1. Introduction

With the continuous advancement of oil and gas field extraction technologies, the importance of plugging agent materials in enhancing oil recovery [

1] and extending the lifespan of oil wells [

2] has become increasingly recognized. Polymer-based plugging agent systems are commonly used in oilfield operations to plug high permeability zones, adjust water injection profiles, and improve crude oil recovery [

3]. Typically, polymer monomers such as acrylamide (AM) [

4] and 2-acrylamido-2-methyl-1-propane sulfonic acid (AMPS) [

5] react with crosslinking agents like phenolic resin [

6] and N,N’-methylenebisacrylamide [

7] to form three dimensional network structures under specific conditions, thereby achieving effective plugging.

However, conventional plugging materials often suffer from poor stability and durability when exposed to extreme geological conditions, such as high temperatures (e.g., 130°C) and high salt concentrations (e.g., 20×10

4 mg·L

-1). [

8] These limitations restrict their range of applications and challenge long-term operational efficiency. [

9] To address these challenges, recent efforts have focused on modifying chemical structures, [

10] introducing nanoparticle composite materials [

11], and incorporating natural macromolecules with superior biocompatibility [

12] aiming to enhance the comprehensive performance of plugging agent materials, especially exploring advanced materials that can adapt to complex underground environments and possess special functionalities [

13]

In response to the aforementioned issues of mismatched crosslinking agents and shear failure of polymer gels under harsh conditions, molecular dynamics simulations have been employed to systematically investigate the crosslinking effects of three agents (EI, PF, and MBA) on AM monomer and AMPS copolymer systems, as well as their stability under high temperature (130°C) and high salt conditions (20 × 104 mg·L-1). This study aims to not only improve the stability of polymer gels under extreme conditions but also enhance their self-healing and mechanical properties for more efficient and durable plugging applications.

Furthermore, to further improve the application potential of these materials, a dynamic crosslinking network based on carboxymethyl cellulose (CMC) and magnetic iron oxide (Fe3O4) nanoparticles was introduced. The integration of this network with a PF-crosslinked polymer system formed a double-network gel, significantly improving the self-healing capabilities of the material. This approach has promising implications for developing advanced, high-performance, self-healing plugging agents that can adapt to complex and demanding underground environments.

2. Materials and Methods

Reagents and Instruments:

Polyacrylamide (PAM), Purchased from McLean, 99.0%. 2-acryloyl Amino-2-methyl-1-propanesulfonic acid (AMPS), McLean, 98%.Phenolic resin (PF), McLean, BR. Sodium carboxymethyl cellulose (CMC), McLean, viscosity 600-3000 mpa. s. FeCl2·2H2O, McLean, AR. Ammonium persulfate, McLean, AR.

Methods:

Prepare a certain volume of 0.1M FeCl2·4H2O solution and an equal volume of 0.02g/mL CMC aqueous solution. Stir the FeCl2 solution while adding CMC solution, adjust the pH to 11, and obtain CMC @ Fe3O4 dispersion. Weigh 7wt% AM, 3wt% AMPS, 3wt% PF, and 1wt% ammonium persulfate and add them to the above dispersion to obtain the precursor solution. Place the precursor solution in a 140℃ oven for high-temperature curing to obtain PAA@PF / CMC@Fe3O4 Blocking agent.

Characterization:

SEM: support PAAA@PF / CMC@Fe3O4 Freeze dry the blocking agent, spray gold for 15 minutes, and characterize its microstructure under scanning electron microscopy.

FTIR: Freeze dry the blocking agent, grind it, and use infrared spectroscopy for chemical characterization.

Rheological characterization: The plugging agent was tested using an Anton Paar rheometer to obtain its storage modulus and loss modulus, and its self-healing properties were tested.

TG: Use a thermal analyzer to test the plugging agent from room temperature to 300 degrees Celsius, obtain the weight loss curve, and evaluate the temperature resistance performance.

3. Results

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

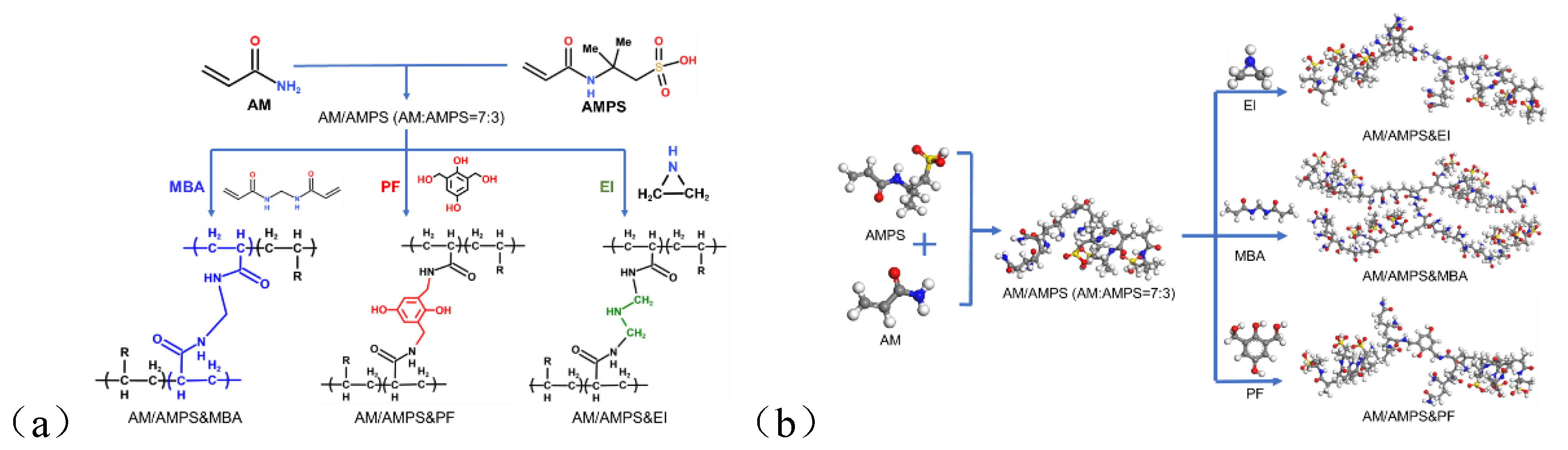

3.1. Molecular Simulation Results

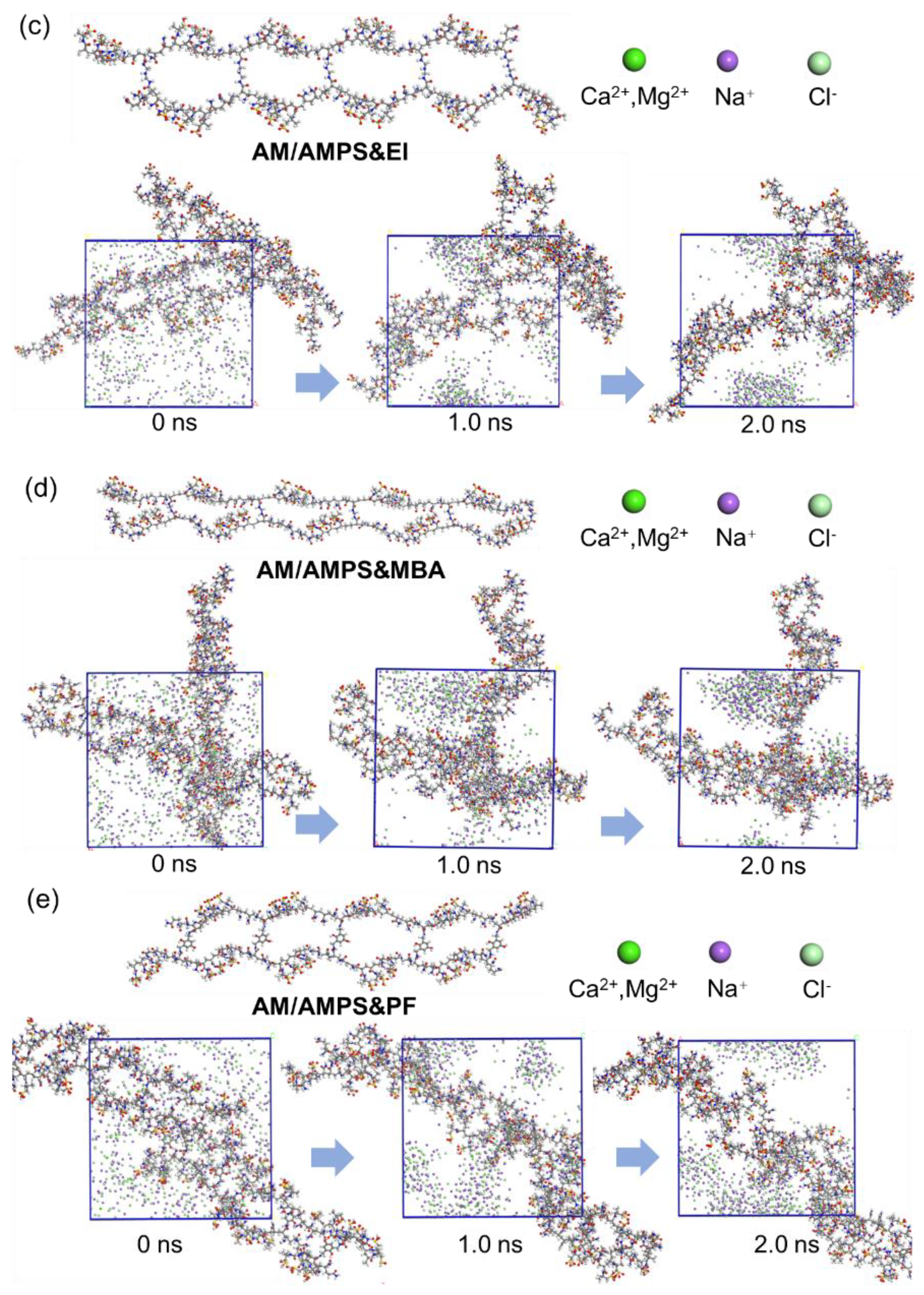

In this study, we selected AM and AMPS as the primary constituent units of the polymer, forming AM/AMPS polymer chains as the main agent. To enhance the strength, stability, heat resistance, and chemical corrosion resistance of the polymer, we introduced various crosslinking agents, specifically MBA, PF, and EI. As shown in

Figure 1, the molecular dynamics models of AM/AMPS binary polymers with different crosslinking agents were compared to identify the optimal AM/AMPS&X crosslinked polymer, which would be further investigated in subsequent experiments. To assess the stability of the AM/AMPS&X crosslinked polymers, we constructed a full atomic molecular model for dynamic simulation. This simulation was designed to mimic the high-temperature (140°C), high-salt (20 × 10⁴ mg/L), and high-calcium/magnesium-ion (1.0 × 10⁴ mg/L) environments, which are relevant to real-world applications. Additionally, the quantities of other molecules, such as H

2O, Ca²⁺, Mg²⁺, Na⁺, and Cl⁻, were carefully determined to ensure the accuracy of the system. As shown in

Figure 1, the molecular structures before and after simulation are represented at 0 ns and 2 ns, respectively.

The simulation results revealed that, compared to the AM/AMPS&EI system, the structural changes in the AM/AMPS&MBA and AM/AMPS&PF polymers were minimal, and no significant molecular curling was observed. This suggests that MBA and PF provide stronger crosslinking effects, which contribute to greater stability of the molecular structure. However, structural changes alone are insufficient to assess the stability of crosslinked polymers under high-temperature and high-salt conditions. It is generally accepted that a lower overall energy corresponds to a more stable system. Therefore, we further analyzed energy parameters, including electrostatic energy, van der Waals energy, total potential energy, and total kinetic energy, to compare the stability of the different systems during the simulation.

As depicted in

Figure 2, the differences in van der Waals energy and total kinetic energy between the three systems were not significant. However, a distinct distinction was observed in the electrostatic energy and total potential energy, particularly in the AM/AMPS&PF crosslinked polymer system, where the energy was consistently the lowest. The PF system, with its multiple phenolic hydroxyl groups capable of forming hydrogen bonds, and its rigid benzene ring structure, demonstrated exceptional stability, which was less affected by high-temperature and high-salt conditions. Based on these findings, it can be concluded that the AM/AMPS&PF crosslinked polymer system exhibits superior stability under harsh environmental conditions.

In summary, molecular simulations were employed to investigate the crosslinking effects of three crosslinking agents (EI, PF, and MBA) on the AM and AMPS monomers. Quantitative calculations of electrostatic energy, van der Waals force energy, total potential energy, and total kinetic energy were performed to evaluate the stability of each system. The results indicated that the PF system, which demonstrated the lowest energy and best stability, outperformed the other systems under high-temperature and high-salt environments.

Furthermore, to enhance the performance of the polymer, CMC@Fe₃O₄ was incorporated into the system. This modification introduced multiple hydrogen bonding and metal coordination bonds, allowing for dynamic crosslinking of the network. As a result, the PAA@PF/CMC@Fe₃O₄ system exhibited self-healing properties, reducing the fracturing behavior of the plugging agent under shear force. This innovation improves both the service life and the plugging efficiency of the agent, providing a promising theoretical and practical approach for developing advanced plugging agents that can significantly save time, labor, and resources.

4. Discussion

Figure 4.

FTIR and Rheological characterization.

Figure 4.

FTIR and Rheological characterization.

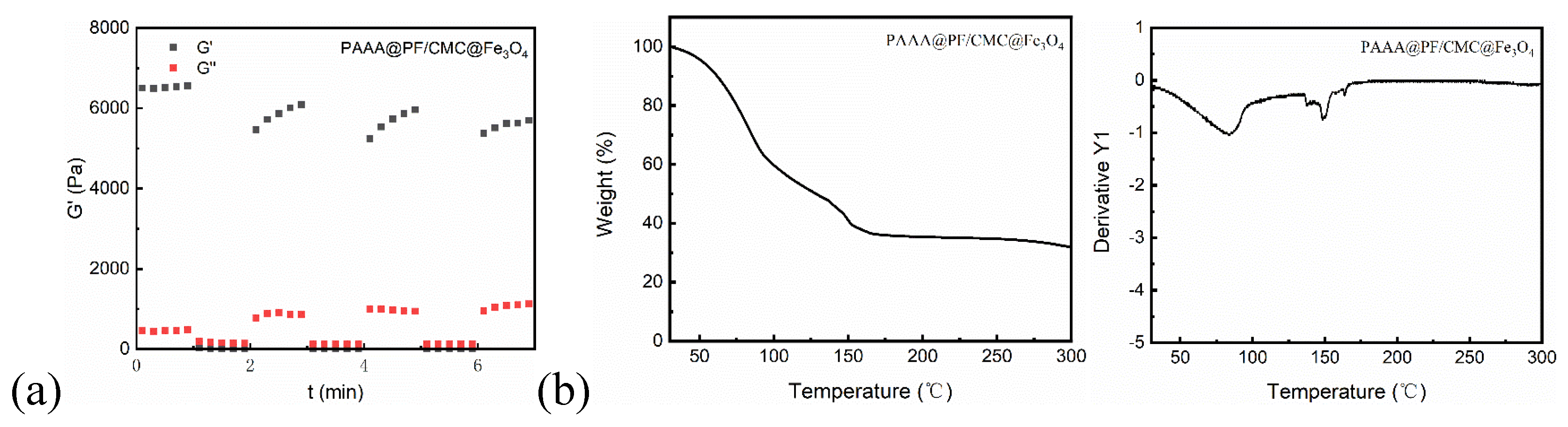

Figure 5.

(a) Stage time scanning. (b)TG and DTG.

Figure 5.

(a) Stage time scanning. (b)TG and DTG.

Figure 6.

Self-healing property of PAA@PF/CMC@Fe3O4.

Figure 6.

Self-healing property of PAA@PF/CMC@Fe3O4.

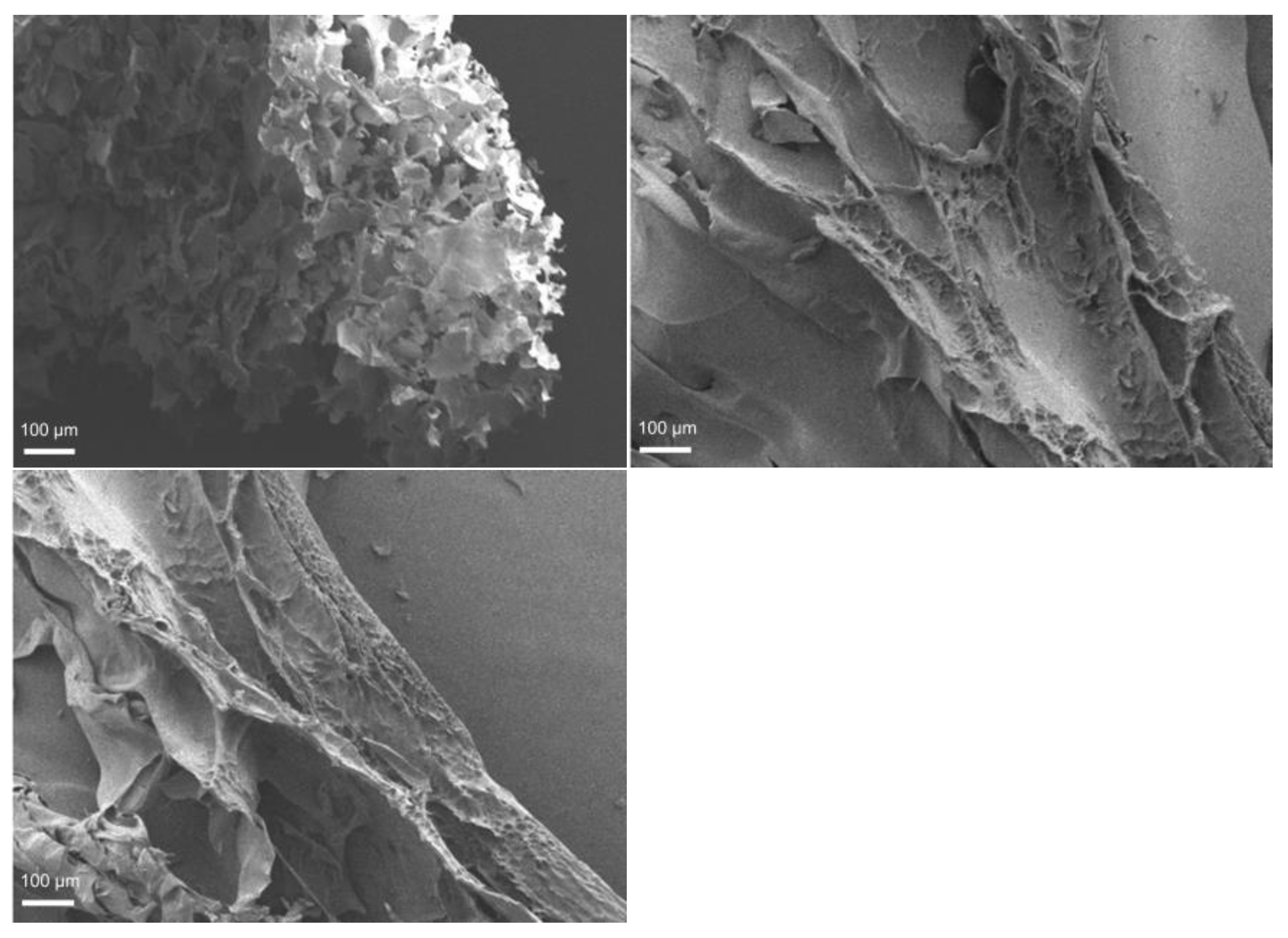

4.1. SEM

The microstructure of PAA@PF/CMC@Fe

3O

4 was characterized using scanning electron microscopy (SEM), as shown in

Figure 2a. The SEM images reveal that the sample exhibits a porous structure with uniformly distributed pores. Under the crosslinking effect of PF, the sample surface displays a lamellar structure. This lamellar structure not only enhances the mechanical strength of the material but also provides improved thermal stability and salt resistance. Furthermore, the incorporation of CMC@Fe

3O

4 further optimizes the microstructure, beneficial for the material to self-heal through a dynamic crosslinking network after mechanical damage. The SEM images also show the presence of small granular particles on the sample surface, which are likely aggregates of Fe

3O

4 nanoparticles. These nanoparticles not only enhance the mechanical properties of the material but also impart magnetic responsiveness, broadening its potential applications.

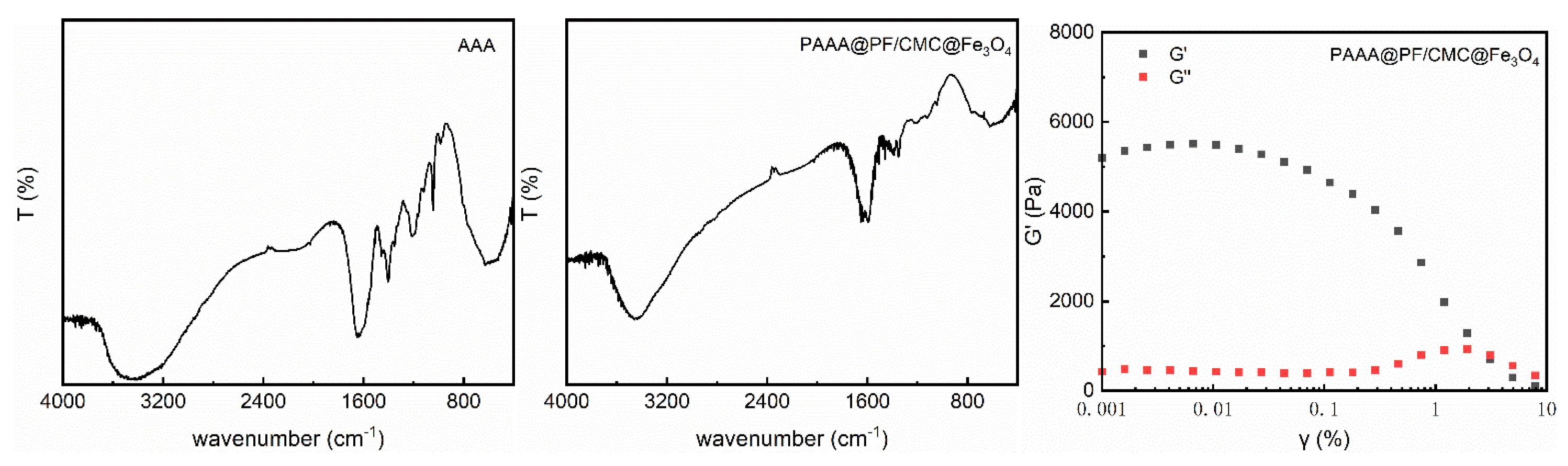

4.2. FTIR

The FTIR of the prepared PAA@PF/CMC@Fe

3O

4 was characterized as shown in

Figure 2b-c. The FTIR analysis confirms the crosslinking reaction and the formation of a stable gel structure. Under the crosslinking effect of PF, the absorption peak of the amide II band (1550-1500 cm

-1) significantly decreases, indicating that the -NH

2 groups participated in the dehydration condensation reaction, forming a crosslinked network. Additionally, the characteristic peaks of CMC are observed in the fingerprint region (1600-1200 cm

-1), confirming the successful incorporation of CMC@Fe

3O

4 into the system. The introduction of CMC not only enhances the dynamic crosslinking ability of the material but also provides self-healing properties. A broad peak around 3400 cm

-1 is attributed to the stretching vibrations of -OH and -NH groups, indicating the presence of abundant hydroxyl and amino groups in the sample. These groups provide numerous hydrogen bonding sites, further enhancing the stability and self-healing capability of the material. Moreover, the peak near 1650 cm

-1 corresponds to the stretching vibration of C=O, confirming the polymerization of AM monomers.

4.3. Rheological Characterization

The rheological of PAA@PF/CMC@Fe

3O

4 was systematically investigated through strain sweep and step frequency sweep tests, as shown in

Figure 2d-e. Under low shear strain (0.001-0.1 %), the sample exhibits typical linear viscoelastic behavior, with the storage modulus (G’) and loss modulus (G’’) remaining almost constant. This indicates that the material maintains a stable network structure under low strain. As the strain increases to a critical value (yield point), the sample enters a nonlinear transition region, where G’ and G’’ begin to decrease significantly, indicating the onset of structural breakdown. When the strain further increases (>1 %), the sample enters a fully flowing state, with G’ approaching zero and G’’ dominating, suggesting that the material primarily exhibits viscous flow. This behavior demonstrates that the material possesses good deformability under high strain while maintaining stable solid-like properties at low strain. In the step frequency sweep test, the sample exhibits remarkable self-healing behavior. After applying high strain to disrupt the material structure, reducing the strain to the initial level allows G’ to recover to approximately 83 % of its original value. This indicates that the material has excellent self-healing properties and can quickly restore its mechanical performance after external damage. This self-healing behavior is primarily attributed to the dynamic crosslinking network introduced by CMC@Fe

3O

4, including the reversibility of hydrogen bonds and metal coordination bonds. The rheological results demonstrate that the PAA@PF/CMC@Fe

3O

4 possesses a stable network structure under low strain, while exhibiting good deformability and self-healing properties under high strain. This unique rheological behavior makes it highly promising for applications in reservoir environments.

4.4. Thermal Stability

The thermal stability of the PAA@PF/CMC@Fe

3O

4 plugging agent was investigated using thermogravimetric analysis (TG) and derivative thermogravimetry (DTG), as shown in

Figure 2f-g. Within the temperature range of room temperature to 300℃, the mass loss of the sample occurs in two main stages. First stage was around 80℃, showing a mass loss of approximately 40 %, primarily attributed to the evaporation of adsorbed water. Second stage was around 150℃, showing a significant mass loss which corresponds to the breakdown of polymer chains and the decomposition of the crosslinked network. The DTG curve further reveals the thermal decomposition behavior of the sample at different temperatures. Two distinct peaks are observed at ~80℃ and ~150℃, corresponding to the two mass loss stages in the TG curve. The peak temperature in the DTG curve indicates that the primary thermal decomposition of the material occurs around 150℃, which is closely related to the thermal stability of the PF crosslinking agent.

5. Conclusions

In conclusion, the molecular simulation study has provided valuable insights into the stability and performance of AM/AMPS-based crosslinked polymers in high-temperature and high-salt environments. Among the various crosslinking agents tested, PF demonstrated the best overall stability, making it a promising candidate for future polymer systems in harsh conditions. The integration of CMC@Fe3O4 further enhances the self-healing performance of the polymer, suggesting potential for improved service life and plugging effectiveness. This study opens new avenues for the development of more efficient and durable polymer-based materials for industrial applications.

Author Contributions

J.F. and P.X. contributed equally. J.F.—conducted research, article text writing, P.X.—conducted research, literature selection, statistical data processing, illustrative material preparing, article text writing; L.H.—conducted research, literature selection, statistical data processing, illustrative material preparing, article text writing; Y.L.—conducted research, Z.Y.—conducted research; D.W.—conducted research, literature selection.

Funding

This work was supported by the Tianshan Talents Engineering Technology R&D Team Program of Xinjiang Uygur Autonomous Region (Grant No.: 2022TSYCGC0003). This work was supported by the Postdoctoral Program of Sinopec Northwest Oilfield Company(Grant No.: KJ202335)and Tianshan Talents Engineering Technology R&D Team Program of Xinjiang Uygur Autonomous Region (Grant No.: 2022TSYCGC0003).

Data Availability Statement

Data are available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lili Yang, Yunpeng Wu, Guancheng Jiang, Chunlin Xie, Yongwei Zhang. Lost Circulation Material and Technology Research of Self-healing Hydrogel. Drilling Fluid & Completion Fluid,2023,40(1): 47-53. [CrossRef]

- Zhuyang Jiang, Huan Yang, Zhenning Ji, Qianhong Pan, Zhi Ye, Xiaorong Yu, Gaoshen Su, Yancheng Zheng. Lignocellulosic hydrogel for profile control and water plugging in high salt reservoirs. Journal of Molecular Liquids, 2024, 401, 124707. [CrossRef]

- Wei Ma, Yikun Li, Pingde Liu, Zhichang Liu, and Tao Song. Progress of Research into Preformed Particle Gels for Profile Control and Water Shutoff Techniques. Gels, 2024, 10, 372. [CrossRef]

- Yuhai Zhou, Zhuo Luo, Min Xu, Tianyu Zhao, Xiao Ma, Shuai Zhou, Bianying Wen, and Dongzhi Yang. Preparation and Properties of Temperature-Sensitive P(NIPAM-AM) Nano–Microspheres in Enhanced Oil Recovery. Energy & Fuels, 2023, 37(1), 204-213. [CrossRef]

- Zhifeng Luo, Jianbin Li, Nanlin Zhang, Haoran Fu, Jiahong Huang, Qiang Zhang, Huan Li, and Hao Sun. 2023. Performance Evaluation and Field Verification of a Selective Water Plugging Agent. Journal of Dispersion Science and Technology, 2023, 45(12): 2302-14. [CrossRef]

- Qinzhe Li, Yu Zhang, Lizhen Zhou, Peng Lei, Jiangyan Liu, Fuli Wang, Xueyun Xiang, Hang Wu, Wen Wang, and Fuhui Wang. Preparation and High-Temperature Resistance Properties of Phenolic Resin/Phosphate Hybrid Coatings. Materials, 2024, 17, 2081. [CrossRef]

- Xianwen Song, Gang Lu, Jingxing Wang, Jun Zheng, Shanying Sui, Qiang Li, and Yi Zhang. 2022. Molecular Dynamics-Assisted Design of High Temperature-Resistant Polyacrylamide/Poloxamer Interpenetrating Network Hydrogels. Molecules, 2022, 27, 5326. [CrossRef]

- Yuanwei Sun, Jinsheng Sun, Li Li, Kaihe Lv, Xianfa Zhang, Zonglun Wang, Zhiwen Dai, Zhe Xu, Taifeng Zhang, and Jingping Liu. Development of High-Temperature and High-Mineralization-Resistant Adaptive Plugging Agent and Its Performance Evaluation. Energy & Fuels, 2023, 37(13), 8999-9010. [CrossRef]

- Siyu Lu, Qiwei Bo, Guang Zhao, Azizullah Shaikh, Caili Dai. Recent advances in enhanced polymer gels for profile control and water shutoff: A review. Frontiers in Chemistry, 2023, 11, 2296-2646. [CrossRef]

- Yuanyuan Bai, Wanfen Pu, Xing Jin, Chao Shen, Huilin Ren. Review of the micro and Macro mechanisms of gel-based plugging agents for enhancing oil recovery of unconventional water flooding oil reservoirs. Journal of Molecular Liquids, 2024, 399, 124318. [CrossRef]

- Jinke Zhang, Lipeng Gou, Man Zhang, Guo-Cheng Wang, Jinfeng Yang, Juan Du, Pingli Liu. A Self-healing Gel for Water Shutoff and Water Control in Oil Wel. Chinese Journal of Applied Chemistry, 2021, 38(7): 807-815.

- Shao Geng, Weifeng Zhang, Langman Luo, Limei Fu, Hongfang Chen, Yangbing Wen. Study on Lignin Hydrogel Reinforced by Dialdehyde-modified Cellulose Nanofibril and Its Temperature and Salt Tolerance. Transactions of China pulp and paper, 2022, 37(1):29-35.

- Shaofei Lei, Jinsheng Sun, Kaihe Lv, Qitao Zhang, and Jingbin Yang. Types and Performances of Polymer Gels for Oil-Gas Drilling and Production: A Review. Gels 2022, 8, 386. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).