1. Introduction

Essential oils (EO) are oils or volatile compounds extracted from various parts of plants, especially fruits that contain chemical compounds and medicinal properties, whether they are in the fruit, flowers, peel, seeds, leaves, roots, underground stems, and bark. There are many types and species of plants that can provide EO. The use of EO is diverse. The trend of its use is increasing currently and will continue in the future because market demands and populations around the world are paying greater attention to health and products that do not harm the environment. Medicinal herbs and plants are the first choices for extraction to produce natural EO. This has led to increased need for essential oils in various industries, such as the food and pharmaceutical industries, and as ingredients for fragrance in products promoting health and wellness. EO are also used as ingredients in consumer products such as toothpaste, soap, shampoo, and detergent. Due to their medicinal properties and fragrant smell, they serve as key ingredients in the cosmetic and medical industries. Furthermore, essential oils serve as insect repellents in environmentally friendly agriculture without using pesticides. In high-value agriculture, 100% organic farming plots use essential oils either directly or as diluted mixtures in sprays to repel pests. Research has shown that some essential oils contains compounds derived from carnosol, rosmanol and rosmaridif, which have higher antioxidant activity than synthetic antioxidants [

1]. Some essential oils (EO) contain biologically active compounds and chemical volatile compounds that are distinctive. These compounds have unique smells that are naturally created by the conditions in which the plant is grown. Some plants are well-accepted and well-known, having been in the retail market for many years, especially export markets, on a global scale, focusing on developed countries. Approximately 80% of the world’s essential oil exports go to Europe, Japan, and North America. Each region has its own unique characteristics, and the growth of the plants is different. Many plants are indigenous plants that are known and used regularly by people in that area. To obtain the essential oils from each plant, extraction methods are used to obtain essential oils from various parts of the plant, such as leaves, bark, roots, flowers, and seeds. The most popular method of extraction to obtain essential oils is "distillation". Essential oil extraction by distillation is used for almost 90% of essential oils produced [

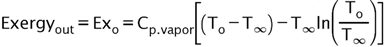

2]. The steam used in the distillation extraction method is produced and created in the boiler area or steam source. The steam will rise and pass through the distillation tank with a screen containing the raw materials or plants to be extracted. When the heat from the steam hits the raw materials, the steam will carry the essential oils. In that type of plant, flows out through a pipe that is a route through a spiral pipe that is nourished with cold water in the condensation area to reduce the temperature and condense into a liquid. After that, the liquid from the condensation that is obtained will flow through the condensation pipe into a glass tube. The essential oil is separated from the water and then the essential oil (EO) and essential oil extract (Hydrosol) that are obtained are taken together with the container to check the quality and standards of Chemical composition [

3,

4] The steam used in the distillation extraction method is produced in the boiler area or steam source. The steam rises and passes through the distillation tank with a screen containing the raw materials to be extracted. When the heat from the steam contacts the raw materials, the steam carries the essential oils. The mixture flows through a pipe through a spiral pipe that is cooled with cold water in the condensation area to reduce the temperature and condense into a liquid. Subsequently, the condensate flows through the condensation pipe into a glass tube. The essential oil becomes separated from the water, and the essential oils (EO) and hydrosol are collected to check quality and standards of their chemical composition [

3,

4].

For EO extraction by distillation method, the advantage is that the form, method and equipment are not complicated. Another advantage is that almost all parts of the plant that need to be extracted can be distilled, and the distilled EO is of good quality and pure. Some active ingredients in some essential oils do not actually exist in nature, but will occur under the steam distillation process, such as Chamazulene, which is a blue substance that is an active ingredient in EO [

3,

5,

6]. The amount of essential oil in most plants or raw materials that are extracted is usually low, about 0.2 to 3 percent of the weight of the plant. When extracted, it results in a small amount of EO. Therefore, the quality and standard of the extracted EO must be checked, that is, it must have a quality that can be verified with a quality analysis process called Gas chromatography–mass spectrometry (GC-MS): which is widely used and accepted to examine volatile substances or chemical components of the extracted essential oils [

4,

5]. Considering the market and trade trends of essential oil usage, it tends to increase in the present and future world, both domestically and internationally, as mentioned above. With the nature of the health of the population in every country, as well as the concern for nature and the environment [

2], which is a challenge in producing essential oils in sufficient quantities to meet the demand, along with having quality and standards when passing the GC-MS inspection process. From the aforementioned problems, there have been studies and researches to find methods to increase the efficiency of extraction to obtain a higher amount of essential oils along with the quality of essential oils from extracted food, as well as the development and design of modern essential oil distillation equipment that is ready for use with the development of extraction techniques, whether it is the form and size of the essential oil distillation machine to be used with small and medium-sized enterprises (SMEs). Due to the importance of business and advantages, it was found that SMEs have more business flexibility than large companies and industries. It is more difficult for large companies and industries to operate smoothly. With the advantages of SMEs mentioned above, they have played an important role in many economies around the world [

7].

Therefore, this research focuses on studying and applying it to entrepreneurs or SMEs community enterprises. In the past, there have been studies on the process and formats of essential oil extraction (EO) by various methods, such as Supercritical Fluid Extraction (SCFE), Ultrasonic Extraction (UE), Solvent Extraction (SE), Hydro distillation (HDD), Steam Distillation (SD), Superheated Steam Distillation (SHSD), or even Cold Extraction (CE). These methods are considered popular essential oil extraction or distillation methods that are currently used. Each method is suitable for different plants or raw materials to be extracted [

3], [

8]. Case study of cannabis leaf distillation with HDD or SD and SCFE. The test results found that the use of supercritical fluid extraction techniques (Supercritical Fluid Extraction, SCFE) gives the highest amount of essential oil (EO) [

9] and to clearly see the form and extraction process in the comparison of essential oil amounts. The quality and standard of EO extracted in each method, whether it is supercritical fluid extraction, CO

2 is often used as the extraction liquid. Because it has better benefits than other solvents, whether it is inertness, easy availability, as well as the ability to select suitable for heat-sensitive compounds. Including being non-toxic to nature and the environment It is considered an advanced technique for the extraction of bioactive compounds. Each extraction method has both advantages and disadvantages. For example, Supercritical Fluid Extraction (SCFE) has the limitation that it is suitable for non-polar substances. Which will increase the polarity a lot.

It can be done by adding methanol to the mixture. The gas used to extract plant substances is popularly CO2. But because pure CO2 is expensive, along with the preliminary extraction, there is often resin precipitation leading to blockage at the channel where the extract will flow out [

10,

11]. Therefore, it is necessary to solve the problem by using heat to assist in the industry. When the extraction method must be used, it brings about the following complications. It must be designed to be suitable for the extraction of each type of substance. In addition, studies have been conducted on Hydro distillation (HD), Steam Distillation (SD), and Supercritical Fluid Extraction (SCFE). The tests found that SCFE gave a higher amount of essential oil than all the tested methods, with the amount of oil obtained from SCFE equal to 0.039%, HD equal to 0.035%, and SD equal to 0.032%, respectively [

12]. Due to the nature of water distillation, in the case of having to distill a large amount of plants, the heat given to the distillation vessel will not be consistent throughout the distillation vessel. Causing combustion or decomposition of some components causing the smell of the essential oil to change or there may be a smell of the container. Including studies Extraction of essential oil from betel stems by steam distillation and comparison of microwave oven distillation. From the test, it was found that SD gave the essential oil content of 54.0 percent, which was higher than microwave distillation which gave the essential oil content of 34.6 percent [

13]. For the extraction of essential oil by distillation method, it is another method that has been popular from the past until now. With the advantages of the distillation method as mentioned above. For EO distillation, it is divided into Hydrodistillation (HDD), Water and Steam Distillation (WASD), Steam distillation (SD), Superheated Steam Distillation (SHSD), each distillation method has differences and advantages. Therefore, it can be seen that there are many methods of extracting essential oils from natural plants. The selection of essential oil extraction method must consider the characteristics and various factors, such as the part of the plant to be extracted, the chemical and physical properties of the essential oils required, and the purpose of using the essential oil.

From the previous research, there was a study on the development of the method of distillation of essential oil from parsley by steam distillation (SD) and superheated steam distillation (SHSD). When considering the test results, it was found that SHSD gave a higher amount of essential oil than SD distillation. The results were analyzed by GC-MS, showing that essential oil (EO) obtained from SHSD has the highest antimicrobial potential [

13]. Superheated steam is steam that is heated to a temperature higher than the boiling point at a specified pressure. The temperature of superheated steam (101 °C to more than 1,000 °C) depends on the pressure and the source of the steam. It has high heat conductivity and pressure, low oxygen capacity and high extraction or distillation efficiency, leading to the ability to separate a variety of polar and non-polar substances [

14,

15]. Superheated steam distillation (SHSD) requires very hot steam for extraction. The properties of the steam are especially hot and the state of the steam has an important factor in controlling, which is pressure. This is an important factor in the separation of essential oil (EO) with SHSD [

15,

16]. Inside the distillation tank and throughout the system, the pressure must be controlled at a constant level. Another thing that must be controlled is the system and equipment when extracting essential oils with SHSD to prevent condensation of steam that will turn into liquid [

17]. Past research found that SHSD is a highly efficient method for extracting EO, but it is still not widely applied to large-scale industries or SMEs [

18]. It may be due to the relatively high investment cost and the use of the system that requires experts to control the distillation machine if it is used in industry. Therefore, it can be seen that Superheated steam distillation for EO The experiment was mostly in the laboratory. The experiment was in the form of When considering the extraction of essential oils from flowers such as roses, it was also found that rose essential oil is not popular with SHSD extraction, perhaps because it is not suitable for plants or raw materials that are easily destroyed. When faced with the intense heat of steam from the superheated stream as with jasmine essential oil [

19,

20] this is another important problem of superheated stream distillation. In the past, it can be seen that each method of extracting and distilling essential oils has its own advantages and disadvantages as mentioned above. For the problems and limitations found in each distillation method mentioned above and the suitability of the technology that must be used and supported in each distillation method, in addition to the past, there was also information found that the extraction of essential oils by the re-distillation technique with water and steam is considered a new distillation technique.

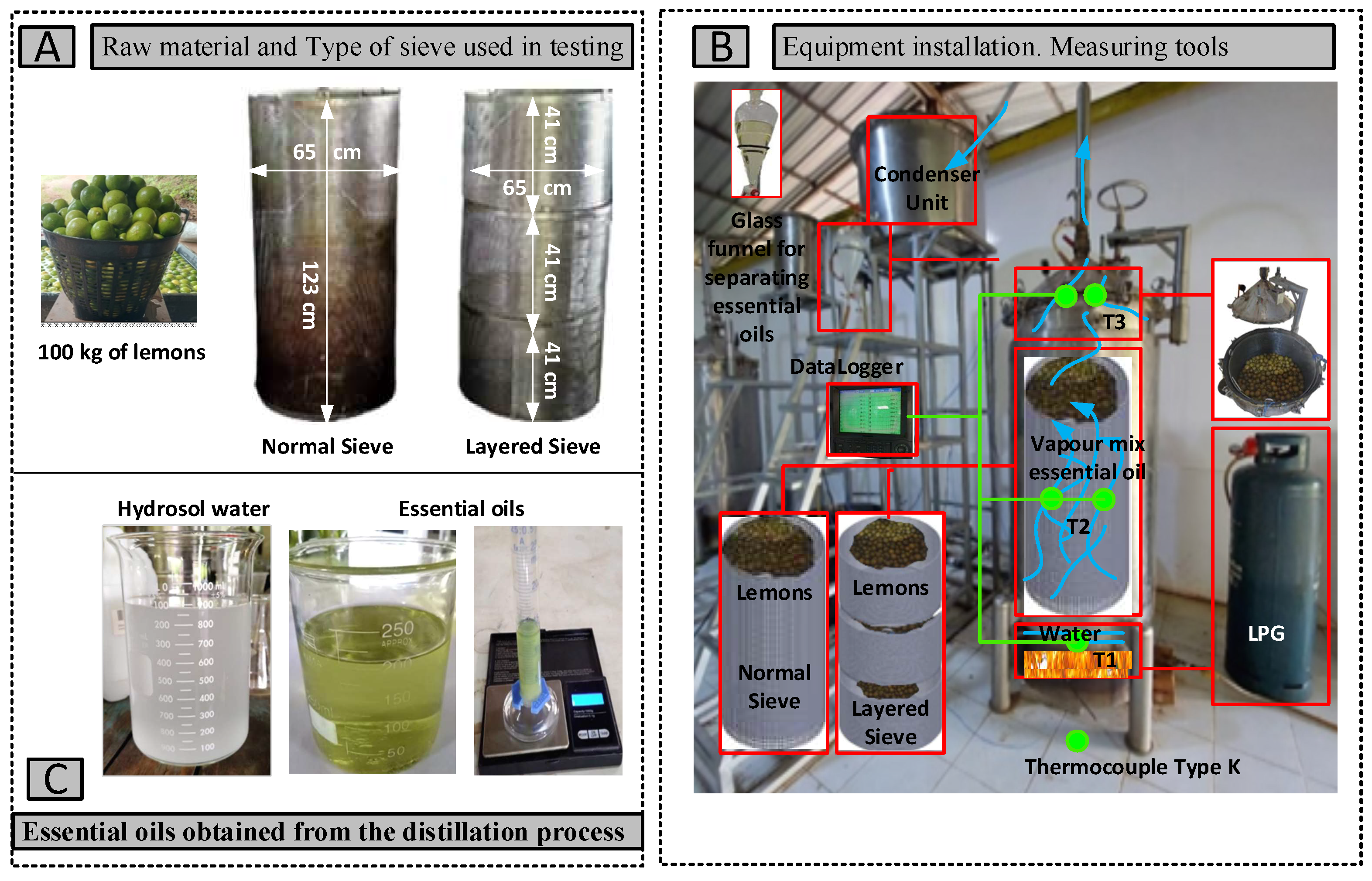

Therefore, this research aims to increase the efficiency of essential oil distillation by re-distillation with water and steam, which is applied to a 500-liter prototype distillation machine that has been designed and built, along with comparative testing of its use with different raw material grids, namely, a normal grid and a layered grid, along with confirming the standard and quality of the distilled EO from the GC-MS analysis process, focusing on the development and creation of applications to medium-sized and small-sized enterprise industries, respectively, in order to provide basic information for future development and development.

2. Related Principles and Theories

2.1. Extraction of Essential Oils by Distillation

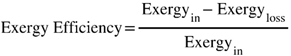

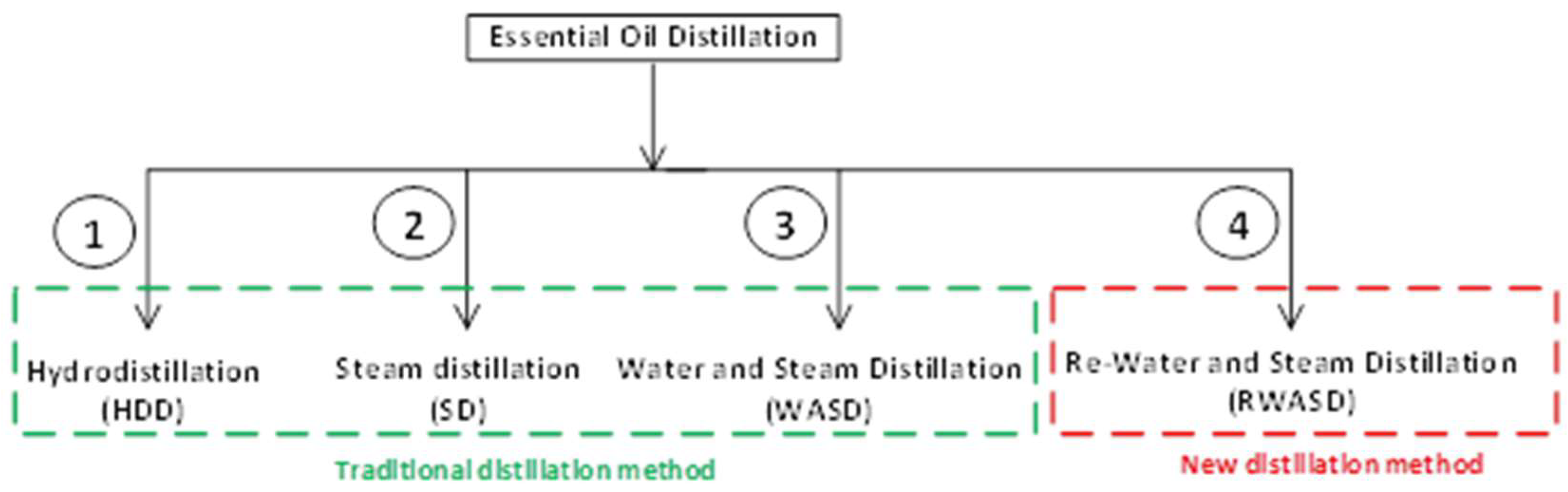

For distillation, it is another popular and widely used method for extracting essential oils because of its many advantages. Distillation is an economical method and can be used to separate almost all types of essential oils. Essential oil extraction by distillation is divided into Hydrodistillation (HDD), steam distillation (SD), and steam distillation (SD). There are many types of plants that give off aromatic scents on their leaves, stems, bark, fruits, and roots. Such aromas can be extracted and separated to obtain a clear or light-yellow liquid similar to oil that evaporates at room temperature. The liquid obtained from the extraction is called essential oil (EO).

Essential oils will be effective and of good quality. There are important things to control in distillation: the duration, temperature, and distillation method that are appropriate for each type of plant or raw material, which will directly affect both the quantity and quality of EO. Therefore, the extraction or distillation of essential oils must be carefully considered because EO consists of many compounds or volatile substances. For the 3 essential oil distillation processes, the principles, operations, and steps are as follows:

1) Hydrodistillation (HDD) is the process of distilling the plants or raw materials to be distilled by placing them in a nearby pot, adding water until the plants or raw materials to be distilled are completely submerged, and boiling until the water boils. When the boiling water evaporates into vapor, the vapor will rise and move through the plants or raw materials. The vapor will help carry the essential oils in the plant tissues out. When passing through a condenser, the vapor and the essential oil vapor will condense into a liquid that becomes water, and the essential oils will be separated. The disadvantage of this method is that in the case of distilling a large amount of plants, the heat given to the distillation pot will not be consistent throughout the distillation pot, causing some components to burn, causing the smell of the essential oil to change, or there may be a burnt smell attached to the EO. This method is suitable for distilling small quantities of plants in the laboratory.

2) Steam distillation (SD) by placing the plants to be distilled on a grid above the distillation pot, with steam produced from the steam source flowing through a conveyor pipe into the distillation pot. The steam used in this distillation method is saturated steam. The steam will float up. The heat from the steam will carry the essential oils in the plants to evaporate quickly. The limitation and inconvenience of this method is the additional equipment, which is a set of steam sources, which makes the distillation machine more expensive and the maintenance during use is higher than both HDD and WASD distillation. Therefore, it affects commercial use and the essential oil industry, which is not very much. Plants that are not suitable for distillation by this method are usually flowers.

3) Water and Steam Distillation (WASD) will place the plants to be distilled on a grid above a boiler. Heat until the water boils and turns into steam. The steam used in this method of distillation is saturated steam or wet steam as shown in

Figure 2 and

Table 1. The steam will help carry the essential oils through the conveyor pipes. Condensation occurs in the condensing area by the steam cooling the low-temperature cold water flowing in and out of the condensing section. This results in a change of state from steam to liquid with essential oils mixed in as shown in

Figure 1. This distillation method uses saturated steam, the properties of which will be discussed in the next section as shown in

Figure 2 and

Table 1. Essential oils distilled by this method are of good quality and are another method of distillation widely used in the production of essential oils in industry and commercial use.

All three methods of essential oil distillation are considered as distillation methods that have been used for a long time from the past to the present. Every distillation method has both advantages and disadvantages, depending on many factors that affect the selection of distillation methods, such as the type of plant or raw material, the amount of oil to be used, the cost of the owner in distillation, the size of the industry, and the components of distillation technology in each area, as well as the amount and quality of essential oils to be used. For another new method used in distilling essential oils that will be used and presented is re-distillation with water and steam, as shown in

Figure 2.

2.2. Re-Water and Steam Distillation (RWASD)

For the Re-Water and Steam Distillation (RWASD) method, it is another new distillation method to be presented in this research, in addition to the three traditional essential oil distillation methods, of which RWASD is the fourth method, as shown in

Figure 2.

1) Hydrodistillation (HDD), 2) Steam distillation (SD), 3) Water and Steam Distillation (WASD) and 4) Re-Water and Steam Distillation (RWASD). For RWASD,

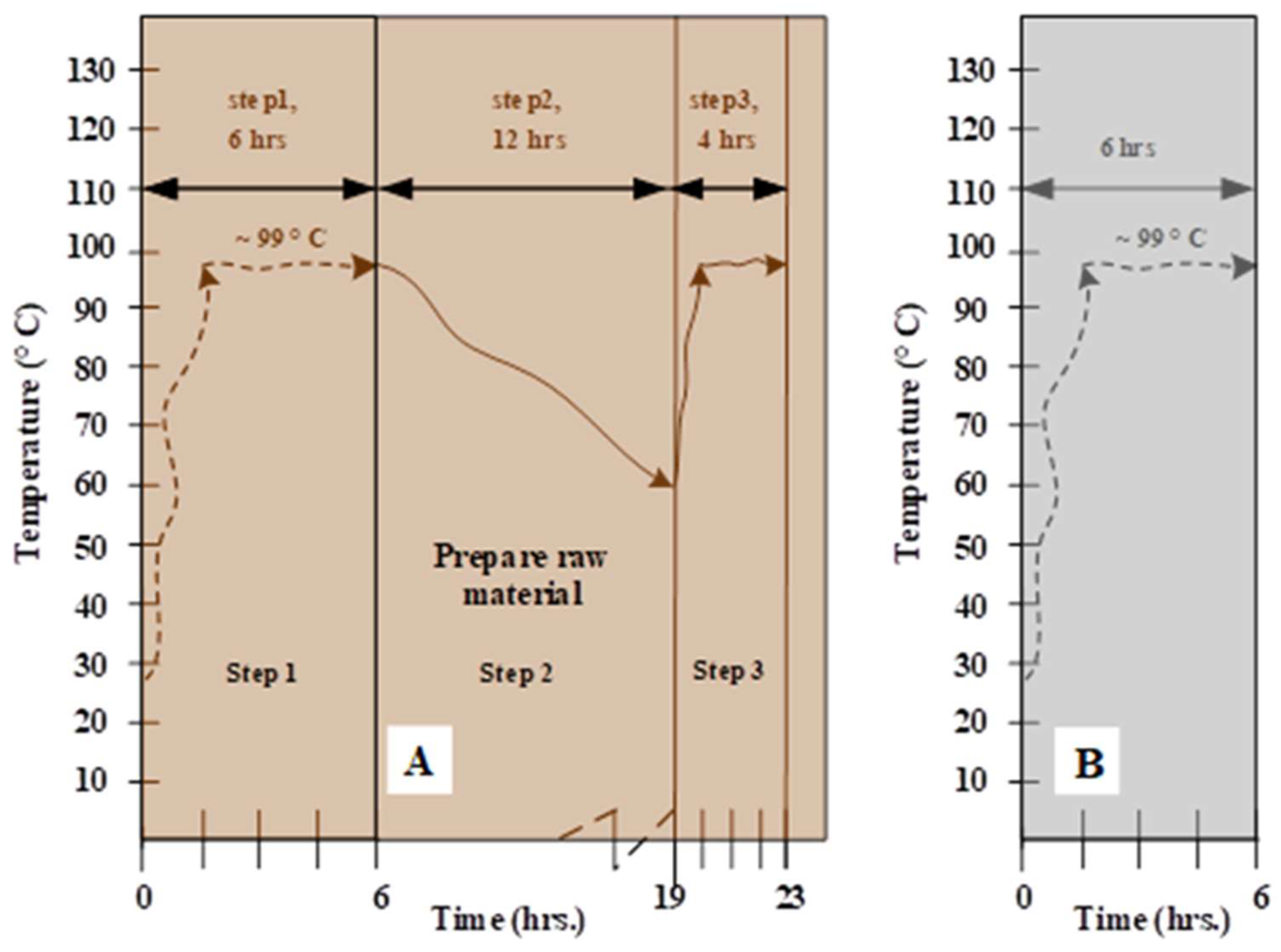

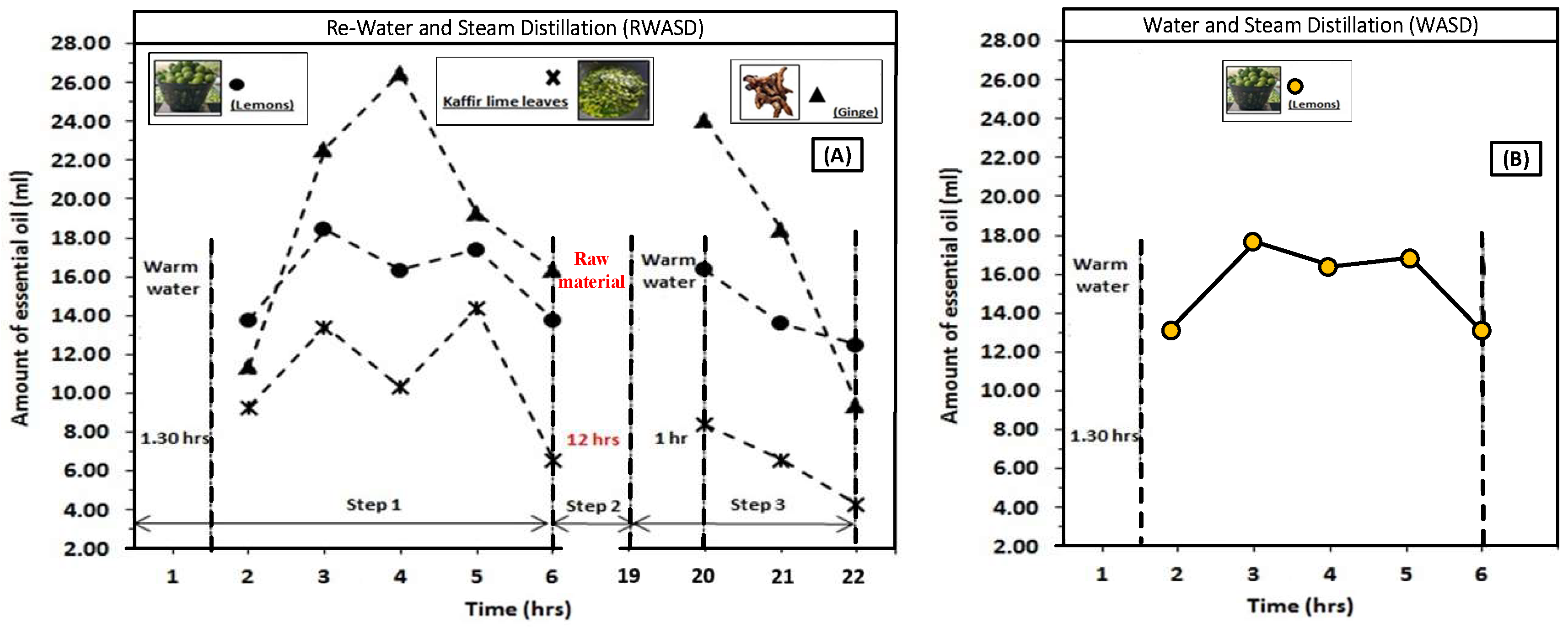

Figure 3 shows the relationship between distillation time and temperature of water and steam.

Figure 3 (A) is the re-distillation method with water and steam (RWASD). RWASD is the distillation tested in this research. It will be distilled together with a 500-liter prototype distillation machine using lime as the raw material. From

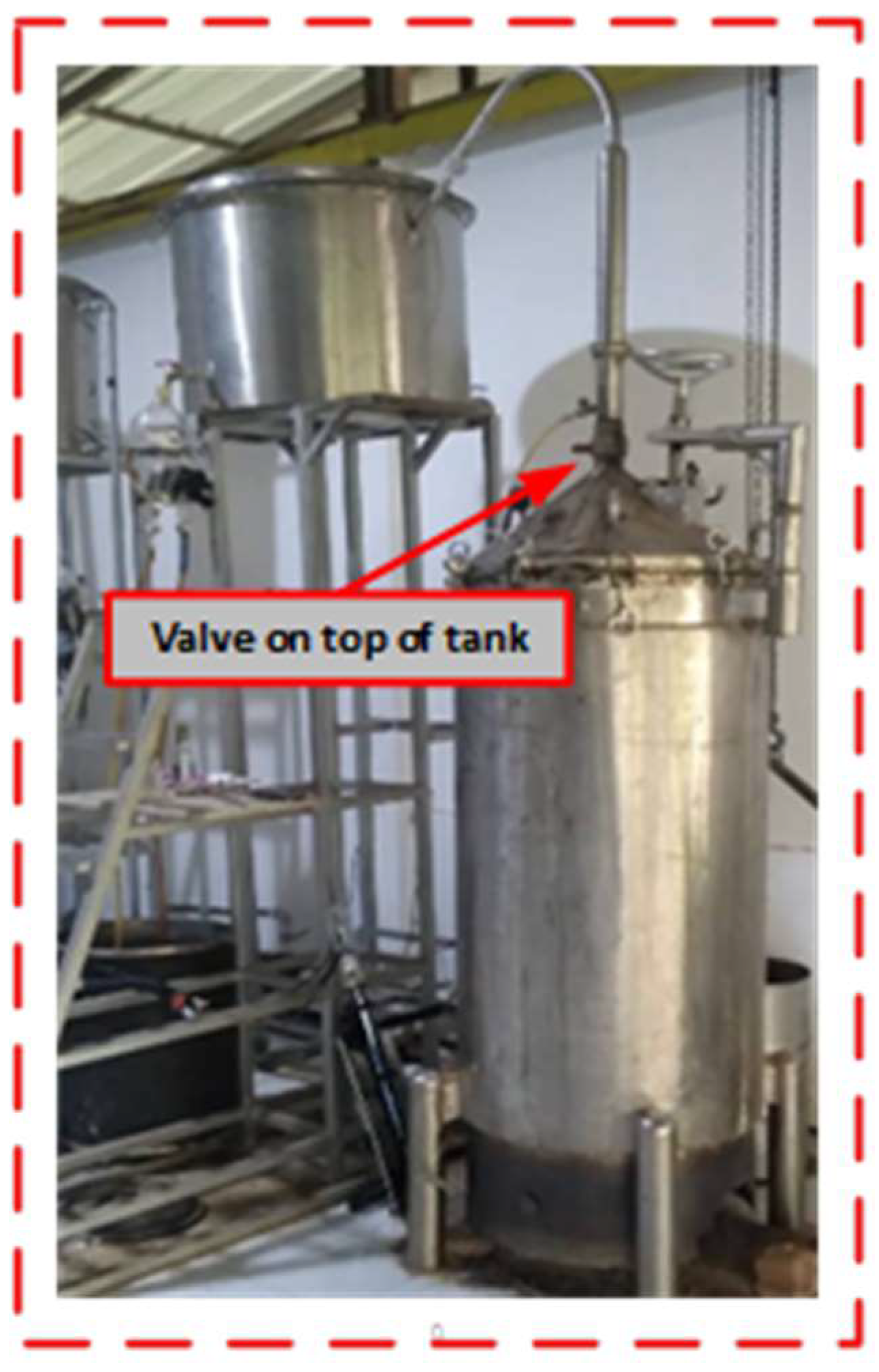

Figure 3, the re-distillation with water and steam will initially start at the Step 1 or ZONE 1 area, which is when the raw materials are loaded into the grid and the essential oil distillation pot. The burner is ignited. The water contained in the 100-liter water storage area is heated and will begin to change state from liquid to vapor. The steam temperature rises to approximately 99 °C for 1 hour and 30 minutes. At that time, the valve on the top of the distillation vessel head is in the closed position as shown in

Figure 4. Until approximately 1 hour and 30 minutes, the valve is opened in order to prevent heat loss from the steam and the steam floats into the condensing section too quickly and leads to the boiling of water in the water storage area, which will take longer time. In Zone 1 of the essential oil distillation process by RWASD method, it has been started for 6 hours. When considering together with

Figure 3(B), the water and steam distillation (WASD) has a pattern that has a relationship between time and temperature, as well as the properties of the steam used in the distillation as shown in

Figure 5 and

Table 1. When considering Zone 2 of RWASD, it can be seen that the steam temperature is low to approximately 60 °C after 19 hours and in Zone 2, it will take almost 12 hours, which will be the closing of the LPG fuel valve, no fuel is used and the valve at the distillation vessel head position is closed. This results in the raw materials used to distill essential oils being aged in the distillation tank for 12 hours in ZONE 2. The process in ZONE 2 is important because it is considered a step to prepare the raw materials to be sent to the ZONE step. In this step, the raw materials will release their substances without stress, resulting in the essential oil transport route within the raw materials. Expanded and helped the heat from steam to gradually penetrate into every surface area of the raw material better, that is, the remaining hot steam will move and penetrate through the fibers of the raw material with enough time to extract the remaining volatile substances in the raw material. When starting the distillation process in ZONE 3 as shown in

Figure 3 (A), the stove is lit. It can be observed that the heat temperature of the steam has increased to approximately 99 °C for approximately 1 hour. At that time, the valve on the top of the distillation tank will be in the closed position until the steam temperature and pressure are in a saturated steam relationship and the valve is opened. Continue distillation for another 4 hours for ZONE 3. For the distillation period of 4 hours in ZONE 3, it is considered a suitable time. When considering the break-even point of both the cost of purchasing LPG gas and the amount of oil obtained after the distillation time of 4 hours, when considering together with the distillation method with water and steam, it can be seen that the differences of the RWASD distillation method.

WASD distillation method, i.e., ZONE 2 and ZONE 3 areas, these steps are rarely described and combined with the presentation of a single common distillation technique. Therefore, it can be said that this is a prototype of a high-value steam distillation extraction process in the future. The repetitive distillation technique can be used to extract essential oils to maximize their benefits and create cost-effectiveness in using raw materials. Although the repetitive distillation technique is not suitable for all herbal plants, this research uses fresh lime as a raw material. In addition, the RWASD distillation method was tested on herbal plants that contain essential oils in the leaves and tubers or shoots to confirm and demonstrate that the RWASD distillation method can be used to cover all parts of herbal plants. It is well known that extracting essential oils in sufficient quantities to meet demand and control marketing costs requires a large amount of raw materials for distillation, as well as considering the quality or chemical composition of the distilled EO. Therefore, the RWASD distillation method is considered another new distillation method that should be disseminated and more widely used to meet the needs and solve the problems of the essential oil distillation process [

21,

22,

23].

2.3. Status and Properties of Steam Used in Re-Distillation with Water and Steam

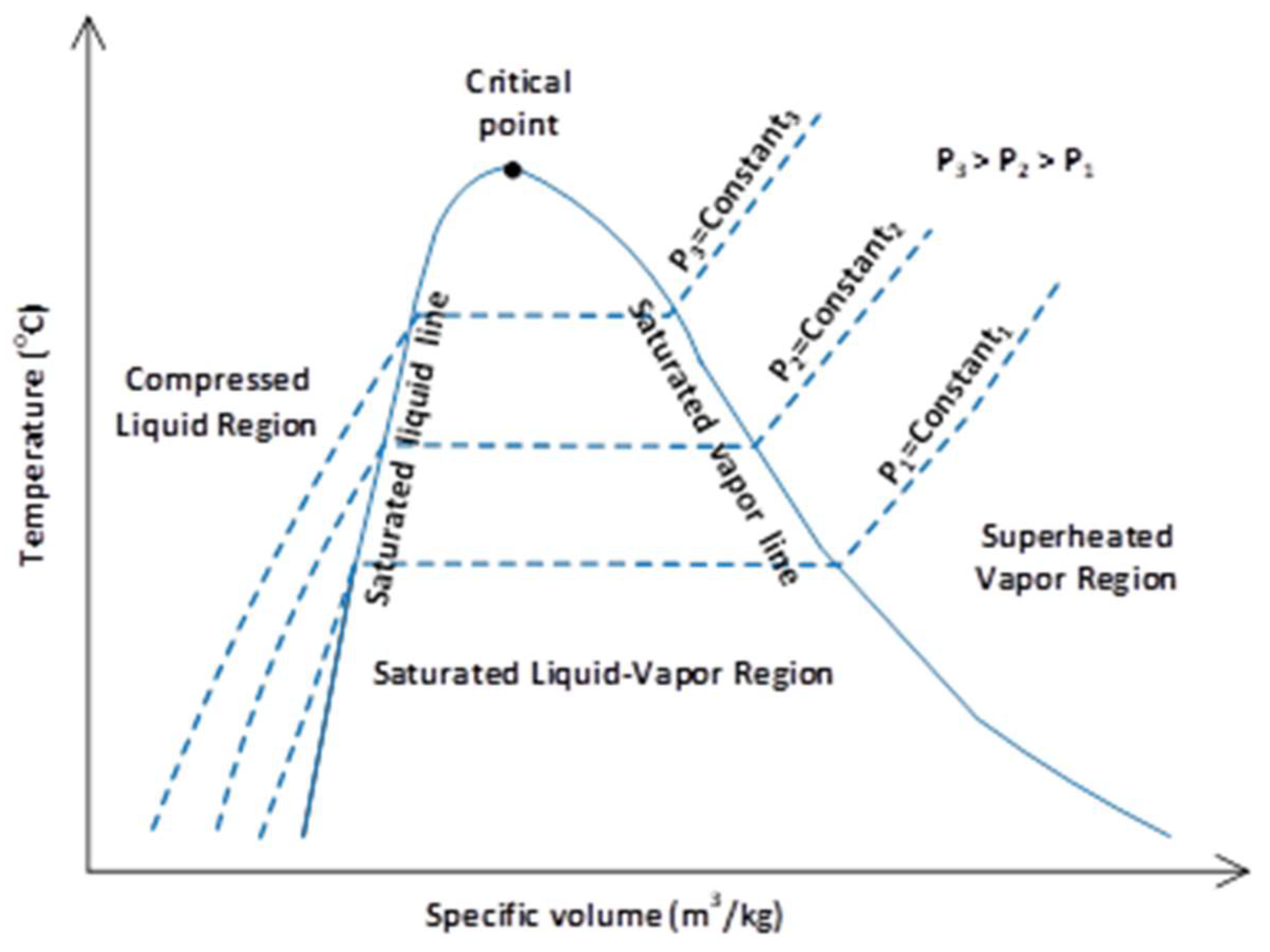

When considering the status of pure substances, in this case, steam is used as a medium for distillation of essential oils. The change in state of water to steam can be explained as shown in

Figure 5, which shows the state of pure substances (water) at the relationship between temperature and specific volume at different constant pressure values. It can be seen that at different pressures (P), water in the liquid state in the Compressed Liquid Region will have a higher temperature when heated, but the state will remain completely liquid. For water, when it receives sensible heat, that is, the amount of heat that causes the temperature of the substance to increase, but the state remains the same. Water is ready to evaporate into vapor immediately. If it receives more heat, this state is called saturated liquid. After this state, when water is heated up until it starts to evaporate into vapor, but the temperature is still not up to or close to 100 °C, water receives latent heat, that is, the amount of heat used to change the state of pure substances, with a constant temperature, which is the latent heat of vaporization. When considering at a pressure of 1 atmosphere, at this state, water will be in a state of saturated liquid and saturated vapor or a mixture. Water will evaporate into vapor more and more, and the liquid water will decrease. But there is still a constant temperature in the Saturated liquid-vapour Region, along with the liquid water evaporating into vapor completely at this condition called saturated vapor. If only a small amount of heat is lost, the vapor is ready to condense into liquid water droplets immediately. In addition, after this, when the vapor is heated until the temperature rises to, this condition is called superheated vapor in the region of, as shown in

Figure 5 [

24,

25,

26]. The vapor that can be used in the distillation of essential oils can be divided into 2 types: saturated vapor and superheated vapor, which have properties as shown in

Table 1.

Table 1.

State and properties of steam used in water-steam redistillation [

23,

27,

28,

29].

Table 1.

State and properties of steam used in water-steam redistillation [

23,

27,

28,

29].

| Types of steam, |

Characteristics of steam/heat transfer |

temperature of steam |

| Superheated steam |

- Steam that still contains moisture or sometimes called wet steam, formed when water begins to boil and turns into steam. The amount of heat in saturated steam will have a greater or lesser value depending on the pressure. Steam with low pressure has more energy to transfer heat (Latent heat).

- When heat is transferred, the temperature does not decrease. The amount of heat transferred is equal to the latent heat of vaporization. This is heat transfer by condensation into condensate with the same temperature and pressure as saturated steam

- saturated steam will immediately become superheated steam when the pressure is lowered. |

Temperature 99.15 °C but not exceeding 100 °C |

| Superheated steam |

- Superheated steam occurs when saturated steam is further heated at constant pressure until it becomes steam with a temperature higher than the boiling temperature of water at that pressure.

- When superheated steam transfers heat, the temperature drops to the saturation point. The heat transferred is of the gas, so there is no condensation of water.

- Saturated steam becomes superheated steam when the pressure is lowered. |

Temperature 99.15 °C but not exceeding 100 °C |

2.4. The Amount of Essential Oil Obtained by Repeated Distillation with Water and Steam (RWASD)

Essential oil quantity can be calculated from the equation below, expressed in the form of essential oil percentage, which has 2 calculation formats as follows [

30,

31]

Where (%) V

oil/W

dry is the percentage of distilled essential oil, V

oil the distilled essential oil volume (ml), W

dry is the dry weight of the raw material per distillation cycle (g), (%) W

oil/W

dry is the percentage of distilled essential oil, W

oil is the weight of distilled essential oil (g), and W

dry is the dry weight of the raw material used per distillation cycle (g). W

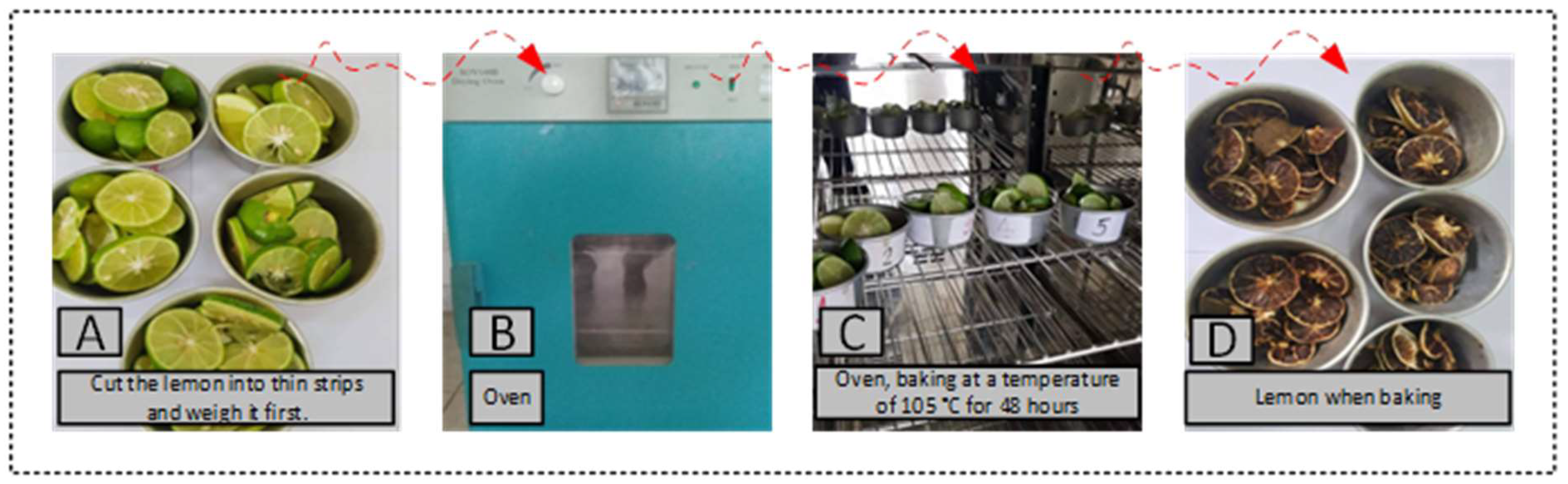

dryto find the value a preliminary experiment was conducted by drying samples of chopped limes at a temperature of 105 °C for 48 hours [

31,

32] as shown in

Figure 6. In

Figure 6(A), the lime was cut into thin, uniform slices and weighed before drying in the oven at 105 °C for 48 hours as shown in

Figure 6(B,C), respectively. After drying for the required time, the lime was removed from the oven and weighed as shown in

Figure 6(D). The initial weight of the lime before and after drying were taken to find %Dry and from Equations (3) and (4) [

3,

32,

33].

2.5. GC-MS Analysis of Volatile Substances

Essential oils that in this research were separated using the GC-MS (Carrier gas, GC-Injector, GC-Column, and Detector), where each volatile component has different dispersion ability. The substances obtained from the column were presented in the form of chromatogram, which showed the retention time and signal size of each substance. The signal size found at a certain time is called a peak, and MS measures the mass per charge (m/z) of a compound, recorded in the form of a spectrum. With GC-MS measurement and analysis, the chemical composition of the refined oil is often affected by the temperature at the exit from the condenser section. That does not correspond to the steam flow rate or even the coolant flow rate at the condenser section. That tells you how important it is to the design and construction of distillers. Including the distillation techniques and processes that must be related and is considered an analysis of the chemical components that are important to the essential oils that can be distilled [

8,

34,

35].

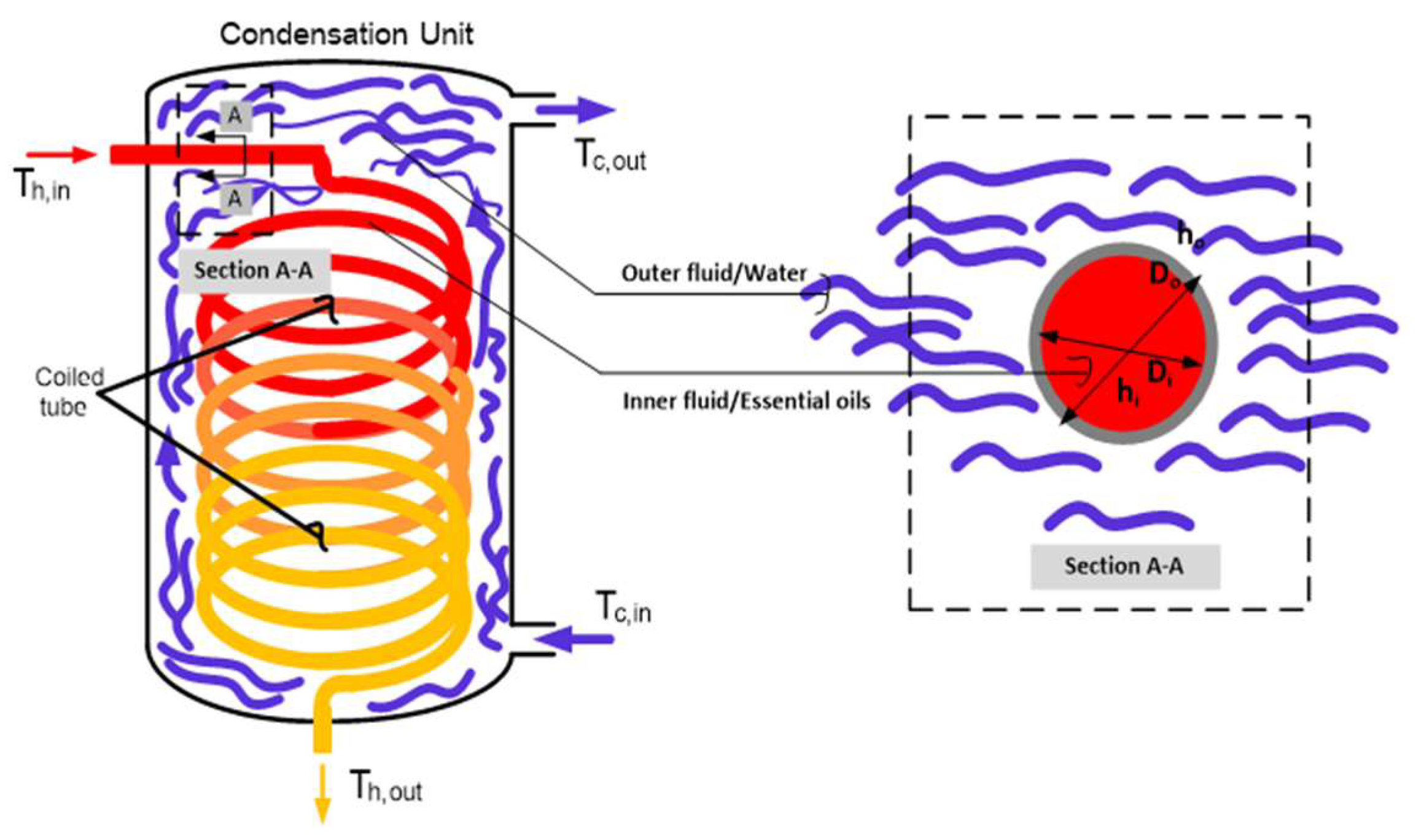

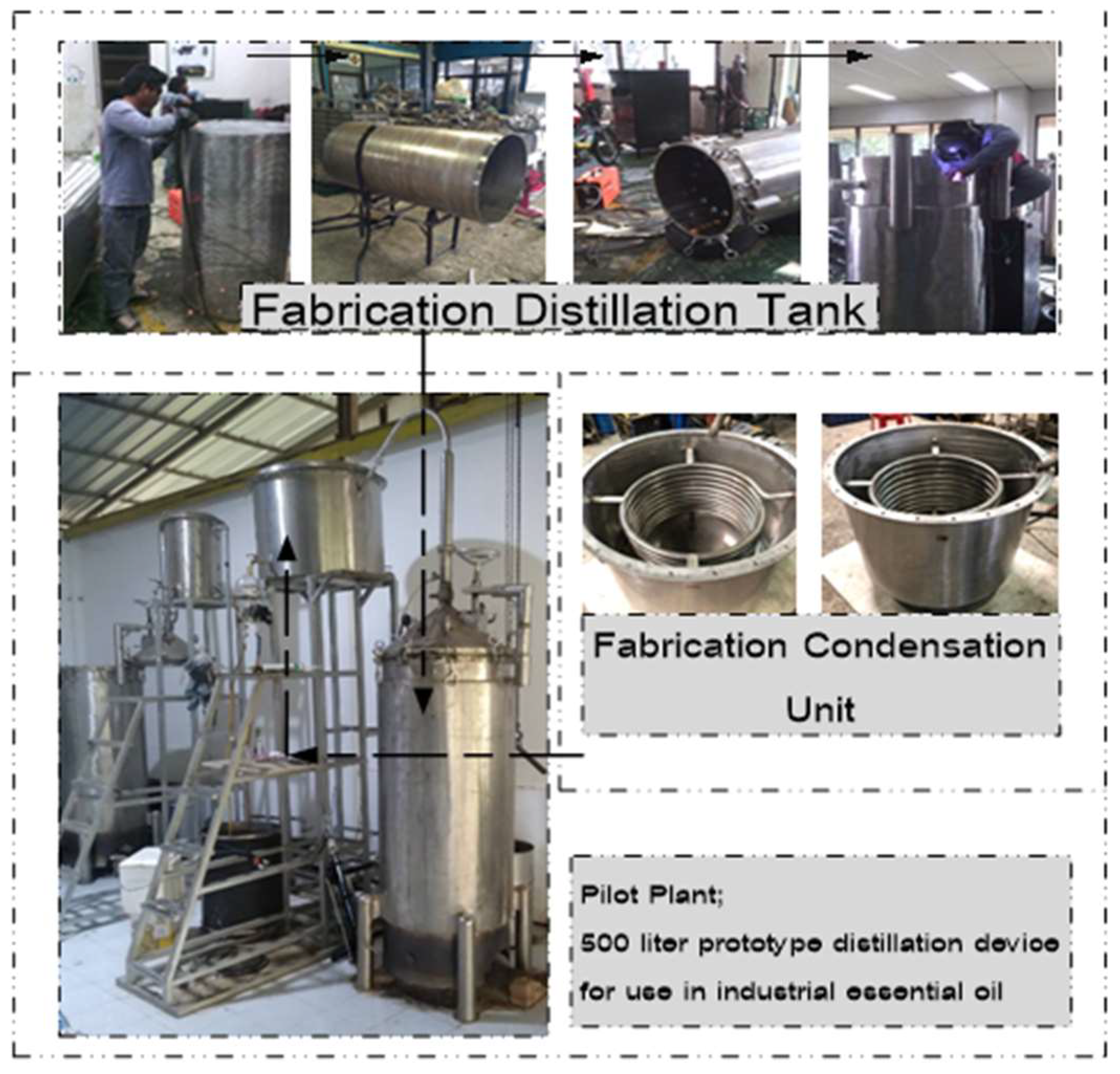

2.6. Design and Manufacturing of Distillers

The sequence of calculating, designing and building a 500-liter industrial grade commercial essential oil concentrator for distillation with water and was discussed in this section. This is a popular method [

19] where steam flows through the medicinal plants during extraction. The essential oils mix together with the water vapor and travel through a pipe connected to the condensation unit. When the steam enters the condensing section, it is cooled, changing its state from vapor to liquid and stored in an oil separator, which is a glass cone container [

36,

37]. The main and important equipment in the industrial-scale commercial essential oil distillation process are distillation pot or boiler and a condensing tank set. In order to have appropriate and safe effective equipment, design and construction procedures are important [

37,

38]. For the distillation pot, SS-304 grade stainless steel is used, which is a material that has no direct or indirect impact on the industry. For calculations of different parts of a 500-liter prototype distillation plant, as shown in

Table 2 and

Figure 7 and

Figure 8.

The format and steps for designing and calculating values to meet the objectives are as follows: 1) Check the calculation list and related documents; 2) Order materials and equipment; 3) Check if the materials meet standards and design; 4) Construct and weld; 5) Check work quality such as dimension; and whether various distances meet the design or not; 6) Test pressure, as shown in

Figure 9,

Figure 10 and

Figure 11. A 500-liter essential oil distillation machine was designed, built and installed.

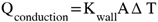

For the error value in the heat transfer value, Heat loss is determined by the heat conduction through the wall of the distillation process equipment, The wall heat transfer rate loss was calculated as shown in Equation (5) and (6) [

36,

39].

Where K

wall is the thermal conductivity of the wall (W/m °C). A is the area of the wall, (m

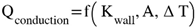

2). ∆T is the difference between the average temperature of the wall between the outside and inside (°C). The design and construction error values of a 500-liter distillation plant are calculated using Equation (7).

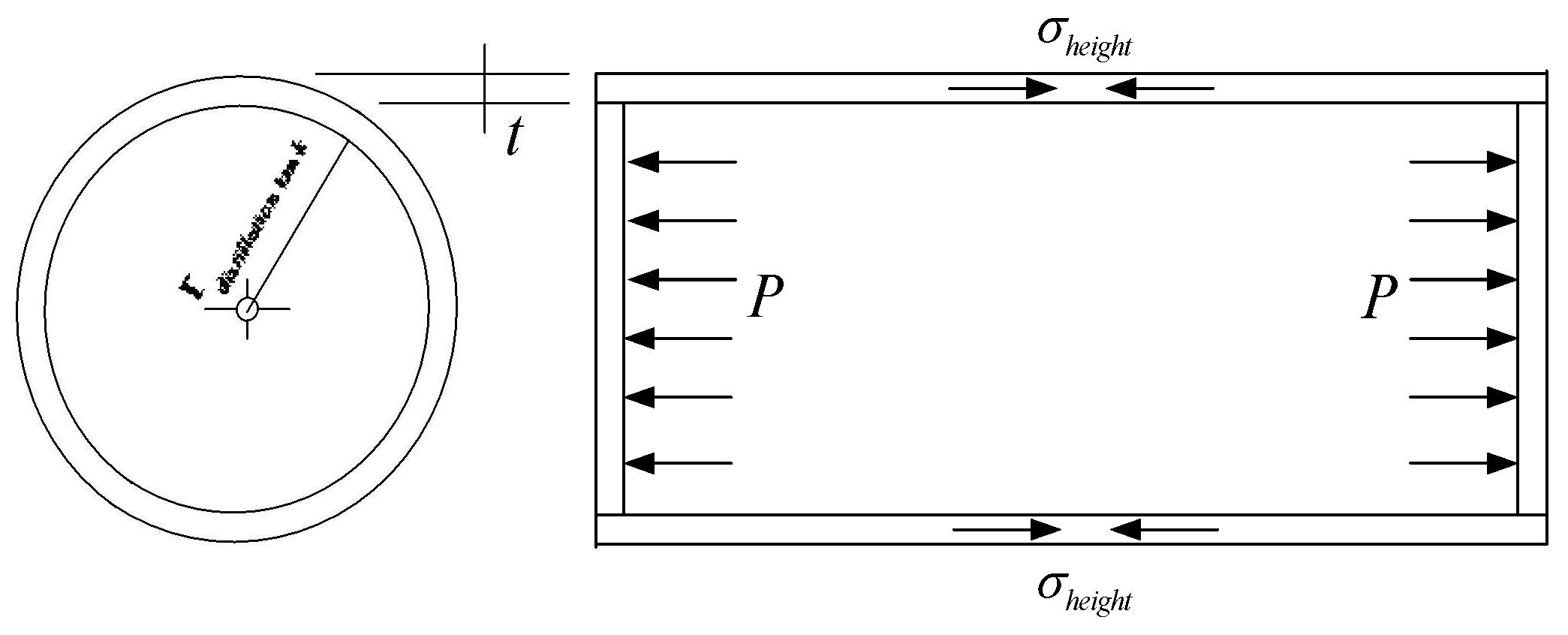

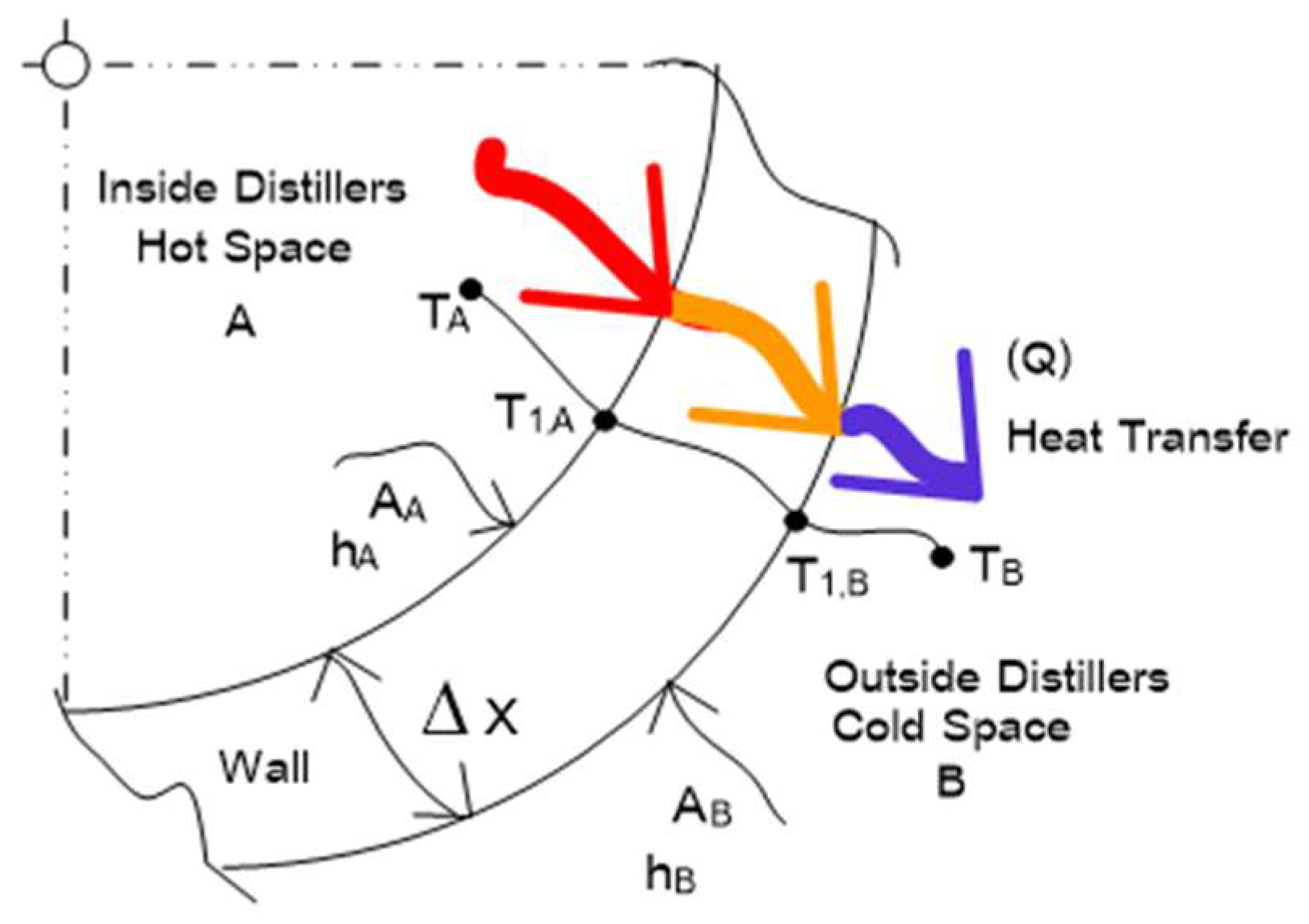

From

Figure 9 and

Figure 10 and

Table 2, which define Q

C is the heat transfer at the condensing section of the distillation process (kW) T

c,out, T

c,in are the temperature of cold water out and inlet at the condensing section (°C), Q

convection is the heat transfer value caused by convection (kW), T

f, T

s is are the temperature of the fluid and solid at the considered position (°C), T

1,A, T

1,B are the temperature of the inner and outer surface of the distillation tank at the considered position, r

distillation tank is the radius of the distillation tank (m), h

distillation tank is the height of the holding tank (m) as shown in

Figure 7 and

Figure 8 respectively, P is the pressure inside the distillation tank (N/m

2), ρ is the liquid density (Kg/m

3), g is the gravitational force (m/s

2), h is the liquid height (m) as shown in

Figure 7 and

Figure 8 respectively. σ

height is stress acting along the height (MPa), σ

perimete is stress acting circumference the distillation tank and distillation cap (Mpa). t

distillation tank, t

distillation cap are the thickness of the distillation tank and distillation cap (m), respectively. r

distillation cap are the radius of the distillation tank and distillation cap (m), as shown in

Figure 7 and

Figure 8 respectively. V

condensation tank, V

coiled tube are the volume of the distillation tank and coiled tube (m

3), respectively. D

condensation tank, D

coiled tube are the dimeter of the distillation tank and coiled tube (m). h

condensation, L

coiled tube are the height of the condensation tank and the length coiled tube (m) respectively as shown in

Figure 7 and

Figure 8 respectively, Kis the thermal conductivity of the medium (W/m K), A

cond is the area of thermal conductivity (m

2),shown in

Figure 7. h

conv is the convection coefficient (W/m

2 K), A

conv is the area where convection occurs (m

2), A

s is the heat transfer area coiled tube (m

2), T

h/e,in-T

c/w,out is the temperature difference between the hot essential oils inlet and cold water outlet (°C)respectively. T

h/e,out-T

c/w,in is the temperature difference between the hot essential oils outlet and cold-water inlet (°C) respectively, as shown in

Figure 9. U is the total heat transfer coefficient (W/m

2 K). The wall thickness of the tube is small, the thermal resistance of the tube is negligible (R

wall=0). Where A

i ≈ A

o ≈ A

s is inner and outer surface of heat transfer coiled tube (m

2). Where h

i, h

o is the determined using the heat convection coefficient of inner and outer fluids (W/m

2 K), as shown in

Figure 8 and

Figure 9

2.7. Energy and Exergy Analysis of Re - Water and Steam Distillation (RWASD) Process

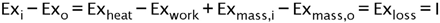

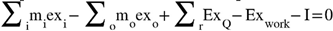

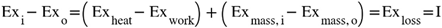

In this analysis, the energy efficiency and energy losses occurring in RWASD are determined by the balance of mass and energy input and output in the control volume system, using the first law of thermodynamics. The steady state of the system is expressed in Eq. (8) [

41,

42,

43].

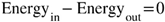

It can also be represented in terms of energy that is subject to the law of conservation of energy, where energy cannot be created or destroyed. The energy balance can be written as another equation as follows:

The amount of fuel energy supplied to the system (Energy

in= Energy

out) for producing saturated steam in Equation (10).

Where Energy

in, Energy

out are the input and output heat energy (kJ) respectively, ṁ

LPG is the mass flow rate of the fuel (kg/s), LHV

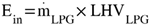

LPG is the low heating value of LPG gas fuel (kcal/kg). In addition, there is energy loss throughout the system, whether through the cooling water system or the piping system, with the uncalculated energy losses being other products. The energy produced is given by Equation (11).

The heat energy distributed to the cooling water (E

cw) is calculated using Equations (13)

Where ṁ

cw is the mass flow rate of the cooling water (kg/s) and c

p,w is the heat capacity of the coolant water (kJ/kg°C), and ∆T is the difference between the inlet and output temperatures of the cooling water (°C) For the energy efficiency ratio useful for essential oil re-water and steam distillation (EUREO, RWASD) can be calculated from the ratio of useful energy (heat energy from steam used for evaporation of essential oil to the total heat energy fed to the distillation vessel, which can be calculated from Equation (14) as follows.

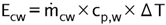

The quality of the energy transfer can be characterised using the exergy analysis. Exergy is the energy a system possesses, and the exergy balance can be calculated using equation (15) for the given control volume. [

44]

The main important difference between energy and exergy: energy is conserved, while exergy, a measure of energy quality or work potential, can be consumed. The general exergy balance for the above system can also be expressed as [

45]

By specifying Exergy

in=Ex

i=ex

i, Exergy

out=Ex

o=ex

o, Ex

heat = Exergy heat (kJ), Exergy work = Exergy

work, Exergy mass in =Ex

mass,i, Exergy mass out =Ex

mass, o, Ex

loss = Exergy loss (kJ), I = Irreversibility. Consider the system of re-distillation with water and steam as a one-dimensional flow, from Equation 16 it follows that in Equations (17) and (18).

By specifying m

i, m

o are the mass of fluid flowing into and out of the system (kg), from equation 17, the equation can be modified as shown in Equation (18).

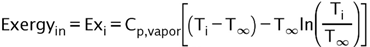

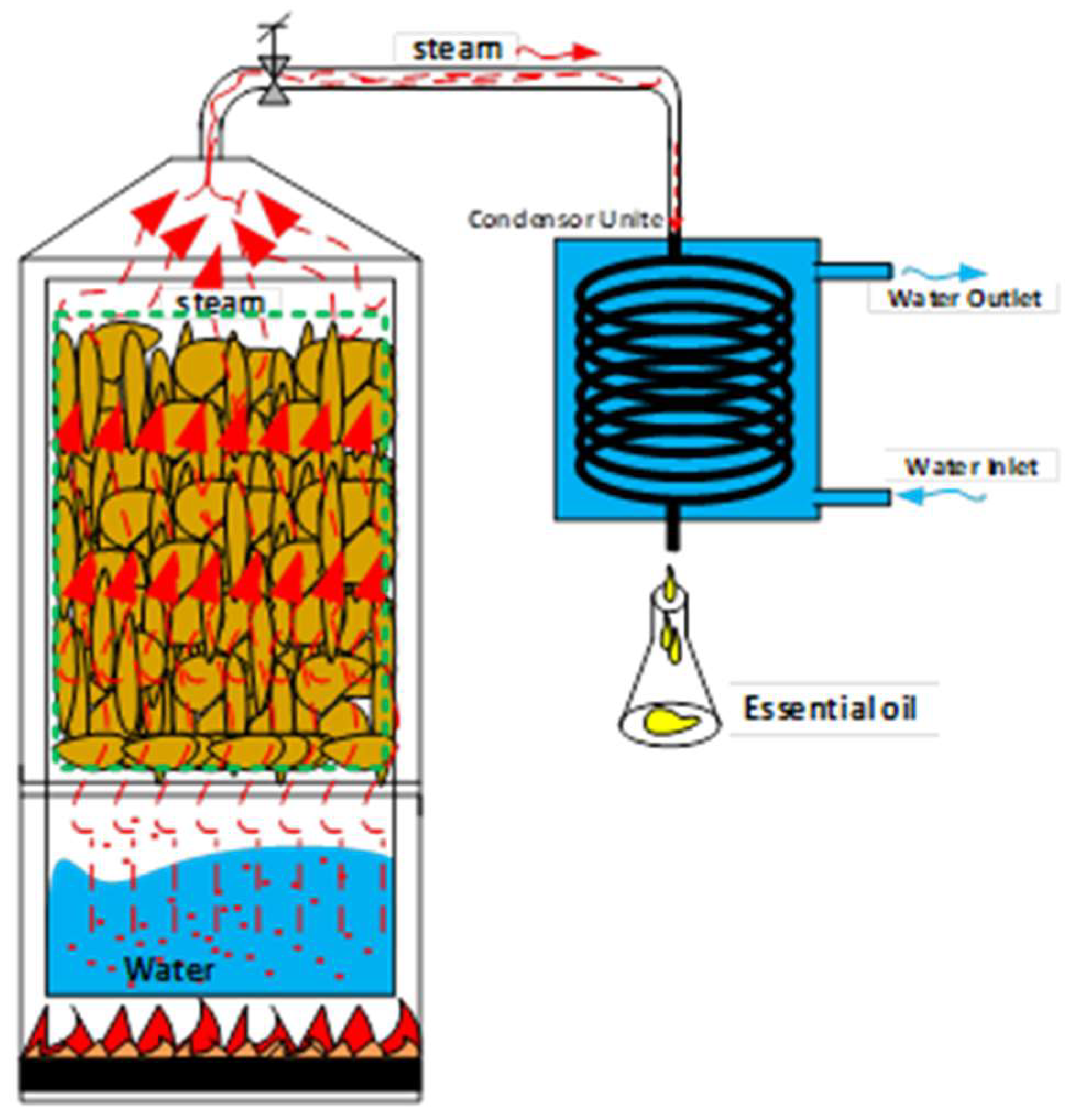

For calculating the exergy of the fluid flowing into and out of the distillation vessel area in the regenerative water and steam distillation (RWASD) process, it can be calculated from Equations (19) and (20) as follows.

Let Exergyin, Exergyout be the exergy of fluid flowing into and out of the RWASD system (kJ), Cp,vapor is the specific heat capacity of the fluid in the vapor state (kJ/kg°C), Ti,To and T∞ are the temperature of the inlet and outlet fluids and the ambient temperature (°C), respectively.

For the loss of exergy, it can be calculated from Equations (17) to (18). For the determination of the exergy efficiency of this water and steam re-distillation process, it can be calculated from Equations (21) and (22).

4. Results and Discussion

This research is a study and presentation of the essential oil distillation process using the regenerative water and steam distillation (RWASD) method, which is a new distillation method that has been invented to solve the problem of the amount of essential oil that can be distilled, which is a limitation of the regenerative water and steam distillation (WASD) method. The regenerative water and steam distillation process is a new alternative method for the essential oil distillation industry. The distillation will be tested with a 500-liter prototype distillation machine that has been designed and built, which is considered a commercial distillation machine, along with the use of different screen patterns. The distillation in this study uses lime as the raw material. Including plants that produce essential oils that accumulate in the bulbs or leaves, such as ginger and kaffir lime leaves. Therefore, there are guidelines for presenting the results and discussion as follows:

4.1 The effect of repeated water and steam distillation (RWASD) on the amount of essential oil (EO)

4.2 The effect of time and steam heating temperature by repeated water and steam distillation (RWASD) method

4.3 The effect of the quality of essential oils obtained from repeated water and steam distillation (RWASD) by GC-MS analysis

4.4 Useful energy efficiency and exergy of essential oil distillation by RWASD method

4.5 The effect of different raw material packing screens on the amount of essential oil (EO)

4.6 Analysis of the results of design and construction of a 500-liter prototype distillation apparatus

4.1. Effect of Reflux Water and Steam Distillation (RWSD) on Essential Oil (EO)

Essential oil extraction in order to obtain a higher amount of essential oil from the same amount of raw materials, as well as to maintain the quality and chemical composition standards of the extracted volatile compounds within the standard criteria, has led to the proposal of Reflux Water and Steam Distillation (RWSD) method that affects the amount of essential oil. This topic will present the test of the essential oil extraction method by RWSD method that affects the amount of essential oil distilled as shown in

Figure 13, which shows the relationship between time and amount of essential oil of each distillation method. For

Figure 13(A,B), which show the relationship between the time in each period and the amount of essential oil extracted by Reflux Water and Steam Distillation, and Reflux Water and Steam Distillation, respectively, along with further explanations of the steps and methods in the Reflux Water and Steam Distillation section as shown in

Figure 3(A), which shows the relationship between time and steam temperature for the RWASD step in each period.

From

Figure 13, the test uses lemon as a raw material for distillation. From the test, it was found that when considering the first 1 hour and 30 minutes of the distillation of essential oils by the recurrent distillation method with water and steam (RWASD), no essential oils were extracted because the temperature of the steam during that time was not high and the steam pressure was not high enough to penetrate into the tissue or the essential oil transport route. When considering the distillation time of 2 hours, there will be 13.89 ml of essential oils distilled. Along with the consideration in

Section 2.2, it can be seen that the temperature of the steam during that time and area has a higher value up to approximately 99 °C. Due to the properties of saturated steam with a higher pressure according to the steam temperature, it can permeate into the essential oil tissue transport route. That steam will take the essential oils stored in that area out and mix with the steam and move higher and flow through the pipe connected to the condenser of the system. The heat of the steam will transfer heat to the cold water that flows in a circulating system to receive heat from the steam. Condensation occurs, causing the steam to change its state from vapor to liquid. Normally, the extraction will produce 2 products: the insoluble part Essential oils will float on the top layer and the hydrosol extract will be on the bottom layer. Due to the nature of essential oils having a lower density than water, it causes the essential oils to float on top of the hydrosol as a thin film coating the top surface above the hydrosol area. Before passing through the filter set to separate the essential oil and hydrosol as shown in

Figure 12, when the distillation time was 3 hours, it was found that the distilled EO was 18.65 ml, and EO was still extracted in a sufficient amount at 4 and 5 hours of distillation, which were 16.36 and 17.64 ml, respectively. From the test data, it was found that the EO extracted by repeated distillation with water and steam (RWASD) tended to decrease to 13.91 ml at a distillation time of 6 hours, with a total accumulated EO volume of 80.45 ml, as shown in

Figure 13 (A). The test results were consistent with the amount of essential oil distilled from the research data of many researchers [

39,

40,

41,

42,

43]. In addition, it was also found that the test by repeated distillation with water and steam (RWASD) with raw materials that had essential oils accumulated or stored at different parts, whether ginger or kaffir lime leaves, to demonstrate the diversity of the ability of the RWASD distillation method to extract or distill essential oils from all parts of the plant, for ginger, which the shoots or rhizomes contain approximately essential oil 3% and kaffir lime leaves, which have the main biological substances with about 10% essential oil, the aroma is similar to fresh kaffir lime, popularly used in aromatic products, perfumes, spa products, soaps, shampoos, insect repellent sprays, etc. From using the RWASD distillation method, it was found that the amount of essential oil obtained from the distillation of ginger and kaffir lime leaves has the amount of essential oil in the same direction and trend as using lime as a raw material in the first 6 hours, which is considered step 1 of the RWASD process and steps that show the relationship between the distillation time and the amount of essential oil as shown in

Figure 13 (A).

In addition, the comparative test of essential oil distillation between water-steam distillation (WASD) and recurrent water-steam distillation (RWASD) was conducted using the same lime raw material with the same characteristics and test samples as shown in

Figure 13 (B). The relationship between the process time and the amount of essential oil extracted from WASD was shown. The test found that no essential oil could be extracted because the steam temperature during that time was not high and the steam pressure was not high enough to penetrate into the tissue or the essential oil transport route. When considering the distillation time of 2 and 3 hours, the heat temperature from the steam was hot and the amount of steam was high enough to penetrate into the tissue or the EO transport route that was accumulated in the raw material. This resulted in a continuous increase in the amount of EO obtained from WASD from the 2nd and 3rd hours, with the values of 13.80 and 18.72 ml, respectively. In addition, it was found that the EO distilled at the next time had the values of 16.39, 17.58 and 13.82 ml, with the total EO distilled amount of 80.31 ml. During the 6-hour distillation period of WASD method, the amount of EO distilled had the same decreasing direction and trend as RWASD method [

39,

40,

41,

42,

43] and was considered the end of the WASD distillation process, as can be seen from the data shown in

Figure 13 (B). This is another limitation of water and steam distillation (WASD) because when the raw materials are heated by steam for a long time, it will cause the raw materials to condense and reduce in size, leading to the essential oil transport path being narrowed and reduced. As a result, the extraction and distillation of essential oils for more than 6 hours will result in a lower amount of essential oil than the break-even point of the fuel cost lost in boiling water to produce saturated steam at that time. This is another limitation that is often found in the extraction of essential oils by the distillation method with water and steam shown in the content of

Section 2.1 and

Figure 13. This is in contrast to the extraction of essential oils (EO) by the recurrent distillation method with water and steam (RWASD) as shown in

Figure 13(A), which has an additional process continuously in Step 2 (Step 2), which is considered a different step from the distillation with water and steam (WASD). In this step, it is an important technique in preparing raw materials. The aforementioned step The valve at the distillation tank installed at the top of the distillation tank will be closed as shown in

Figure 4, along with the LPG fuel supply system that has been opened since the boiling of water into saturated steam from the 1st to 6th distillation hours, etc., with the distillation process and format in step 2 (step 2) that has been changed from the WASD distillation method, which in this step will last for 12 hours, resulting in the raw materials being cured inside the distillation tank for 12 hours, along with the reduction of the heat temperature from the steam caused by the shutdown of the LPG fuel, allowing the raw materials, which are limes, to release their tissues and help expand the conveying channel that will allow the steam to flow more easily to start the distillation process in step 3 (step 3).

For the step 2 of the RWASD distillation method, no fuel (LPG) was used. This is another technique that has advantages along with affecting the desorption of the raw materials. Leading to the expansion of the transportation route of the essential oil collection more. This is considered the preparation of the raw materials of RWASD. In this test, the whole lemon was used as the raw material. It was entered into the distillation process in step 3 (Step 3), which will start at 19 hours, as shown in

Figure 3 (A) and

Figure 13(A), respectively. At that time, the steam temperature in the distillation tank is approximately 60 °C. Due to the steam changing state from vapor to liquid, the temperature in the distillation tank is lower, as shown and explained in

Section 4.2 and

Figure 3. The decrease in steam temperature is a result of shutting down all systems in step 1 (Step 1) at the end of the 6-hour distillation time of the RWASD method. From the test at that time, it was found that when the LPG fuel was turned on to boil water in the boiler to convert it to saturated steam The steam in the boiler will have the temperature of the water that has already been heated. It will take about 1 hour to boil the water. When the temperature of the steam is about 99 °C, which is in the range of saturated steam properties, and the raw material has been prepared in step 2 as mentioned above, the test found that at a distillation time of 20 hours, the amount of EO that can be distilled will be 16.30 ml. After that, the trend of EO will be seen to decrease. At a distillation time of 21 and 22 hours of the RWASD method, the amount of EO will be 13.93 and 12.75 ml, respectively, as shown in

Figure 13(A). The amount of EO that is additionally distilled in Zone 3 is 42.98 ml. The total amount of essential oil (EO) accumulated from the amount of essential oil in step 1 to step 3 is 123.43 ml.

When comparing the amount of essential oil obtained from RWASD and WASD distillation, it was found that RWASD distillation gave a higher amount of essential oil than WASD distillation by 53.69 percent or 43.12 ml. It can be considered that the use of water and steam re-distillation technique can help solve the problem and improve the efficiency of the essential oil distillation process to obtain a higher amount of essential oil from distillation very well as shown in

Figure 13. In addition, the water and steam re-distillation (RWASD) method was tested with raw materials that accumulated essential oil in the leaves and shoots. In this research, kaffir lime leaves and ginger were used as test materials to demonstrate the capability of the RWASD essential oil distillation process that can be used with various types of raw materials as shown in

Figure 13(A). From the test, it was found that both kaffir lime leaves and ginger can be extracted by RWASD distillation very well, and the trend of the amount of essential oil obtained from distillation is in the same direction as using lime as a raw material. The total volume of essential oil (EO) obtained from the raw materials of kaffir lime leaves and ginger was 72.31 and 146.93 ml, respectively.

Figure 13 shows that the application of the new distillation technique for re-distillation with steam and a 500-liter commercial prototype distiller can increase the volume of essential oil distilled from both fruits, leaves and shoots, respectively, as shown in

Figure 13.

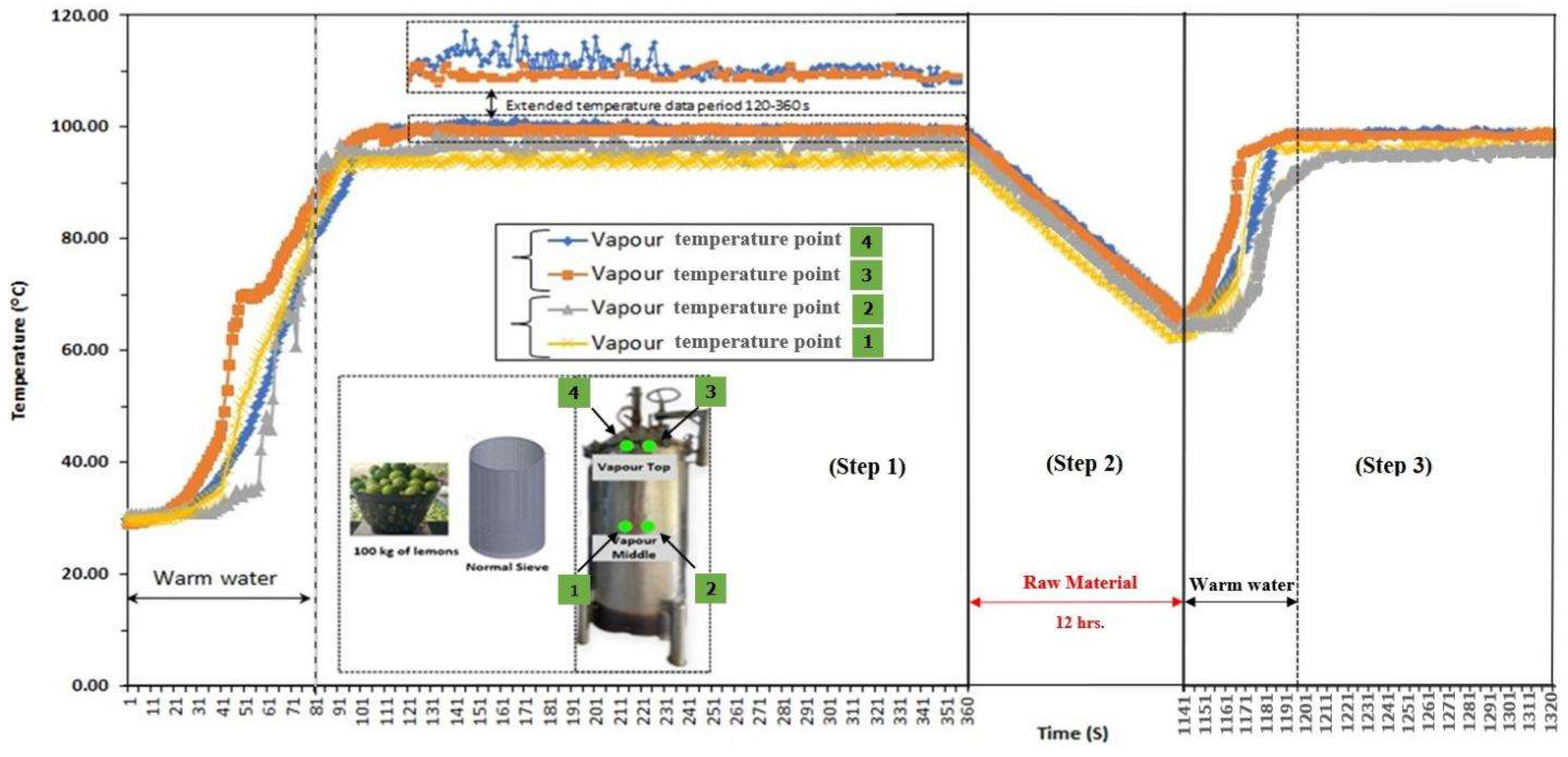

4.2. Effect of Time on Steam Heating Temperature Using Regenerative Water-Steam Distillation (RWASD) Method

From

Figure 14 shows the results of the time and the temperature of the steam by the re-distillation method with water and steam (RWASD). The test results found that the re-distillation method with water and steam (RWASD) can be seen that in the beginning at approximately 81 to 120 minutes, the heat from the combustion chamber using LPG fuel gas has transferred heat to the water in the liquid state. And the water will start to change the liquid state into vapor and float up from the bottom of the distillation tank. Which can be seen from the temperature of the steam that starts to rise as a steep line during that time. At that time, the valve will be closed on the side as shown in

Figure 4. Along with the continuous heating from the combustion chamber to the steam and water until the average temperature of the steam starts to rise to a constant level of approximately 99 °C. With the properties of the saturated steam that occurs, it leads to the relationship in terms of heat and pressure of the steam that occurs, leading to the penetration into the tissue or the essential oil transport route in the raw materials. Therefore, it can be seen that the initial amount of essential oil was distilled at 120 minutes or 2 hours as shown in

Figure 13 (A). With continuous heating from the combustion chamber and the flow rate of LPG fuel, the steam temperature was constant throughout the 360 minutes, i.e., the average steam temperature throughout the test at Step 1 was approximately 99.51 °C, which is consistent with the distillation with the amount of essential oil extracted at distillation times of 2, 3, 4, 5, and 6 hours, respectively, as shown in

Figure 13 (A). Steam affects the extraction of essential oil. With both the steam temperature properties that are directly related to higher pressure and lower density, it helps the steam to penetrate into the channels where essential oils are accumulated or where the raw materials are distilled very well. With the RWASD process and steps, when the 6-hour distillation time is completed, all systems will be shut down. Whether it is the LPG fuel heating system along with closing the valve on top of the distillation tank as shown in

Figure 4, which will have a period of time from 361 to 1,140 minutes or 12 hours, resulting in the heat temperature inside the distillation tank to drop to 65 °C as shown in

Figure 14. During that period, the raw materials brought to be distilled will evaporate due to the decrease in the heat temperature inside the distillation tank, resulting in some steam condensing into liquid and having a state of water or more liquid in a compressed liquid state. The remaining heat vapor can flow into the channels or essential oil storage sources in large quantities and for a long time throughout the period of 12 hours. Because the heat temperature of the steam is lower, it will result in lower pressure, resulting in steam at Step 2 having no direction to float up vertically. When Step 2 of RWASD ends at a total distillation time of 19 hours, the state of the vapor in the distillation tank will be in the form of a compressed liquid as shown in

Figure 5 and

Table 1. Initially, the water in the compressed state will be heated as mentioned. Until the temperature increases to approximately 99.07 °C, causing the water in the form of a compressed liquid to become saturated vapor, taking approximately 60 minutes. This results in saturated vapor with a constant heat value, leading to the distillation that yields essential oils from using lime as raw material at distillation times of 20, 21, and 22 hours, respectively, in Step 3, as shown in

Figure 13, assuming the relationship between the distillation time and the temperature of the vapor, as well as the steps regarding the details of the equipment as described above.

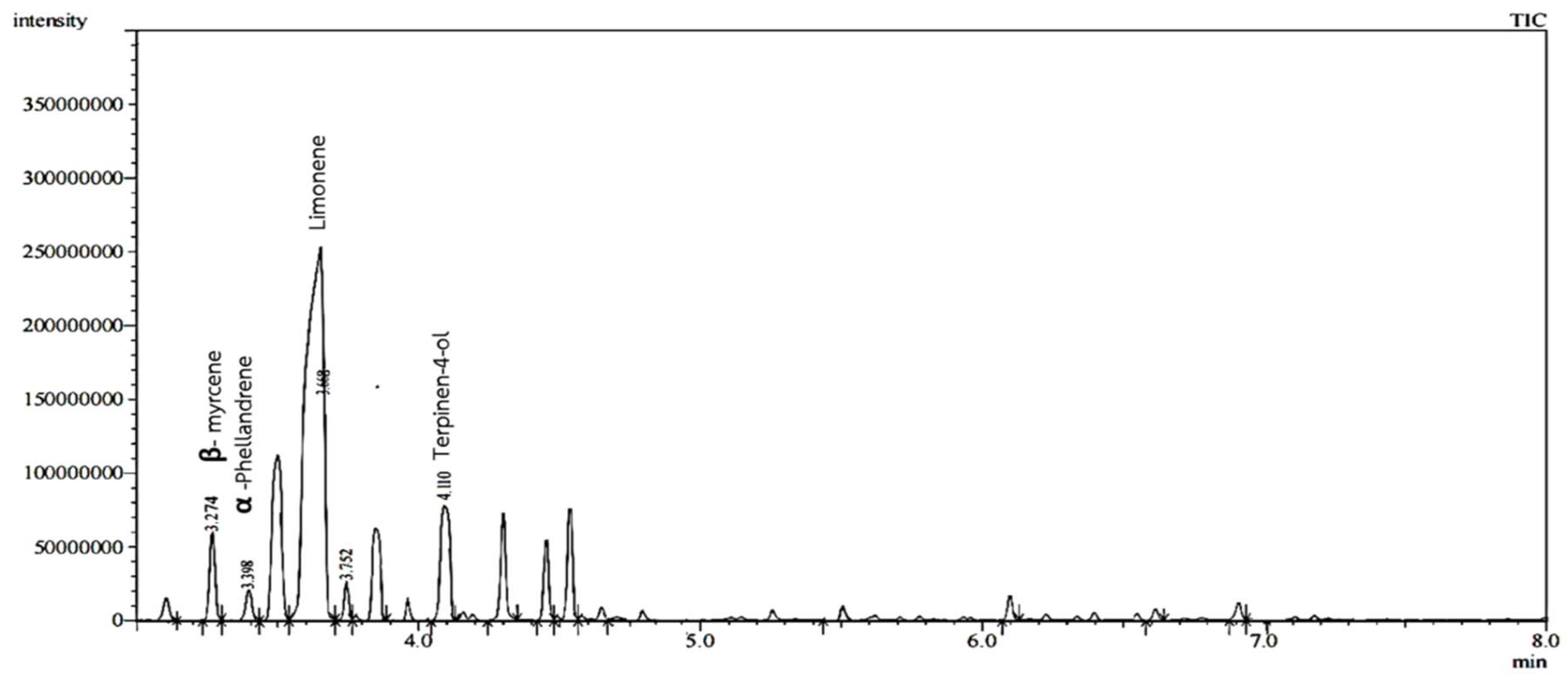

4.3. Effect of Quality of Essential Oil Obtained from Re-Distillation with Water and Steam (RWASD) by GC-MS Analysis

From the distillation of lemon fruit to obtain essential oil from lemon fruit, which was tested as raw material by re-distillation with water and steam (RWASD) to extract essential oil from lemon fruit, and was analyzed and identified using gas chromatography-mass spectrometry (GC-MS) to know the quality of essential oil with different percentages of identified according to the stability of GC. The main bioactive compounds selected for examination in this research The selected EO was analyzed to explain the medicinal properties of lemon essential oil distilled from RWASD. The selected bioactive compounds were constant detected by GC, namely β-Myrcene (2.72%), Limonene (20.72%), α -Phellandrene (1.27%), Terpinen-4-ol (3.04%). The results of the test were compared with the GC-MS analysis of lemon raw materials obtained from previous researches by [

46,

47,

48] as shown in

Table 3 and

Figure 15. It shows that the use of repeated water and steam distillation (RWASD) method to distill lemon essential oil with the use of a designed and built essential oil distillation apparatus found that the quality and standard of the resulting EO still maintain the quality and standard of the found volatile compounds which are consistent with the results from the tests of many researchers [

46,

47,

48]. The compounds have the following properties:

- β-Myrcene is used in food, beverages and cosmetics as a flavoring agent and other aromatic substances, as an insecticide, and has anti-muscular pain, anti-inflammatory, antibacterial and mental relaxation properties [

49,

50].

- Limonene is used as a bittering agent, as a seasoning in the pharmaceutical industry and as a wood paint to kill moths and termites. Limonene is also used as an ingredient in essential oils for medicinal purposes, also known as aromatherapy. In terms of its pharmacological properties, it is beneficial to health, such as its antioxidant properties, its ability to treat Alzheimer’s disease, and its ability to lower blood pressure [

51,

52].

- α-Phellandrene is a substance that helps relieve pain, fights free radicals, fights bacteria, reduces inflammation, aids digestion, is a diuretic and lowers blood pressure [

53,

54].

- Terpinen-4-ol is a substance that helps reduce skin inflammation caused by sunburn, reduces redness and helps heal wounds by helping them recover faster. It is an ingredient in facial cleansing foam and helps destroy bacteria and germs that cause acne [

55,

56].

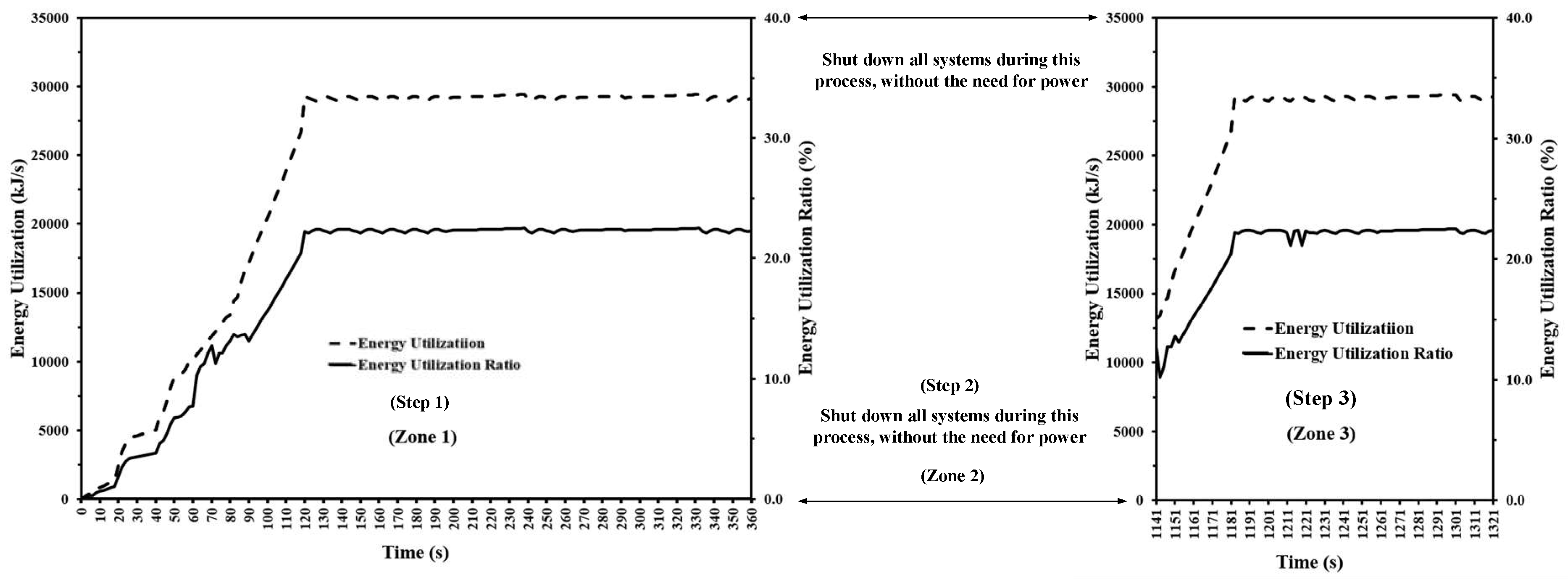

4.4. Useful Energy Efficiency and Exergy Analysis of Essential Oils Distillation by RWASD

From

Figure 16, which shows the relationship of heat energy consumption and distillation time by recurrent water and steam distillation (RWASD) with a 500-liter prototype distillation machine, which focuses on industrial applications at the small and medium enterprises (SMEs) level, it can be seen from the figure that the heat energy used in distilling EO accumulated in the lime fruit in the early stages of distillation. It can be seen that the useful heat energy will be high due to the need to produce steam in a saturated state in order to have sufficient steam heat temperature and pressure that can penetrate into the raw material to the reservoir and lime tissue containing essential oil. With a distillation raw material volume of 100 kilograms and a distillation machine size of 500 liters, the first period of approximately 120 minutes requires a relatively high amount of useful heat energy, resulting in a useful energy ratio that is consistent with the same trend as shown in

Figure 16. And when the process time increases The energy consumption, thermal energy and useful heat ratio will start to stabilize at 29,880 kJ/s and 22.47%, respectively. With the steam thermal energy, the system is controlled in a controlled volume or open system form by considering the design and construction principles [

57,

58,

59]. This is consistent with the constant steam thermal temperature in the system, which leads to the constant pressure in the distillation system and constant energy consumption and useful energy ratio throughout the distillation process in Zone 1 or Step 1 as shown in

Figure 16. However, due to the RWASD distillation process and steps, when reaching Step 2, the entire system will be shut down, resulting in a decrease in the temperature of all parts in the distillation vessel as shown in the steam thermal temperature in

Figure 14 in Step 2 or Zone 2. The efficiency of useful energy utilization mainly depends on the steam thermal temperature. As a result, there is residual heat energy stored in the system. As a result, the initial usable residual heat energy is 126,300 kJ/s at the beginning of Zone 3 or Step 3 as shown in

Figure 16. The trend of the data is in line with the behavior in Zone 1 or Step 1 but takes a shorter time than Step 1. As a result, the first period of approximately 120 minutes requires relatively high usable heat energy at approximately 1141-1191 or approximately 50 minutes. As the process time at Step 3 increases, the heat energy consumption and the usable heat energy ratio become constant until the completion of the RWASD essential oil distillation process.

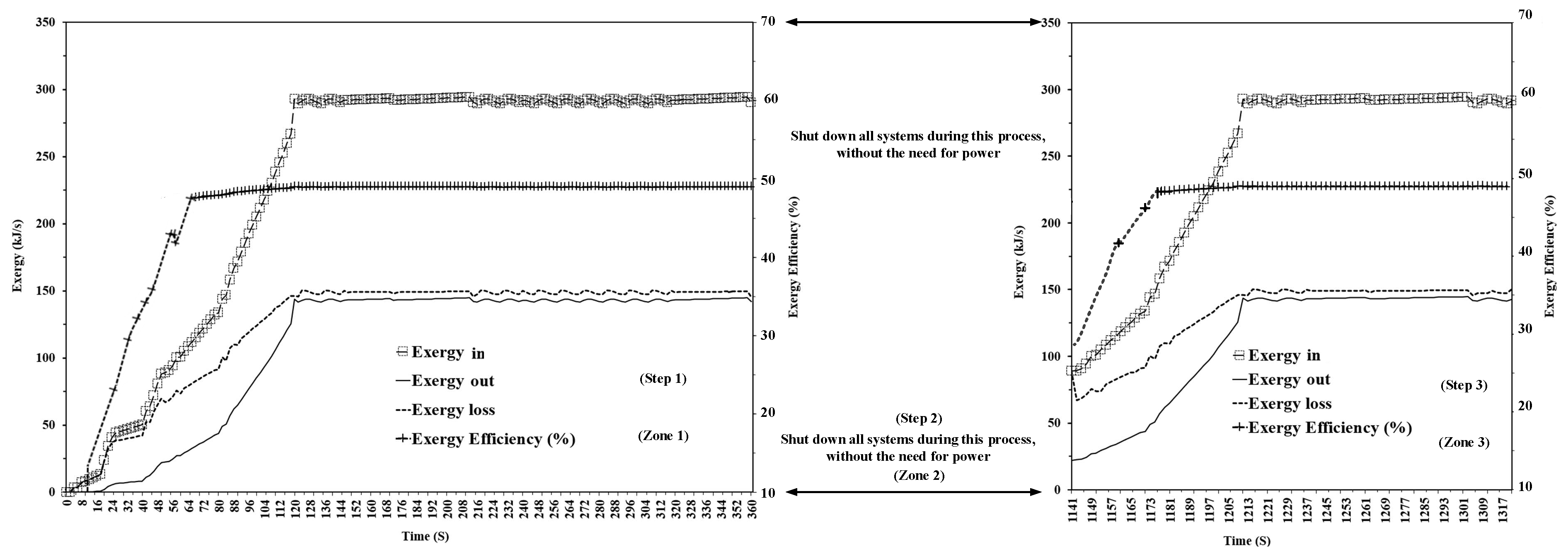

In addition, when considering the analysis obtained from the effects of Exergy and time as shown in

Figure 17, it is the change of the inlet, outlet and lost exergy with the time of distillation of essential oil (EO) because the saturated steam production source will be produced from the boiler that is designed and built in the same area as the distillation pot, but in the lower position as shown in

Figure 1. The design and construction of the distillation machine is suitable for commercial applications in the small and medium enterprises (SMEs) industry by providing the use of re-distillation with water and steam that is suitable for both the use and the purchase price of the distillation machine by using LPG fuel as the energy source for the boiler containing liquid water to become steam. It can be seen that the inlet exergy is high and steep in the initial period of distillation in both Zone 1/Step 1 and Zone 3/Step 3. The characteristics of Exergy are related to the heating temperature. Therefore, it can be seen that it is a factor resulting from the acceleration of saturated steam production as mentioned above in this section. In addition, as mentioned in

Figure 16, it can be seen that in the initial period of distillation of essential oils by the RWASD method, the efficiency of the useful energy ratio is high because the useful energy is high. Due to the volume of the distillation machine and the raw materials must be heated by the pressurized steam to penetrate into the storage chamber where the essential oil (EO) is collected. As a result, the raw materials absorb some of the heat from the steam and the steam production must be accelerated to have a constant volume control. When the time is increased, it results in the exergy at the entrance having a constant value of approximately 300 kJ/s until the end of step 1. This behavior and trend will occur and be similar to the pattern in step 3/zone 3. It can be observed that the efficiency of the exergy is the ratio of the beneficial exergy to the total exergy flowing in, which continuously affects the trend of the efficiency of the exergy in the same direction as shown in

Figure 17. With such characteristics, it results in the loss of exergy from the difference between the total exergy flowing in and the total exergy flowing out of the essential oil distillation (RWASD). From the calculation of the efficiency of the exergy, it can be seen that in the early stages of the distillation, the efficiency of the exergy is low because the exergy is lost or close to the exergy at the entrance. When the time of EO distillation increases, the efficiency of the exergy will also increase. Because of the relatively slow increase in exergy loss as shown in the time period of 0-30 minutes and 1141 – 1151 minutes for the distillation at the said time in Zone 1 and Zone 3 respectively, from the test and calculation of various Exergy values as follows: Exergyin, Exergyout have the highest values of 294.29 and 144.76 kJ/s and found that Exergyloss has the highest value of 150.22 kJ/s. It was also found that the essential oil distillation process by RWASD method has η

Ex equal to 49.97% respectively. The data obtained from Exergy in different sections have a tendency that is consistent with the previous research works of many researchers [

60,

61]. Considering the comparison of the exergy efficiency values obtained in this research with other methods used to distill essential oils, it was found that the exergy efficiency obtained is at a high level. It can be considered that the use of water and steam re-distillation method with a 500-liter prototype essential oil distiller can significantly improve the efficiency in increasing the amount of essential oil as well as the efficiency in utilizing the heat energy from steam as shown in

Section 4.1 and

Figure 18, respectively.

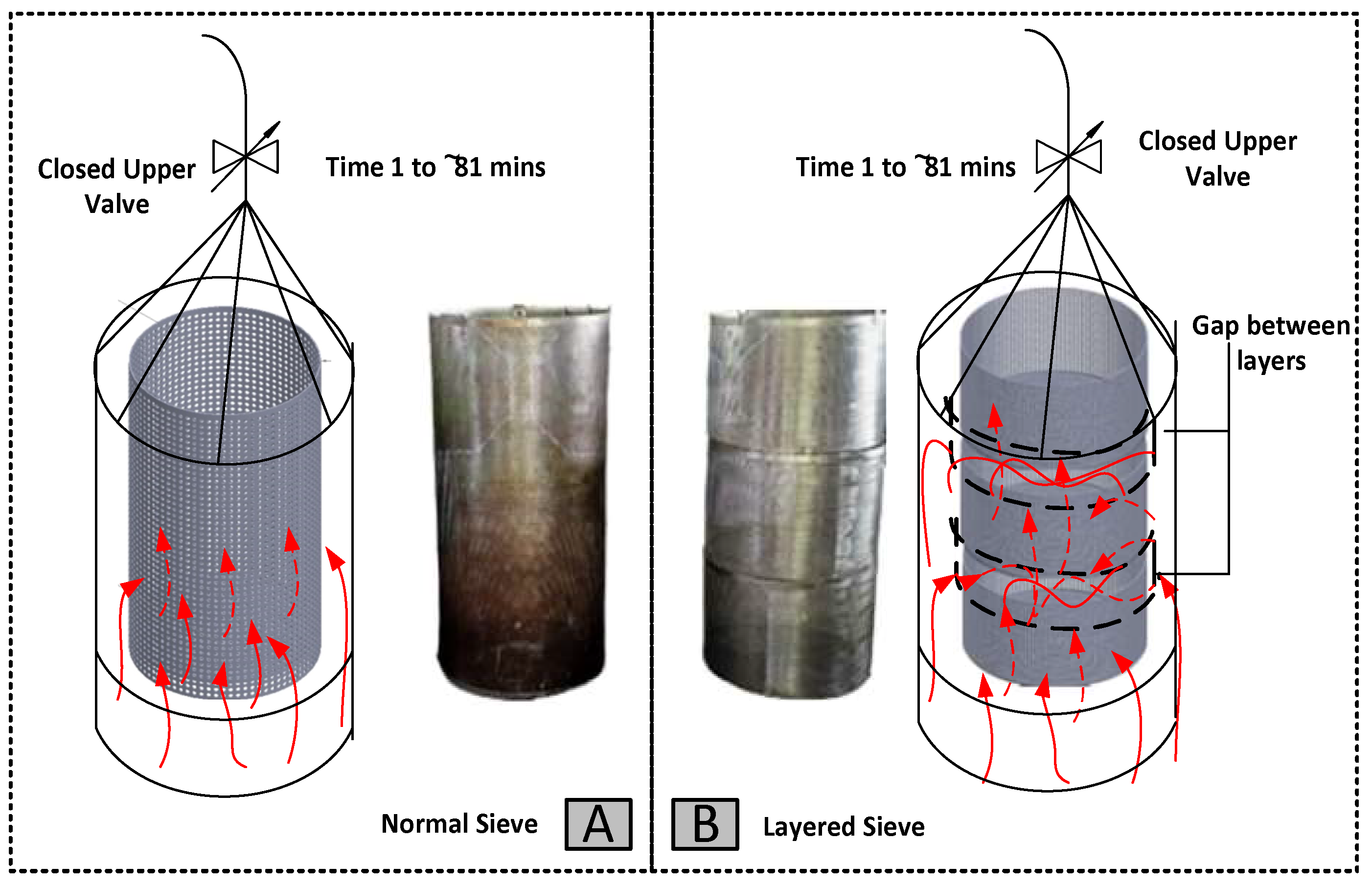

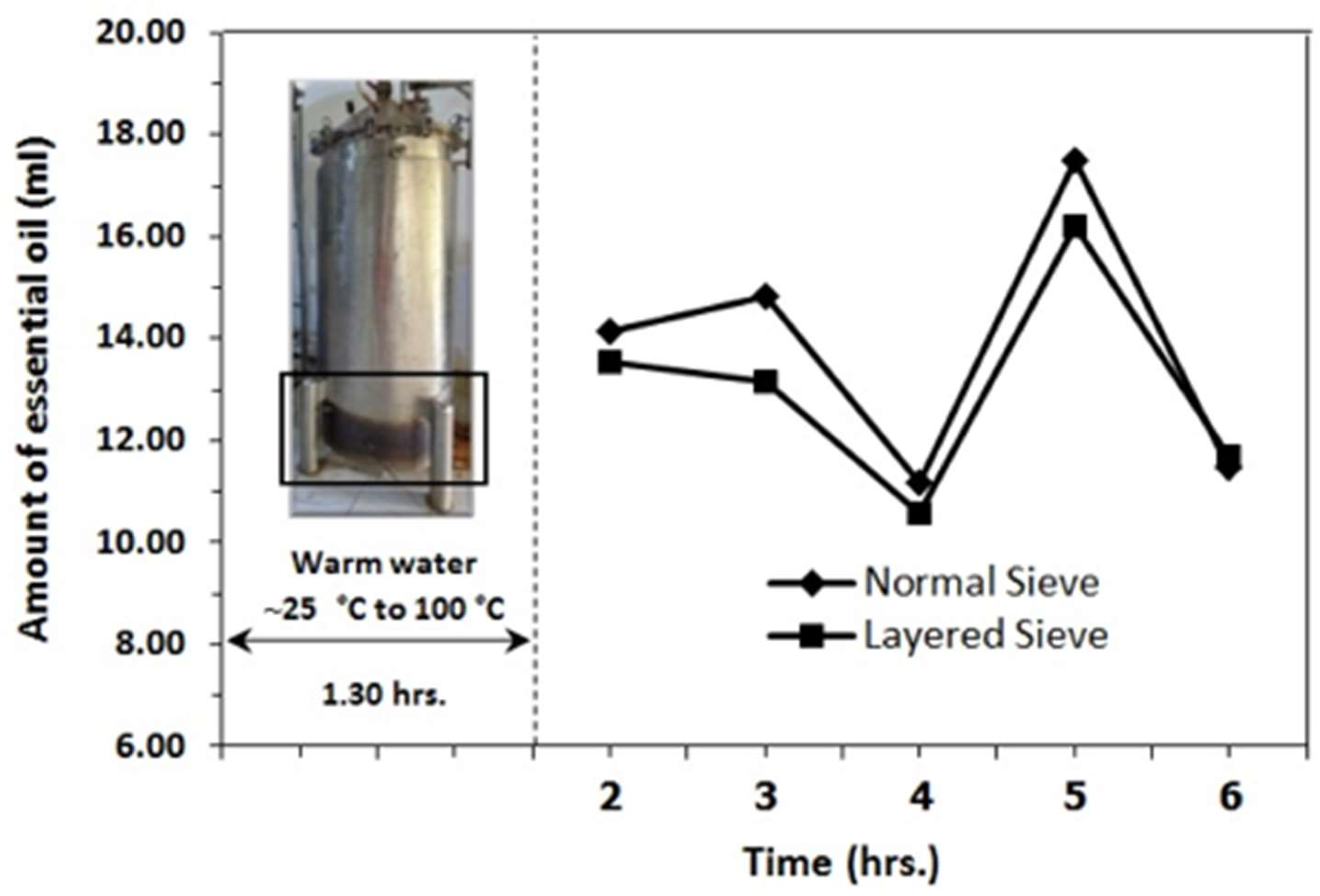

4.5. Effect of Different Raw Material Loading Screens on the Amount of Essential Oil (EO)

Using a simple grid, it was found that the steam behaved as waves when changing from liquid to vapor in the combustion chamber. The center and top of the distillation chamber using a simple grid had lower temperatures than the layered distillation chamber, which was due to the structure of the layered grid with gaps between the layers as shown in

Figure 19. From the test in

Figure 20, it was found that when considering the comparative test at a distillation time of 6 hours, in order to show the results of evaluating the heat characteristics and heat transfer of each type of grid in each test under the same controlled conditions, the steam moved through the gaps between the layers relatively faster than the simple grid. It can be observed that the steam moved up from the surrounding area and penetrated into the gaps between the layers, while some steam passed through the bottom of the grid and floated up. As a result, the steam entering from the sides of the grid into the gaps between the grids would create a turbulent flow pattern, causing the flow to stop due to the rapid penetration of steam through the gaps between the layers of the grids, which can be seen from the trend of the data at the temperature contact points measured. The temperature of the layered grid was initially higher than the common grid, both at the center and the top of the distillation chamber, for approximately 81 minutes, as shown in

Figure 19. In order to maintain a constant temperature and steam inside the distillation chamber, a shut-off valve was installed at the top of the distillation chamber. This includes the installation of a gauge that measures the temperature and pressure of the steam with a valve at the top of the distillation vessel opened after about 81 minutes, which allows the steam to move through the conveyor to the condenser. The steam flows continuously from the distillation vessel to the conveyor to the condenser throughout the period until the distillation reaches 6 hours. It was found that the use of multi-layer screens has a low steam temperature, which may be due to the gap and the position of the valve on the top that is open, which causes the steam to flow faster along the gap between the screens and the sides, which means less time for temperature contact with the raw material because the direction of movement floats up from the opening of the valve at the top position, including the large gap, resulting in uneven steam flow and lower temperature compared to ordinary screens. Although the ordinary screen has raw materials that block the steam flow, it provides a uniform area for steam movement and time for steam absorption into the tissue. In addition, the steam coming out of the combustion chamber will mix with the original steam, which causes energy to accumulate and produce larger steam waves. It was found that using ordinary screens results in a temperature increase in the tank during distillation of 10.14% compared to using multi-layer screens. This is because the heat and flow of steam inside the storage tank affect the penetration and fibers of the raw material, making it easier for the volatile substances to be absorbed, which affects the amount of essential oil that can be extracted. For the analysis of the amount of essential oil, it was found that On average, the yield of EO using a conventional screen was 8.07% higher than that of a layered screen, as shown in

Figure 19 and

Figure 20. This may be due to the steam flow characteristics in the conventional screen, which allows the steam to continuously penetrate through the gaps throughout the distillation process. Therefore, the steam has sufficient time to penetrate into the fibers of the raw materials and has sufficient time to transport volatile substances or essential oils with the steam. Therefore, to obtain higher oil yields, it is more suitable to distill using a conventional screen rather than a layered screen. The heating temperature, flow direction, and distribution of steam are shown in

Figure 19 and

Figure 20, respectively.

4.6. Analysis of Design and Construction of Distillation Apparatus

The calculation of the design the prototype machine is an important factor to be considered in order to provide guidelines or basic information for its further development. The calculation and design of the prototype distillation machine with data from both before construction and during operational use, including the process of distilling evaporated water is shown in

Table 4 The amount of essential oil extracted was dependent on the performance of the machine, which were affected by tolerances obtained from the design and construction as discussed in the next section. The average thermal energy and heat transfer discrepancy in all variables throughout the test was 8.41%, and the structural discrepancies for all variables throughout the experiment were 4.66% respectively.

5. Conclusions

For the improvement of the efficiency of essential oil (EO) distillation by the recurrent water and steam distillation (RWASD) method applied to a 500-liter prototype essential oil distillation machine, as well as using it with different raw material packing grids, using lime as the raw material in the distillation using the RWASD method, which is considered a new technique of EO distillation, focusing on the use in the SMEs industry, including being able to use it as basic information to expand the results to develop related research. The results can be summarized as follows:

Retention of essential oils by re-distillation with water and steam (RWASD) with using lime as raw material will give the amount of essential oil (EO) distilled throughout the test with a high value of 53.69% when compared to water and steam distillation (WASD) at the same test conditions or equal to 43.21 ml. For re-distillation with water and steam, saturated steam is used as a medium to distill the essential oil from lime, which can be seen from the measured steam temperature as shown in the distillation tank in

Figure 14, which has an average value throughout the test, collected during the distillation system reaching equilibrium equal to 99.51°C and 99.07°C at steps 1 and 3 of Zone 1 and 3, respectively, as well as the measured steam pressure. With the advantage of RWASD that has a technique to add a step in step 2, it will help the raw material to cure and release from the stop of heating from LPG gas, including the entire system when it is closed, and it also helps reduce the use of gas energy, which will prepare the raw material that makes the transport channel or the collection of essential oil expand, resulting in the remaining steam in the distillation tank at step 2. Quarantine and time to extract essential oils from the existing steam temperature mixed with the steam is considered a raw material preparation before entering step 3 of the water and steam re-distillation method. In addition, in order to maintain the quality of EO distilled by the RWASD method, it is analyzed and identified using gas chromatography-mass spectrometry (GC-MS) to determine the quality of essential oils with a fixed percentage of selected bioactive compounds of GC, which is in accordance with the research data of many people in the past [

46], [

47], namely β- Myrcene (2.72%), Limonene (20.72%), α - Phellandrene (1.27%), Terpinen-4-ol (3.04%), as well as explaining the medicinal properties of the bioactive compounds mentioned in the above topic, which indicates that the use of the RWASD distillation method with a 500-liter prototype distillation machine can increase the amount of essential oil and still have an effect that does not destroy the bioactive compounds from the distillation of lemon essential oil, as well as using beneficial energy in the distillation process analyzed from the use of the RWASD distillation method equal to 29,880 kJ/s with the design and construction of a good essential oil distillation machine. When analyzing the heat energy extracted from the system, which is combined with the RWASD distillation method and the 500-liter prototype essential oil distiller, the efficiency of the exergy η

Ex is 49.97%. Since the exergy is directly affected by the steam temperature, the use of the raw material grid will result in a uniform heat distribution. The use of the grid in the normal shape has a higher temperature and essential oil volume during the essential oil distillation by 10.14% and 8.07%, respectively, compared to the use of the layered grid. For the 500-liter prototype essential oil distiller, considering the average error from heat loss and the structure design and construction, is 8.41% and 4.66%, respectively.

Figure 1.

Schematic diagram of water and steam distillation process.

Figure 1.

Schematic diagram of water and steam distillation process.

Figure 2.

Schematic classification of essential oil distillation methods using steam.

Figure 2.

Schematic classification of essential oil distillation methods using steam.

Figure 3.

The relationship between distillation time and steam temperature distribution of distillation methods: (A) Re-Water and Steam Distillation (RWASD) and (B) Water and Steam Distillation (WASD).

Figure 3.

The relationship between distillation time and steam temperature distribution of distillation methods: (A) Re-Water and Steam Distillation (RWASD) and (B) Water and Steam Distillation (WASD).

Figure 4.

Position of the distillation vessel top valve during RWASD operation.

Figure 4.

Position of the distillation vessel top valve during RWASD operation.

Figure 5.

Phase diagram of water showing relationships between temperature, specific volume and pressure.

Figure 5.

Phase diagram of water showing relationships between temperature, specific volume and pressure.

Figure 6.

Experimental procedure for determining %Dry and Wdry.

Figure 6.

Experimental procedure for determining %Dry and Wdry.

Figure 7.

Pressure distribution along the circumference of the distillation unit.

Figure 7.

Pressure distribution along the circumference of the distillation unit.

Figure 8.

Analysis of stress distribution in the height direction.

Figure 8.

Analysis of stress distribution in the height direction.

Figure 9.

Schematic diagram of heat transfer network showing convection and conduction mechanisms.

Figure 9.

Schematic diagram of heat transfer network showing convection and conduction mechanisms.

Figure 10.

Temperature measurement locations at the condensation section with directional indicators.

Figure 10.

Temperature measurement locations at the condensation section with directional indicators.

Figure 11.

Schematic diagram of the 500-liter essential oil distillation unit assembly and construction.

Figure 11.

Schematic diagram of the 500-liter essential oil distillation unit assembly and construction.

Figure 12.

Schematic representation of the essential oil Re-Water and Steam Distillation (RWASD) process.

Figure 12.

Schematic representation of the essential oil Re-Water and Steam Distillation (RWASD) process.

Figure 13.

The relationship between distillation time and essential oil yield for different distillation methods: (A) Re-Water and Steam Distillation, (RWASD) and (B) Water and Steam Distillation, (WASD).

Figure 13.

The relationship between distillation time and essential oil yield for different distillation methods: (A) Re-Water and Steam Distillation, (RWASD) and (B) Water and Steam Distillation, (WASD).

Figure 14.

Time-dependent steam temperature profile during regenerative water-steam distillation (RWASD) process.

Figure 14.

Time-dependent steam temperature profile during regenerative water-steam distillation (RWASD) process.

Figure 15.

GC-MS chromatogram of lemon essential oil obtained by re-water and steam distillation (RWASD).

Figure 15.

GC-MS chromatogram of lemon essential oil obtained by re-water and steam distillation (RWASD).

Figure 16.

Time-dependent analysis of useful energy efficiency and energy utilization ratio.

Figure 16.

Time-dependent analysis of useful energy efficiency and energy utilization ratio.

Figure 17.

Time-dependent exergy performance analysis.

Figure 17.

Time-dependent exergy performance analysis.

Figure 18.

Comparison of thermal energy excitation efficiency among different essential oil distillation methods.

Figure 18.

Comparison of thermal energy excitation efficiency among different essential oil distillation methods.

Figure 19.

Steam flow patterns and directions in different sieve designs: (A) Normal sieve and (B) Layered sieve.

Figure 19.

Steam flow patterns and directions in different sieve designs: (A) Normal sieve and (B) Layered sieve.

Figure 20.

Movement and direction of steam flow within a conventional sieve and a layered sieve.

Figure 20.

Movement and direction of steam flow within a conventional sieve and a layered sieve.

Table 2.

Details and equations of different parts of a 500 L prototype distillation apparatus [

39,

40].

Table 2.

Details and equations of different parts of a 500 L prototype distillation apparatus [

39,