2.1. Definition of tilt and CaF2[110] and [111] crystal direction

CaF2 crystal is a cubic crystal, by definition of reciprocal space, the direction is always perpendicular to the plane, a universal relationship valid for all crystal systems (triclinic, monoclinic, orthorhombic, tetragonal, trigonal, hexagonal and cubic. CaF₂ single crystals were supplied by Beijing Keyi Hongyuan Co., Ltd using Modified Bridgman-Stockbarger Method

Due to the effect of symmetry extinction, CaF

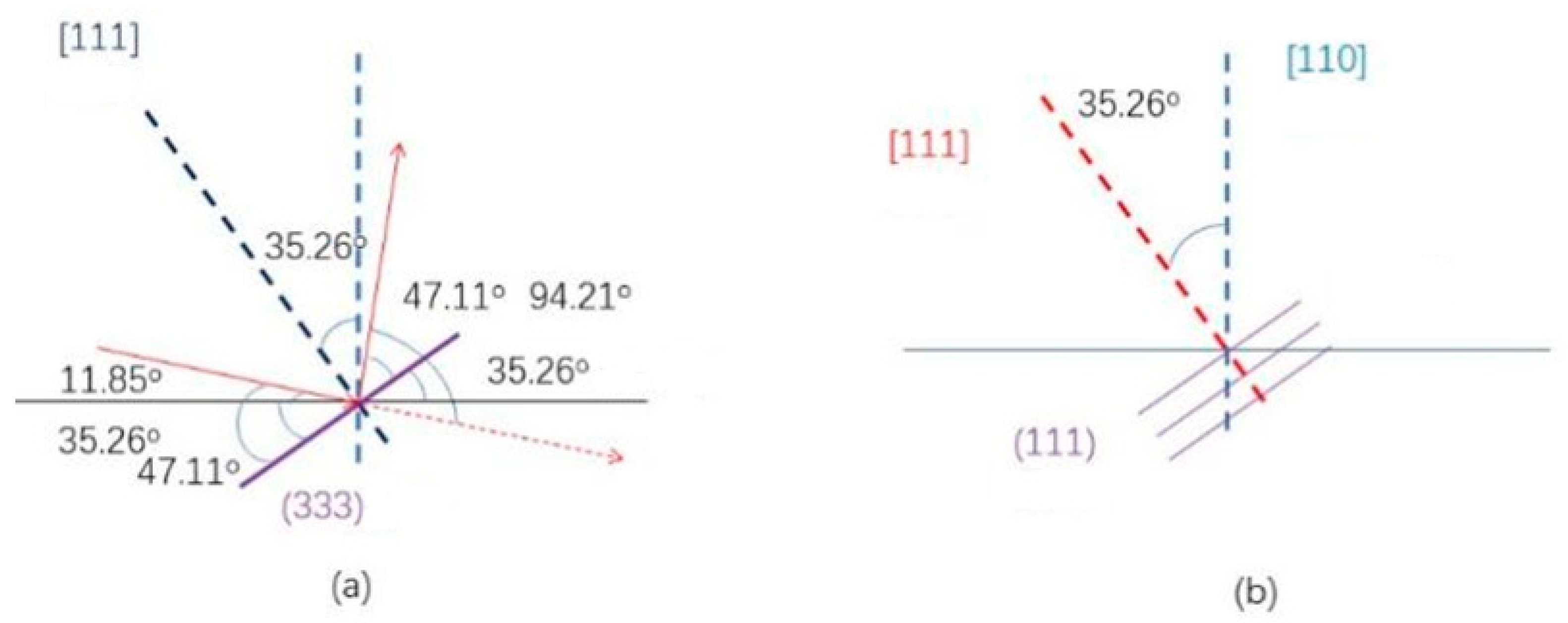

2 crystal only has diffraction peak corresponding to the (220) crystal surface without the corresponding (110) direction peak. In order to facilitate the elaboration of the direction and Angle between different crystal surfaces, it is necessary to define the single crystal lens rotation and rotation axis. First of all, the Cartesian coordinate system is used to determine the direction of the single crystal lens. As shown in

Figure 1,

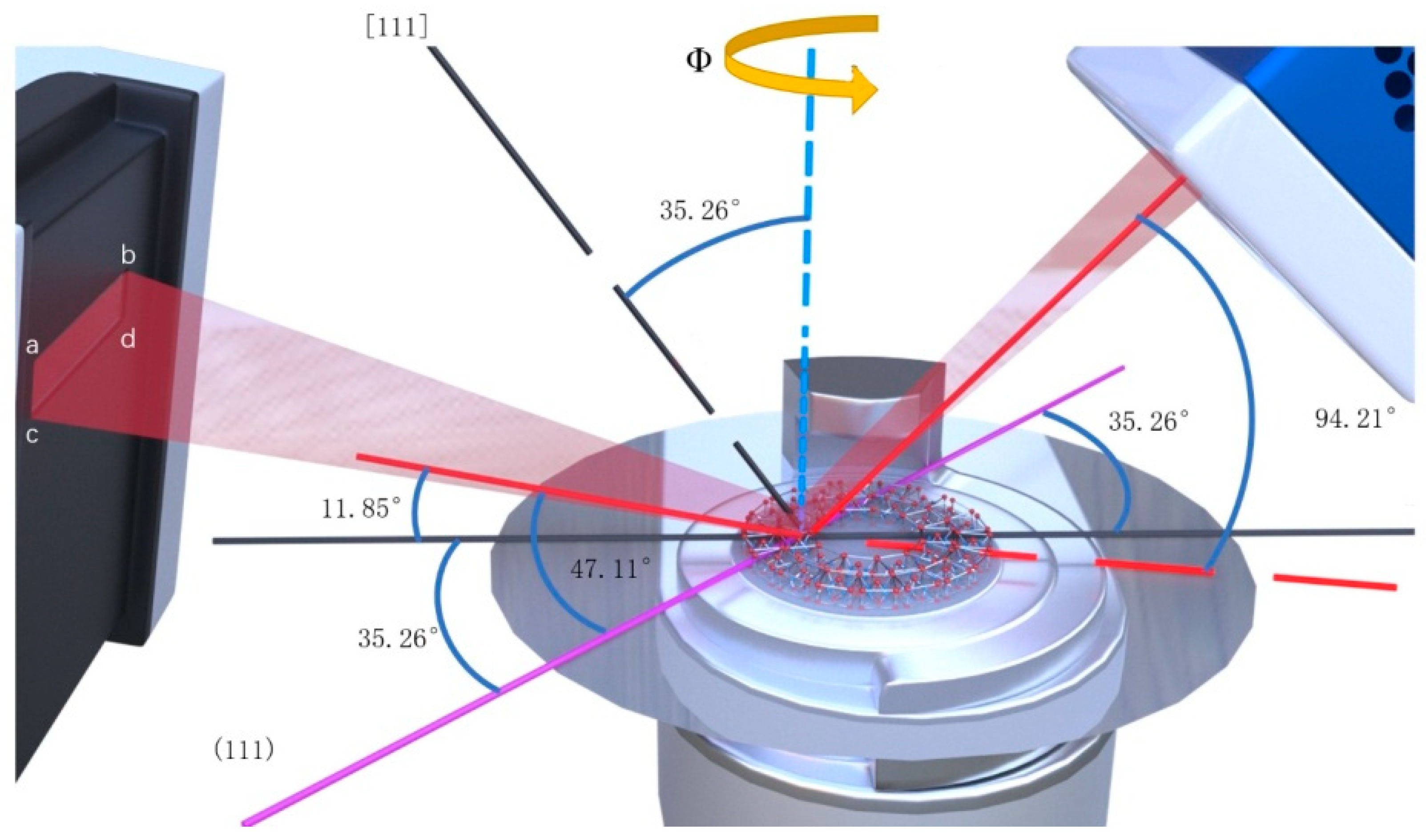

Figure 1(a) X-ray alignment configuration with a blank substrate, showing rotations ω (X-axis), χ (Y-axis), and φ (Z-axis).

Figure 2(b) Optical laser deflection setup with a plano-convex lens, illustrating beam deflection via crystal lattice interaction. Tilt angles ω (X-axis), χ (Y-axis), and φ (Z-axis) are defined for optical alignment. Axes X, Y, Z are labeled in both subfigures.

the central axis normal on the lens surface is the Z axis, the arrow in the lens marking the central line is the X axis direction, and the direction perpendicular to the X and Z axis is the Y axis direction. The reason for this marking is that in practical use, the laser enters the lens surface at a certain angle in the XZ plane, during the X-ray diffraction test, the X-ray also enters the lens surface at a specific angle inside the XZ plane.

It is worth noting that if the lens rotates, the ω and χ axes of the instrument are unchanged in the X-ray diffraction, because the diffraction plane is in the XOZ plane and the sum axis of the sample changes accordingly, which is because the crystal surface normal is following the Ф rotation. Therefore, attention should be paid to the axis of the diffractometer or the axis of the sample.

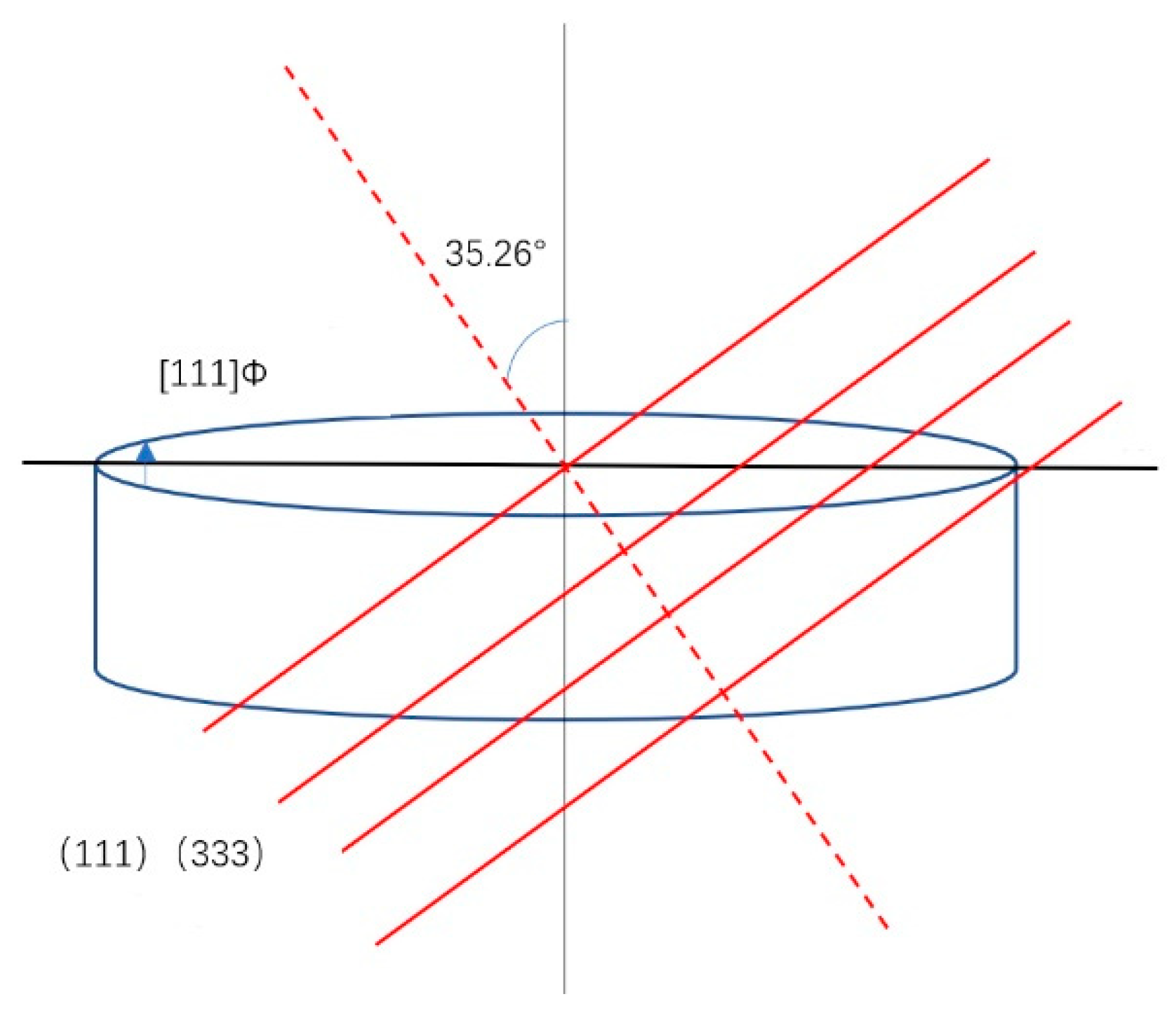

Figure 2 shows the single crystal lens, all CaF₂ crystals were cut with[111] as surface normal (Z-axis), with [220] (equivalent to [110]) as the primary axis. The [220] crystal direction is perpendicular to the sample surface, the angle between [111] and [110] is 35.26° (Note: [220] is the second harmonic of [110]).

Since the angle between the single crystal [111] and [220] of CaF2 is 35.26°, to achieve the angle between the [111] crystal direction and the mirror normal reaches the set value of 35.26 °± 1°, the CaF2 single crystal was cut 1° along the (220) crystal surface, cutting into one of the [111] axes and the mirror normal at 35.26°, and the Ф direction was determined as "↑". And in the process of cutting, it is difficult to accurately cut along the specified direction, that is to say, there is error in the cutting, accurate orientation is needed at this stage.

For the verification of the CaF2 and the cutting effect of the single crystal lens, X-ray diffraction is needed to determine the accuracy of the calibration "↑" position Ф, and CaF2[111], and the precise angle between the crystal direction and the mirror normal. Its principle is, when a beam of monochromatic X-ray is incident to crystal, as the crystal is composed of regular arrangement atoms, the atomic distance and the incident X-ray wavelength has the same order of magnitude, so it is easy to satisfy the x-ray interference, for diffraction in some special direction orientation.

As shown in

Figure 3, the angle between the lens blank surface and the (111) crystallographic plane (theoretical value: 35.26°) is equivalent to the angle between the crystal orientation and the normal vector of [111]. To ensure ω > 0° and prevent X-ray blockage, the θ angle must satisfy θ > 35.26°. According to the PDF card of CaF₂ (00-012-0248), the (111) plane corresponds to a diffraction peak at 2θ = 28.27°, meaning the angle between the incident X-ray and the crystal plane is 14.13° (= 28.27°/2). Since this value is below the critical angle of 35.26°, the (111) diffraction peak cannot be used to determine the [111] crystal direction.

Therefore, we turn to the analysis of higher-index planes: While the (333) plane's diffraction angle 2θ = 47.11° corresponds to θ = 23.56° (still <35.26°), the cumulative diffraction effect (nλ=2d sinθ) yields an effective diffraction angle: θeff = arcsin(3λ/2d₃₃₃) = 47.11° > 35.26°.Geometrically, this allows us to determine the equivalent [111] direction via the [333] direction (in cubic crystal systems, [333] ≡ [111]).

The diffraction peak corresponding to the (333) is required to test the position of the [111] crystal. The angle between the incident X-ray and the crystal surface of an ideal system without skew is 47.11°, and the Angle with the sample plane is 11.85°; the angle between the reflected X-ray and the crystal plane is 47.11°. First, put the CaF2 lens to be tested on the Smartlab 3D rotating table, and then conduct leveling, which ensures that the maximum number of the outgoing X-ray photon is in the leveling position.

Table 1.

Calcium fluoride XRD card information.

Table 1.

Calcium fluoride XRD card information.

| NO. |

2-Theta |

(hkl ) |

| 1 |

28.266 |

[111] |

| 2 |

32.760 |

[200] |

| 3 |

47.004 |

[220] |

| 4 |

55.763 |

[311] |

| 5 |

58.457 |

[222] |

| 6 |

68.672 |

[400] |

| 7 |

75.848 |

[331] |

| 8 |

78.181 |

[420] |

| 9 |

87.370 |

[422] |

| 10 |

94.214 |

[333] |

For the CaF

2 to be tested, the above characteristics of the single crystal lens are adopted to determin the lens [111] crystal axis calibration as the "↑" position. The detail of this method is shown in

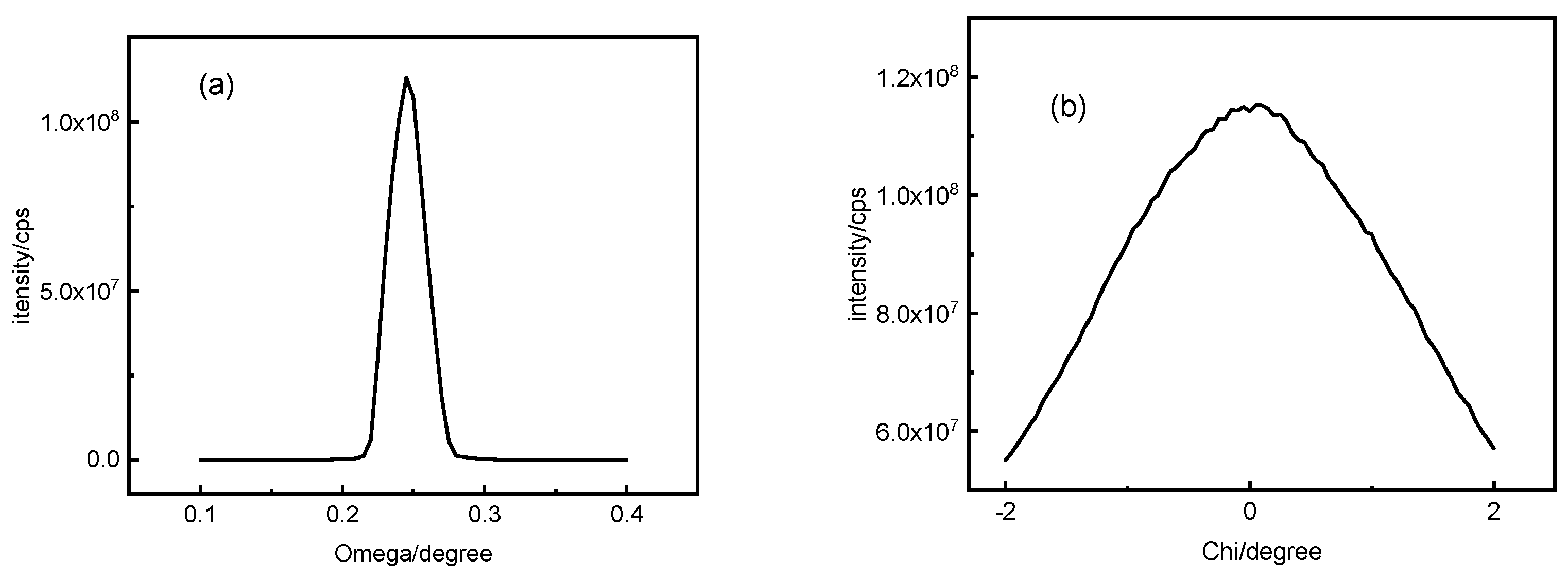

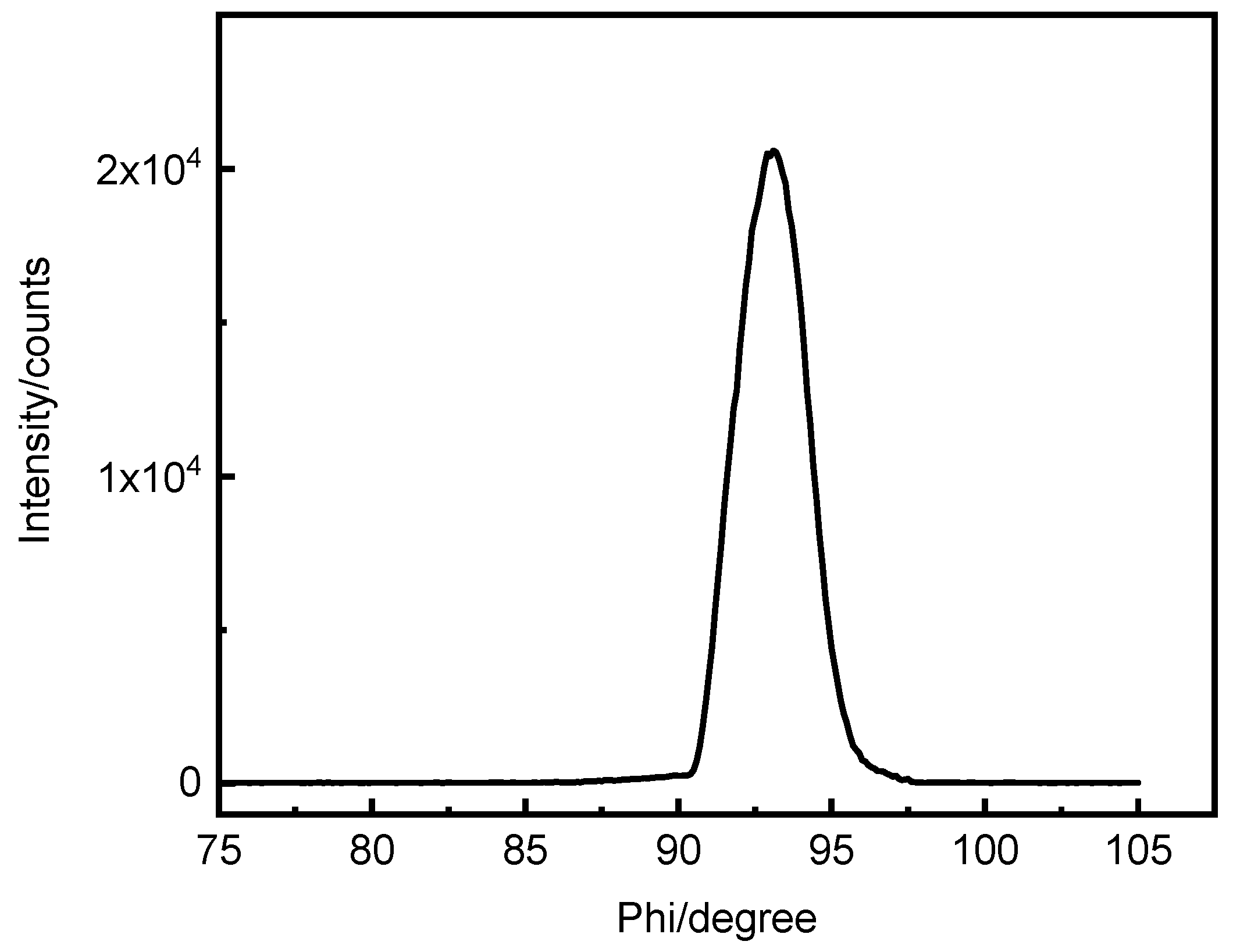

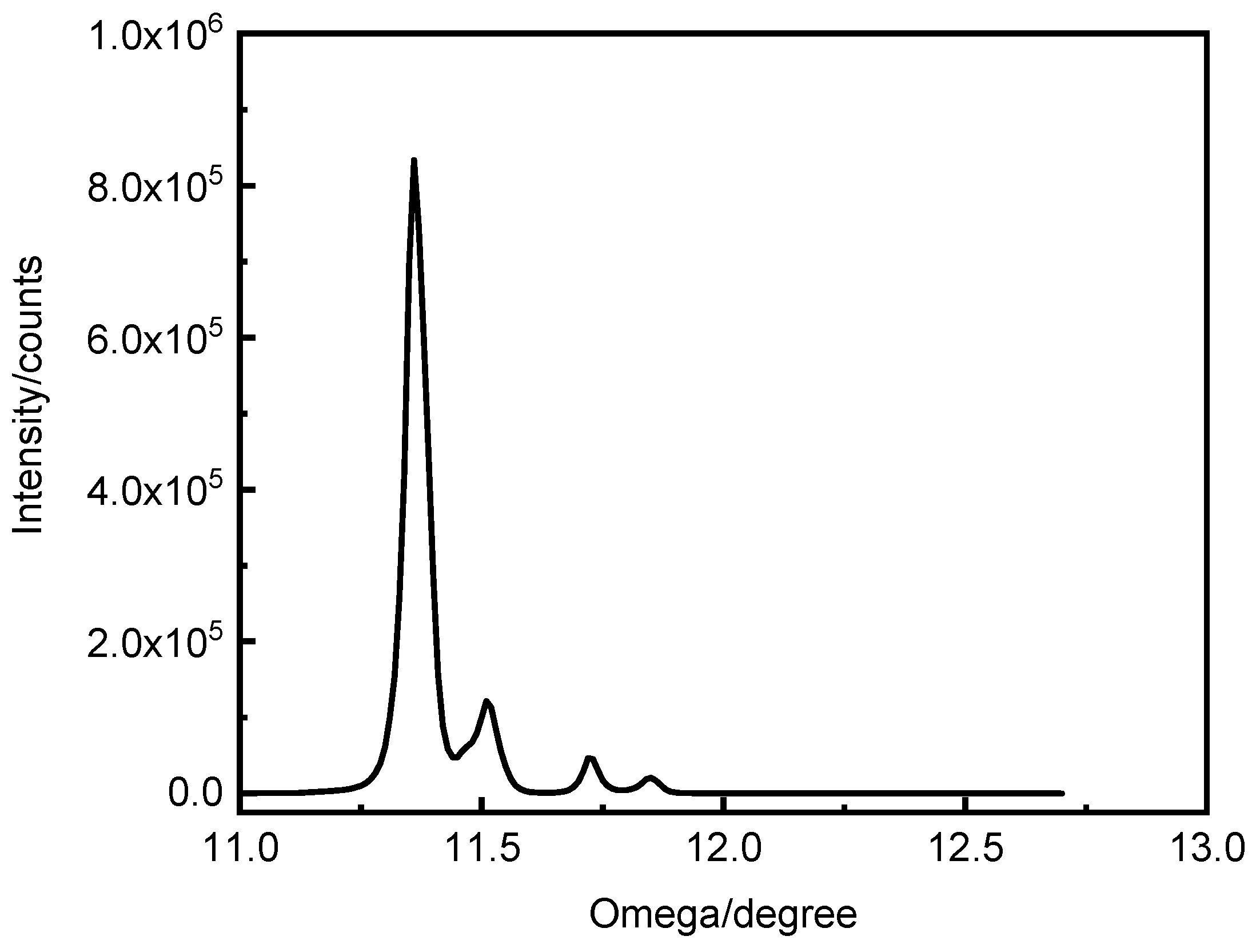

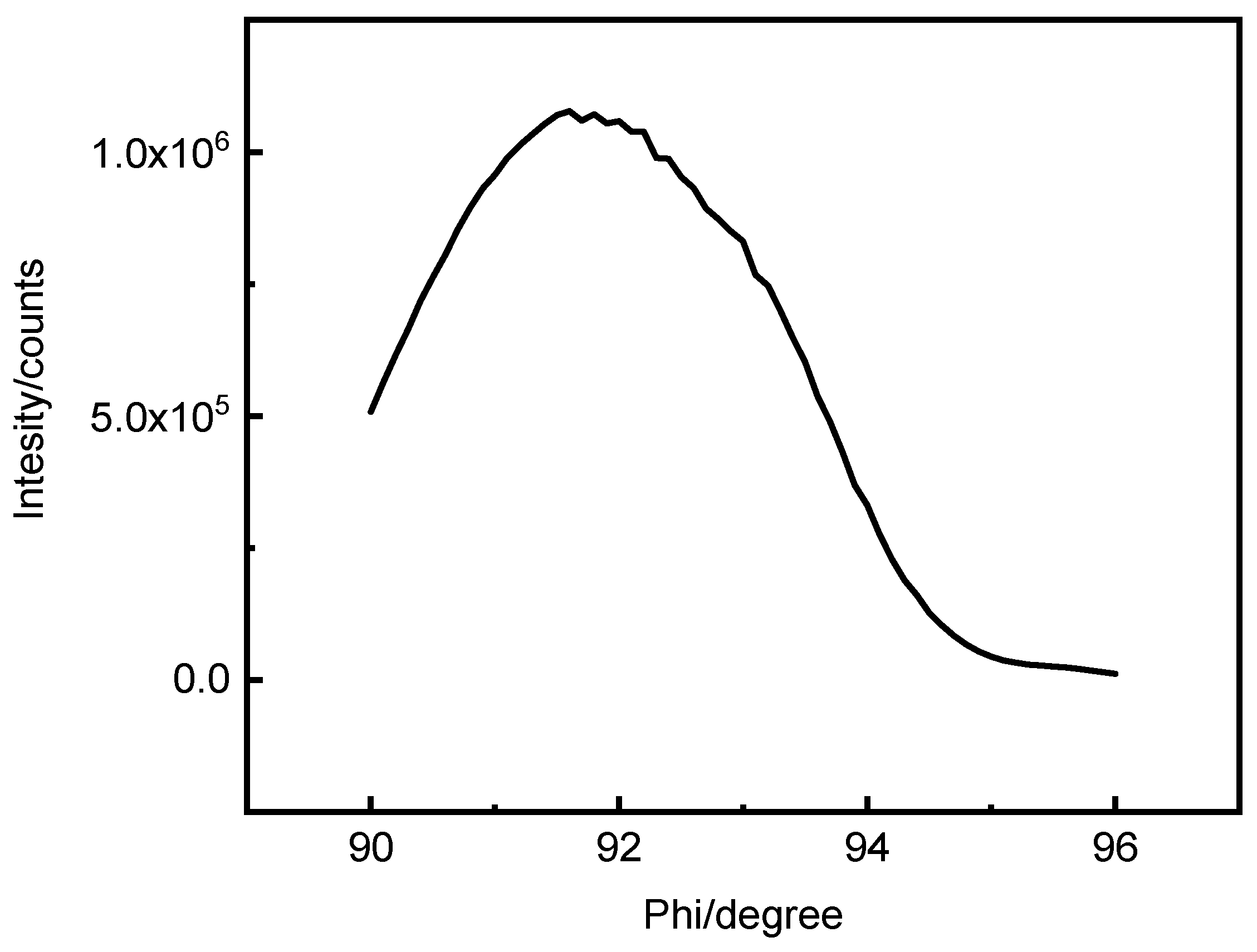

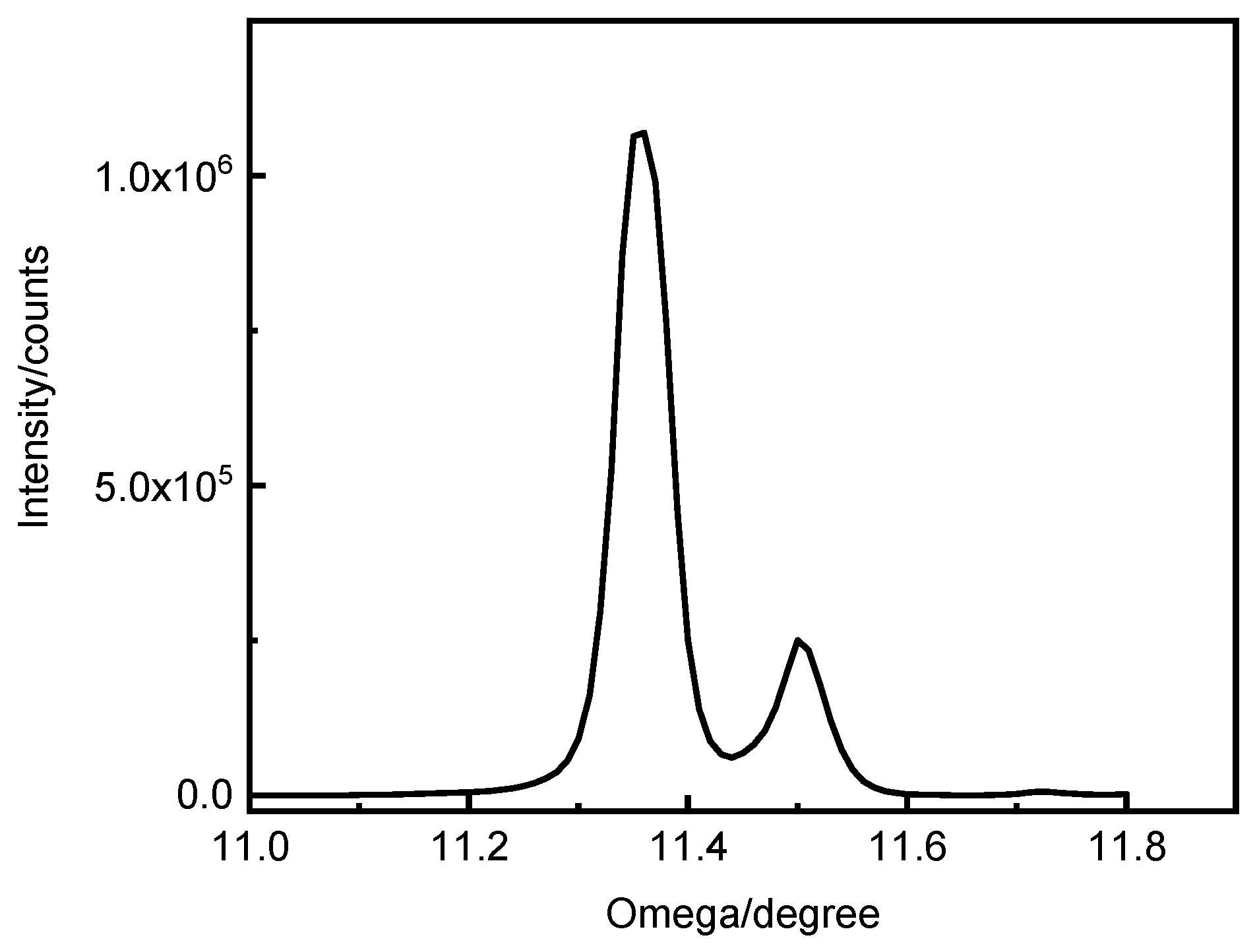

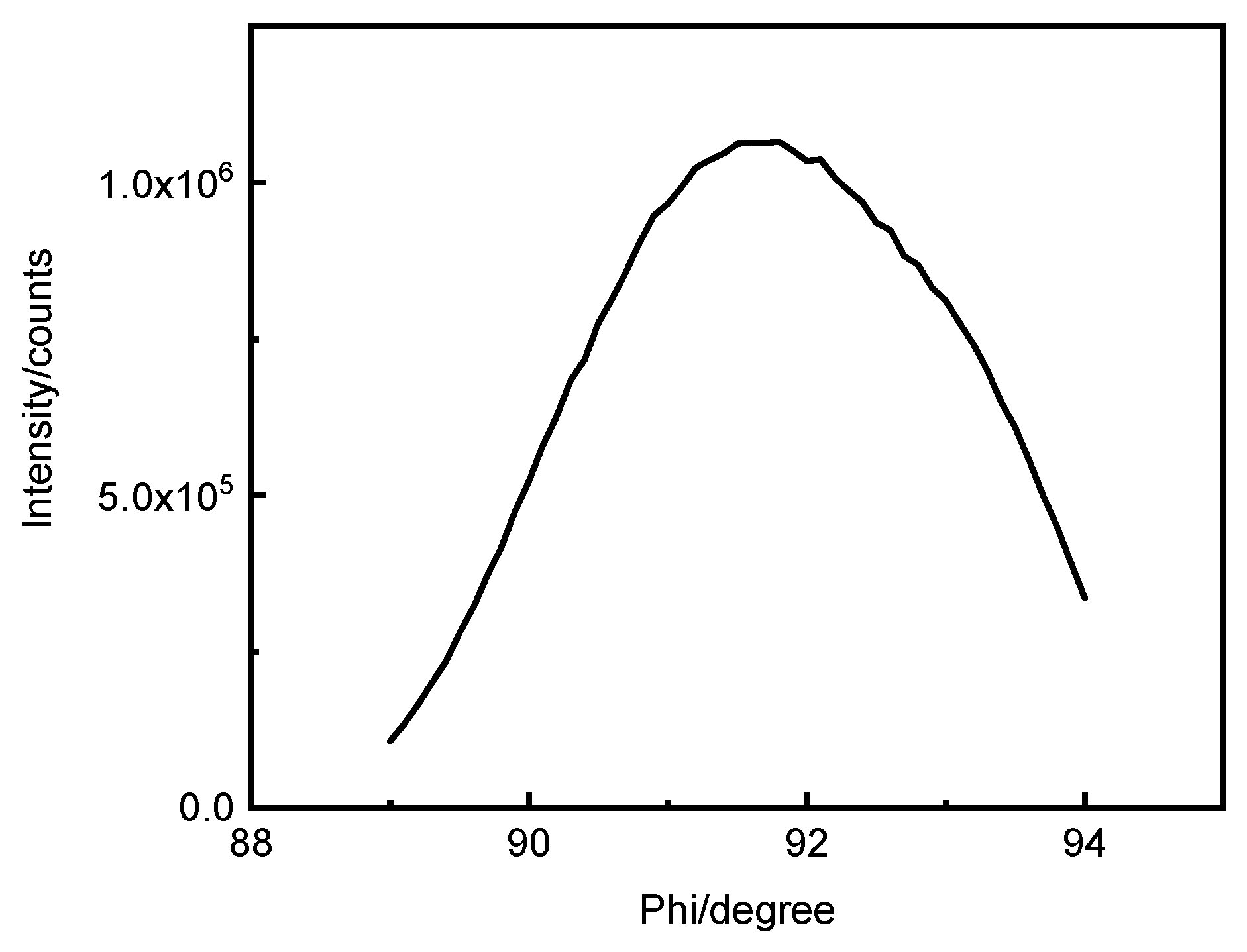

Figure 4. Since the [111] crystal direction passes through the diffraction plane of the XOZ during Ф scanning, at the 2θ position it can detect the diffraction line within the (111) plane. Although initially the ω/2θ is fixed according to the true value corresponding to the [111] axis without oblique cutting, since the X ray has a width, parts of the X-ray light that is not at the maximum light intensity can still satisfy the Bragg diffraction condition, the detector can still receive diffracted light, satisfying the crystal surface to inspection (111). However, not the strongest part of the X-ray light source corresponds to the diffraction light path of the crystal surface to be inspected (111). Therefore, it is not possible to determine the ω and Ф corresponding to the [111] axis. In addition, because the position of [111] crystal is determined by ω and Ф, we set a fixed ω, to find the Ф corresponding to the maximum light intensity, and then determine ω for fixed Ф; and finally satisfy the diffraction equation of the crystal surface of the (111) at the strongest outgoing X-ray direction, and obtaining the Ф and ω of the [111] crystal axis.

From the above idea, we designed the following method. First, check the CaF2 single crystal calibration, "↑" is directed at the X axis direction of the 3D rotating table, and calibrate the lens, letting the reflected light θ/2θ at 0.00°/0.00° and the direct through light at 0.25°/05° to ensure that the sample surface is parallel to the direct through light. This is also equivalent to zero point calibrating, ensuring the maximum emission diffraction intensity at 0.00°. Then ω/2 is fixed at 11.85°/94.21°, and Ф scanning is performed. Then we measure φ1 when assigning the maximum Ф value as the [111] position. Fixing φ at φ1, perform ω scanning by setting 2θ=94.21°, then obtain the ω1 value when achieving maximum at [111]. Again, setting ω at ω1, fixing 2θ at 94.21°, perform the φ scan, and assign the Ф as [111] at the maximum φ, and measure φ2. Finally, fixing φ at φ2, and set 2θ at 94.21°, to perform ω scan, and obtain ω2 at the maximum ω. Comparing ω1 and ω2, we will find ω1=ω2, that is, ω2 is the accurate ω value [111] axis corresponds, and Ф2 is the accurate Ф, which is also the Ф when 3D rotating table at the 0.00°. Knowing that the angle between incident X ray and the(111)crystal surface is 47.11o, by subtracting ω2 from 47.11o, we can obtain the angle between the(111)surface and the sample plane, that is also the angle between the [111] axis and the sample normal. Hereto we calibrated the φ2 and ω2, that is the orientation of CaF2 [111] direction.