Submitted:

30 March 2025

Posted:

31 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Case Study Scenario

- -

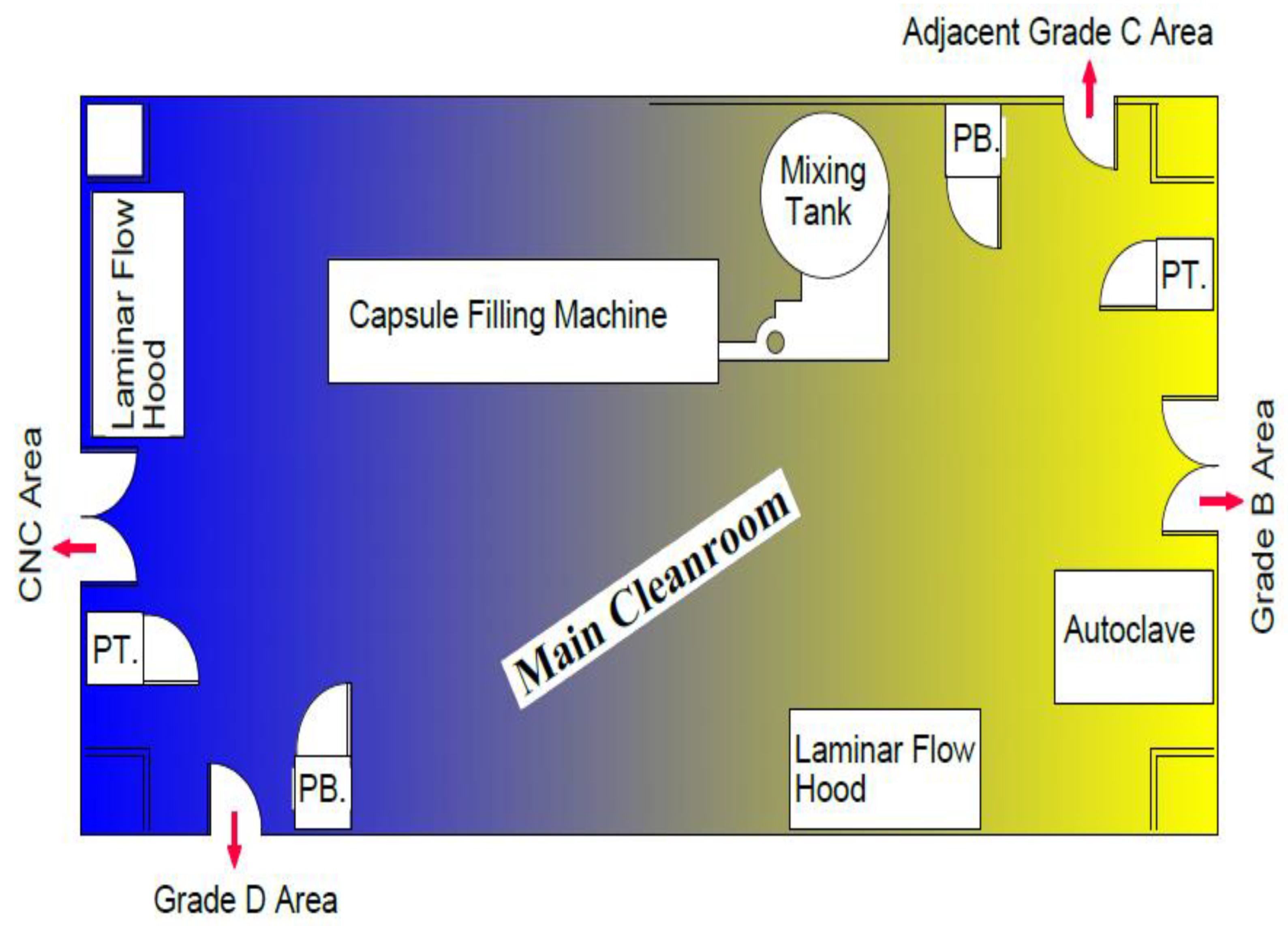

- -Design Basis: Location: Central Tehran, Iran (ASHRAE Zone 4B). Summer Design: 100.4°F dry bulb, 66.2°F wet bulb. Winter Design: 23°F dry bulb. Barometric Pressure: 26.4 inHg (elevation: 3900 ft above sea level). Dew Point: 55°F (typical summer). Cleanroom: Grade C (ISO 7), 9155 ft² (43.2 ft × 21.6 ft × 9.8 ft height, adjusted for 108 ft² ducting space), volume 89,719 ft³. Conditions: 68±3.6°F, 45% RH. Pressure Target: 0.06 inWG relative to CNC area (0.02 inWG).

- -

- Components: Doors: 2 double doors: 5.9 ft × 5.9 ft (34.8 ft² each). 2 single doors: 2.95 ft × 5.9 ft (17.4 ft² each). Connections: Grade B (0.1 inWG), Grade D (0.04 inWG), CNC (0.02 inWG), adjacent Grade C (0.06 inWG). Passboxes: 2 units (1.64 ft × 1.64 ft each): static (to Grade D), dynamic (to adjacent C). Passthroughs: 2 units (2.95 ft × 3.94 ft each): to CNC, adjacent C. Laminar Flow Hoods: 2 units, each exhausting 500 CFM. Pharmaceutical Equipment: 1 Capsule Filling Machine (5 hp, 3.73 kW heat load). 1 Mixing Tank (3 hp, 2.24 kW heat load). 1 Autoclave (10 hp, 7.46 kW heat load). Occupancy: 10 seated (100 Btu/h sensible, 100 Btu/h latent each). 5 standing/walking (150 Btu/h sensible, 150 Btu/h latent each). 5 transients (200 Btu/h sensible, 200 Btu/h latent each, 50% occupancy). Air Distribution: Supply: 40 swirl diffusers (1000 CFM each, total 40,000 CFM base). Return: 4 corner grilles (8000 CFM each) + 2 honeycomb ceiling (4000 CFM each), total 40,000 CFM. Exhaust: 2 vents, 10% fresh air (4000 CFM).

- -

| Parameter | Traditional | AI-Driven | Change (%) |

| Design Time | 22 days | 3 days | -86% |

| Airflow (CFM) | 71,890 | 55,420 | -23% |

| Fan Power (hp) | 37.6 | 22.8 | -39% |

| Pressure Accuracy | 90% (±0.006 inWG) | 96% (±0.002 inWG) | +6% |

| Ducting Cost (£) | 85,000 | 70,000 | -18% |

| Energy Use (hp) | 33.5 | 20.1 | -40% |

|

| State Description | Traditional Pressure (inWG) | AI-Driven Pressure (inWG) | Traditional Deviation (±inWG) | AI Deviation (±inWG) | Airflow Adjustment (CFM) |

| State 1: All closed | 0.060 | 0.060 | 0.000 | 0.000 | 0 |

| State 2: 1 double door (B) | 0.055 | 0.060 | -0.005 | 0.000 | +2355 |

| State 3: 2 double doors (B) | 0.052 | 0.061 | -0.008 | +0.001 | +4710 |

| State 4: 1 single door (D) | 0.058 | 0.060 | -0.002 | 0.000 | +1178 |

| State 5: 1 single door (CNC) | 0.062 | 0.059 | +0.002 | -0.001 | +1178 |

| State 6: Passbox to D | 0.061 | 0.060 | +0.001 | 0.000 | +18 |

| State 7: Passbox to C | 0.060 | 0.060 | 0.000 | 0.000 | 0 |

| State 8: Passthrough to CNC | 0.063 | 0.058 | +0.003 | -0.002 | +79 |

| State 9: Passthrough to C | 0.060 | 0.060 | 0.000 | 0.000 | 0 |

| State 10: 2 double + 1 single (D) | 0.050 | 0.062 | -0.010 | +0.002 | +5888 |

| State 11: 2 single (D + CNC) | 0.059 | 0.059 | -0.001 | -0.001 | +2356 |

| State 12: All doors open | 0.048 | 0.062 | -0.012 | +0.002 | +7066 |

| State 13: 1 double + Passbox (D) | 0.054 | 0.061 | -0.006 | +0.001 | +2373 |

| State 14: 1 single + Passthrough (CNC) | 0.064 | 0.058 | +0.004 | -0.002 | +1257 |

| State 15: 2 double + Passbox (C) | 0.051 | 0.061 | -0.009 | +0.001 | +4710 |

| State 16: All Passboxes + Passthroughs | 0.062 | 0.059 | +0.002 | -0.001 | +194 |

| State 17: 1 double + 1 single + Passbox (D) | 0.053 | 0.060 | -0.007 | 0.000 | +3551 |

| State 18: 2 single + Passthrough (CNC) | 0.065 | 0.058 | +0.005 | -0.002 | +2435 |

| State 19: All doors + 1 Passthrough | 0.047 | 0.063 | -0.013 | +0.003 | +7145 |

| State 20: Random (4 components open) | 0.066 | 0.057 | +0.006 | -0.003 | +4800 |

| Average | 0.0577 | 0.0599 | ±0.006 | ±0.002 | N/A |

2.2. Base Calculations

- -

-

Airflow (CFM):ACH Base: 25 (GMP Grade C).Base CFM: [Formula: CFM = (89,719 × 25) / 60 = 37,383 CFM].

- -

-

Leakage:Double door (34.8 ft² = 50,112 in²): [Formula: 50,112 × 0.047 = 2355 CFM].Single door (17.4 ft² = 25,056 in²): [Formula: 25,056 × 0.047 = 1178 CFM].Worst-case (all open): [Formula: (2 × 2355) + (2 × 1178) = 7066 CFM].Passbox (2.69 ft² = 387 in²): [Formula: 387 × 0.047 = 18 CFM].Passthrough (11.62 ft² = 1673 in²): [Formula: 1673 × 0.047 = 79 CFM].Total auxiliary (all open): [Formula: (2 × 18) + (2 × 79) = 194 CFM].

- -

- Hoods: [Formula: 2 × 500 = 1000 CFM]. Exhaust: 4000 CFM (10% fresh air).

- -

-

Occupancy Fresh Air (ASHRAE 62.1):seated: [Formula: 10 × 5 = 50 CFM].standing: [Formula: 5 × 7.5 = 37.5 CFM].transients (50%): [Formula: 5 × 10 × 0.5 = 25 CFM].Total: [Formula: 50 + 37.5 + 25 = 112.5 CFM (rounded to 120 CFM)].

- -

-

Cooling Load:Envelope: U = 0.088 Btu/h·ft²·°F, Area = 1270 ft², ΔT = 32.4°F[Formula: Q = 0.088 × 1270 × 32.4 = 3620 Btu/h].Equipment: [Formula: (3.73 + 2.24 + 7.46) × 3412 = 45,800 Btu/h].Occupancy: [Formula: (10 × 200) + (5 × 300) + (5 × 400 × 0.5) = 4500 Btu/h].Total: [Formula: 3620 + 45,800 + 4500 = 53,920 Btu/h ≈ 4.5 tons].Additional CFM: [Formula: 4.5 × 400 = 1800 CFM].

- -

-

Traditional (Worst-Case):[Formula: 37,383 + 7066 + 194 + 1000 + 4000 + 120 + 1800 = 51,563 CFM].With 20% safety factor: [Formula: 51,563 × 1.2 = 71,890 CFM].

- -

-

AI (Optimized): Average leakage: [Formula: (7066 + 194) / 2 = 3630 CFM].Total: [Formula: 37,383 + 3630 + 1000 + 4000 + 120 + 1800 = 47,933 CFM].With 15% adjustment: [Formula: 47,933 × 1.15 = 55,420 CFM].

- -

-

Fan Power: Traditional: [Formula: hp = (71,890 × 2) / (6356 × 0.8) = 28.3 hp].With 30% safety factor: [Formula: 28.3 × 1.3 = 37.6 hp].

- -

-

AI: [Formula: hp = (55,420 × 2) / (6356 × 0.8) = 21.8 hp].Optimized: 22.8 hp.

2.3. Proposed Method

3. Conclusions

References

- ISO 14644-1:2015, Cleanrooms and associated controlled environments — Part 1.

- Classification of air cleanliness by particle concentration, International Organization for Standardization.

- European Commission, EU GMP Annex 1: Manufacture of Sterile Medicinal Products, Revision 2022, Brussels.

- British Standards Institution, BS EN 16798-1:2019, Energy performance of buildings — Ventilation for buildings, BSI Standards Limited.

- Chen, S. (2017). Model Predictive Control of the HVAC System in Industrial Cleanrooms for Energy Saving, ProQuest Dissertations Publishing.

- ASHRAE, Handbook — HVAC Applications, Chapter 18: Clean Spaces, American Society of Heating, Refrigerating and Air-Conditioning Engineers, 2023.

- Loomans, M. et al. Experimental investigation into cleanroom contamination build-up. Building and Environment 2020, 182, 107–119. [Google Scholar]

- Nassif, N. Modeling and Optimization of HVAC Systems Using Artificial Intelligence Approaches. ASHRAE Transactions 2012, 118, 133–140. [Google Scholar]

- Wang, S. (2023). Intelligent Building Control Systems: HVAC, Lighting, and Security, Springer.

- ISO 14644-4:2001, Cleanrooms and associated controlled environments — Part 4: Design, construction and start-up, International Organization for Standardization.

- World Health Organization, Good Manufacturing Practices for Pharmaceutical Products, WHO Technical Report Series, 2021.

- Adelekan, D.S.; et al. Artificial intelligence models for refrigeration, air conditioning and heat pump systems. Energy Reports 2022, 8, 744–753. [Google Scholar] [CrossRef]

- Autodesk, Revit MEP User Guide, 2023 Edition, Autodesk Inc.

- Carrier Corporation, Hourly Analysis Program (HAP) Manual, Version 5.11, 2022.

- Ni, H. P., & Chou, J. S. Optimizing HVAC systems for semiconductor fabrication: a data-intensive framework. Journal of Building Engineering 2024, 82, 108–123.

- Zhang, L.; Wang, Y. AI-driven optimization of HVAC systems for energy efficiency. Energy and Buildings 2023, 280, 112–125. [Google Scholar]

- Kumar, R., et al. Machine learning applications in HVAC control systems: A comprehensive review. Renewable and Sustainable Energy Reviews 2023, 170, 111–130.

- Krarti, M. (2022). Artificial Intelligence for Building Energy Analysis, CRC Press.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).