1. Introduction

In the production process of goods, the planning and scheduling of the activities required for their construction and maintenance play a pivotal role [

1]. The evaluation of construction site operations is inherently dynamic, influenced by management characteristics closely tied to the variability of space, budget and time [

2]. Each construction site is shaped by its unique organizational framework, encompassing workers, technologies, materials and equipment, which collectively define the processes and procedures. Depending on the type of the project, the allocation and coordination of diverse competencies and resources are essential for successful implementation [

3].

Within this context, adopting the guidelines of the Building Information Modeling (BIM) methodology introduces innovative opportunities for analyzing and optimizing construction processes [

4,

5]. BIM is widely recognized for its ability to create integrated models that combine virtual objects contributed by various professionals involved in the project. These models extend beyond the well-known structural, architectural, and MEP (Mechanical Electrical Plumbing) engineering domains; regulatory frameworks increasingly emphasize the importance of developing specific BIM objects tailored to the various phases of the project [

6,

7,

8]. Among these, the construction site model stands out as a crucial component, offering the potential to transform traditional approaches to site planning and management.

Historically, the design and management of construction sites have been predominantly static and document-based, often relying on two-dimensional graphics or basic three-dimensional representation. However, with the evolution of BIM technology, large-scale construction projects within the architecture, engineering and construction (AEC) industry could now be executed with greater precision and efficiency [

9]. BIM has emerged as a key driver of IT-based transformations, fostering significant advancements in the organization and execution of construction operations.

The use of BIM technologies leads to new ways of operating [

10,

11,

12], conceptually different for various reasons: (a) it facilitates accurate representation of construction site layouts, ensuring that spatial configurations are faithfully modeled; (b) it allows for the inclusion of contextual information, such as terrain topography, site-specific challenges, and the surrounding urban environment, including road networks, existing buildings, and natural features such as vegetation and watercourses; (c) it supports the integration of discipline-specific models (e.g., architectural, structural) into a unified site model, leveraging interoperable formats such as IFC; (d) BIM libraries offer an extensive range of objects—representing equipment, machinery, excavations, and vehicles—that enable the detailed modeling of a virtual construction site.

Beyond its modeling capabilities, BIM enables a new innovative mode of working by, providing a common environment [

13,

14], improving transparency, productivity and quality across process chains [

15,

16]. By embedding installation methods, safety requirements, and other critical information within BIM objects, the methodology supports advanced functionalities such as code checking and clash detection. These capabilities allow project teams to study potential interferences between processes and operational spaces, reducing conflicts and improving safety [

17,

18]. Moreover, the aggregation of BIM entities based on their associated information provides innovative tools for project management. For instance, in construction site operations, grouping entities by work activities and their durations enables a structured analysis of interdependencies, helping to optimize workflows and minimize risks for workers [

19,

20]. Similar considerations could be made for the integration of Airport Pavement Management Systems within BIM platforms, to better organize interventions on superstructures while interacting with underground utilities. [

21]

In this context, the present study investigates the potential of BIM implementation in the management of construction sites at airports. Using a simulated project at an international airport in Southern Italy, it demonstrates how BIM technology could streamline processes, detect conflicts, and document the phases of site construction. The research emphasizes the importance of addressing site-specific challenges, particularly in the context of obstacles and hazards to air navigation, highlighting the benefits of BIM as a tool for simplifying complex operations.

To further enhance the methodology, the study incorporates external technologies, specifically Geographic Information Systems (GIS), to complement spatial analysis capabilities into BIM. This integration allows for a more comprehensive approach to managing the spatial and operational complexities of construction sites in airport environments.

The findings of this study underline the untapped potential of BIM in construction projects, particularly in fostering collaborative design and enhancing project outcomes. While BIM adoption continues to grow, many of its advantages remain underutilized, and further research is needed to explore its full capabilities [

22,

23]. Future studies should focus on advancing the role of BIM in integrating safety management, environmental analysis, and real-time monitoring, particularly in complex, high-stakes environments such as airports. By addressing these gaps, the construction industry can unlock new opportunities for innovation and efficiency, contributing to the broader diffusion of BIM methodologies across diverse project types.

2. Background

In the design and construction phases of the infrastructure lifecycle, the generation of large amounts of data necessitates a structured approach to acquisition and transfer, particularly during the facilities management phase [

24].

In recent years, the advent of Building Information Modeling (BIM) has significantly supported the AEC sector by simplifying processes, optimizing productivity and ensuring the achievement of pre-established quality standards. BIM is defined as “a shared digital representation of physical and functional characteristics of any built object (including buildings, bridges, roads, etc.) which forms are liable basis for decisions during its life-cycle; defined as existing from earliest conception to demolition” [

25]. This methodology integrates various aspects of a project into a unified information model, encompassing architectural, structural, plant engineering, energy and management phases.

BIM is not a single software application, but rather an entire process based on interoperable design principles. It enables integrated design, fostering collaboration among various professionals (e.g., architects, engineers, builders) throughout the lifecycle of an architectural work. By facilitating a circular economy perspective, often described as “from cradle to cradle" [

26], BIM connects the asset management phase with the design, construction, operation, decommissioning, reuse, and recycling processes [

27].

Given these benefits, it is evident why the AEC sector increasingly invests in BIM technology. When considering the advantages of adopting BIM, the mandatory use of this technology as per relevant legislation is perceived as a strategic investment [

28,

29]. The benefits include: (a) Time and cost savings: BIM eliminates the need to draw numerous lines, polylines, and geometric shapes typical of CAD software, which can be time-consuming. Instead, it involves the insertion of objects with specific properties and information, such as materials, costs, thermal capacities, and maintenance rules; (b) Errors reduction: Plans, elevations, and sections in BIM are merely different views of the same object, ensuring that any modifications to the model are reflected across all related views and graphics; (c) streamlined workflows: BIM enables the design of highly complex structures within a reasonable timeframe. These advantages are effectively illustrated in the well-known graphic representation developed by Patrick MacLeamy [

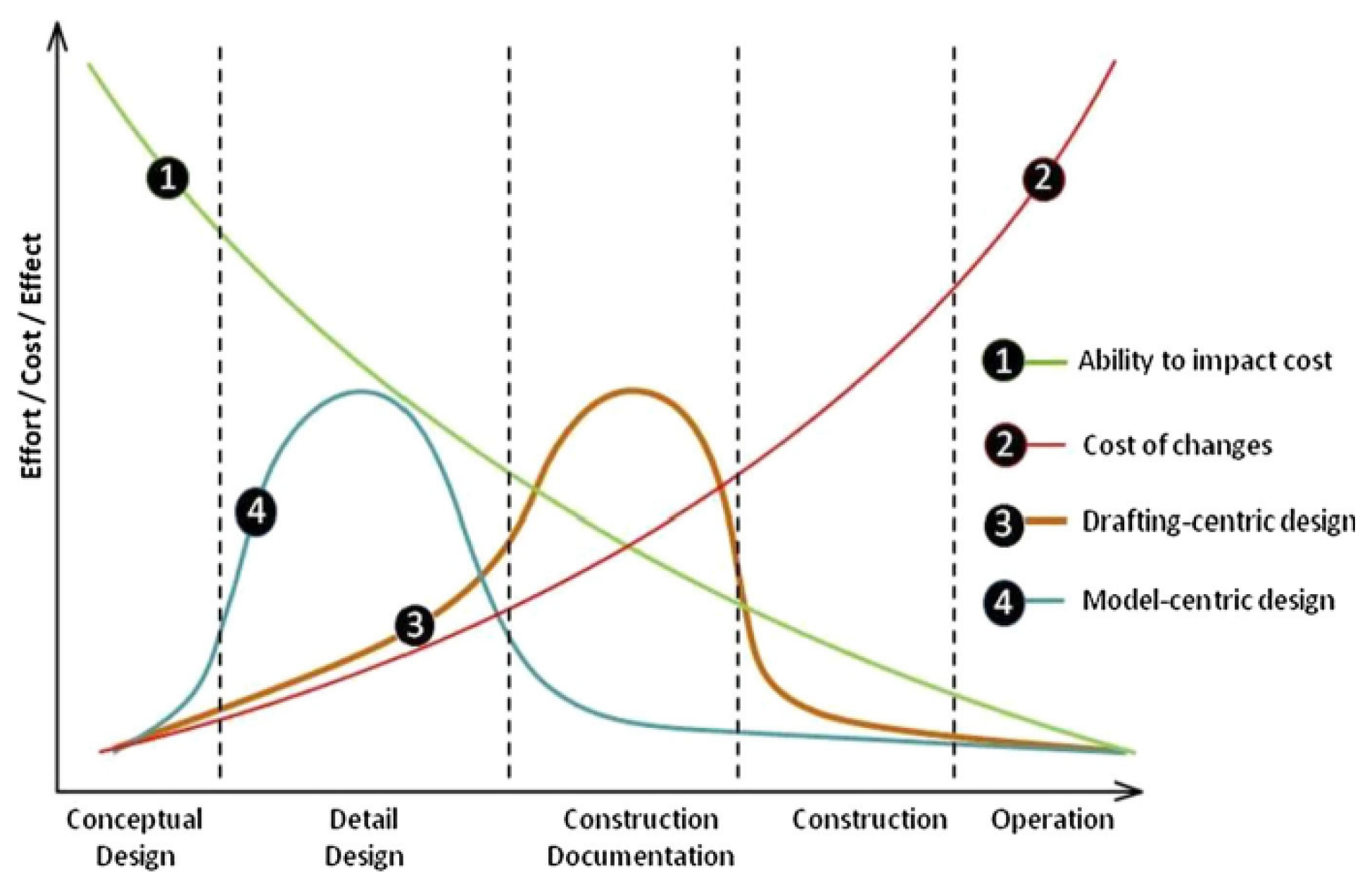

30], as shown in

Figure 1.

The graph demonstrates how the integrated approach, typical of BIM, positively impacts cost reduction, particularly in the phases of modifications, integrations and corrections.

Several studies have attempted to quantify the benefits of BIM for architects, engineers and owners. For instance, the "SmartMarket Report: The Business Value of BIM in North America" [

31] has revealed the following: (a) reduced document errors and mission: 57% for architects, 34% for engineers and 61% for owners; (b) reduced rework: 45% for architects and 26% for engineers; (c) reduced project duration: 22% for owners.

The extent of these benefits depends on the quality and quantity of information embedded within BIM objects, which varies based on the level of maturity and the scale of the BIM model.

Furthermore, the use of a Common Data Environment (CDE), preferably web-based to enable real-time data exchange [

32], enhances coordination among stakeholders. This leads to standardized procedures for data sharing and ensures seamless electronic information exchange across various applications.

A recent challenge for the AEC sector is the integration of BIM with other systems, such as Geographic Information Systems (GIS). Stakeholders have recognized the potential of situating digital projects within their geographical contexts through BIM-GIS integration [

33]. This integration revolutionizes the design and management phases of structures and infrastructures.

The use of GIS data—such as orthophotos, cartographic surveys, and technical maps—simplifies the management and analysis of relationships between structures, infrastructures, and their surrounding environments [

34,

35]. Often referred to as the "science of where," the BIM-GIS model acts as a central data repository connected to different platforms, placing data at the core of the entire process.

In the context of airfields, BIM could serve as a valuable tool for simplifying asset management related to design and maintenance [

36,

37]. Integrating BIM and GIS allows for the analysis of interactions between airport assets and their surrounding areas. This integration could also help mitigate risks associated with flight safety, as conceptualized in the Swiss Cheese Model [

38], where reducing "holes" corresponds to preventing hazards from escalating into accidents.

For example, combining BIM and GIS technologies can enhance the management of obstacles and hazards in air navigation. This includes analyzing the impact of aeronautical operations, with implications for constructing new assets and adapting existing ones. Additionally, integrating GIS data into BIM can streamline site management during the planning phase, assess operational impacts, and optimize activity scheduling, as detailed below.

2.1. The use of BIM in the Construction Site Management

In recent years, construction sites management reveals a common denominator: growing complexity [

39]. It has become challenging to maintain a comprehensive overview of the processes involved, as well as to fully understand their interrelationships and the spatiotemporal contexts in which they occur. This complexity, in turn, raises the likelihood of errors and their propagation throughout the entire process, from the design phase to the construction phase [

40,

41]. For this reason, effective planning is essential, as poor site organization can negatively affect productivity, lead to project delays, and increase costs beyond those estimated during the design phase [

42].

Although numerous studies have investigated the causes of errors, it remains difficult to quantify their impact on actual project costs, including the effects on the lifecycle of the asset. Literature suggests that errors in the construction sector can account for up to 10% of the total investment in a project [

43]. In the United Kingdom, the Building Research Establishment reports that at least 50% of construction and asset lifecycle errors originate in the design phase, with errors in tender documents alone accounting for up to 5% of the contract value [

44].

In this context, it becomes evident that adopting innovative technologies, such as Building Information Modeling (BIM), could significantly reduce such errors. BIM enables the continuous detection and resolution of interdisciplinary design interferences, thereby improving consistency and reliability in project outcomes [

28,

45].

The integration of BIM into construction site management entails organizing all construction activities in terms of spatial and temporal dimensions while linking them to the 3D geometric model of the project [

21,

46]. If implemented correctly, BIM simplifies the planning and logistics processes, enabling more efficient and structured management of construction sites.

Traditionally, the segregation of design and construction phases has led to a lack of collaboration among stakeholders at various stages of the project [

47,

48].

Designers often worked independently, making decisions without considering their impacts on other disciplines. As a result, contractors frequently received incomplete or inaccurate documentation, particularly when working under tight deadlines. In contrast, BIM promotes collaboration by enabling all stakeholders to adopt a unified strategy, supported by a centralized platform with role-specific access permissions [

49,

50].

In the specific context of construction site planning, the multidisciplinary nature of the professionals involved necessitates the use of a shared BIM platform to ensure effective coordination across different workflows. One of the key aspects to address is the planning of the site layout [

51,

52].

Site layout planning involves determining the optimal placement of site facilities to ensure efficient operations [

53]. The positioning of facilities and service areas is critical, as improper allocation can negatively impact construction efficiency [

54]. A well-planned site layout must prioritize accessibility and safety while minimizing material handling and travel distances [

55,

56].

In recent years, various researchers have developed multiple approaches to optimize site layout planning. In this context, BIM serves as a valuable information source for construction planning and management [

57]. It facilitates the calculation and quantitative analysis of building materials [

58] and simplifies the determination of equipment movement paths based on the geometry of both internal and external site areas [

59].

While BIM excels in managing geometric information, it is limited in its capacity for spatial analysis, which is where Geographic Information Systems (GIS) offer complementary strengths. Over the years, researchers have explored the integration of GIS into BIM workflows for database management [

60], material quantification during project phases [

61], and topographical analysis [

62].

The integration of BIM and GIS is increasingly recognized as a strategic approach to addressing various challenges in construction projects. For example, Irizarry and Karan [

63] developed a BIM-GIS model to optimize the placement of tower cranes on construction sites. Zhao et al. [

64] proposed an integrated BIM-GIS model for highway planning, facilitating data exchange between the two platforms. Similarly, AlSaggaf and Jrade [

56] introduced a combined BIM-GIS framework for site layout planning.

However, given that BIM has limited capabilities in spatial analysis and GIS is not designed for detailed building modeling, model simplifications are often necessary, particularly for complex projects.

This study investigates the integration of GIS and BIM to optimize construction site layout planning. Specifically, the proposed methodology focuses on addressing obstacles and hazards related to air navigation. By integrating construction design information with the geometry of obstacle-free zones, the method enables three-dimensional visualization. This facilitates the representation of spatial relationships, dimensions, and changes in the internal and external configurations of the site throughout the various project phases.

3. Methodology

This study demonstrates how the integrated use of BIM and GIS could be effectively applied to the analysis phases of construction site management. Specifically, the methodology leverages BIM as a tool for presenting information and data on assets and facilities, while GIS is employed for conducting spatial analysis.

The integration of the three-dimensional representation of BIM into GIS proves highly beneficial for situating assets within a territorial context. The study assumes the use of the InfraWorks® software, due to its ability to integrate data from various sources and formats into a unified environment.

The analysis focuses on a specific airport domain, namely the management of obstacles and hazards for air navigation. Nevertheless, the proposed methodology can be adapted to any context combining BIM and GIS, as the underlying processes are independent of the specific applications used.

From a practical standpoint, the methodology is divided into three phases: (a) development of BIM models; (b) definition of Geographic Information in GIS; (c) BIM-GIS integration.

3.1. Development of BIM models

To ensure process standardization, it is crucial to identify the key elements and specifications necessary for BIM modeling. The volume and type of data required depend on several factors, including: (a) the intended application; (b) the disciplines involved; (c) the minimum information needed for subsequent analysis and evaluation phases.

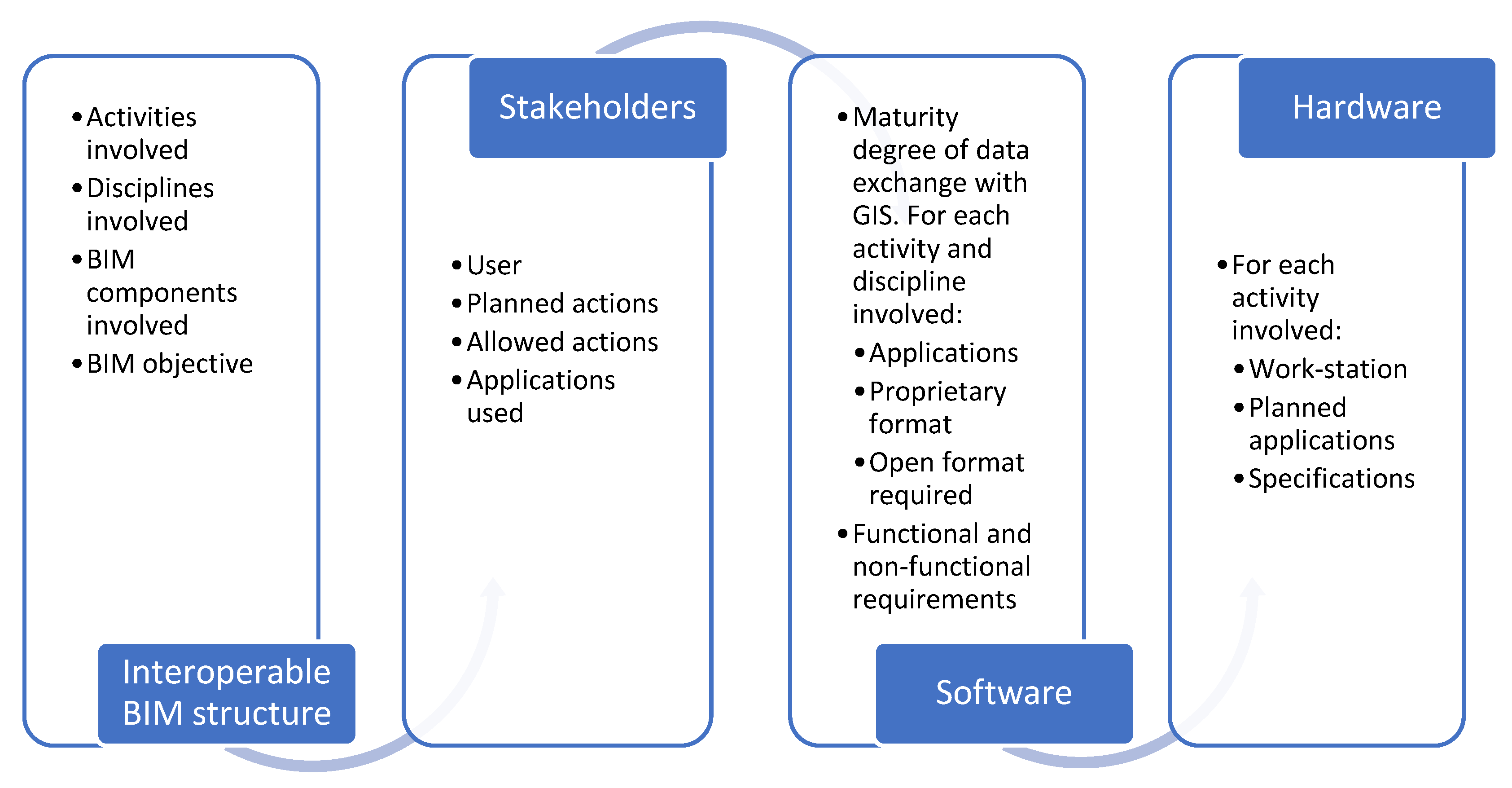

To this end,

Figure 2 illustrates the processes involved in the development of BIM models.

The input data implemented in BIM models are directly influenced by the level of accuracy required, which varies depending on the specific project [

65]. BIM enables the creation of highly detailed virtual models that are carefully calibrated to prevent redundancies or information gaps [

66]. For this reason, it is essential to define a development level (LOD), which specifies the depth of geometric and informational attributes associated with digital objects within the models [

67].

3.2. Definition of Geographic Information in GIS

GIS information is fundamental for executing spatial analyses required during the construction site management process. GIS serves as a computerized system for implementing, visualizing, analyzing, and sharing geographic data [

68].

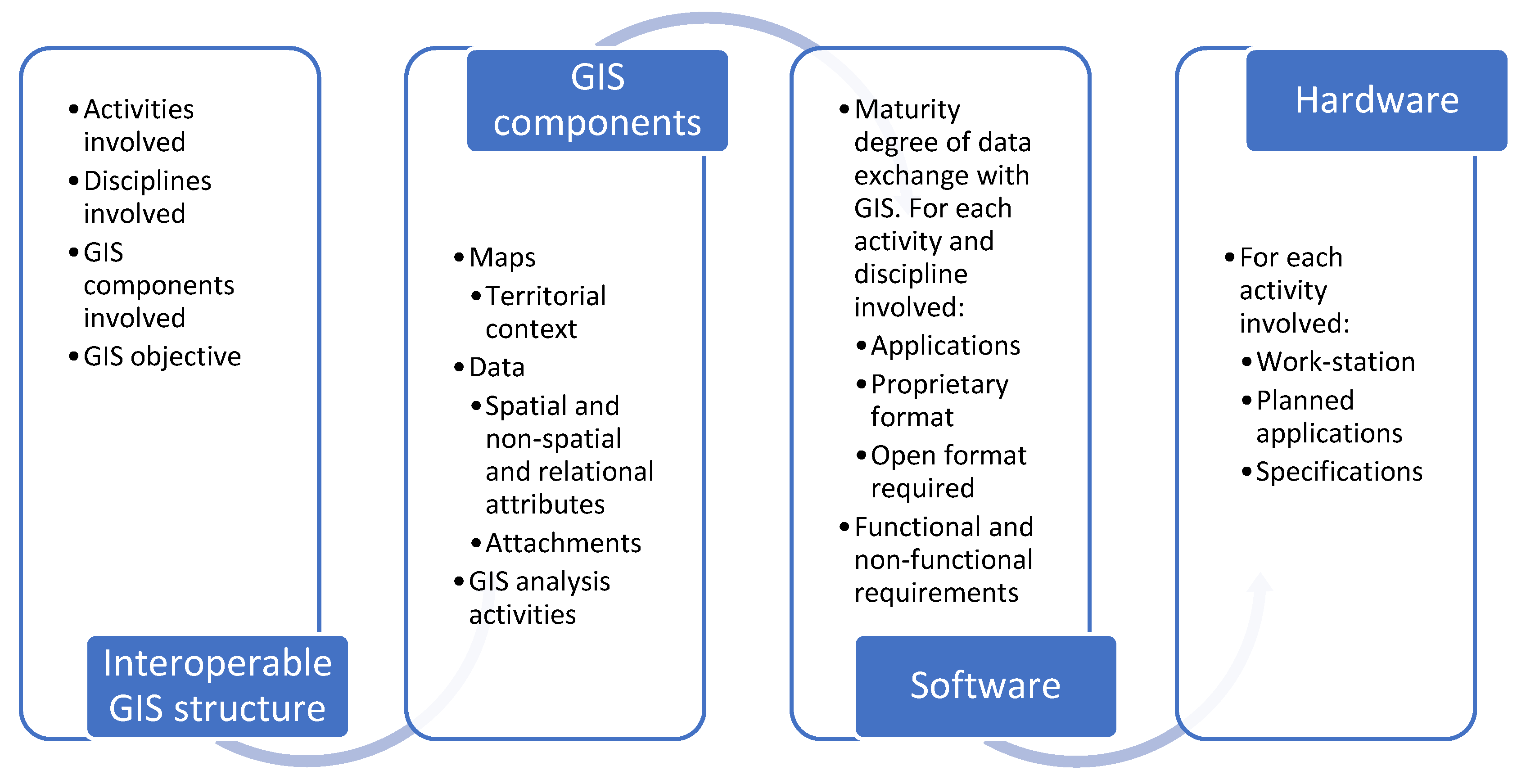

Geographic data are used to model reality by combining a graphical component (spatial data, such as rasters and vectors) with a thematic component (alphanumeric attributes). By linking these data to a map, GIS integrates information about both location and attributes, improving data management and decision-making capabilities. The processes associated with GIS technology are summarized in

Figure 3.

The quality of GIS data depends on the scale of analysis, which represents a critical parameter for ensuring accuracy [

69].

3.3. BIM-GIS integration

The integration of BIM and GIS aims to enable seamless data exchange between the two systems, compensating for their respective limitations. The two systems differ significantly in terms of their management approaches, scopes, and data generation methods [

70].

Over the years, various methods have been proposed for exchanging data between BIM and GIS, often relying on standardized exchange formats such as Industry Foundation Classes (IFC), shapefiles (.shp), and City Geography Markup Language (CityGML) [

70,

71].

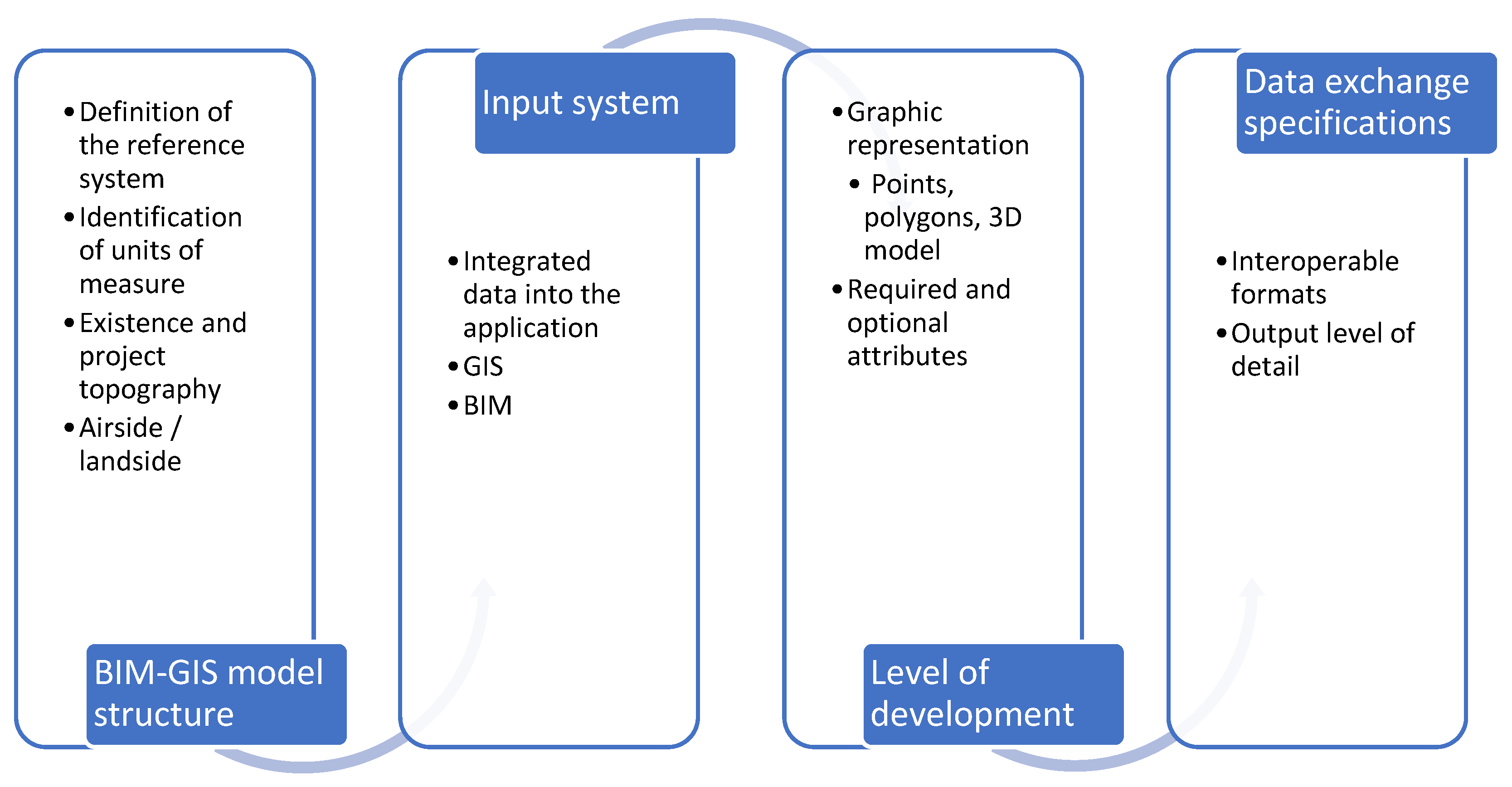

This study adopts the shapefile format—an open spatial vector data format developed by ESRI—because it stores geometric and attribute information without relying on topology. Using shapefiles, GIS objects can be directly implemented within the InfraWorks® application, eliminating the need for third-party conversion tools that could lead to data loss or distortion during analysis.

Figure 4 outlines the processes involved in the BIM-GIS integration phase.

In terms of geolocation, it is advisable to define a unified coordinate system at the outset. However, if the models are referenced in a different local or geographic coordinate system, coordinate transformations may be necessary to align the data.

In general, one of the potentials of BIM is the possibility of representing a dynamic environment [

72]. For instance, when applied to the operational management of a construction site, BIM can accommodate both static and dynamic representations, depending on the expected changes to the site.

The integration of temporal or planning information with the model elements is a critical feature. This capability allows for mapping the construction program across different project phases, as will be discussed in the following section.

4. Results: Model Application and Discussion

The present section applies the methodology discussed in

Section 3 to analyze and demonstrate the potential of BIM-GIS model for the operational management of construction sites. The selected application focuses on a critical airport context: managing obstacles and hazards for air navigation during pavement maintenance works [

73].

In airfield operations, an effective Airport Pavement Management System (APMS) is crucial for maintaining the safety, durability, and operational efficiency of flight infrastructures [

74]. By systematically assessing pavement conditions and prioritizing maintenance works, APMS helps extend the useful life of runways and taxiways while optimizing resource allocation. A proactive approach to pavement management reduces the risk of unexpected failures, minimizes operational disruptions, and ensures compliance with aviation safety standards [

75]. As air traffic demand grows, a well-structured APMS becomes essential for sustaining reliable and high-performance airport infrastructure.

In recent years, the integration of BIM and GIS has been transforming airport pavement management by enabling precise planning and real-time monitoring of maintenance activities. By leveraging advanced data visualization and spatial analysis, it becomes possible to detect potential hazards and improve overall safety. This methodology paves the way for a more sustainable, cost-effective, and technologically advanced approach to managing airport infrastructures [

76]. By the way of examples, managing obstacles and hazards for air navigation represents one of the most critical aspects in the planning phases of maintenance interventions.

Focusing on managing obstacle and hazards for air navigation during pavement maintenance works, it is essential to mention the Obstacle Free Zones (OFZ), i.e. the critical airport areas designed to ensure that no obstacles interfere with aircraft takeoff and landing procedures. These zones are defined based on international regulations [

77], considering factors such as aircraft category, runway configuration, and obstacle clearance requirements. During construction activities, the OFZ may be temporarily altered or adjusted to accommodate site operations while maintaining safety standards. As construction progresses through different phases, the OFZ may require temporary modifications, such as shifting the runway threshold or implementing operational restrictions [

78]. BIM-GIS integration plays a crucial role in these adjustments, enabling real-time visualization and simulation of the impact of temporary obstacles. The precise georeferencing of obstacles allows for proactive risk assessment, facilitating construction site planning without compromising airport functionality. GIS supports the creation of three-dimensional maps that aid in obstruction simulations and impact analysis, considering both visual and aerodynamic factors. By dynamically updating the OFZ model, airport operators could assess the minimum clearance distances required for safe operations, ensuring compliance with aviation regulations while optimizing construction scheduling [

79,

80]. The ability to manage these modifications interactively provides a significant advantage in coordinating work phases and minimizing disruptions to air traffic.

For this research work the case study focuses on the layout of Catania Airport, specifically on an area that underwent extraordinary maintenance during 2021–2022. Catania Airport has a single runway measuring 2,666.01 meters in length and 45 meters in width, with 7.5-meter-wide shoulders on either side. The airport is classified with an Aerodrome Reference Code of 4D [

77]. Given the operational constraints, managing a construction site within the maneuvering area while maintaining airport operations represents a significant challenge.

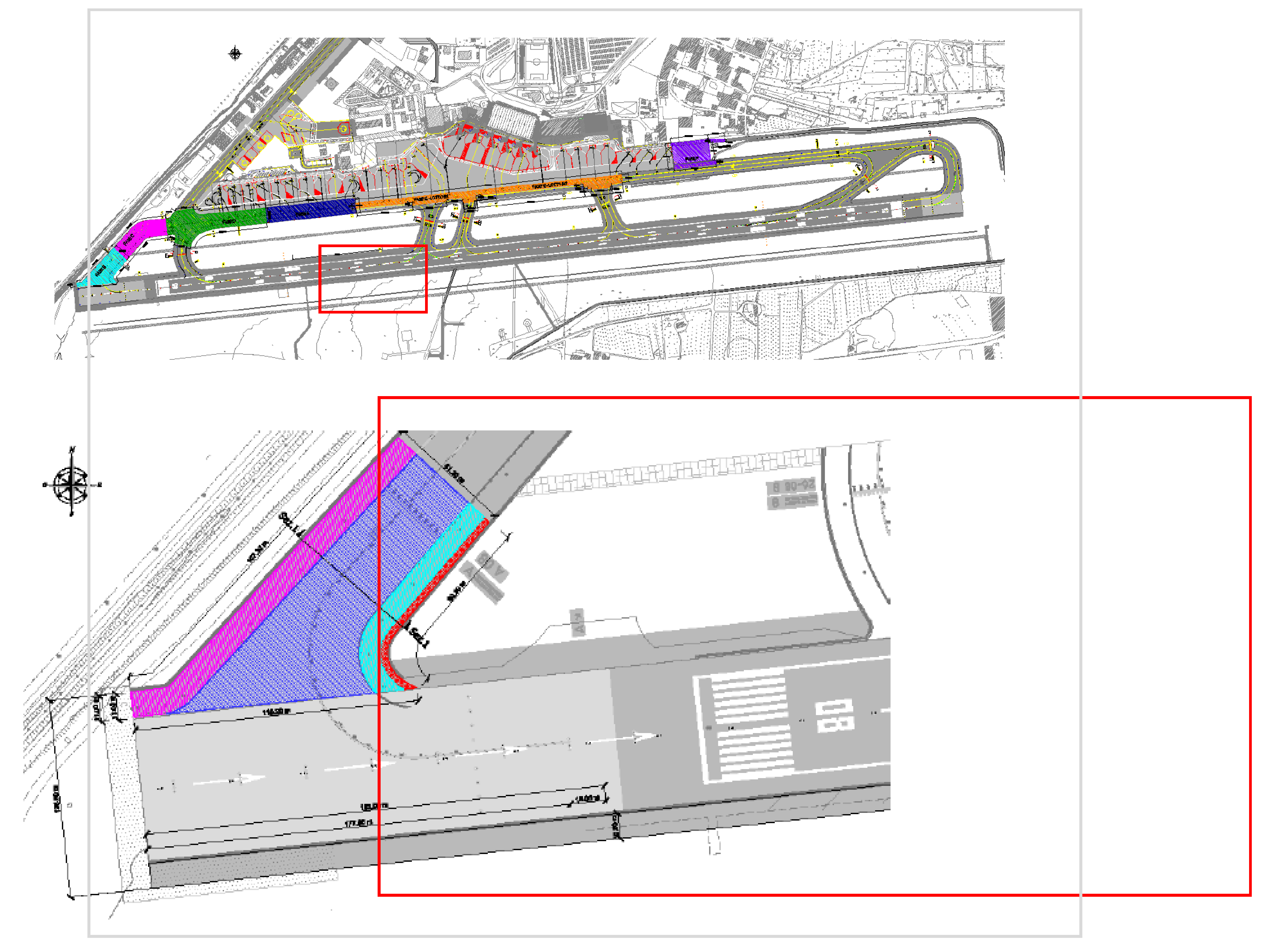

The maintenance work under examination focused on a portion of Taxiway A, addressing critical deterioration issues related to bearing capacity and surface regularity. The project involved constructing a rigid pavement designed to accommodate the airport's traffic volume for 20 years. To avoid airport closure, the work was executed in phases, as depicted in

Figure 5.

For this study, the simulation of construction site management focuses on a specific portion of the taxiway located entirely within the strip areas, as it represents the most operationally impactful zone.

Addressing obstacles and hazards for air navigation in construction site operations, the BIM-GIS prototype offers a significant advantage in verifying and validating temporary obstacles. Within the strip areas, any object is considered an obstacle. By simulating the construction site in BIM, including planned operational machinery, the model identifies factors that may pose risks to airport operations.

The BIM simulation process encompasses the following steps: (a) Importing the intervention area from native CAD, GIS, or BIM files; (b) Implementing components for each construction phase; (c) Ensuring compliance with regulatory requirements.

Table 1(a) outlines the minimum components to be included in the BIM-GIS model, along with their specifications in terms of applications, coordinate systems, measurement units, and exchange formats.

Table 1(b) details the level of detail (LOD) required for each component.

In this application, the generation of the intervention area starts from the GIS system although, depending on availability, it is also possible to import it from CAD or BIM files. Specifically, BIM modeling concerned the surfaces relating to the OFZs, through the Autodesk Revit® software. Parameterization of these surfaces simplifies updates and enables transferability to other runways with different characteristics.

The planimetric-altimetric development of the OFZ surfaces in BIM follows the category of the airport, as prescribed in the reference regulations [

77]. The implementation point within the territorial model starts from the knowledge of some known cartographic coordinates and the elevations of the runway threshold.

Regarding the GIS data, spatial context and temporary obstacles have been generated within the application Infraworks®. Only the intervention area has been created in a GIS application and implemented in the model using the shapefile interchange format.

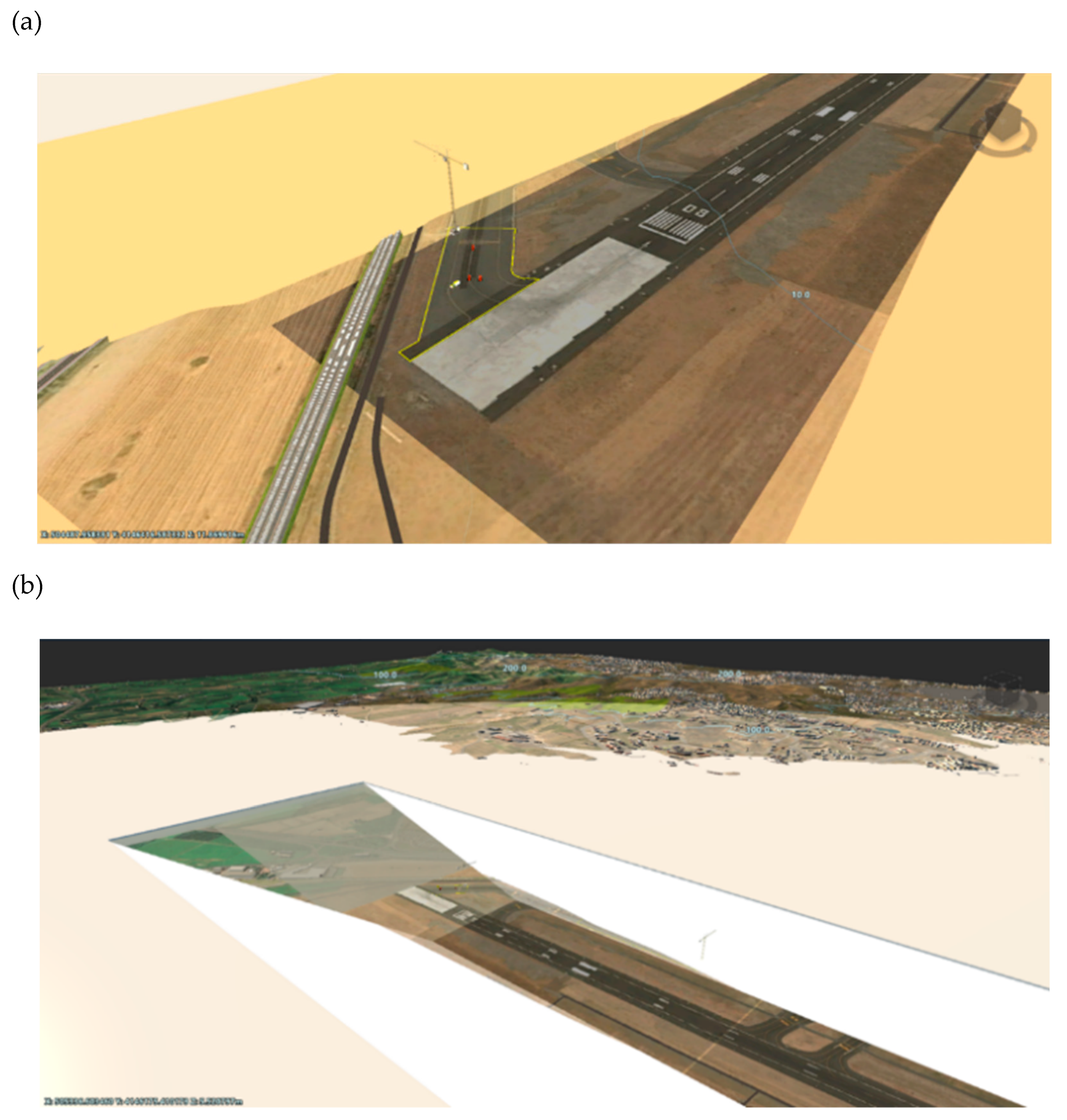

Figure 6(a) shows the result obtained in the integration phase between the area of the construction site and the OFZ surfaces. In accordance with regulatory requirements, maintaining the operation of the runway is possible through a change management procedure, with the specific temporary shift of the runway threshold. Through the use of BIM, it is possible to interactively modify the OFZ model, so as to identify and/or verify the minimum distance that guarantees the management of the construction site in complete safety (

Figure 6(b)).

Through this application it is clear how the integrated BIM-GIS interface could allow to manage three-dimensional monitoring with all the information necessary for geographical localization and the progress of construction site activities.

Focusing on the integration of the pavement management system within BIM, the connection with the subsurface utilities is a key factor in optimizing maintenance works strategies. BIM enables the precise mapping and monitoring of underground infrastructure, such as drainage systems, electrical conduits and fuel pipelines, i.e. critical to airside operations [

81]. By leveraging BIM’s parametric modeling capabilities, subsurface utilities could be visualized in relation to pavement structures, facilitating predictive maintenance and reducing the risk of damage during construction activities. This approach helps avoid unexpected and costly corrective interventions while optimizing maintenance scheduling, ultimately improving the lifecycle management of both pavement and subsurface utilities.

The benefits of using BIM integrated with GIS are evident, also in terms of safety management. By the way of example, it is demonstrated the possibility of facilitating the identification and monitoring of operational interference existing between workers and machines in the same area, indicating any hazards. Furthermore, through this application the procedures could be simplified to authorize the possibility of simultaneously supervising multiple construction sites located in areas that are even very distant from each other, with a clear optimization of the processing times.

5. Conclusions

This paper aims to analyze the adoption of advanced technologies, particularly Building Information Modeling (BIM), as a tool for streamlining processes in the AEC sector. BIM offers a dynamic and realistic system model, enabling innovative collaboration within a shared environment. When considering the advantages of BIM, such as time and cost savings, error reduction, and streamlined workflows, the mandated use of this technology, as required by reference legislation, becomes a strategic investment rather than a mere compliance measure.

To validate the effectiveness of the proposed methodology, this research applies it to a case study focusing on the operational management of an airport construction site. Specifically, the study examines one critical airport area: obstacles and hazards for air navigation. Recognizing the limitations of using BIM alone for spatial analysis, the research integrates BIM with external technologies, particularly GIS. The adopted methodology is divided into three main phases: (a) development of BIM models, (b) definition of geographic information in GIS, and (c) BIM-GIS integration. Each phase includes clearly defined processes to ensure precision and efficiency.

The findings underscore the significant potential of an integrated BIM-GIS interface in enhancing the management of construction sites. This approach enables precise three-dimensional monitoring, combining detailed information about geographic localization with real-time tracking of construction activities. One of the most notable advantages of this integration lies in its impact on safety management. For instance, the combined system facilitates the identification and mitigation of potential hazards by monitoring operational interferences between workers and machinery within the same area. Furthermore, the integration simplifies oversight procedures, enabling simultaneous supervision of multiple construction sites, even those geographically distant from each other. This capability not only enhances safety but also optimizes resource allocation and reduces processing times.

While the benefits of integrating BIM and GIS are evident, the study also highlights some inherent limitations of the two technologies. The limited spatial analysis capabilities of BIM and the unsuitability of GIS for developing detailed building models make certain model simplifications unavoidable, especially in complex projects. The integration process, while promising, is not always seamless, revealing challenges in achieving full interoperability between the systems. These limitations point to a need for further advancements in both technologies and their integration frameworks.

Ultimately, this research demonstrates the transformative potential of combining BIM and GIS in addressing complex challenges in construction site management, particularly in high-risk environments such as airports. The proposed methodology not only enhances project efficiency but also strengthens safety outcomes, making it a valuable approach for future applications. However, the study also serves as a call to action for continued research aimed at refining integration processes, improving interoperability, and expanding the practical applications of BIM-GIS collaboration across various sectors. By addressing these challenges, the full potential of these technologies can be unlocked, offering innovative solutions for the evolving needs of the AEC industry.

Conflicts of Interest

Declare conflicts of interest or state “The authors declare no conflicts of interest.” Authors must identify and declare any personal circumstances or interest that may be perceived as inappropriately influencing the representation or interpretation of reported research results. Any role of the funders in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results must be declared in this section. If there is no role, please state “The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results”.

Abbreviations

The following abbreviations are used in this manuscript:

| AEC |

Architecture Engineering Construction |

| APMS |

Airport Pavement Management System |

| BIM |

Building Information Modeling |

| ENAC |

National Civil Aviation Authority |

| GIS |

Geographic Information System |

| OFZ |

Obstacle Free Zone |

References

- Geurtsen, M.; Didden, J.; Adan, J.; Atan, Z.; Adan, I. Production, maintenance and resource scheduling: A review. European Journal of Operational Research 2023, 305(2), 501–529. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, Z.; Hammad, A. Automated excavators activity recognition and productivity analysis from construction site surveillance videos. Automation in Construction. [CrossRef]

- Manoharan, K.; Dissanayake, P.; Pathirana, C.; Deegahawature, D.; Silva, R. A guiding model for developing construction training programmes focusing on productivity and performance improvement for different qualification levels. Construction Innovation 2023, 23(4), 733–756. [Google Scholar] [CrossRef]

- Georgiadou, M. An overview of benefits and challenges of building information modelling (BIM) adoption in UK residential projects. Construction innovation. [CrossRef]

- Pan, Y.; Zhang, L. Automated process discovery from event logs in BIM construction projects. Automation in Construction. [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM handbook: A guide to building information modeling for owners, managers, designers, engineers and contractors, 2nd ed., Vol. 2. Publisher: John Wiley & Sons, 2011. [CrossRef]

- Bhagwat, P.; Shinde, R. Clash detection – A new tool in project management. International Journal of Scientific Research in Science, Engineering and Technology 2016, 2(4), 193-197.

- Ciribini, A.L.C.; Mastrolembo Ventura, S.; Paneroni, M. Implementation of an interoperable process to optimise design and construction phases of a residential building: A BIM Pilot Project. Automation in Construction 2016, 71, 62–73. [Google Scholar] [CrossRef]

- Cafiso, S.; Di Graziano, A.; D'Agostino, C.; Pappalardo, G.; Delfino, E. A new perspective in the road asset management with the use of advanced monitoring system & BIM. MATEC Web of Conferences 2018, 231. [Google Scholar] [CrossRef]

- Babatunde, S.; Ekundayo, D.; Babalola, O.; Jimoh, J. Analysis of the drivers and benefits of BIM incorporation into quantity surveying profession: Academia and students’ perspectives. Journal of Engineering, Design and Technology. [CrossRef]

- Charef, R. The use of Building Information Modelling in the circular economy context: Several models and a new dimension of BIM (8D). Cleaner Engineering and Technology. [CrossRef]

- Lidelöw, S.; Engström, S.; Samuelson, O. The promise of BIM? Searching for realized benefits in the Nordic architecture, engineering, construction, and operation industries. Journal of Building Engineering. [CrossRef]

- Kocakaya, M.N.; Namlı, E.; Işıkdağ, Ü. Building Information Management (BIM), A New Approach to Project Management. Journal of Sustainable Construction Materials and Technologies 2019, 4(1), 323–332. [Google Scholar] [CrossRef]

- Daniotti, B.; Pavan, A.; Lupica Spagnolo, S.; Caffi, V.; Pasini, D.; Mirarchi, C. Collaborative Working in a BIM Environment (BIM Platform). in BIM-Based Collaborative Building Process Management 2020, C. Springer, Ed., Springer Tracts in Civil Engineering. [CrossRef]

- Čuš-Babič, N.; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-chain transparency within industrialized construction projects. Computers in Industry 2014, 65(2), 345–353. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.; Xue, F.; Wu, L.; Zhao, R.; Lou, J.; Xu, J. Blockchain-Enabled IoT-BIM Platform for Supply Chain Management in Modular Construction. Journal of Construction Engineering and Management. [CrossRef]

- Koo, H.; O’Connor, J. Building information modeling as a tool for prevention of design defects. Construction Innovation 2022, 22(4), 870–890. [Google Scholar] [CrossRef]

- Peng, J.; Liu, X. Automated code compliance checking research based on BIM and knowledge graph. Scientific Reports. [CrossRef]

- Z. G. J. L. D. a. D. V. Jin. Using 4D BIM to assess construction risks during the design phase. Engineering, Construction and Architectural Management. [CrossRef]

- Parsamehr, M.; Perera, U.; Dodanwala, T.; Perera, P.; Ruparathna, R. A review of construction management challenges and BIM-based solutions: perspectives from the schedule, cost, quality, and safety management. Asian Journal of Civil Engineering 2023, 24(1), 353–389. [Google Scholar] [CrossRef]

- Yin, J.; Luo, S.; Rui, J.; Yao, J.; Zhang, F.; Fu, B.; Kassem, M. BIM-based detection and optimization of spatial-temporal clashes in underground pipeline construction. Automation in Construction. [CrossRef]

- Beach, T.; Petri, I.; Rezgui, Y.; Rana, O. Management of Collaborative BIM Data by Federating Distributed BIM Models. Journal of Computing in Civil Engineering. [CrossRef]

- Blay, K.; Tuuli, M.; France-Mensah, J. Managing change in BIM-Level 2 projects: benefits, challenges, and opportunities. Built Environment Project and Asset Management 2019. [Google Scholar] [CrossRef]

- Kula, B.; Ergen, E. Implementation of a BIM-FM Platform at an International Airport Project: Case Study. Journal of Construction Engineering and Management. [CrossRef]

- ISO Standard. ISO 29481-1:2016(E): Building Information Modeling - Information Delivery Manual - Part 1: Methodology and Format., 2016.

- European Standards. BS EN 15978:2011: Sustainability of construction works. Assessment of environmental performance of buildings. Calculation method, 2011.

- Yang, B.; Fang, T.; Luo, X.; Liu, B.; Dong, M. A BIM-based approach to automated prefabricated building construction site layout planning. KSCE Journal of Civil Engineering 2021, 26, 1535–1552. [Google Scholar] [CrossRef]

- Chahrour, R.; Hafeez, M.; Ahmad, A.; Sulieman, H.; Dawood, H.; Rodriguez-Trejo, S. Cost-benefit analysis of BIM-enabled design clash detection and resolution. Construction Management and Economics. [CrossRef]

- Sompolgrunk, A.; Banihashemi, S.; Mohandes, S. Building information modelling (BIM) and the return on investment: a systematic analysis. Construction Innovation 2023. [Google Scholar] [CrossRef]

- MacLeamy, P. AIA/HOK 2009, From: Zhang, J.; Wu, C.; Wang, Y.; Ma, Y.; Wu, Y.; Mao, X. (2018) The BIM-enabled geotechnical information management of a construction project, in Computing 2009, 100(2). 100(2).

- Construction, M.H. Smart Market Report: The Business Value of BIM in North America, Bedford, MA, United States, 2012.

- Matarneh, S.; Elghaish, F.; Rahimian, F.; Dawood, N.; Edwards, D. Automated and interconnected facility management system: An open IFC cloud-based BIM solution. Automation in Construction. [CrossRef]

- Zhu, J.; Tan, Y.; Wang, X.; Wu, P. BIM/GIS integration for web GIS-based bridge management. Annals of GIS, 2021. [Google Scholar] [CrossRef]

- Di Mascio, P.; Dinu, R.; Loprencipe, G.; Moretti, L. Land Use Around Airports: Policies and Methods for Third-Party Risk Assessment—A Review. Future Transportation 2024, 4(4), 1501–1519. [Google Scholar] [CrossRef]

- Di Graziano, A.; Ragusa, E.; Trifilò, D.; Triaca, L.M.; Trombetti, M.; Arcidiacono, C. Interaction Between Airport Facilities And The Surrounding Area Within The GIS And BIM Interoperability. Transportation Research Procedia 2023, 69, 273–280. [Google Scholar] [CrossRef]

- Ayeni, A. Assessment of Potential Aerodrome Obstacles on Flight Safety Operations Using GIS. Journal of Geographic Information System 2018, 10, 1–24. [Google Scholar] [CrossRef]

- Álvarez, A.; Ordieres-Meré, J.; Loreiro, A. d. M. L. Opportunities in airport pavement management: Integration of BIM, the IoT and DLT. Journal of Air Transport Management 2021, 90. [Google Scholar] [CrossRef]

- Eurocontrol. Revisiting the "Swiss Cheese" model of accidents, Bruxelles, 2006.

- Tagliabue, L.; Ciribini, A. A BIM-Based IoT Approach to the Construction Site Management. Ricerche E Progetti Per Il Territorio, La Città E l’architettura.

- Deng, Y.; Gan, V.; Das, M.; Cheng, J.; Anumba, C. Integrating 4D BIM and GIS for Construction Supply Chain Management. Journal of Construction Engineering and Management. [CrossRef]

- Wang, J.; Zhang, S.; Fenn, P.; Luo, X.; Liu, Y.; Zhao, L. Adopting BIM to Facilitate Dispute Management in the Construction Industry: A Conceptual Framework Development. Journal of Construction Engineering and Management. [CrossRef]

- Lee, J.; Yang, H.; Lim, J.; Hong, T.; Kim, J.; Jeong, K. BIM-based preliminary estimation method considering the life cycle cost for decision-making in the early design phase. Construction Management 2020, 0, 384–399. [Google Scholar] [CrossRef]

- Bijen, J. Durability of engineering structures: Design, repair and maintenance, Woodhead Publishing: Cambridge, UK, 2003.

- Lopez, R.; Love, P. Design Error Costs in Construction Projects. Journal of Construction Engineering and Management. [CrossRef]

- de Souza, M.; Fialho, B.; Ferreira, R.; Fabricio, M.; Codinhoto, R. Modelling and coordination of building design: an experience of BIM learning/upskilling. Architectural Engineering and Design Management 2021, 19(1), 74–91. [Google Scholar] [CrossRef]

- Dashti, M.; RezaZadeh, M.; Khanzadi, M.; Taghaddos, H. Integrated BIM-based simulation for automated time-space conflict management in construction projects. Automation in Construction. [CrossRef]

- Love, P.; Skitmore, R.; Earl, G. Selecting a suitable procurement method for a building project. Construction Management and Economics 1998, 16(2), 221–233. [Google Scholar] [CrossRef]

- Liu, H.; Skibniewski, M.; Ju, Q.; Li, J.; Kiang, H. BIM-enabled construction innovation through collaboration: a mixed-methods systematic review. Construction innovation. [CrossRef]

- Gaur, S.; Tawalare, A. Investigating the Role of BIM in Stakeholder Management: Evidence from a Metro-Rail Project. Journal of Management in Engineering. [CrossRef]

- Ullah, K.; Witt, E.; Lill, I. The BIM-Based Building Permit Process: Factors Affecting Adoption. Building 2022, 22. [Google Scholar] [CrossRef]

- Xu, M.; Mei, Z.; Luo, S.; Tan, Y. Optimization algorithms for construction site layout planning: a systematic literature review. Engineering, Construction and Architectural Management. [CrossRef]

- Al Hawarneh, A.; Bendak, S.; Ghanim, F. Construction site layout planning problem: Past, present and future. Expert Systems with Applications. [CrossRef]

- Fathy, M.; Elbeltagi, E.; Elsheikh, A. Dynamo visual programming-based generative design optimization model for construction site layout planning. MEJ Mansoura Engineering Journal. [CrossRef]

- Olugboyega, O.; Wemimo, O. Construction site layout optimization and 3D visualization through BIM tools = Visualización 3D y optimización a través de herramientas BIM aplicado a los planos de Proyecto. BMA 2018, 2(2), 35–52. [Google Scholar] [CrossRef]

- Kumar, S.; Cheng, J. A BIM-based automated site layout planning framework for congested construction sites. Automation in Construction 2015, 59, 24–37. [Google Scholar] [CrossRef]

- AlSaggaf, A.; Jrade, A. ArcSPAT: an integrated building information modeling (BIM) and geographic information system (GIS) model for site layout planning. International Journal of Construction Management 2023, 23(3), 505–527. [Google Scholar] [CrossRef]

- Chan, D.; Olawumi, T.; Ho, A. Perceived benefits of and barriers to building information modelling (BIM) implementation in construction: the case of Hong Kong. Journal of Building Engineering 2019, 25, 100764. [Google Scholar] [CrossRef]

- Tao, G.; Feng, H.; Feng, J.; Wang, T. Dynamic multi-objective construction site layout planning based on BIM. KSCE Journal of Civil Engineering 2022, 26(4), 1522–1534. [Google Scholar] [CrossRef]

- Zavari, M.; Shahhosseini, V.; Ardeshir, A.; Seby, M. Multi-objective optimization of dynamic construction site layout using BIM and GIS. Journal of Building Engineering. [CrossRef]

- Cheng, M.; O’Connor, J. ArcSite: Enhanced GIS for Construction Site Layout. Journal of Construction Engineering and Management. [CrossRef]

- Su, X.; Andoh, A.; Cai, H.; Pan, J.; Kandil, A.; Said, H. GIS-based dynamic construction site material layout evaluation for building renovation projects. Automation in Construction 2012, 27, 40–49. [Google Scholar] [CrossRef]

- Bansal, V. Integrated CAD and GIS–based framework to support construction planning: case study. Journal of Architectural Engineering. [CrossRef]

- Irizarry, J.; Karan, E. Optimizing location of tower cranes on construction sites through GIS and BIM integration. Journal of Information Technology in Construction 2012, 17. [Google Scholar]

- Zhao, L.; Liu, Z.; Mbachu, J. Highway alignment optimization: an integrated BIM and GIS approach. International Journal of Geo-Informatics. [CrossRef]

- International Organization for Standardization. ISO 19650-1:2018: Organization and digitization of information about buildings and civil engineering works, including building information modelling (BIM) — Information management using building information modelling - Part 1: Concepts and principles, 2018.

- Murphy, M. Implementing innovation: a stakeholder competency-based approach for BIM. Construction Innovation. [CrossRef]

- International Organization for Standardization. ISO 19650-1:2018 - Organization and digitization of information about buildings and civil engineering works, including building information modelling (BIM) — Information management using building information modelling — Part 1: Concepts and principles, 2018.

- International Organization for Standardization. ISO 19115:2003 - Geographic information — Metadata, 2003.

- Goodchild, M. Scale in GIS: An overview. Geomorphology 2011, 130(1-2), 5-9.

- International Organization for Standardization. ISO/TR 23262:2021 - GIS (geospatial) / BIM interoperability, 2021.

- Sani, M.; Rahman, A. GIS and BIM integration at data level: a review. The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences - International Conference on Geomatics and Geospatial Technology (GGT 2018). [CrossRef]

- Zhang, H.; Yu, L. Site layout planning for prefabricated components subject to dynamic and interactive constraints. Automation in Construction. [CrossRef]

- Di Graziano, A.; Costa, A.; Ragusa, E. Using an Airport Pavement Management System to Optimize the Influence of Maintenance Alternatives on Operating Conditions. Applied Science 2024, 14, 7158. [Google Scholar] [CrossRef]

- Di Graziano, A.; Ragusa, E.; Marchetta, V.; Palumbo, A. Analysis of an Airport Pavement Management System during the Implementation Phase. KSCE Journal of Civil Engineering 2021, 25(4), 1424–1432. [Google Scholar] [CrossRef]

- Ragusa, E.; Costa, A.; Di Graziano, A. Exploring New Computational Strategies for Managing Maintenance Activities of Airport Pavement Systems. International Journal of Pavement Research and Technology 2024, 17(1), 80–101. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Wang, L. Research on information management of Airport pavement quality based on BIM and GIS integration. Green and Intelligent Technologies for Sustainable and Smart Asphalt Pavements 2021, 469–475. [Google Scholar] [CrossRef]

- International Civil Aviation Organization (ICAO). Annex 14 to the Convention on International Civil Aviation – Volume I – Aerodrome Design and Operation, Eighth Edition, Montréal, Quebec, Canada, 2018.

- Contreras-Alonso, R.; Ezquerra-Canalejo, A.; Pérez-Martìn, E.; Herrero-Tejedor, T.R.; Medina, S.L. Environmental assessment of Obstacle Limitation Surfaces (OLS) in airports using geographic information technologies. Plos One 2020. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Hao, P. Hub Airport End-Around Taxiway Construction Planning Development: A Review. Applied Sciences. [CrossRef]

- Chang, S. A GIS Model for Analyzing Airspace Obstructions and Safety near Airports. Journal of Civil Engineering and Architecture 2016, 10, 553–562. [Google Scholar] [CrossRef]

- Yin, J.; Luo, S.; Rui, J.; Yao, J.; Zhang, F.; Fu, B.; Kassem, M. BIM-based detection and optimization of spatial-temporal clashes in underground pipeline construction. Automation in Construction 2024, 166. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).