1. Introduction

High purity quartz refers to the content of SiO

2 in more than 99.9 % after purification with quartz as raw material, and an impurity content that meets industry standards [

1]. Due to its excellent performance, high-purity quartz is widely used in photovoltaics and semiconductors, and is an emerging strategic non-metallic mineral resource. With the rapid development of photovoltaics, semiconductors, and other advanced technology, quartz (especially high-purity quartz) is playing an increasingly important role in national strategic industries. However, natural high-quality quartz deposits are gradually depleting, resulting in shortages.

Research shows pegmatitic quartz deposits have become targets for high-purity quartz resources due to their large scale, low impurity, stable quality, and low fluid inclusion content [

2]. 4N8 grade and above high-purity quartz raw materials have currently only been found in the muscovite granite pegmatite resources of the Spruce Pine area in North Carolina in the United States. In China, granite pegmatite deposits are mainly distributed in the Henan and Xinjiang regions [

3]. The mineral composition of granite pegmatite is complex, and the size of its quartz particles varies. Therefore, understanding and optimizing the purification process of quartz sand is of great significance.

From quartz ore to quartz sand, the process primarily involves crushing and grinding. The primary focus of ore grinding is to liberate minerals and decrease their particle size, which requires a substantial amount of energy [

4]. A large fraction of total energy consumption is attributed to ore grinding operations, accounting for approximately 40 ~ 50% of the overall energy utilized and equating to roughly 2% of country’s gross electricity generation [

5]. In contrast, the portion of energy effectively utilized in this procedure is small, ranging from about 3 ~ 8% of the initial energy input [

6]. Therefore, understanding the characteristics of ore breakage is crucial for optimizing ore grinding and minimizing energy consumption.

In the grinding process, the ore particles are broken or comminution by the impact, extrusion, shear and other forces generated by the grinding medium ( such as steel balls, steel rods ). Various studies have investigated the fragmentation behaviors of particles [

7]. Breakage within a group setting becomes intricate due to the exchange of energy among the particles. Moreover, multiple factors come into play during the breakage of a cluster of particles. For example, the thickness of the layer and the size of particles within the particle cluster significantly influence the energy required for the fragmentation process [

8,

9].

Given the significant impact of various fracture patterns on the release of minerals, utilization of energy is adjusted and managed based on the physicochemical characteristics of minerals. Wills et al. assessed how the rate of crack propagation influences the occurrence of intergranular and transgranular fractures under applied load conditions, concluding that low energy consumption and a reduced strain rate could enhance the former [

10]. To a certain extent, this led to increased liberation of magnetite. Similarly, Bradt et al. observed a size dependency in particle breakage during a loading experiment and determined the critical particle size for intergranular fracturing in ore particles [

11]. Additionally, a novel approach was devised by Leißner et al. to distinguish between intergranular and transgranular cracks on a mineral’s surface [

12]. This study facilitated the quantification of exposed cracks both before and after particle fracture, leveraging the metric of specific surface area.

Exploring the correlation between energy and mineral liberation should aid in developing a model for particle breakage. Nevertheless, the complexity of mineral liberation has hindered the establishment of a clear connection between energy input and mineral liberation. Garcia et al. developed a system to measure the area of mineral interfaces using X-CT reconstruction images, which enabled the computation of the ratio of areas occupied by various mineral interfaces, both before and after particle breakage [

13]. This revealed valuable insights into changes in interfacial properties; it was observed that minerals primarily undergo intergranular fracture at low energy levels, promoting their liberation. Fu et al. studied the characteristics of coal breakage through an impact test system, their analysis of mineral liberation revealed that within a specific energy range, the fracture of interfaces among various minerals will contribute to increased liberation [

14]. Mariano et al. performed breakage tests on pyrites and copper sulfides at varying energy levels using the JKRBT (Julius Kruttschnitt Rotary Breakage Tester), leading to the conclusion that the distribution of mineral liberation remained relatively unaffected by the applied energy [

15]. Si et al. used eight different ball diameters in grinding processes, revealing that the enhanced breakage energy resulting from larger ball diameter sizes could impede the liberation of minerals [

16,

17]. Grinding medium can change the breakage mode of ore, and the optimization of grinding medium can improve mineral liberation in the grinding product, while also preventing excessive grinding.

Steel balls and ceramic balls and other spherical grinding media is point contact, compared to steel rods and other rod-shaped media in the grinding process has a stronger impact, stronger grinding effect. However, steel rods and other rod-shaped grinding media because of its contact with the mineral in the grinding process for the line contact, so its grinding product size is more uniform. Therefore, steel rods are suitable for grinding brittle minerals with small hardness, and their grinding efficiency is relatively low. In the case of the same size of the ball, the ball material also has a great impact on the grinding. Steel balls are suitable for grinding hard ores, and their wear resistance is good, which can prolong the service life. Ceramic balls, as a new type of grinding media, have the characteristics of high wear resistance, high toughness against grinding, and strong surface grinding force. Compared with steel balls, ceramic balls are more effective in light grinding of crushed materials and can reduce the overgrinding phenomenon of ores. However, ceramic balls have a lower density, and a higher filling rate may be required to achieve the same grinding effect as steel balls.

Therefore, In order to obtain an efficient grinding method for preparing high purity quartz, adjusting the ore grinding method is crucial for improving the mineral liberation degree. With this background in mind, we use different grinding media to conduct grinding experiments on muscovite granite pegmatite, exploring the influence of the grinding methods on product particle size distribution, mineral liberation degree, and breakage mode. This study provides theoretical support and empirical data for applications involving the grinding and disintegration of quartz and feldspar.

2. Materials and Methods

2.1. Mineral Composition and Dissemination Characteristics

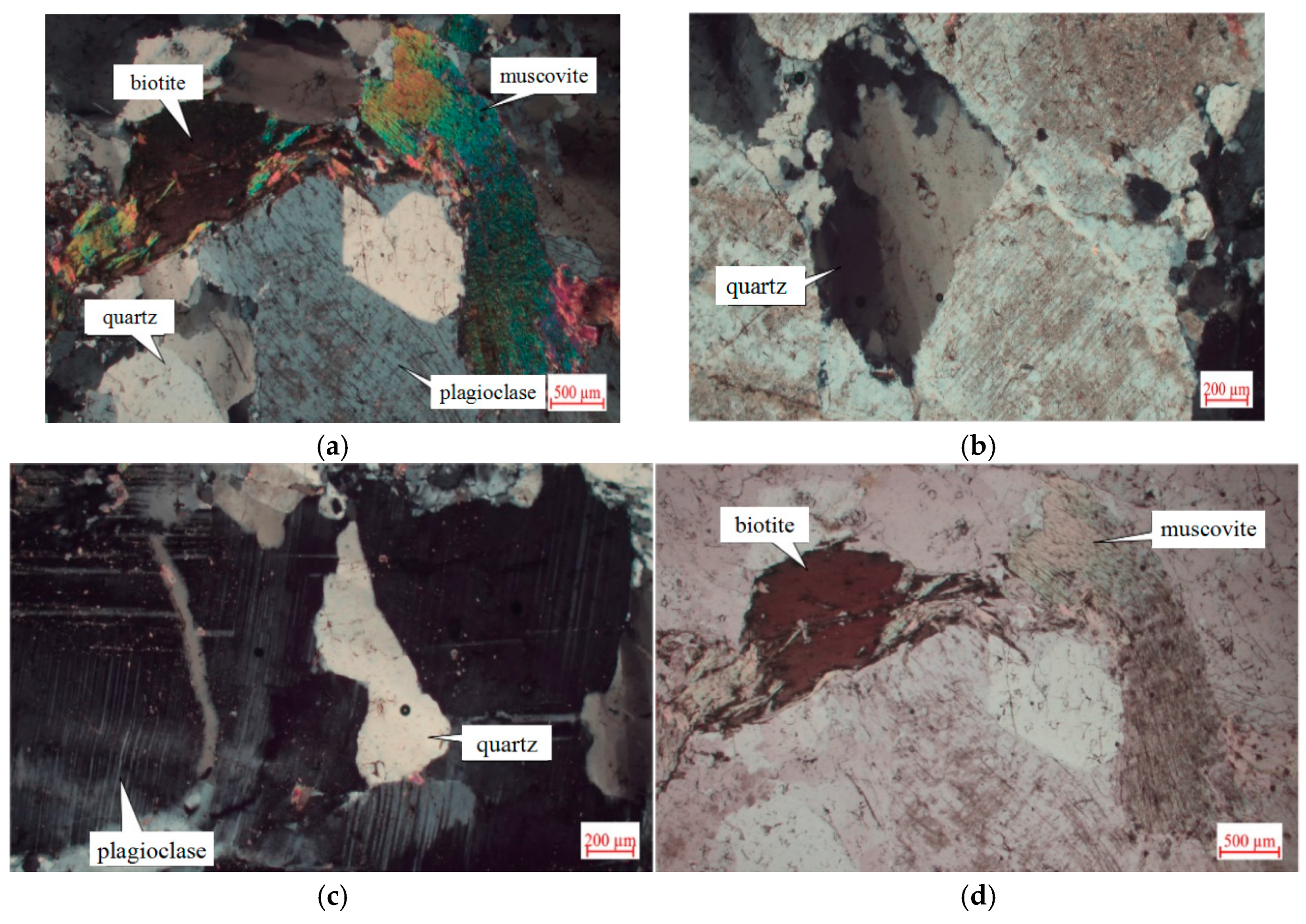

In this study, the samples were collected from a granitic pegmatite vein in the Qinling Mountains of Henan Province, China. Thin sections of the samples were observed and identified under a ZEISS Axioskop 40 polarized light microscope. The lithology was determined to be muscovite granitic pegmatite. The main mineral composition included plagioclase, quartz, microplagioclase, and muscovite, with a small amount of biotite and calcite (

Figure 1a). Quartz is colorless and transparent under single polarized light, and some particles have developed internal cracks. Under orthogonal polarized light, it is visible in the form of differently shaped granules, mostly in the form of aggregates. Wavelike extinction is generally visible (

Figure 1b). It can also be seen that some quartz particles are wrapped in plagioclase. The particle size varies (about 0.02 ~ 3.2 mm), and the phenomenon of fine graining can be seen locally. The plagioclase is colorless and transparent under single polarization, and cracks can be seen inside some particles. Under orthogonal polarization, a semi-automorphic-allotriomorphic lath or granular structure can be observed, and the flake double crystal structure is generally visible; also, some particles are wrapped with quartz (

Figure 1c), muscovite, and calcite. Sericitization and clayization can be seen locally. The particle size is about 0.2 ~ 10 mm. The microcline is colorless and transparent under single polarization. Under orthogonal polarization, it shows an all-shaped granular structure, and lattice twins are generally visible. The particle size is approximately 0.1 ~ 1 mm. The muscovite is colorless, light blue or light green under single polarized light, with obvious polychromaticity and flashes. The flaky crystal form is seen, with a group of extremely complete cleavage (

Figure 1d). Under orthogonal polarization, the second-order bright interference color can be seen, nearly showing parallel extinction. The muscovite particles are mostly distributed between quartz and feldspar particles, and some can be seen wrapped in plagioclase particles. Their diameter is about 0.1 ~ 3 mm. The biotite is colorless and dark brown under single polarized light (

Figure 1d), with obvious absorption and median protrusion. The flaky crystal form is observed, with a group of extremely complete cleavage. Near-parallel extinction is also seen under orthogonal polarization. The diameter of the slice was about 0.05 ~ 1.4 mm. The calcite is colorless under single polarized light. It is granular in shape, with a particle size of 0.05 ~ 0.1 mm, and shows obvious flashes. The high-level white interference color can be seen under orthogonal polarization.

2.2. Grinding Test

In this study, a laboratory wet ball milling process was employed, with an idle preparatory period of 10 minutes and subsequent cleaning alongside the grinding media. Ore samples were pre-crushed using a jaw crusher, selecting particles of -2 mm for grinding. Utilizing steel and ceramic balls of diameters 15 mm, 20 mm, and 25 mm (equal weights), a hammer-type laboratory ball mill was operated with 500 g of mineral samples and 300 g of water, maintaining a slurry concentration of 62.5%. In this study, the steel ball material used is high chromium cast ball with a density of 7.65 g/cm3, the main material of ceramic ball is alumina with a density of 3.7g/cm3, and the steel rod material is spring steel with a density of 7.85 g/cm3.Fineness tests were conducted using various grinding media (steel balls, ceramic balls, and a rod mill) over varying durations. Based on the resulting time-fineness curve, a target grinding size of -200 mesh with a 60% cumulative distribution was established. Subsequently, we investigated the correlation between particle size distribution and mineral liberation degree, in particular by varying the size of the steel balls used as grinding media. The objective was to identify the steel ball size that maximized liberation efficiency.

3. Results and Discussion

3.1. Particle Morphological Properties

Fractography is a science that studies the morphological characteristics of fractures, such as type, mode, path, processes, and properties [

18]. Due to the heterogeneity of rocks, that is, the diversity of mineral particles and the anisotropy of mechanical properties of mineral crystals, there are complex impacts on mechanical mechanisms. In this experiment, the micro-fracturing mechanism of muscovite granite pegmatite was analyzed through SEM images of the fractures of muscovite granite pegmatite-type quartz under different force application methods. Accordingly, the product particles under different grinding methods were graded, and the surfaces of the particles were cleaned by an ultrasonic method after the particles were divided. The samples were sprayed with gold, and the images were then analyzed by scanning electron microscopy.

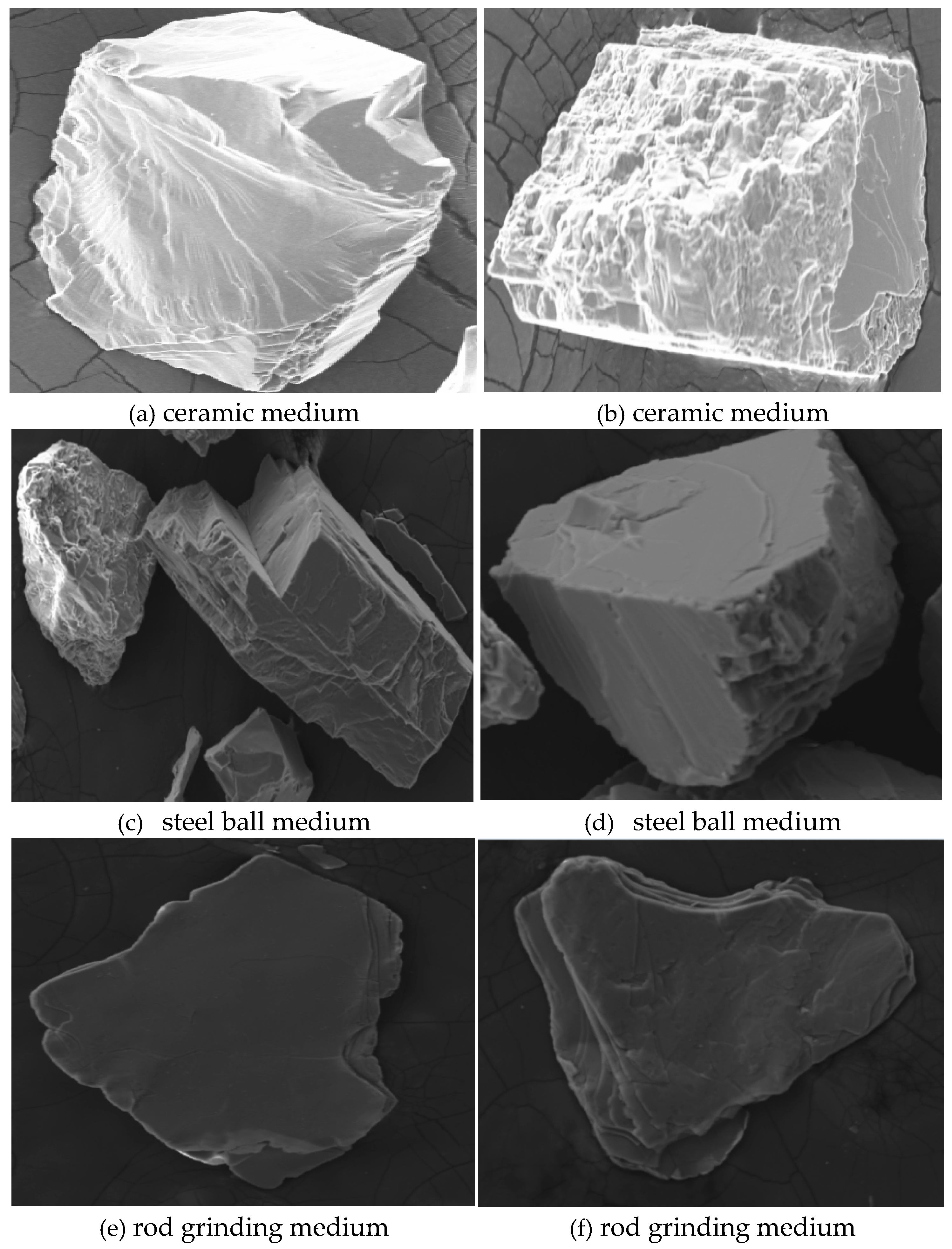

The morphological characteristics of quartz ore subjected to different grinding methods are shown in

Figure 2. Since quartz has no cleavage, high strength, high hardness, and the content of quartz in granite is large, the crystal cluster during crystallization is relatively large. The brittle fracture morphology of quartz minerals is mainly irregular intergranular failure, which will produce some shell-like, step-shaped, and river-like fractures, among other shapes. The morphological characteristics show that the rock is affected by heterogeneity and lattice defects when brittle fracture failure occurs under tensile stress. It can be seen from

Figure 2 (a)-(b) that under the action of a ceramic medium, the fracture morphology of quartz is dominated by river patterns. When cleavage cracks are generated and expanded in a certain grain, or propagate through a grain to adjacent grains, they will be disconnected on different crystal surfaces to form cleavage cracks. Steps will be formed at the intersection of these cleavage cracks, and the dissociation steps show a river-like morphology in the SEM images. It is clear from

Figure 2 (c)-(d) that under the action of steel ball medium, the fracture morphology of quartz is mainly step-like. Because there are different cleavage planes or joint planes inside the ore, under the impact of the steel ball medium, the crack propagates along these cleavage planes or joint planes, and a step-like fracture is formed at the intersection. From

Figure 2 (e)-(f), one can see that under the action of the rod grinding medium, quartz slips and breaks along the dissociation plane or crystal plane, and a large number of shear bands and flat surface patterns appear in the microscopic fracture morphology. The above analysis shows that the quartz fracture morphology produced by different grinding media vary significantly. For the same ball diameter, the grinding energy produced by steel balls is larger than that produced by ceramic balls during the throwing process, and the stress wave propagation rate in the ore is higher. The force application method of the rod mill is mainly extrusion grinding, and the stress wave propagation in the ore is lower. Therefore, the main reason for the difference in quartz fracture morphology is the difference in the propagation rate of the stress wave generated in quartz during the force application.

3.2. Fractal Characteristics of Fracture Surface Roughness

The fracture of ore is affected by many factors in the process of grinding , and the fracture surface is often very irregular and rough. The fracture surface morphology reflects the mechanical properties of the ore and the fracture mechanism of the grinding process. Quantitative analysis of fracture surface roughness can provide information that cannot be obtained by macroscopic fracture mechanics analysis methods. The conventional fracture surface morphology is only qualitatively divided into brittleness, toughness or their mixed form, etc. Such a classification method is difficult to combine the microscopic mechanism of fracture with the macroscopic mechanical parameters. Fractal theory is an important tool to describe and quantitatively analyze complex irregular geometry with self-similarity. Fracture cracks of materials have the characteristics of irregularity and nonlinearity. In this paper, the fractal dimension of rock fracture surface is calculated by box segmentation pixel coverage method. As a quantitative index to describe roughness, fractal dimension can reflect the development trend of fracture fracture mode and fracture mechanism as a whole. The energy applied by rod grinding medium is small, the ceramic medium is moderate, and the energy produced by steel ball medium is the largest. It shows that with the increase of medium energy, more and more transgranular fracture and coupling fracture appear on the fracture surface of ore sample. The larger the crack propagation rate is, the rougher the fracture morphology is. To quantitatively test the variational characteristics of mineral fracture morphology under different grinding media, fractal dimension theory is commonly employed to measure the roughness of fracture surfaces. There are many methods for calculating the real fractal dimension of a rough surface. In this paper, the fractal dimension of a mineral fracture surface is calculated by using the box segmentation pixel coverage method in the Fractal Dimension software [

19].

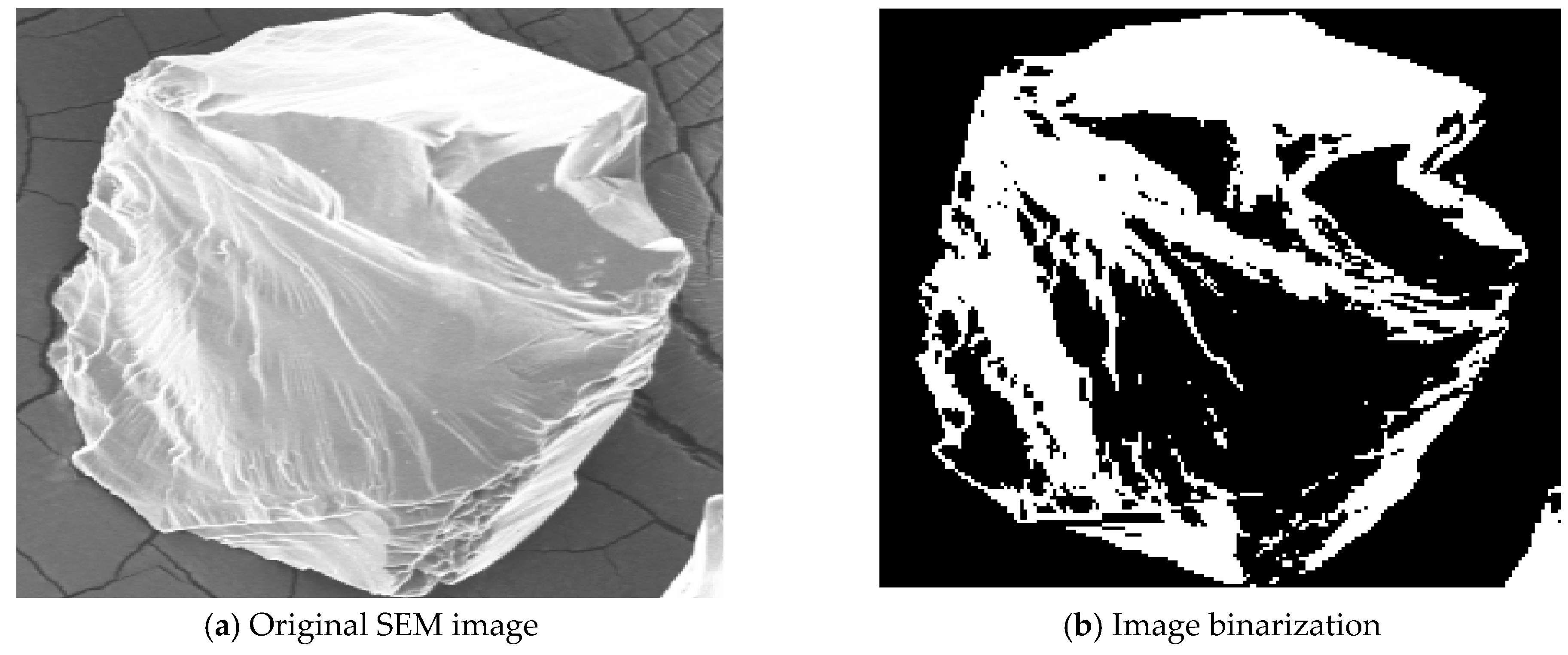

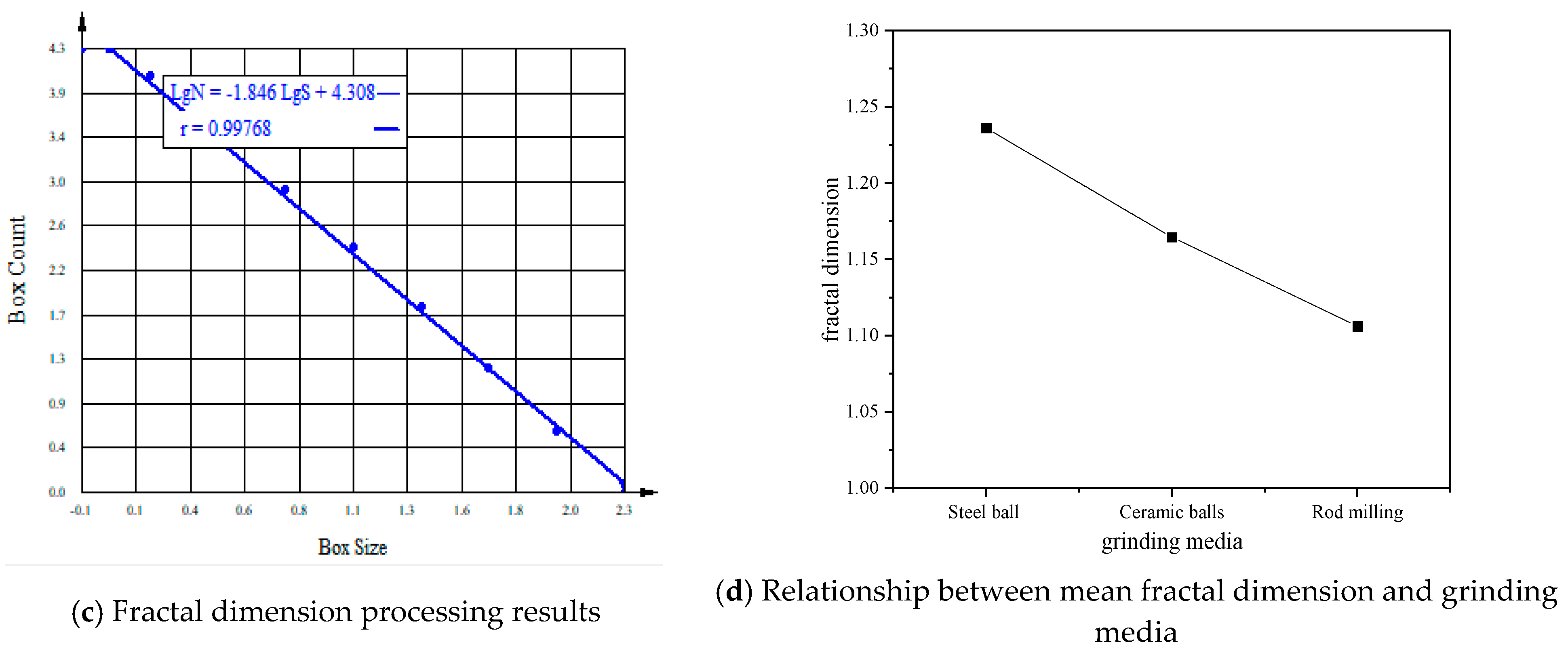

The fractal dimension regression line of the quartz fracture is obtained using the Fractal Dimension software[

20], and the linear fitting degree reaches 0.997, as seen in

Figure 3 (a)-(c). This indicates that this fractal method is reasonable for quantitative detection of fracture roughness. From

Figure 3 (d), The fractal dimension of quartz mineral fractures is directly correlated with the characteristics of the grinding medium. The fractal dimension of the fracture morphology under the action of the steel ball medium is larger, and the fractal dimension of the mineral under the action of the rod grinding medium is lower. Relevant studies have shown that the fractal dimension of the fracture morphology of a rock increases with the increase of the grinding energy, and that the two have a linear relationship. Moreover, under the same grinding conditions, the grinding energy of the steel ball medium applied to the quartz mineral is large, and the grinding energy generated by the rod grinding medium is low. As the grinding energy increases, the fractal dimension of the mineral fracture increases, and greater numbers of transgranular fractures and coupled fractures appear on the mineral fracture; this significantly increases the roughness of the fracture surface. Therefore, using the fractal dimension as a quantitative index to describe the roughness. This index can reflect the fracture mode and fracture mechanism of quartz minerals under different grinding media.

3.3. Particle Size Distribution

The purpose of grinding is to separate the useful components in minerals into single component particles, so that the required particle size for subsequent mineral processing operations can be reached, enabling effective recovery. The particle size distribution of the ground product has a direct impact on mineral separation, and the quality of the concentrate is largely determined by the quality of the ground product. If the ground product particle size is insufficient, then the target mineral will be difficult to effectively recover no matter which beneficiation method is used. The ground product is over-crushed, it will worsen product indicators, increase the amount of flotation reagents, cause the reagents to lose selectivity in the flotation stage, hinder flotation processes, and make flotation processes difficult to control. When minerals are ground effectively to the required particle size for flotation, the yield of qualified particles in the product and the efficiency of the grinding system will both be higher.

Impact energy is an important factor affecting the crack growth rate. Under the impact load, as the impact energy increases, the stress generated inside the material increases, which accelerates the crack propagation, and the crack propagation rate usually increases. The crack propagation rate not only affects the failure rate of the material, but also is closely related to the fracture mode. When the crack propagation rate is faster, the material is more prone to volume fracture, because the crack will quickly pass through multiple grains of the material. When the crack propagation rate is slow, the material is more likely to undergo surface fracture, because the crack may be affected by the surface defects or stress concentration during the propagation process. The magnitude of the impact energy also affects the fracture mode of the material. At higher impact energy, the material is more prone to volume fracture, because the crack has enough energy to penetrate the interior of the material. At lower impact energy, the material is more likely to undergo surface fracture, because the crack may be limited by the surface factors of the material during the propagation process.

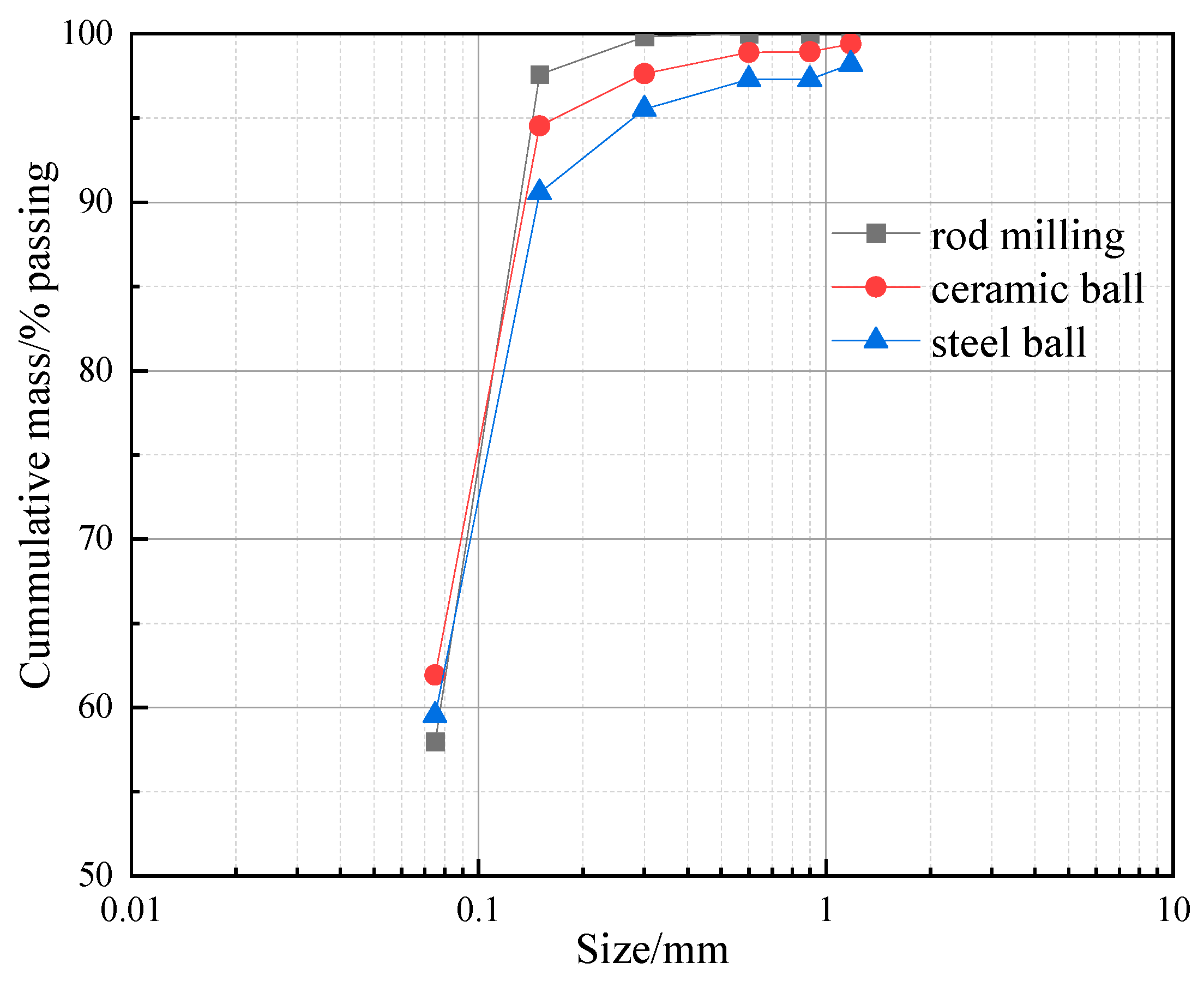

The comminution of ore in a rod mill is primarily accomplished through the impact and extrusion . During the grinding process, the grinding rods exhibit a superior crushing effect on coarse - grained ores. Fine - grained materials can pass through the inter - rod gaps, which effectively prevents the over - comminution of fine - grained mineral materials. Consequently, the rod mill possesses the characteristic of selective grinding, resulting in a more uniform particle size distribution of the ground products. The ball mill mainly relies on the impact force generated by the steel ball being thrown from a high place to break the ore. In contrast, the impact force generated by the ceramic ball is relatively small compared to the steel ball, so the generated grinding force is smaller. The particle size distribution of ore products under different grinding media is shown in

Figure 4. There are obvious differences in the particle size distribution of grinding products under different grinding media. An analysis of the particle size distribution ratio between rod and ball milling products shows that compared with ball milling, the particle size distribution of the products after rod milling is more detailed, while the particle size of the grinding products of ceramic balls is coarser than that of steel balls. The main reason for this is that the grinding energy generated by ceramic balls is smaller than that of steel balls (for the same ball diameter). The degree of breakage is primarily influenced by inherent microcracks and other imperfections within magnetite ores. Based on the theory of particle breakage proposed by Martins et al. [

21], particles within the -2.00 mm size range primarily undergo volumetric and crack fractures.

3.4. Liberation Properties

During mineral sorting, ores undergo breakage and grinding to facilitate mineral liberation, with the pivotal factor being the energy utilized during impact breakage. Consequently, we employed mineral liberation analysis to evaluate the liberation degree of muscovite granite pegmatite being crushed into varying sizes under different energy levels. To guarantee data accuracy, each sample underwent testing on over 30,000 particles.

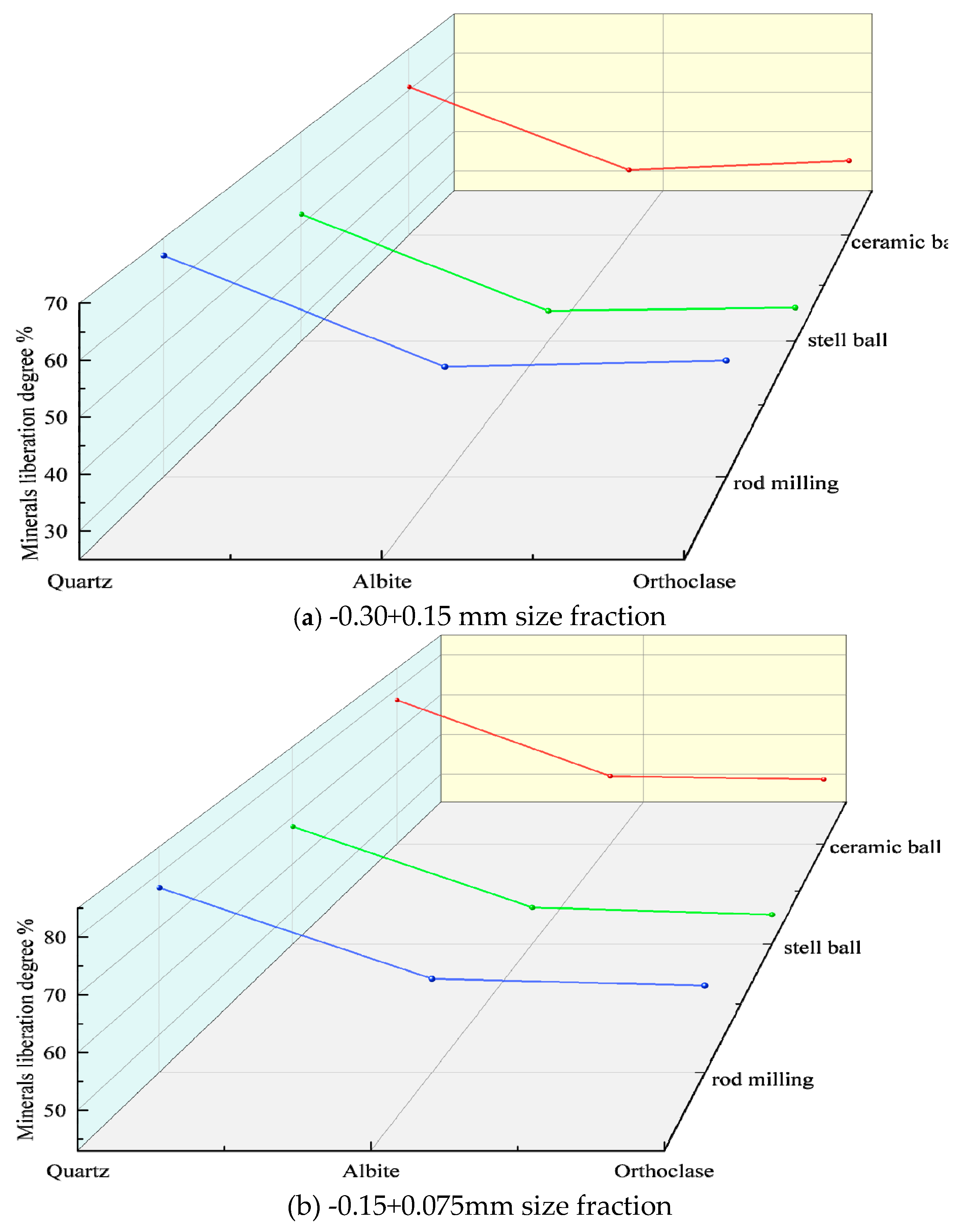

Figure 5 displays the liberation degree distribution of quartz and feldspar under different grinding media. In the particle size range of -0.30 + 0.15 mm, the liberation degree of quartz under the action of ball, ceramic, and rod milling media is 52.29%, 60.80%, and 66.78%, respectively. In the particle size range of -0.15 + 0.075 mm, the liberation degree of quartz under the action of ball, ceramic, and rod milling media is 77.35%, 67.99%, and 77.41%, respectively. For the particle size range of -200 mesh, the liberation degree of quartz under the action of ball, ceramic, and rod milling media is 90.11%, 87.63%, and 92.70%, respectively.

In the grinding process, the medium is too large, and when the impact force is too large, there will be no selective liberation through the grinding ; at the same time, the excessive impact force also increases the particle size of excessive grinding ; the ball diameter is too large, the number of hits is reduced, and the coarse grain level is also increased. That is to say, when the energy applied in the grinding process is too large, the selective liberation effect is weakened, and the particle size unevenness of the product is aggravated. As a result, the product liberation degree is low and the particle size characteristics are poor. Therefore, when the energy generated by the medium during the grinding process is accurate, the mineral liberation degree of the grinding product will be higher and the particle size over-grinding will be avoided.

These results show that the energy required for coarse-grained grinding is large, and that the liberation degree of the grinding product of the ball mill medium is higher. In the intermediate particle size range, the grinding effect of the ball mill and the ceramic medium is similar, while the grinding effect of the rod mill medium is poor. The primary reason for this is that for the intermediate particle size, there is mainly volume grinding and surface grinding involved. The rod mill mainly relies on extrusion particle grinding, and the relative strength of the ball mill is small. Because the mineral liberation degree is poor in the fine particle size range, the particle grinding is mainly surface grinding, and the force is too large to cause breakage along the particle crystal; also, the grinding behavior is non-selective. And because the quartz liberation degree of the fine-grained product of the rod mill is large, we see that the different force application methods lead to large differences in the liberation degree of the grinding product. Given that the primary objective of comminution is to achieve mineral liberation, with optimal particle size being a secondary concern, ensuring a suitable specific energy input is the most important factor for maximizing the liberation degree of the resultant products.

3.5. The Influence of Mineral Liberation Degree on Flotation Recovery Rate

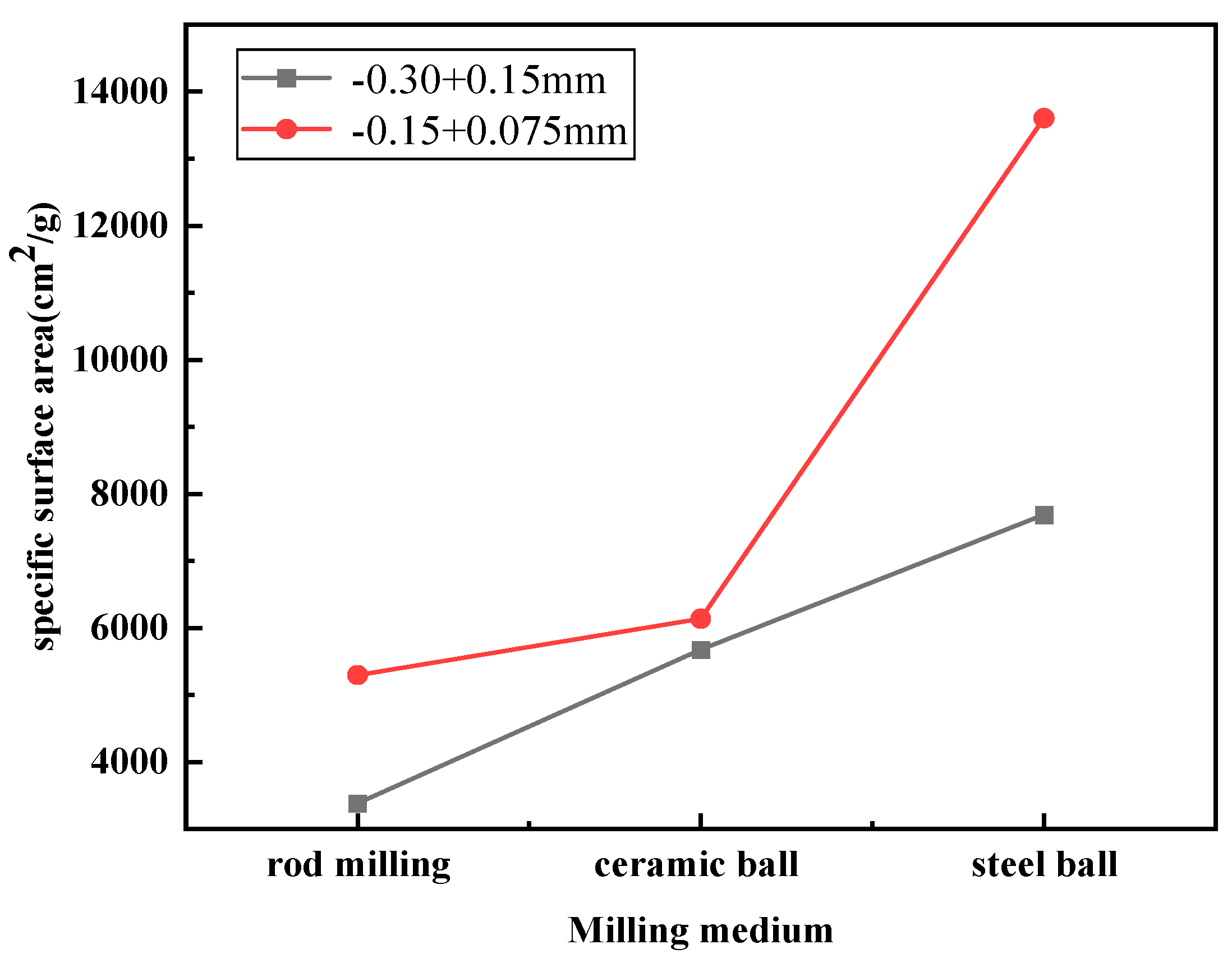

The specific surface area of grinding product particles was measured by an automatic specific surface area analyzer (Belsorp MAX II), and the effect of the grinding medium on the specific surface area of mineral particles was investigated. These test results are shown in

Figure 6.

It can be seen from

Figure 6 that the specific surface area of the grinding products under three different grinding media varies significantly. In general, the specific surface area of steel ball grinding products is higher than that of the other two media, and the specific surface area of grinding products under rod grinding media is smaller. The larger the specific surface area, the better the adsorption effect on the agent in the subsequent flotation process, and the greater dosage that is needed.

Flotation experiments were carried out using an XFD hanging-trough flotation machine with different media grinding product samples of 300 g and -200 mesh particle size. The flotation cell volume was 1.5 L, and the test water used was tap water. Hydrofluoric acid was used as an acid-base regulator to adjust the pH value of the pulp. The test temperature of the suspension pulp is 36.5℃, pH is 2, Dodecylamine for collector, 150g/t, No.2 oil for foaming agent, 20g/t. Dodecylamine was used as the collector, and pine oil was employed as the foaming agent. The dosing interval was 2 minutes, and then scraping flotation was performed for 3 minutes. After flotation was completed, the foam product and the product in the tank were filtered, dried, and weighed. After sampling, the grade of SiO2 in the concentrate is measured by ICP(Inductively Coupled Plasma Spectrometer), and the recovery rate is calculated.

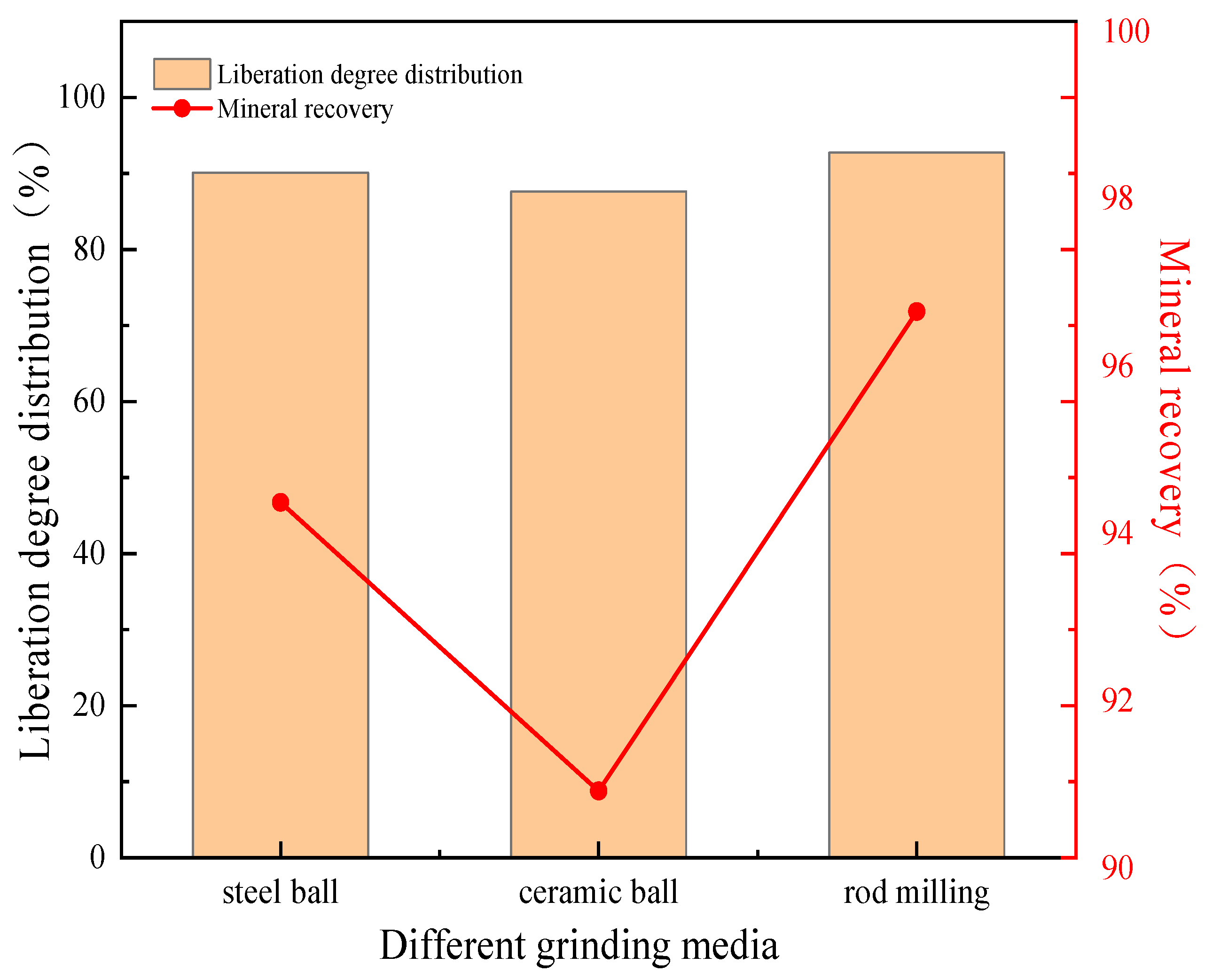

The effect of mineral liberation degree on the flotation recovery of SiO

2 is shown in

Figure 7. The liberation degree of quartz under the actions of ball, ceramic, and rod milling media is 90.11%, 87.63%, and 92.70%, and the recovery rate of SiO

2 after flotation is 94.25%, 90.8%, and 96.53%, respectively. The fractal dimension is related to the degree of fragmentation and complexity of the mineral particle. As mineral particles are broken into smaller particles, their shapes may become more complex and the fractal dimension usually increases. There is a correlation between the degree of fragmentation and the degree of dissociation of mineral particles. The higher the degree of fragmentation, the larger the contact area between the mineral particles may be, thus favoring the dissociation of minerals. Therefore, the higher the liberation degree of SiO2 is, the higher the flotation recovery. The degree of mineral liberation directly affects the flotation recovery rate. When the mineral liberation degree is high, intergrowth between useful minerals and gangue minerals is reduced, which is conducive to the collection of useful minerals by flotation reagents; accordingly, the flotation recovery rate is improved. On the contrary, when the liberation degree is low, the useful minerals and gangue minerals are mixed together, which makes separation difficult, resulting in a decrease in flotation recovery.

4. Conclusions

This study presented a grinding experiment conducted on granite pegmatite, focusing on a comparison between steel balls and ceramic rods as grinding media. We investigated how these different media impact the mineral liberation and particle size distribution of the resulting ground products, with the goal of offering insights into optimizing grinding media selection for industrial processes.

Through an analysis of the particle size distribution of the grinding products, it was observed that the grinding particle size under the action of a rod grinding medium was coarser, and the particle size of grinding products under the action of a ball grinding medium was finer, and also prone to overgrinding. The grinding ability of ceramic balls was also weak for fine-grained products. Thus, choosing a suitable grinding medium can optimize the particle size distribution of grinding products.

By using fractal dimension as a quantitative index, we described how roughness can reflect the development trends of fractures, in terms of their modes and mechanisms. The fractal dimension of particle morphology roughness was found to be larger for steel ball-milled products, and smaller for rod-milled products.

Through an analysis of the distribution of mineral liberation degree of the grinding products, it was seen that the energy required for a coarse grain grade is larger, the grinding effect of a steel ball medium is generally superior, and the grinding effect of a rod mill is better for fine grain grades. Furthermore, we found that the mineral liberation degree of grinding products, and thus the grinding effect, can be improved by optimizing the grinding medium.

The analysis of muscovite granite pegmatite comminution products revealed a trade-off between optimal particle size and mineral liberation degree. A rod mill can improve the dissociation degree of the mineral monomer and the yield of the qualified fraction of quartz minerals through grinding.

Finally, in the same amount of flotation reagents, it was found that the specific surface area of particles was not the main factor affecting mineral flotation, and that the degree of mineral liberation had a direct impact on flotation recovery. The mineral liberation degree of rod grinding products was high, the specific surface area was small, and the flotation recovery rate was high. Therefore, the mineral liberation degree is improved by optimizing the grinding force, which can improve the recovery rate of SiO2.

Acknowledgments

This work was supported by the China Geological Survey Project (DD20243361) and the National Key R&D Program of China (2024YFC2910105).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, S.; Yu, D.; Ma, C.; Wei, F.; Zhang, H. A New Insight into the Influence of Fluid Inclusions in High-Purity Quartz Sand on the Bubble Defects in Quartz Glass: A Case Study from Vein Quartz in the Dabie Mountain. Minerals 2024, 14, 794. [Google Scholar] [CrossRef]

- Zhang, H.Q.; Tan, X.M.; Ma, Y.M.; Chen, C.L.; Zhang, S.H.; Wang, L.; Liu, L.; Zhu, L.K.; Guo, L.X.; Zhang, H.L.; Liu, G.X. 2022, Geological characteristics of pegmatite type high-purity quartz in Altai, Xinjiang and preparation techonology of 4N8 grade products. Conservation and Utilization of Mineral Resources, pp. 5, 1-7.

- Zhang, H.Q.; Zhang, H.L.; Ma, Y.M.; Zhu, L.K.; Guo, L.X.; Liu, G.X.; Guo, F.; Wang, S.J. Establishment and practice of a whole chain survey and evaluation system for pegmatite-type high purity quartz resources: a case study in North Qinling region, China. Conservation and Utilization of Mineral Resources, 5, pp. 15-21.

- Ferreira, R.F.; Lima, R.M.F. An automated mineralogy derived criterion for clustering ore samples for mineral liberation studies. Minerals Engineering 2024, 212, 1–13. [Google Scholar] [CrossRef]

- Yu, J.; Sun, H.; An, Y. Energy conservation and consumption reduction in grinding operations through ceramic media stirring mill: An industrial validation test. Powder Technology 2023, 429, 2–11. [Google Scholar] [CrossRef]

- Zeng, Y.; Forssberg, E. Effects of mill feed size on product fineness and energy consumption in coarse grinding. Miner. Eng. 1991, 4, 599–609. [Google Scholar] [CrossRef]

- Yu, P.; Xie, W.; Liu, L.; Powell, M. Applying Fréchet distance to evaluate the discrepancy of product size distribution between single particle and monolayer multi-particle breakage. Powder Technol. 2019, 344, 647–653. [Google Scholar] [CrossRef]

- Han, T.; Petukhov, Y.; Levy, A.; Kalman, H. Theoretical and experimental study of multi-impact breakage of particles. Adv. Powder Technol. 2006, 17, 135–157. [Google Scholar] [CrossRef]

- Danha, G.; Legodi, D.; Hlabangana, N.; Bhondayi, C.; Hildebrandt, D. A fundamental investigation on the breakage of a bed of silica sand particles: An attainable region approach. Powder Technol. 2016, 301, 1208–1212. [Google Scholar] [CrossRef]

- Wills, B.; Atkinson, K. Some observations on the fracture and liberation of mineral assemblies. Miner. Eng. 1993, 6, 697–706. [Google Scholar] [CrossRef]

- Bradt, R.C.; Lin, C.L.; Miller, J.D.; Chi, G. Interfacial fracture of multiphase particles and its influence on liberation phenomena. Minerals Engineering 1995, 8, 359–366. [Google Scholar] [CrossRef]

- Leißner, T.; Hoang, D.; Rudolph, M.; Heinig, T.; Bachmann, K.; Gutzmer, J.; Schubert, H.; Peuker, U. A mineral liberation study of grain boundary fracture based on measurements of the surface exposure after milling. Int. J. Miner. Process. 2016, 156, 3–13. [Google Scholar] [CrossRef]

- Garcia, D.; Lin, C.; Miller, J. Quantitative analysis of grain boundary fracture in the breakage of single multiphase particles using X-ray microtomography procedures. Miner. Eng. 2008, 22, 236–243. [Google Scholar] [CrossRef]

- Fu, Y.; Li, Z.; Zhou, A.; Xiong, S.; Yang, C. Evaluation of coal component liberation upon impact breakage by MLA. Fuel 2019, 258. [Google Scholar] [CrossRef]

- Mariano, R.; Evans, C. The effect of breakage energies on the mineral liberation properties of ores. Miner. Eng. 2018, 126, 184–193. [Google Scholar] [CrossRef]

- Si, L.; Cao, Y.; Fan, G. The Effect of Grinding Media on Mineral Breakage Properties of Magnetite Ores. Geofluids 2021, 2021, 1–9. [Google Scholar] [CrossRef]

- Si, L.; Cao, Y.; Fan, G. Breakage Characterization of Magnetite under Impact Loads and Cyclic Impact Loading. Energies 2020, 13, 5459. [Google Scholar] [CrossRef]

- Yongfa, Z.; Yu, Z.; Arno, Z.; et al. Acoustic Emission Evolution and Hydraulic Fracture Morphology of Changning Shale Stressed to Failure at Different Injection Rates in the Laboratory. Rock Mechanics and Rock Engineering 2024, 1287–1308. [Google Scholar]

- Xu, C.; Wang, K.; Wu, Y.S. Fractal characteristics of mining-induced overburden fracture development during fully mechanized coal mining. Environmental earth sciences 2024, 83, 113.1–11316. [Google Scholar] [CrossRef]

- Liu, H.; Xie, H.; Wu, F.; Li, C.; Gao, R. A novel box-counting method for quantitative fractal analysis of three-dimensional pore characteristics in sandstone. Int. J. Min. Sci. Technol. 2024, 34, 479–489. [Google Scholar] [CrossRef]

- Martins, S. Size-energy relationship exponents in comminution. Miner. Eng. 2020, 149, 106259. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).