1. Introduction

1.1. Current Research Status

In recent years, with the continuous growth of global demand for clean energy, LNG, as a clean and efficient energy source, has been increasingly widely used in the energy field. As a key link in the LNG industry chain, the design, construction and application research of LNG bunkering vessels have also attracted extensive attention [

1].

In Europe, America, South Korea and other countries and regions started early in the research of LNG bunkering ships, and the technology is relatively mature. In terms of design, they focus on the optimization of the overall performance of the ship. Through advanced computational fluid dynamics (CFD) technology and finite element analysis (FEA) technology, they conduct in-depth research on the fluid dynamics performance, structural strength and stability of the ship to improve the navigation efficiency and safety of the ship [

2,

3,

4,

5,

6,

7,

8]. In terms of material application, there are some research on the application of aluminum alloy materials in LNG bunkering ships, continuously exploring new aluminum alloy materials, and optimizing welding processes to improve the reliability and low temperature resistance of aluminum alloy structures. For example, The Welding Institute (TWI) in Cambridge, UK have achieved remarkable results in the research of friction stir welding (FSW) processes and joint performance of aluminum alloy materials, effectively solving the problems of defects such as pores and cracks in the welding process of aluminum alloys [

9,

10].

In terms of cargo containment systems, it has been continued to deepen the research on type B tanks and are committed to improving their thermal insulation performance and safety and reliability [

11,

12,

13,

14,

15]. China and South Korea are at the world’s leading level in the design and manufacturing technology of type B tanks. By adopting new thermal insulation materials and optimizing structural design, it has reduced the Boil-off Rate (BOR) of LNG and improved transportation efficiency. In terms of application, LNG bunkering ship operators start to accumulate rich operating experience, have conducted a lot of research on bunkering operation processes and safety management, and have formulated complete operating specifications and safety standards [

16,

17,

18,

19,

20,

21,

22]. For example, some LNG bunkering ship operators in the United States and Europe have achieved real-time monitoring and remote management of bunkering operations by establishing an information management system, improving operational efficiency and safety.

In China, with the rapid development of the LNG industry, the research on LNG bunkering ships has also made some progress. In terms of design, some scientific research institutions and universities have conducted in-depth research on the overall design, structural design and system design of LNG bunkering ships using independently developed ship design software, and have achieved a series of results [

2,

23]. In terms of material application, China has strengthened the localization research on aluminum alloy materials. Through cooperation with steel companies, aluminum alloy materials have been developed and applied on some LNG ships [

25,

26,

27]. In terms of cargo containment systems, the research mainly focuses on the localization design and manufacturing technology of type B tanks [

12].

However, there are still some deficiencies in the current research on aluminum alloy B-type tank LNG bunkering ships. In terms of material application, although aluminum alloy materials are increasingly used in LNG ships, the welding process and joint performance of aluminum alloy materials still need to be further improved to ensure the reliability and safety of ship structures. In terms of cargo containment systems, there is still room for improvement in the thermal insulation performance and safety reliability of B-type tanks, and further research is needed on new thermal insulation materials and optimized structural design. In terms of ship system integration, the collaborative performance and reliability between systems need to be further optimized to improve the overall performance of the ship. In terms of intelligent technology application, although the application of intelligent technology in the field of ships has received more and more attention, its application in LNG bunkering ships is still in its infancy and needs to be further strengthened in research and development. Future research can be carried out in these directions to promote the continuous development and improvement of aluminum alloy B-type tank LNG bunkering ship technology.

1.2. Research Methods and Innovations

In the research process of this paper, a variety of scientific research methods were used to ensure the comprehensiveness, depth and accuracy of the research of aluminum alloy B-type tank LNG bunkering ship.

Literature research is one of the basic methods of this study. By extensively reviewing academic papers, research reports, patent literature, industry standards, and relevant policies and regulations on LNG bunkering ships at home and abroad, the research status and development trends in the field of LNG bunkering ships were comprehensively sorted out, and the application of aluminum alloy materials in shipbuilding, the design and technical characteristics of type B tanks, and the research results and existing problems in the system integration and intelligent development of LNG bunkering ships were deeply understood. This provides a solid theoretical foundation for the research of the paper, clarifies the direction and focus of the research, and avoids the blindness of the research. For example, when studying the welding process of aluminum alloy materials, through the analysis of a large number of literature, we can understand the research progress and existing technical difficulties in this field at home and abroad, which provides a reference for subsequent research.

Numerical simulation played an important role in this study. With the help of advanced computational fluid dynamics (CFD) software and finite element analysis (FEA) software, the fluid dynamics performance, structural strength and stability of the B-type tank LNG bunkering ship were numerically simulated [

28,

29,

30]. By establishing a mathematical model and a physical model of the ship, the operating state of the ship under different working conditions is simulated, such as resistance during navigation, propulsion efficiency, and structural response under wave loads. This helps to gain a deeper understanding of the performance characteristics of the ship, optimize the design parameters of the ship, and improve the performance and safety of the ship. At the same time, numerical simulation and simulation technology can also reduce the number of physical tests, reduce research costs, and improve research efficiency. For example, when studying the thermal insulation performance of the B-type tank, CFD software was used to simulate the temperature distribution and evaporation of LNG in the tank, which provided a basis for optimizing the thermal insulation structure [

31,

32].

Case analysis is one of the important methods of this study. Through in-depth analysis of the design, construction and operation cases of typical LNG bunkering ships, the successful experience and existing problems are summarized, providing a practical basis for the research of the paper. Through case analysis, we can not only intuitively understand the actual application of this ship type, but also draw lessons from practice, providing a reference for further improvement and perfection of this ship type.

This paper also has the following innovations: In terms of material application and structural optimization, a new type of aluminum alloy material and B-type tank structure optimization combination scheme is proposed. By optimizing the composition and heat treatment process of the aluminum alloy material, the strength and low temperature resistance of the aluminum alloy material are improved; at the same time, the structure of the B-type tank is innovatively designed, and a new type of insulation material and structural form are used, which effectively reduces the evaporation rate of LNG and improves the transportation efficiency and economy of the ship. In terms of ship system integration and intelligent control, a ship system integration and intelligent control scheme based on the Internet of Things and big data technology is proposed, which realizes information sharing and collaborative work among various ship systems and improves the overall performance and reliability of the ship; at the same time, by establishing an intelligent monitoring and management system, real-time monitoring and remote control of the ship’s operating status is realized, which improves the efficiency and safety of ship operation management. In terms of green environmental protection and sustainable development, from the perspective of the entire life cycle, the green environmental protection performance of the aluminum alloy B-type tank LNG bunkering ship was studied, and a series of energy-saving, emission-reduction and environmental protection measures were proposed, such as the use of efficient power systems, optimization of ship navigation routes, and recycling of LNG cold energy, etc., to achieve sustainable development of ships. These innovations provide new ideas and methods for the development of aluminum alloy B-type tank LNG bunkering ships, which have important theoretical significance and practical value.

2. Overview of Aluminum Alloy Type B Tank LNG Bunkering Ship

2.1. Development History of LNG Bunkering Ships

The development history of LNG bunkering ships is a history of continuous pursuit of technological breakthroughs and innovations. Its development trajectory closely follows the changes in the global energy landscape and the growth of the shipping industry’s demand for clean energy. In the mid-20th century, with the continuous increase in global energy demand and the extensive development of natural gas resources, the efficient transportation of natural gas to consumption areas became an urgent problem to be solved, and LNG bunkering ships came into being. In 1959, the United States built the world’s first LNG ship, the “Methane Pioneer”. Its successful voyage marked the realization of LNG transportation through shipping and opened the prelude to the development of the LNG industry. Since then, with the continuous advancement of technology and the accumulation of experience, the capacity of LNG ships has gradually increased, and the sailing distance has become longer and longer.

Early LNG bunkering ships had relatively simple technology, mainly using relatively basic cargo containment systems and power units. In terms of cargo containment, simple insulation materials and structures were mostly used to achieve low-temperature LNG storage, but the insulation effect and safety were far behind those of modern ships. The power system also mostly used traditional fuel engines, which had high energy consumption and caused great environmental pollution. LNG bunkering ships during this period mainly served a few countries and regions that had demand for natural gas, and the scale of transportation was relatively small.

Entering the 1980s, with the growing global demand for clean energy, the market demand for LNG bunkering ships has also risen. During this period, LNG bunkering ships have made significant technological progress. In terms of cargo containment systems, a variety of advanced LNG cargo tank forms have been developed, such as self-supporting type A and type B tanks and membrane cargo tanks. Self-supporting cargo tanks withstand the pressure of LNG cargo through their own structure. Type A tanks are generally prismatic and have a complete secondary barrier; Type B tanks are commonly spherical or prismatic, with some secondary barriers. Membrane tanks use extremely thin metal films as the sealing layer of LNG cargo, and use special insulating materials and structures to ensure their thermal insulation and safety. The emergence of these new cargo tanks has greatly improved the storage safety and transportation efficiency of LNG. In terms of power systems, dual-fuel engines have begun to be used, which can use both LNG as fuel and traditional fuel oil, reducing pollution to the environment and improving energy efficiency.

Since the 21st century, with the rapid development of science and technology, LNG ships have achieved a qualitative leap in technology. In terms of material application, new materials such as aluminum alloy and high-strength steel are widely used in shipbuilding. Aluminum alloy has the advantages of low density, high strength and corrosion resistance, which can effectively reduce the weight of the ship itself and improve transportation efficiency. High-strength steel can withstand greater pressure and load, and improve the structural strength and safety of the ship. In terms of cargo containment system, the design and material selection are continuously optimized to further improve the thermal insulation performance and safety and reliability. For example, the use of new thermal insulation materials such as polyurethane foam and aerogel effectively reduces the evaporation rate of LNG. In terms of power system, new engines and propulsion systems are continuously developed to improve energy efficiency and reduce emissions. At the same time, intelligent technology has begun to be applied to LNG bunkering ships, realizing real-time monitoring and remote control of the ship’s operating status, and improving operational management efficiency and safety.

2.2. Features of Aluminum Alloy Type B Tank LNG Bunkering Ship

2.2.1. Aluminum Alloy Material Characteristics and Advantages

Aluminum alloy plays a key role in the construction of aluminum alloy B-type tank LNG bunkering vessels. Its unique characteristics bring many significant advantages to the performance improvement of ships.

Aluminum alloy has an excellent strength-to-weight ratio. Compared with traditional shipbuilding materials such as steel, the density of aluminum alloy is about one-third of that of steel. Under the premise of ensuring structural strength, it can significantly reduce the weight of the ship itself. According to relevant data, the LNG bunkering ship built with aluminum alloy can reduce the weight of the hull structure by 20% - 30%. This not only reduces the energy consumption of the ship during navigation and improves fuel economy, but also enables the ship to achieve a higher sailing speed under the same power conditions. Studies have shown that for every 10% reduction in ship weight, fuel consumption can be reduced by 8% - 10%, and the sailing speed can be increased by about 5%.

Aluminum alloy has good corrosion resistance. In the marine environment, ships are corroded by corrosive media such as seawater, sea breeze and salt in the marine atmosphere for a long time. The corrosion resistance of the material directly affects the service life and safety of the ship. A dense aluminum oxide protective film can be formed on the surface of the aluminum alloy, which can effectively prevent the contact between the corrosive medium and the aluminum alloy matrix, thereby improving the corrosion resistance of the aluminum alloy. Compared with steel, the corrosion resistance of aluminum alloy in the marine environment can be improved several times, which greatly reduces the cost of ship maintenance and prolongs the service life of the ship. According to statistics, the maintenance cycle of ships made of aluminum alloy materials can be extended by 2-3 times, and the maintenance cost can be reduced by more than 50%.

Aluminum alloys also have good low-temperature performance. The storage temperature of LNG is usually around -162°C, which places extremely high demands on the low-temperature performance of shipbuilding materials. In a low-temperature environment, the strength of aluminum alloys will not decrease, but will increase, while its toughness and ductility will also remain good. This enables aluminum alloys to stably maintain structural integrity and reliability in the low-temperature environment of LNG, ensuring the safe storage and transportation of LNG. Experimental data show that at a low temperature of -162°C, the yield strength of aluminum alloys can be increased by 10% - 20%, and the impact toughness remains at a high level, which can effectively avoid dangerous situations such as brittle fracture of materials at low temperatures.

In addition, aluminum alloys also have good processing and welding properties. Aluminum alloys are easy to process and can be processed into various complex shapes through various processing techniques, such as casting, forging, extrusion, etc., to meet the diverse needs of shipbuilding. In terms of welding, with the continuous development of welding technology, the welding quality of aluminum alloys has been effectively guaranteed, and high-quality welded joints can be achieved to ensure the strength and sealing of ship structures.

2.2.2. Structural Features of Type B Tank

As the core cargo containment system of the aluminum alloy B-type tank LNG bunkering ship, the unique structural design of the B-type tank is highly adaptable to the storage and transportation of LNG.

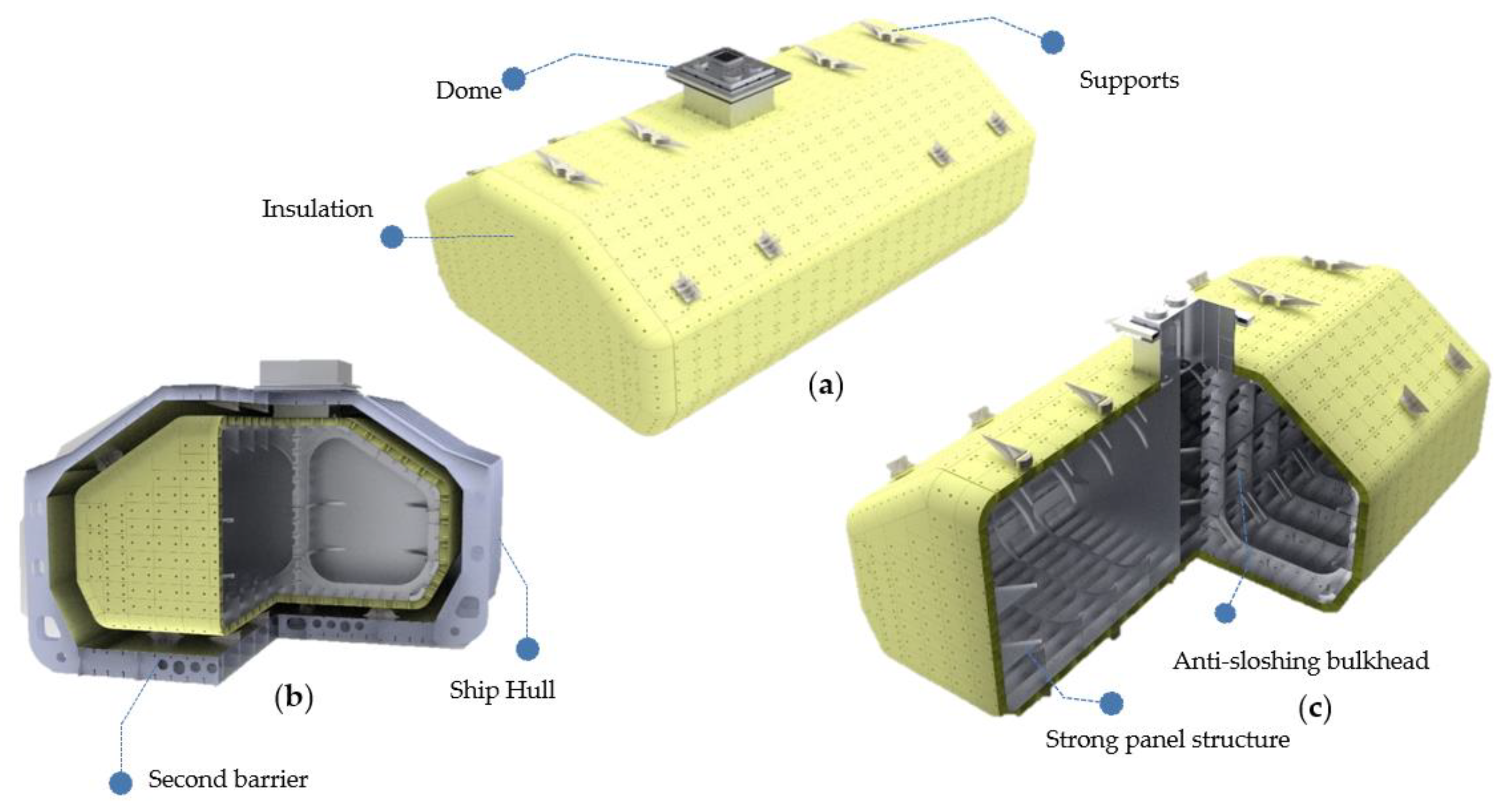

B -type tanks are spherical or prismatic. Spherical B-type tanks have the characteristics of compact structure and uniform force, and can effectively withstand the internal LNG pressure and external loads. Its spherical structure makes the stress distribution on the tank wall more uniform, reduces stress concentration points, and improves the strength and safety of the tank. Prismatic B-type tanks have certain advantages in space utilization, and can better adapt to the internal layout of the ship and increase the cargo capacity of the ship (

Figure 1 and

Table 1).

In terms of size, the size of the B-type tank is reasonably configured according to the design requirements and cargo capacity of the ship. The B-type tank of the LNG bunkering ship usually has a larger volume to meet the transportation needs of the ship. The design size of the B-type tank also needs to consider the compatibility with other systems of the ship to ensure the coordinated operation of the entire ship system.

The internal structure of the B-type tank is also very unique. It is equipped with a partial secondary barrier, which consists of a splash wall and a drip tray. The splash wall can effectively prevent LNG from splashing out due to shaking during transportation, and the drip tray is used to collect LNG that may leak, thereby protecting against small amounts of cargo leakage. The interior of the B-type tank is also equipped with advanced insulation materials and structures to reduce heat transfer and reduce the evaporation rate of LNG. Common insulation materials include polyurethane foam, aerogel, etc. These insulation materials have extremely low thermal conductivity and can effectively prevent heat from invading. The design of the insulation structure has also been carefully optimized, and a multi-layer insulation design is used to further improve the insulation effect. Through these insulation measures, the BOR of LNG can be controlled at a low level, generally reaching 0.1% - 0.2% (e.g. for a 20,000m³ LNGBV), effectively ensuring the storage quality and transportation efficiency of LNG.

2.2.3. Overall Performance Characteristics of the Ship

The aluminum alloy B-type tank LNG bunkering ship shows excellent overall performance advantages in terms of cargo capacity, sailing speed, stability, etc.

In terms of cargo capacity, this type of ship can achieve a large cargo capacity with its reasonable design and advanced cargo containment system. A 20,000m³ LNG storage capacity enables it to meet large-scale LNG transportation needs and provide strong support for the supply of the energy market. Compared with other LNG bunkering ships of the same type, this type of ship has certain competitiveness in cargo capacity, can improve transportation efficiency and reduce unit transportation costs.

In terms of sailing speed, due to the use of aluminum alloy materials, the weight of the ship itself is reduced, and the advanced power system and optimized hull design enable this type of ship to achieve a higher sailing speed. In general, its design speed can reach more than 15 knots, which can quickly transport LNG to the destination and improve the timeliness of transportation. The fast sailing speed also helps the ship to avoid danger in time under severe weather conditions and ensure the safety of the ship and cargo.

The stability of a ship is also one of its important performance indicators. The design of the aluminum alloy B-type tank LNG bunkering ship can fully considers the stability of the ship. Through reasonable hull structure design and weight distribution, the stability of the ship during navigation is improved. The layout position and center of gravity control of the B-type tank have also been accurately calculated to ensure that the ship can maintain good stability under various working conditions. Under full and empty load conditions, the stability indicators of the ship meet the requirements of relevant specifications and standards, and can effectively prevent dangerous situations such as capsizing during navigation. The ship is also equipped with advanced navigation and control systems, which can monitor the operating status of the ship in real time and adjust the ship’s posture in time, further improving the stability and safety of the ship.

2.3. Technical Advantages of Aluminum Alloy B Tank vs. 9% Nickel Steel B Tank

In the LNG cargo containment systems, aluminum alloy B tank and 9% nickel steel B tank are two common types. There are significant differences between them in material properties, structural design and performance. Aluminum alloy B tank has shown broad application prospects in the field of modern LNG bunkering ships with its unique technical advantages.

In terms of material properties, the density of aluminum alloy is about 2.7g/cm³, which is only about one-third of the density of 9% nickel steel (about 7.85g/cm³). This allows the B tank built with aluminum alloy to significantly reduce the weight of the ship. Relevant research data shows that under the same size and structural design, the aluminum alloy B tank can reduce the weight by about 40% - 50% compared with the 9% nickel steel B tank. This weight advantage not only reduces the energy consumption of the ship during navigation and improves fuel economy, but also enables the ship to achieve a higher sailing speed under the same power conditions, enhancing the ship’s operational efficiency.

Aluminum alloy has excellent corrosion resistance. In the marine environment, 9% nickel steel is easily corroded by seawater, salt, etc., which will cause corrosion, which will not only affect the structural strength and safety of the B tank, but also increase the maintenance cost and frequency of the ship. A dense aluminum oxide protective film can be formed on the surface of aluminum alloy, which effectively prevents the contact between the corrosive medium and the aluminum alloy matrix, making its corrosion resistance in the marine environment several times higher than that of 9% nickel steel. According to actual application cases, ships using 9% nickel steel B cabins need to perform anti-corrosion maintenance 1-2 times a year, and the maintenance cost is relatively high; while ships using aluminum alloy B tanks can extend their maintenance cycle to 3-5 years, and the maintenance cost is reduced by more than 50%.

In terms of structural design, aluminum alloy has good processing performance and is easy to form. It can be used to manufacture parts with complex shapes through various processing techniques to meet the diverse structural design requirements of B tanks. In contrast, 9% nickel steel is more difficult to process and has high requirements for processing equipment and processes, which limits its flexibility in structural design. Aluminum alloy B tanks can adopt more optimized forms in structural design, such as thin-walled structures, which can further reduce weight and improve space utilization while ensuring structural strength.

In terms of performance, the aluminum alloy B tank has obvious performance advantages in low temperature environments. The storage temperature of LNG is usually around -163℃. In such a low temperature environment, the strength of aluminum alloy will not decrease, but will increase, and its toughness and ductility will also remain good. However, the toughness of 9% nickel steel will decrease at low temperatures, and there is a risk of brittle fracture. Experimental data show that at a low temperature of -163℃, the yield strength of aluminum alloy can be increased by 10% - 20%, and the impact toughness remains at a high level; while the impact toughness of 9% nickel steel will decrease by 20% - 30%. This enables the aluminum alloy B tank to maintain the integrity and reliability of the structure more stably in the low temperature environment of LNG, ensuring the safe storage and transportation of LNG.

The thermal insulation performance of the aluminum alloy B tank is also better than that of the 9% nickel steel B tank. During the storage and transportation of LNG, good thermal insulation can effectively reduce the transfer of heat and reduce the BOR of LNG. The thermal conductivity of aluminum alloy is low, about one-third of the thermal conductivity of 9% nickel steel, which gives the aluminum alloy B tank a natural advantage in thermal insulation. By adopting advanced thermal insulation materials and structures, the aluminum alloy B tank can control the BOR of LNG at a lower level, generally reaching 0.1% - 0.2% (e.g. for a 20,000m³ LNGBV). Compared with the 9% nickel steel B tank, the LNG BOR can be reduced by about 30% - 40%, effectively reducing energy loss and improving transportation efficiency and economy.

2.4. Technical Advantages of Aluminum Alloy B Tank vs. 9% Nickel C Tank

In the LNG cargo containment systems, aluminum alloy B tank and nickel C tank are two important types, which have significant differences in many key aspects. Aluminum alloy B tank has many technical advantages, making it a hot topic in the field of modern LNG bunkering ships.

In the previous section, the aluminum alloy B tank is compared with the 9% nickel steel B tank. From the perspective of material properties, the density of aluminum alloy is significantly lower than that of 9% nickel steel, which makes the aluminum alloy B tank have a clear advantage in weight.

In terms of structural design and capacity efficiency, the B-type tank uses a prismatic structure to achieve higher capacity utilization by optimizing the space layout, which is about 20 % higher than the traditional C-type tank. In addition, the C-type tank expands due to heat and pressure when loading LNG. The lower the actual loading limit is than the B-type tank, the greater the difference in capacity utilization between the two will be. The prismatic structure can effectively reduce the redundancy of the hull space, and is particularly suitable for the complex ship adaptation requirements of inland shipping and offshore transportation. In contrast, the C-type tank is usually cylindrical or spherical in design. Although it has the characteristics of simple structure, the capacity is limited by the geometric shape, and additional hull space is required to meet the safety spacing requirements. And because the space utilization rate of the B-type tank is higher than that of the C-type tank, the layout of the ship is more compact, the main dimension is much lower, and the ship deadweight is at least 5% lighter.

In terms of construction technology and installation efficiency, since the B-type tank adopts a modular construction method, the construction period can be greatly shortened through the process of segment prefabrication and overall assembly. Practice has shown that the segment production and overall assembly process of the B-type tank reduces the construction time by about 30% compared with the C-type tank. Its independent structural design allows prefabrication outside the shipyard, avoiding the complex process of welding piece by piece in the dock for the traditional C-type tank, and reducing the dependence on large lifting equipment. In addition, the support structure of the B-type tank is separated from the hull, which reduces the impact on the hull structure during installation and improves construction flexibility.

In terms of safety and reliability, the B-type tank ensures structural stability under complex load conditions through precise stress analysis and fatigue life assessment. Its self-supporting design does not need to rely entirely on the hull strength and can independently withstand liquid cargo pressure and environmental loads. According to international standards, the B-type tank only needs to set up a partial secondary barrier as a safety redundancy, which is lighter than the fully enclosed secondary barrier system of the C-type tank. Taking the prismatic aluminum alloy B-type tank as an example, it not only has excellent low-temperature performance, but also effectively reduces the risk of liquid cargo sloshing and improves the safety of ship navigation by optimizing the design of internal anti-sloshing components.

In terms of application scenario adaptability, when the bunkering ship is bunkering, the pressure and temperature between the bunkering ship and the receiving ship need to match. The bunkering conditions are shown in

Table 2:

From

Table 2, the B-type tank bunkering ship has wider compatibilities. If the C-type tank needs to be able to bunker all types of tanks, it must be kept at a low pressure state, and the pressure-encapsulated characteristics of the C-type tank cannot be brought into play. When the insulation thickness is the same, the BOR of a 20,000m³ aluminum alloy B-type tank LNG bunkering ship is about 0.19% or lower, while the corresponding BOR of the C-type tank is about 0.22%, which reduces cargo loss.

The prismatic design and shallow draft characteristics of the aluminum alloy B-type tank give it a significant advantage in direct river-sea transportation. A 20,000m³ LNG bunkering ship equipped with aluminum alloy B-type tanks can pass through the Nanjing Yangtze River Bridge in China all year round and adapt to the extremely low water level conditions of the Yangtze River waterway, realizing the “one-stop river-sea” bunkering function. In contrast, the C-type tank is more suitable as a ship fuel tank on the deck or for short-distance transportation scenarios due to its higher design pressure (usually above 3.75bar), but its cylindrical structure faces geometric limitations in large-scale expansion and is difficult to meet the transportation needs of long distances and large volumes.

2.5. Technical Advantages of Aluminum Alloy B Tank vs. Membrane Tank

In the LNG cargo containment systems, aluminum alloy B tanks and membrane tanks have their own characteristics, but aluminum alloy B tanks, with their unique technical advantages, have a dimensionality reduction attack on membrane tanks in modern LNG bunkering ships.

From the perspective of structural design, aluminum alloy B tank has obvious advantages. Prismatic aluminum alloy B tank, this structural form makes B tank have good mechanical properties, can effectively withstand the internal LNG pressure and external load, and improve the strength and safety of the tank. In contrast, the structure of the membrane tank is relatively complex. It uses an extremely thin metal film as the sealing layer of liquid cargo, and uses special insulating materials and structures to ensure its thermal insulation performance and safety. This structure has extremely high process requirements during construction, and the construction is difficult. In addition, the strength of the film is relatively low, and it is easy to be damaged when it is impacted by external forces, affecting the storage and transportation safety of the cargo. The strong plate structure in the aluminum alloy B tank can meet the impact of liquid cargo on the tank under any liquid level filling, while the membrane tank cannot load liquid cargo with a filling rate of 10 %-70% under standard working conditions. In order to use membrane tanks on fuel tanks and bunker ships, the shipyard has to carry out a large number of structural reinforcements in the tank, which adds a lot of construction costs. In addition, expensive patent fees must be paid to the membrane tank design company.

In terms of material properties, the aluminum alloy B tank also shows many advantages. Aluminum alloy has the characteristics of low density, high strength, and corrosion resistance. Its density is about 2.7g/cm³, which is much lower than materials such as Invar steel commonly used in membrane tank. Aluminum alloy meets the use requirements of LNG bunkering ships and can also load liquid ammonia. Under the premise of ensuring structural safety, it provides the possibility of multi-liquid cargo bunkering. Aluminum alloy has good corrosion resistance. In the marine environment, a dense aluminum oxide protective film can be formed on the surface of aluminum alloy, which effectively prevents the erosion of corrosive media, prolongs the service life of B tank, and reduces maintenance costs. Although the materials such as Invar steel used in membrane tanks have excellent performance in low temperature performance, they are relatively weak in corrosion resistance and need to take additional protective measures to prevent corrosion.

In terms of thermal insulation performance, the aluminum alloy B tank also performs well. The storage of LNG requires good thermal insulation to reduce heat transfer and reduce evaporation rate. The aluminum alloy B tank can effectively achieve the insulation goal by adopting advanced thermal insulation materials and structural design. Common thermal insulation materials such as polyurethane foam and aerogel, combined with the structure of the aluminum alloy B tank, form a good thermal insulation system, which can control the daily evaporation rate of LNG at a low level, generally less than 0.2%. Although the membrane tank also adopts a multi-layer insulation structure, due to its structural characteristics and material limitations, the density of the insulation material used is much greater than the density of the insulation material used in the aluminum alloy B tank (e.g.: the insulation density of the Mark III Flex is 130-170 kg/m3 vs. the insulation density of the aluminum alloy B tank is only 40-50 kg/m3). There is still a certain gap in thermal insulation performance compared with the aluminum alloy B tank. Relevant research shows that under the same conditions, the BOR of the aluminum alloy B tank can be reduced by 10% - 20% compared with the membrane tank, which means that the aluminum alloy B tank can more effectively reduce the evaporation loss of LNG and improve the economy and energy efficiency of transportation.

In terms of safety, the aluminum alloy B tank also has certain advantages. The partial secondary barrier design of the aluminum alloy B tank, composed of splash walls and drip trays, can effectively prevent a small amount of cargo from leaking, reducing the risk of leakage accidents. The stability and reliability of its structure also provide guarantees for the safe transportation of LNG. However, due to the particularity of its membrane structure, once the membrane is damaged, it may cause a large amount of LNG to leak, causing serious safety accidents. Therefore, in terms of safety, the aluminum alloy B tank is relatively more reliable.

7. Conclusion and Perspectives

7.1. Summary of Research Results

This paper conducted a comprehensive and in-depth study on the aluminum alloy B-type tank LNG bunkering ship and achieved important results in many key aspects.

In terms of technical analysis, the key technologies of aluminum alloy B-type tanks were deeply analyzed. For aluminum alloy material welding technology, the difficulties in the welding process were clarified, such as oxide film, high thermal conductivity, deformation and cracks, hydrogen pores, and difficulty in temperature judgment. A series of effective solutions were proposed, including pre-welding cleaning and gas protection, selection of appropriate welding methods and control of preheating temperature, optimization of welding structure and parameters, control of hydrogen sources, use of temperature monitoring equipment and strengthening of welder training. In the thermal insulation and cold-insulating structure technology of B-type tanks, the performance of common insulation materials such as polyurethane foam, aerogel, and polystyrene foam board was compared in detail. Taking all factors into consideration, polyurethane foam was determined to be the best insulation material, and the design principle of cold preservation structure of B -type tanks with multi-layer insulation design and strict sealing measures was explained. In terms of tank safety assurance technology, the working principle and important role of the pressure control and monitoring system, as well as the detection methods and processing procedures of leak detection and emergency treatment technology were analyzed.

In terms of design and construction, the overall design points, construction technology and quality control measures of the aluminum alloy B-type tank LNG bunkering ship are systematically explained. In terms of ship design, the influence of factors such as hull line, aspect ratio, draft and freeboard on ship performance is considered, and the navigation performance, operation performance and economy of the ship are improved through optimized design. In terms of cabin layout planning, following the scientific and reasonable principles, the LNG tank, the engine room and living cabin are reasonably laid out to ensure the use function, safety of the ship and the working and living conditions of the crew. In terms of construction technology, the process from material processing to component assembly to overall closure is introduced in detail, as well as the key technologies and quality control points of each link. In terms of quality control, the methods and standards of welding quality inspection and tank sealing test are emphasized to ensure the construction quality of the ship.

Through the actual application case analysis of a specific 20,000m³ aluminum alloy B-type tank LNG bunkering ship project, the application effect of this type of ship was comprehensively evaluated. In terms of economic benefits, this type of ship has significant advantages in transportation costs. The application of aluminum alloy materials reduces energy consumption, and the thermal insulation performance of the B-type tank reduces the evaporation loss of LNG. At the same time, its large cargo capacity and efficient transportation capacity bring higher operating income. In terms of social benefits, it promotes the use of clean energy, reduces environmental pollution, drives the development of related industries, creates employment opportunities, and strengthens energy exchanges and cooperation between regions. In terms of technical benefits, a number of technical achievements have been achieved, such as aluminum alloy material welding technology, B-type tank thermal insulation and cold preservation technology, which have promoted the development of industry technology.

7.2. Future Research Perspectives

In the future, the research on the aluminum alloy B-type tank LNG bunkering vessels will focus on several key areas to meet current challenges, seize development opportunities and promote continuous progress in the industry.

In terms of technological innovation, it is necessary to further study the welding technology of aluminum alloy materials, develop more advanced welding processes and equipment, so as to solve the problems of deformation and cracks during welding of large and complex structures, and improve the stability and reliability of welding quality. Strengthen the research and development of new thermal insulation and cold-insulating structure materials, explore materials with lower thermal conductivity, higher durability and better economy, further optimize the thermal insulation and cold preservation structure design of type B tanks, reduce the BOR of LNG, and improve energy efficiency. Increase investment in the research and development of ship intelligent technology, improve the integration and application of intelligent systems, improve the accuracy and reliability of systems, realize intelligent management of the entire life cycle of ships, and improve the operational efficiency and safety of ships.

In terms of market expansion, it should strengthen the research on global LNG market demand, conduct in-depth analysis of energy policies, market size and development trends in different regions, and provide a strong market basis for opening up new routes and serving new customer groups. It should strengthen cooperation and coordinated development with energy companies, shipping companies and other related industries, establish long-term and stable cooperative relations, jointly promote the improvement and development of the LNG industry chain, and create a good industrial environment for the market expansion of aluminum alloy B-type tank LNG bunkering ships. It should strengthen brand building and market promotion, improve the visibility and reputation of ships, and enhance the competitiveness of ship companies in the international market.

In terms of policies and regulations, it should pay close attention to changes in international and domestic policies and regulations, strengthen communication and coordination with relevant departments, keep abreast of the requirements and directions of policies and regulations, and provide policy support for the design, construction and operation of ships. It should actively participate in the formulation and revision of policies and regulations, fully reflect the actual needs and development of the industry, promote the improvement and optimization of policies and regulations, and create a favorable policy environment for the development of aluminum alloy B-type tank LNG bunkering ships. It should strengthen the publicity and training of policies and regulations, improve the policy and regulatory awareness of ship companies and practitioners, and ensure that the operation of ships complies with the requirements of relevant policies and regulations.

The aluminum alloy B-type tank LNG bunkering ships have broad prospects in future development, but they also face many challenges. Through continuous technological innovation, active market expansion and effective response to policies and regulations, they are expected to play a more important role in the global LNG energy transportation field and make greater contributions to promoting energy structure adjustment and sustainable development.