3.2.1. Steady-State Operation

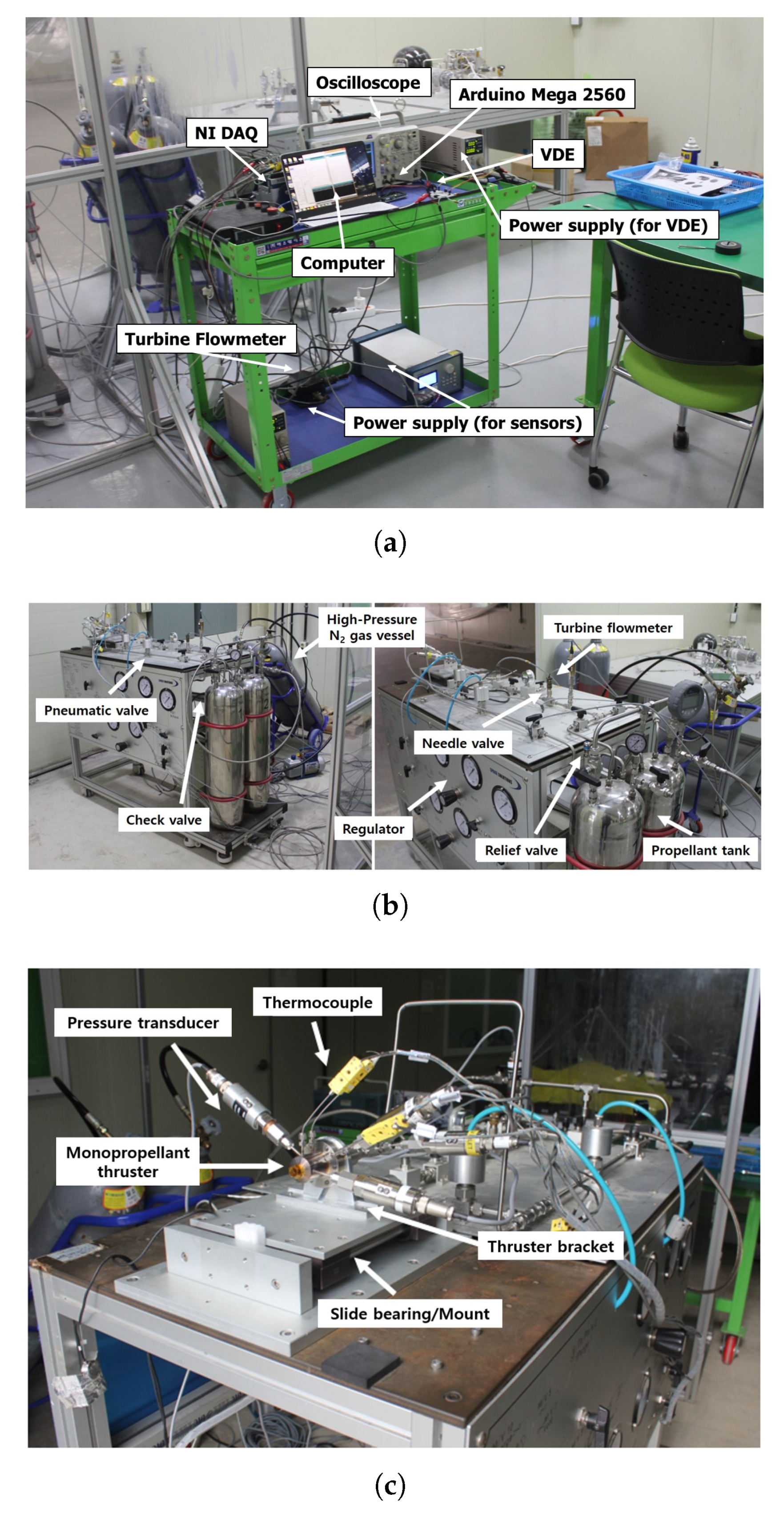

Before pulse-mode hot fire tests, steady-state hot fire tests evaluated thruster performance against design targets to detect design or fabrication flaws.

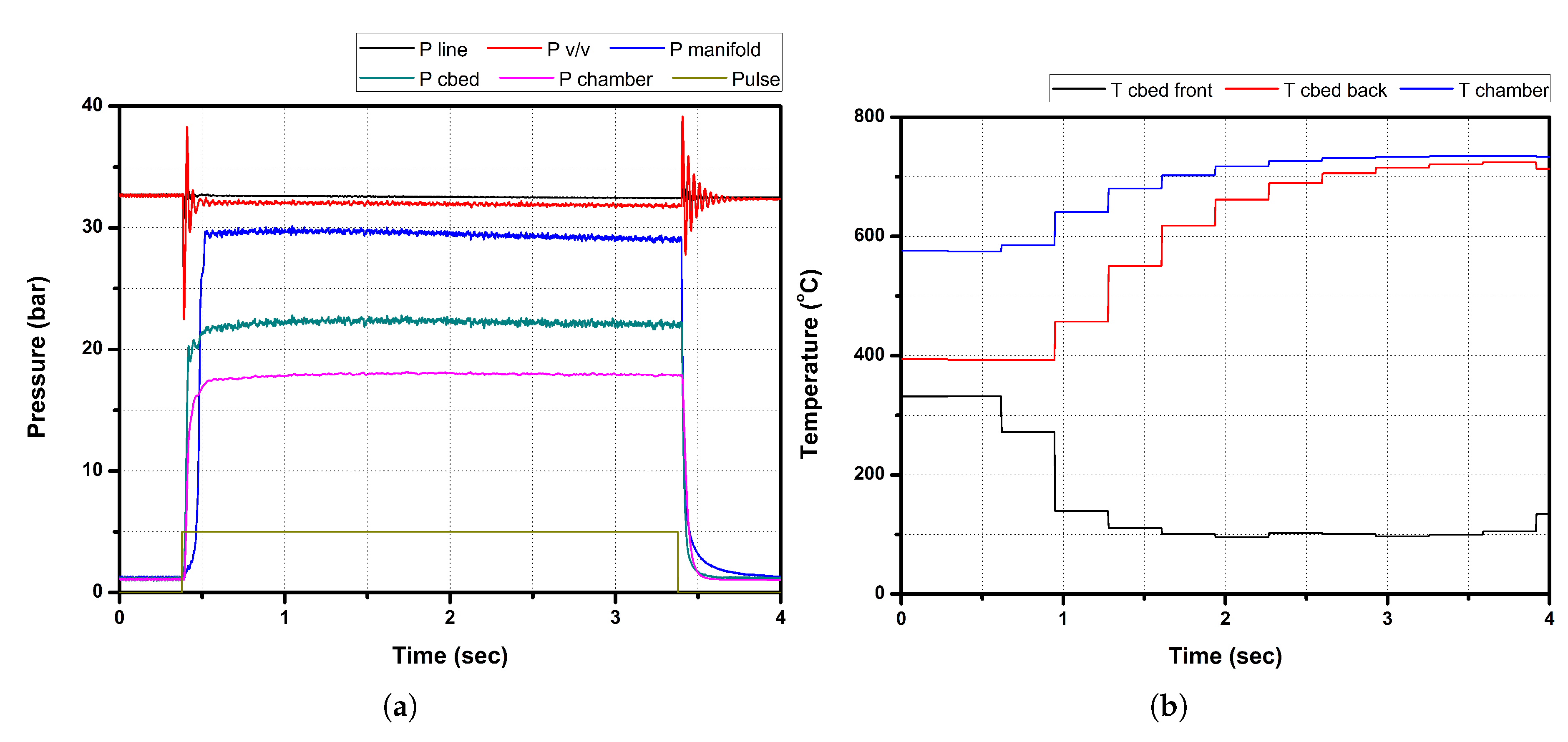

Table 7 summarizes steady-state test outcomes, while

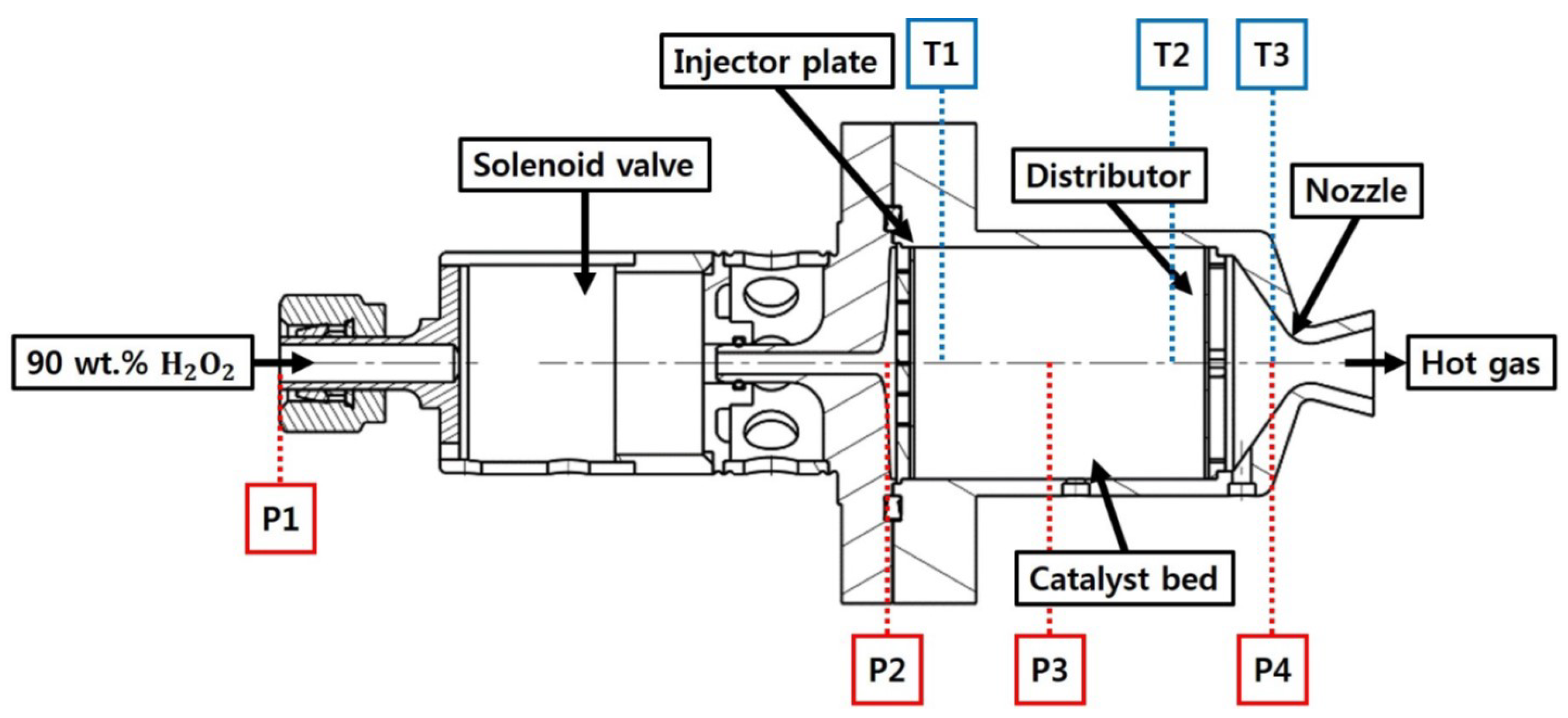

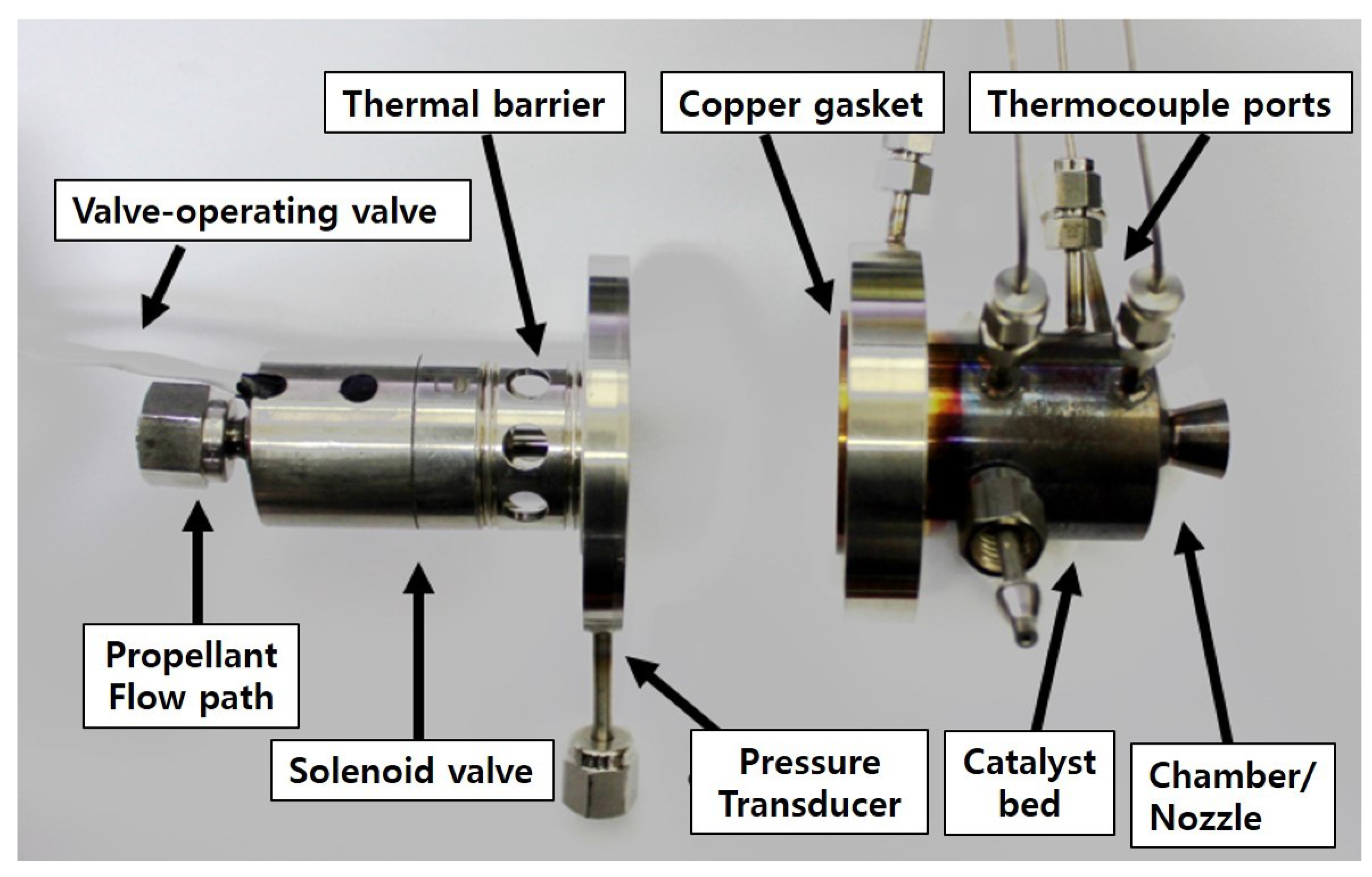

Figure 9 displays pressure and temperature data. The chamber pressure reached 18 bar, which is 2 bar less than the design value, due to a mismatch between the designed (4.86 mm) and fabricated (5.3 mm) nozzle throat diameters. This increased throat area reduced chamber pressure buildup, degrading performance. Also, a thermocouple failure hindered accurate temperature measurement at the catalytic reactor’s midpoint and neglected in the measurement.

Figure 9 shows temperature trends at the reactor inlet, outlet, and chamber. The chamber temperature of 734.55°C closely aligned with the adiabatic decomposition temperature of 90 wt.% HTP (746.17°C), suggesting an effective catalyst bed design with minimal heat loss through the thruster walls.

The mean surge pressure in steady-state hot fire tests was 39.33 bar, with a mean pressure at valve upstream of 32 bar. The lower surge pressure relative to water likely stems from HTP’s smaller bulk modulus, preventing cavitation and the onset of the secondary water hammer.

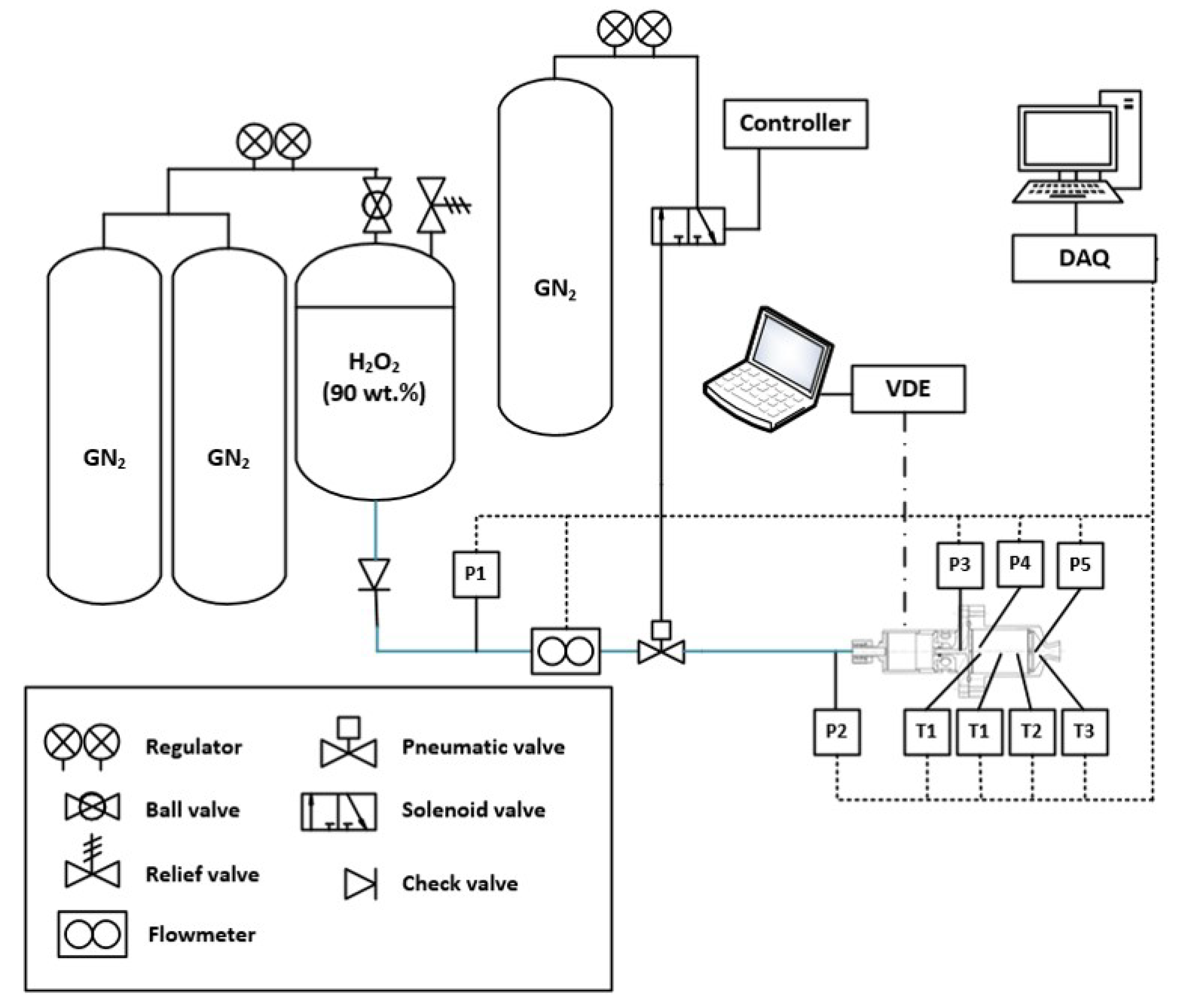

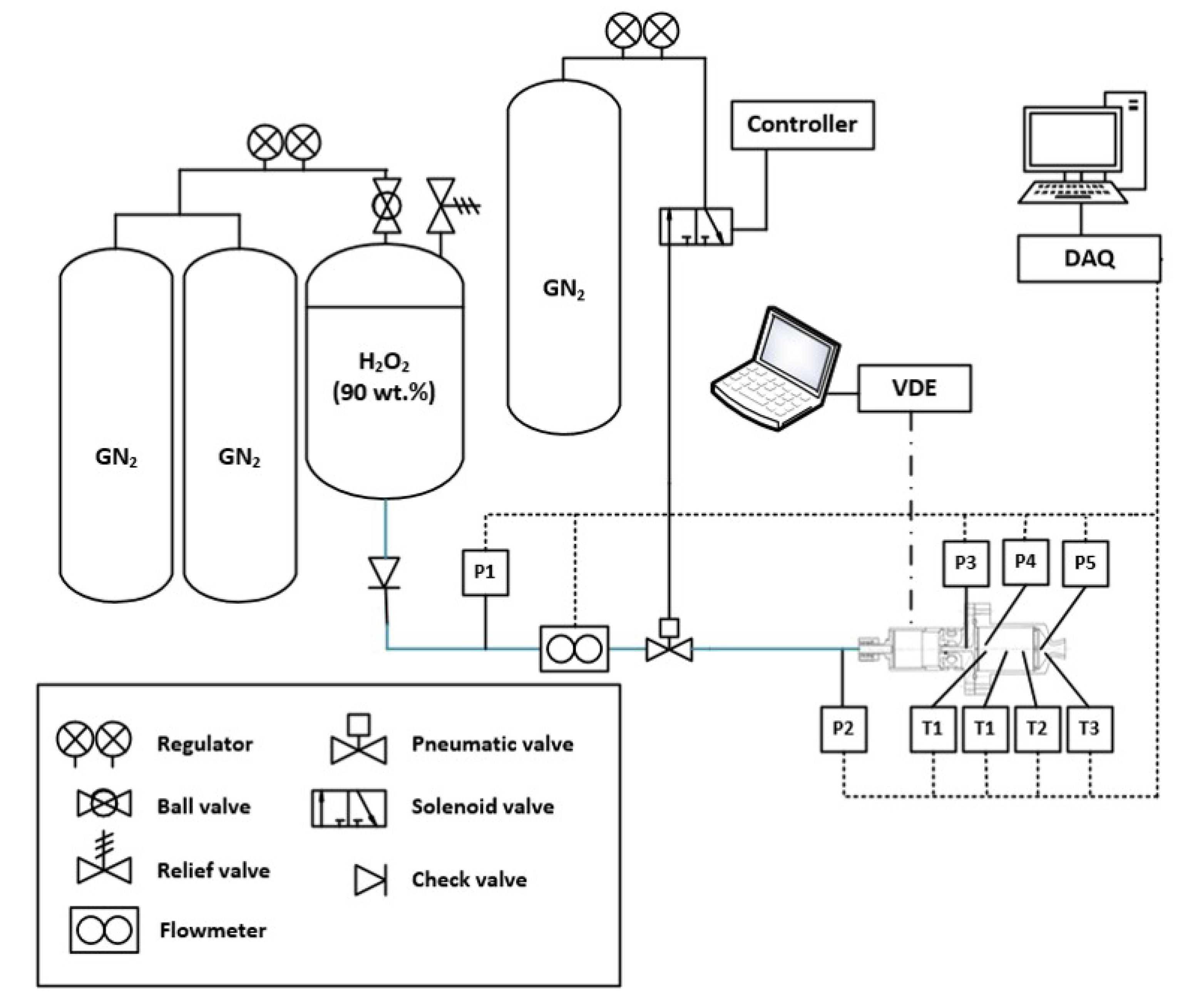

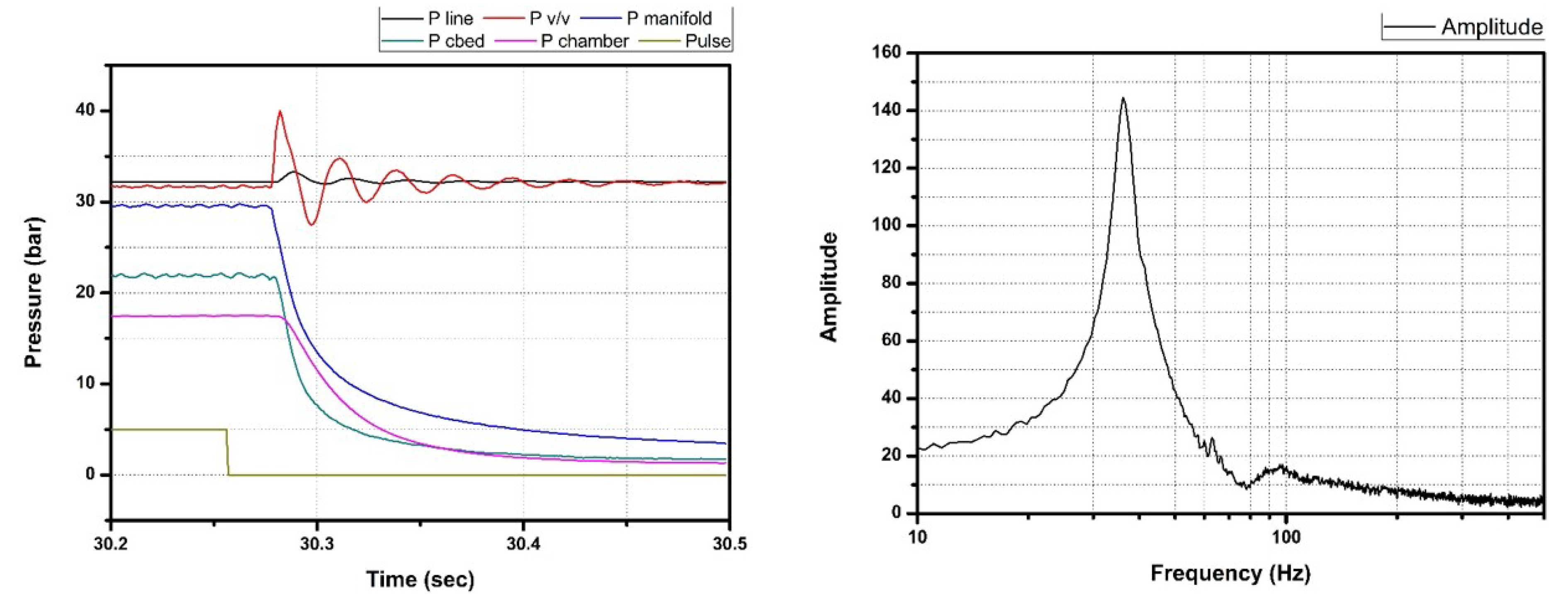

Feed line characteristics was investigated using pressure perturbation measurement obtained from steady-state hot fire tests. The "ping test", per Martin et al. [

8], uses the pressure response after valve closure to determine the natural frequency of the propellant feeding system. To determine the natural frequency, pressure data upstream of the valve (P2) were converted from time to frequency domain, shown in a power spectral density (PSD) plot (

Figure 10). The ping test indicated that the feed line’s natural frequency with the valve closed (

) was 36.11 Hz. Similarly, the feed line’s natural frequency with the valve opened (

) was obtained as 24.51 Hz through FFT analysis using the the pressure oscillation measurement acquired at the valve upstream at the moment of valve opening.

3.2.2. PWM Throttling Operation

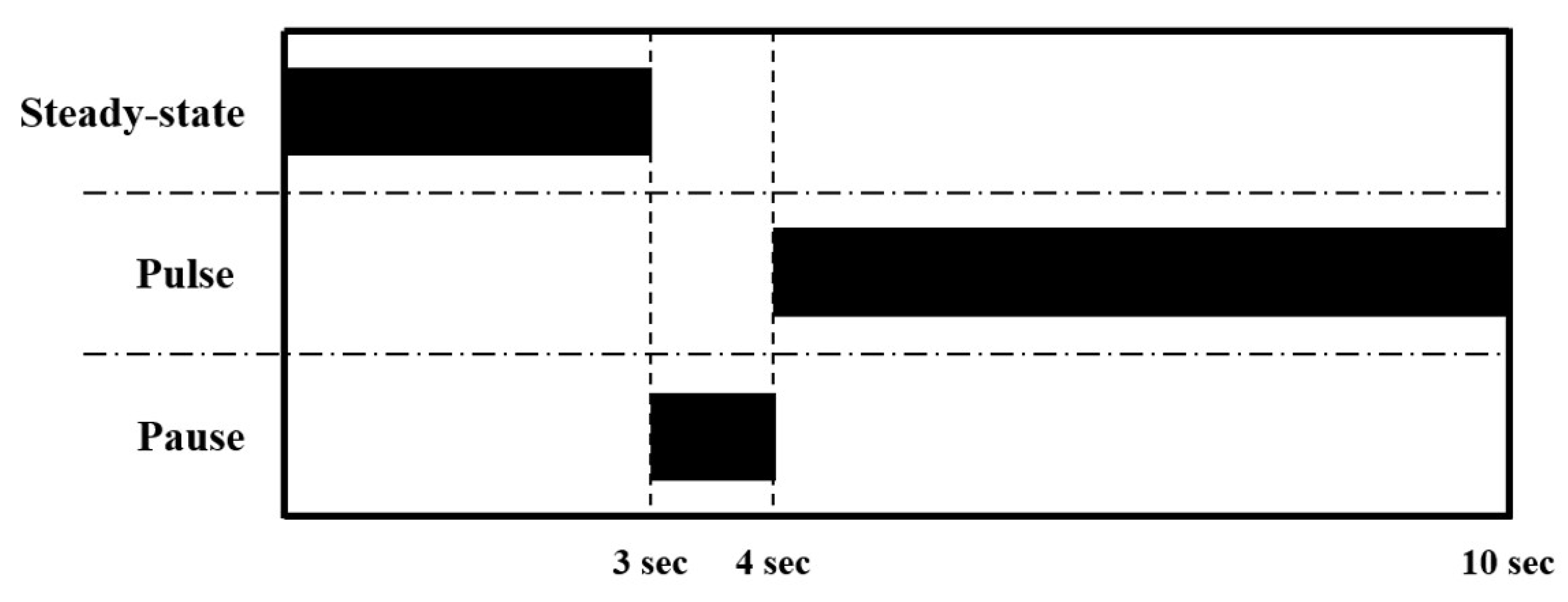

The hot fire test sequence for pulse operation, depicted in

Figure 11, proceeded as follows. Since decomposition capability of the catalyst is highly dependent on its temperature, it was essential to keep the catalyst’s temperature identical for all cases before the pulse mode firing begins in order to make an appropriate comparison Hence, the thruster operated steadily for 3 seconds to elevate the catalyst bed temperature, ensuring complete propellant decomposition. A 1-second pause then mitigated steady-state effects and water hammer perturbations from influencing the propulsion system operating PWM throttling. Subsequently, command signals for preset pulse conditions actuated the solenoid valve for 6 seconds, enabling thruster pulse operation. In the hot fire test, PWM throttling operated at

Hz. A trade-off exists: higher frequencies favor precise and responsive maneuvers, crucial for lander applications, but require a high-performance solenoid valve with limited mass flow rate and DC range. Thus, 10 Hz is a suitable compromise for lander applications, validated by prior references including MPL, Phoenix, Mighty Eagle, and DALBIT-1 [

3,

5,

6,

8].

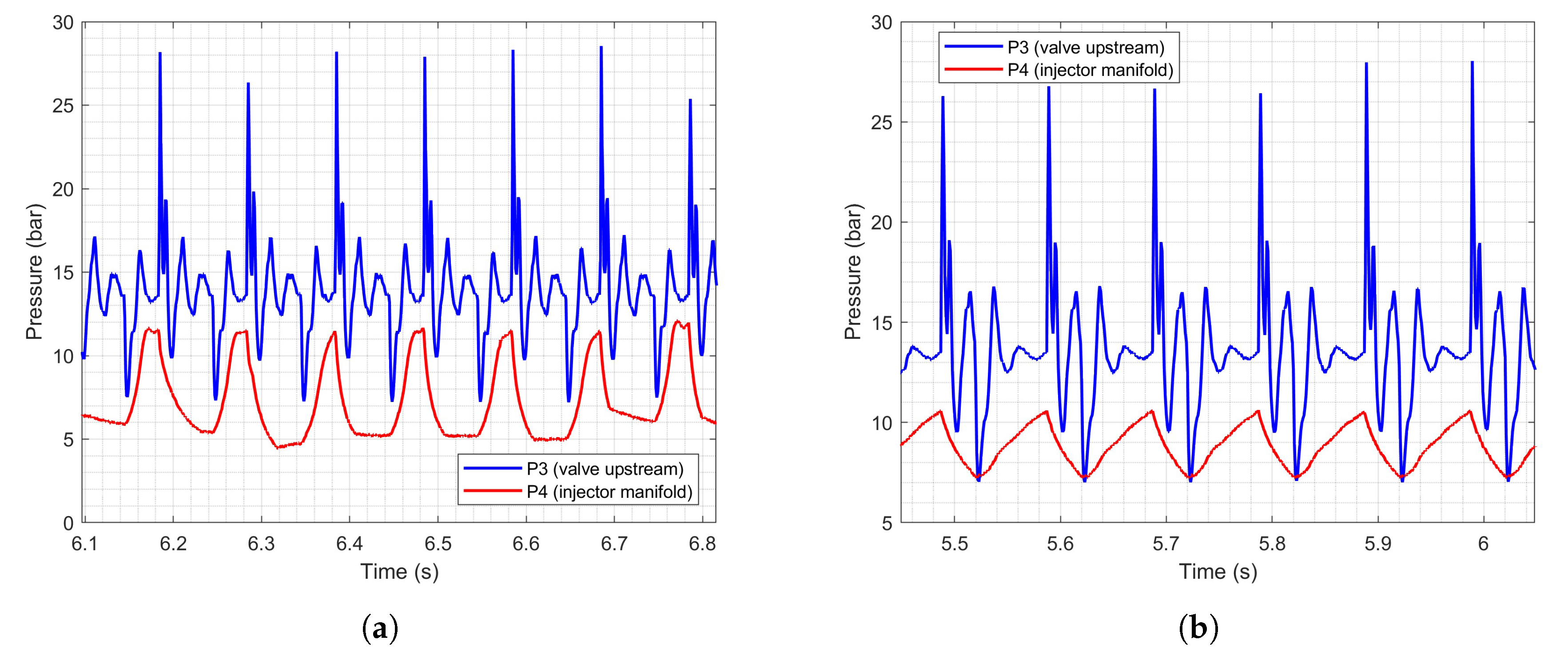

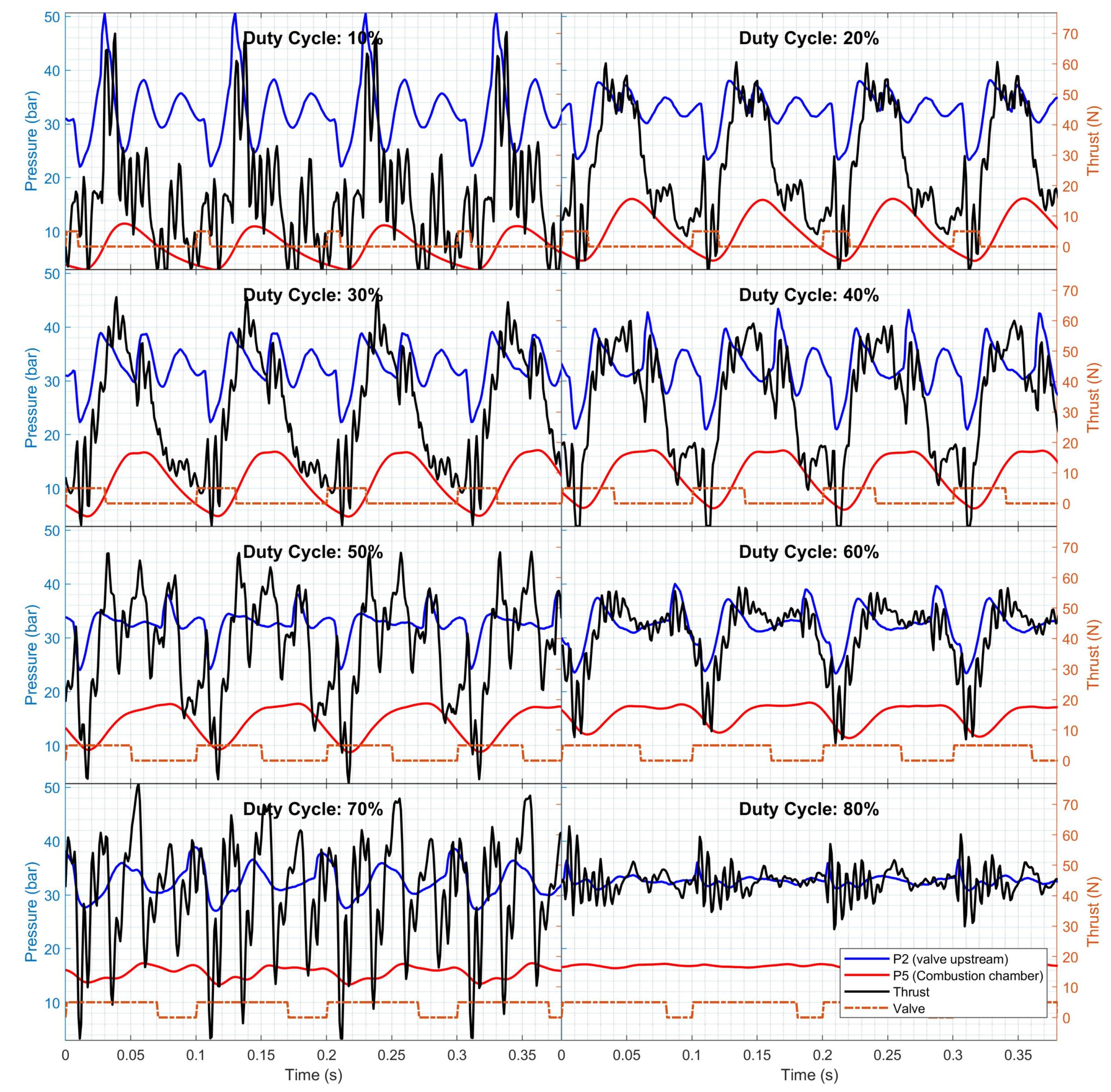

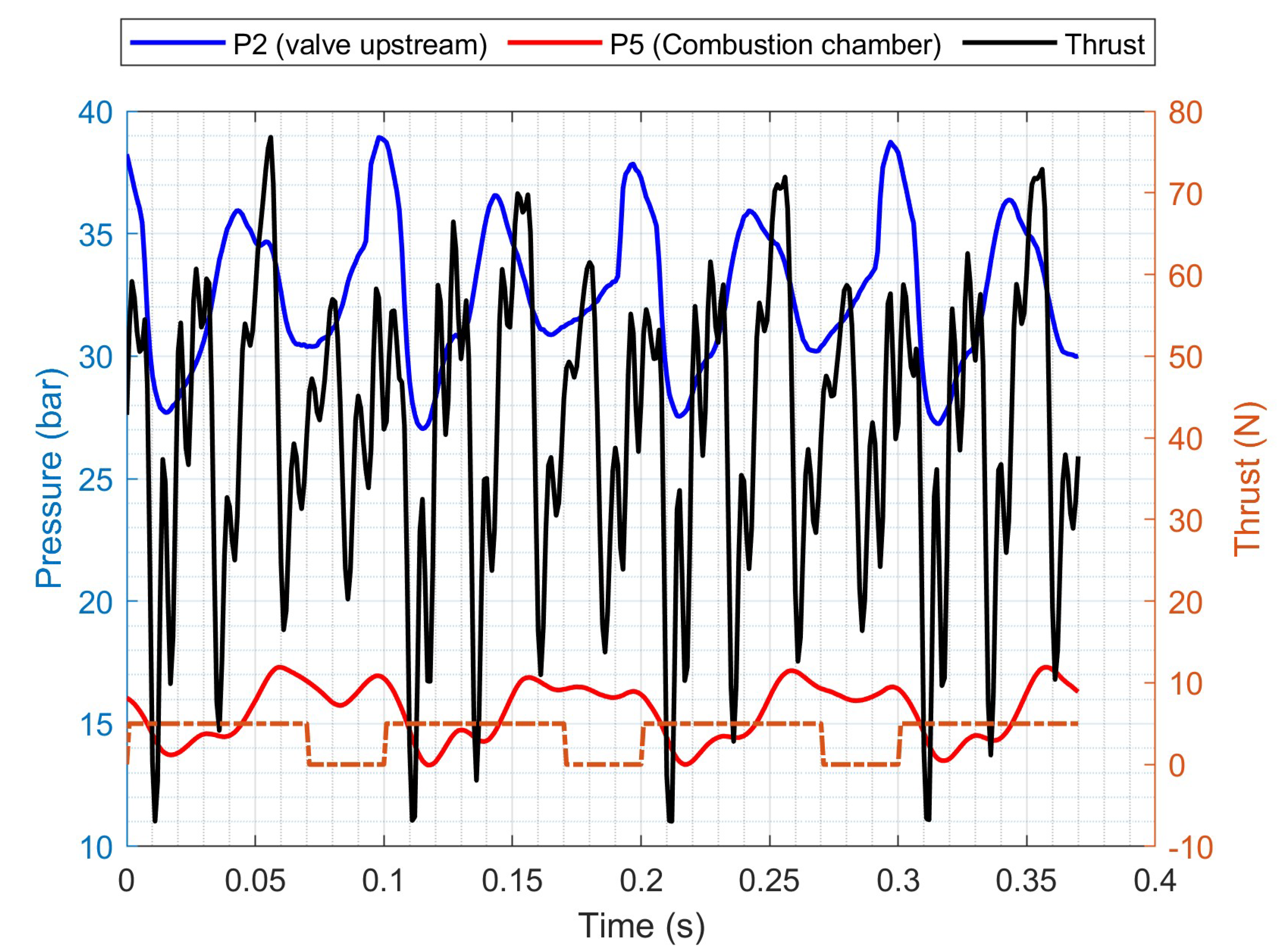

Figure 12 shows pressure, thrust, and valve drive signal data from a 50 N-class HTP monopropellant thruster operated in pulse mode at

= 10 Hz with DC = 10 - 90%. Pressure spikes and subsequent oscillations in the propellant feed system occur shortly after the "off" signal, while sharp pressure drops follow the "on" signal. These drops stem from rarefaction waves traveling through the feed line upon valve opening. Oscillations decay faster for rarefaction waves than for compression waves, as liquid flow dissipates and suppresses wave propagation. Similar to cold flow test results, the valve did not close at

= 10 Hz with DC = 80 and 90% and at

= 5 Hz with DC = 90%. Upstream pressure measurements showed no compression or rarefaction waves, indicating no valve actuation and thus no PWM throttling.

Figure 12 displays fluctuating thrust readings during valve closure, likely due to structural vibration in the propellant feed system affecting the measurement device. This suggests that past pulse operations influence future fluid dynamics not only via wave propagation through the feed line but also through residual structural vibration.

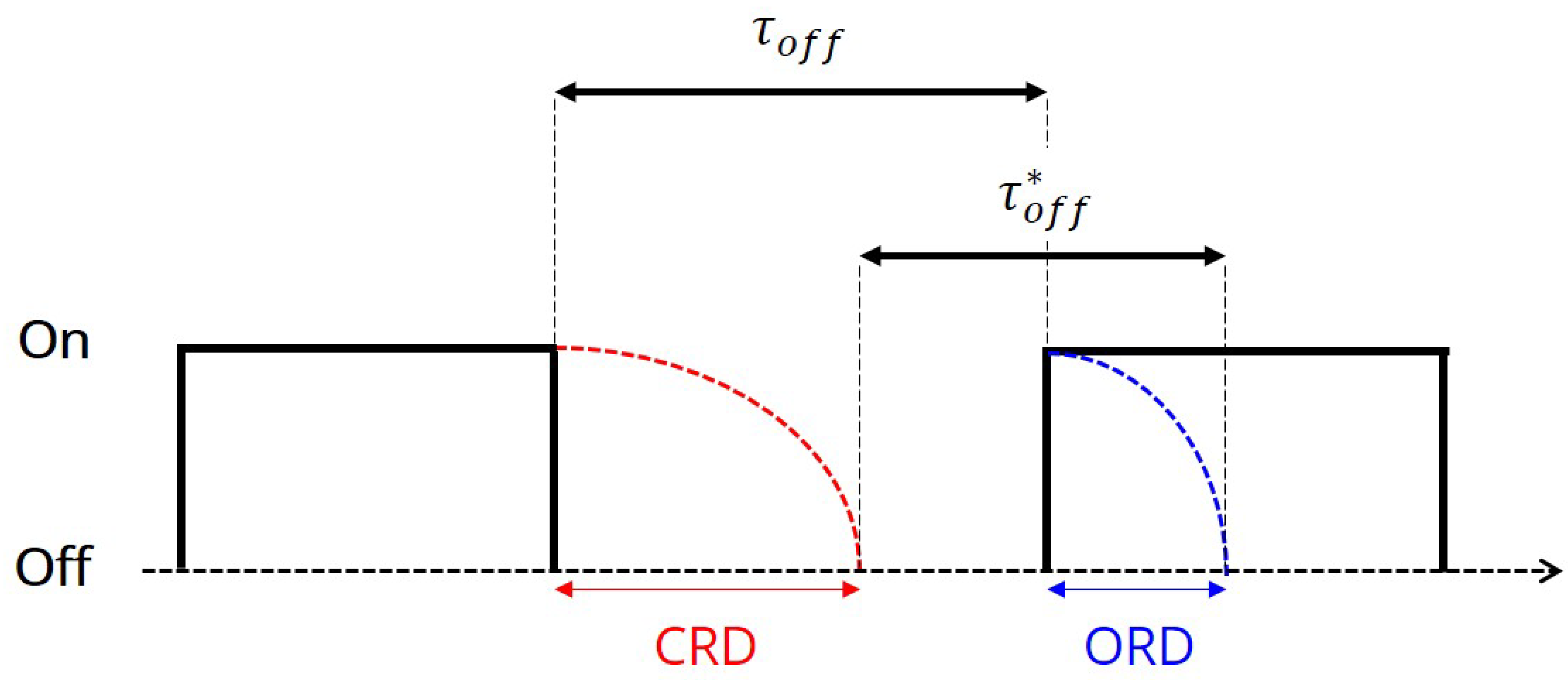

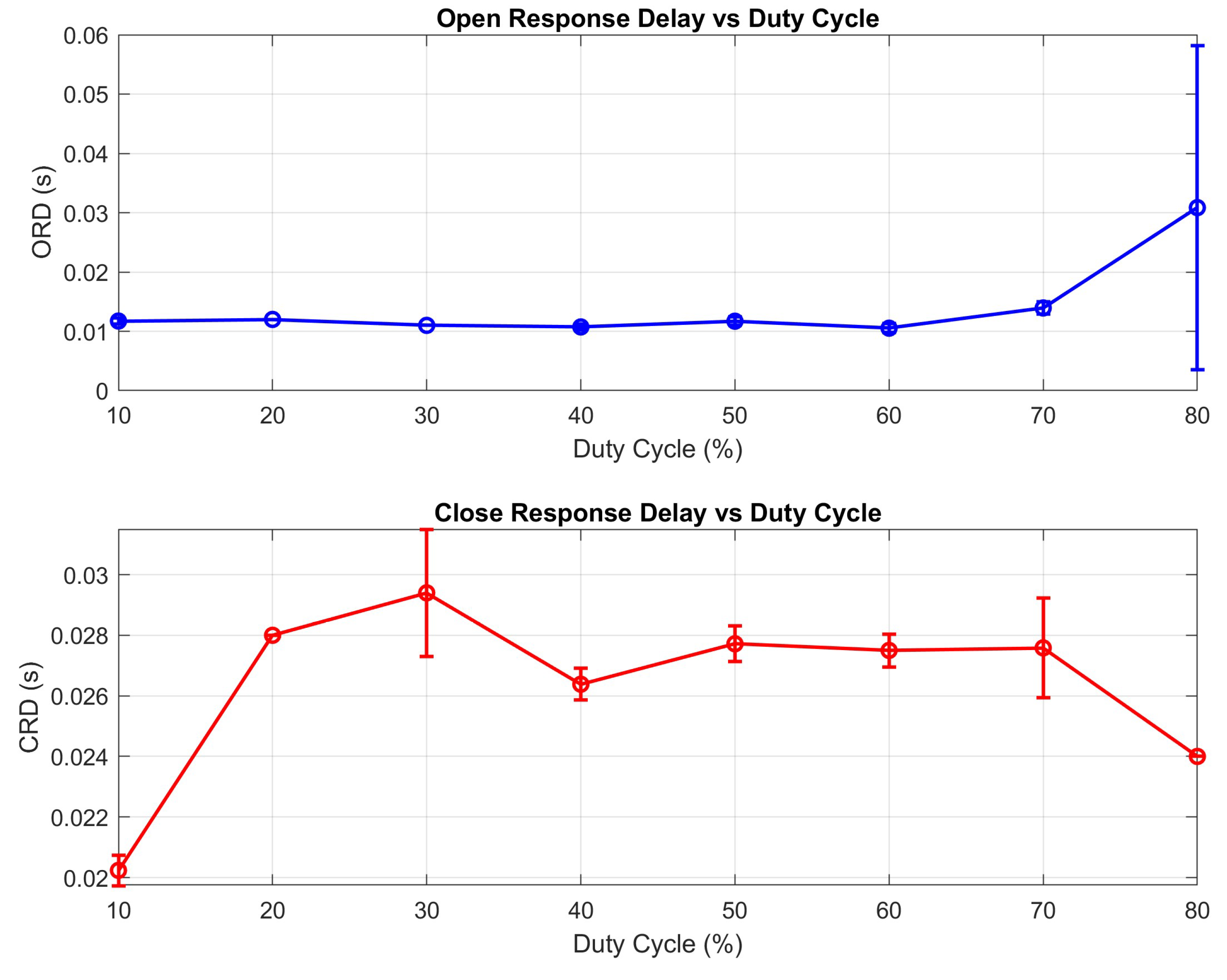

Figure 13 illustrates the opening response delay (ORD) and closing response delay (CRD) from PWM throttling at

Hz across various duty cycles (DC). Both ORD (11 ms) and CRD (27.5 ms) increased relative to the cold flow test, likely due to elevated upstream pressure. Data for DC = 80% are disregarded, as the prolonged CRD causes the valve to remain open throughout the pulse operation. Notably, the CRD at DC = 10% is shorter than other pulse condition, which will be further described below.

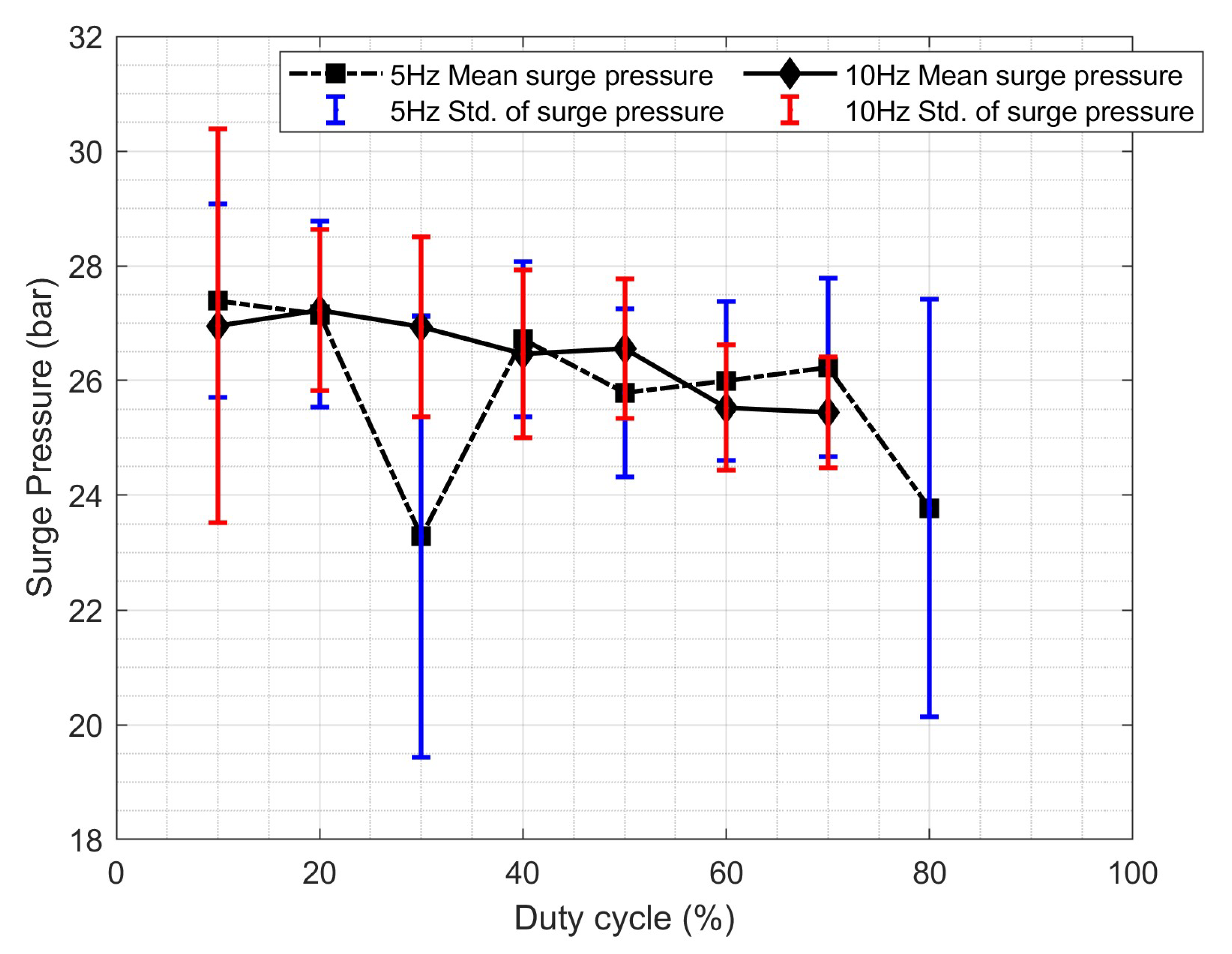

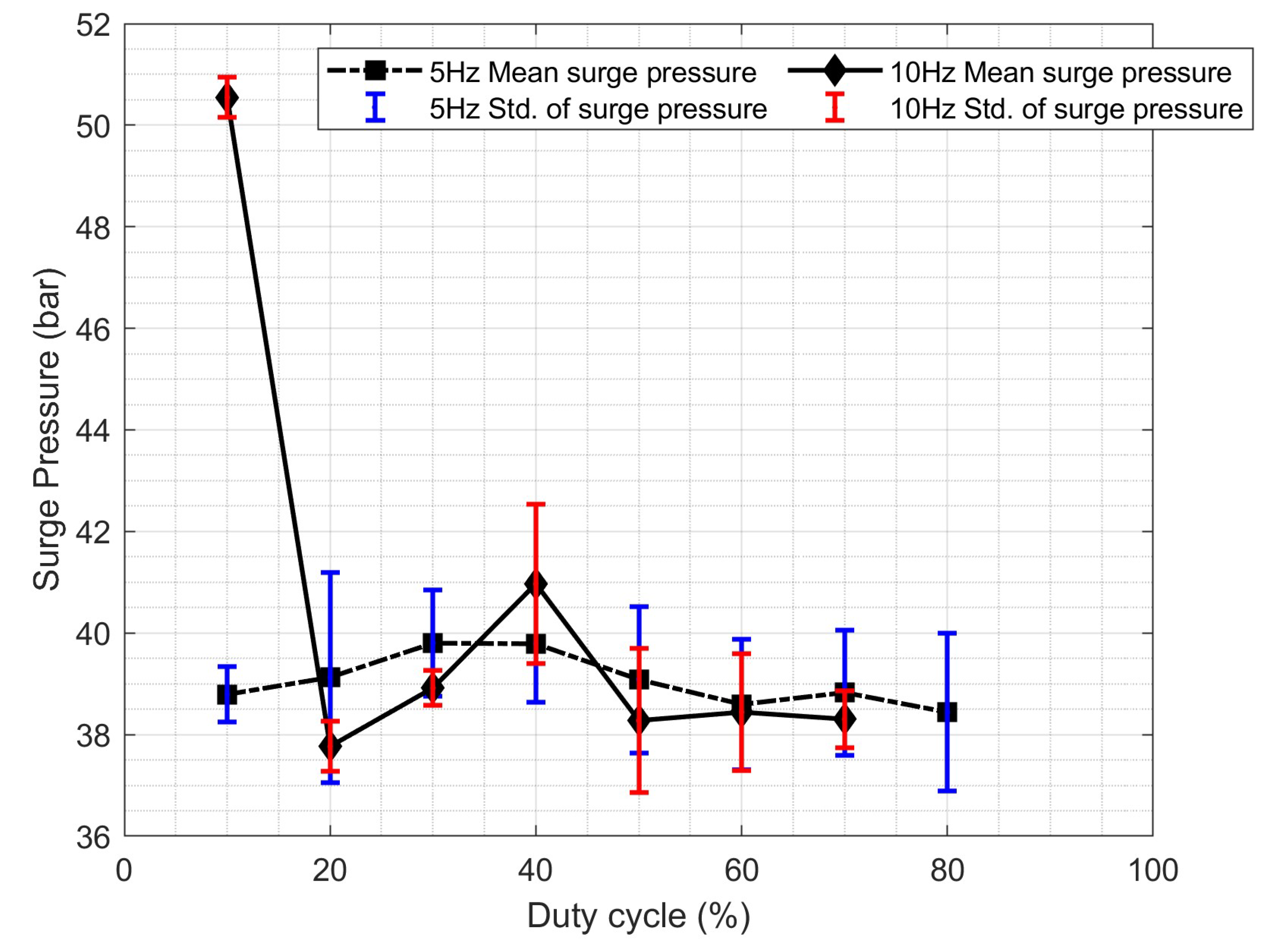

Water hammer pressures from pulse-width modulation (PWM) throttling at both frequencies were compared to steady-state measurements.

Figure 14 shows the mean and standard deviation of surge pressures across duty cycles. In pulse operation, surge pressures generally align with the steady-state value of 39.33 bar. However, at

= 10 Hz with DC = 10% and 40%, surge pressures exceed this average, peaking at 50.55 bar for the 10 Hz, 10% duty cycle condition. At

= 5 Hz, surge pressure variations were minimal. Unlike cold flow tests, prolonged valve closure does not account for the amplification observed in

= 10 Hz with DC = 10% condition, as surge pressures remained stable at

= 5 Hz, DC = 10% despite that the injector manifold pressure was lower than that of

= 10 Hz, DC = 10% duty cycle.

The amplified surge pressure at

Hz, DC = 10% likely explains the shorter CRD compared to other conditions. In the solenoid valve, an elastomer seal on the armature blocks the flow path when springs return it to its base upon power cessation. Elevated upstream pressure assists this motion. When surge pressure significantly exceeds that in other conditions, the increased force on the armature reduces closure time, thereby reducing CRD, as shown in

Figure 13.

Prior research offers insight into this phenomenon. Martin et al. [

8] noted that waves from prior water hammer events affect subsequent pressure fluctuations. The solenoid valve’s electromagnetic force induces fluid oscillations, generating compression or rarefaction waves in the feed line based on actuation mode. When the valve opens, a rarefaction wave is generated at

Hz. Conversely, a compression wave arises upon valve closure at

Hz. Thus, repetitive actuation fills the feed line with pressure waves at frequencies of either

or

, propagating between the propellant tank and valve with varying phases. Superposition between these waves, under specific pulse conditions, can lead to amplified surge pressure or pressure drops, as shown in

Figure 14. Two scenarios emerge: (1) valve closure induces a pressure surge via water hammer and the peak of the surge aligns with the crest of the pressure oscillation created from prior valve opening, or (2) valve opening induces a perturbation and the phase of undermost pressure drop aligns with the trough created from the prior valve closure.

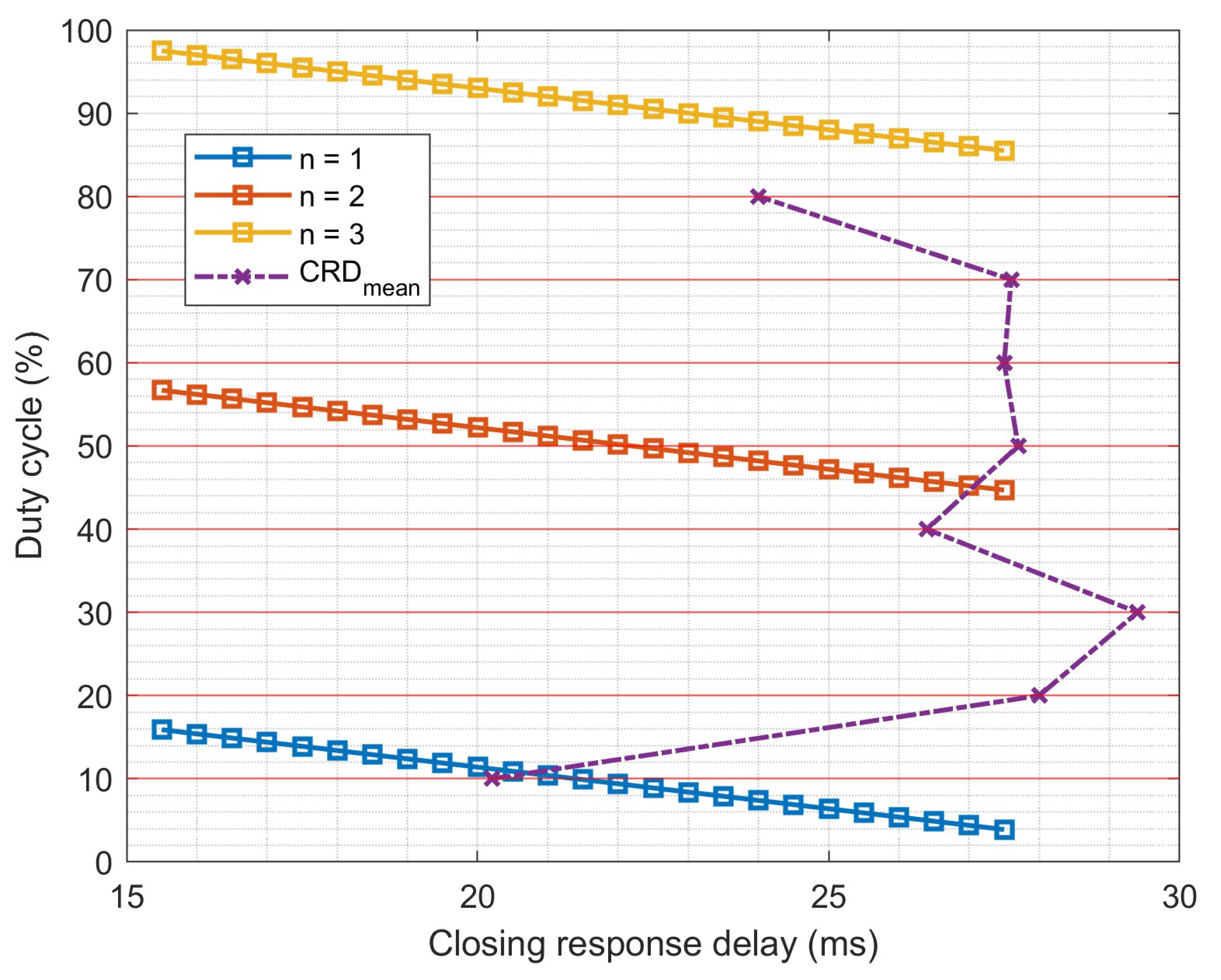

The first scenario is described by Equation (

6), which identifies pulse conditions that satisfy the criterion for constructive interference of pressure waves from consecutive valve actuations. Notably, CRD decreases with escalating surge pressure. The extended propagation of a wave before it superposes with the next actuation gradually dampens its intensity, thereby reducing the interference effect of the pulse conditions with higher

n.

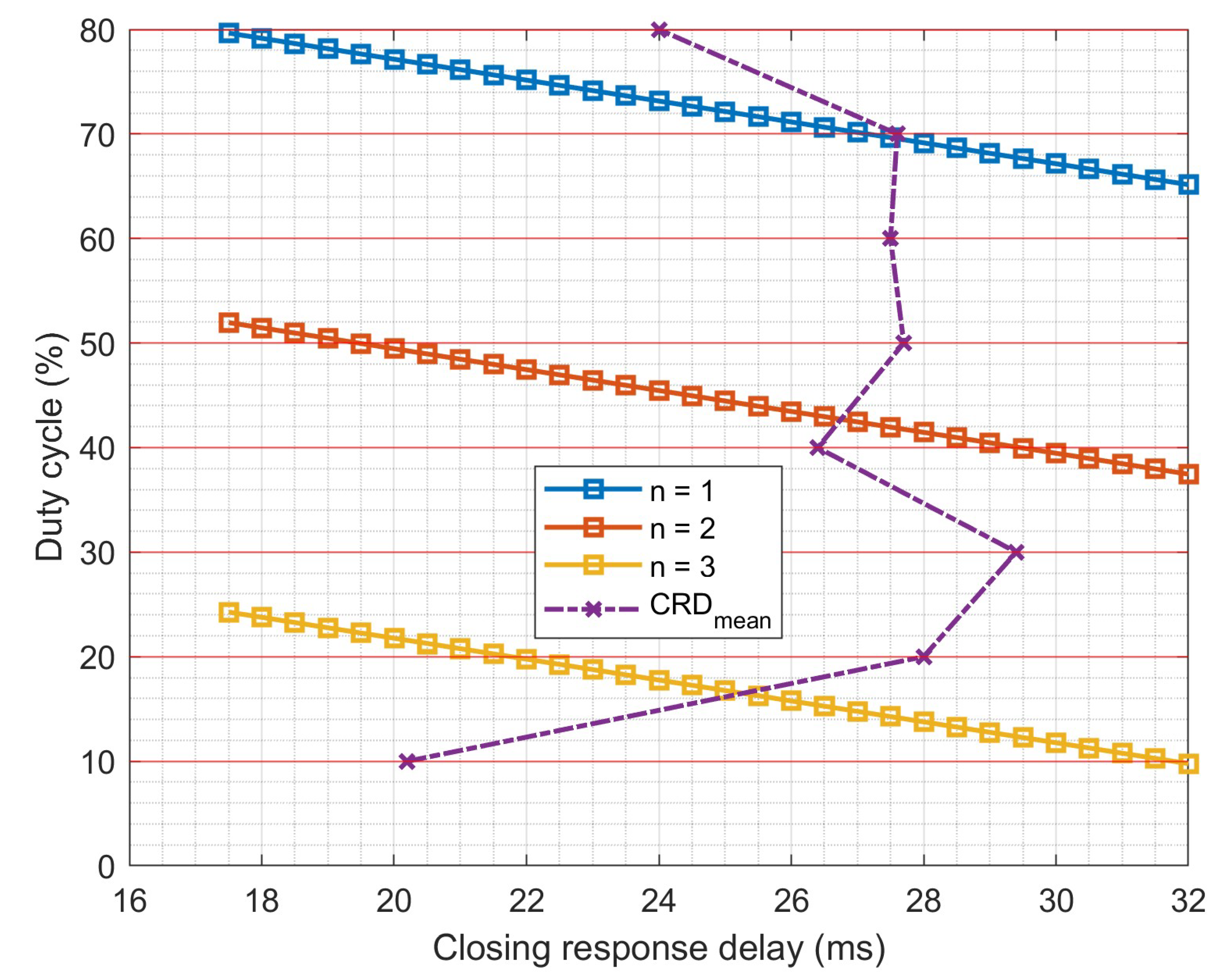

Figure 15 depicts pulse conditions that satisfy this criterion with varying CRD. For

n = 1 to 3, DC = 10% and 45% can provoke amplification, contingent on matching CRD to surge pressure. DC = 10% closely aligns with the criterion, explaining the amplified surge pressure in

Figure 14, while DC = 40% borders an unstable point, offset by 5%, resulting in moderate surge pressure increase as shown in the Figure. The unstable point at

(DC = 80%) cannot be achieved, as it causes the valve to remain open during PWM throttling.

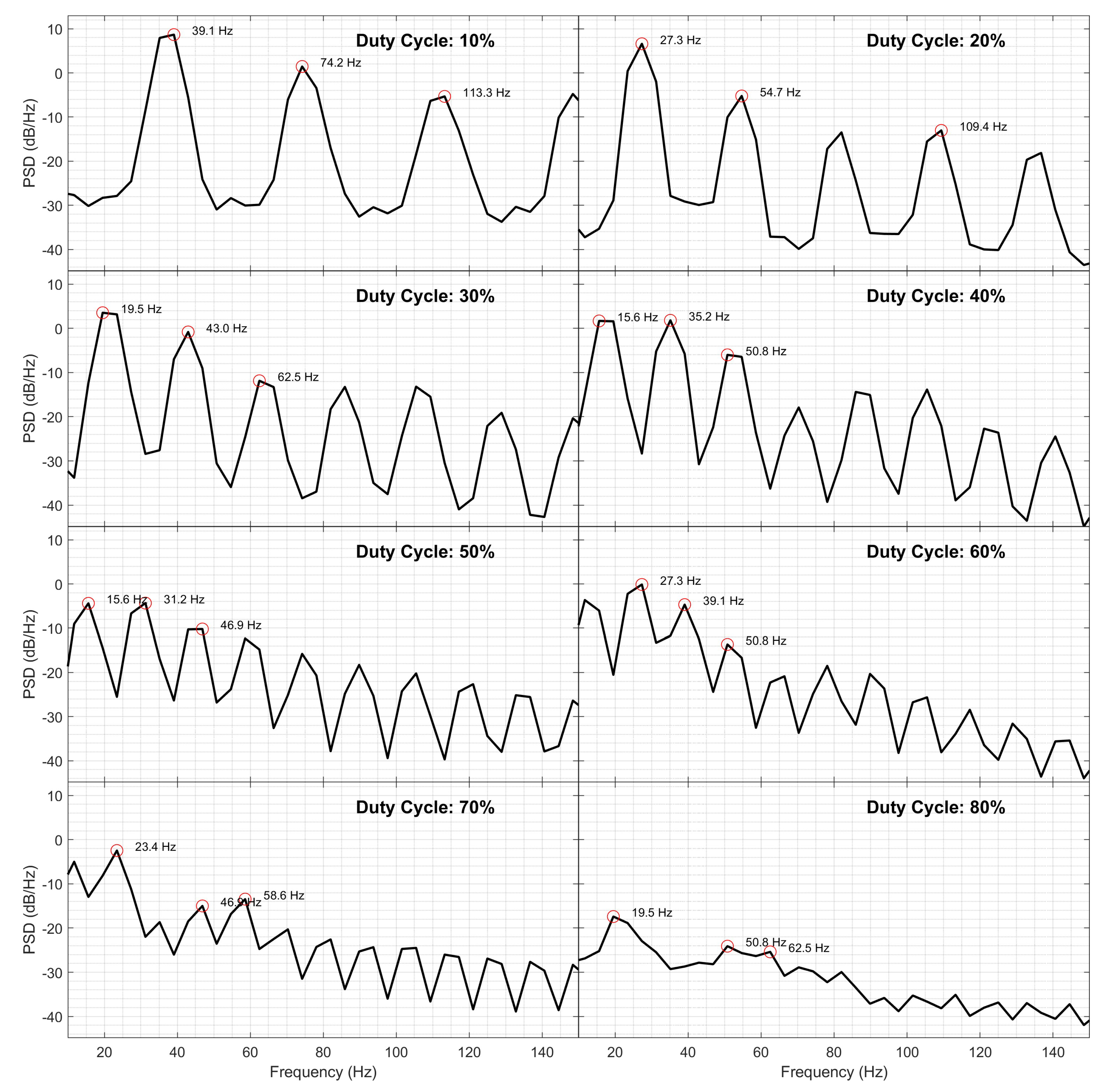

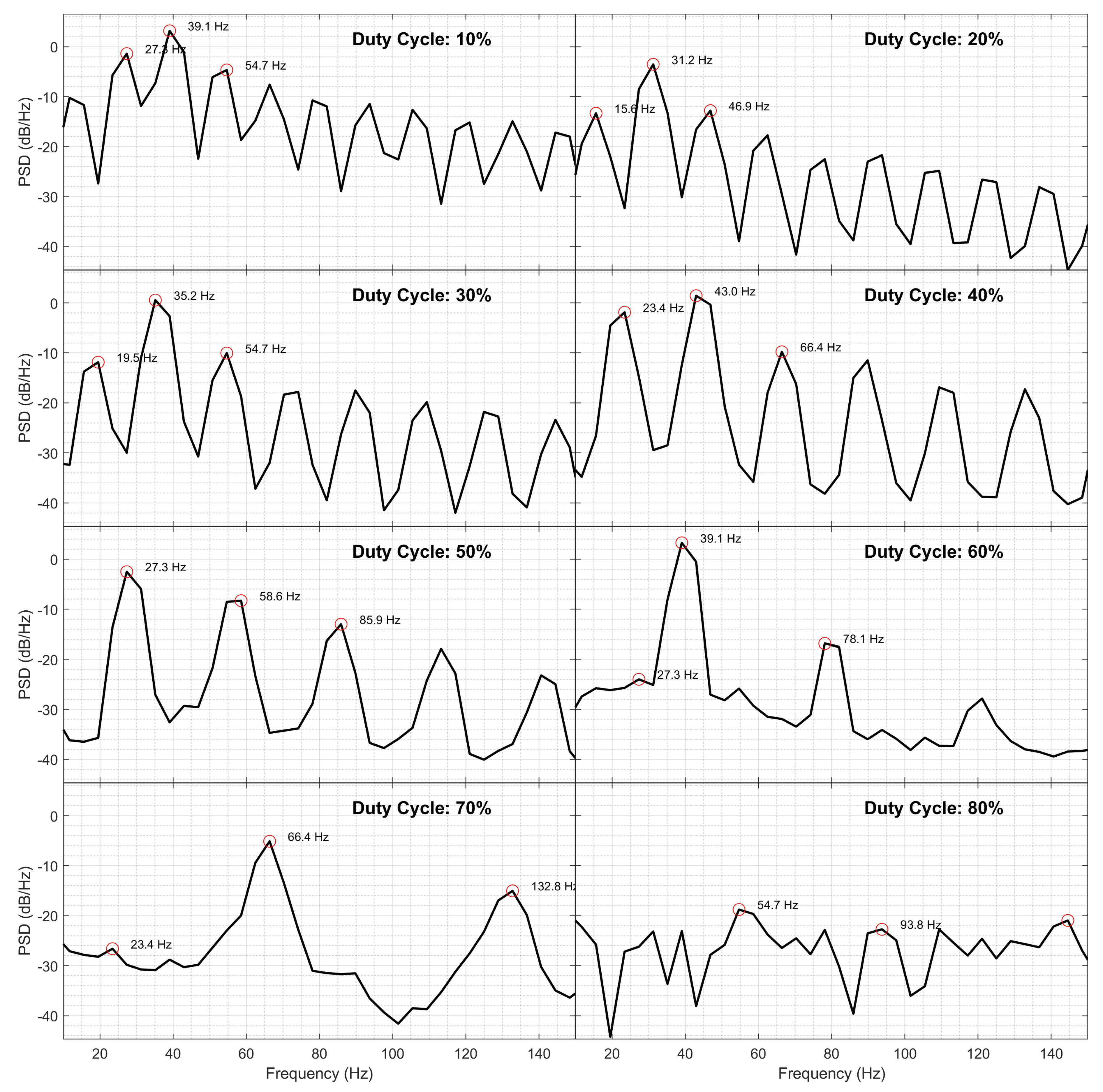

Figure 16 shows the power spectral density (PSD) estimate, derived via Welch’s method from pressure data at the solenoid valve upstream during valve opening. Due to abrupt flow changes from valve actuation, PSD analysis includes only measurements during valve opening. The figure reveals peaks at harmonics of the fundamental frequency, indicating that cyclic valve actuation serves as a source of forced oscillation. High surge pressure conditions (DC = 10% and 40%) exhibit a dominant peak and its first overtone near the natural frequency for the closed-valve configuration (

Hz). This demonstrates that existing perturbations constructively interfere with newly generated oscillations from water hammer, intensifying the oscillation.

The second scenario is described by Equation (

7), which identifies pulse conditions that the opening of the valve constructively interfere with the existing perturbation created by the previous valve closure, so that the pressure drop by the rarefaction wave could be amplified. Similar to CRD shortens with the increase of mean and surge pressure, the drop in valve upstream pressure could also shorten the ORD, by reducing the force acting on the armature that pushes it against the base.

Figure 17 depicts pulse conditions satisfying this criterion for varying CRD, which depends on upstream valve pressure. For

to 3, DC = 70%, 40%, and 16% can induce amplification if CRD aligns with surge pressure. DC = 70% matches the constructive interference condition, while DC = 40% nears the sufficient condition but undergoes greater damping in the first overtone due to extended propagation before interference. Unlike the first scenario, constructive interference here significantly lowers pressure when the valve opens, flushing liquid out of the feed line. Given the valve closure duration and wave propagation dampening the perturbation, the pressure oscillation contributing to surge pressure increase is negligible by valve closure.

Figure 18 shows the PSD estimate from pressure measurements upstream of the valve while it is closed. Many peaks correspond to those in

Figure 16, indicating that pressure perturbations persist through valve actuation. Notably, the PSD in the second scenario is less significant than the first, obscuring differences between conditions with and without constructive interference. This trend arises from liquid flow: when the valve opens, rarefaction waves propagating counter to the flow direction undergo significant energy loss, reducing perturbation amplitude despite constructive interference.

Reduced pressure during liquid injection significantly affects propulsion system stability. Chugging instability arises from dynamic interactions between the propellant feed and catalytic reactor; its suppression requires decoupling these dynamics with a sufficient pressure drop across feed components. If pressure during propellant injection decreases markedly, the reduced pressure drop heightens the likelihood of chugging instability onset. The pulse conditions for maximum rarefaction wave superposition are at a DC of 70%, with a valve closure duration (

) of 13.5 ms. This brief period limits gas ejection without propellant injection, sustaining high reactor pressure and further reducing the pressure drop.

Figure 19 illustrates significant thrust fluctuations during continuous valve opening. Conversely, smaller DCs involve discrete thrust generation without steady-state operation, rendering chugging instability less significant.

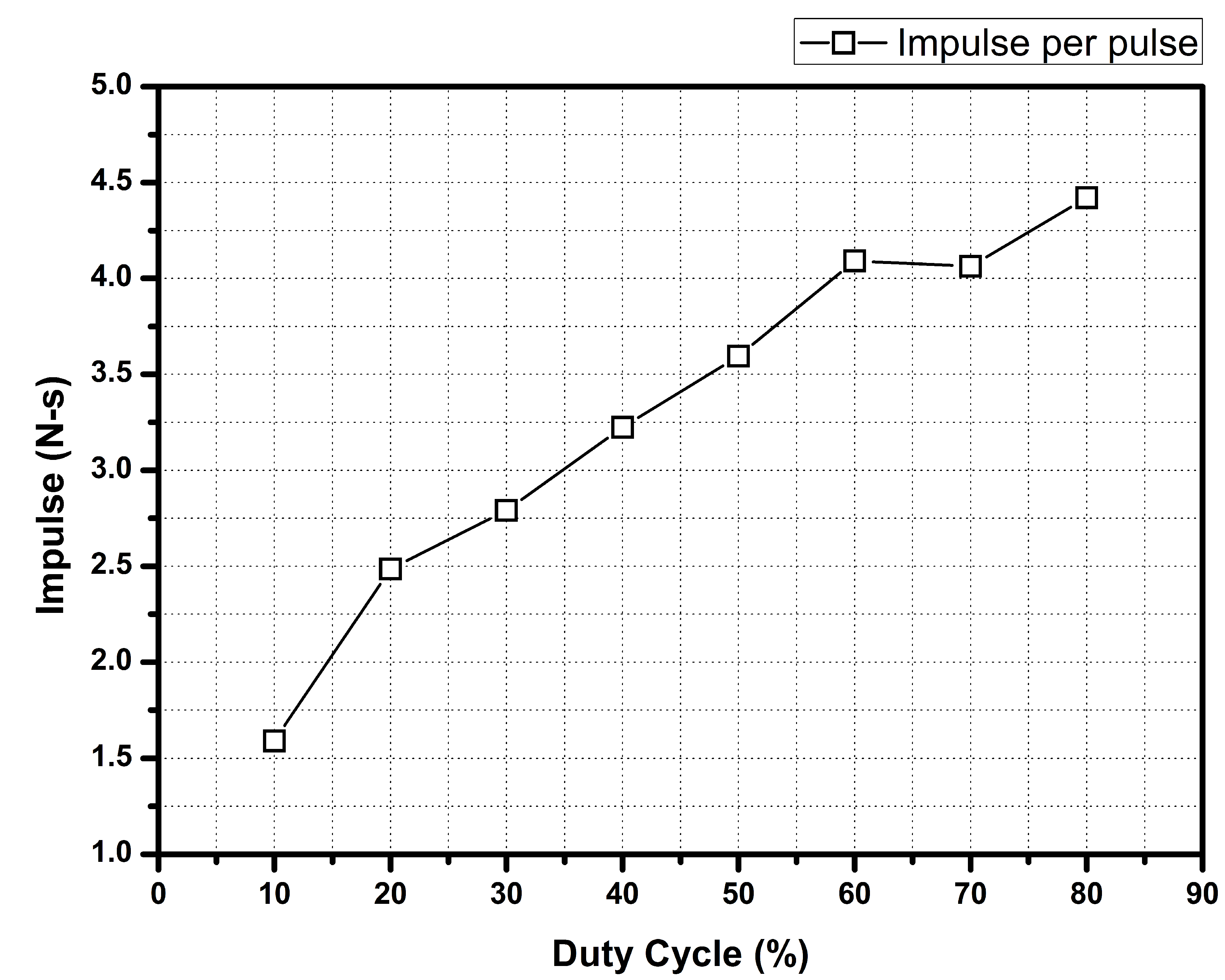

The ideal impulse per pulse for any condition is given by Equation (

8). However, accounting for valve response delays, propellant injection fluctuations during transients and due to chugging instability, and residual pressure post-closure, the actual impulse per pulse was measured using Equation () and is shown in

Figure 20. Negative thrust readings, attributed to thruster and feed system vibrations, fell below the load cell’s offset and were thus ignored in calculating impulse per pulse against duty cycle (DC). The results indicate that, as with the 10 Hz condition, impulse per pulse generally increases linearly with DC, but deficiencies occurred at DC = 10% and 70%. At DC = 10%, reduced thrust likely results from significant structural vibrations induced by amplified surge pressure, disrupting measurement. At DC = 70%, chugging instability, triggered by low pressure drop across feed components, induces periodic propellant injection fluctuations, reducing thrust.