1. Introduction—Obstacles to Overcome

Drive train components are bearings, gears and clutches in motion under lubrication [

1,

2].

Tribology and lubrication has to be stated as a cross discipline of chemistry, physics, mathematics, data science, computing and mechanical engineering over huge dimensions, reaching from atomic scale (10-10 meters) toward macro scales (for example main bearings in wind turbines (> 3 meters). Until now and despite considerable efforts, a holistic theory of tribology covering all phenomena is still missing. According to these difficulties, tribology and lubrication is a vast playground of sciences rather than a closed theory. As this aspect is confronted with the pressure of innovation, all scales and disciplines are involved. In order to overcome the scale problems test rigs are used to get information about the reliability of a given construction under artificially forced conditions. The mechanical part of the construction is defined by the load capacity of the materials (e.g. bearing steel), related to load. Lubricants however, have to be tested as they have to carry additional functions (e.g. preventing corrosion, ageing, friction and wear) which are derived from their molecular structure. Actually, these tests are carried out by applying harsh conditions (temperature, load, etc.) in order to provoke damages in a reasonable time. The disadvantages using this approach are on hands :

There is no learning about how the molecules, defined by their chemical structure, contributes to the result of the test. Nothing is known about a structure – property relationship. As a consequence, the development of a lubricant is based on what is known empirically.

Test rigs are executing unrealistic assumptions compared to what is apparent in the real life cycle of the component (load, temperature, environment, etc.). So far, no one can be sure, how relevant results are compared to service life: a) what is the logic chain of a failure and b) how is the logic chain between the test rig and the intended service life.

The induction problem: how do tests, conditioned in test rigs reflect a broad population under multiple conditions. This problem is serious, as test rig results often represent one simple condition, not letting pass any conclusion about the influence of multiple and varying impacts.

Predictions on how molecular scales couple with macroscales are hard to achieve by the use of test rigs. However, as novel tribology concepts in drive train applications may start from new molecules, they ultimately lead to the question how to prove their suitability in real-service life. However, as novel tribology concepts in drive train applications may start from new molecules, they ultimately lead to the question how to prove their suitability in real-service life.Innovations in drive train technologies related to lubricants are therefore on a low technical readiness level (TRL), hence high in costs and time consumption.

Efforts should be made, to overcome the test rig rituals, often simplifying reality without substantial learning. There is a potential? to enforce trans-scale research combined with extensive materials an chemical modelling by Machine Learning (ML). ML appears as inevitable to overcome the obstacles for introducing new Lubricant concepts. ML allows the reduction of dimensions given by the molecular predictors in combination with mechanical engineering and service life.

2. New Aspects

Novel Tribology Concepts in Drivetrain Components may subdivide into the categories

Sustainability

Ecology and Toxicity

Coatings

Nano Tribology

Chemistry

Electricity

Sensors

Digital Concepts

A drivetrain basically converts energy-density into motion assisted by mechanical components and soft matter like lubricants. Within the past, the controlled combustion of fossil derived electron-rich sources by oxygen, led to energy density in motor technology, turning into motion by drive train components assisted by lubricants.

Fossiles derive from sunlight harvesting, with a complex turnover of electrons, water combustion to oxygen and CO2 fixation in the nutrition cycle. This cycle conveys all life processes including bio-mobility. Life processes are governed by oxygen rich organic molecules (e.g. sugar and diverse nutriants), leaving organic molecules with no or significant low oxygen as waste.

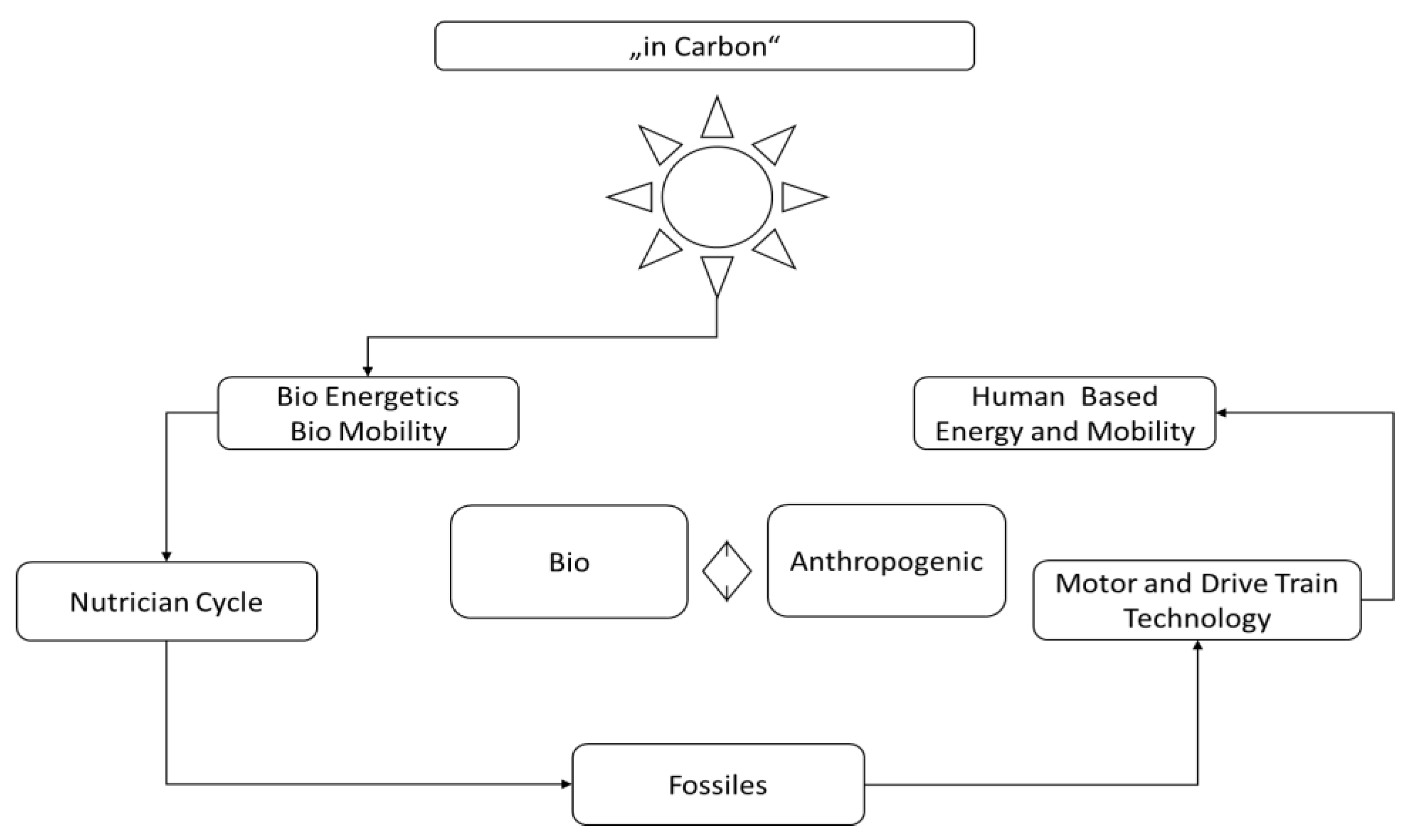

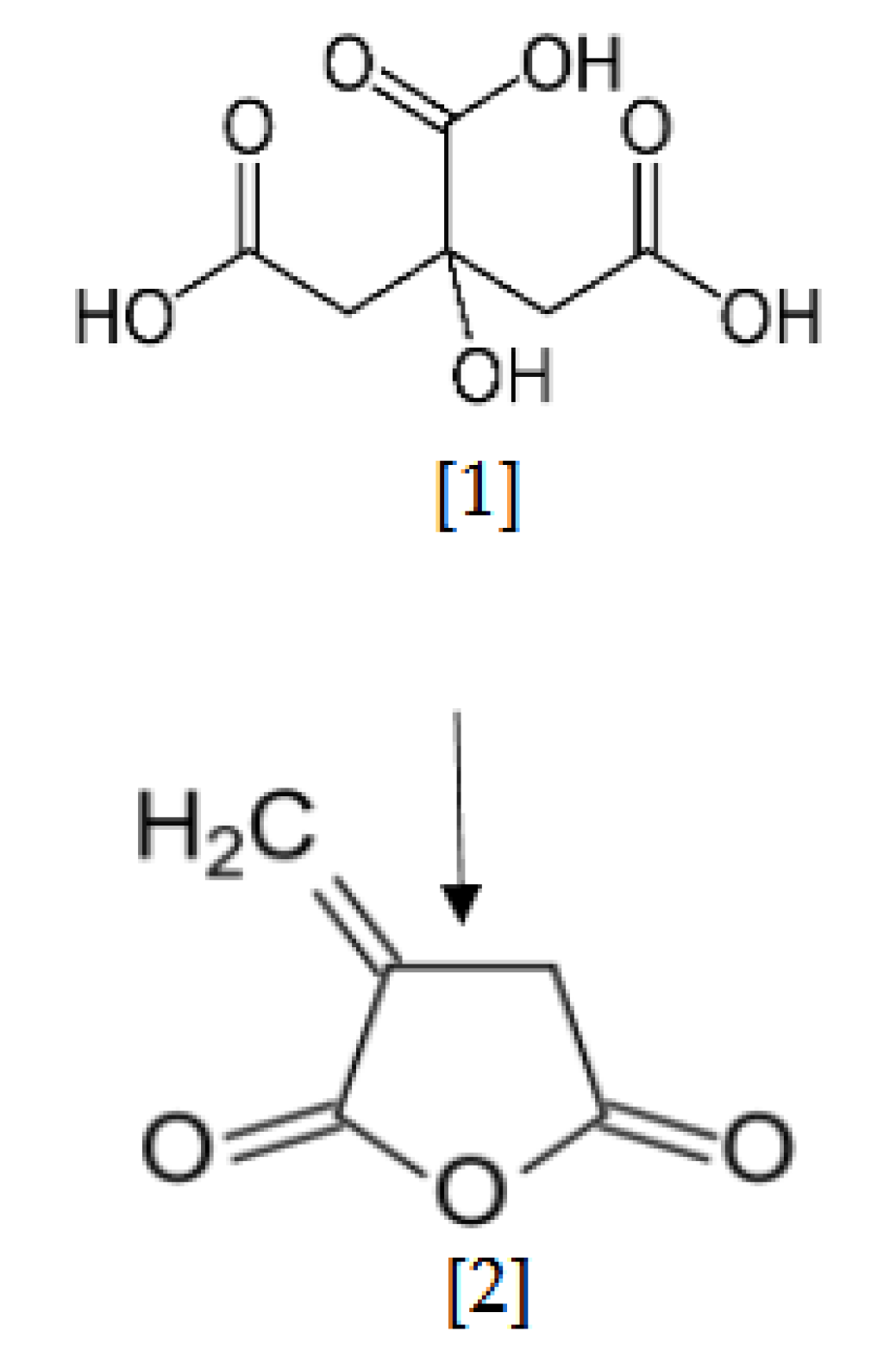

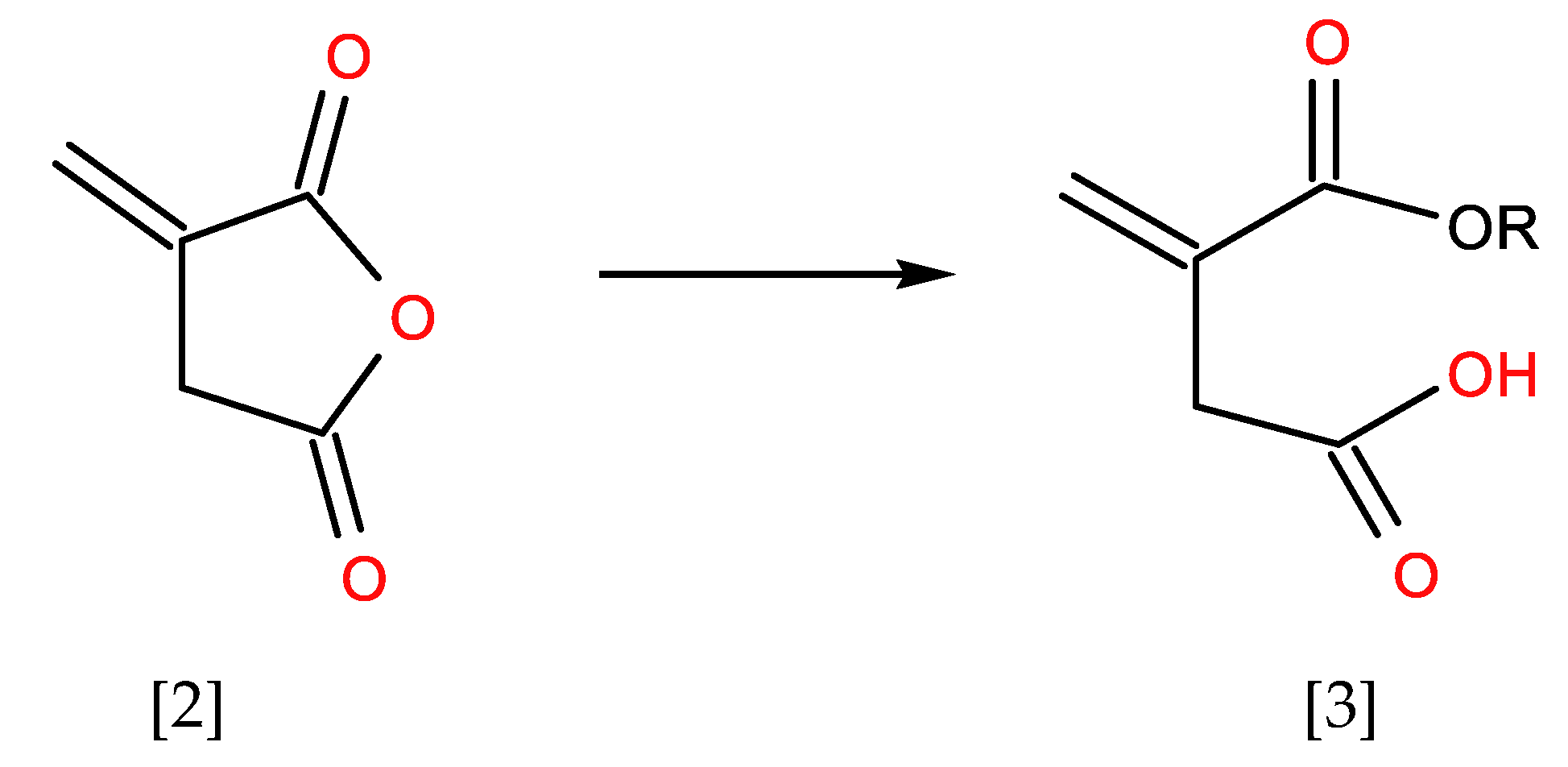

Figure 1 tries it to simplify : sun light is turned to the bio life cycle, including bio mobility. Bio life cycle and bio-mobility are the base of fossilation

, Fossilation then turns to be the base of industrial mobility and production as a second, human based life cycle (as in

Figure 1):

So far, both cycles are mutually stimulating each other, and, compared to the “in-silico” phrase, reflect the “in-carbon” technology. Since the sunlight based bio-cycle perpetuates without costs, the fossilation stays cheap. As such, the bio cycle is actually the most exciting and effective storage of renewable energy by the use of complex electron pathways. In essence, fossilation turns to be a sink for electrons, caught in the fossile.

Combustion by the use of oxygen (combustion motors) reverts this process by shifting an electron rich fossile toward the electron demanding oxygen.

As long as fossile based technology was comparable cheap due to its worldwide availability, the creation of value stays high. Tribology in such a conventional drive train technology has a focus in reducing friction and preventing the mechanical components from wear in order to save energy and sequentially keeps the earned value high.As such, tribology has become essential by shifting the life cycle of a drive train toward long term usage. However, the role of tribology is under change.

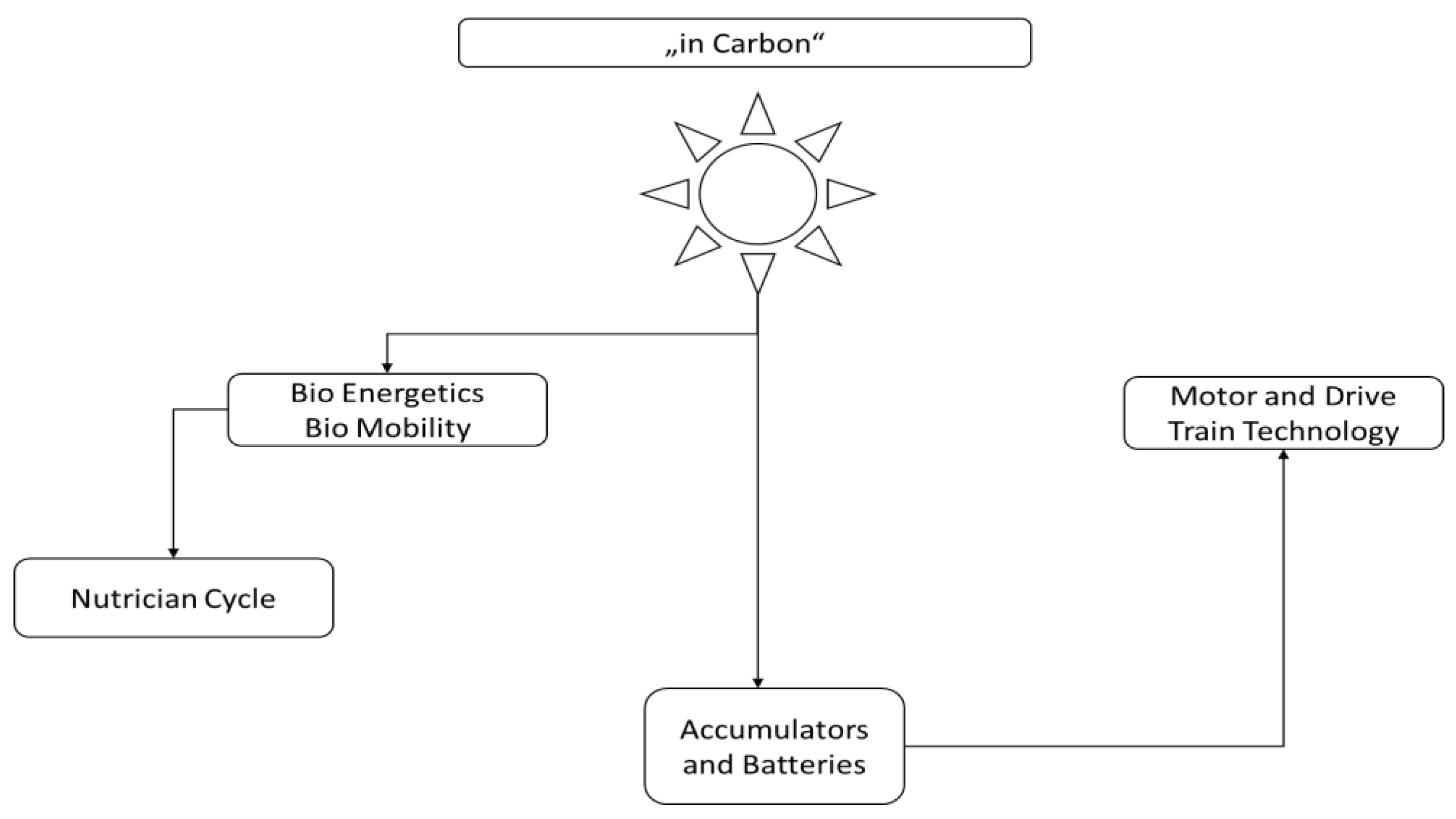

The high added value in the final product by gaining energy via a comparable inexpensive fuel and/or coal combustion technology, has been undermined by restricted sources due to conflicts worldwide, ecology and toxicity as well as the debate about CO

2 footprint. Now, in order to make energy accessible, electrons derived from alternative fugitive sources, e.g. sun -and wind power have to be stored by the use of batteries and accumulators (see

Figure 2):

EV technology as a part of the upcoming mobility is in focus worldwide [

3,

4].

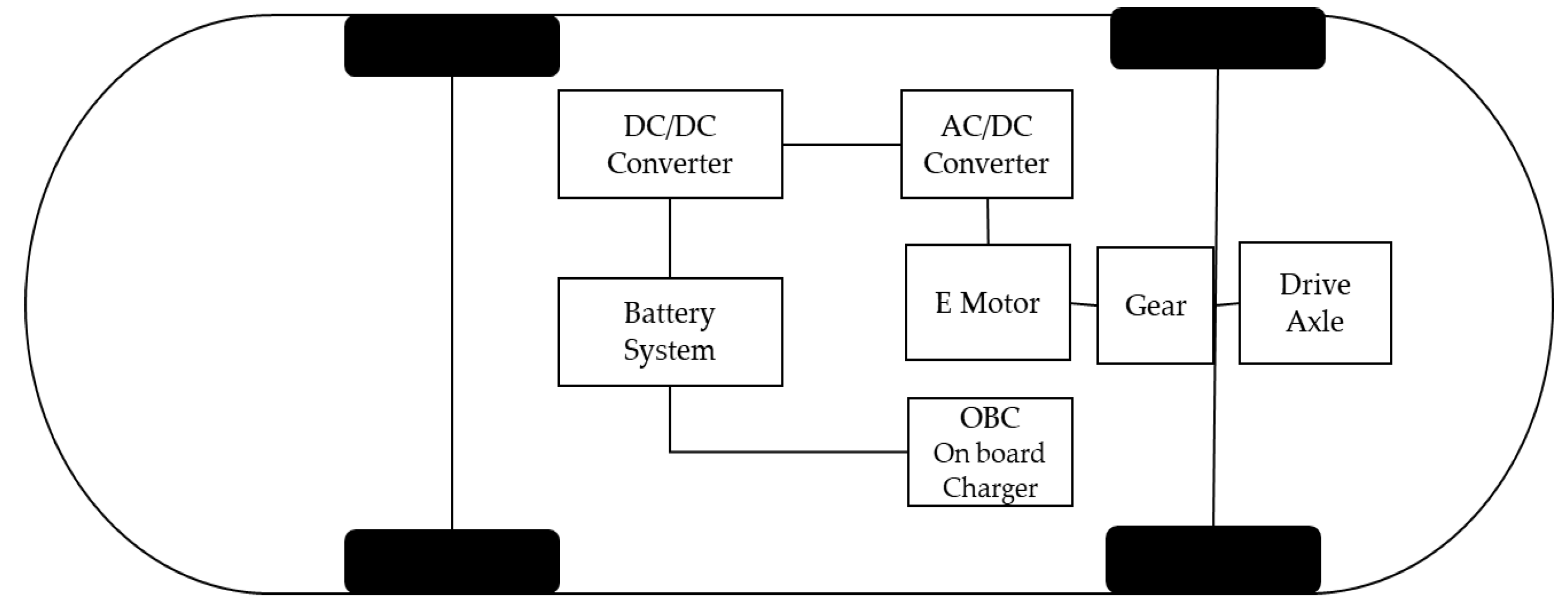

Figure 3 schematically shows how an electrical unit, comprising a battery system and a DC/DC converter, couples with the the gear unit and the axle via an AC/DC converter, assisted by an onboard charger (OBC). This system falls into two categories, namely a thermal management that takes care of cooling the electrical unit and the lubrication of the drive train.

While the permanent storage and regain of electrical power has become a central technological problem, tribology has to adapt this as well as the loss of energy in motion has to be compensated by the battery. Conventually the role of a lubricant is to cover metal parts in motion by viscosity. Lowering viscosity inevitable leads to a reduction of this coverage. Lubricants with reduced viscosity have to be reconsidered with respect to friction and wear and how service life is influenced. As additives have to compensate this, their contribution is getting important. Along with these facts, their ecological and toxicology footprint has to be evaluated. Lubricants additionally are part of the thermal drive train management and have to be reconsidered with respect to their thermal conductivity and heat capacity. Searching for fluids with high heat capacity and thermal conductivity apart from water stays as a big challenge of the fluid dynamics and the role of additives.

2.1. Sustainability [5]

Sustainability appears as a strategy of tribological engineering, covering various aspects . In general, the United Nations have defined sustainable development goals. Combatting climate change is being the one most frequently referenced in the field of tribology. However, other sustainability goals can also be influenced by tribologists, such as “Zero Hunger”, by selecting raw materials not being used as food ingredients, e.g. rape seed oil. These two goals could also be in conflict, as a renewable raw material may have a low carbon footprint and thus suitable for carbon reduction, but their technical usage could influence world market prices, making them less affordable as food products. Furthermore, the technical use of renewable raw materials may conflict with the goal to protect terrestrial ecosystems, for instance, through the unsustainable production of palm oil. Lubricant formulators can also influence the sustainability goals “life below water” and “life on land” as, even nowadays, a significant proportion of lubricants sold are still released into the environment in an uncontrolled manner. Key areas for tribologists to enhance sustainability are discussed below.

2.2. Re-Use of Wasted Lubricants

Lubrication as a part of the Drive Train tribology uptakes temperature, friction, wear and their combinations appearing as random events. Over time these impacts are causing changes in the chemical composition of the lubricant. Those changes might be a tolerable pollution, however, after reaching a limit, the lubricant has to be changed as the given guarantees in function are getting lost. Unfortunately, even if the concentration of the pollutant is low, the lubricant is often disposed as waste by burning, as recycling options are not universally accessible.

The combustion of 1kg of a mineral-oil based lubricant releases an amount of approx. 3.1 kg CO2 equivalents (CO2eq) directly into the atmosphere. Furthermore, the energy invested to produce this 1kg of lubricant is entirely lost.

This energy sums up for typical base oil from 0.7 kg CO

2eq (per kg Group I base oil) to significantly higher values for lubricant formulations containing a diverse range of additives. However, the CO

2eq associated with the combustion and the production of the base oils can be mitigated by re-refining used lubricants. Although re-refining also requires energy (approx. 0.4 CO

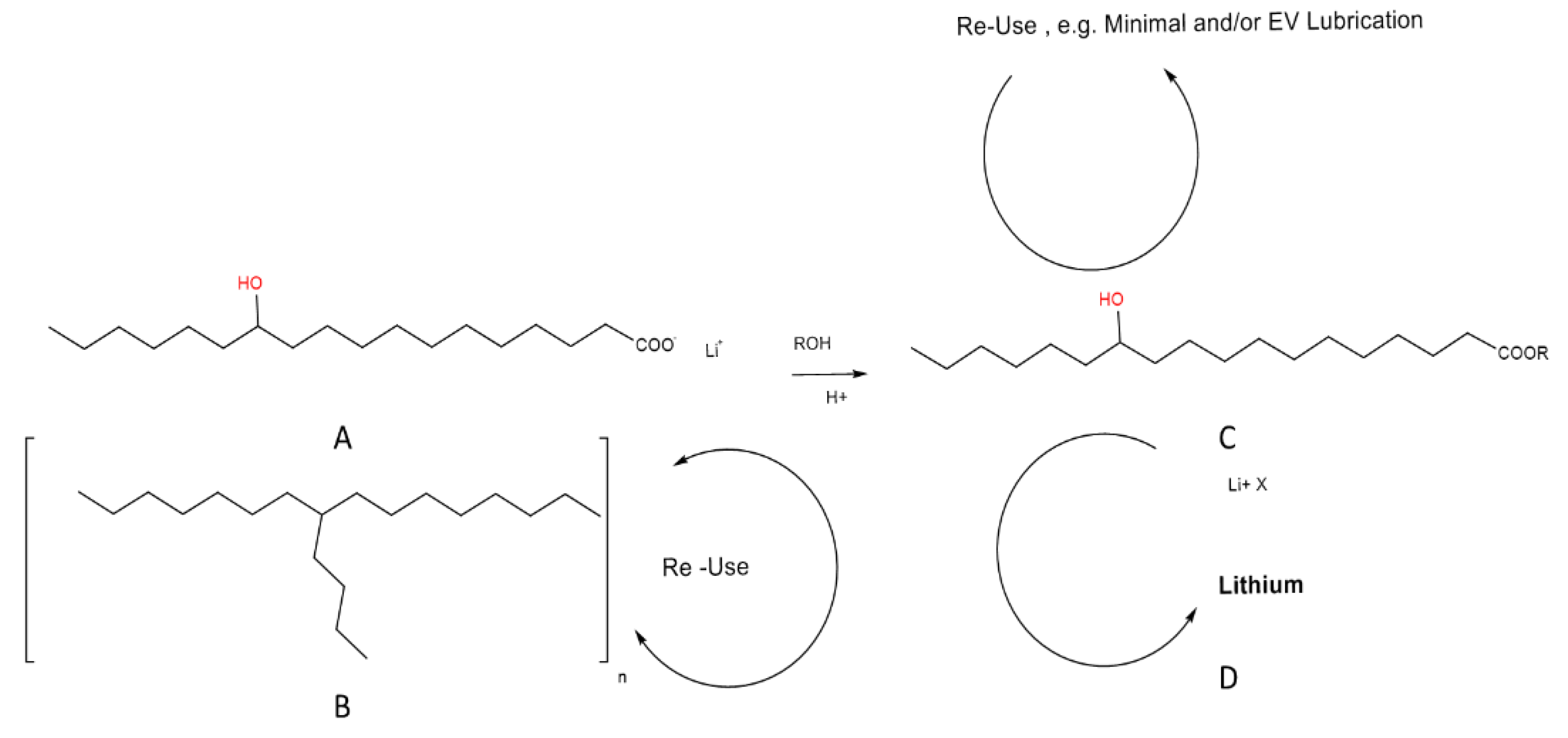

2eq/kg, it offers significant savings compared to burning used lubricants. The sustainability balance is even worse considering greases as, until now, greases are the dominant choice in for-life bearing lubrication. The majority of those greases is based on Lithium Soap derived from long chain fatty acids. During their life cycle, greases upload pollutants, namely debris making it un-useable at a certain level, even though more than 80% of the grease is still intact. Currently there are sparingly strategies to use polluted greases as a new raw material by recycling the carboxylates to carboxylic acids and derivatives and even more regain Lithium as a valuable source for EV technology.

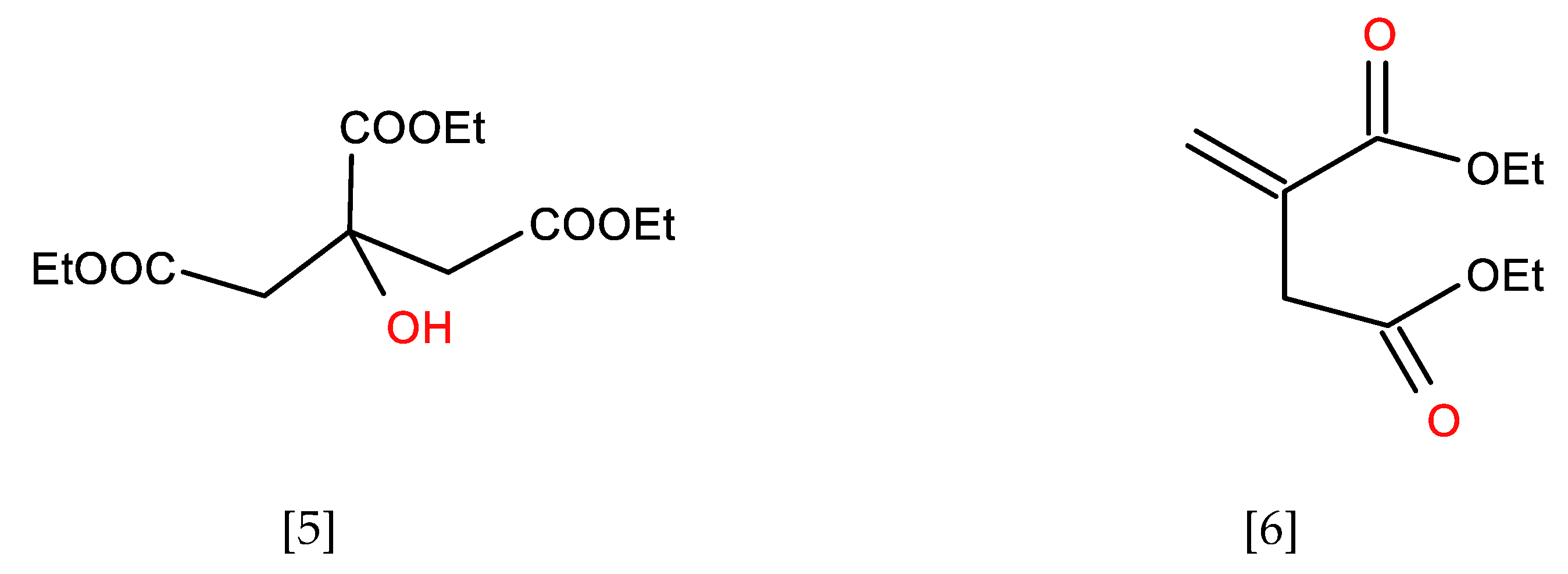

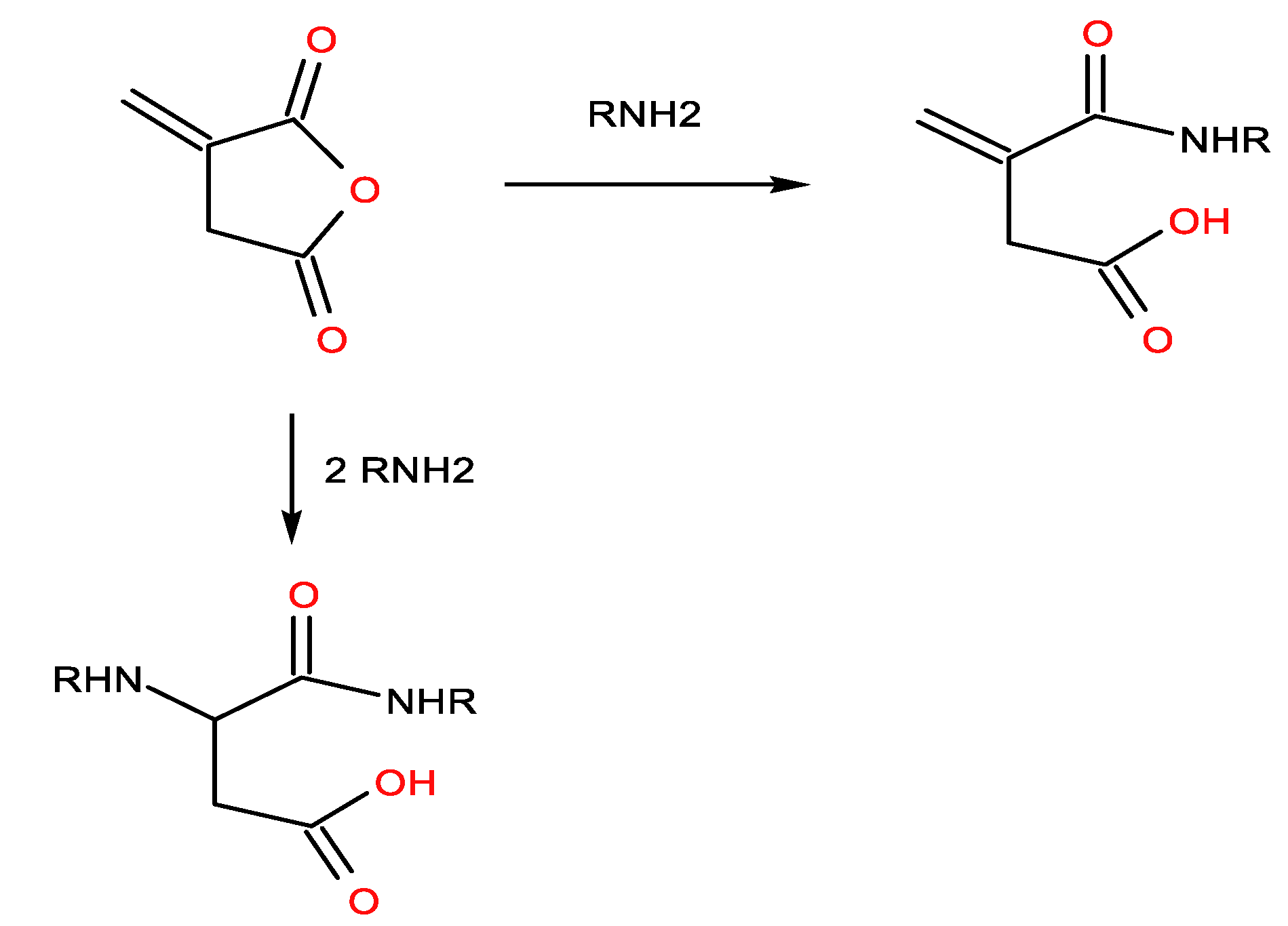

Figure 4 gives an example for the re-use of a common grease. A used Lithium-12-hydroxistearate (A) thickened base oil (B, schematically drawn as branched hydrocarbon) undergoes acidic treatment in the presence of alcoholes (for example green Methanole (R=CH

3) or bio.ethanole (R=C

2H

5) or butanole (R= C

4H

9) to yield the corresponding ester (C). Such esters are useful for example in minimal and/or EV lubrication. The Li-Residues (Li

+ X) may be stepwise converted to Lithium (D) for the use in EV technology (whereas X might be hydrogensulfate (if the treatmment has been carried out with H

2SO

4 as acid)):

Restoring Greases into new valuable raw materials would merge aspects of the past with the upcoming new technologies.

2.3. Cradle to Cradle (C2C) and Waste to Cradle (W2C) [6]

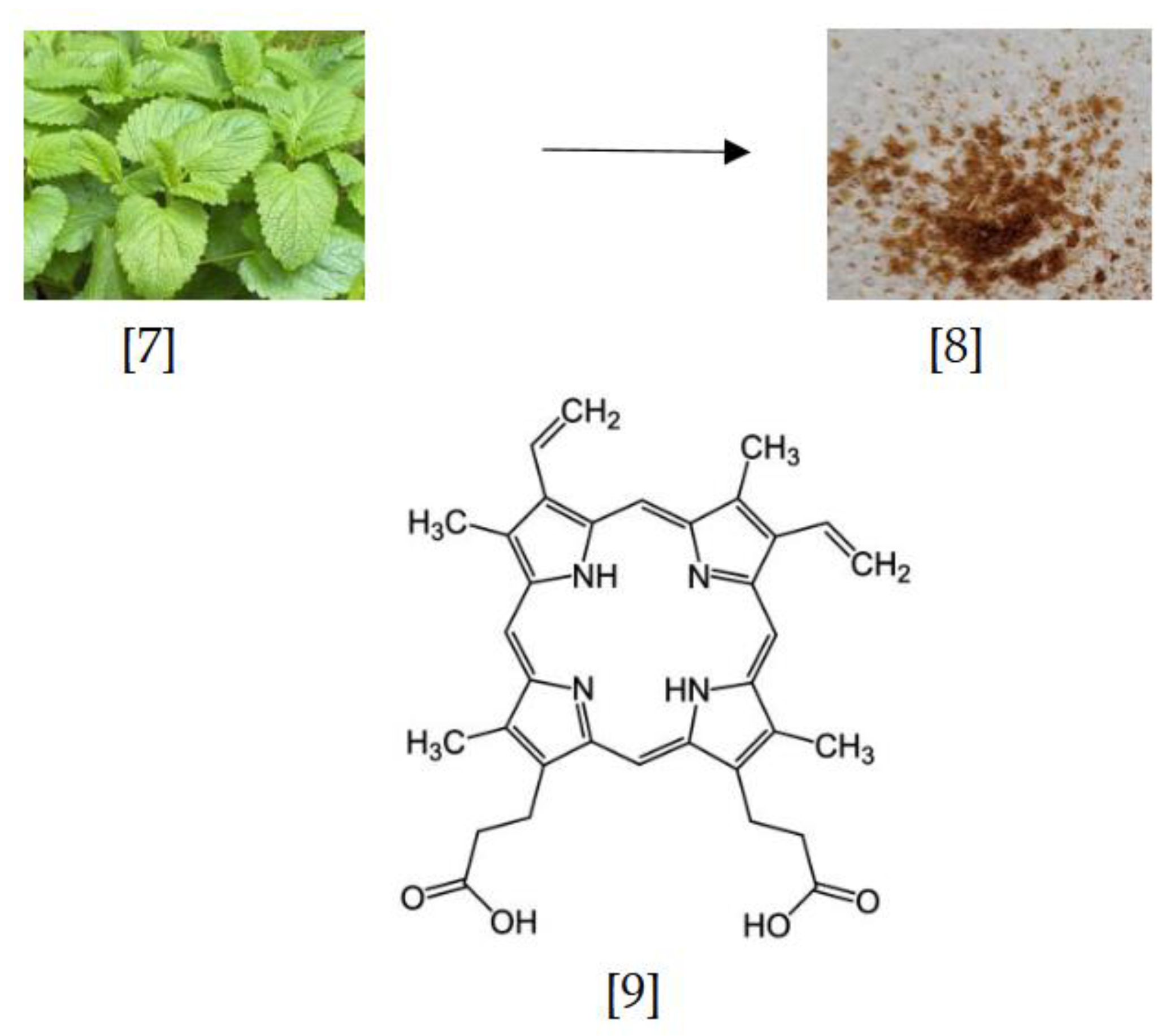

C2C and W2C are novel concepts to explore how products in the biological turn-over are suitable to use them as raw materials in industrial applications, for example in drive train technology.

As a contribution to C2C, the use of chemicals derived from forestry and agricultural waste offers a vast resource of raw materials apart from fossils.

Problems arising with C2C and W2C are given by the chemistry of possible candidates. Carbon based molecules, present in the biological turnover are rich in oxygen, somehow nitrogen and sulfur and often very polar. Representatives are glycerole, sugar and similar structures. Prominent examples for biopolymers are the lignine and cellulose. Lubrication in conventional drive train lubricants are based on nonpolar molecules with none or low oxygen content (mineraloils) while C2C or W2C derived lubricants are highly polar as a matter of their high oxygen content and naturally are most likely water miscible. Conventional drive train lubrication with C2C respective W2C derived lubrication has to compete the inherent incompatibility of low oxygen hydrocarbons with water. Apart from the inherent incompatibility the presence of water and water like molecules brings up problems with steel corrosion and reactivity related to water.

2.4. Minimal Lubrication [7]

Minimal Lubrication has been established in tooling and high speed (spindle bearings) applications over decades. In principal a jet is used to place the lubricant in time and at the place where it’s needed. This technique is in contrast to common lubrication where the lubricant is used in excess while a minimum is needed.

Considering minimal lubrication apart from niches could contribute significantly to the reduction of waste. Moreover, applying minimal lubrication could allow the use of ecological friendly lubricants with low toxicological hazards.

However, even though the technology has been established, a general expansion to a broad variety of applications needs a plenty of subcomponents attached, such as a digital monitoring and exactly adjusted pumps. So far this technology has to be considered to be low in technological readiness (TRL) but high rated in sustainability.

2.5. Ecology and Toxicology [8]

Ecology, e.g. the interaction of lubrication with environment has become a fast growing feature in tribology, being pushed by a plentitude of national and international standards for their proof. Lubricants are a broad scatter of chemicals carrying various physical and chemical properties and preventing drive train components (gears, bearings and more) from damages. During the past a huge number of chemicals and their combinations were sold on the market. By passing a drive train, lubricants may get lost and enter the environment. Their bio-mobility and biodegradation subsequently may lead to pollute vast areas in the environment, or conversely, by covering the ground lead to suffocate organisms. Persistency, combined with immobility in the environment, can lead to the accumulation of chemicals in ecological and biochemical processes, often with unknown consequences. Fluorinated components are one example (PFAS) but also others, e.g. chlorinated paraffines. Sequentially those processes may lead to hazardous metabolites, and, by uncontrolled migration harming the human life cycle. Until now extensive screening tests are not to circumference in order to evaluate a potential hazard. Searching for substitutes needs to scrutinize alternatives. However, these alternatives have to pass the life cycle requirements of the drive train by time and cost consuming excessive testing. In the case, if tests are contradicting the search has to start again.

Inevitably this leads to the fact that the Technical Readiness Level (TRL) has to be stated low along with a high demand in pre-screening and validation tests. As a way out, digital concepts, e.g. reversed engineering, may facilitate to find a valuable solution, since plenty of data are accessible covering structure-property relationship of chemicals. However, digital concepts predicting friction, wear and related phenomena as essentials in tribology are rare until now. Similar as stated before, Machine Learning (ML) routines could lead to a way out by getting accessed to data bases. Harmonizing ecology and toxicity with technical requirements has to be judged as a high hanging fruit in a kings discipline. It points in the direction of lubrication substantiated by highly polar molecules It has to be foreseen that progresses in ecological and low toxicity lubrication using polar molecules as a base, also ends up to adapt them to the surfaces and materials in touch within the tribological contact.

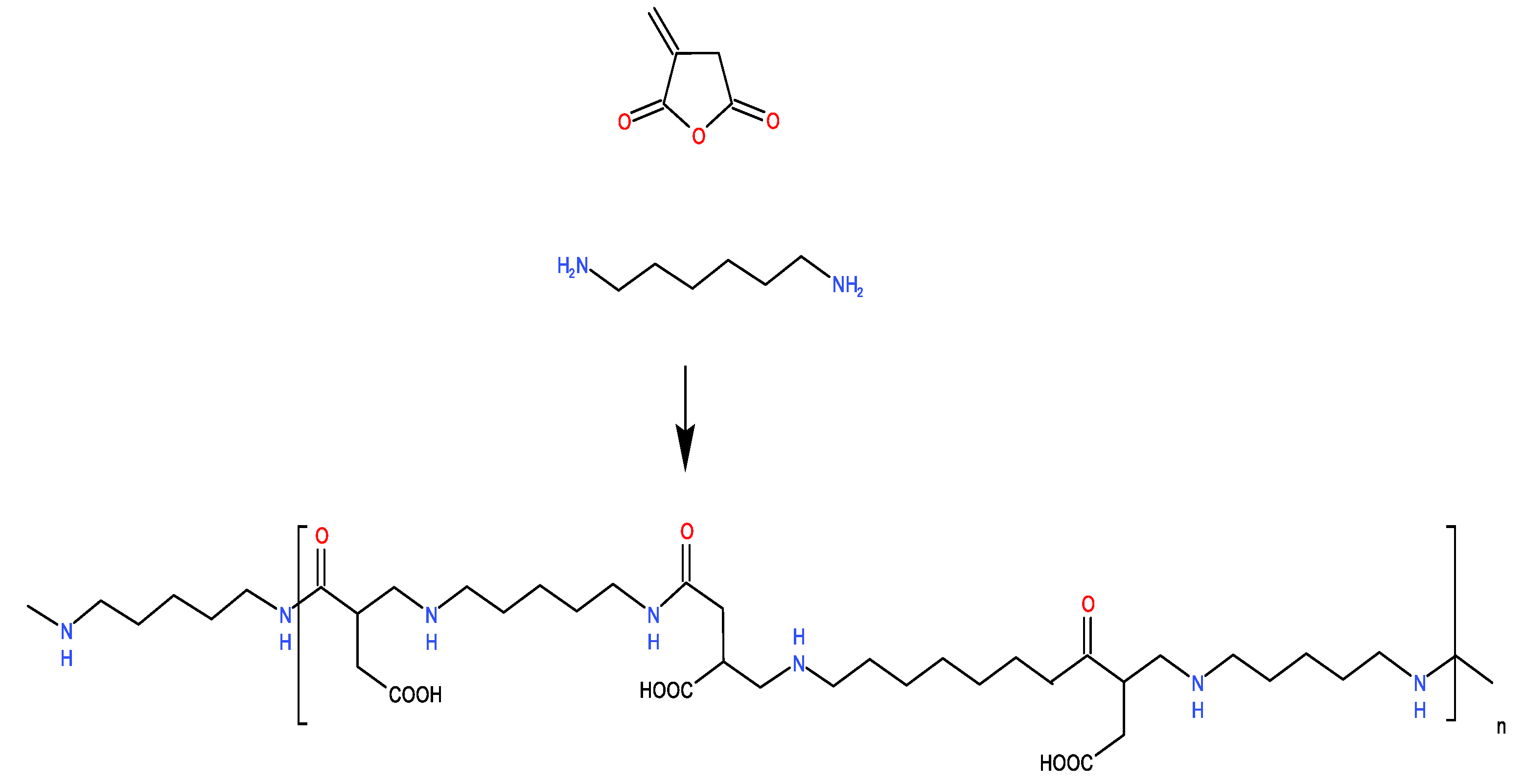

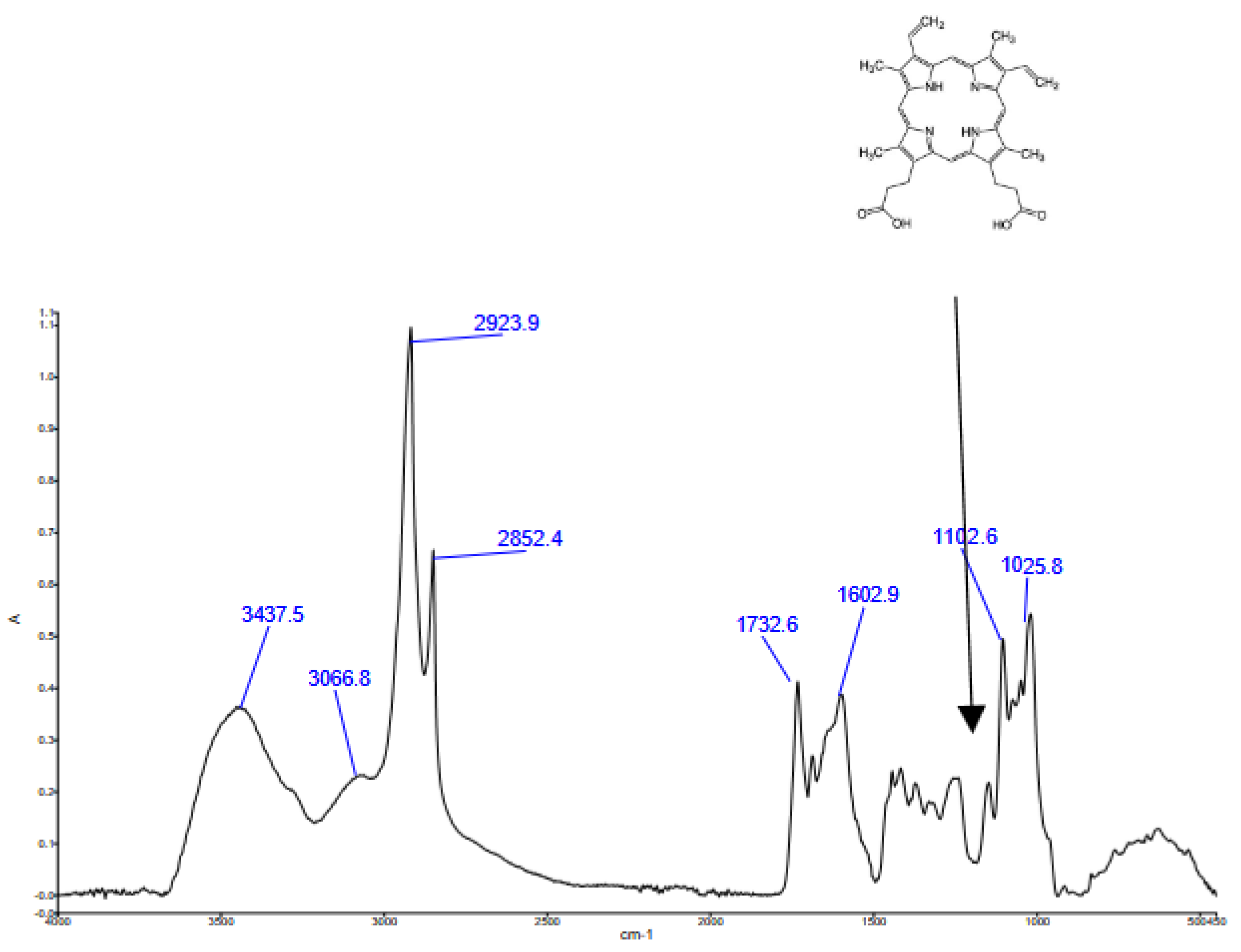

2.6. Coatings [9]

Coatings are used within tribology for the reduction of friction, wear and preventing corrosion. Prominent examples are DLC (diamond like carbon), ceramics like titanium and chromium nitride for the reduction of wear, zinc, nickel and chromium plating against corrosion. Soft coatings based on Molybdenum-disulfide or dark oxide as a conversion layer are widely used. Innovative trends are coatings based on biopolymers or hybrid coatings based on organic and inorganic chemistry and organic pre-polymers as precursors applied as aqueous solution.

2.7. Nano Tribology [10]

Nano Tribology covers the scales of nanometers. Atomic Force Micrography (AFM) is a prominent example for recording molecular based friction which is an important topic in bio- tribology or reliability of micromechanical (MEMS) systems. New materials in nanometer dimension are fore coming, such as nanoparticles or 2D materials like graphene. As an innovative new aspect the use of the Moire effect in 2D materials like graphene comes up. Moire effects appear as a self- org anizing phenomenon by tilting a layer of a fine structured pattern against another steady pattern namely at small angles. The sensitive instantaneous formation of structured patterns could play an important role in Nano-tribology or overlaying nanosized 2D structures like graphene. Nano rheology by rotating finely dispersed particles in volume could show Moire effects by unexpected changes in viscosity and friction, hence are a promising and valuable field of advanced studies [

11].

2.8. Chemistry

Chemicals are playing a key role in Lubrication technology. Decades of research have shown, that chemistry significantly impacts the life cycle of a drive train. International and national standards define the function of lubricants with respect to a given application. Lubrication has brought up numerous chemicals, with a base oil component as a major part and functional additives in a range of few percentages. The chemical structure of additives comprises often a hydrocarbon like frame in order to make the additive accessible to the base oil and a core, carrying the intended function. Additives are intended to prevent steel against corrosion and wear, supporting low friction properties of the base oil and inhibit their oxidation. As a consequence of broad requirements in the life cycle, different additives are mixed in order to come to a multiple functionality. The high degree of complexity combined with an unknown dimensionality makes it impossible to come to a numerical description of chemistry by predictor-descriptor sets. Consequently, plenty of test rigs in relation with a given application are in use to ensure the function of a lubricant. Test rigs often reflect results in relation the conditions specifically chosen within the test The relation of those conditions to the even more complex situation within a life cycle operation remains unclear. A pressure to innovate lubrication chemistry comes up from various sites:

2.8.1. White Etching Cracks (WEC)

WEC are part of intense research in the past bringing up the potential of lubrication chemicals, mechanical influences e.g. slip and straying electricity. WEC remains a topic within the upcoming wind turbine technology, bringing the Return of Invest considerably down. Notably, design rules allowing the prediction and prevention of WEC are missing until now.

2.8.2. Electricity

Drive trains are affected by permanent or arbitrary presence of electrical currents. Their magnitudes are often incidental. Sources are frequency converters, electrostatic effects such as tribocharging due to the presence of materials that are on opposing ends of the tribolectric series, and induced currents from magnetic asymmetry. Lubricants are basically reacting on currents, either AC or DC. The constituent molecules especially additives are often polar due to their intended functionality. The polarity is given by an unequal charge distribution between the constituent atoms. This causes a permanent charge displacement realized as dipole moment.

Dipoles directly follow the presence of an electrical field. Capacity sensors allowing to measure the transient film thickness of a contact are based on this principal. Molecules exposed to AC current try to follow its frequency by rotation as impedance. Rotation will lead to a higher rate of collision or – if the AC frequency is too high in a stand-still of motion, hence acting as resistor. DC voltage leads to an uptake of charge upon the molecular surface and subsequently influence their mutual attraction as clusters. These clusters are realized as additional resistor. If the induced charging passes a limit in magnitude a breakthrough appears as erratic high frequency ignition. Notably this effect is observed even if the application is not exposed to electricity but only by self -charging due to motion. The very complex interaction of lubricants in a drive train with electrical fields opens possibility of innovation. As a lubricant present in a drive train naturally loses its adherence as the viscosity drops-down by temperature, the presence of an electrical field could balance this, and hence improve lubricity. Lubricants, namely in EV drives are in tendency low in viscosity in order to compete splash losses and contrarily to the construction guide lines, hence leading to the risk of boundary lubrication. Electrical effects increasing the adherence by dipolar clustering could be of innovative interest. Tuning friction and wear under the control of imposed external electricity could be combined with sensors and latest with a digital management. It would offer the possibility of autonomic drive train tribology.

2.9. Sensors

Sensors as applied in Drive Trains (see for example [

12] are state-of-the art recording namely

Temperature

Friction and Torque

Viscosity

Chemical Monitoring

Electricity Sensors

and more. Mostly any of these sensors are monitoring the status-quo of the application. Alerting takes place if a given limit (threshold) value is exceeded. A few of the signals are related to the remaining life, e.g. viscosity or Infrared Monitoring leading to reactive maintenance. Apart from the big advancements in acquisition and data processing a general holistic concept is missing as innovation, since all current sensor concepts serve along a status-quo recording. A concept is still missing that judges a priori the vulnerability of an application.

As an example, the reliability of a bearing in the life cycle is given by the ratio of load capacity versus loading (ISO standard 281). Lubrication is set as a scale factor and mainly based on viscosity parameters. Load capacity is stated as steady over the whole period of the application. However, it is clear, that the load capacity is related to all impacts, e.g. environment, oil status and more, hence progressively changeing. Currently there are no sensors available to measure the load capacity and its change under operation even though examples are reported. Chemical Sensors are widely in use but seldom explored deeper. For example Infrared Spectrometry is in use worldwide in order to track bands of interest, e.g. oxidation. However, advanced data processing (Derivative Spectrometry), analysis of real time series could increase its value considerable. Real time data processing should be supplemented by a significance test and take care of signal-to noise value. Early processes, harming the application and subsequent the load capacity are often signalized in the chemistry of the lubricant and hence are subjected to infrared spectrometry.

2.10. Digital, ML and AI – Autonomic Digital Twinned Drive Train [13,14]

Digital technologies based on Machine Learning are indispensable techniques competing the immense flood of data. A drive train may be seen

- A.

As a messenger giving internal signals like structure born noise, temperature, torque and friction signals from accelerometers, but also electrical signals as transient status recording and more, like for example human observations.

- B.

As recipient of external impacts, e.g. temperature, environmental impacts, e.g. moisture, chemicals, electrical impact, structure born vibrations and more like for example human observations.

The operational data either from A) or B) are to match with the life cycle insurance standards in terms of judging the remaining life.

- A.

Physical and chemical laws should be implemented.

- B.

Lastly, if a such observed application gets critical, the system alert should end-up in a maintenance action (predictive-reactive-maintenance).

There is no doubt that the vision of autonomy needs a solid base of different data sources and is packed into an unknown set of dimensions and degrees of freedom. From this point it is clear that unsupervised machine learning is inevitable in terms of dimensional reduction and the immanent principal components. The architecture should be connected to a humanized distribution grid making the system information accessible. Moreover, as the different sources of information are different in entropy and inertia (action-reaction time) the digital surveillance should reflect the importance of a message, hence increase the robustness of the system.