Components and Functions

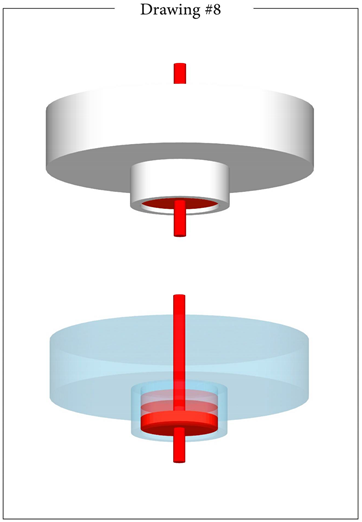

These vertically-aligned air-filled cylinders with movable pistons can have two solutions:

First solution:

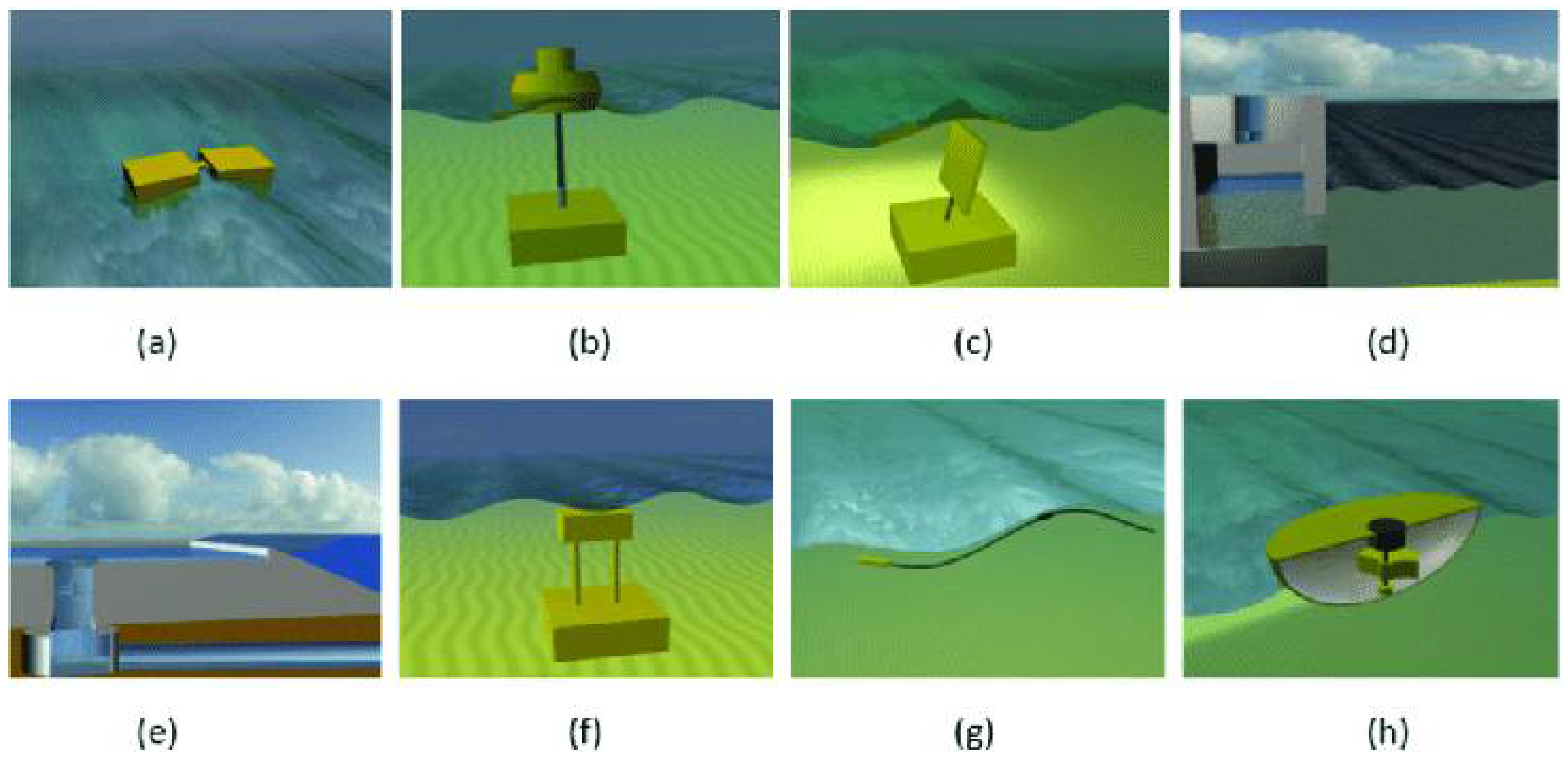

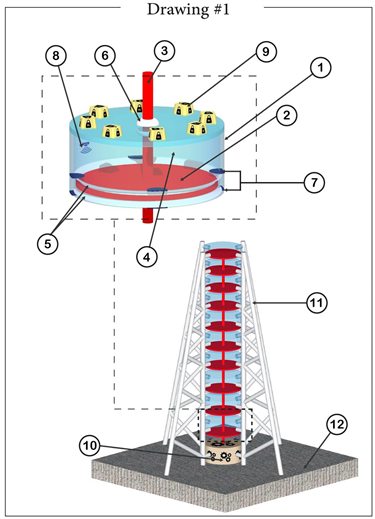

These cylinders have specific quantitative reduced volumes form bottom to top, each one has pressurized air as per its depth average equilibrium, and all of them has the same area and same piston area too, they are vertically stacked over each other, (As shown in figure 3. drawing #1)

Second solution:

These cylinders have the same volume and cap area, and each one is pressurized to the targeted level as per its designated depth, but since each one is located at different depth, then each one will do different work and exert different force on its piston with different displacement, and in order to unify this displacements, we will quantitatively reduce the area of each piston from top to bottom in order for all pistons to do different works but to produce same displacement, the different forces produces in this setup will not impose any hurdle since the design utilizes the displacement only, (As shown in figure 3. drawing #2).

In other words, all same size cylinders will experience same pressure changes because they are vertically aligned and they will exert same internal pressure on the same area pistons, hence exert same internal force on each piston and push it for the same distance, but since cylinders exist on different depths, meaning the water will exert different external pressures, specifically, the external pressure will increase as go deeper, so the net force on the pistons will decrease by depth because of the increasing external force against the same internal force, meaning every piston will experience same internal force with increased external resistive force with depth, which will cause it to be displaced for less distance and do less work, these different displacements will create discrepancy for the central shaft and we need to unify them, so we have to reduce the force quantitatively on each piston by reducing its area as per its depth to let each one do different work by exerting decreased force from top to bottom but do the same displacement.

Since both solutions achieve the same objective, we will focus mainly on the first one, only to avoid redundancy, beside since it has the merit of smaller volumes at the tops which will make this solution slightly more sensitive to pressure changes, so the main reason to opt out of mentioning the second solution is only not to explain the same scenario twice every time, not because the second solution is less valid.

These cylindrical air reservoirs—can be in any other suitable structure—can be manufactured from stainless steel or hardened steel to withstand the exerted pressure without being deformed, but the in order to solve the problem of corrosion, the best option is not to face it at all and use alternative materials.

Any other suitable non-corrosive material can be used if they can withstand the pressure and marine environment, materials like—but not limited to—GRP, PVC, HDPE, FRP, acrylic or marine concrete with reinforcement rebars.. etc.., Since corrosive is one of the biggest challenge in the marine environment, so non-corrosive material will have big advantage in this regard.

Using slightly deformable materials like some of the mentioned up list, will require installing internal ring from very rigid non-deformable alloy at the range -position- of the piston’s oscillations, so it will not experience any resistance due to slight deformation in the cylinder structure.

To reduce the thickness of the cylinders, we can use internal supportive reinforcement structure which will be very important to support the cylinder’s structural integrity under pressure in order not to collapse or deform, this design will prevent buckling or bending of the outer walls, doing this, will significantly reduce the cost,—the cylinder’s internal supportive structure is not showing in the drawings since it could have numerous designs-.

Since most of this apparatus is mainly empty cylinders, and since these cylinders have to withstand the pressure changes only not the entire pressure of the water column, because their internal pressure of air will keep them in equilibrium, plus the internal reinforcement framework will significantly reduce the cost and these reasons will be the main factors in deciding how cost-effective and competitive this devise will be in the final math because the very thin wall due to non-heavy duty function when fixed in depth, will require much less materials and may significantly reduce the cost.

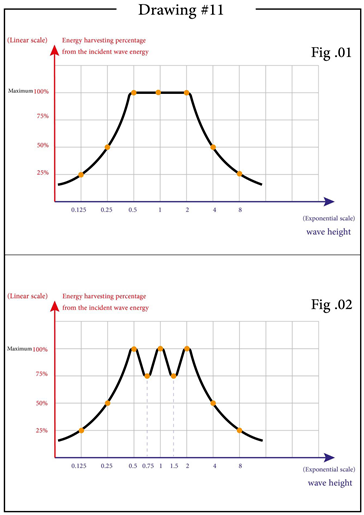

The energy of the wave will quadruple if the height of the wave was doubled, so more energy will translate to more pressure fluctuations, and since this increment is exponential, so the force on the cylinder and its piston and internal supportive structure will significantly increase, so the system should be designed to handle specific range of energy, and beyond this range, the stoppers will prevent the piston from further displacement and the thickness and internal supportive structure will be able withstand this extra pressure.

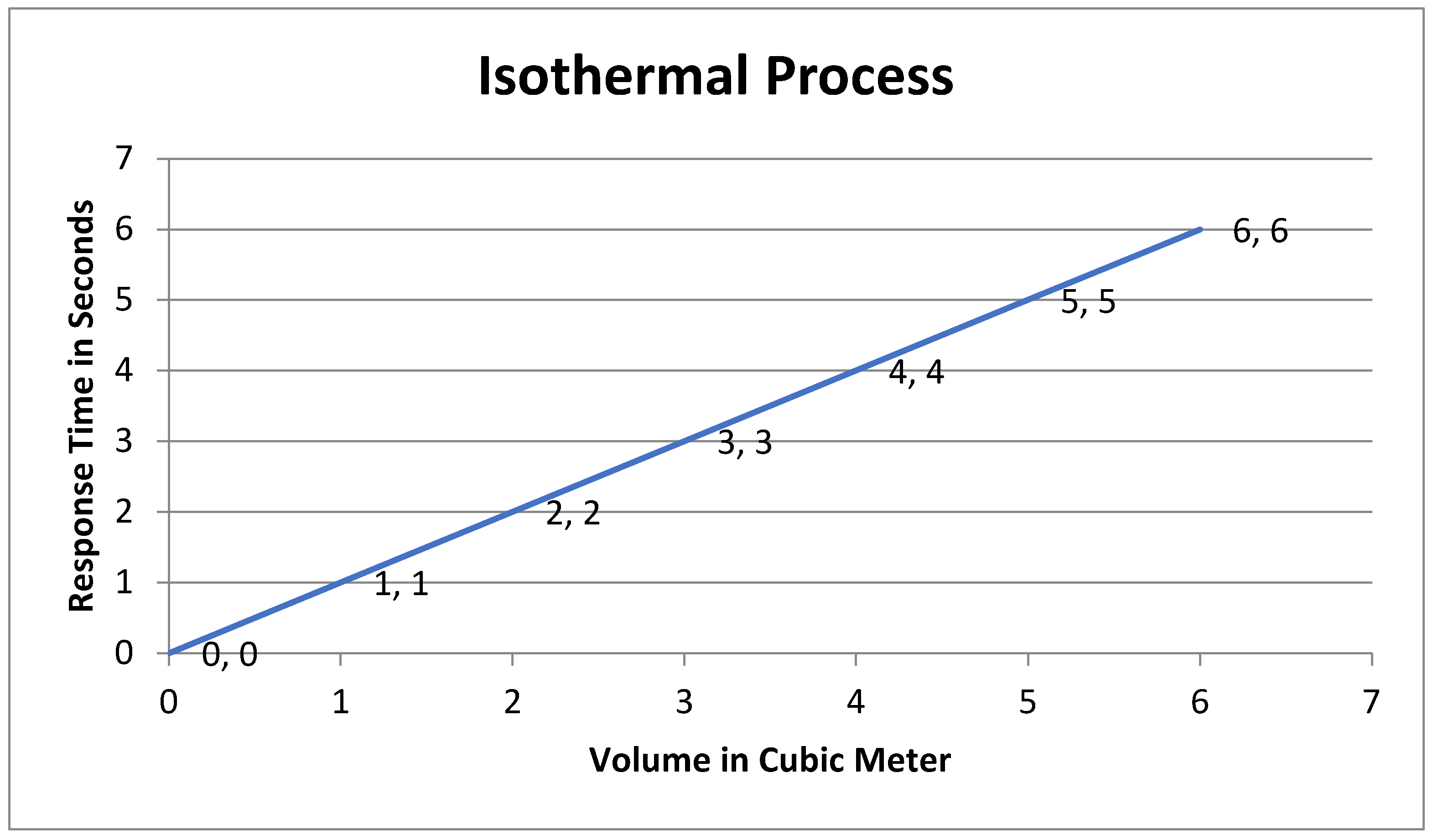

As we mentioned earlier, what we mean with isothermal in this system is the maximum work harnessing in the given time frame, so technically we mean the optimal response time which achieve this task not the literally completely isothermal process, so in this system the heat will be even produced at what we refer to as optimal isothermal or optimal response time, and since heat is inevitable, so if we chose non-heat-conductive materials, we should factor in the heat increment and heat exchange rate even in optimal response time.

Appropriate protective coating, anti-fouling paint—or technology like ultrasonic—should be applied on the submerged reservoir’s surfaces to prevent the unwanted growth of organisms like barnacle, algae and slime etc.

Marine coating can be like epoxy coating, polyurethane coating, vinyl ester coating or using methods like cathodic protection or sacrificial anodes as one of many other options, applying silicone-based coatings which makes the surface slick and slippery to prevent the organisms from adhering to the surface will be good choice, if the biofouling were attached to the surface, they will tend to detach easily when there is movement or cleaning.

Each cylinder is mainly two parts, the circular wall with the top cap and the movable piston at the bottom,- this configuration will be adopted in the following explanation design, but off course it can be vice versa and the piston can be at the top, (As shown in figure 3. drawing #3).

Being on the top will have the advantage of doing more work due to less resistive external force, but in most cases we might opt out of this option as we will see later.

The piston can be anywhere on any shape since it will retract and protrude due to the hydrostatic pressure changes, but in vertical oscillation movement it should be on the top or bottom to serve the motion conversion process.

We will consider cylindrical shape in this explanation since it has omni-shape and can harness the wave’s energy from all directions beside it will be practical shape volume wise—occupy less volume with minimal spaces in between for the overall apparatus volume- and to withstand the ocean’s deep currents, or the circular motion of the water particles near the surface regarding the high cylinders near the sea surface with minimal drag force.

The top cap of the cylinder has an opening at the center that allows the central shaft to slide in and out freely through this opening with the designated distance range, this opening should be properly lubricated to reduce the friction to minimal level for not to hinder the response time.

A suitable protective flexi sealant will be connecting the oscillating shaft with this opening at the top of the cylinder to ensure complete water insulation.

Each piston is firmly fixed to the central shaft at the center, so they all make one unit that moves up and down together with unified oscillation.

The cylinder body—the cylinder wall and top cap- is firmly fixed in position on firmly anchored steel structure—or any other suitable mooring mechanism like tensile cables—so they don’t move at all, leaving the freedom of motion for the pistons only which are connected to the central shaft to oscillate upward and downward.

Each cylinder will have thicker wall from top to the bottom, the deeper the cylinder is positioned, the thicker its wall should be, in order to withstand the increasing pressure, but this thickness can be reduced with the best engineering solution for an internal reinforcement supportive structure that makes the cylinder more resistive to pressure.

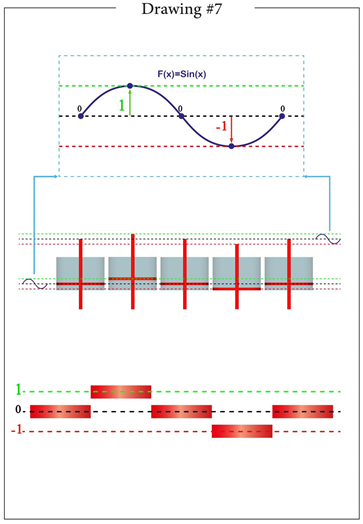

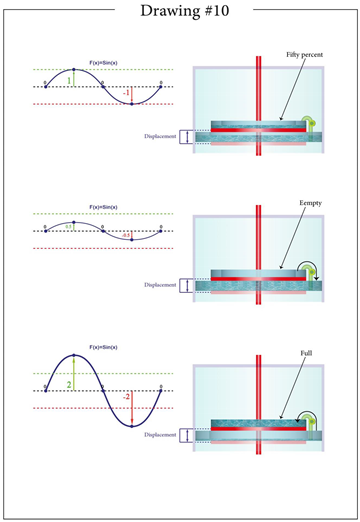

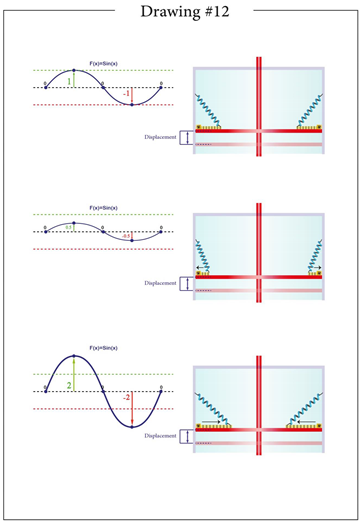

Theses cylinders will have decreasing height -hence decreasing volume as first option- as we move from bottom upward in order to cause the same piston oscillation amplitude, because if all cylinders have the same volume at different depths, then they will do different work regarding piston displacement as the water column height changes, because each one is positioned at different pressure, so each cylinder’s volume will change differently leading to different pistons’ displacements in their positions, which will create inconsistency in the central shaft’s total force and dissipate most of the force instead of creating consolidated constructive forces to add up to unified output on the central shaft.

The filled air should balance the water pressure for each cylinder as per its designated depth, the bottom cylinder have more volume, so it will do more work on the gas since it can harness more energy from the incident wave, but it will oscillate with less displacement and hence do less work on the piston because it is moving under more pressure so it will require more energy to exert the same force as we go deeper, as we move from the bottom cylinder upward, the work done by the gas in each cylinder will be decreasing, because the volume of each cylinder is decreasing, in order to decrease the oscillation displacement to match the bottom cylinder, so all pistons will oscillate with the same displacement, hence reducing the volume comes to play to unify the different works done on the gas to become same work done on the piston, so all the pistons will oscillate with the same synchronization and for the same displacement.

For example, if two cylinders with same volume, first one is positioned at 1 m depth under the water and the second one under 12m depth, the second one will contain almost double the air moles than the first one and oscillate with half volume change -half piston’s displacement- and it will do the same work on the gas like the upper cylinder, but this work at this depth will produce half the force on the piston compared to the upper one.

To maintain the same volume reduction and expansion -which will cause same displacement for each piston—for each cylinder to be in line with the targeted oscillation displacement, so no piston can move pulling the central shaft with it faster or slower than the other one, all will have synchronized oscillation with unified designated displacement, with decreased pressure as we move upward.

The other influence—although it is minor- on the required unified volume oscillation will be imposed by the gradient temperature decrement as move down due to the differences arise from the water temperature from the ocean surface as we go deeper, because of this fact, we should consider air filling with even less air moles according to the designated amount of volume fluctuation from top to bottom cylinder, since the extra temperature will impose slightly more pressure which will lead to more forces applied on the pistons at the upper cylinders, and by factoring in this slight volume reduction, it should not affect the designated oscillation displacement.

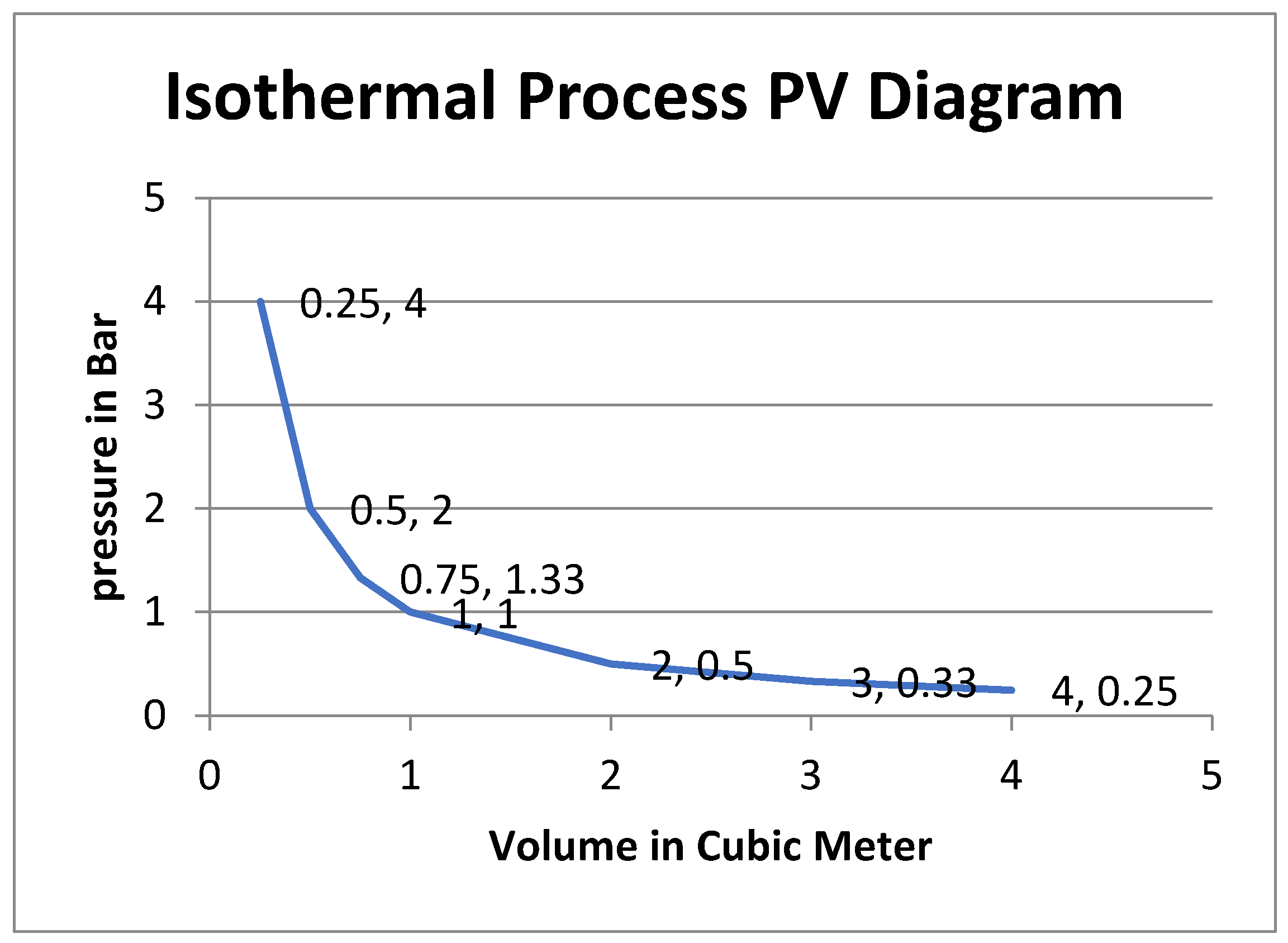

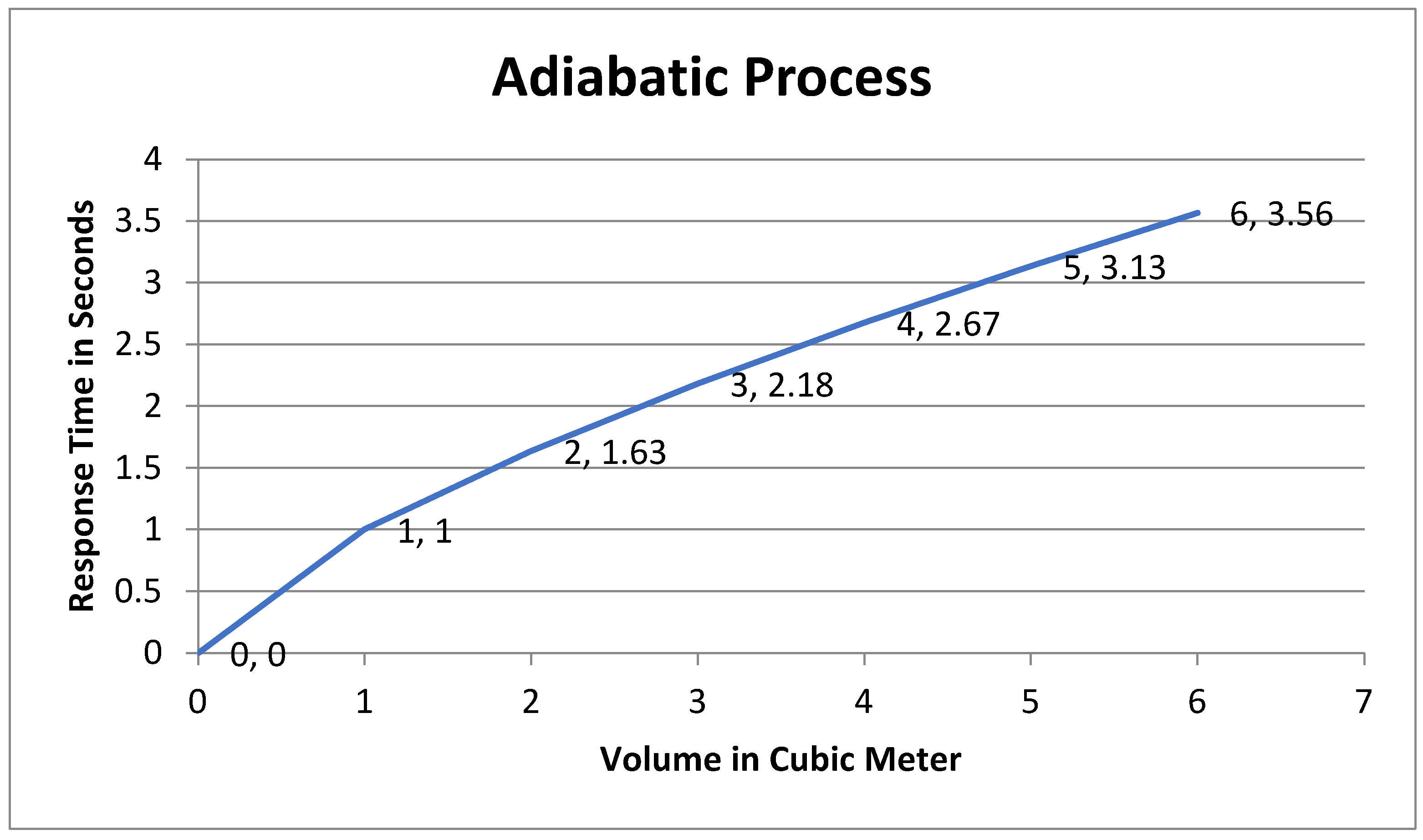

If we achieved the required response time to consider this system complete isothermal -we are explaining this system in static condition for specific wave for the time being, but later on, it will be dynamically seeking and achieving the isothermal process for different waves-, then we can use the following formulas to decide the air moles count in each one -hence the volume for each cylinder-.

As per Boyle’s low and since we need to dictate the final volume after contraction for each cylinder, so we need to decide the filled air moles in the initial volume before contraction

where:

Pi is the pressure on the piston before expansion (in Pascal)

Vi is the volume of the cylinder before expansion (in M^3)

Pf is the pressure on the piston after expansion (in Pascal)

Vf is the volume of the cylinder after expansion (in M^3)

The ideal gas formula:

where:

P is pressure (in Pascal)

V is the cylinder volume (in M^3)

n is the number of moles of gas (in moles)

R is the gas constant (8.314 J/mol*K)

T is the absolute temperature (in Kelvin)

So the air moles count inside the cylinder will be:

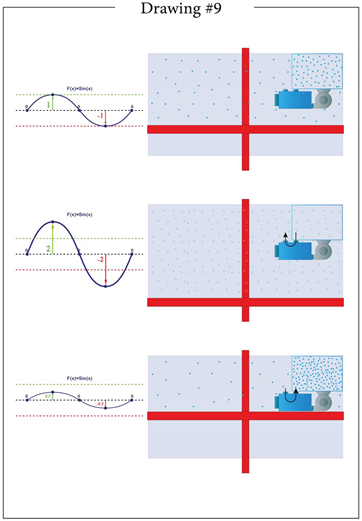

The air moles inside each cylinder will be calibrated for optimal response time and to harness the maximum energy from the incident wave with specific characteristics as per its allowed time frame which is creating specific pressure change rate.

So we should calculate the mean average wave height in the installation area and specify the air moles and the volume as per this average, and when the system becomes dynamically responsive, it will cover the targeted range to harness its wave’s energy effectively as per its capacity around this mean average.

If smaller wave—low pressure rate change- is passing over, the response time of the cylinder will be slow and not enough to capture all the energy of the incident wave, and if the passing wave is big—higher pressure rate- the response time will be quicker than the required response time and the system will even nudge toward the adiabatic process, that’s why we need the dynamically responsive system.

The piston will be positioned at the bottom of the cylinder, the cylinder side wall height should be adequate as per oscillation maximum amplitude beneath the piston mean average position in order for the piston’s oscillation will only take place inside the cylinder during the maximum piston displacement positions inside the cylinder, stoppers will be fixed at the cylinder’s internal wall to exert constraint force which is normal force to prevent the piston’s oscillation more than the designated amplitude.

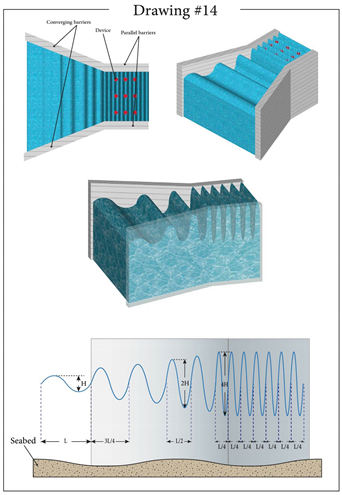

The cylinders should have wide diameter as possible and little height, the more the diameter is, the more energy we can capture because of more volume, but considering the effective spot area of wave height on the surface, the most effective width will vary according to the wave or swell characteristics—which we will be discussed later -, but practically speaking the diameter of the cylinder can be about 3.5 m in average.

Increasing the diameter of the cylinder more than the effective area, can cause the cylinder to experience parts of both the trough and crest or misses out on the most effective area to harness the water column changes as per wave length—horizontal width from crest to crest -, missing out will lead the cylinder to harness less energy from the incident wave, since the device will be installed near the coastline where the shoaling effect will take place, and this means higher water column with shorter wave length.

The buoyancy center and gravity center—for both the cylinder and its buoyancy counter weight—will always be in balance for all cylinders which fixed by the chosen mooring system, and these two centroids will be vertically on the same line and in balance all the time and will not impose torque or any load fluctuations on the fixing structure.

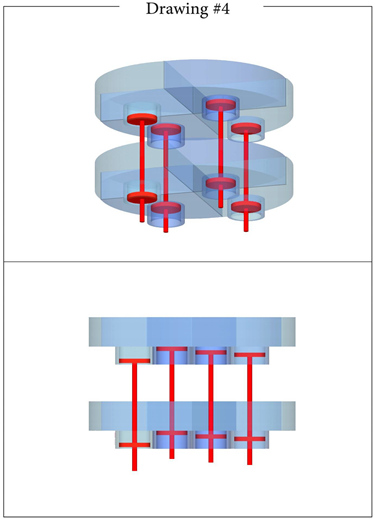

Since the surface to volume ratio decreases as the volume grows bigger, so we can increase the volume of the cylinder then divide it by smaller thin partitions inside the cylinder to create more chambers, the thickness of these partitions will be less, since the internal pressure difference is less, and the cost of the cylinder will be less due to less surface area required material for bigger volume, (As shown in figure 3. drawing #4).

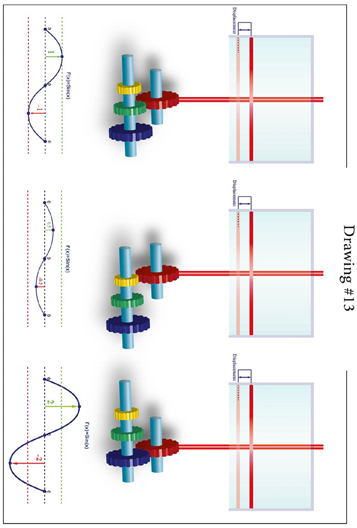

So each cylinder or reservoir can be more than one chamber with its designated piston, and each one vertical line of these chamber’s pistons will move independently from the horizontally next one and together as one unit in the vertical line, and their forces output will be harnessed by independent gear box –if we chose this PTO system-, but all gear boxes output will be harnessed by one generator using flywheel as moderator for example, this scaling will even drive the cost further down.

As for the second solution, since all cylinders have the same volume but positioned at different depth, so they will all do the same work by gas, but they will face different external resistance to the motion of the piston due to gradual higher pressure as we go deeper outside, so they will do increased work on each one’s piston from bottom to top leading to apply same force for longer displacements, and this will impose problem for the central shaft.

So to address this challenge we manipulate the variables of these simple formulas:

And by reducing the area of the pistons for the lower cylinders which are doing less work on the piston, then we will be reducing the force, and since the work is fixed in this case, so the distance will increase.

The cylinder can have many other ancillaries like one way check valve, internal sensors etc.

Since these vertically stacked cylinders are filled with air and submerged under water, the buoyancy force will be huge, that’s why the fixing structure with its foundation should be suitable to withstand such big force, another method to put high density material on the top and sides of each cylinder to increase the downward gravitational force to oppose the buoyancy upward force and reduce the load on the fixing structure which can reduce its cost.

- 2.

Piston -the Actuator:

The movable piston is located at the bottom of the cylinder—but it can be on the top- and it will oscillate upward and downward as per the incident wave’s crest and trough imposed pressure.

One important feature of the piston is to be manufactured from light, hard, non-malleable and non-deformable material, extremely rigid to ensure no deformation, denting or bending will take place.

The material rigidity will ensure the cylinder’s volume change is transferred into motion of the piston inward and outward instead of bending or denting in order for the entire volume change to cause piston displacement rather than being deformed in place.

Since cylinder volume and piston’s mass are both proportional to the response time, so it will be advantageous to reduce the piston mass to maximum limit without sacrificing the required characteristics in order for the volume to increase on the expense of this mass decrement, because after all, the air is the element who is doing the work, this will be very important as the system reaches it maximum response for the small waves, the mass of the piston will be one of the dynamically changing elements as we will discuss in the dynamic response.

We can place the piston on the top as another option (As shown in figure 3. drawing #3), this will have great advantage of doing more work due to less external resistive force because of less depth position for every piston, but since we may need to place the buoyancy counter weight on the top of the cylinder, or the horizontal beam of the fixing structure will be installed on the top of the cylinder to exert normal force against buoyancy force, we have to opt out of this option.

On the other hand if the piston and its connecting flexi sealant was at the top, in the marine environment, the floating organelles will be so dense, so the biofouling as result and the decomposing of bigger size living beings as it accumulates and chemically decomposed on the piston’s surface and its connecting flexi sealant will be greatly affected, hence there chemical property will change and degrade at faster rate.

Beside the cylinder volume and the piston area addressed earlier, the hysteresis arises due to friction, fluid dynamics and properties of the involved materials.

The piston will experience friction as it moves inside the cylinder, this friction will create resistance to motion leading to lag in piston’s movement as the pressure changes, this lag is undesirable unlike the other deliberately introduced hysteresis, since the friction force will be lost.

When the piston moves it has to overcome the static friction before it moves, and when pressure changes, the piston will not reverse motion direction immediately due to kinetic friction, which will lead to lag or phase shift in piston’s movement relative to pressure changes.

Also the mass of the piston plays important role, since inertia means resistance to motion, when the pressure changes rapidly, the piston will take some time to accelerate, which will cause delay to be factored, in some cases we need to introduce delay to harness more energy by increasing the mass of the piston as we will see later, this introduced hysteresis force will not be lost like the force of the friction.

And when the pressure drops, the piston will not stop moving and reverse direction immediately since it has momentum, and this will also create lag.

Viscosity and mechanical damping beside the drag imposed by the piston speed in water will also increase the response time and these forces also will be lost.

Friction, inertia and damping will significantly affect the response time and introduce unwanted hysteresis, the piston’s response to pressure changes will depend on overcoming these resistances which will make it respond slower and increase the lag.

So to address these hindering factors, the piston path should be properly lubricated to minimize friction, and the shape of the piston should be with minimum drag coefficient, and the speed of the piston should be slow as possible because drag increases exponentially with speed.

When the wave’s trough passes over the cylinder, the cylinder starts to expand until the piston will be completely protruded—suppose maximum trough the system can withstand—exerting downward force during this expansion to enable the central shaft to move as per the piston displacement, the opposite scenario will take place upon the wave’s crest is passing over.

Giving the piston’s slender profile, there is a risk of it tilting or veering off its intended cylindrical oscillatory trajectory, in this case we can either increase the thickness of the piston on the side, or we can install lateral surface—thin rigid ring with adequate height—on the edge of the piston to increase its contact surface with the cylinder in order to oscillate smoothly in its path without deviation or tilting.

So this lateral surface should also be made from rigid non-deformable alloy and will be oscillating inside the rigid alloy ring which is fixed internally inside the cylinder, this area should be always properly lubricated, these alloys should be suitable to withstand friction for long time without tearing or wearing, the range of piston oscillation should be within the range of this rigid ring and the stoppers will protect the pistion from moving out of it,—this illustration not mentioned in the drawings -.

The central shaft is fixed vertically to the center of each piston to harness all its upward and downward displacements and apply the collective work done by these pistons on the energy harnessing unit which is located at the bottom cylinder resting on the seabed.

Since inertia will increase hysteresis which is not desired with slow rate of pressure change, the mass of the central shaft should be as small as possible, besides being rigid and made from marine suitable material since some parts of it will be exposed to sea water.

Each cylinder has specific air moles inside it as per its pressure which is dictated by its height over the seabed , this air will be compressed like spring and store potential energy when the crest is passing over—the water column height increased-, then it will release this energy when the trough comes over its spot.

The air bulk modulus is analogues to spring constant, if we want more sensitive spring, we should reduce its constant, and similarly, if we want more sensitive gas than the air, we can use gas with less bulk modulus value like helium.

If the wave interference pattern is dominant at the area of installation, and the water column changes over smaller spots and these changes has shorter time frames, the air volume with the cylinder’s diameter should be reduced accordingly.

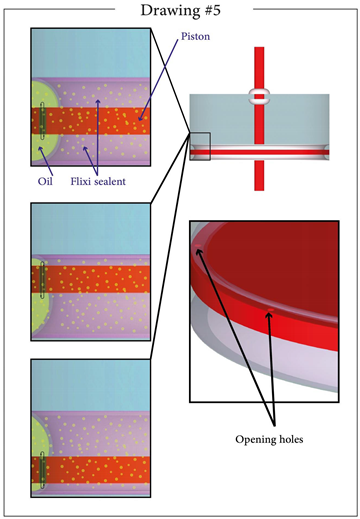

This is double sealant system, internal and extranet, each one filled with lubricating oil and these two pockets are connected together via small opening in the piston to keep the pressure of the two small formed pockets -trapped volume- containing the oil, always in balance, (As shown in figure 3. drawing #5).

The external flexi sealant connects the piston edge to the bottom of the side wall of the cylinder to prevent the water from entering to the cylinder, this sealing fabric is made from suitable material which can withstand the harsh marine environment and facilitate the motion of the piston without hindering it.

Another flexi sealant will be installed inside the cylinder and connected to the piston, its trapped volume will also be filled with the same liquid lubricator.

The liquid lubricator should be with low viscosity in order to ensure maximum smoothness in the piston movement and reduce piston friction with the cylinder which will cause hysteresis.

This liquid will always be under semi constant internal pressure, since liquids aren’t compressible, it will immediately apply the changed pressure to the oil in both chambers equally since liquids transfer pressure faster than gas, so the pressure on the piston areas in touch with the oil will always be in balance and there will be no changes in the internal pressure since those two pockets will always be in equilibrium, hence it will cause no opposing force which will lead to hysteresis.

The low viscosity oil pockets will be connected through small opening in the piston, and as it moves up and down, the oil will flow between the two pockets back and forth and hence there volumes will keep changing, since liquid is uncompressible and respond immediately to the pressure changes, this process will distribute the pressure evenly over the contacting surfaces and the connecting internal and external flexi sealants, providing a continuous lubricating film between the piston and the cylinder internal wall, when pressure fluctuates on the lubricant oil in these two small chambers, it will be balanced immediately due to liquids nature in fast transmitting the pressure, then the pressure on the flexi sealant will always be in balance, so it will not be folded and get between the movable piston and its contacting surface.

Since we have balanced the pressure on the connecting flexi sealant fabric, this will give us more freedom to choose among more materials, unlike the scenario where we employ the rolling sealant, then we will be limited to specific materials with its life span beside the hysteresis level it will introduce.

Now we can choose more robust material which have very long lifespan and wouldn’t be affected with marine environment like the Nano carbon fiber fabric, this is extremely strong material and will prevent the oil from leaking out and wouldn’t be raptured easily.

This method with the appropriate material will increase the lifespan of the sealant fabric and reduce the hysteresis which is the most important challenge we need to address.

The complexity and cost of this method compared to the widely-used and well-established method of the rolling sealant will be offset by its more merits.

Off course the well-known method of rolling sealant can also be used as a readily available option.

- 6.

The Shaft and Cylinder’s-Top-Cap Connecting Flexi Sealant:

This same sealing system like the previous one and it connects the cylinder’s top area to the central shaft oscillating upward and downward through it to prevent the water from getting in and the air from going out of the cylinder.

Also it is constituted of internal and external pockets filled with lubricant and wrapped with flexi sealant fabric to seal the cylinder and to balance the pressure on the piston and smooth the motion.

- 7.

Piston Stoppers:

These plates are firmly fixed inside the cylinder over and under the piston to exert restrain force to prevent it from displacement over the designated limits, the maximum limit corresponds to the maximum displacement the piston will make as per the maximum wave height it can withstand in order for the piston not to move out of the cylinder boundaries or overload the PTO system.

These stoppers preferably to be as two rings inside the cylinder to exert the normal force on the entire edge of the piston in order to distribute the mechanical tension over bigger surface.

- 8.

Sensors:

Appropriate sensors as required will be installed inside each cylinder in order to monitor its conditions, these parameters will be an important part of the data to be fed to the logarithms to control the dynamic response as we will see later, for example pressure sensor inside the cylinder, beside the useful data for the logarithms to work, it can determine whether there is leakage in the cylinder.

If the water started leaking into the cylinder, the corresponding sensor will signal special safety gate in the cylinder to open in order to let the water flow into the cylinder to keep it in equilibrium, so the water will not be trapped inside the cylinder and create pressure imbalance which will hinder the piston movement in this case and affect the entire system since all pistons are connected to single shaft, so the other pistons will still be operational while this piston is broken down and oscillate in water.

Other sensors can be installed like temperature sensor to monitor the temperature inside each cylinder, horizontal position sensor to monitor the verticality status of the apparatus to determine the tilting condition of the cylinders especially during ocean currents in case they were fixed using tensile cables.

The required power for these sensors, ultrasonic device prevent the biofouling and the dynamic system equipment be will be extended to each cylinder from the PTO unit at the bottom.

- 9.

Buoyancy counter weight:

The buoyancy force is a real challenge in the device, the bigger the volume, the more challenging this problem becomes.

Depending on the mooring method we will choose, we can specify the quantity of this force, if we chose the fixing structure, then the main load to counter the buoyancy force will come from this fixing structure and it foundations, yet we still can add some weight to reduce the load on this fixing structure, this method will reduce the gap between the cylinder since there will be no volume occupied by the weight.

But if we chose the tensile cable mooring method, then this buoyancy counter weight will be the main force which counters the buoyancy force especially if the tensile cable or chain strength is not entirely adequate to counter the buoyancy force.

These weights will be placed on the cylinder, whether on its top or side, placing it on side will be very advantageous to reduce the overall device height, this weight will exert gravitational downward force to counteract the upward buoyant force in order for the cylinders not to exert huge upward force on the tensile cables.

These weights preferably to be from dense and cost-effective material to reduce the volume it will occupy, but since dense materials will be costly, so practical solution can be sand bags to be placed on the top of the cylinder, in this case its upper surface will have ring shape boundary around its edge to accommodate this weight.

The height of this boundary should be adequate to accommodate the weight as per its relatively big volume.

The drawback of this method, this weight will occupy volume when placed on the top of the cylinders, so the overall height will increase, which is big disadvantage for the efficiency.

- 10.

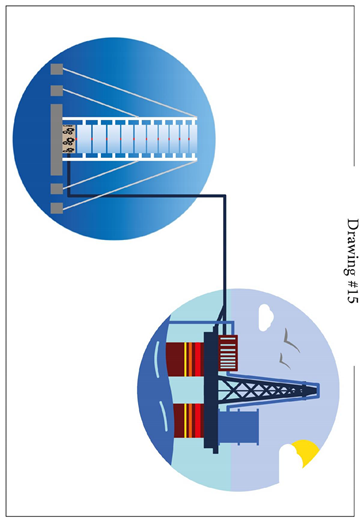

Energy harvesting unit PTO:

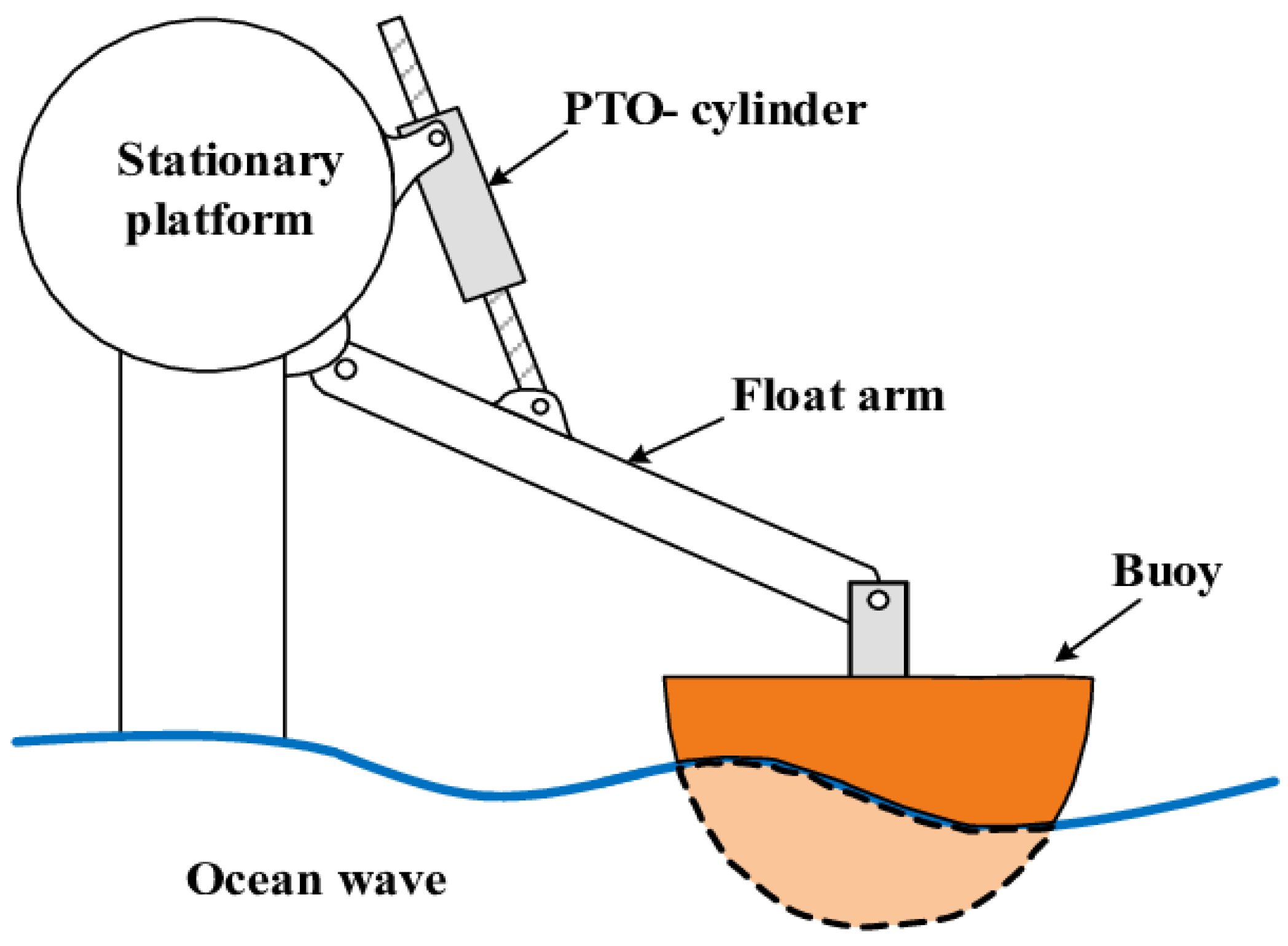

This unit is located inside the bottom cylinder resting on the seabed, although we will delve into the diversification of energy harvesting methods, but we will briefly summarize some of them here.

The first option PTO system and the most efficient solution is high torque gearbox—high gear ratio—connected to the oscillating central shaft, as the first high torque and slow motion disc is connected to the central shaft, the final fast spinning disk will be coupled with the generator, this solution will have the highest energy conversion ratio, but it is more susceptible to mechanical failure and will be maintenance demanding solution.

The most practical solution is to let the piston pressurize sea water in a vessel to let it flow through pipe where underwater turbine is running, but the big trade off this solution has way less energy conversion efficiency since tidal turbine are approximately 30% to 50% conversion ratio, so if simplicity and nonexistence of complicated mechanical parts are the objective, then this solution can be considered.

All the other electrical components will be inside this unit, so only the cable will extend out of it to the main unit for all devices in case of many systems installed or directly to the seashore which is the final destination where the power will be delivered.

Another way to harness this power is by compressing air in chamber then uses this compressed air to do work, like generating electricity.

- 11.

Fixing structure:

These fixing methods are to fix the cylinders in both vertical and horizontal position over seabed, a heavy foundation made from ecological & ocean harmless material will be installed to firmly anchor the erected apparatus and provide the required downward force for the fixing structure.

First method is to use steel structure—or any other suitable material- which will accommodate and fix all the cylinders, this structure is designed to exert adequate force on the cylinder to counter the buoyancy force and to withstand the ocean under water current and the hydrostatic fluctuating force on the cylinders which will prevent them from oscillating up and down.

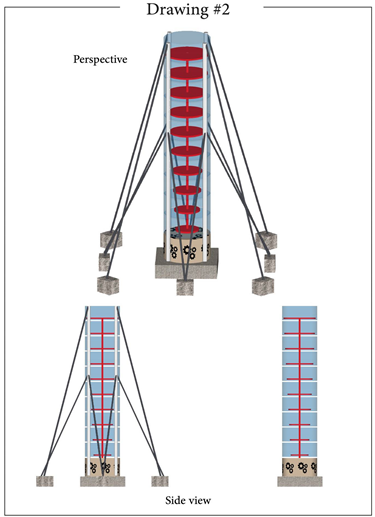

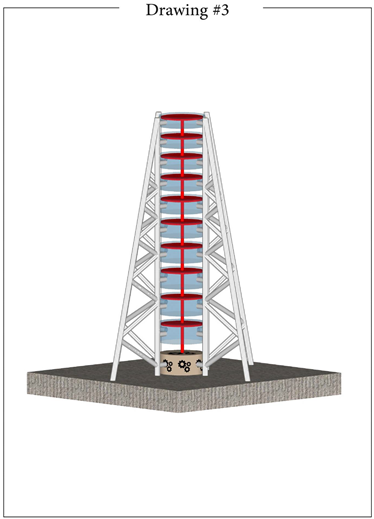

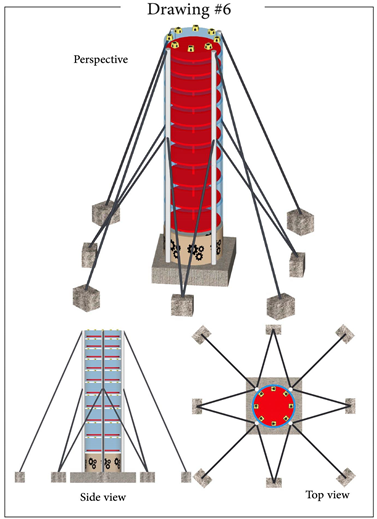

The second alternative method to anchor the cylinders is to connect them together with long steel pipes for example along with the energy harvesting unit and make them all as one long unit, then connect this vertically installed device via high tensile strength cables—marine synthetic cables- to the heavy foundations points or anchor bolts on the seabed to fix it in position and prevent it from tilting and horizontal swinging, this method preferably to use the buoyancy counter weight in order to reduce the load on the tensile cable beside it the minimal foot print on the seabed.( As shown in figure 3. drawing #6).

This tethering method has the advantage of being easy straight-forward and cost effective, and it could be the preferred mooring method if the buoyancy counter weight height on the top of the cylinder was short.

Another mooring method is we can assemble the device as one long unit and balanced with adequate weight to stay floating under very specific depth, but the weight shouldn’t reduce the buoyancy force more than the hydrostatic fluctuation, i.e the tensile in the cable and the upward buoyancy will stay more than the downward force imposed by pressure changes, otherwise the device will move up and down with the wave like all free floating living beings at certain depth, so some of the pressure will be lost in this case due to the change in depth and the system will seek to stay in pressure equilibrium by moving up and down rather than being pressurized in its position, this method will be preferred where the marine environment is rich and we should avoid installing anything on the seabed in order not to disrupt the marine ecosystem, or where the desired installation spot has relatively deep seabed.

This method has very important feature where we can connect the fixing cables to rotating pulley or roller and it will rotate via remotely control motor to wrap the cable on it and shorten or lengthen the cable and hence let the device float higher or lower under the sea surface, so the cables will be lengthened during small waves to let the device float at higher altitude over seabed to stay as close to the surface as possible to reduce the pressure of depth which will act as opposite force and reduce the energy output, and the cables will be shortened during the high waves to pull the device down so it will not be exposed to the surface and will stay as close as possible to the surface.

The cost of more complexity will be offset by more energy conversion, this dynamic mechanism is very important to keep harnessing maximum energy.

And to reduce the required weight, we can install long anchor bolts on the seabed where it will impose minimal impact on the marine ecosystem and connect this floating apparatus to these firmly installed anchor bolts with suitable tensile cables to exert tensile force that will adequately oppose the buoyancy force.

The best anchoring system is to be decided as per each location conditions and cost considerations.

- 12.

Foundation:

This foundation should be made from echo environment materials, in order for the apparatus to be erected on it, it will be important to the mooring system since its weight will provide the required downward force to system against the buoyancy force.

We can also use anchor bolts with Fischer shape and insert them deep in the seafloor and use them as fixing points.