1. Introduction

The presence of persistent contaminants in wastewater poses risks to human health and the environment as they can transform into hazardous forms [

1]. The discharge of substantial amounts of pollutants, such as dyes [

2], heavy metals [

3], pharmaceuticals [

4,

5], pesticides [

6], and nano/microplastics [

7,

8,

9], is continuously deteriorating water quality on a global scale [

3]. The exponential population expansion witnessed in recent decades has led to the expansion of urban areas and industrial activities. Consequently, this surge in urbanization and industrialization has aggravated the scarcity of water resources and led to a substantial increase in the occurrence of emergent pollutants [

7]. These developments present formidable obstacles to maintaining environmental sustainability and ensuring the well-being of human populations [

1]. According to the published data by the United Nations (UN) in 2017, globally about 2.2 billion people still lack formidable access to potable water due to contaminated water sources around the globe [

10]. According to recent report by the year 2030 more than 700 million people could be displaced because of inability to have access to potable drinking water. A report from the United Nations (UN) states that as of 2017, due to pollution, nearly 2.2 billion people lacked access to safely regulated drinking water [

5]. In order to address this issue in accordance with the SDG-6 (Ensure availability and sustainable management of water and sanitation for all) and SDG-3 (Ensure healthy lives and promote well-being for all at all ages) various techniques have been employed for the treatment of wastewater [

11].

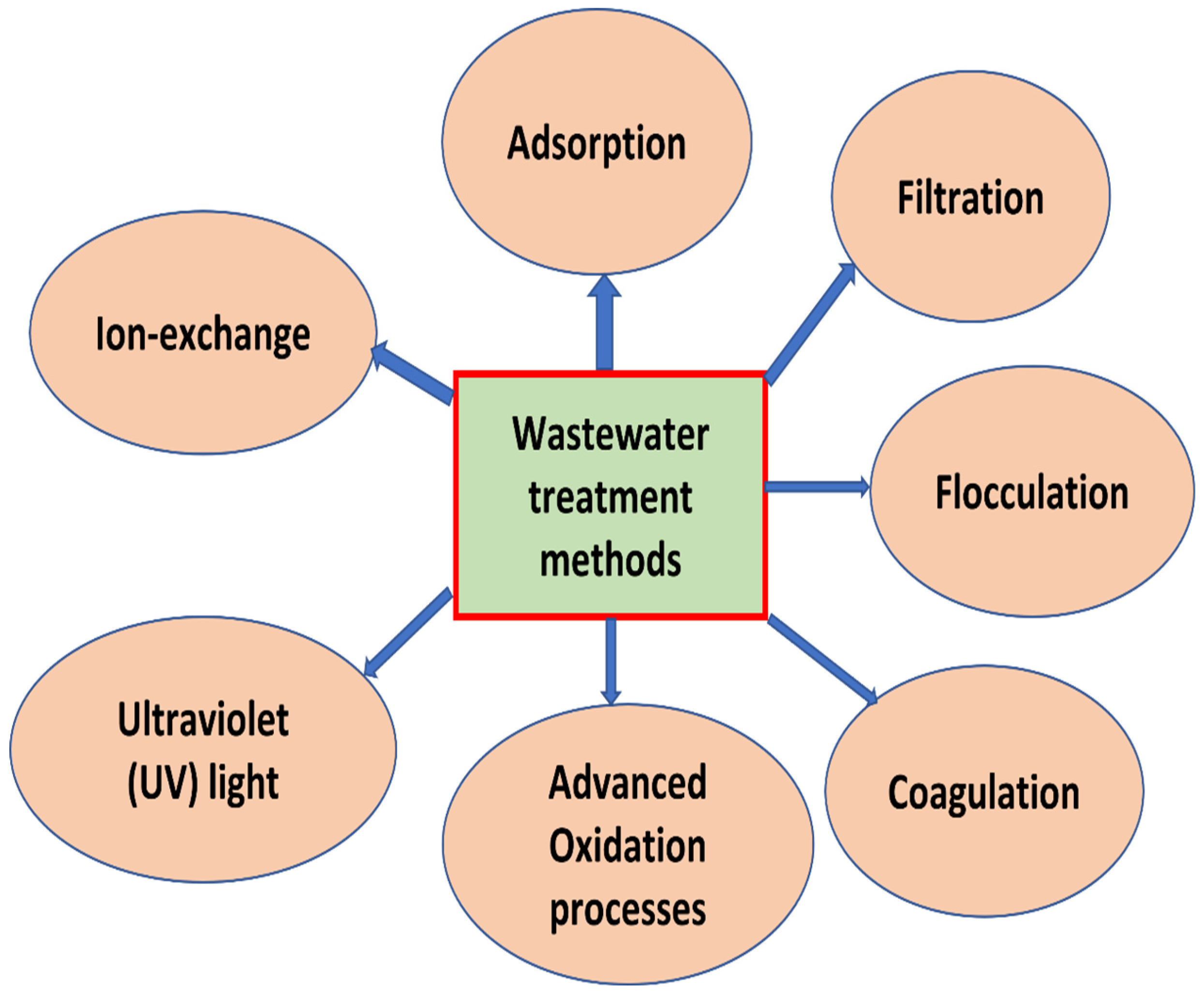

Figure 1 shows the current and existing applicable wastewater treatment techniques [

11,

12]. To address these risks, it is essential to employ environmentally friendly removal techniques in order to effectively remove these contaminants from wastewater [

13].

Therefore, there is a need for efficient adsorbents that can enhance the removal of these contaminants from wastewater. Residues generated from agricultural activities, such as crop residues, animal manure, and food processing by-products are becoming suitable precursors for the production of various value-added materials (VAMs) and such serves as a greener way of dealing with high volumes of agro-wastes generated globally [

14].

The aim of this review is to comprehensively explore various aspects related to biochar. The study specifically review focuses on the efficacy of agro-wastes as suitable precursors, understanding biochar modification approaches, investigating adsorption mechanisms for the removal of inorganic and organic contaminants, and evaluating the resource sustainability achieved through the utilization of biochar in water and wastewater treatment. It also aims to highlight the connections between the use of agro-waste-derived biochar, and principles of Green Chemistry and circular economy. Furthermore, it explores the applications of agro-waste-derived biochar in energy, remediation, soil enhancement, construction industry, and waste management. The review also examines the role of biochar in the synthesis of functional materials and its relevance to Sustainable Development Goals (SDGs). Overall, this study aims to emphasize the significance of biochar as an efficient adsorbent and its potential contributions to achieving sustainable and environmentally friendly wastewater treatment approaches, surpassing the limitations of conventional methods by leveraging on its suitability in sustainability, Green Chemistry, and circular economy.

1.1. Efficacy of Agro-Wastes as Precursors for the Synthesis of Value-Added Materials (VAMs)

The agro-wastes are abundant globally in agricultural sector, representing a significant portion of the agricultural biomass produced annually and have recently become a subject of interest for sustainable waste management strategies [

15,

16]. Reckless utilization of petroleum derived materials has led to various issues ranging from climate changes to pollution of various types [

14] Petroleum derived materials are not equally distributed equally in all global geographical regions, therefore, there is crisis in continuous using without back-up or sourcing source of renewable materials to complement it [

17]. Biomass as a material renewable in nature, equally distributed almost across the world and eco-sustainable compliance without environmental degradation are suitable for the synthesis of various materials that are equally obtainable from petroleum such biofuels (

e.g. ethanol, biodiesel) [

18].

Recently Li et al synthesized bio-jet fuels from lignocellulose biomass [

17]. Activated carbon has also been synthesized with the aid of biomass as precursors [

14], it has been employed as catalytic materials for the synthesis of various materials such as value-added chemicals [

19], for sensor applications and as adsorbents for various applications [

20]. It is an important renewable feedstock owing to its environmental-friendliness and renewability credentials [

21]. Therefore, this is the reason they are being explored for various uses. Agro-wastes are from biomass and are suitable for the applications enumerated above [

16]. Apart from plant-derived biomass, biochar can also be synthesized from animal wastes such as bone. For instance, Adeniyi and his colleagues’ metal oxide-based biochar from bone

via pyrolysis [

22]. The biochar synthesized was reported to be suitable as low-cost adsorbent for the treatment of wastewater and catalytic materials to produce biofuel as alternative fuel at lower cost [

19,

22]. The entire production was said to be low-cost and eco-friendly [

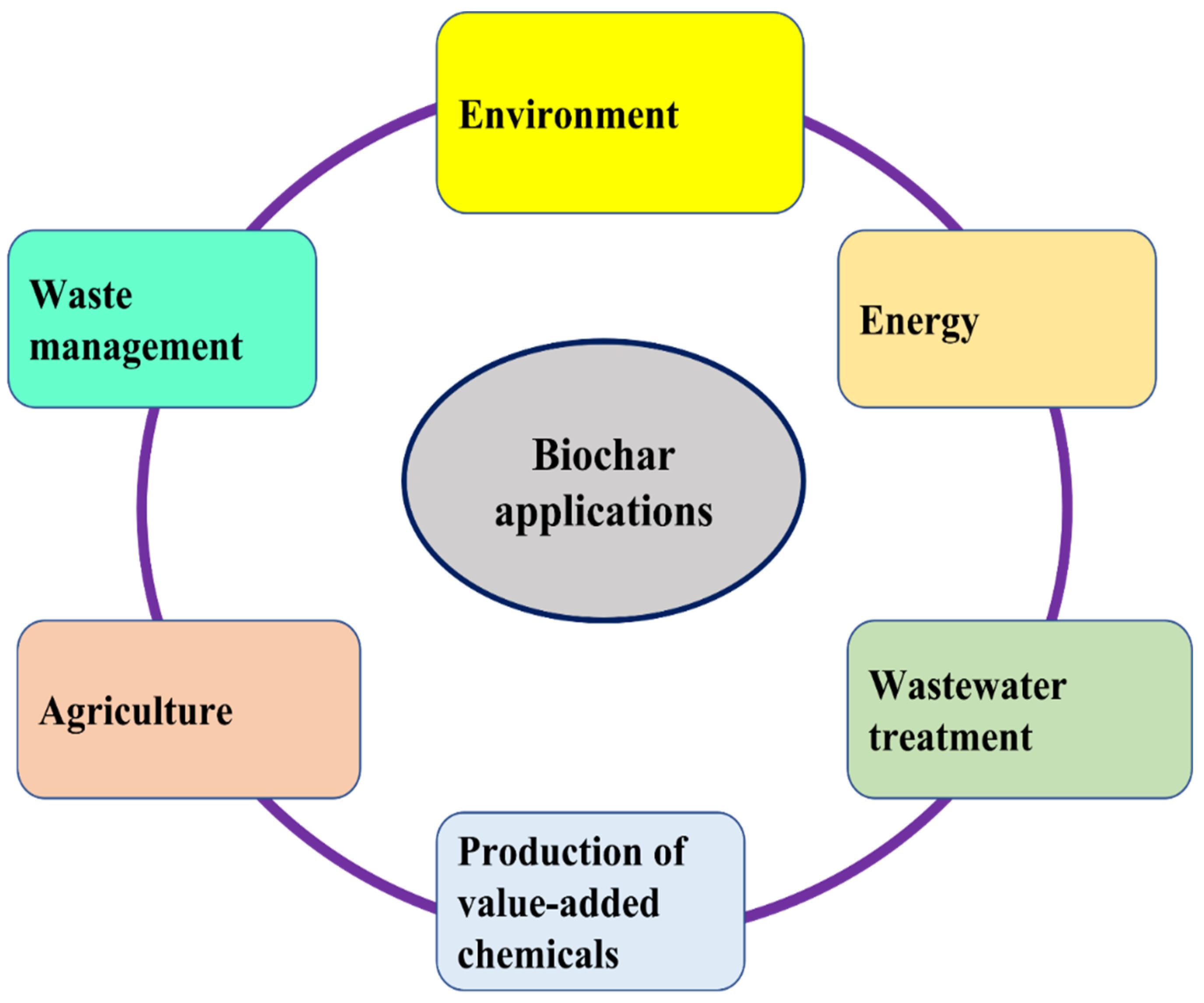

20]. Sustainable applications of biochar in various fields are shown in

Figure 2 [

23,

24,

25]. In addition to the wastewater treatment methods depicted in

Figure 1, various traditional technologies are used globally to remove wastewater contaminants singly or in combination to meet the goal of efficient treatment. Such as reverse osmosis, ion- electrochemical treatment, flotation, coagulation-flocculation, chemical precipitation, and solvent extraction for the remediation of various contaminants [

26]. Though, these treatment techniques have

pros and cons, some are inefficient in nature or not cost-effective due to the cost of the required equipment and maintenance, sometimes high consumption of energy made them unaffordable [

6].

1.2. Biochar Modification Approach

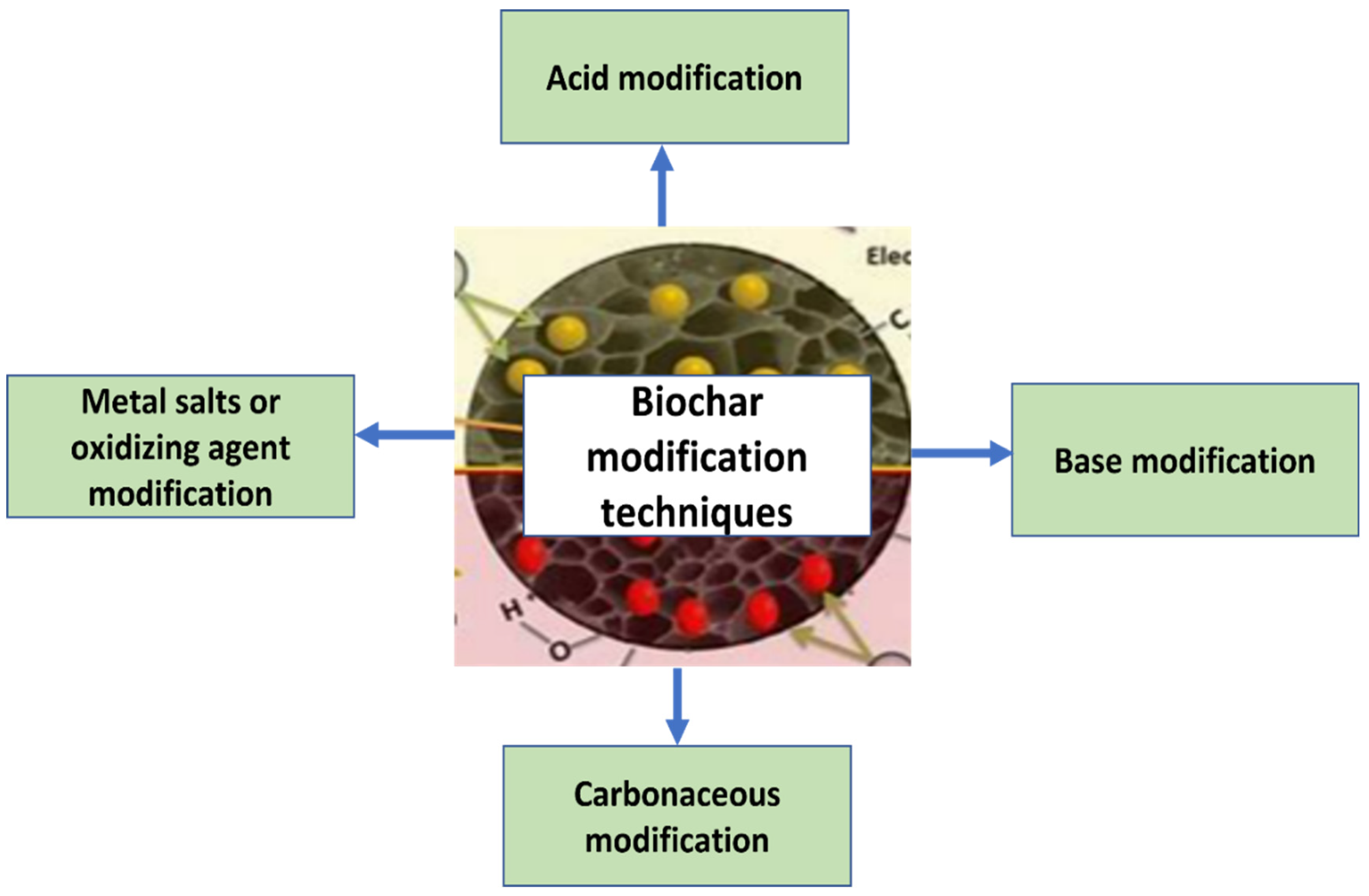

To enhance the adsorption and catalytic performance of biochar, various methods of modification have been employed. These include chemical functionalization, physical activation, thermal treatment, composite formation, surface modification, mesopore formation, and gas activation [

27]. The efficiency and viability of the method adopted for the treatment must be considered if they are economical affordable, environmental compliance and potential to scale up to industrial adoption. These qualities taken into consideration could help reduce the treatment costs and improve the effectiveness of the water treatment process [

28]. The most frequently used chemical methods applicable for the modification of biochar derived materials are shown in

Figure 3 [

29].

Table 1 shows the different modification techniques for the preparation of enhanced biochar.

The pyrolytic conversion of agricultural wastes into biochar presents a valuable opportunity to curtail terrestrial CO

2 emissions, making a significant contribution to climate change mitigation efforts [

39]. Biochar as a renewable and eco-sustainable material obtained from renewable sources with green credentials are gaining attention recently [

20,

21]. Biochar is a material suitable for various environmental and energy applications [

20]. Biochar is being employed and studied as material with multipurpose in various fields. Biochar plays a multifaceted role in enhancing soil characteristics, such as improving soil structure, and nutrient retention [

40]. Additionally, it aids in carbon sequestration, effectively reducing greenhouse gas emissions [

41]. Furthermore, biochar serves as a valuable tool for removing organic compounds and heavy metal pollutants from the environment [

42]. It also holds potential for biofuel production, the synthesis of useful chemicals, and even the creation of cementitious materials, further highlighting its versatility and significance in various fields [

40].

2. Adsorption Mechanisms for Inorganic and Organic Contaminants Removal by Biochar

This section briefly discusses the diverse mechanisms employed by biochar to remove organic and inorganic contaminants from polluted soil and water. Sorption is a crucial mechanism by which biochar interacts with both inorganic and organic pollutants [

43,

44]. Biochar adsorbs organic contaminants like pesticides, facilitating their immobilization [

45]. Additionally, it exhibits strong affinity for heavy metals, effectively reducing their bioavailability through adsorption [

36]. These sorption processes contribute significantly to the remediation of polluted environments. Electrostatic attraction plays a key role in the interaction between biochar and pollutants. For instance, biochar's surface exhibits a negative charge, attracting positively charged heavy metals like lead (Pb) [

46]. Hydrogen bonding serves as a mechanism for interactions between biochar and pollutants. Organic pollutants, such as pesticides, can form hydrogen bonds with the functional groups present on biochar's surface [

47]. Hydrogen bonding plays a vital role in immobilizing PAH derivatives in soil. These compounds including oxygenated-PAHs, hydroxy-PAHs, and nitro-PAHs, form through similar processes as PAHs. Functional groups like hydroxyl and nitro can engage in hydrogen bonding with biochar and soil particles, increasing their adsorption capacity and reducing mobility. Hydrogen bonding can also affect the behaviour and fate of PAH derivatives, influencing their solubility and retention in the soil matrix [

48].

Precipitation also plays a significant role in the interaction between biochar and pollutants. The presence of inorganic elements in biochar enhances heavy metal adsorption through ion exchange and precipitation, increasing the binding capacity and providing additional sites for metal adsorption from the surrounding medium [

49]. Additionally, the formation of insoluble complexes between biochar and organic pollutants like phenols can lead to their precipitation, aiding in their elimination [

50]. Surface complex formation is a mechanism through which biochar interacts with pollutants. In their study, a recent work prepared magnetic biochar doped with Ce and La using the co-precipitation technique. They then utilized these materials for phosphate adsorption, finding that the predominant mechanism for phosphate removal was inner-sphere complexation under neutral conditions, as revealed by the evaluated results [

51]. In a different research investigation, it was observed that biochar derived from seaweed exhibited significantly higher adsorption efficiency (227.27 mg.g

−1) for the remediation of Copper (II) compared to biochar derived from agricultural residues and macroalgae biomass without chemical activation. The Authors confirmed that the primary mechanism responsible for the adsorption of Copper (II) onto seaweed biochar was the process of surface adsorption [

43]. The effectiveness of biochar (BC) in the remediation of hydrophobic pollutants such as polycyclic aromatic hydrocarbons (PAHs) is highly reliant on its specific physicochemical characteristics. Biochars exhibit hydrophobic properties primarily due to their limited surface oxidation. Different types of biochar engage in hydrophobic interactions with hydrophobic organic compounds, enabling efficient removal of organic pollutants [

35]. For instance, Chaukura et al demonstrated that the presence of ferric oxide-biochar nanocomposites can intricately interact with methyl orange (MO) molecules, effectively removing MO from a solution with only a single solute [

52]. Similarly, hydrophobic interactions also play a role in the adsorption of inorganic pollutants, such as heavy metals and metalloids, by biochar [

44].

Similarly, inorganic pollutants like arsenic (As) can diffuse into biochar, where they can be immobilized through surface adsorption or complexation [

53].

3. Application of Biochar-Based Catalyst to Wastewater Treatment

3.1. Industrial Wastewater Remediation

Industrial wastewater, which is primarily made up of heavy metals and organic pollutants, has been treated using catalysts made of biochar. Biochar derived adsorbents have been exploited for adsorptive removal of heavy metals from industrial generated wastewater with efficient performance [

54]. For instance, Rajapaksha et al stressed that the combination ratio of chitosan/biochar materials is crucial for the efficient adsorption of heavy metals from wastewater produced by the industries [

30]. Additionally, in another study bagasse was used as precursor to produce biochar for the removal of lead from aqueous solution generated from battery-based industry and adsorption capacity of 13 mg.g

-1 was reached. However, the adsorptive pathway was dependent of a moderate pH value, concentration, and reaction time [

55]. Pan et al synthesized biochar from a variety of agricultural wastes, including rice husk, peanut shells, soybeans, and canola, and showed that the adsorption capacity of the biochar increases as the number of functional groups increases. This was largely explained by the presence of active complexation in addition to the biochar's functional groups as the primary significant factor affecting the remediation mechanism for the heavy metal, trivalent chromium [

56].

Additional research by Chen et al found a connection between the Cr

3+ absorbed and the Ca

2+ and Mg

2+ cations released into solution after adsorption. Electrostatic interaction serves as a regulating mechanism for the elimination of chromium in an aqueous environment at lower pH value (2.5), the surface of biochar was negative while the trivalent chromium (Cr) species was still positive during adsorption process. However, most of the reported works were done in the lab-scale there is need to scale up the adsorption technology of biochar for real application in the purification and separation of water for various uses [

57].

4. Wastewater Treatment in the Agricultural Sector

The rapid progress of agricultural technologies has resulted in the emergence of agricultural pollution, whereby significant quantities of agro-chemicals containing toxic chemicals are released into the environment, posing environmental concerns [

29]. The most frequently used pesticides in agriculture include atrazine and pentachlorophenol and they pose degradation to the environment. The obtained biochars from soybean and corn straw were also explored for the removal of atrazine and high adsorption capacity was reached, however, the adsorption performance was dependent of the pore volume of the biochar and pH level [

58]. Sulfamethazine can be effectively removed by steam-activated biochar, and the pH level affects how quickly it absorbs this contaminant [

20,

21].

However, the catalytic materials need to be improved for an effective remediation process. There are various types of catalysts available for wastewater treatment, including homogeneous, heterogeneous, and enzyme-based catalysts [

59]. Homogeneous catalysts are soluble in the reaction medium and are typically metal ions or complexes. They offer high selectivity and activity but suffer from poor stability and separation from the reaction medium. Heterogeneous catalysts are typically insoluble and are supported on solid substrates, such as zeolites, activated carbon, or biochar [

59,

60]. They offer high stability, selectivity, and recyclability, but their activity is typically lower than that of homogeneous catalysts. Enzyme-based catalysts are biologically derived catalysts that offer high specificity and efficiency, but their production is expensive and suffers from stability issues [

61]. To improve the performance of catalysts for future generations of green catalysts in wastewater treatment, several approaches can be taken. One approach is the development of new catalysts that offer high activity, selectivity, and stability while being environmentally benign and sustainable [

62]. For example, the use of green solvents and renewable energy sources for catalyst production can reduce the environmental impact of catalyst synthesis [

63]. Another approach is the optimization of existing catalysts through the modification of their physicochemical properties, such as their surface area, porosity, and surface chemistry [

64].

For example, the incorporation of metal nanoparticles into biochar-based catalysts can enhance their catalytic activity and selectivity, while the modification of zeolites' surface chemistry can improve their adsorption capacity. Furthermore, the development of novel reactor designs and process intensification techniques, such as micro-reactors and membrane reactors, can improve the efficiency and scalability of catalyst-based wastewater treatment processes [

64]. The development of green catalysts for wastewater treatment requires a critical evaluation of the types of catalysts available and the improvement of their properties through various approaches, such as the development of new catalysts, modification of existing catalysts, and the optimization of reactor designs and process intensification techniques [

65]. These efforts will pave the way for more sustainable and eco-friendly wastewater treatment processes in the future. Adsorption isotherms describe the correlation between the concentration of the contaminants being adsorbed in the adsorbent phase and the quantity of the contaminants that remains in solution at the point of equilibrium [

66]. Both the Langmuir and Freundlich isotherms have been extensively used to model the adsorption of heavy metals onto biochar derived from various feedstocks, such as rice husk, sugarcane bagasse, cattle manure biochar, bamboo. For instance, a study used Langmuir and Freundlich isotherms to model the adsorption of cadmium, lead and nickel onto cattle manure biochar. The study found that the Langmuir isotherm provided a better fit than the Freundlich isotherm and that the maximum adsorption capacity (see

Table 1) while both the pseudo-first-order (PFO) and pseudo-second-order kinetic (PSO) perfectly described their results [

49]. Therefore, pseudo-first-order (PFO) and pseudo-second-order kinetic (PSO) models were employed to describe the adsorption kinetics of the heavy metals onto biochar obtained using cattle manure as precursors [

49]. For example, a study by Wang

et al used the pseudo-second-order kinetic model to evaluate the adsorption of methylene blue onto corn straw biochar. The study found that the adsorption rate was rapid during the initial stage and gradually slowed down as the equilibrium was approached, and that the adsorption process was governed by both external and internal mass transfer. The thermodynamic parameters, such as Gibbs free energy, enthalpy, and entropy, have been used to assess the feasibility and nature of the adsorption process [

67]. For instance, a study conducted on the thermodynamic models to evaluate the adsorption of tetracycline onto biochar found that the adsorption process was spontaneous, exothermic, and accompanied by a decrease in entropy, indicating a favourable adsorption process [

66]. See

Table 2 for summary of kinetics, isotherms, thermodynamics, and adsorption capacity of various biochar derived adsorbents for different pollutants.

5. Resource Sustainability Through the Utilization of Biochar in Water and Wastewater Treatment

In order to achieve resource sustainability, it is important to engage in accountability, effectiveness, and environmental consideration compliance [

14,

16]. Utilization of plant or animal derived feedstocks are inevitable to accomplish the Green Sustainable Remediation (GSR) task as a better approach towards admirable clean-up of the contaminated environment [

22] which is very fundamental to eco-sustainability and green approach as stated under principle #7 (use of renewable feedstock) [

14]. Since biochar is obtainable from waste resources from both plant and animal sources, it is an added advantage to environmental waste management sector as wastes are converted to value-added products capable of improving economy and agricultural sectors; this can as well generate indirect employments [

14,

16,

22]. Therefore, we anticipate the utilization of bio-derived biochar to facilitate implementation of

‘Green Chemistry’, ‘Circular Economy’, and ‘Sustainable Development’ towards achieving cleaner and habitable environment [

14]. The recent study reported by Neogi et al has demonstrated the efficacy of biochar as a versatile and sustainable tool capable of achieving

‘Green Chemistry’, ‘Circular Economy’, and ‘Sustainable Development’ approaches with potential capacity in dealing with both environmental and energy related issues [

40].

6. Agro-Wastes, Agro-Waste-Derived Biochar and Green Chemistry Principles

The recent advances in the utilization of agro-waste derived biochar as efficient adsorbents in water and wastewater treatments align with the principles of green chemistry, which aim to promote the design of chemical products and processes that are environmentally sustainable and minimize the use and generation of hazardous substances [

70].

The 1

st principle of green chemistry is the prevention of waste. The use of agro-waste as feedstock for biochar production can contribute to this principle by preventing the disposal of these materials as waste, reducing the need for landfill space and promoting the efficient use of resources. Additionally, the use of biochar as an adsorbent in water and wastewater treatment can reduce the amount of sludge produced, leading to a more efficient use of resources [

29].

The 4

th principle of green chemistry is the design of safer chemicals and products. Agro-wastes-derived biochar is a safer alternative to conventional adsorbents that often contain hazardous chemicals, such as activated carbon [

71]. Biochar is a natural and renewable material that is biodegradable and has a low potential for toxicity, making it a safer alternative for water and wastewater treatment.

The 7

th principle of green chemistry is the use of renewable feedstocks. Agro-wastes derived biochar is a renewable feedstock that can be produced from a variety of agricultural residues, such as rice husk, coconut shells, and corn cobs. The use of renewable feedstocks can reduce the reliance on fossil fuels and promote the sustainable use of resources [

70]. The 6

th principle of green chemistry is the design of energy-efficient processes [

70]. The production of biochar from agro-wastes is a low-energy and low-emission process that can be performed using simple and inexpensive equipment, such as kilns and pyrolysis reactors [

61]. Additionally, the use of biochar as an adsorbent in water and wastewater treatment can reduce the energy consumption associated with conventional treatment methods, such as membrane filtration and reverse osmosis [

72].

The 9

th principle of green chemistry is the use of catalysts. Agro-wastes derived biochar can act as a catalyst in water and wastewater treatment, enhancing the removal of contaminants and reducing the treatment time and energy consumption [

70]. Additionally, biochar can be modified with other catalysts, such as metal oxides and nanoparticles, to improve its adsorption capacity and selectivity. Thus, the recent advances in the utilization of agro-wastes derived biochar as efficient adsorbents in water and wastewater treatments align with the principles of green chemistry [

70]. The use of biochar can promote the efficient use of resources, reduce the generation and use of hazardous chemicals, promote renewable feedstocks, and reduce energy consumption. These benefits can contribute to a more sustainable and environmentally friendly approach to water and wastewater treatment [

61].

In the era of green chemistry, incorporating agricultural wastes into different uses presents a promising opportunity to make substantial contributions to the creation and enforcement of comprehensive national policies and laws. These regulations would be specifically crafted to discourage the harmful practice of burning such materials, which is a recognized source of significant air pollution [

3]. Through sustainable and environmentally friendly utilization of agricultural waste, pollution can be dealt with as wastes equally constitute to the menace [

73]. Therefore, this approach suitably aligns with the proposed fundamental principles of green chemistry, which adequately and meticulously prioritize the development of innovative strategies that minimize the environmental impact of diverse industries [

3]. Already stated in this study various reports have been reported on the utilisation of waste material as a viable solution for addressing the pressing issue emanated from contamination of water and soil [

22,

74,

75].

Through meticulous and well-planned implementation strategies, agro-wastes can be harnessed effectively to combat the contamination caused by the reckless discharges of contaminants by both human and industrial activities [

14]. Furthermore, integrating agricultural wastes into various applications not only facilitates the establishment of national policies and legislation against burning these materials but also holds significant potential for reducing air pollution and addressing the problem of air, water and soil pollution in water and soil which can further pave the way for sustainable and environmentally conscious practices across different industries [

14,

16,

75].

7. Agro-Wastes, Agro-Waste-Derived Biochar and Circular Economy (CE)

The circular economy is an economic model that aims to reduce waste and promote the efficient use of resources. It is a system that mimics the natural ecosystem, where resources are reused, recycled, and regenerated to create a closed-loop system [

76]. The recent advances in the utilization of agro-wastes-derived biochar as efficient adsorbents in water and wastewater treatments align well with the principles of the circular economy [

77]. Agro-waste, such as agricultural residues, forestry waste, and animal manure, are often used as feedstock for biochar production [

78]. The resulting biochar has a high surface area and porosity, making it an excellent adsorbent for various pollutants in water and wastewater. Various applications of agro-waste and agro-waste-derived biochar in the circular economy approach are briefly discussed in the following sections.

8. Application of Agro-Waste-Derived Biochar in Energy

For many centuries, the widespread use of fossil fuels has significantly contributed to the escalation of carbon dioxide (CO

2) levels. Currently, CO

2 emissions from human activities account for approximately 40% of the total carbon emissions present in the atmosphere [

79]. The application of agro-waste-derived biochar in energy within a circular economy has gained attention due to its potential environmental and economic benefits [

78]. Biochar has been reportedly produced from various agricultural residues, such as crop residues and animal manure, through pyrolysis and further employed as a renewable energy source through processes like combustion or gasification, contributing to the reduction of greenhouse gas emissions and promoting a sustainable energy system [

80]. Additionally, the obtained byproducts, such as bio-oil and syngas, can as well further been converted into valuable products towards forming a closed-loop system that facilitate the utilization of resource efficiency [

80,

81]. Biochar, derived from the gasification process, possesses a substantial carbon content and high calorific value, making it an ideal candidate for recycling as fuel in subsequent gasification processes. This innovative approach allows the residual carbon from a previous gasification process to be converted into additional gaseous fuel by utilizing gasification biochar as the feedstock. With its exceptional heating values, gasification biochar serves as a valuable resource for maximizing energy recovery and promoting the efficient utilization of carbonaceous materials in the gasification cycle [

82,

83]. Therefore, this approach aligns with the principles of the circular economy which can facilitate the reduction of waste generation, and promote a sustainable energy transition [

81].

9. Application of Agro-Waste-Derived Biochar in Remediation and Soil Enhancement

The application of agro-waste-derived biochar in remediation and enhancement within a circular economy offers promising opportunities [

84]. Biochar can be utilized as a soil amendment to remediate contaminated lands, improving soil quality and promoting plant growth [

85]. Additionally, biochar can be used to enhance nutrient cycling and carbon sequestration, contributing to sustainable agricultural practices and closing the loop on agro-waste utilization in a circular economy framework [

80]. In a recent study, activated Phosphorus-loaded biochar derived from rice husk was examined for its effectiveness in remediating Pb-contaminated soil. The P-loaded biochar demonstrated a significant reduction in the bioavailability of Pb, while simultaneously increasing the bioavailability of P. Furthermore, the study found that the phytotoxicity test and soil enzymatic activity correlated with the decrease in bio-available Pb, highlighting the potential of bio-monitoring as an alternative method for assessing soil quality post-remediation [

85]. Research has shown that agro-industrial residue-derived biochars, upon P loading, exhibit enhanced adsorption capabilities for removing Pb from aqueous solutions. The adsorption values achieved range from 36 to 162 mg.g

-1, indicating the improved effectiveness of these biochar in binding and reducing Pb concentrations [

86]. In their study, Sepúlveda-Cadavid et al discovered that incorporating a P-loaded biochar derived from corn residues resulted in enhanced bioavailability of nutrients and improved absorption in spinach cultivation. This approach outperformed traditional fertilization methods and the co-application of biochar with traditional fertilizer, highlighting the positive effects of P-loaded biochar on the nutritional quality of crops [

84].

10. Application of Agro-Waste-Derived Biochar in Construction Industry

Typically, the construction of buildings and infrastructure using cement-based materials like concrete leads to substantial emissions of CO

2 throughout the manufacturing and application processes [

84]. The application of agro-waste-derived biochar in the construction industry presents numerous potential advantages. Biochar can be utilized as a sustainable additive in various construction materials, such as concrete and cement, enhancing their properties and performance. It can improve the strength, durability, and thermal insulation of these materials [

87,

88]. Additionally, the incorporation of biochar in construction products promotes environmental sustainability by utilizing agricultural waste and reducing the reliance on non-renewable resources [

89,

90]. A recent study showcased the potential of incorporating biochar-mortar composites for carbon sequestration, effectively reducing CO2 emissions while maintaining the mortar's engineering properties. The study focused on creating these composites using wood chips, biosolids, and rice straw to achieve environmental benefits and carbon sequestration. Results indicated that higher biochar content in the composites resulted in decreased levels of benzene and toluene in the air, suggesting biochar's ability to remove volatile toxic contaminants associated with sick building syndrome. Safety assessments through toxicity leaching procedures and Micotox® bioassay tests confirmed the non-toxic nature of the biochar-mortar composites. Therefore, incorporating biochar in construction products provides a sustainable alternative to conventional materials, contributing to a more environmentally friendly construction industry [

84].

Moreover, a recent study conducted found that the utilization of biochar derived from rice husks in cenosphere-mortar exhibited enhanced strength retention properties when subjected to high temperatures. This suggests that biochar integration can effectively improve the thermal performance and durability of the cenosphere-mortar composite [

87]. Furthermore, incorporation of biochar in biochar-cement composites offers advantages such as facilitating CO

2 diffusion and regulating moisture content. This becomes especially significant during accelerated carbonation processes, enhancing the overall performance and stability of the composites [

91].

11. Application of Agro-Waste-Derived Biochar in Waste Management

The application of agro-waste-derived biochar in waste management offers practical solutions to various challenges. For instance, biochar can be used in composting processes to improve organic waste decomposition, enhance nutrient retention, and reduce odours. It can also be applied in landfill covers to mitigate the release of greenhouse gases, such as methane, and reduce leachate generation [

92]. The rising human population necessitates an increase in livestock populations to meet the growing demand. As livestock populations expand, significant quantities of manure are generated, which can be valuable resources if managed effectively. Pyrolysis offers an alternative solution for handling large volumes of manure while concurrently producing renewable and sustainable energy. By subjecting the manure to pyrolysis, it can be transformed into useful energy sources, addressing the challenge of manure management while contributing to the generation of clean and sustainable energy [

93]. With application of pyrolysis, the management of extensive manure quantities can be addressed, transforming them into a valuable energy source that aligns with the principles of sustainability [

93]. According to Ahmad and colleagues, solid waste materials like animal litter and sewage sludge can be efficiently converted to biochar, effectively eliminating active pathogens. Additionally, during the production of biochar, the volatiles and gases released can as well be captured and condensed into bio-oil and syngas, which can serve as renewable energy sources. This approach not only addresses the issue of waste management but also offers the potential for generating sustainable energy from waste materials, contributing to a more environmentally friendly and resource-efficient focus [

92]. The conventional practices of land-filling organic waste and anaerobic digestion of animal waste contribute to substantial emissions of CH

4 and N

2O. However, utilizing these wastes for biochar production and subsequent applications offers an effective waste management approach. This strategy not only helps in reducing greenhouse gas (GHG) emissions but also helps in minimizing waste disposal costs associated with traditional waste management methods. By converting waste into biochar, a valuable carbon-rich material, the potential environmental impact is reduced while creating a beneficial resource for various applications. This approach promotes sustainable waste management practices and contributes to mitigating climate change [

94].

12. Biochar in the Synthesis of Functional Materials

Researchers are actively working towards mitigating climate change and environmental pollution by exploring economically feasible and environmentally friendly energy sources. The synthesis of functional materials plays a vital role in current and future strategies [

95]. For example, catalytic materials demonstrate the potential to convert biomass into biofuels, while high-capacity materials enable efficient storage of renewable energy [

96,

97]. Adsorbents and catalysts are being developed to effectively tackle pollution and capture CO

2 [

97]. Carbon-based materials such as nanotubes, nanofibers, graphene, activated carbon, and carbon black, known for their controllable properties, are of great significance in addressing practical challenges associated with pollution and global warming [

96]. Lisowski et al employed a multistep synthetic process with ultrasound mechanisms to prepare TiO

2–softwood pellets and TiO

2–

miscanthus straw pellet biochar, resulting in mesoporous structures and enhanced visible light sensitivity through the growth of TiO

2 crystal size and structure facilitated by ultrasound treatment which was employed as photocatalysts [

98]. Combining photocatalytic nanoparticles with biochar templates enables the production of biochar-supported photocatalysts (BSPs), which exhibit superior surface properties, crystallinity, chemical stability, recoverability, and enhanced photocatalytic performance compared to bare semiconductor photocatalysts [

24].

The remarkable surface functionality and porosity of biochar make it an attractive candidate for synthesizing various functional materials. The utilization of agro-wastes derived biochar as efficient precursors in the synthesis of functional materials for various applications align well with the principles of the circular economy and on the path of contributing to a more sustainable and efficient use of resources [

76,

78].

13. Agro-Wastes, Agro-Waste-Derived Biochar and Sustainable Development Goals (SDGs)

The Sustainable Development Goals (SDGs) are a set of 17 goals adopted by the United Nations in 2015 to address global challenges related to poverty, inequality, climate change, and environmental degradation [

73]. The recent advances in the utilization of agro-wastes derived biochar as efficient adsorbents in water and wastewater treatments align with several of the SDGs, including SDG 6 (Clean Water and Sanitation), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). SDG-6 aims to ensure access to clean water and sanitation for all. The use of agro-wastes derived biochar as efficient adsorbents in water and wastewater treatments can contribute to this goal by improving the quality of water and wastewater, making it safe for human consumption and reducing the risk of waterborne diseases [

97]. Additionally, the use of biochar can help to reduce the reliance on energy-intensive and costly conventional treatment methods, making water and wastewater treatment more affordable and accessible [

73]. SDG-12 aims to promote responsible consumption and production patterns. The use of agro-wastes as feedstock for biochar production, instead of disposing of them as waste, can contribute to this goal by promoting the efficient use of resources and reducing waste. Additionally, the use of biochar in water and wastewater treatment can help to reduce the amount of sludge produced, leading to a more sustainable and efficient use of resources. SDG-13 aims to take urgent action to combat climate change and its impacts [

73,

96].

The use of agro-wastes derived biochar as efficient adsorbents in water and wastewater treatments can contribute to this goal by reducing greenhouse gas emissions. Agro-wastes are often burned or left to decompose, leading to the release of carbon dioxide and methane, both of which are potent greenhouse gases. The use of agro-wastes as feedstock for biochar production can help to sequester carbon in the form of biochar, which has a long-term stability, leading to a net reduction in greenhouse gas emissions [

73]. Therefore, the recent advances in the utilization of agro-wastes derived biochar as efficient adsorbents in water and wastewater treatments align with several of the SDGs, including SDG 6, SDG 12, and SDG 13 [

73,

77]. The use of biochar can contribute to a more sustainable and efficient use of resources, reduce the reliance on conventional treatment methods, improve the quality of water and wastewater, and reduce greenhouse gas emissions [

73]. The significant advantage of utilizing biochar-based functional materials on a large scale lies in its sustainability, as it allows for the mitigation of anthropogenic CO

2 emissions by converting waste biomass into biochar [

96]. These benefits can contribute to the achievement of the SDGs and promote a more sustainable and resilient future for all [

99].

14. Significance of Current Technique over Conventional Wastewater Treatment Approach

Wastewater treatment is becoming ever more critical due to diminishing water resources, increasing wastewater disposal costs, and stricter discharge regulations that have lowered permissible contaminant levels in waste streams [

5]. Conventional wastewater treatment methods like chlorination, electrochemical treatment, and membrane filtration have been extensively used but have demonstrated inefficiency and high costs [

100]. In response to these challenges, innovative methods including adsorption, ultra-filtration, chemical precipitation, and coagulation have been devised. Nonetheless, certain techniques produce sludge that requires proper disposal, posing environmental risks and escalating treatment costs. Furthermore, these methods demand significant energy input, further amplifying the economic strain associated with wastewater treatment [

100]. Over the last few decades, adsorption has gained importance as a separation, purification and/or detoxification process on an industrial scale. Adsorption is used to purify, decolorize, detoxify, deodorize, separate and concentrate to allow removal and to recover the harmful products from liquid solutions and gas mixtures [

101]. Adsorbents commonly employed in various applications include natural materials, synthetic materials, and waste products. These encompass naturally occurring clays and waste materials such as nutshells [

102], industrial byproducts like fly ash and oven slag [

103], as well as metal-derived oxides and hydroxides produced through synthesis, such as activated aluminum oxide and coarse ferric hydroxide [

104]. Despite widespread use, these adsorbents have drawbacks such as high production costs, environmental concerns, inconsistent performance, and regeneration challenges, highlighting the need for alternative, cost-effective, and environmentally sustainable options [

105].

The excessive application of fertilizers can lead to contamination of groundwater, the emission of greenhouse gases, the process of eutrophication, and the acidification of soil. On the other hand, insufficient nutrient supply can result in reduced crop yields. These extreme conditions have caused significant apprehension concerning the costs of fertilizers, financial losses, deficiencies in nutrients, and the degradation of soil quality [

106]. The recovery of wastes serves as the fundamental principle underlying the circular economy, promoting resource conservation, sustainability, and the efficient utilization of waste materials [

16]. In recent years, there has been significant interest in the utilization of biochar derived from agro-industrial wastes as low-cost adsorbents in wastewater treatment. However, there is a notable lack of assessment and evaluation regarding the fate and potential reuse of saturated adsorbents. Bridging this knowledge gap is crucial to understand their long-term sustainability and explore innovative solutions that address environmental challenges, enabling effective management in wastewater treatment processes [

90]. For instance, in the utilization of conventional adsorption technique the spent or exhausted or saturated adsorbents are associated with disposal issues which the current approach addressed with the use of biochar leveraging on circular economy credentials to prevent secondary pollution [

90,

107]. A recently reported article employed pine sawdust and pine sawdust char previously used as adsorbents for Ni(II), Zn(II), Cd(II) and their mixture, in the manufacture of porous fired clay bricks, which are an important kind of bricks due to their low weight and low thermal conductivity. Therefore, it is possible to take advantage of wood waste used as heavy metal adsorbents in wastewater treatment to address improper disposal in order to prevent secondary pollution [

90]. In a separate study conducted, the feasibility of landfill leachate management was innovatively investigated using a synergistic approach combining advanced oxidation (AOP) and biochar adsorption (BC) techniques [

108]. However, biochar has emerged as a promising and cost-effective adsorbent with comparable characteristics to activated carbon. Another study utilized biochar derived from waste rice husk, collected from a rice processing plant, as an adsorbent for heavy metal ions. During the boriding process, significant transformations were carried out on the spent adsorbent (biochar/heavy metals) to convert it into a heterostructured electrocatalyst (NiCuFeB/spent adsorbent). The outstanding catalytic performance of the electrocatalyst was attributed to a synergistic combination of precursors of the synthesized electrocatalyst. Moreover, the heterostructure and amorphous nature of the catalyst were identified as unique characteristics features contributing to its enhanced catalytic performance [

107].

Additionally, in a recent study, microwave pyrolysis was employed for the conversion of rice husk into biochar, which was then utilized for the treatment of tertiary wastewater. The biochar demonstrated the ability to adsorb approximately 65% of nitrate and 75% of phosphate. Furthermore, when applied to soil, the biochar released 68 grams of phosphate and 220 grams of nitrate per kilogram of rice husk biochar, thus contributing to soil enrichment indicating dual purposes. Moreover, biochar is increasingly recognized as an environmentally friendly and effective sorbent for mitigating both organic and inorganic pollutants, presenting an opportunity to alleviate the environmental impact caused by pollutants on a global scale [

50,

56]. The overdose of fertilizers can cause groundwater contamination, greenhouse gas emissions, eutrophication, and soil acidification. In contrast, an insufficient supply of nutrients can lead to a drop in crop yields. These extreme conditions have been a matter of great concern from the perspective of fertilizer costs, profits incurred, nutrient deficiencies, and soil quality degradation [

109,

110].

Biochar-based fertilizer is a notable example that harnesses the advantages of biochar for soil improvement and utilizes fertilizers as a valuable nutrient source [

110]. Notably, numerous studies have provided evidence that biochar can significantly enhance the efficiency of chemical fertilizers, as supported by recent research studies [

109,

111]. Therefore, biochar offers a significant advantage over conventional wastewater treatment methods in the circular economy approach by simultaneously adsorbing pollutants, such as heavy metal ions and organic pollutants, as precursors for catalytic materials, improving soil fertility and structure through soil amendment, and facilitating nutrient recycling. This multi-functional capability fosters a sustainable and integrated approach to wastewater treatment and resource management.

15. Challenges and Prospects of Biochar Catalyst to Wastewater Treatment

Wastewater treatment is an essential process in modern society, as it helps to ensure that water resources are conserved and protected. However, conventional wastewater treatment methods are often energy-intensive, costly, and produce large amounts of sludge that require disposal. Therefore, there is growing interest in the use of biochar catalysts for wastewater treatment, as they have the potential to offer a more sustainable and cost-effective approach. Biochar is a carbon-rich material that is produced by heating organic matter in the absence of oxygen. It has a high surface area and porosity, which makes it an excellent adsorbent for pollutants in water. Additionally, biochar can be modified to act as a catalyst, which can facilitate the breakdown of pollutants through various mechanisms such as oxidation, reduction, and hydrolysis. However, the use of biochar catalysts in wastewater treatment still faces several challenges. One of the main challenges is the lack of standardization in biochar production, which can lead to variability in the properties of biochar catalysts [

29,

112]. This can impact the effectiveness of the catalysts in treating specific pollutants in wastewater. Therefore, there is a need to develop standardized production methods and quality control measures to ensure consistent biochar catalyst properties. However, the use of biochar catalysts in wastewater treatment still faces several challenges. One of the main challenges is the lack of standardization in biochar production, which can lead to variability in the properties of biochar catalysts [

66]. This can impact the effectiveness of the catalysts in treating specific pollutants in wastewater. Therefore, there is a need to develop standardized production methods and quality control measures to ensure consistent biochar catalyst properties. Another challenge is the limited understanding of the mechanisms involved in biochar catalysis [

69]. The complex chemical and physical interactions between biochar and pollutants make it difficult to predict the behaviour of biochar catalysts in different wastewater treatment scenarios. Therefore, more research is needed to fully understand the mechanisms of biochar catalysis and to optimize the design and operation of biochar-based wastewater treatment systems [

49]. Despite these challenges, there are several prospects for the use of biochar catalysts in wastewater treatment [

29,

112]. Biochar can be produced from a wide range of feedstocks, including agricultural waste and forestry residues, which can provide a low-cost and sustainable source of biochar. Additionally, biochar has been shown to have long-term stability, which can reduce the need for frequent replacement of the catalysts. Generally, the use of biochar catalysts in wastewater treatment offers promising prospects for a more sustainable and cost-effective approach to wastewater treatment. However, the evaluation of costs is a critical factor to consider in various applications, including remediation, as emphasized in the previous studies [

113,

114] While the raw materials for biomass and biochar production are typically readily accessible with little or without charge, as stated in another study recently published [

115], the expenses associated with pyrolysis, transportation, biomass cleaning, and labour

per kilogramme of biochar production raise apprehensions about the overall cost, as critically evaluated [

116,

117]. However, further research is needed to address the challenges associated with biochar production and catalysis mechanisms to optimize their use in wastewater treatment systems [

68].

16. Research Gaps, Limitations and Future Perspectives

Further research is required to assess the long-term effects of biochar application on soil health, crop productivity, and potential leaching of adsorbed contaminants. Comparative studies between different types of agro-wastes-derived biochar and conventional adsorbents are necessary to determine their relative performance and cost-effectiveness. Optimization of biochar production processes, such as pyrolysis conditions, feedstock selection, and activation techniques, can enhance the adsorption capacity and overall efficiency of biochar as an adsorbent. Despite the promising adsorption capabilities of biochar, there is room for improvement to achieve higher adsorption capacities, especially for certain types of pollutants. Biochar's effectiveness as an adsorbent varies depending on the type of pollutant, necessitating a better understanding of its selectivity and applicability to different wastewater treatments. Developing effective methods for regenerating and reusing spent biochar adsorbents can reduce waste generation and enhance the economic viability of biochar-based wastewater treatment systems. Challenges associated with scaling up biochar production and incorporating it into large-scale wastewater treatment processes need to be addressed to facilitate practical application.

Utilizing advanced characterization techniques can provide deeper insights into the structural properties and surface chemistry of biochar, enabling better design and optimization of adsorbents. Integration of biochar-based wastewater treatment with other technologies, such as membrane filtration or advanced oxidation processes, can enhance overall treatment efficiency and address specific limitations. Conducting comprehensive life cycle assessments can evaluate the environmental impacts and sustainability of biochar-based wastewater treatment systems, supporting informed decision-making. By addressing these research gaps, overcoming current limitations, and implementing the suggested way forwards, the utilization of agro-waste derived biochar as efficient adsorbents in wastewater treatments can be further optimized and contribute to green chemistry, circular economy, and overall sustainability.

17. Conclusion

The review highlights the significance of biochar as a versatile and sustainable adsorbent. Various aspects have been discussed, including biochar modification approaches, adsorption mechanisms for the removal of inorganic and organic contaminants, and the resource sustainability achieved through its utilization in water and wastewater treatment. The utilization of agro-waste for biochar production not only addresses waste management concerns but also aligns with the principles of circular economy. The application of agro-waste-derived biochar spans multiple sectors, including energy, remediation, soil enhancement, construction industry, and waste management. This demonstrates the potential for biochar to contribute to resource efficiency and environmental sustainability in diverse fields. Furthermore, the integration of biochar in the synthesis of functional materials presents opportunities for the development of innovative and value-added products. The utilization of agro-wastes and agro-waste-derived biochar in line with Sustainable Development Goals (SDGs) reinforces the importance of this approach in achieving global sustainability targets. Compared to conventional wastewater treatment methods, the use of biochar offers distinct advantages, including its ability to efficiently adsorb contaminants, reduce waste generation, and promote green chemistry principles.

The application of agro-waste-derived biochar represents a promising alternative that can contribute to a more sustainable and environmentally friendly approach to wastewater treatment. In conclusion, the mini-review underscores the significance of agro-waste-derived biochar as an efficient adsorbent in wastewater treatments, highlighting its suitability in green chemistry, circular economy, and sustainability. Moreover, their environmentally benign features have made them suitable materials for circular economy and greener process towards achieving sustainable environment. Overall, the study highlights the importance of further research to optimize biochar production, explore innovative applications, and ensure its long-term performance and effectiveness in various wastewater treatments.

18.0. Declaration Section

Ethics approval and consent to participate

Not applicable

Availability of data and material

Not applicable

Competing interests

The Authors declare that there are no known financial/interpersonal competing interests concerning this manuscript.

Funding

The Alexander von Humboldt (AvH) Stiftung, Germany.

The Carl Friedrich von Siemens (CFvS) Stiftung, Germany.

Authors’ contributions

ATT; KIJ; SM: Conceptualization, methodology, formal analysis, data curation, software,

validation, investigation, writing-original draft and writing-review & editing. BOO: Writing-review and editing. MOO: Methodology, formal analysis, data curation, software, validation, investigation,

writing-original draft, writing-review & editing, visualization, supervision, project administration and funding acquisition.

Acknowledgement

MOO is immensely grateful to the AvH Stiftung, Germany and the CFvS Stiftung, Germany for

the award of Research Fellowship for Experienced Researcher/Senior Fellow (NGA-1201082-HFST-E).

References

- Amalina, F.; Krishnan, S.; Zularisam, A.W.; Nasrullah, M. Biochar and sustainable environmental development towards adsorptive removal of pollutants: Modern advancements and future insight. Process Safety and Environmental Protection 2023, 173, 715-728. [CrossRef]

- Adeleye, A.T.; John, K.I.; Ighalo, J.O.; Ogunniyi, S.; Adeyanju, C.A.; Adeniyi, A.G.; Elawad, M.; Omorogie, M.O. Photocatalytic remediation of methylene blue using hydrothermally synthesized H-Titania and Na-Titania nanotubes. Heliyon 2022, 8, e12610. [CrossRef]

- Abbey, C.Y.B.; Duwiejuah, A.B.; Quianoo, A.K. Removal of toxic metals from aqueous phase using cacao pod husk biochar in the era of green chemistry. Applied Water Science 2022, 13, 57. [CrossRef]

- John, K.I.; Agbor, D.; Sani, L.A.; Adeleye, A.T.; Adenle, A.A.; Idris, A.M.; Omoniyi, A.O.; Babalola, J.O.; Osiboye, O.O.; Elawad, M. Adsorption Performance of Zinc Semiconductor Nanoparticles in Tetracycline Removal. Journal of Cluster Science 2022. [CrossRef]

- Igenepo John, K.; Abdul Adenle, A.; Timothy Adeleye, A.; Pearl Onyia, I.; Amune-Matthews, C.; Omorogie, M.O. Unravelling the effect of crystal dislocation density and microstrain of titanium dioxide nanoparticles on tetracycline removal performance. Chemical Physics Letters 2021, 776, 138725. [CrossRef]

- Rout, P.R.; Zhang, T.C.; Bhunia, P.; Surampalli, R.Y. Treatment technologies for emerging contaminants in wastewater treatment plants: A review. The Science of the total environment 2021, 753, 141990-141990. [CrossRef]

- Adeleye, A.T.; Bahar, M.M.; Megharaj, M.; Rahman, M.M. Recent developments and mechanistic insights on adsorption technology for micro- and nanoplastics removal in aquatic environments. Journal of Water Process Engineering 2023, 53, 103777. [CrossRef]

- John, K.I.; Omorogie, M.O.; Bayode, A.A.; Adeleye, A.T.; Helmreich, B. Environmental microplastics and their additives—a critical review on advanced oxidative techniques for their removal. Chemical Papers 2023, 77, 657-676. [CrossRef]

- Omorogie, M.O.; Helmreich, B. Exploring the Potential of Amino-Functionalized Zeolite Series/H3PO4-Biochar for Environmental Microplastic Removal. Industrial & Engineering Chemistry Research 2024, 63, 3947-3961.

- John, K.I.; Omorogie, M.O.; Bayode, A.A.; Adeleye, A.T.; Helmreich, B. Environmental microplastics and their additives—a critical review on advanced oxidative techniques for their removal. Chemical Papers 2022. [CrossRef]

- John, K.I.; Adeleye, A.T.; Adeyanju, C.A.; Ogunniyi, S.; Ighalo, J.O.; Adeniyi, A.G. Effect of light on concomitant sequestration of Cu(II) and photodegradation of tetracycline by H-MOR/H-β/H-ZSM5 zeolites. Environmental science and pollution research international 2021, 29, 11756-11764. [CrossRef]

- John, K.I.; Obu, M.; Adeleye, A.T.; Ebiekpe, V.; Adenle, A.A.; Chi, H.; Iseoluwa, O.J.; Omorogie, M.O. Oxygen deficiency induction and boundary layer modulation for improved adsorption performance of titania nanoparticles. Chemical papers 2022, 76, 3829-3840. [CrossRef]

- Amos Adeleke, A.; Aderemi Timothy, A.; Abraham Abdul, A.; Bonex Wakufwa, M. Micro Nano Manufacturing Methods for Chemical, Gas and Bio Sensors, Water Purification and Energy Technologies. In Nanofibers, Brajesh, K., Ed.; IntechOpen: Rijeka, 2020; p. Ch. 10.

- Adeleye, A.T.; Akande, A.A.; Odoh, C.K.; Philip, M.; Fidelis, T.T.; Amos, P.I.; Banjoko, O.O. Efficient synthesis of bio-based activated carbon (AC) for catalytic systems: A green and sustainable approach. Journal of industrial and engineering chemistry (Seoul, Korea) 2021, 96, 59-75. [CrossRef]

- Aderemi, T.A.; Hitler, L.; Ozioma, U.A.; Innocent, J.; Obieze, C.E.; Dass, P.M. A Review on the conversion of levulinic acid and its esters to various useful chemicals. AIMS Energy 2019, 7, 165-185. [CrossRef]

- Adeleye, A.T.; Odoh, C.K.; Enudi, O.C.; Banjoko, O.O.; Osiboye, O.O.; Toluwalope Odediran, E.; Louis, H. Sustainable synthesis and applications of polyhydroxyalkanoates (PHAs) from biomass. Process biochemistry (1991) 2020, 96, 174-193. [CrossRef]

- Timothy, A.A.; Han, F.; Li, G.; Xu, J.; Wang, A.; Cong, Y.; Li, N. Synthesis of jet fuel range high-density dicycloalkanes with methyl benzaldehyde and acetone. Sustainable energy & fuels 2020, 4, 556-5567. [CrossRef]

- Adeleye, A.T.; Solomon, O.T.; Ankelie, O.C.; Adeleye, P.G.; Odoh, C.K. Synthesis and applications of levulinic acid (LA) and its derivatives from biomass materials-accessibility to bioeconomy. PROCEEDING BOOK 2022, 1.

- Chi, N.T.L.; Anto, S.; Ahamed, T.S.; Kumar, S.S.; Shanmugam, S.; Samuel, M.S.; Mathimani, T.; Brindhadevi, K.; Pugazhendhi, A. A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel (Guildford) 2021, 287, 119411. [CrossRef]

- Li, N.; He, M.; Lu, X.; Yan, B.; Duan, X.; Chen, G.; Wang, S.; Hou, L.a. Municipal solid waste derived biochars for wastewater treatment: Production, properties and applications. Resources, conservation and recycling 2022, 177, 106003. [CrossRef]

- Afolalu, S.A.; Ikumapayi, O.M.; Ogundipe, A.T.; Okwilagwe, O.O.; Oloyede, O.R.; Adeoye, A.O.M. Development of composite filters from biochars for wastewater treatment. Advances in materials and processing technologies (Abingdon, England) 2022, ahead-of-print, 1-18. [CrossRef]

- Adeniyi, A.G.; John, K.I.; Adeleye, A.T.; Iwuozor, K.O.; Ogunniyi, S.; Adeyanju, C.A.; Yusuf, I.I. Metal oxide rich char from muffle furnace and retort heated reactor treated cow bone. Cleaner Engineering and Technology 2022, 8, 100485. [CrossRef]

- Kumar, A.; Bhattacharya, T. Biochar: a sustainable solution. Environment, Development and Sustainability 2021, 23, 6642-6680. [CrossRef]

- Mian, M.M.; Liu, G. Recent progress in biochar-supported photocatalysts: synthesis, role of biochar, and applications. RSC advances 2018, 8, 14237-14248.

- Xiang, W.; Zhang, X.; Chen, J.; Zou, W.; He, F.; Hu, X.; Tsang, D.C.W.; Ok, Y.S.; Gao, B. Biochar technology in wastewater treatment: A critical review. Chemosphere (Oxford) 2020, 252, 126539-126539. [CrossRef]

- Sarayu, K.; Sandhya, S. Current Technologies for Biological Treatment of Textile Wastewater–A Review. Applied biochemistry and biotechnology 2012, 167, 645-661. [CrossRef]

- El-Naggar, A.; Mosa, A.; Ahmed, N.; Niazi, N.K.; Yousaf, B.; Sarkar, B.; Rinklebe, J.; Cai, Y.; Chang, S.X. Modified and pristine biochars for remediation of chromium contamination in soil and aquatic systems. Chemosphere 2022, 303, 134942. [CrossRef]

- Adeyemi, J.O.; Ajiboye, T.; Onwudiwe, D.C. Mineralization of Antibiotics in Wastewater Via Photocatalysis. Water, air, and soil pollution 2021, 232. [CrossRef]

- Amusat, S.O.; Kebede, T.G.; Dube, S.; Nindi, M.M. Ball-milling synthesis of biochar and biochar–based nanocomposites and prospects for removal of emerging contaminants: A review. Journal of Water Process Engineering 2021, 41, 101993. [CrossRef]

- Rajapaksha, A.U.; Vithanage, M.; Ahmad, M.; Seo, D.-C.; Cho, J.-S.; Lee, S.-E.; Lee, S.S.; Ok, Y.S. Enhanced sulfamethazine removal by steam-activated invasive plant-derived biochar. Journal of Hazardous Materials 2015, 290, 43-50. [CrossRef]

- Paunovic, O.; Pap, S.; Maletic, S.; Taggart, M.A.; Boskovic, N.; Sekulic, M.T. Ionisable emerging pharmaceutical adsorption onto microwave functionalised biochar derived from novel lignocellulosic waste biomass. Journal of colloid and interface science 2019, 547, 350-360.

- Zhang, X.; Xiang, W.; Miao, X.; Li, F.; Qi, G.; Cao, C.; Ma, X.; Chen, S.; Zimmerman, A.R.; Gao, B. Microwave biochars produced with activated carbon catalyst: Characterization and sorption of volatile organic compounds (VOCs). Science of The Total Environment 2022, 827, 153996. [CrossRef]

- Xiang, W.; Wan, Y.; Zhang, X.; Tan, Z.; Xia, T.; Zheng, Y.; Gao, B. Adsorption of tetracycline hydrochloride onto ball-milled biochar: Governing factors and mechanisms. Chemosphere 2020, 255, 127057. [CrossRef]

- Goswami, R.; Shim, J.; Deka, S.; Kumari, D.; Kataki, R.; Kumar, M. Characterization of cadmium removal from aqueous solution by biochar produced from Ipomoea fistulosa at different pyrolytic temperatures. Ecological Engineering 2016, 97, 444-451. [CrossRef]

- Jha, S.; Gaur, R.; Shahabuddin, S.; Tyagi, I. Biochar as Sustainable Alternative and Green Adsorbent for the Remediation of Noxious Pollutants: A Comprehensive Review. Toxics 2023, 11, 117.

- He, R.; Yuan, X.; Huang, Z.; Wang, H.; Jiang, L.; Huang, J.; Tan, M.; Li, H. Activated biochar with iron-loading and its application in removing Cr (VI) from aqueous solution. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2019, 579, 123642. [CrossRef]

- Yao, Y.; Gao, B.; Wu, F.; Zhang, C.; Yang, L. Engineered Biochar from Biofuel Residue: Characterization and Its Silver Removal Potential. ACS Applied Materials & Interfaces 2015, 7, 10634-10640. [CrossRef]

- Sizmur, T.; Fresno, T.; Akgül, G.; Frost, H.; Moreno-Jiménez, E. Biochar modification to enhance sorption of inorganics from water. Bioresource Technology 2017, 246, 34-47. [CrossRef]

- Hagenbo, A.; Antón-Fernández, C.; Bright, R.M.; Rasse, D.; Astrup, R. Climate change mitigation potential of biochar from forestry residues under boreal condition. Science of The Total Environment 2022, 807, 151044. [CrossRef]

- Neogi, S.; Sharma, V.; Khan, N.; Chaurasia, D.; Ahmad, A.; Chauhan, S.; Singh, A.; You, S.; Pandey, A.; Bhargava, P.C. Sustainable biochar: A facile strategy for soil and environmental restoration, energy generation, mitigation of global climate change and circular bioeconomy. Chemosphere 2022, 293, 133474. [CrossRef]

- Yek, P.N.Y.; Cheng, Y.W.; Liew, R.K.; Wan Mahari, W.A.; Ong, H.C.; Chen, W.-H.; Peng, W.; Park, Y.-K.; Sonne, C.; Kong, S.H.; et al. Progress in the torrefaction technology for upgrading oil palm wastes to energy-dense biochar: A review. Renewable and Sustainable Energy Reviews 2021, 151, 111645. [CrossRef]

- Wan Mahari, W.A.; Waiho, K.; Azwar, E.; Fazhan, H.; Peng, W.; Ishak, S.D.; Tabatabaei, M.; Yek, P.N.Y.; Almomani, F.; Aghbashlo, M.; et al. A state-of-the-art review on producing engineered biochar from shellfish waste and its application in aquaculture wastewater treatment. Chemosphere 2022, 288, 132559. [CrossRef]

- Katiyar, R.; Patel, A.K.; Nguyen, T.-B.; Singhania, R.R.; Chen, C.-W.; Dong, C.-D. Adsorption of copper (II) in aqueous solution using biochars derived from Ascophyllum nodosum seaweed. Bioresource Technology 2021, 328, 124829. [CrossRef]

- Ambaye, T.G.; Vaccari, M.; van Hullebusch, E.D.; Amrane, A.; Rtimi, S. Mechanisms and adsorption capacities of biochar for the removal of organic and inorganic pollutants from industrial wastewater. International Journal of Environmental Science and Technology 2021, 18, 3273-3294. [CrossRef]

- Deolikar, R.; Patil, R. Chapter 11 - Recent advances in pesticides removal using agroindustry based biochar. In Development in Wastewater Treatment Research and Processes, Shah, M., Rodriguez-Couto, S., Biswas, J., Eds.; Elsevier: 2022; pp. 265-290.

- Nzediegwu, C.; Naeth, M.A.; Chang, S.X. Lead(II) adsorption on microwave-pyrolyzed biochars and hydrochars depends on feedstock type and production temperature. Journal of Hazardous Materials 2021, 412, 125255. [CrossRef]

- Ćwieląg-Piasecka, I.; Dębicka, M.; Medyńska-Jureszek, A.; Weber, J.; Jamroz, E. The role of humic acids and biochar as specific sorbents of pesticides in soil. April 01, 2017, 2017; p. 16827.

- Trine, L.S.D.; Davis, E.L.; Roper, C.; Truong, L.; Tanguay, R.L.; Simonich, S.L.M. Formation of PAH Derivatives and Increased Developmental Toxicity during Steam Enhanced Extraction Remediation of Creosote Contaminated Superfund Soil. Environmental Science & Technology 2019, 53, 4460-4469. [CrossRef]

- Ye, Q.; Li, Q.; Li, X. Removal of heavy metals from wastewater using biochars: adsorption and mechanisms. Environmental Pollutants and Bioavailability 2022, 34, 385-394. [CrossRef]

- Shaaban, M.; Abid, M. Chapter 9 - Biochar as a sorbent for organic and inorganic pollutants. In Sorbents Materials for Controlling Environmental Pollution, Núñez-Delgado, A., Ed.; Elsevier: 2021; pp. 189-208.

- Nie, J.; Zhi, D.; Zhou, Y. Chapter 8 - Magnetic biochar-based composites for removal of recalcitrant pollutants in water. In Sorbents Materials for Controlling Environmental Pollution, Núñez-Delgado, A., Ed.; Elsevier: 2021; pp. 163-187.

- Chaukura, N.; Murimba, E.C.; Gwenzi, W. Synthesis, characterisation and methyl orange adsorption capacity of ferric oxide–biochar nano-composites derived from pulp and paper sludge. Applied Water Science 2017, 7, 2175-2186. [CrossRef]

- Kirmizakis, P.; Tawabini, B.; Siddiq, O.M.; Kalderis, D.; Ntarlagiannis, D.; Soupios, P. Adsorption of Arsenic on Fe-Modified Biochar and Monitoring Using Spectral Induced Polarization. Water 2022, 14, 563.

- Jung, K.-W.; Lee, S.Y.; Choi, J.-W.; Lee, Y.J. A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar nanocomposites: Adsorption behavior and mechanisms for the removal of copper(II) from aqueous media. Chemical engineering journal (Lausanne, Switzerland : 1996) 2019, 369, 529-541. [CrossRef]

- Qian, K.; Kumar, A.; Zhang, H.; Bellmer, D.; Huhnke, R. Recent advances in utilization of biochar. Renewable & sustainable energy reviews 2015, 42, 1055-1064. [CrossRef]

- Pan, J.; Jiang, J.; Xu, R. Adsorption of Cr(III) from acidic solutions by crop straw derived biochars. Journal of environmental sciences (China) 2013, 25, 1957-1965. [CrossRef]

- Chen, T.; Zhou, Z.; Xu, S.; Wang, H.; Lu, W. Adsorption behavior comparison of trivalent and hexavalent chromium on biochar derived from municipal sludge. Bioresource technology 2015, 190, 388-394. [CrossRef]

- Fischer, B.M.C.; Manzoni, S.; Morillas, L.; Garcia, M.; Johnson, M.S.; Lyon, S.W. Improving agricultural water use efficiency with biochar – A synthesis of biochar effects on water storage and fluxes across scales. The Science of the total environment 2019, 657, 853-862. [CrossRef]

- Wei, Z.; Wang, J.J.; Meng, Y.; Li, J.; Gaston, L.A.; Fultz, L.M.; DeLaune, R.D. Potential use of biochar and rhamnolipid biosurfactant for remediation of crude oil-contaminated coastal wetland soil: Ecotoxicity assessment. Chemosphere (Oxford) 2020, 253, 126617-126617. [CrossRef]

- Issaka, E.; Fapohunda, F.O.; Amu-Darko, J.N.O.; Yeboah, L.; Yakubu, S.; Varjani, S.; Ali, N.; Bilal, M. Biochar-based composites for remediation of polluted wastewater and soil environments: Challenges and prospects. Chemosphere (Oxford) 2022, 297, 134163-134163. [CrossRef]

- Abhishek, P.; Bishnu, A.; Aitazaz, F. Biochar-Assisted Wastewater Treatment and Waste Valorization. In Applications of Biochar for Environmental Safety, Ahmed, A.A., Mohammed, H.H.A., Eds.; IntechOpen: Rijeka, 2020; p. Ch. 14.

- Gasim, M.F.; Choong, Z.-Y.; Koo, P.-L.; Low, S.-C.; Abdurahman, M.-H.; Ho, Y.-C.; Mohamad, M.; Suryawan, I.W.K.; Lim, J.-W.; Oh, W.-D. Application of Biochar as Functional Material for Remediation of Organic Pollutants in Water: An Overview. Catalysts 2022, 12, 210.

- Mohamad, M.; Wannahari, R.; Mohammad, R.; Shoparwe, N.F.; Lun, K.W.; Wei, L.J. Adsorption of malachite green dye using spent coffee ground biochar: optimisation using response surface methodology. Jurnal Teknologi 2020, 83, 27-36. [CrossRef]

- Khan, T.; Mustafa, M.R.U.; Isa, M.H.; Manan, T.S.B.A.; Ho, Y.-C.; Lim, J.-W.; Yusof, N.Z. Artificial Neural Network (ANN) for Modelling Adsorption of Lead (Pb (II)) from Aqueous Solution. Water, Air, & Soil Pollution 2017, 228, 426. [CrossRef]

- Suzaimi, N.D.; Goh, P.S.; Malek, N.A.N.N.; Lim, J.W.; Ismail, A.F. Performance of branched polyethyleneimine grafted porous rice husk silica in treating nitrate-rich wastewater via adsorption. Journal of Environmental Chemical Engineering 2019, 7, 103235. [CrossRef]

- Cheng, D.L.; Ngo, H.H.; Guo, W.S.; Liu, Y.W.; Zhou, J.L.; Chang, S.W.; Nguyen, D.D.; Bui, X.T.; Zhang, X.B. Bioprocessing for elimination antibiotics and hormones from swine wastewater. Science of The Total Environment 2018, 621, 1664-1682. [CrossRef]

- Wang, F.; Li, L.; Iqbal, J.; Yang, Z.; Du, Y. Preparation of magnetic chitosan corn straw biochar and its application in adsorption of amaranth dye in aqueous solution. International Journal of Biological Macromolecules 2022, 199, 234-242. [CrossRef]

- Wu, J.; Wang, T.; Wang, J.; Zhang, Y.; Pan, W.-P. A novel modified method for the efficient removal of Pb and Cd from wastewater by biochar: Enhanced the ion exchange and precipitation capacity. Science of The Total Environment 2021, 754, 142150. [CrossRef]

- Chakraborty, P.; Show, S.; Banerjee, S.; Halder, G. Mechanistic insight into sorptive elimination of ibuprofen employing bi-directional activated biochar from sugarcane bagasse: Performance evaluation and cost estimation. Journal of Environmental Chemical Engineering 2018, 6, 5287-5300. [CrossRef]

- Ratti, R. Industrial applications of green chemistry: Status, Challenges and Prospects. SN Applied Sciences 2020, 2, 263. [CrossRef]

- Burachevskaya, M.; Minkina, T.; Bauer, T.; Lobzenko, I.; Fedorenko, A.; Mazarji, M.; Sushkova, S.; Mandzhieva, S.; Nazarenko, A.; Butova, V.; et al. Fabrication of biochar derived from different types of feedstocks as an efficient adsorbent for soil heavy metal removal. Scientific Reports 2023, 13, 2020. [CrossRef]

- Chia, W.Y.; Chia, S.R.; Khoo, K.S.; Chew, K.W.; Show, P.L. Sustainable membrane technology for resource recovery from wastewater: Forward osmosis and pressure retarded osmosis. Journal of Water Process Engineering 2021, 39, 101758. [CrossRef]

- He, M.; Xu, Z.; Hou, D.; Gao, B.; Cao, X.; Ok, Y.S.; Rinklebe, J.; Bolan, N.S.; Tsang, D.C.W. Waste-derived biochar for water pollution control and sustainable development. Nature Reviews Earth & Environment 2022, 3, 444-460. [CrossRef]

- Thang, P.Q.; Jitae, K.; Giang, B.L.; Viet, N.M.; Huong, P.T. Potential application of chicken manure biochar towards toxic phenol and 2,4-dinitrophenol in wastewaters. J Environ Manage 2019, 251, 109556. [CrossRef]

- Mishra, R.K.; Mohanty, K. Pyrolysis of low-value waste sawdust over low-cost catalysts: physicochemical characterization of pyrolytic oil and value-added biochar. Biofuel Research Journal 2022, 9, 1736-1749. [CrossRef]

- Jindo, K.; Sánchez-Monedero, M.A.; Mastrolonardo, G.; Audette, Y.; Higashikawa, F.S.; Silva, C.A.; Akashi, K.; Mondini, C. Role of biochar in promoting circular economy in the agriculture sector. Part 2: A review of the biochar roles in growing media, composting and as soil amendment. Chemical and Biological Technologies in Agriculture 2020, 7, 16. [CrossRef]

- You, S.; Ok, Y.S.; Chen, S.S.; Tsang, D.C.W.; Kwon, E.E.; Lee, J.; Wang, C.H. A critical review on sustainable biochar system through gasification: Energy and environmental applications. Bioresour Technol 2017, 246, 242-253. [CrossRef]

- Hu, Q.; Jung, J.; Chen, D.; Leong, K.; Song, S.; Li, F.; Mohan, B.C.; Yao, Z.; Prabhakar, A.K.; Lin, X.H.; et al. Biochar industry to circular economy. Science of The Total Environment 2021, 757, 143820. [CrossRef]

- Spigarelli, B.P.; Kawatra, S.K. Opportunities and challenges in carbon dioxide capture. Journal of CO2 Utilization 2013, 1, 69-87.

- Singh, E.; Mishra, R.; Kumar, A.; Shukla, S.K.; Lo, S.-L.; Kumar, S. Circular economy-based environmental management using biochar: Driving towards sustainability. Process Safety and Environmental Protection 2022, 163, 585-600. [CrossRef]

- Pawar, A.; Panwar, N.L.; Salvi, B.L. Comprehensive review on pyrolytic oil production, upgrading and its utilization. Journal of Material Cycles and Waste Management 2020, 22, 1712-1722. [CrossRef]

- Le, C.; Kolaczkowski, S. Steam gasification of a refuse derived char: Reactivity and kinetics. Chemical Engineering Research and Design 2015, 102, 389-398.

- Pacioni, T.R.; Soares, D.; Di Domenico, M.; Rosa, M.F.; Moreira, R.d.F.P.M.; José, H.J. Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste management 2016, 58, 221-229.

- Sepúlveda-Cadavid, C.; Romero, J.H.; Torres, M.; Becerra-Agudelo, E.; López, J.E. Evaluation of a biochar-based slow-release P fertilizer to improve Spinacia oleracea P use, yield, and nutritional quality. Journal of Soil Science and Plant Nutrition 2021, 21, 2980-2992.

- Acosta-Luque, M.P.; López, J.E.; Henao, N.; Zapata, D.; Giraldo, J.C.; Saldarriaga, J.F. Remediation of Pb-contaminated soil using biochar-based slow-release P fertilizer and biomonitoring employing bioindicators. Scientific Reports 2023, 13, 1657. [CrossRef]

- Tan, Y.; Wan, X.; Zhou, T.; Wang, L.; Yin, X.; Ma, A.; Wang, N. Novel Zn-Fe engineered kiwi branch biochar for the removal of Pb (II) from aqueous solution. Journal of Hazardous Materials 2022, 424, 127349.