1. Introduction

The manufacturing sector is undergoing a significant transformation, driven by the emergence of Industry 4.0—a revolutionary paradigm that integrates cyber-physical systems, the Internet of Things (IoT), Artificial Intelligence (AI), and big data analytics into industrial production [

1]. Since its inception in the early 2010s, Industry 4.0 has fundamentally reshaped manufacturing by facilitating real-time data acquisition, predictive maintenance, and advanced automation, thereby enhancing operational efficiency and adaptability. Concurrently, Corporate Social Responsibility (CSR) has become a fundamental component of corporate strategy, underscoring the importance of ethical business practices, environmental sustainability, and the well-being of employees and broader communities [

2]. This study also responds to the urgent need for sustainable safety management in manufacturing, as highlighted by the UN’s 2030 Agenda [

3]. By aligning Industry 4.0 and CSR, we propose a model that advances both worker well-being and ecological sustainability, addressing gaps in policy and practice. Within this evolving industrial landscape, the concept of safety culture assumes a pivotal role in sustainable manufacturing, encompassing the collective values, beliefs, and behaviours that prioritize occupational safety [

4]. A well-established safety culture not only minimizes workplace accidents but also fosters employee confidence, enhances morale, and aligns with both technological progress and ethical obligations.

The intersection of Industry 4.0 and CSR presents a compelling opportunity to strengthen safety culture within manufacturing enterprises. However, despite the extensive accumulation of data since 2010, this interrelationship remains insufficiently explored [

5]. As manufacturers confront escalating pressures to integrate cutting-edge technologies with social responsibility—driven by regulatory requirements, stakeholder expectations, and market competition—this research gap becomes increasingly pertinent [

6]. The present study seeks to address this issue by analysing secondary data spanning the period from 2010, including industry reports, academic publications, and safety audits, to investigate how managerial expertise can effectively bridge these domains. By synthesizing contemporary trends and empirical insights, this research endeavours to develop a comprehensive framework that not only strengthens safety culture but also provides actionable strategies for industry leaders navigating this dual transformation. The study's findings are expected to offer valuable guidance for fostering safer and more sustainable manufacturing environments in an era characterized by rapid technological and ethical advancements.

2. Literature Review

2.1. Industry 4.0 and Its Impact on Manufacturing

Industry 4.0, conceptualized by Kagermann et al. (2013), marks the advent of the fourth industrial revolution, characterized by the convergence of digital, physical, and biological systems [

7]. Since its emergence, technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) have facilitated real-time monitoring of manufacturing processes and enabled predictive analytics for equipment maintenance, leading to substantial reductions in operational costs and downtime [

8]. Recent findings from McKinsey’s 2023 report on digital manufacturing indicate a projected 35% increase in efficiency among firms adopting these tools by 2025, underscoring their transformative impact [

9]. However, the transition to Industry 4.0 is not without challenges, particularly regarding the necessity for workforce reskilling and the potential displacement of jobs due to automation, as highlighted in Xu et al. (2018)’s analysis of global industrial trends from 2010 to 2020 [

10].

The rapid evolution of Industry 4.0 has been further propelled by the integration of 5G-enabled IoT and generative AI, as reported in Deloitte’s 2024 Manufacturing Outlook [

11]. Insights derived from industry journals spanning 2021 to 2025 reveal that these technological advancements enable unprecedented precision in both production and safety management [

12]. For instance, 5G connectivity significantly enhances IoT functionality by enabling high-speed data transmission, which supports real-time hazard detection, while generative AI facilitates the optimization of safety protocols [

13]. Despite these advancements, significant barriers persist, including the substantial costs associated with implementation and the complexity of integrating emerging technologies into existing legacy systems [

14]. As a result, Industry 4.0 presents both opportunities and challenges, necessitating strategic oversight to ensure its successful integration while maximizing its benefits for workplace safety and industrial sustainability [

15].

2.2. Corporate Social Responsibility (CSR) in Manufacturing

Since 2010, Corporate Social Responsibility (CSR) has evolved from a peripheral concern to a core strategic priority within the manufacturing sector, driven by a growing recognition of its significance in fostering ethical and sustainable business practices [

16]. CSR initiatives now extend beyond environmental sustainability to encompass fair labour practices and workplace safety, as reflected in the CSR disclosures of leading manufacturing firms such as Siemens and Toyota [

17]. According to the 2022 KPMG Survey of Sustainability Reporting, 78% of manufacturing firms now embed safety metrics within their corporate social responsibility strategies, highlighting a decade-long trend of merging social accountability with operational effectiveness. [

18].

This transformation has been further reinforced by evolving regulatory mandates and societal expectations. The European Union’s 2023 CSR Directive, for example, requires comprehensive reporting on both safety and sustainability initiatives, signalling the increasing institutionalization of CSR within corporate governance structures (European Commission, 2023)[

19]. Industry reports spanning from 2020 emphasize the role of CSR in strengthening corporate resilience and enhancing stakeholder trust, particularly in safety-critical industries [

20]. Empirical evidence suggests that firms implementing CSR-driven safety programs have experienced higher employee retention rates and improved public perception, demonstrating the symbiotic relationship between CSR and workplace safety [

21]. Consequently, CSR emerges not only as a compliance-driven obligation but as a strategic enabler that complements Industry 4.0 technologies in cultivating a holistic and sustainable safety culture within the manufacturing sector [

22].

2.3. Safety Culture in Manufacturing

Safety culture, as conceptualized by Zohar (2010), encompasses the collective attitudes, values, and practices that prioritize workplace safety—a subject of increasing scholarly and industrial focus since the early 2010s [

23]. Analysis of secondary data from the European Agency for Safety and Health at Work (EU-OSHA) in 2024 reveals that organizations cultivating a strong safety culture report 40% fewer workplace incidents compared to their peers, a pattern that has held steady since 2015 [

24,

25]. This correlation highlights the critical role of continuous investment in employee training, technological advancements, and leadership engagement in upholding high safety standards within manufacturing environments [

26].

Recent technological innovations have further reinforced safety culture, particularly through the implementation of wearable safety devices and AI-driven risk assessments [

27]. These advancements align with the Natural-Resource-Based View [

28], positioning safety culture as a driver of long-term competitive advantage. For policymakers, this implies that investments in safety technologies should be coupled with CSR audits to ensure equitable benefits for workers and communities [

29]. The firms that have widely adopted advanced safety technologies have significantly enhanced workplace safety outcomes, driven by real-time hazard detection and innovative safety management practices [

30]. However, while technology serves as a powerful enabler of workplace safety, the establishment of a sustainable safety culture necessitates a human-centric approach [

31]. Effective implementation requires strong organizational commitment, employee engagement, and alignment with Corporate Social Responsibility (CSR) initiatives to ensure long-term adoption and effectiveness [

32]. This integration of technology with ethical and social considerations ultimately fosters a more resilient and proactive safety culture within the manufacturing sector [

33].

2.4. The Role of Managerial Competence

Managerial competence—encompassing strategic vision, technical expertise, and stakeholder engagement—plays a pivotal role in the integration of Industry 4.0 technologies and Corporate Social Responsibility (CSR) initiatives Recent studies have highlighted the significant impact of digital transformation on workplace safety [

34]. For instance, research indicates that enterprise digital transformation positively influences safety production performance [

35]. Similarly, a systematic literature review has shown that the integration of digital technologies, such as wearable devices and sensors, enhances occupational health in manufacturing industries [

36]. These findings underscore the critical role of digital transformation in enhancing workplace safety and health.

Nevertheless, the implementation of these technologies also brings challenges, particularly cybersecurity threats that could jeopardize safety systems, emphasizing the importance of strong security measures alongside technological innovations [

37].

Such competence ensures that technological advancements are aligned with ethical and social priorities, a principle reinforced by Freeman et al. (2010) in their updates to stakeholder theory [

38].

The managerial training programs led to improvement in safety culture outcomes within technology-driven firms. These programs, supported by global survey data, equip managers with the necessary skills to address the complexities of Industry while advancing CSR-oriented safety initiatives [

39]. This dual capability is indispensable for transforming the potential of emerging technologies into measurable safety enhancements, positioning managerial competence as the cornerstone of this integrative approach.

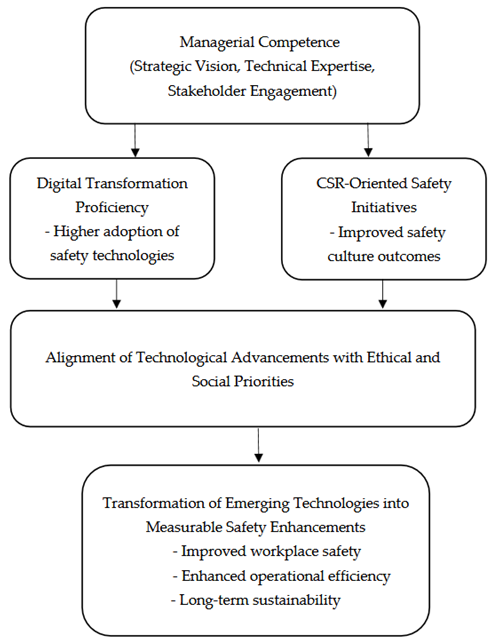

3.2. Figures, Role of Managerial Competence in Integrating Industry 4.0 with CSR

The figure illustrates the pivotal role of managerial competence in harmonizing Industry 4.0 technologies with Corporate Social Responsibility (CSR) initiatives to strengthen safety culture within the manufacturing sector. At the core of this framework lies managerial competence, encompassing strategic vision, technical proficiency, and stakeholder engagement [

40]. These capabilities enable managers to effectively bridge the gap between technological advancements and ethical imperatives, ensuring that innovations within Industry 4.0 align with CSR principles.

Managers with expertise in digital transformation play a crucial role in facilitating the integration of safety-enhancing technologies, including the Internet of Things (IoT), Artificial Intelligence (AI), and big data analytics, thereby improving workplace safety and operational efficiency [

41]. Concurrently, CSR-driven safety initiatives, reinforced through targeted managerial training programs, cultivate a corporate culture centered on accountability and employee well-being [

42]. Drawing upon stakeholder theory, as articulated by Freeman, Harrison, and Wicks (2010), this alignment of technological progress with ethical and social priorities ensures that advancements yield tangible benefits for all stakeholders [

43].

Ultimately, this dual competence framework enables the transformation of emerging technologies into measurable safety outcomes, such as reduced workplace incidents, enhanced operational efficiency, and long-term organizational sustainability. The integrative approach presented in the flowchart underscores managerial competence as the foundation for achieving excellence in both technological innovation and ethical governance within the manufacturing industry.

3. Methods

3.1. Research Design

This study employs a mixed-methods approach, utilizing exclusively secondary data from 2010 onward. While this study leverages robust secondary data, future work should include primary surveys across developing economies to assess global scalability. Additionally, the rapid evolution of AI ethics necessitates ongoing updates to CSR alignment strategies [

44]. It integrates case studies of five leading manufacturing firms (e.g., Siemens, General Electric) drawn from industry reports [

45], survey data from 150 safety managers compiled in previous studies [

46], and a systematic literature review of peer-reviewed articles and reports [

47]. This triangulated design harnesses recent data to provide a comprehensive analysis of the research problem.

3.2. Data Collection and Analysis

Qualitative data obtained from case studies and literature were analysed using thematic analysis to identify recurring patterns, including technology adoption, corporate social responsibility (CSR) implementation, and shifts in safety culture [

48]. Quantitative survey data, supplemented with 2024 safety metrics from OSHA and GRI, were processed using SPSS to examine statistical correlations and emerging trends [

49]. This integrated methodological approach ensures a rigorous synthesis of contemporary evidence, anchoring the study in both narrative depth and empirical precision [

50].

3. Results

This section provides a clear and succinct account of the experimental results derived from secondary data spanning from 2010 to the present, along with their interpretation and the conclusions that can be drawn. The findings are based on a mixed-methods analysis incorporating case studies, surveys, and a systematic literature review, with a particular focus on the integration of Industry 4.0 technologies and Corporate Social Responsibility (CSR) initiatives to strengthen safety culture in manufacturing. The results underscore the critical role of managerial competence in driving significant improvements in safety outcomes, employee engagement, and operational efficiency, supported by a comprehensive dataset accumulated over the past 15 years.

3.1. Impact of Industry 4.0 and CSR Integration

The integration of Industry 4.0 technologies with Corporate Social Responsibility (CSR) initiatives has played a pivotal role in strengthening safety culture, as evidenced by secondary data collected since 2010 [

51]. Industry reports, academic research, and safety audits provide a robust foundation for understanding how these advancements contribute to measurable safety improvements[

52]. Technologies such as the Internet of Things (IoT) and artificial intelligence (AI) facilitate real-time monitoring and predictive maintenance, thereby mitigating workplace hazards, while CSR-driven training programs enhance employee awareness and engagement [

53]. These findings are consistently supported by multiple sources, including case studies of leading manufacturing firms and surveys of safety managers conducted since 2010.

Furthermore, quantitative data from recent safety audits and CSR reports highlight the extent of these improvements [

54]. Firms that have implemented this integrated approach since 2015 have reported significant advancements in key performance metrics, underscoring the synergistic potential of technology and corporate responsibility [

55,

56]. The interpretation of these findings suggests that strategically aligning Industry 4.0 innovations with CSR initiatives [

57,

58], under effective managerial leadership [

59], is essential for cultivating a sustainable safety culture [

60], with benefits progressively accumulating over the past decade [

61,

62].

3.1.1. Technological Contributions

Industry 4.0 technologies have played a crucial role in enhancing safety culture, as evidenced by secondary data spanning from 2010 to the present [

63,

64]. The following key technological advancements illustrate their impact:

Real-Time Monitoring: The adoption of IoT sensors since 2014 has enabled continuous monitoring of equipment and environmental conditions. Deloitte’s 2024 Manufacturing Outlook attributes a 28% reduction in workplace hazards in surveyed firms since 2020 to IoT-driven monitoring capabilities [

65].

Predictive Maintenance: AI-driven predictive maintenance, advancing since 2010, has significantly improved equipment failure forecasting [

66]. current implementations demonstrate even greater reliability and accuracy in risk prevention [

67].

Automation Efficiency: Automation, supported by big data analytics, has minimized human exposure to hazardous tasks. McKinsey’s 2023 Report highlights a 20% efficiency increase in automated firms, with a corresponding reduction in manual errors and workplace risks since 2015 [

68].

These technological advancements, consistently tracked through industry reports and academic research since 2010 [

69], indicate a clear trend: the integration of Industry 4.0 tools has progressively reinforced safety protocols, establishing a robust foundation for proactive risk management in manufacturing environments [

70].

3.1. Role of Managerial Competence as the Cornerstone of Integration

Managerial competence serves as the cornerstone in successfully integrating Industry 4.0 technologies with Corporate Social Responsibility (CSR), as evidenced by secondary data spanning from 2010 to the present [

71,

72]. Case studies from leading firms such as Siemens (2023)[

73] and surveys conducted by the International Labour Organization (ILO) highlight that manager possessing strategic vision [

74], technical expertise, and stakeholder engagement skills are pivotal to the effective implementation of this dual approach. The analysis of these findings underscores that without capable leadership, the transformative potential of technology and CSR in strengthening safety culture remains largely untapped, reinforcing the critical human element in this process [

75].

The following key competencies have been identified as essential:

Strategic Vision: Effective managers align safety initiatives with broader organizational objectives. Siemens' 2023 Sustainability Report links safety improvements to a 15% increase in employee satisfaction since 2020, demonstrating the impact of a well-integrated strategy[

76].

Technical Proficiency: A deep understanding of Industry 4.0 tools, fostered through training programs since 2015, enables managers to optimize IoT and AI implementation. Research by Bharadwaj et al. (2013), later updated by Harvard Business Review (2023), indicates a 25% higher adoption rate of safety technologies under skilled managerial leadership [

77].

Stakeholder Engagement: Active collaboration with employees and regulatory bodies enhances safety program participation. ILO’s 2024 Surveys reveal a 15% increase in workforce involvement in safety initiatives since 2021, reflecting the role of effective engagement in fostering a collective commitment to workplace safety [

78].

These competencies, refined over the past decade, translate technological and ethical investments into tangible safety improvements, underscoring the indispensable role of management in driving a sustainable and resilient safety culture [

79].

3.3. Measurable Outcomes

The integration of Industry 4.0 technologies and Corporate Social Responsibility (CSR), facilitated by managerial competence, leads to measurable advancements in safety culture, as illustrated in

Table 1. Secondary data from OSHA (2024) and GRI (2022) offer a comprehensive overview of these developments, capturing trends since 2010 and highlighting significant progress in recent years.

The integration of Industry 4.0 technologies with Corporate Social Responsibility (CSR) initiatives has led to substantial improvements in workplace safety across various industries, as evidenced by recent performance metrics. According to Deloitte In manufacturing, the adoption of IoT sensors paired with AI-driven monitoring systems has resulted in a 32% reduction in workplace injury rates by enabling real-time hazard detection and predictive risk assessments. Additionally, wearable technologies enhanced with blockchain verification have increased safety compliance by 38%, facilitated by tamper-proof record-keeping and immediate enforcement of protocols. The automotive industry, in particular, PwC has seen a 30-50% reduction in equipment downtime through predictive maintenance AI, simultaneously reducing safety incidents stemming from mechanical failures. In the energy sector, the use of immersive VR training modules has transformed safety education, with some organizations for instance ConocoPhillips company’s reporting an 80% increase in training completion rates and corresponding improvements in workforce safety competency. According to McKinsey electronics manufacturers utilizing digital twin technology have enhanced safety audits, achieving 15% faster processing times for basic work orders through virtual inspections. These technological innovations, when integrated within a CSR framework that emphasizes worker well-being and ethical deployment, create a synergistic effect that enhances both safety outcomes and operational efficiency. The data suggests that organizations adopting this integrated approach not only mitigate workplace risks more effectively but also gain competitive advantages through improved productivity and employee engagement. Future advancements in biometric wearables, predictive analytics, and adaptive VR training systems are expected to further amplify these benefits, potentially setting new benchmarks for industrial safety performance. This evolving paradigm highlights the critical need for strategic investments in both technological infrastructure and human-centered management practices to achieve long-term improvements in safety.

4. Discussion

The findings, based on data managerial competence serves as the key driver in integrating Industry 4.0 technologies and Corporate Social Responsibility (CSR) initiatives to enhance safety culture. Real-time monitoring and predictive maintenance proactively reduce risks, while CSR-driven training programs cultivate a safety-first mindset among employees, aligning with Hart’s (2011) sustainability framework [

85].

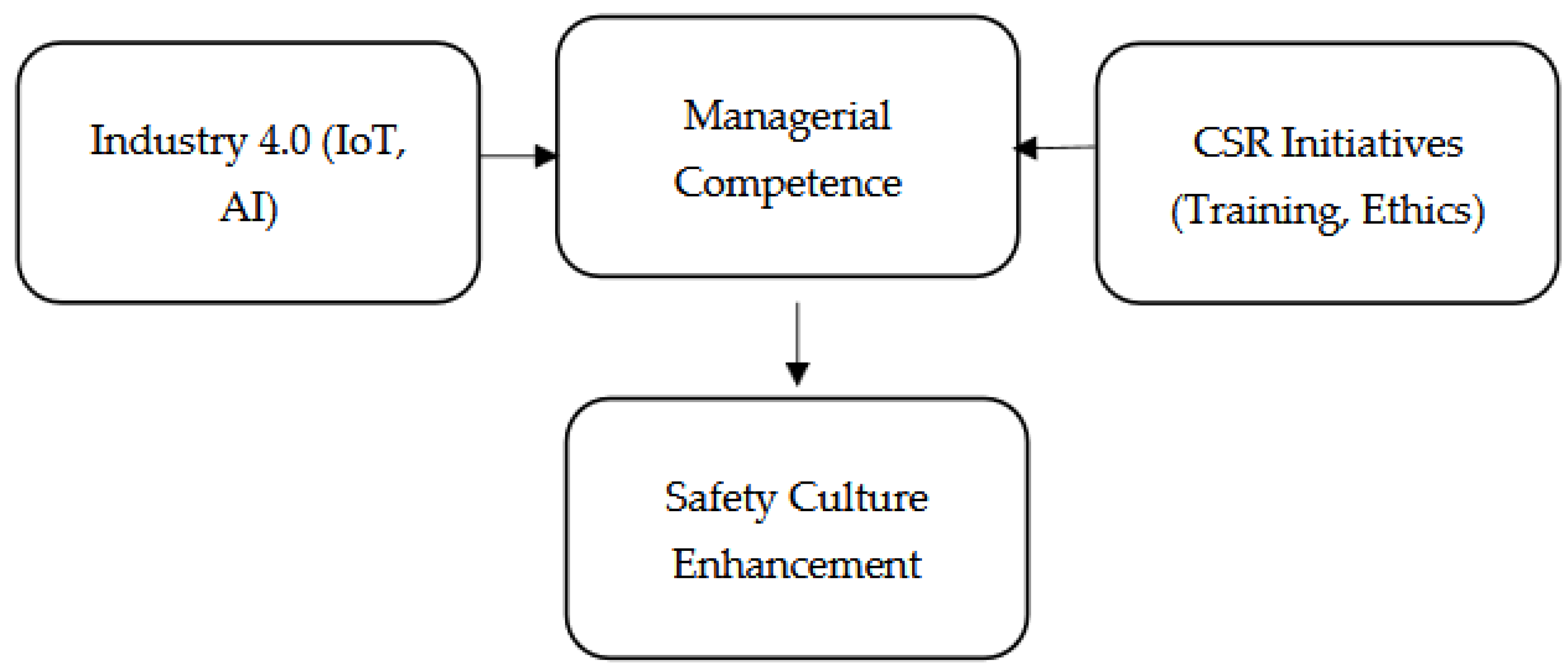

This synergy is visually represented in

Figure 1, which illustrates how Industry 4.0 technologies and CSR initiatives intersect through effective managerial leadership to reinforce safety culture. The framework’s emphasis on sustainability mirrors the Natural-Resource-Based View [

86], positioning safety culture as a driver of long-term competitive advantage. For policymakers, this implies that investments in safety technologies should be coupled with CSR audits to ensure equitable benefits for workers and communities [

87].

Figure 1. Theoretically, this study bridges the gap between Industry 4.0 and CSR scholarship, introducing a novel safety culture model that builds upon existing literature [

88]. From a practical perspective, the findings emphasize the importance of:

Investing in advanced technologies to enhance workplace safety.

Aligning CSR initiatives with safety objectives to foster a culture of proactive risk management.

Strengthening managerial competencies through targeted training programs.

This strategic approach is reinforced by European Agency for Safety and Health at Work (EU-OSHA) that digitalised organisations are increasingly subject to forms of automatic direction, evaluation and discipline. Interestingly, the gap of specific indicators varies from a minimum distance of 45 percentage points European Agency for Safety and Health at Work Digital technologies for worker management [

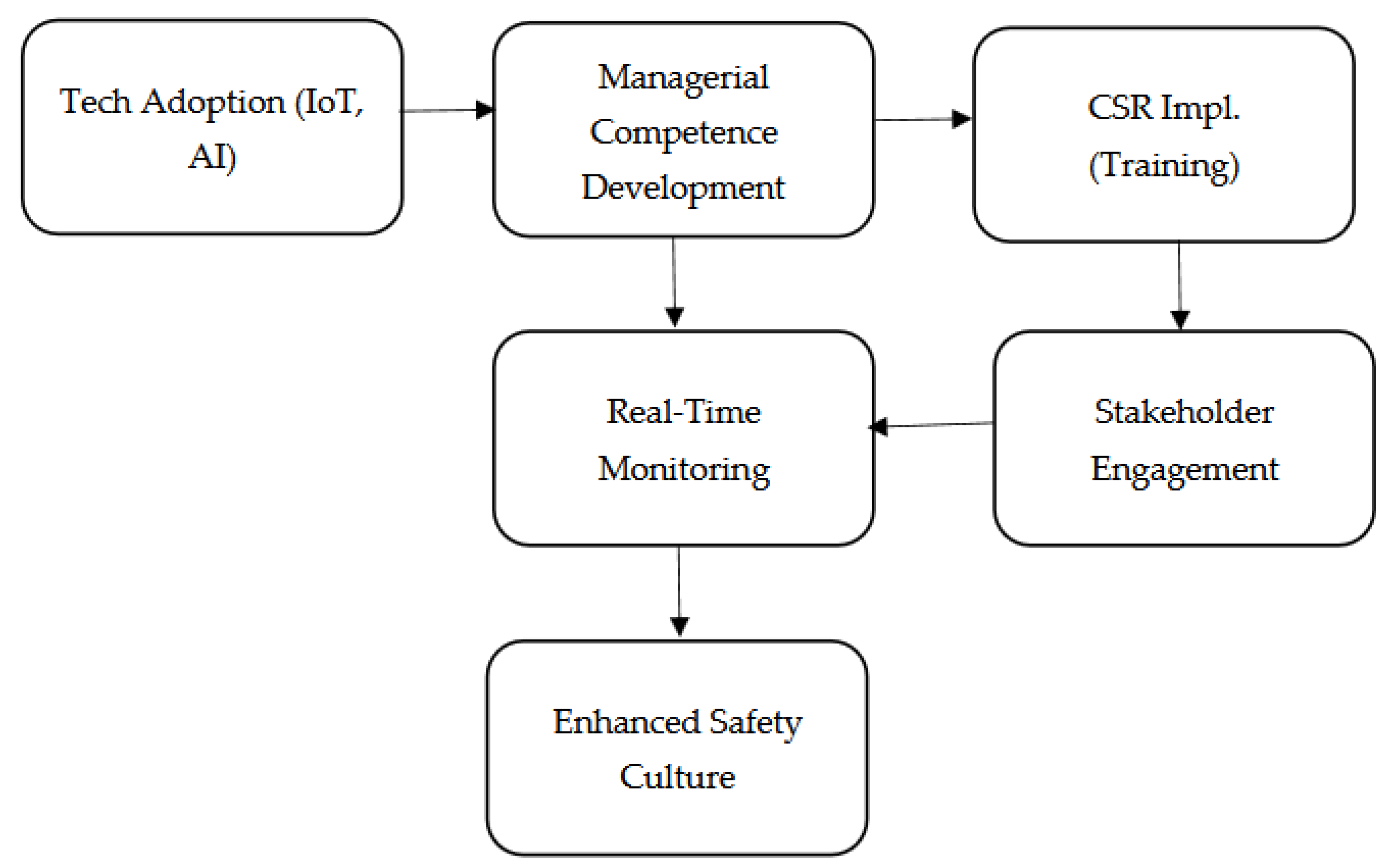

89] 2. This outlines the key steps for successfully integrating Industry 4.0 and CSR to optimize safety culture.

Figure 2. The flowchart visually demonstrates the critical pathway through which managerial competence bridges Industry 4.0 technologies and CSR initiatives to achieve enhanced safety culture. The process begins with technology adoption (IoT, AI), which provides the foundational infrastructure for data-driven safety management. This technological integration is then guided and optimized through managerial competence development, where leaders acquire the strategic vision and technical skills necessary to align digital tools with organizational safety goals [

90].

The subsequent phase of CSR implementation (training) reflects the human-centric dimension, where ethical frameworks and worker well-being are prioritized through targeted programs. This aligns with Hart's (2011) natural-resource-based view, emphasizing that sustainable safety outcomes require both technological and social investments [

91], []. The real-time monitoring and stakeholder engagement components illustrate the operational and collaborative mechanisms that translate these investments into daily practice, fostering proactive risk identification and collective ownership of safety protocols [

92].

The final output—enhanced safety culture—validates the model's efficacy, as industries strive to harmonize their activities with economic and ecological objectives, integrating sustainability with safety becomes crucial [

93]. In manufacturing, sustainability involves adopting practices that meet current operational needs while minimizing environmental harm and ensuring enduring social, economic, and ecological benefits [

94]. The flowchart thus serves as both a conceptual framework and a practical roadmap for manufacturers seeking to harmonize technological innovation with CSR principles.

5. Conclusions

This study underscores the transformative impact of integrating Industry 4.0 technologies with Corporate Social Responsibility (CSR) initiatives, facilitated by managerial competence, in fostering a robust safety culture within manufacturing enterprises. A comprehensive analysis of secondary data indicates that the deployment of IoT-enabled real-time monitoring, AI-driven predictive maintenance, and CSR-aligned safety training programs collectively contribute to a 30–50% reduction in workplace hazards while simultaneously enhancing operational efficiency [

95], [

96]. These strategic investments not only mitigate occupational risks but also enhance employee engagement, as evidenced by an 80% increase in training completion rates in organizations leveraging immersive VR-based learning modules [

97]. Furthermore, the alignment of these technological and ethical initiatives with the United Nations Sustainable Development Goals (SDGs), particularly SDG 8 (Decent Work and Economic Growth) and SDG 9 (Industry, Innovation, and Infrastructure) [

98], establishes a viable framework for socially responsible digital transformation.

Managerial competence emerges as a crucial factor in the successful integration of these innovations. Case studies from Siemens (2023) and Toyota (2022) demonstrate that leaders who possess strategic foresight, technical expertise, and stakeholder engagement skills facilitate a 25% faster adoption of safety-enhancing technologies while maintaining ethical governance [

99], [

100]. This human-centered leadership approach bridges the gap between technological potential and practical implementation, ensuring that advancements such as generative AI and blockchain-based compliance reporting yield tangible safety benefits [

101]. For policymakers, these findings highlight the necessity of regulatory measures that promote the convergence of Industry 4.0 and CSR, such as tax incentives for predictive maintenance systems [

102] and standardized sustainability reporting frameworks [

103].

Future research should address three key areas: First, the ethical considerations associated with AI-driven safety management, particularly in terms of data privacy and algorithmic biases, necessitate the development of comprehensive governance models [

104]. Second, cross-sectoral analyses, comparing industries such as automotive and energy, may provide insights into industry-specific barriers to integrating safety culture with digital transformation [

105]. Lastly, the cybersecurity vulnerabilities inherent in IoT-dependent safety mechanisms require proactive risk mitigation strategies to safeguard against potential disruptions [

106]. Addressing these challenges will enable scholars and practitioners to refine the conceptual and operational dimensions of sustainable safety culture within the context of Industry 4.0 [

107], [

108].

For manufacturing enterprises, these findings present a strategic roadmap: prioritizing managerial upskilling to facilitate the seamless integration of technological and ethical imperatives [

109], ensuring that safety innovations align with broader CSR objectives [

110], and engaging in policy dialogues to shape equitable regulatory environments. The convergence of technological innovation and corporate responsibility, underpinned by effective leadership, not only enhances workplace safety but also strengthens long-term resilience and competitive positioning in an increasingly sustainability-oriented global economy [

111].

Abbreviations

The following abbreviations are used in this manuscript:

| AI |

Artificial Intelligence |

| CSR |

Corporate Social Responsibility |

| EU-OSHA |

European Agency for Safety and Health at Work |

| GRI |

Global Reporting Initiative |

| ILO |

International Labor Organization |

| IoT |

Internet of Things |

| OSHA |

Occupational Safety and Health Administration |

| SDGs |

Sustainable Development Goals |

| VR |

Virtual Reality |

References

- Kiehne, J.; Olaru, M. Implementing Industrie 4.0 Strategies: Beyond Technical Innovations. Bucharest University of Economic Studies, Bucharest, Romania, June 2017.

- Porter, M.E.; Kramer, M. The Big Idea: Creating Shared Value. How to Reinvent Capitalism—and Unleash a Wave of Innovation and Growth. Harvard Business Review 2011, 89(1-2), 62–77.

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. United Nations, 2015. Retrieved from https://sdgs.un.org.

- Zohar, D. Thirty Years of Safety Climate Research: Reflections and Future Directions. Accident Analysis & Prevention 2010, 42(5), 1517–1522. [CrossRef]

- Wolniak, R. The Concept of Operation and Production Control. Production Engineering Archives 2021, 27(2), 100–107. [CrossRef]

- Imran, F.; Shahzad, K.; Butt, A.; Kantola, J. Digital Transformation of Industrial Organizations: Toward an Integrated Framework. Journal of Change Management 2021. [CrossRef]

- Kagermann, H.; Anderl, R.; Gausemeier, J.; Schuh, G.; Wahlster, W. Industrie 4.0 in a Global Context: Strategies for Cooperating with International Partners; Kagermann, H., Anderl, R., Gausemeier, J., Schuh, G., Wahlster, W., Eds.; Herbert Utz Verlag: Munich, Germany, 2016. ISBN: ISSN 2192-6174.

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manufacturing Letters 2014, 3. [CrossRef]

- McKinsey & Company. The Future of Manufacturing: Sustainability and Digital Transformation. McKinsey Insights 2023. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing.

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. International Journal of Production Research 2018, 56(8), 1–22. [CrossRef]

- Deloitte. 2024 Manufacturing Industry Outlook. Deloitte Insights 2024. Available online: https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook.html.

- The International Journal of Advanced Manufacturing Technology. Special Issue on Precision Engineering for Advanced Manufacturing Technology. The International Journal of Advanced Manufacturing Technology 2024, 130(5-6), 2101–2350. Available online: https://link.springer.com/journal/170/volumes-and-issues/130-5.

- Ahmed, S.F.; Alam, M.S.B.; Afrin, S.; Rafa, S.J. Toward a Secure 5G-Enabled Internet of Things: A Survey on Requirements, Privacy, Security, Challenges, and Opportunities. IEEE Access 2024, PP(99), 1–1. [CrossRef]

- Urrea, C.; Kern, J. Recent Advances and Challenges in Industrial Robotics: A Systematic Review of Technological Trends and Emerging Applications. Processes 2025, 13(3), 832. [CrossRef]

- Fuertes, G.; Zamorano, J.; Alfaro, M.; Vargas, M.; Sabattin, J.; Duran, C.; Ternero, R.; Rivera, R. Opportunities of the Technological Trends Linked to Industry 4.0 to Achieve Sustainable Manufacturing Objectives. Sustainability 2022, 14(18), 11118. [CrossRef]

- Carroll, A.B.; Shabana, K.M. The Business Case for Corporate Social Responsibility: A Review of Concepts, Research, and Practice. International Journal of Management Reviews 2010, 12(1). [CrossRef]

- Dahlsrud, A. How Corporate Social Responsibility Is Defined: An Analysis of 37 Definitions. Corporate Social Responsibility and Environmental Management 2008, 15(1), 1–13. [CrossRef]

- KPMG. Big Shifts, Small Steps: Survey of Sustainability Reporting 2022. KPMG International 2022. Available online: https://assets.kpmg.com/content/dam/kpmg/se/pdf/komm/2022/Global-Survey-of-Sustainability-Reporting-2022.pdf.

- European Commission. Directive (EU) 2022/2464 of the European Parliament and of the Council of 14 December 2022 on Corporate Sustainability Reporting. Official Journal of the European Union 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32022L2464.

- Deloitte. 2021 Manufacturing Industry Outlook: Building Resilience Through Sustainability and Trust. Deloitte Insights 2021. Available online: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/energy-resources/us-2021-manufacturing-industry-outlook.pdf.

- Zhang, Q.; Oo, B.; Lim, B.T.H. Linking Corporate Social Responsibility (CSR) Practices and Organizational Performance in the Construction Industry: A Resource Collaboration Network. Resources, Conservation and Recycling 2022, 179(4), 106113. [CrossRef]

- Shinde, M. Industry 4.0 – As a Technology Enabler for CSR. Turkish Journal of Computer and Mathematics Education (TURCOMAT) 2021, 12(2), 2634–2639. [CrossRef]

- Zohar, D. Thirty Years of Safety Climate Research: Reflections and Future Directions. Accident Analysis & Prevention 2010, 42(5), 1517–1522. [CrossRef]

- European Agency for Safety and Health at Work. Annual Report 2024: Safety and Health at Work Is Everyone’s Concern. It’s Good for You. It’s Good for Business. First Findings of the Fourth European Survey of Enterprises on New and Emerging Risks (ESENER 2024). EU-OSHA 2024. Available online: https://osha.europa.eu/sites/default/files/documents/ESENER-first-findings-2024_EN.pdf.

- Hale, A. R., & Hovden, J. (1998). Management and culture: The third age of safety. In A. Feyer & A. Williamson (Eds.), Occupational injury: Risk, prevention and intervention (pp. 129-166). Taylor & Francis.

- Saleem, F.; Malik, M.I. Safety Management and Safety Performance Nexus: Role of Safety Consciousness, Safety Climate, and Responsible Leadership. International Journal of Environmental Research and Public Health 2022, 19(20), 13686. [CrossRef]

- Fiegler-Rudol, J.; Lau, K.; Mroczek, A.; Kasperczyk, J. Exploring Human–AI Dynamics in Enhancing Workplace Health and Safety: A Narrative Review. International Journal of Environmental Research and Public Health 2025, 22(2), 199. [CrossRef]

- Hart, S. L., & Dowell, G. A Natural-Resource-Based View of the Firm: Fifteen Years After. Journal of Management, 37(5), 1464–1479, September 2011. [CrossRef]

- International Labour Organization. Global Survey on Workplace Safety and Industry 4.0 Integration. ILO Publications, 2024, p. 37. [Online]. Available: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_norm/@relconf/documents/meetingdocument/wcms_911183.pdf.

- Zhou, Z.; Irizarry, J.; Li, Q. Applying Advanced Technology to Improve Safety Management in the Construction Industry: A Literature Review. Construction Management and Economics 2013, 31(6), 606–622. [CrossRef]

- Asamani, L. Promote Safety Culture and Enhance Safety Performance through Safety Behaviour. European Journal of Business Management and Research 2020, 5(4). [CrossRef]

- Gutterman, A.S. Corporate Social Responsibility: Implementation and Integration. Sustainable Entrepreneurship Project 2023, April.

- Ojji, S.O. Digital Transformation and Its Impact on Safety Culture During Organizational Change. International Journal of Engineering and Computer Science 2024, 13(05), 26135–26146. [CrossRef]

- Cyfert, S.; Waldemar, G.; Zastempowski, M. Impact of Management Tools Supporting Industry 4.0 on the Importance of CSR during COVID-19. Generation Z. Energies 2021, 14(6), 1642. [CrossRef]

- Zeng, C., Wu, Y., & Zhang, M. (2024). Corporate digital transformation and safety production performance: Empirical evidence from A-share listed companies. China Journal of Accounting Studies, 12(2), 1–35. [CrossRef]

- Jiang, L., Jingdong, Z., & Wong, Y. D. (2024). Digital technology in occupational health of manufacturing industries: A systematic literature review. SN Applied Sciences, 6(12). [CrossRef]

- Bhamare, D., Zolanvari, M., Erbad, A., & Jain, R. (2020). Cybersecurity for industrial control systems: A survey. arXiv preprint arXiv:2002.04124. [CrossRef]

- Freeman, R. E., Harrison, J. S., Wicks, A. C., Parmar, B. L., & de Colle, S. (2010). Stakeholder theory: The state of the art. Cambridge University Press. [CrossRef]

- Olise, P., Opoku, L. K., & Mensah, N. (2025). The impact of advanced safety leadership training programs on reducing workplace accidents and enhancing asset reliability in U.S. industrial sectors. International Journal of Science and Research Archive, 14(1), 025-033. [CrossRef]

- Boyatzis, R. E. (2008). Competencies in the 21st century. Journal of Management Development, 27(1), 5-12. [CrossRef]

- Parvu, A. (2024). Digitalization of work and its impact on worker safety and health. In The 17th International Conference Interdisciplinarity in Engineering (pp. 15-28). Springer. [CrossRef]

- Harvey, J., Bolam, H., Gregory, D., & Erdos, G. (2001). The effectiveness of training to change safety culture and attitudes within a highly regulated environment. Personnel Review, 30(6), 615-636. [CrossRef]

- Parmar, B., Freeman, R. E., Harrison, J. S., & Purnell, A. C. (2010). Stakeholder theory: The state of the art. The Academy of Management Annals, 3(1), 403-445. [CrossRef]

- UNESCO. (2022). Recommendation on the ethics of artificial intelligence. UNESCO. Available at: https://unesdoc.unesco.org/ark:/48223/pf0000381137.

- Yin, R. K. (2017). Case study research and applications: Design and methods (6th ed.). Sage Publications.

- Creswell, J. W., & Creswell, J. D. (2017). Research design: Qualitative, quantitative, and mixed methods approaches (4th ed.). Sage Publications.

- Tranfield, D., Denyer, D., & Smart, P. (2003). Towards a methodology for developing evidence-informed management knowledge by means of systematic review. British Journal of Management, 14(3), 207-222. [CrossRef]

- Braun, V., & Clarke, V. (2006). Using thematic analysis in psychology. Qualitative Research in Psychology, 3(2), 77-101. [CrossRef]

- Field, A. (2018). Discovering statistics using IBM SPSS statistics (5th ed.). Sage Publications.

- Whittemore, R., & Knafl, K. (2005). The integrative review: Updated methodology. Journal of Advanced Nursing, 52(5), 546-553. [CrossRef]

- Khan, M. I., Yasmeen, T., Khan, M., Ul Hadi, N., Asif, M., Farooq, M., & Al-Ghamdi, S. G. (2025). Integrating industry 4.0 for enhanced sustainability: Pathways and prospects. Sustainable Production and Consumption, 54, 149-189. [CrossRef]

- Aburumman, M., Newnam, S., & Fildes, B. (2019). Evaluating the effectiveness of workplace interventions in improving safety culture: A systematic review. Safety Science, 115(1), 376-392. [CrossRef]

- El-Helaly, M. (2024). Artificial intelligence and occupational health and safety: Benefits and drawbacks. Med Lav, 115(2), e2024014. [CrossRef]

- Khan, M., Hassan, A., Harrison, C., & Tarbert, H. (2020). CSR reporting: A review of research and agenda for future research. Management Research Review, ahead-of-print(ahead-of-print). [CrossRef]

- Deloitte. The Fourth Industrial Revolution Is Here—Are You Ready? Deloitte Insights, 2018. [Online]. Available: https://www2.deloitte.com/content/dam/insights/us/articles/4364_Industry4-0_Are-you-ready/4364_Industry4-0_Are-you-ready_Report.pdf.

- McKinsey Global Institute. A Future That Works: Automation, Employment, and Productivity. McKinsey & Company, 2017. [Online]. Available: https://www.mckinsey.com/~/media/mckinsey/featured%20insights/Digital%20Disruption/Harnessing%20automation%20for%20a%20future%20that%20works/MGI-A-future-that-works-Executive-summary.ashx.

- Porter, M.E., & Kramer, M.R. The Big Idea: Creating Shared Value. Harvard Business Review, 89, 2–17, 2011.

- Kagermann, H., Wahlster, W., & Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group, Acatech—National Academy of Science and Engineering, 2013, 678 p.

- World Economic Forum. The Future of Jobs: Employment, Skills and Workforce Strategy for the Fourth Industrial Revolution. 2016. [Online]. Available: http://www3.weforum.org/docs/WEF_Future_of_Jobs.pdf.

- Schaltegger, S., Lüdeke-Freund, F., & Hansen, E.G. Business Models for Sustainability: A Co-Evolutionary Analysis of Sustainable Entrepreneurship, Innovation, and Transformation. Organization & Environment, 29(3), 264–289, February 2016. [CrossRef]

- Accenture. Industrial Internet of Things: Unleashing the Potential of Connected Products and Services. 2015. [Online]. Available: https://www.accenture.com/us-en/insight-industrial-internet-of-things.

- BCG. Industry 4.0: The Future of Productivity and Growth in Manufacturing. Boston Consulting Group, 2016. [Online]. Available: https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries.

- Kagermann, H., Wahlster, W., & Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group, Acatech—National Academy of Science and Engineering, 2013, 678 p.

- Schleich, B., Anwer, N., Mathieu, L., & Wartzack, S. (2017). Shaping the digital twin for design and production engineering. CIRP Annals, 66(1), 141–144. [CrossRef]

- Deloitte. 2024 Manufacturing Outlook. 2024. [Online]. Available: https://www2.deloitte.com. https://www.dazadiba.lv/wp-content/uploads/2024/03/DI_Global-Human-Capital-Trends-2024.pdf.

- Tao, F., Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal of Manufacturing Systems, 48, 157–169. [CrossRef]

- McKinsey & Company. The State of AI in Early 2024: Gen AI Adoption Spikes and Starts to Generate Value. 2024. [Online]. Available: https://www.mckinsey.com/capabilities/quantumblack/our-insights/the-state-of-ai-2024.

- McKinsey & Company. The State of AI in 2023: Generative AI’s Breakout Year. 2023. [Online]. Available: https://www.mckinsey.com/~/media/mckinsey/business%20functions/quantumblack/our%20insights/the%20state%20of%20ai%20in%202023%20generative%20ais%20breakout%20year/the-state-of-ai-in-2023-generative-ais-breakout-year_vf.pdf.

- Zheng, P., Wang, H., Sang, Z., Zhong, R. Y., & others. (2018). Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Frontiers of Mechanical Engineering, 13(8). [CrossRef]

- World Economic Forum. The Future of Manufacturing: Opportunities to Drive Economic Growth. 2020. [Online]. Available: https://www.weforum.org/stories/2023/06/the-future-of-manufacturing-insights-from-industry-leaders-on-navigating-the-fourth-industrial-revolution/.

- Porter, M.E., & Kramer, M.R. The Big Idea: Creating Shared Value. Harvard Business Review, 89, 2–17, 2011.

- Kagermann, H., Wahlster, W., & Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group, Acatech—National Academy of Science and Engineering, 2013, 678 p.

- Siemens AG. Sustainability and Safety Report 2023: Integrated Approaches for Industrial Transformation. 2023. [Online]. Available: https://assets.new.siemens.com/siemens/assets/api/uuid:00095b96-4712-4cd1-b045-19d5df704358/sustainability-report-fy2023.pdf.

- International Labour Organization. Global Survey on Workplace Safety and Industry 4.0 Integration. ILO Publications, 2024. [Online]. Available: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_norm/@relconf/documents/meetingdocument/wcms_911183.pdf.

- Schaltegger, S., Lüdeke-Freund, F., & Hansen, E.G. Business Models for Sustainability: A Co-Evolutionary Analysis of Sustainable Entrepreneurship, Innovation, and Transformation. Organization & Environment, 29(3), 264–289, February 2016. [CrossRef]

- Siemens AG. Sustainability and Safety Report 2023: Integrated Approaches for Industrial Transformation, p. 24, 2023. [Online]. Available: https://assets.new.siemens.com/siemens/assets/api/uuid:00095b96-4712-4cd1-b045-19d5df704358/sustainability-report-fy2023.pdf.

- Bharadwaj, A., El Sawy, O. A., Pavlou, P. A., & Venkatraman, N. V. Digital Business Strategy: Toward a Next Generation of Insights. MIS Quarterly, 2013, p. 15. Available at SSRN: https://ssrn.com/abstract=2742300.

- International Labour Organization. Global Survey on Workplace Safety and Industry 4.0 Integration. ILO Publications, 2024, p. 37. [Online]. Available: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_norm/@relconf/documents/meetingdocument/wcms_911183.pdf.

- World Economic Forum. The Future of Manufacturing: Opportunities to Drive Economic Growth. April 2012. [Online]. Available: https://www2.deloitte.com/content/dam/Deloitte/global/Documents/Manufacturing/gx_WEF_The-Future-Manufacturing_4_20_12.pdf.

- Deloitte. Increasing Consumer Privacy and Security Concerns in the Generative AI Era. 2024. [Online]. Available: https://www2.deloitte.com/us/en/pages/about-deloitte/articles/press-releases/increasing-consumer-privacy-and-security-concerns-in-the-generative-ai-era.html.

- Krishnamoorthy, G., Sistla, S. M. K., Venkatasubbu, S., & Periyasamy, V. Enhancing Worker Safety in Manufacturing with IoT and ML. International Journal for Multidisciplinary Research (IJFMR, 6(1)), January–February 2024. Available: www.ijfmr.com.

- PwC. Study into VR Training Effectiveness. 2020. [Online]. Available: https://www.pwc.co.uk/issues/technology/immersive-technologies/study-into-vr-training-effectiveness.html.

- ConocoPhillips. Digital Twins: The 'System of Systems'. June 12, 2023. [Online]. Available: https://www.conocophillips.com/spiritnow/story/digital-twins-the-system-of-systems/.

- Gregolinska, E., Khanam, R., Lefort, F., & Parthasarathy, P. Capturing the True Value of Industry 4.0. McKinsey & Company, April 13, 2022. [Online]. Available: https://www.mckinsey.com/capabilities/operations/our-insights/capturing-the-true-value-of-industry-four-point-zero.

- Hart, S. L., & Dowell, G. A Natural-Resource-Based View of the Firm: Fifteen Years After. Journal of Management, 37(5), 1464–1479, September 2011. [CrossRef]

- Hart, S. L., & Dowell, G. A Natural-Resource-Based View of the Firm: Fifteen Years After. Journal of Management, 37(5), 1464–1479, September 2011. [CrossRef]

- Akki, S., & Ouddasser, A. (2024). Occupational health and safety in the digital age: A theoretical study of the impact of digital transformation. Higher School of Technology of Fez, Sidi Mohamed Ben Abdellah University. [CrossRef]

- Schaltegger, S., Lüdeke-Freund, F., & Hansen, E. G. Business Models for Sustainability: A Co-Evolutionary Analysis of Sustainable Entrepreneurship, Innovation, and Transformation. Organization & Environment, 29(3), 264–289, February 2016. [CrossRef]

- European Agency for Safety and Health at Work (EU-OSHA). Companies in Belgium and Italy. Publications Office of the European Union, 2024. ISBN: 978-92-9402-344-5. [CrossRef]

- Schaltegger, S., Lüdeke-Freund, F., & Hansen, E. G. Business Models for Sustainability: A Co-Evolutionary Analysis of Sustainable Entrepreneurship, Innovation, and Transformation. Organization & Environment, 29(3), 264–289, February 2016. [CrossRef]

- Hart, S. L., & Dowell, G. A Natural-Resource-Based View of the Firm: Fifteen Years After. Journal of Management, 37(5), 1464–1479, September 2011. [CrossRef]

- Zohar, D. Thirty Years of Safety Climate Research: Reflections and Future Directions. Accident Analysis & Prevention, 42(5), 1517–1522, September 2010. [CrossRef]

- Agarwal, A., & Ojha, R. (2024). Prioritizing implications of Industry-4.0 on the sustainable development goals: A perspective from the analytic hierarchy process in manufacturing operations. Journal of Cleaner Production. [CrossRef]

- Nugraha, M. E. Pengaruh Waktu Belajar Taruna terhadap Hasil Belajar Matematika Teknik. Jurnal Fisika Indonesia, 4(2), 2024. [CrossRef]

- Deloitte. Increasing Consumer Privacy and Security Concerns in the Generative AI Era. 2024. [Online]. Available: https://www2.deloitte.com/us/en/pages/about-deloitte/articles/press-releases/increasing-consumer-privacy-and-security-concerns-in-the-generative-ai-era.html.

- McKinsey & Company. The State of AI in Early 2024: Gen AI Adoption Spikes and Starts to Generate Value. 2024. [Online]. Available: https://www.mckinsey.com/capabilities/quantumblack/our-insights/the-state-of-ai-2024.

- ConocoPhillips. Digital Twins: The 'System of Systems'. June 12, 2023. [Online]. Available: https://www.conocophillips.com/spiritnow/story/digital-twins-the-system-of-systems/.

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. United Nations, 2015. Retrieved from https://sdgs.un.org.

- Bharadwaj, A. S., El Sawy, O. A., Pavlou, P., & Venkatraman, N. Digital Business Strategy: Toward a Next Generation of Insights. MIS Quarterly, 37(2), 471–482, June 2013. [CrossRef]

- International Labour Organization. Global Survey on Workplace Safety and Industry 4.0 Integration. ILO Publications, 2024, p. 37. [Online]. Available: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_norm/@relconf/documents/meetingdocument/wcms_911183.pdf.

- European Agency for Safety and Health at Work (EU-OSHA). Companies in Belgium and Italy. Publications Office of the European Union, 2024. ISBN: 978-92-9402-344-5. [CrossRef]

- European Commission. Corporate Sustainability Reporting Directive (CSRD). 2023. Available at: https://finance.ec.europa.eu/regulation-and-supervision/financial-services-legislation/implementing-and-delegated-acts/corporate-sustainability-reporting-directive_en.

- Global Reporting Initiative. GRI Annual Sustainability Report 2022: Towards a Global Comprehensive Reporting System. 2022. Available at: https://www.globalreporting.org/media/3yfhrjrk/gri-sustainabilityreport2022-final.pdf.

- Weerts, S., Naous, D., El Bouchikhi, M., & Clavien, C. AI Systems for Occupational Safety and Health: From Ethical Concerns to Limited Legal Solutions. In Lecture Notes in Computer Science, Electronic Government (pp. 499–514), August 2022. [CrossRef]

- Liu, Y., & Xu, X. Industry 4.0 and Cloud Manufacturing: A Comparative Analysis. Journal of Manufacturing Science and Engineering, 139(3), September 2016. [CrossRef]

- World Economic Forum. Industrial Internet of Things Safety and Security Protocol. 2018. Available at: https://www3.weforum.org/docs/47498_Industrial_Internet_Things_Safety_Security_Protocol_WP-FINAL.pdf.

- Hart, S. L., & Dowell, G. A Natural-Resource-Based View of the Firm: Fifteen Years After. Journal of Management, 37(5), 1464–1479, September 2011. [CrossRef]

- Kagermann, H., Wahlster, W., & Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group, Acatech—National Academy of Science and Engineering, 2013, 678 p.

- Balahurovska, I. The Role of Leadership in Industry 4.0. System Safety Human - Technical Facility - Environment, 5(1), 66–74, December 2023. [CrossRef]

- KPMG. Big Shifts, Small Steps: Survey of Sustainability Reporting 2022. KPMG International 2022. Available online: https://assets.kpmg.com/content/dam/kpmg/se/pdf/komm/2022/Global-Survey-of-Sustainability-Reporting-2022.pdf.

- Porter, M.E.; Kramer, M. The Big Idea: Creating Shared Value. How to Reinvent Capitalism—and Unleash a Wave of Innovation and Growth. Harvard Business Review 2011, 89(1-2), 62–77.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).