholar] [CrossRef]

- Singh, S.; Gaur, S.; Sharma, N. Starchy Films as a Sustainable Alternative in Food Industry: Current Research and Applications. Starch 2024, 76. [Google Scholar] [CrossRef]

- Shan, Y.; Li, J.; Nie, M.; Li, D.; Zhang, Y.; Li, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. A Comprehensive Review of Starch-Based Technology for Encapsulation of Flavor: From Methods, Materials, and Release Mechanism to Applications. Carbohydr Polym 2025, 348, 122816. [Google Scholar] [CrossRef]

- Mahfouzi, M.; Zhang, H.; Haoran, L.; McClements, D.J.; Hadidi, M. Starch-Based Particles as Stabilizers for Pickering Emulsions: Modification, Characteristics, Stabilization, and Applications. Crit Rev Food Sci Nutr 2025, 65, 1841–1856. [Google Scholar] [CrossRef] [PubMed]

- Pei, J.; Palanisamy, C.P.; Srinivasan, G.P.; Panagal, M.; Kumar, S.S.D.; Mironescu, M. A Comprehensive Review on Starch-Based Sustainable Edible Films Loaded with Bioactive Components for Food Packaging. Int J Biol Macromol 2024, 274, 133332. [Google Scholar] [CrossRef] [PubMed]

- Dutta, D.; Sit, N. Comprehensive Review on Developments in Starch-Based Films along with Active Ingredients for Sustainable Food Packaging. Sustain Chem Pharm 2024, 39, 101534. [Google Scholar] [CrossRef]

- Nazrin, A.; Ilyas, R.A.; Rajeshkumar, L.; Hazrati, K.Z.; Jamal, T.; Mahardika, M.; Aisyah, H.A.; Atiqah, A.; Radzi, A.M. Lignocellulosic Fiber-Reinforced Starch Thermoplastic Composites for Food Packaging Application: A Review of Properties and Food Packaging Abetted with Safety Aspects. Food Packag Shelf Life 2025, 47, 101431. [Google Scholar] [CrossRef]

- Deng, X.; Yan, X.; Yang, W.; Zhang, F.; Liu, Y.; Ren, H.; Song, J.; Xiao, H.; Guo, J. Effect of Sodium Periodate Oxidation of Cassava Starch on Grease Resistance and Waterproofing of Food Wrapping Paper. ACS Sustain Chem Eng 2025, 13, 6801–6812. [Google Scholar] [CrossRef]

- Bibi Nausheen, J.; Pratima, K.; Dinesh, S. Evaluating the Effectiveness of Starch Reinforcement in Paper Production from Tropical Plant Fibers. Chemical Papers 2025, 79, 221–234. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, W.; Lin, B.; Zhu, H.; Deng, F.; Chen, Q. Dually Modified Starch-Based Coating for Improving Barrier and Mechanical Performances of Paper Toward Food Packaging. J Appl Polym Sci 2025, 142. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Cao, S.; Ding, Y.; Wang, H.; Chang, N. Preparation of Crosslinking-Grafting Cationic Starch Flocculant and Its Study on Textile Dyes Removal. J Polym Environ 2024, 32, 3407–3421. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, Y.; Wang, H.; Chang, N. Preparation of Starch-Based Adsorbing-Flocculating Bifunctional Material St-A/F and Its Removal of Active, Direct and Disperse Dyes from Textile Printing and Dyeing Wastewater. Polymer Bulletin 2024, 81, 2777–2800. [Google Scholar] [CrossRef]

- Chang, N.; Cao, S.; Li, J.; Zhang, H.; Wang, H. Preparation of Starch-Based Cationic Flocculants and Its Study on the Removal of Textile Dyes. Ind Eng Chem Res 2024, 63, 2483–2494. [Google Scholar] [CrossRef]

- Kiran, M.; Haq, F.; Ullah, M.; Ullah, N.; Chinnam, S.; Ashique, S.; Mishra, N.; Wani, A.W.; Farid, A. Starch-Based Bio-Membrane for Water Purification, Biomedical Waste, and Environmental Remediation. Int J Biol Macromol 2024, 282, 137033. [Google Scholar] [CrossRef] [PubMed]

- Admase, A.T.; Mersha, D.A.; Kebede, A.Y. Cassava Starch-Based Hot Melt Adhesive for Textile Industries. Sci Rep 2024, 14, 20927. [Google Scholar] [CrossRef] [PubMed]

- Narakaew, P.; Thungprasert, S.; Narakaew, S.; Baison, W.; Promanan, T.; Santakij, P.; Sukdee, S.; Chanogkun, C.; Ruttanateerawichien, K.; Chaisena, A.; et al. The Durable Hydrophobic and Antibacterial Polyester Textile Coating with ZnO/Zn(OH)2/Starch/Stearic Acid Composite. Industria Textila 2024, 75, 722–728. [Google Scholar] [CrossRef]

- Gelaw, B.B.; Dodi, A.; Berihun, B.E.; Hordofa, D.E.; Awoke, A.T. Utilization and Characterization of Cassava Starch as a Natural Thickening Agent for Reactive Dye Printing on Cotton Fabric. Research Square 2024. [CrossRef]

- Nuru, A.M.; Ahmmed, A.S.; Gudayu, A.D. Eco-Friendly Thickening Agent for Cotton Fabric Reactive Dye Printing. AATCC Journal of Research 2025, 12. [Google Scholar] [CrossRef]

- Dhoundiyal, S.; Alam, Md.A.; Kaur, A.; Maqsood, S.; Sharma, S.; Khan, S.A. Biopolymers in Sustainable Textile Dyeing and Printing. In Biopolymers in the Textile Industry; Ahmed, S., Shabbir., *!!! REPLACE !!!*, M., *!!! REPLACE !!!*, Eds.; Springer Nature Singapore: Singapore, 2024; pp. 123–146. [Google Scholar]

- University of Shaoxing. Dyeing Method for Starch Cation Modified Cotton Fabric. CN105862468A. 2016.

- Wurm, F.; Mann, K.; Seidl, B.; Kozich, M.; Bechtold, T.; Pham, T. Cotton Fabric Coating by Cationic Starches to Aim for Salt-Free Reactive Dyeing. ChemistrySelect 2024, 9. [Google Scholar] [CrossRef]

- Fernandes, A.M.; Pinheiro, A.I.; Rodrigues, C.; Silva, C.J. Bioeconomy in Textile Industry: Industrial Residues Valorization Toward Textile Functionalization. Recycling 2025, 10, 78. [Google Scholar] [CrossRef]

- ANGEL. Available online: https://angelstarch.com/about-us/ (accessed on 23 May 2025).

- BlueCraftAgro®. Available online: https://Bluecraftagro.Com/the-Impact-of-Starch-in-the-Textile-Industry/. (accessed on 23 May 2025).

- The Laundress New York. Available online: https://Www.Thelaundress.Com/Blogs/Tips/How-to-360-Wash-Finishing-Starching?Srsltid=AfmBOorw4d0iaezxiamVhVmsjqFnVzXjLWFWCBktJsMnETovqL1ep2oW/ (accessed on 23 May 2025).

- AGRANA. Available online: Https://Www.Agrana.Com/En/Products/All-Productportfolios/Starch-Portfolio/Products-for-Technical-Applications/Starches-for-the-Textiles-Industry (accessed on 23 May 2025).

- Dutta, D.; Sit, N. Comprehensive Review on Developments in Starch-Based Films along with Active Ingredients for Sustainable Food Packaging. Sustain Chem Pharm 2024, 39, 101534. [Google Scholar] [CrossRef]

- Sofía, B.; Juana, J.R.; Karina, F.S. Development of Antimicrobial Starch-Based Composite Films Reinforced with Soybean Expeller for Sustainable Active Packaging Applications. Food Sci Biotechnol 2024, 33, 2559–2569. [Google Scholar] [CrossRef]

- Chirila, L.; Danila, A. Hydrophobic and Oleophobic Finishes for Textiles. In Innovative and Emerging Technologies for Textile Dyeing and Finishing; : Rather, L.J, Haji, A., Shabbir, M. Eds, Eds.; Wiley: New Jersey, USA, 2021; pp. 325–372. [Google Scholar]

- Afonso, T.B.; Bonifácio-Lopes, T.; Costa, E.M.; Pintado, M.E. Phenolic Compounds from By-Products for Functional Textiles. Materials 2023, 16, 7248. [Google Scholar] [CrossRef] [PubMed]

- Lemes, A.C.; Egea, M.B.; Oliveira Filho, J.G. de; Gautério, G.V.; Ribeiro, B.D.; Coelho, M.A.Z. Biological Approaches for Extraction of Bioactive Compounds From Agro-Industrial By-Products: A Review. Front Bioeng Biotechnol 2022, 9. [Google Scholar] [CrossRef] [PubMed]

- Gomes, J.M.; Mariz, J.; Rodrigues, C.; Alves, A.L.; Moreira, J.; Vieira, B.; Silva, R.M.; Zille, A.; Silva, C.J. Bioactive Compounds from Banana Leaf Extracts: Influence of Extraction Methodologies and Their Integration into Knitted Hemp Fabrics. Materials 2024, 17, 5884. [Google Scholar] [CrossRef]

- Santos, J.; Pereira, J.; Escobar-Avello, D.; Ferreira, I.; Vieira, C.; Magalhães, F.D.; Martins, J.M.; Carvalho, L.H. Grape Canes (Vitis Vinifera L.) Applications on Packaging and Particleboard Industry: New Bioadhesive Based on Grape Extracts and Citric Acid. Polymers (Basel) 2022, 14, 1137. [Google Scholar] [CrossRef]

- Saraiva, B.R.; Anjo, F.A.; Vital, A.C.P.; Silva, L.H.M. da; Ogawa, C.Y.L.; Sato, F.; Coimbra, L.B.; Matumoto-Pintro, P.T. Waste from Brewing (Trub) as a Source of Protein for the Food Industry. Int J Food Sci Technol 2019, 54, 1247–1255. [Google Scholar] [CrossRef]

- Abdullah, A.H.D.; Chalimah, S.; Primadona, I.; Hanantyo, M.H.G. Physical and Chemical Properties of Corn, Cassava, and Potato Starchs. IOP Conf Ser Earth Environ Sci 2018, 160, 012003. [Google Scholar] [CrossRef]

- Lopez-Velazquez, M.A.; Santes, V.; Balmaseda, J.; Torres-Garcia, E. Pyrolysis of Orange Waste: A Thermo-Kinetic Study. J Anal Appl Pyrolysis 2013, 99, 170–177. [Google Scholar] [CrossRef]

- Pozo, C.; Rodríguez-Llamazares, S.; Bouza, R.; Barral, L.; Castaño, J.; Müller, N.; Restrepo, I. Study of the Structural Order of Native Starch Granules Using Combined FTIR and XRD Analysis. Journal of Polymer Research 2018, 25, 266. [Google Scholar] [CrossRef]

- Joseph L. Owades. Method for Treating the Skin with Extracts of Hops. US4148873A 1976.

- Kurzawa, M.; Wilczyńska, E.; Brudzyńska, P.; Sionkowska, A. Total Phenolic Content, Antioxidant Capacity and UV Radiation Protection Properties of Marigold (Calendula officinalis), Carrot (Daucus carota), Tomato (Solanum lycopersicum) and Hop (Humulus lupulus) Extracts. Cosmetics 2022, 9, 134. [Google Scholar] [CrossRef]

- Yarovaya, L.; Waranuch, N.; Wisuitiprot, W.; Khunkitti, W. Effect of Grape Seed Extract on Skin Fibroblasts Exposed to UVA Light and Its Photostability in Sunscreen Formulation. J Cosmet Dermatol 2021, 20, 1271–1282. [Google Scholar] [CrossRef]

- Codina-Torrella, I.; Rodero, L.; Almajano, M.P. Brewing By-Products as a Source of Natural Antioxidants for Food Preservation. Antioxidants 2021, 10, 1512. [Google Scholar] [CrossRef] [PubMed]

- Pereira, O.R.; Santos, G.; Sousa, M.J. Hop By-Products: Pharmacological Activities and Potential Application as Cosmetics. Cosmetics 2022, 9, 139. [Google Scholar] [CrossRef]

- Żuk, N.; Pasieczna-Patkowska, S.; Grabias-Blicharz, E.; Pizoń, M.; Flieger, J. Purification of Spent Hop Cone (Humulus Lupulus L.) Extract with Xanthohumol Using Mesoporous Superparamagnetic Iron Oxide Nanoparticles. Antioxidants 2025, 14, 314. [Google Scholar] [CrossRef]

- Petrón, M.J.; Andrés, A.I.; Esteban, G.; Timón, M.L. Study of Antioxidant Activity and Phenolic Compounds of Extracts Obtained from Different Craft Beer By-Products. J Cereal Sci 2021, 98, 103162. [Google Scholar] [CrossRef]

- Dorosh, O.; Rodrigues, F.; Delerue-Matos, C.; Moreira, M.M. Increasing the Added Value of Vine-Canes as a Sustainable Source of Phenolic Compounds: A Review. Science of The Total Environment 2022, 830, 154600. [Google Scholar] [CrossRef]

- Baroi, A.M.; Popitiu, M.; Fierascu, I.; Sărdărescu, I.-D.; Fierascu, R.C. Grapevine Wastes: A Rich Source of Antioxidants and Other Biologically Active Compounds. Antioxidants 2022, 11, 393. [Google Scholar] [CrossRef] [PubMed]

- Suzery, M.; Nudin, B.; Nurwahyu Bima, D.; Cahyono, B. Effects of Temperature and Heating Time on Degradation and Antioxidant Activity of Anthocyanin from Roselle Petals (Hibiscus Sabdariffa L.). International Journal of Science, Technology & Management 2020, 1, 288–238. [Google Scholar] [CrossRef]

- Ursu, M.S.; Aprodu, I.; Milea Ștefania, A.; Enachi, E.; Râpeanu, G.; Bahrim, G.E.; Stănciuc, N. Thermal Degradation Kinetics of Anthocyanins Extracted from Purple Maize Flour Extract and the Effect of Heating on Selected Biological Functionality. Foods 2020, 9, 1593. [Google Scholar] [CrossRef]

- Contreras, M. del M.; Romero-García, J.M.; López-Linares, J.C.; Romero, I.; Castro, E. Residues from Grapevine and Wine Production as Feedstock for a Biorefinery. Food and Bioproducts Processing 2022, 134, 56–79. [Google Scholar] [CrossRef]

- Wei, M.; Ma, T.; Ge, Q.; Li, C.; Zhang, K.; Fang, Y.; Sun, X. Challenges and Opportunities of Winter Vine Pruning for Global Grape and Wine Industries. J Clean Prod 2022, 380, 135086. [Google Scholar] [CrossRef]

- Čabalová, I.; Krilek, J.; Kačík, F.; Lagaňa, R.; Jurczyková, T. Valorization of Wood-Based Waste from Grapevine. Forests 2023, 14, 442. [Google Scholar] [CrossRef]

- Schrickel, F.; Bilge, D.; Pahl, R.; Rettberg, N. Valorization of Spent Hops from Dry Hopping for Bittering of Pilsener Style Beer. Journal of the American Society of Brewing Chemists 2025, 83, 17–29. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).