1. Introduction

In the mining industry, equipment reliability is one of the fundamental pillars to ensure the continuous and efficient operation of processes, especially in key processes such as comminution or material size reduction, where operational performance largely depends on the proper selection of equipment. Decisions related to equipment configuration can critically affect productivity, downtime, and associated costs, making optimization in configuration selection essential for the success of mining operations. Without proper selection, the frequency of failures or underutilization of equipment can increase, resulting in unplanned downtime and rising operational costs. Addressing this issue from a reliability-based approach is crucial to ensure operational continuity.

There are several definitions of reliability quoted in the literature but the one most often stated in textbooks is “the probability that the systems will perform”[

1]. In a mining environment, these principles are crucially applied to equipment and processes. Equipment configurations must meet not only production demands but also reliability standards that ensure continuity over time, minimizing the impact of failures on productivity. However, achieving this balance between productivity and reliability is not straightforward, as the most productive configurations are not always the most reliable, and vice versa. This highlights the need for methodologies that efficiently integrate both aspects.

This study aims to develop and propose a framework for the selection of equipment configurations that allows optimizing operational productivity through improved reliability, specifically applicable to mineral comminution projects. The proposal is based on the use of two main data sources: an APM platform that provides information related to equipment reliability and process simulation module of an AIP software that allows obtaining detailed technical and operational information of the equipment, evaluating alternative configurations composed by alternative equipment picked from a catalog. By integrating both sources, an algorithm was developed that evaluates different configurations and proposes optimal combinations of equipment regarding reliability and productivity requisites.

Furthermore, a key aspect of this methodology is the consideration of the energy consumption of the equipment, which allows generating configurations that not only ensure operational continuity but also optimize energy use without compromising productivity. This is particularly relevant in the mining industry, where energy efficiency is a key factor for cost reduction and operational sustainability. Ultimately, this work contributes to improving decision-making in equipment management and developing a more strategic approach to their configuration, considering not only productivity but also reliability and energy efficiency.

2. Theorical Background

In the current reality, marked by the challenges of a VUCA (Volatile, Uncertain, Complex, and Ambiguous) world and global disruptions affecting production systems (such as health, geopolitical, and climate-related threats), the need arises for implementing reliable and robust systems which can adapt quickly to operational changes and shifting asset conditions, ensuring and improving resilience and sustained performance [

2]. Improving an industrial plant's performance relies on several key factors, including effective execution of preventive maintenance (PM), continuous asset condition monitoring, and comprehensive Asset Performance Management (APM) and Optimization (APO) [

3].

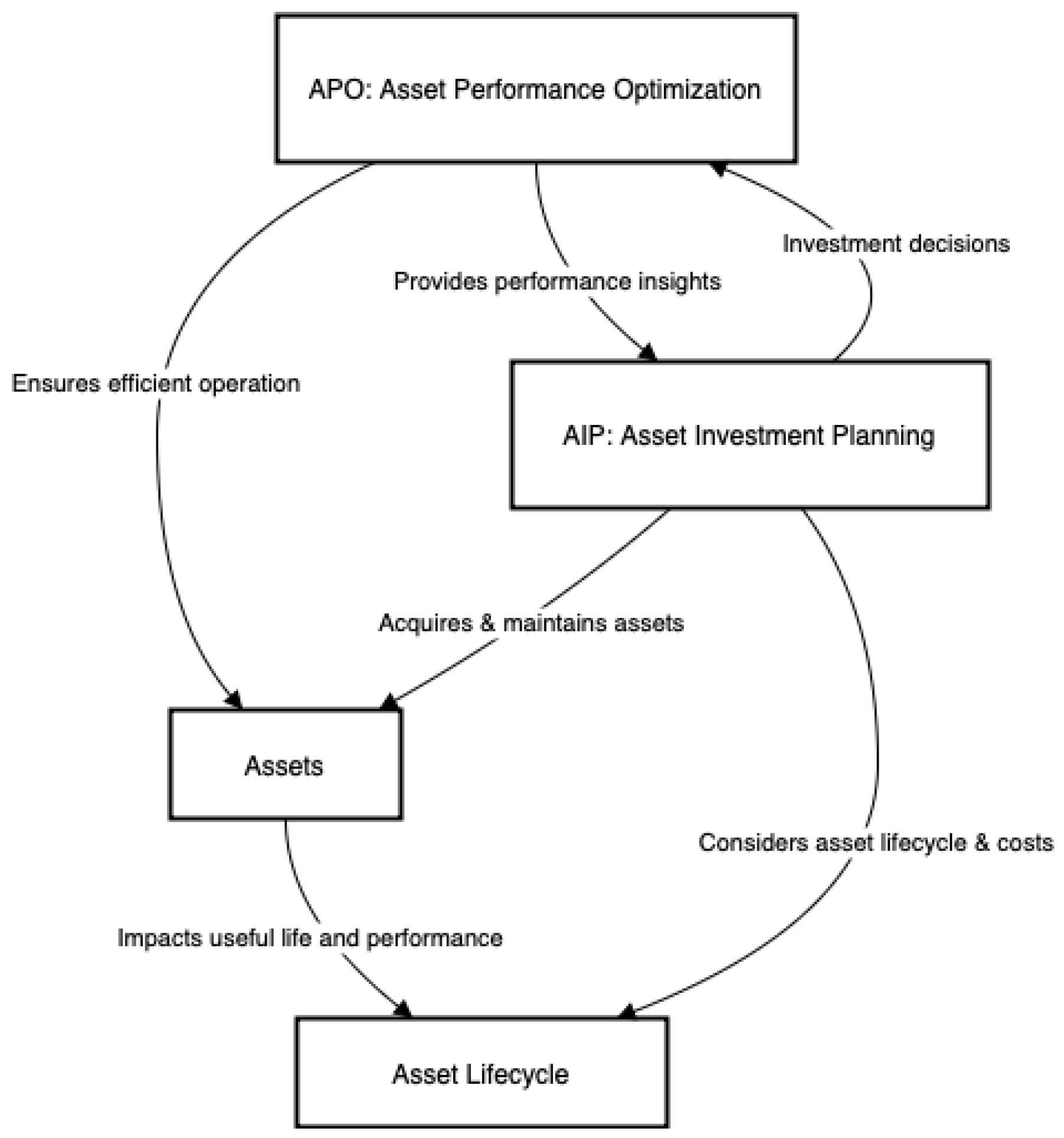

In the management of industrial assets, two critical concepts emerge that aim to optimize both operational and strategic and long-term oriented performance: Asset Performance Optimization (APO) and Asset Investment Planning (AIP). Although these two concepts are closely related, they have distinct purposes, methods, and outcomes that cater to different aspects of asset management. APM focuses on improving the operational performance of assets linked to, mainly, reliable equipment and processes. AIP, essential for improving productivity and reducing risks in industrial systems, should align its results with CAPEX and OPEX optimization throughout the asset lifecycle. Both approaches, jointly, support more sustainable financial and operational asset management [

4]. To enhance strategic decision-making in Asset Management (AM), it is crucial to integrate Asset Performance Management (APM) with Asset Investment Planning (AIP).

Asset Investment Planning (AIP) constitute a strategic approach that helps companies make complex decisions about budget allocation and long-term asset management. Unlike Asset Performance Management (APM) and Enterprise Asset Management (EAM) systems, which focus on tactical and operations, mainly, on assets´ availability, AIP addresses tactical and strategic decisions mainly focused on capital expenditures (CAPEX) [

5] and the composition of the proposed alternative configurations. Although initially adopted in regulated sectors such as energy and water utilities, Asset Investment Planning (AIP) is rapidly expanding into industries like oil and gas, transportation, and manufacturing due to its ability to optimize investment decisions and enhance long-term financial performance [

5,

6].

Asset Performance Management is primarily concerned with the optimization of assets’ operational performance. The primary goal of APO is to maximize the availability, reliability, and efficiency of assets through tools like Reliability engineering, Simulation and Sensibilization (RAM analysis). APM can be seen as a tactical approach to asset management because it addresses the short and medium-term performance and operational challenges faced by assets in an organization.

In APM, the focus is on continuously improving how assets perform within their respective operational environment. The goal is to reduce unplanned downtime, extend the useful life of assets, and ensure that assets are performing at their best, which, in turn, reduces maintenance costs. In a certain manner, the APM approach is dynamic, operational decisions ensuring that the right maintenance actions are carried out at the right time. Moreover, APO is increasingly tied to data analytics, with big data being leveraged to predict failures, optimize processes, and enhance operational productivity and throughput.

On the other hand, Asset Investment Planning deals with strategic decision-making, mainly related to asset investments, focusing on capital expenditures (CAPEX). AIP concerns itself with the strategic point of view of asset management, primarily aiming to plan and allocate and configure resources efficiently to acquire, add, or replace assets in alignment with long-term business goals. In other words, it supports long-term planning by evaluating how investments in assets can provide the maximum return on investment (ROI) over time. AIP involves detailed plant modeling and stage analysis to predict the future costs, performances and outcomes of investments. Approaches like Life Cycle Costing (LCC) are commonly used in AIP to complement the assessment of the total cost of owning and operating an asset throughout its life, including acquisition, and reconfiguration costs. The role of AIP is to make or assist investment decisions that align with the organization’s strategic objectives, balancing financial opportunities and constraints with the operational needs of the business. The AIP approach may be used to determine when and how to invest in new assets, whether through replacement, upgrades, or new acquisitions. A recent approach gaining momentum in physical asset management is the use of Digital Twins. This technology constitutes a powerful tool for analyzing and optimizing production systems by enhancing not only efficiency but also focusing on asset availability and throughputability. Digital Twins enable real-time monitoring, simulation, and performance forecasting, making them essential for improving operational resilience and maximizing system productivity [

5,

6]

Despite their differences, APM and AIP are complementary. The integration between an APM and an AIP is deemed both essential and valuable, hence, the need for these platforms to work in an integrated manner [

5]. AIP ensures that the right assets are being acquired and maintained at the right times and costs, while APM ensures that assets are operating efficiently, which directly impacts their useful life and performance. Both strategies must work together to ensure the overall success of asset management. As

Figure 1 depicts, the insights gained from APM can inform AIP decisions. If APM reveals that certain assets are consistently underperforming or reaching the end of their useful life, AIP can then decide on the need for investment in replacements or upgrades. Similarly, AIP decisions, such as whether to invest in new technologies, can lead to changes in the APM approach to accommodate the capabilities of newer or more advanced assets, mainly from the reliability point of view.

Analyzing different stages in asset investment planning provides a transparent and reproducible basis for evaluating desirables productivity levels and associated costs. This approach supports long-term cost management through strategic infrastructure investments while enabling risk identification and mitigation. Given the critical role of asset risk management in production systems, future research should focus on enhancing these evaluation methods [

7].

Selected studies indicate that economic performance is closely linked to a tactical approach in implementing Asset Performance Management (APM). This adoption is often driven by the potential to reduce maintenance-related costs [

8,

9] or, more broadly, by the need to increase economic returns [

10].

However, customers often have extensive needs and high expectations, which can surpass the capabilities or available resources of individual solution providers, complicating the delivery process. Therefore, integrating Asset Performance Management (APM) and Asset Investment Planning (AIP) platforms is essential for maximizing asset management efficiency. Their integration enables AIP decisions to be supported by APM's operational insights, allowing for stage testing and sensitivity analysis. This approach provides more realistic investment evaluations by considering both financial and operational impacts, such as asset availability and throughput capacity. As a result, organizations can align investment strategies with operational goals more effectively.

The selection and optimization of equipment in mining operations is a critical process that directly influences efficiency and operational costs. Various methodologies have been developed to address this challenge, with the Life Cycle Cost (LCC) Analysis being particularly notable. Such analysis evaluates the total cost of ownership of equipment, including acquisition, operation, maintenance, and final disposal. The study by Baudino et al. [

11] highlights the importance of using simulation models to assess LCC and make informed decisions in machinery selection.

Digitalization has significantly transformed this process, providing advanced tools such as simulation software and performance analysis platforms that allow for comprehensive system evaluation both before and after project implementation. By modeling different combinations of equipment, it is possible to assess their performance under specific conditions, optimizing parameters such as reliability, availability, and energy consumption. This significantly reduces the risks associated with equipment selection, as decisions are based on realistic simulations and precise technical data.

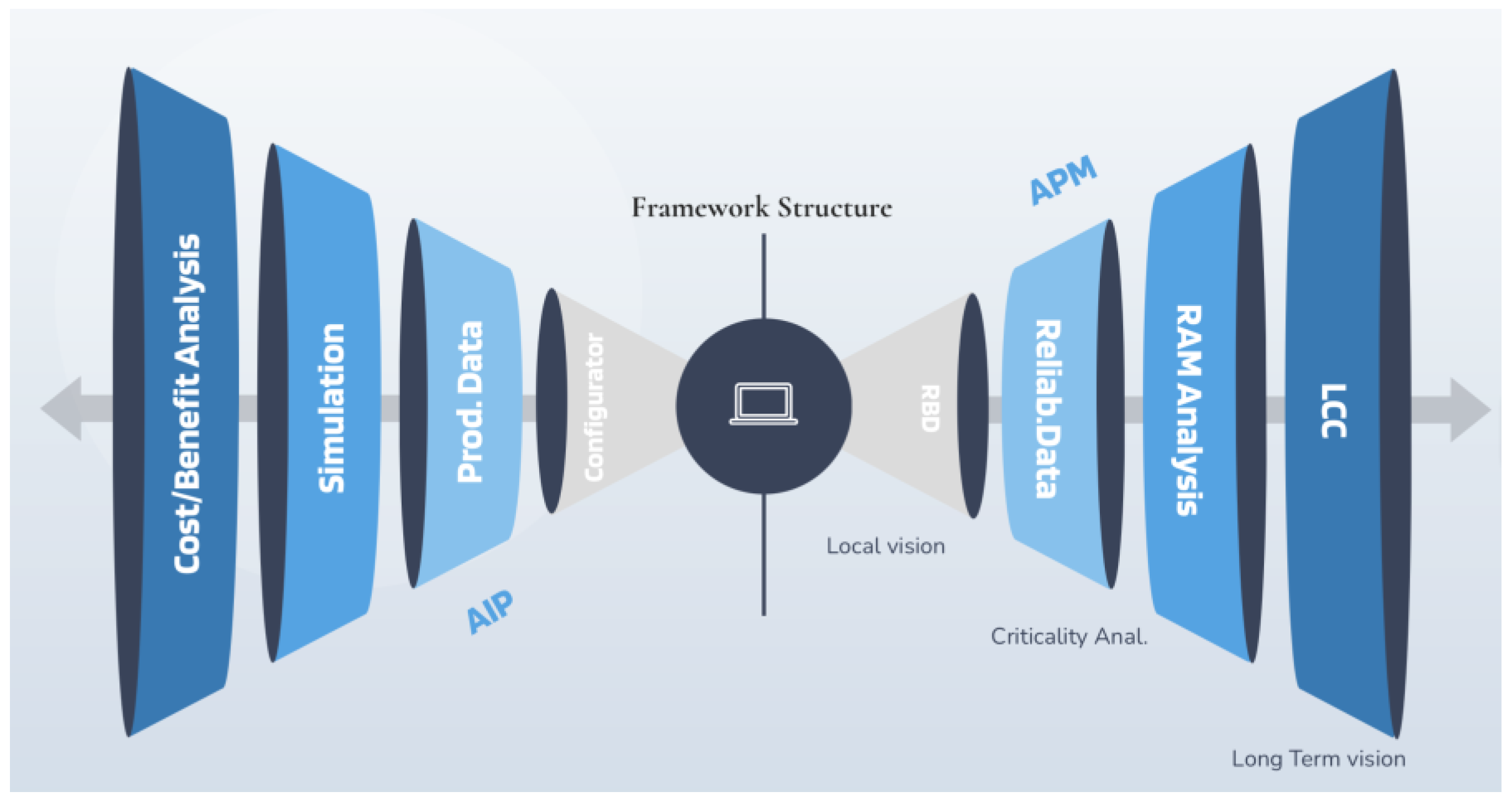

This paper proposes an integration framework of Asset Investment Planning (AIP) and Asset Performance Optimization (APO) platforms to enhance decision-making in mineral crushing plants. This integration, and its corresponding middleware, would enable comprehensive analyses by linking long-term investment strategies with actual asset performance data. By combining AIP’s strategic planning capabilities with APO’s operational insights, it is possible to simulate various operational stages, assess equipment reliability, and evaluate potential upgrades or replacements. Overall, the proposed approach, enhanced by digital tools, focuses on ensuring the durability and stability of plant size and capacity analysis projects. Additionally, probabilistic RAM analyses and Monte Carlo simulations are used to evaluate and optimize considering system reliability. This allows for quantifying the increase in system availability, through greater overall reliability [

12] and lesser risk of critical failures, ensuring long-term operational continuity, runtime and higher throughput.

This approach would improve the accuracy of investment decisions by considering factors such as equipment availability, throughput efficiency, and lifecycle costs, ultimately maximizing the plant's productivity and investment returns.

3. Main Methodology

As it was mentioned before, the scope of this research is defined by the need to integrate two assets management platforms for the optimization of equipment configurations in comminution plants. The project optimization can be seen from two main perspectives or in two different scenarios: the project during the conceptual development stage and the operation of an already functional plant (

Figure 2). This distinction allows the proposed methodology to be adapted to the specific conditions and constraints of each stage, maximizing its applicability and effectiveness.

3.1. Initial Stage: Projects in Conceptual Development

In this stage, the project is in its early phases of design and conceptualization, offering greater flexibility to explore and propose significant changes in configurations. The use of the proposed framework allows for the simulation of different operational stages without incurring real costs, enabling:

Evaluate multiple equipment configurations based on criteria such as reliability, productivity, and energy consumption.

Test optimal combinations/configurations through iterative simulations, ensuring that the decisions made align with production, sustainability, and reliability goals.

Propose significant modifications, such as the inclusion, substitution, or elimination of equipment, without the economic impact and complexity that this would generate in an operational plant.

This stage is the primary focus of the research, as the inherent flexibility at this stage allows for the implementation of advanced optimization strategies without physical or financial constraints.

3.2. Second Stage: Operating Plants

At this stage, the project is already in the operational phase, and the configurations and equipment under analysis are part of an existing operating system. The proposed methodology focuses on analyze practical and realistic alteration strategies, adapted to the actual limitations of an operating plant. These strategies include [

13]:

Maintaining well-regulated basic conditions

Adhering to proper operating procedures

Restoring deterioration

Improving weakness in design

Improving operation and maintenance skill

While the analysis at this stage is more constrained regarding the modifications that can be implemented on an existing and operational system, the integration between an APM and an AIP proves both necessary and valuable in either of the two scenarios.

3.3. Key concepts in Optimization of Equipment Configurations

The proper selection and configuration of equipment is a critical process for optimizing operational efficiency in comminution processes. This optimization process uses several criteria which help to identify which equipment has the greatest impact on the overall reliability of the system. Those criteria are briefly described below:

Availability and Utilization: These criteria is incorporated through the use of an APM Suite software, specifically, performing Monte Carlo simulations. Such experiments consider those metrics to evaluate equipment performance and its effectiveness. Availability is expressed as the percentage of time the system is ready to operate or produce [

12], while utilization, also called service factor, measures the effective time of operation of an asset during a given period [

14]. Both parameters are fundamental to ensuring the continuity and efficiency of operations, and their application in this study ensures the methodological alignment with the proposal.

Criticality: Criticality is a central concept in reliability analysis and engineering, it refers to the level of risk or impact that a piece of equipment's failure can have on overall operations. This analysis is used to identify and prioritize equipment that poses a higher risk to the system and is more likely to cause significant problems in overall performance. This criterion is essential for focusing improvement efforts, helping to select the most vulnerable equipment that needs to be optimized or replaced. This allows for prioritizing equipment that has a disproportionate impact on the continuity of operations and operational reliability. The criticality of equipment can be determined through Failure Modes and Effects Analysis (FMEA) or Fault Tree Analysis (FTA), which help identify the most vulnerable points in the system and prioritize maintenance efforts [

17].

Number of Failures: The inclusion of this criterion responds to the need to quantify the impact of recurring failures on overall operations. Although it may seem redundant when considering criticality, the number of failures provides a direct and specific metric regarding the frequency of interruptions, thus complementing the comprehensive view of equipment performance.

Reliability: is a key concept in maintenance engineering and industrial asset management. It is defined as the probability that an item can perform its required function during a time interval established and under defined conditions of use [

12]. Reliability theory is based on probabilistic models that evaluate the behavior of equipment over time, considering factors such as wear, failure criticality, and failure periodicity (MTBF). These models allow for estimating the capacity of equipment to meet operational goals and ensure operational efficiency [

15]. It is an essential criterion in configuration/equipment selection. This criterion integrates the other aspects and provides a solid framework for evaluating the robustness of the configurations. Reliability analysis and optimization models are applied to evaluate different configurations, where equipment can be arranged in series, parallel, or split, which directly impacts operational redundancy and load distribution among equipment. For example, parallel systems theory allows for the distribution of operational load across multiple pieces of equipment, thereby reducing the criticality of any single piece and improving overall reliability [

16].

Simulation and Advanced Analytics Tools: Simulation tools play a crucial role in the analysis of equipment configurations. In this study, a simulation and process design-based module of an APM software has been used. We consider such platform as a sort of input module linked to the AIP platform through the proposed integration module, because it provides detailed technical information about the equipment and evaluates their performance in different configurations from the equipment and operational level of abstraction. The simulation allows for the recreation of operational conditions in the comminution process and calculates the capacity of the equipment, facilitating decision-making regarding the selection of optimal configurations. The configuration and simulation tool is designed to model and simulate a wide range of processes based on user-defined configurations. It provides a library of predefined setups to guide users in selecting optimal configurations for specific applications. The module calculates critical process parameters, including material flow between components, machine loads, particle size distributions, power consumption, and the efficiency of separators or feeders. These outputs enable users to evaluate how effectively the process aligns with planned requirements, focusing on product quantities while assessing balance through load and flow patterns. Additionally, reduction ratios and machine loads provide insights into attainable product characteristics, such as shape and size. Besides, the APM platform provides data related to equipment reliability, such as availability and the number of failures along a given period of analysis. The tool provides a robust database that supports the configuration optimization process and allows for models to be adjusted to real operational conditions. The integration of such software suites has been fundamental in combining high level operational and more detailed reliability analyses.

By integrating these two platforms, the following was achieved:

Evaluate configurations from both a operational and reliability perspective, ensuring that the proposals not only meet production demands but are also sustainable over time.

Reduce risks associated with unplanned failures by jointly analyzing reliability metrics and technical performance.

Propose more robust configurations aligned with the project's operational and energy objectives.

- 6.

Energy Efficiency: As it was mentioned earlier, energy efficiency is a crucial factor in selecting configurations in heavy duty operations. The energy consumed by, for instance, crushing equipment can represent a significant cost in the operation, making it necessary to consider energy consumption in optimization models. Energy management theory suggests that equipment configurations should seek a balance between productivity and efficiency, minimizing energy consumption without compromising operational reliability [

18].

- 7.

Material Storage Systems: Intermediate storage or inventories, as stockpiles used in mining operations, exist to ensure the continuous availability of materials and avoid process stoppages due to interruptions in equipment feed. These systems act as buffers, allowing the process to continue even if material feed is temporarily interrupted [

19].

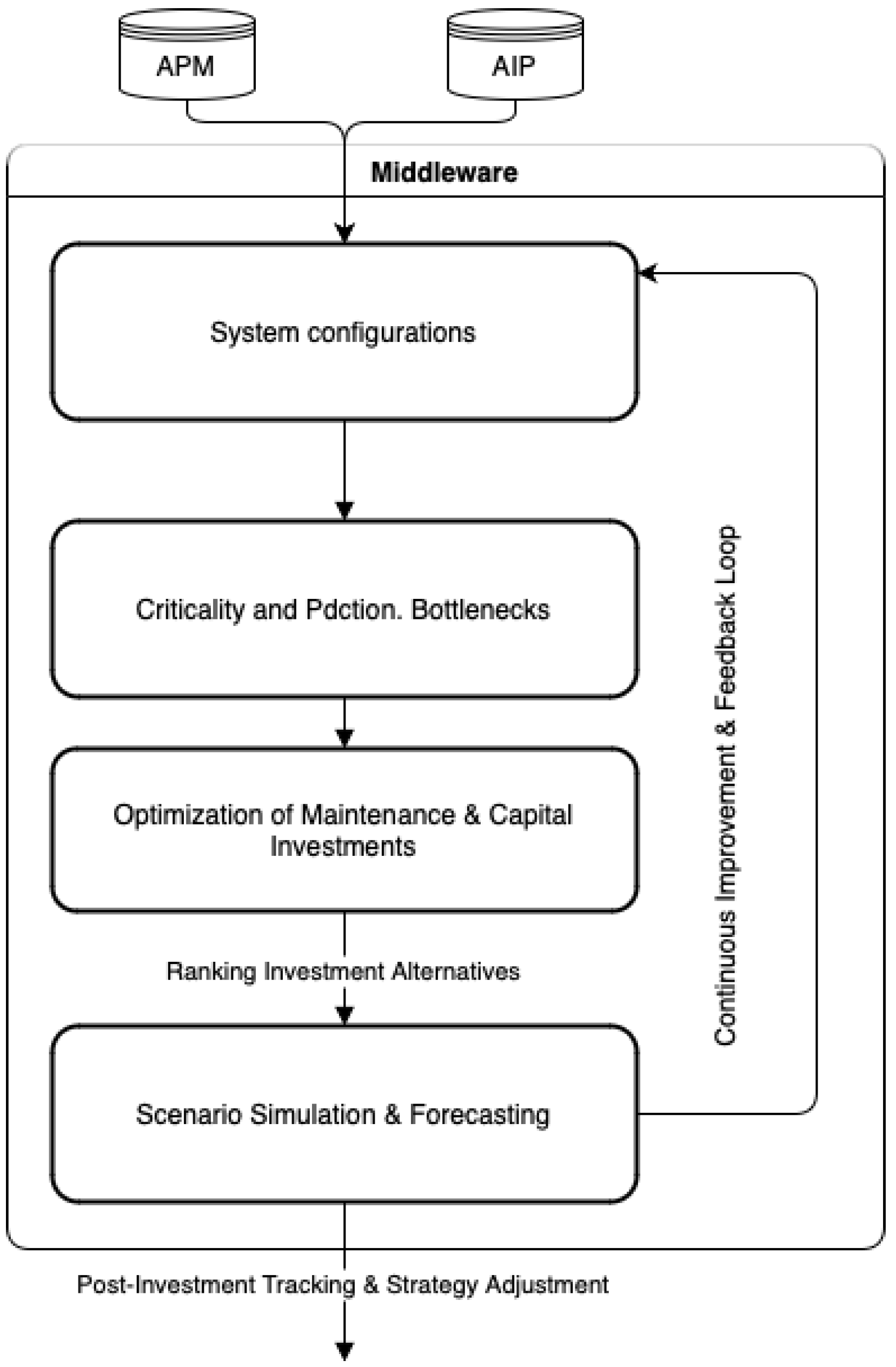

4. Detailed Methodology

The methodological process for selecting configurations through the integration of AIP and APM platforms is detailed below:

4.1. Initial Configuration/Project

The process begins with the development of an initial configuration for the project, specifically outlining the equipment involved. This preliminary configuration is established within the design module of the AIP platform and includes a range of available equipment, which can be arranged in series, parallel, or more complex configurations, such as partial redundancies and fractionality based setups. Within this definition, it is essential to explicitly specify not only the equipment but also the incoming material conditions and the desired output characteristics. This initial configuration results in specific levels of production, energy consumption, and productivity. However, during this first iteration, adjustments or refinements may be required to align the system’s productive performance and energy consumption with the reliability of each constituent component. At the initial configuration phase, key values related to performance and reliability of each piece of equipment are assigned. These values include metrics such as reliability, availability, criticality, utilization, and failures rates. The data is extracted from the APM platform, considering the respective configurations of the components which are represented by the respective Reliability Block Diagram (RBD). This platform includes the relevant data on reliability (MTBF), maintainability (MTTR), and failure rates for each piece of equipment, including those selected in the configuration module of the AIP.

4.2. Selection of Critical Equipment

Every piece of equipment in the initial configuration is evaluated to conduct a criticality analysis. This is done by considering its systemic impact through the propagation of reliability, maintainability, and failure rate values throughout the entire designed system. For this purpose, the RBD (Reliability Block Diagram) is taken into account. This process will allow the selection of the asset with the highest criticality value. This asset is identified as the most prone to failure or having a negative impact on systemic reliability and productivity, making it the focus of efforts to improve its performance or replace it. The effect on systemic reliability is assessed through a set of RAM-type experiments, in which the probabilistic behavior of the reliability and maintainability performance parameters of each piece of equipment in the configuration under analysis is simulated. The probabilistic behavior of these parameters is stored in the APM analysis module repository and, ideally, should be obtained from historical records of actual equipment in comparable situations or contexts. Another alternative for obtaining these parameters and their probability distribution functions is through literature sources or, lastly, expert judgment. Once the RAM analysis is completed, the results of this analysis are used to identify criticalities.

4.3. Selection Criteria Analysis

Once critical equipment has been identified, the previously defined structure within the AIP design module is analyzed to determine potential new configurations. The new configurations are simulated to validate and evaluate their performance, as well as to obtain estimates of autonomy, production and energy efficiency values. These configurations may include new series, parallel, fractionation and stockpiling arrangements. The selected equipment, focused on to address reliability weaknesses, is replaced with new equipment or a more complex configuration. The objective is to ensure that the proposed modifications maintain or improve operational productivity while optimizing system reliability. Additionally, energy consumption is used as a constraint in the search and recommendations of configurations, so that the new configurations should not exceed the current system's energy consumption. This not only keeps energy consumption under control but also enhances the plant's energy efficiency. Eventually, the option of incorporating one or more stockpiles can be considered to strengthen productive capabilities in response to the reliability "weaknesses" detected in the APM module.

This iterative process should be carried out until a termination condition is reached. Such termination condition may occur when the defined configuration meets the requirements of autonomy, productivity, energy efficiency, and exceeds the minimum level of systemic reliability ensuring compliance with the operational parameters. In addition, the APM system will allow for a more comprehensive and long-term analysis by incorporating the variation of parameters and their respective probability distribution functions over an extended period. This involves examining the system from a lifecycle cost (LCC) perspective. The main methodology described is depicted in

Figure 3. The colors used for each phase represent the origin of the module utilized in it.

5. Case Studies

To provide more readiness of the proposed methodology and validate its applicability, a case study is presented, focusing on a mineral comminution plant. The study begins by analyzing an existing operational scenario, identifying key reliability issues that impact the plant’s productivity. Subsequently, alternative configuration strategies are evaluated through the application of the proposed methodological framework.

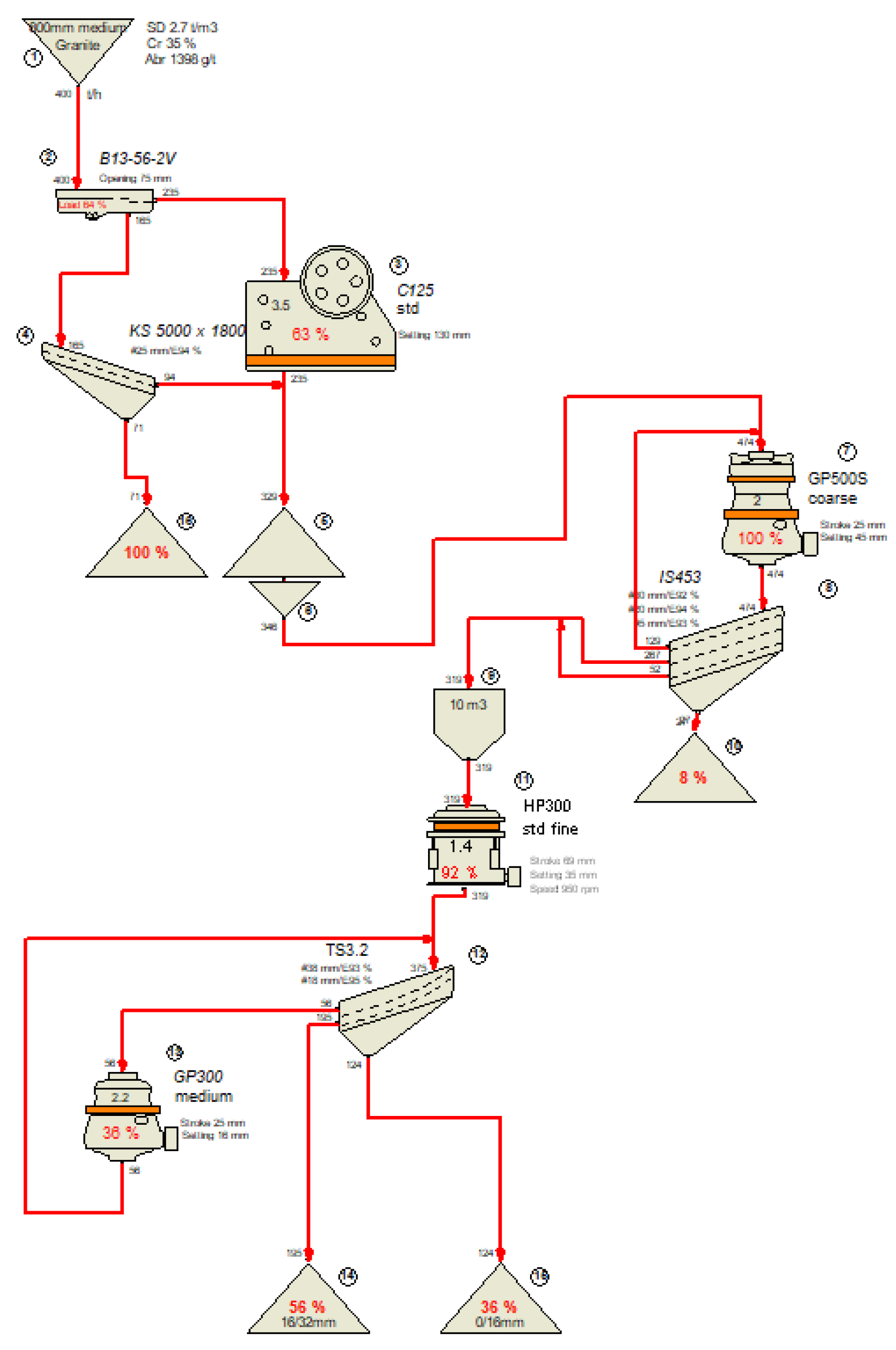

This case study will analyze a size reduction plant that works with granite, initially 800 mm in size, with the aim of optimizing productivity and process reliability. The plant in question is not a real installation but a model created specifically for this simulation. This plant is equipped with various equipment, including crushers, feeders, screens, stockpile, stockfeed, and a silo. Through modifications in configuration and the pieces of equipment that constitute the plant, it is intended to demonstrate how these changes can influence the efficiency and operational robustness of the plant.

Originally, the plant processes granite to obtain four final products with sizes of 5 mm, 38 mm, 18 mm, and 25 mm. The analysis will focus on how changes in configurations and equipment can improve both productivity and process reliability. Three different configurations will be tested to evaluate the optimization of reliability and productivity, and each configuration will subsequently be evaluated. This study seeks to provide a detailed understanding of possible operational improvements and their impact on the overall performance of the plant.

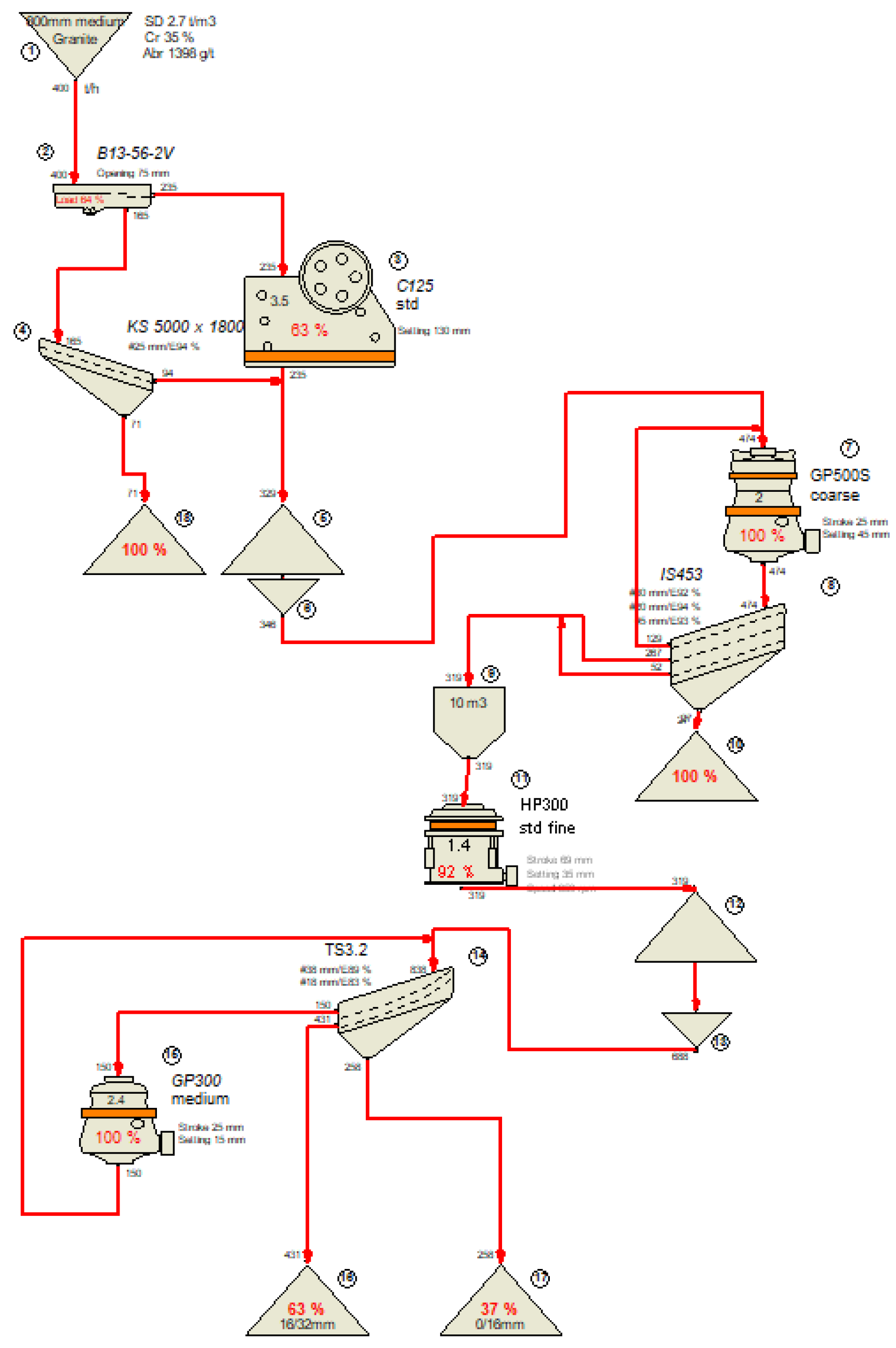

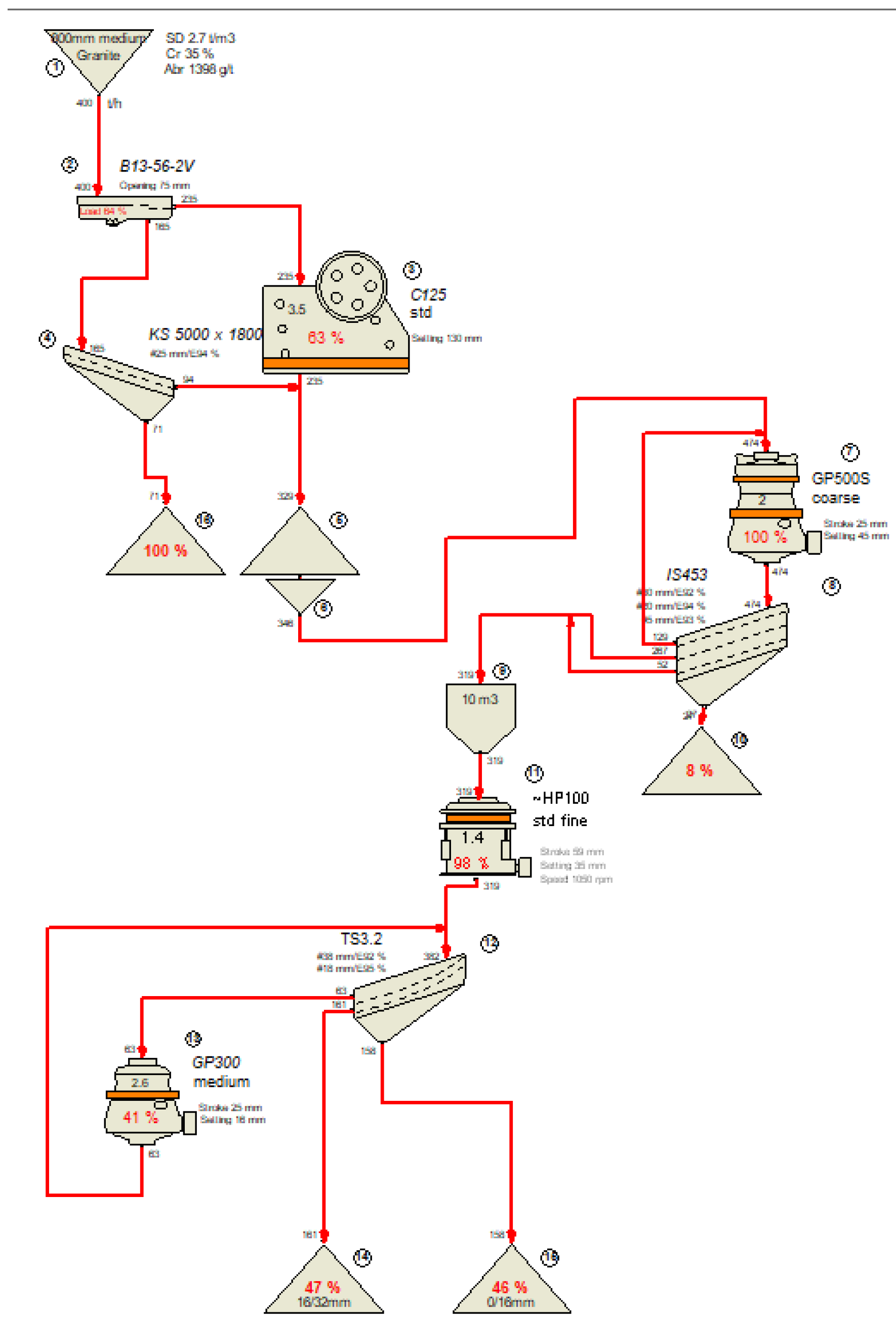

5.1. Stockpile Configuration Results

The incorporation of the stockpile in the plant is undertaken as a possible configuration aimed at improving system operational continuity. The implementation of the stockpile is intended to minimize the problem of low equipment utilization caused by the mutual influence between the two procedures [

19]. The implementation of the stockpile configuration could provide a significant improvement in material availability and operational productivity, ensuring process continuity through the incorporation of intermediate storage systems.

Figure 4 presents the initial configuration, where the stockpile system is not used. In contrast,

Figure 5 shows the configuration with a stockpile system, where a material storage and feeding system was implemented.

In

Table 1, it is observed that the production capacity of some equipment is limited. For example, Product 14 has a capacity of 195 t/h, while Product 15 reaches only 124 t/h. After implementing the stockpile, production capacities significantly improved. Product 16 increased its capacity to 431 t/h, while Product 17 reached a capacity of 258 t/h.

With the incorporation of the stockpile system, the production capacities of several products significantly increased. This change reflects greater efficiency in the material feeding process, resulting in higher total system productivity. The most notable improvement was in Product 16, whose operating capacity increased from 195 t/h to 431 t/h. Similarly, Product 15 increased from 124 t/h to 258 t/h, doubling its capacity.

The implementation of the stockpile reduced the criticality of the feeding equipment, as the intermediate storage system ensures the process continues without interruptions due to material shortages. This change not only increased system reliability but also improved the overall availability of the equipment, ensuring a constant production flow.

The stockpile configuration proved to be an effective strategy to improve reliability and operational productivity in comminution processes. The reduction in downtime, along with the increase in operating capacity, allows us to conclude that this configuration is suitable for ensuring the continuity of the production process and maintaining a constant flow of materials in operation.

5.2. Insertion of equipment in Parallel Configuration

The implementation of the parallel configuration was carried out with the aim of optimizing production capacity by dividing the operational load between multiple pieces of equipment. This configuration is considered as a possible improvement that could increase both the reliability and productivity of the system as a whole (

Figure 6).

This configuration is being tested to observe how the system behaves under different circumstances, ensuring that reliability and productivity do not decrease in the process.

In

Table 1 shows the initial report, where the capacity of Product 14 is 195 t/h.

In

Table 3 reflects the results obtained after the implementation of the parallel configuration, where the capacity of Product 14 increased to 196 t/h. Although this change is small, it indicates an improvement.

The parallel configuration allowed the operating load to be distributed between two crushers, which increased the production of product 14.

The "HP100" crusher is connected in parallel with another one of the same.

The others products maintained a stable capacity, showing that the parallel configuration did not negatively affect its performance.

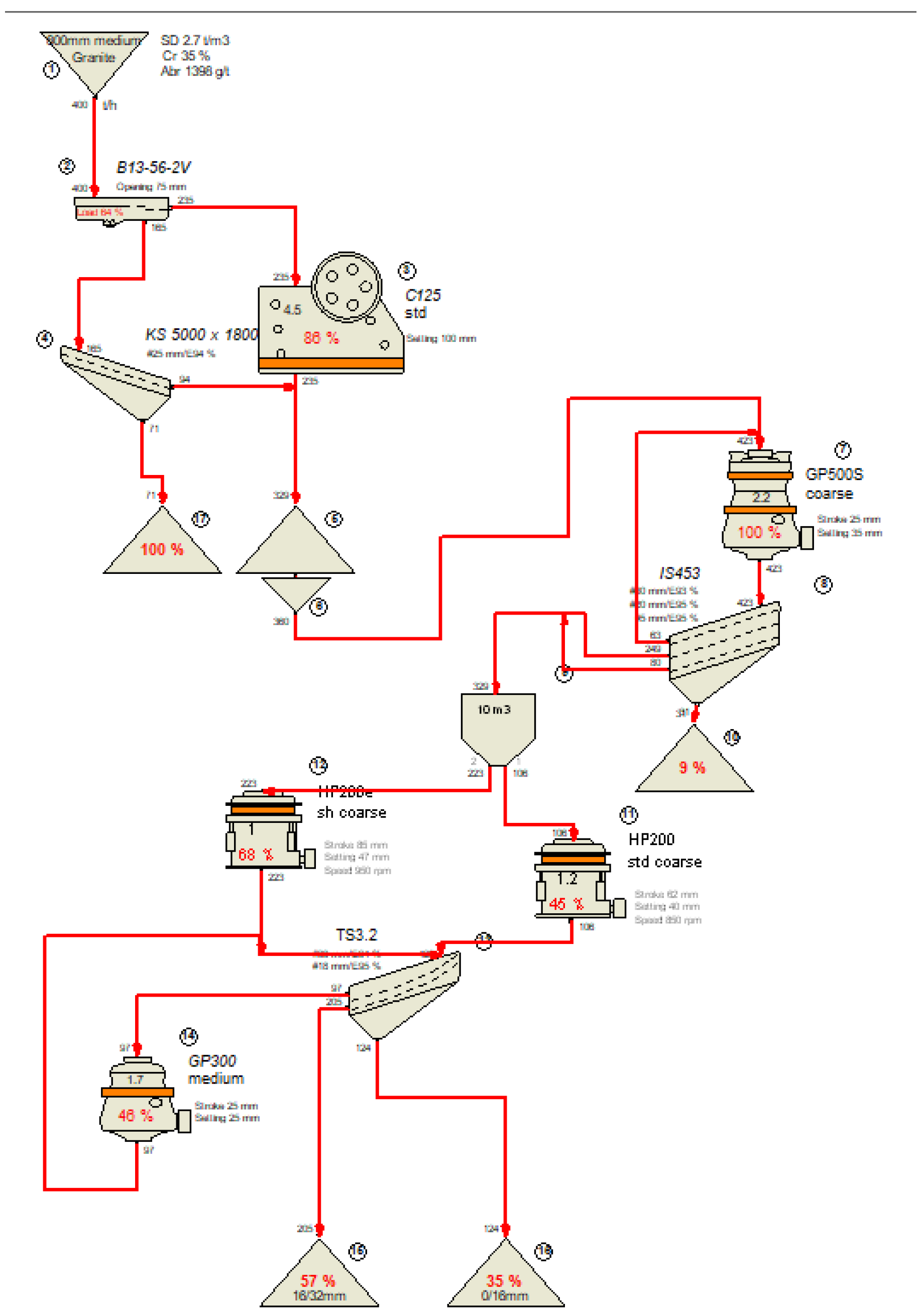

5.3. Fractional Configuration Insertion

The fractional configuration was applied to divide the operational load of critical equipment into several smaller pieces of equipment, with the goal of improving system reliability without compromising productive capacity. In

Figure 7 the fractional configuration is depicted. The operation of the critical HP300 equipment was divided between two HP200 and HP200e units, distributing the operational load. The results obtained are detailed below:

Product 14 has a capacity of 195 t/h. However, after implementing the fractionating configuration, as shown in

Table 4, the capacity of Product 14 increased to 205 t/h. Product 10 also showed improvement, increasing from 27 t/h to 31 t/h. Products 15 and 16 maintained their operational capacity without significant changes, indicating that the new configuration did not negatively affect their productivity. By dividing the load among several smaller pieces of equipment, the criticality of the original equipment was significantly reduced. This configuration is particularly useful in stages where the criticality of a single piece of equipment negatively affects system performance.

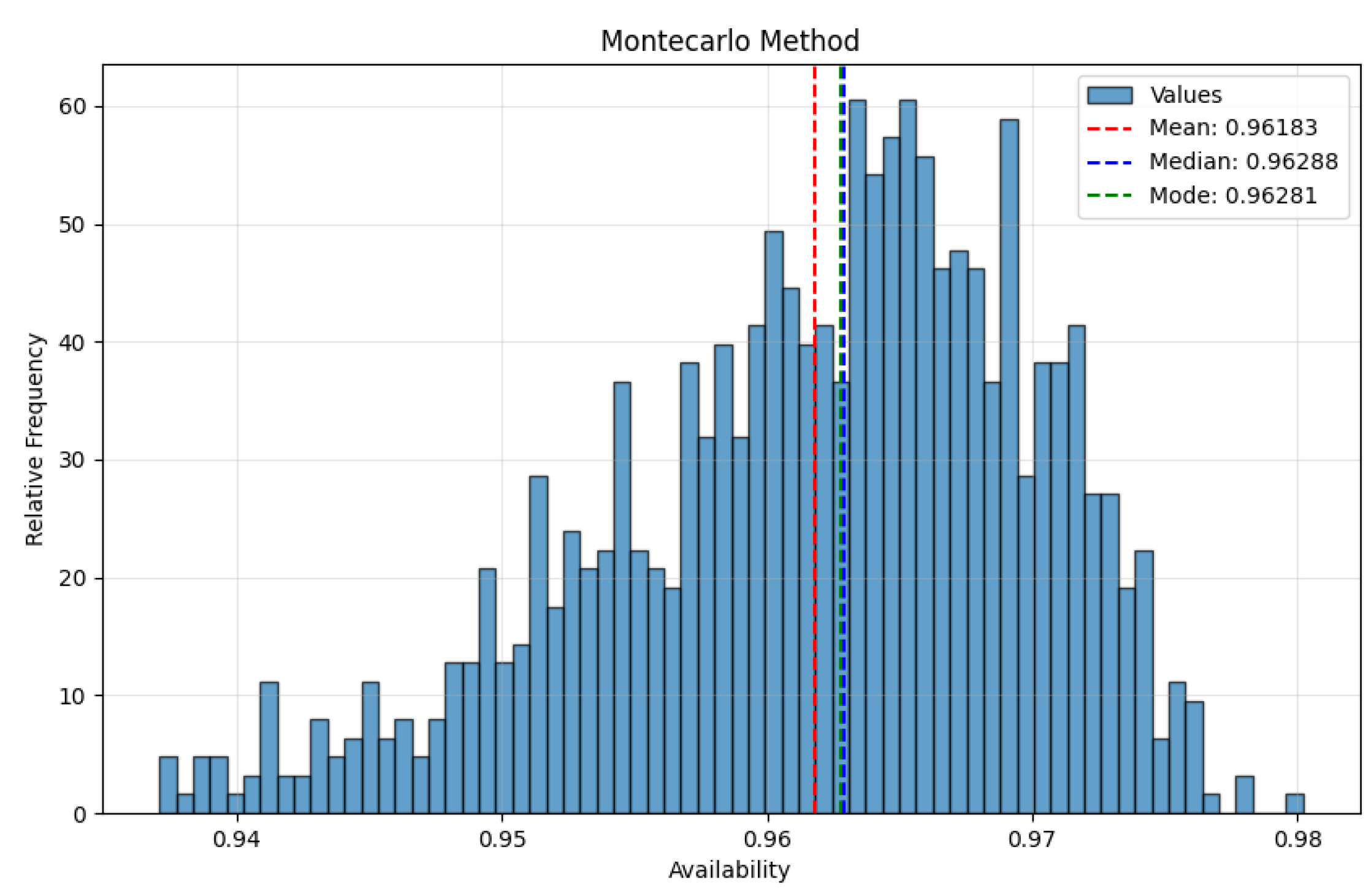

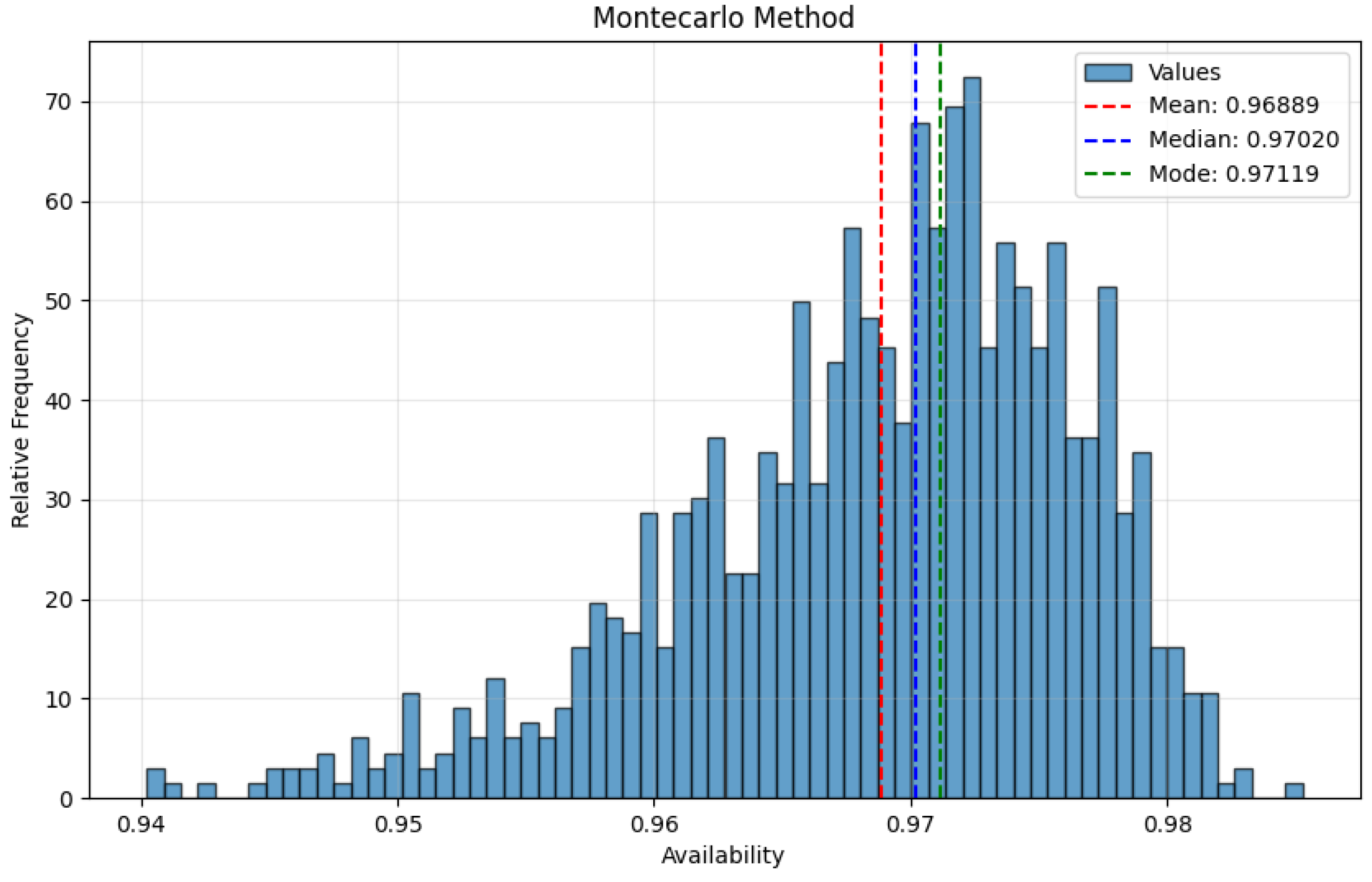

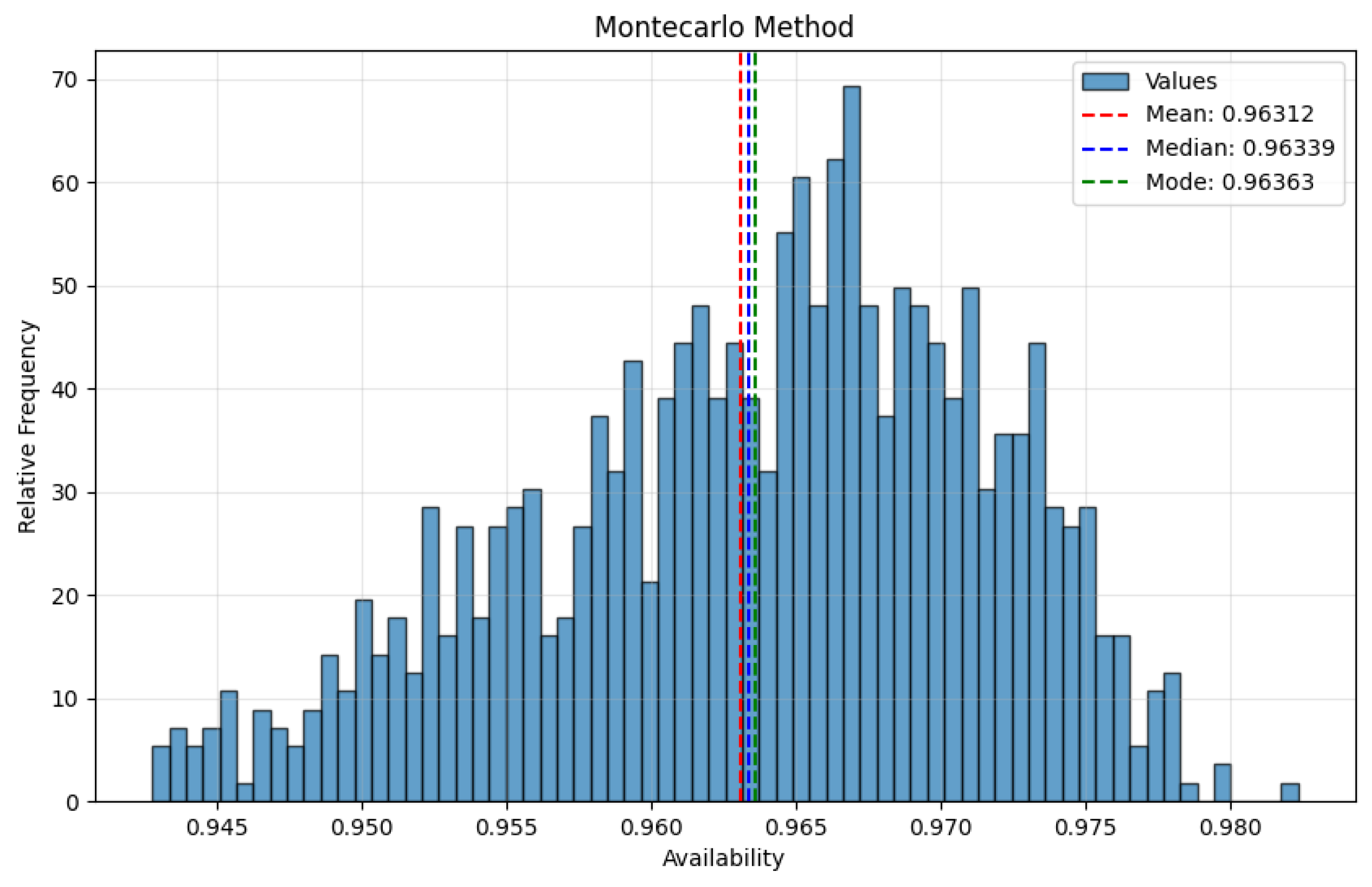

5.4. MonteCarlo Simulations

MonteCarlo simulation is used to evaluate and quantify whether system reliability satisfy the operation and runtime requirement of the plant [

20]. The parameters used in the simulation include data collected, in an actual comminution site, over three years, covering corrective maintenance of mechanical, electrical, and instrumental nature. Additionally, two hundred random simulations were performed covering a one-year period. In this case, three MonteCarlo simulations were performed: the first with the initial configuration (

Figure 8), the second with the parallel configuration (

Figure 9), and finally with the fractional configuration (

Figure 10).

The following results (

Table 5) were obtained from the simulation in

Figure 8:

The following results (

Table 6) were obtained from the simulation in

Figure 9:

6. Discussion

The results obtained in this study allow for a critical evaluation of the analyzed configurations in terms of reliability and productivity. Based on the data obtained from the Monte Carlo simulation, it can be stated that the proposed configurations successfully increased the system's reliability. The main findings for each configuration are discussed below.

The parallel configuration proved to be an effective option for improving system reliability by distributing the load among several pieces of equipment. This configuration reduced the criticality of key equipment and improved operational redundancy, allowing the system to maintain production even if one piece of equipment fails. The results showed that, although the increase in operational capacity was modest in some cases, the overall system reliability significantly increased.

The implementation of a fractional configuration led to a significant improvement in reliability by distributing the operational load of the most critical equipment among several smaller pieces of equipment. This allowed the system's productivity to be maintained, with notable increases in some key products, such as Product 14. However, a limitation of fractionating is that the number of additional pieces of equipment can increase the operational complexity and energy consumption of the system. This must be carefully evaluated to ensure that the improvements in reliability are not counterbalanced by significant increases in operational complexity and energy consumption.

The stockpile configuration proved to be effective in improving material availability, which reduced downtime and allowed for more continuous operation. This approach is particularly useful in processes where material feed is intermittent or limited, as the stockpile acts as a buffer, ensuring a constant flow of materials.

From the point of view of managerial insights, this work has shown that operational reliability can be significantly improved through the correct selection of configurations. Configurations such as the parallel and fractionating setups provide a favorable balance between reliability and productivity. However, each configuration has its limitations, and the choice of the best configuration largely depends on the specific characteristics of the mining operation.

Future research could focus on the analysis of operational costs, an aspect that is emerging as fundamental for the development of this line of research. Delving into the maintenance costs and energy consumption of the selected configurations would allow for the identification of optimization opportunities that increase operational efficiency and profitability. The incorporation of environmental impact, from the perspective of costs associated, would offer an innovative approach to developing configurations aligned with current standards of environmental responsibility and carbon footprint reduction.

7. Conclusions

The proposed methodology for integrating APM and AIP platforms can leverage the joint optimization of productivity and reliability. Through simulation experiments one can effectively optimizing reliability and productivity in industrial projects. Throughout this study, various configurations (parallel, fractionation and stockpiling) were evaluated, identifying those that reduce the criticality of key equipment and improve operational efficiency. Alternative configurations were tested and based on the results and the specific needs of the user, the most appropriate configuration can be selected to maximize both the reliability and productivity of the system.

The integration of technical data from the equipment and reliability criteria has al-lowed for the selection of configurations that maintain or increase productivity without compromising operational continuity. Among the evaluated configurations, the parallel and fractionating setups stood out as the most effective for improving system reliability. The use of Monte Carlo simulations validated that the proposed configurations increase the system's reliability. In particular, the fractionation alternative showed a significant improvement in reliability, raising the modal value from 96.281% to 97.435%.

The findings obtained provide a solid foundation for alternative, and more efficient and sustainable implementations, of more suitable configurations of a production system. By identifying and optimizing equipment configurations at an early stage, operational parameters are established that can be adapted and applied in real environments. This anticipation allows for a smoother transition to large-scale operations, minimizing risks and ensuring greater efficiency from the start and for the long term.

In summary, the presented methodology/framework constitutes a solid foundation for the optimization of configurations in comminution projects. Although there are opportunities for improvement, the obtained results are promising and provide a robust starting point for future research and practical applications in mining operations. This approach allows progress towards more reliable, efficient, and sustainable operations.

Author Contributions

Conceptualization, J.P. and O.D.; methodology, J.P. and C.S.; validation, O.D., J.V. and A.A.; formal analysis, O.D.; investigation, J.P.; resources, A.A.; data curation, J.V.; writing—original draft preparation, O.D.; writing—review and editing, J.P.; visualization, J.P. and J.V.; supervision, A.A.; project administration, O.D.; funding acquisition, A.A and J.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is unavailable due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, C.; Billinton, R. System Reliability, Modelling and Evaluation. 1977.

- Karar, A.N.; Labib, A.; Jones, D.F. A conceptual framework for an agile asset performance management process. J. Qual. Maint. Eng. 2021, 28, 689–716. [Google Scholar] [CrossRef]

- Maherdianta, D.; Ramadhan, E.; Edwantiar, G.A. Optimizing Eam Apm Supported by Iso 55001 Implementation. Proceedings - Annual Reliability and Maintainability Symposium 2019, 2019-January.

- Macchi, M.; Sanchez-Londono, D.; Martínez, A.; Polenghi, A.; Roda, I.; Pozzetti, A.; Barriga, C. Asset Performance Management: current status and future development. IFAC-PapersOnLine 2024, 58, 383–388. [Google Scholar] [CrossRef]

- Crespo Márquez, A. Advanced Asset Performance Management (APM) and Asset Investment Planning (AIP) Systems. Springer Series in Reliability Engineering 2022, 43–53. [Google Scholar]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers From a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Gaul, A.J.; Nilges, J.; Nockmann, E.; Thurlby, R. Strategic Investment Planning. IEE Conference Publication 2005, 6, 153–157. [Google Scholar]

- Ayral, T.; Moran, M. Quantifying the ROI of an Asset Performance Management Program: Maintenance and Reliability; 2007.

- Negi, R. Experience in Asset Performance Management Analytics for Decision Support on Transmission Distribution Assets. In Proceedings of the 2019 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Macao, China, 1–4 December 2019. [Google Scholar]

- Wan, S. Asset Performance Management for Power Grids. Energy Procedia 2017, 143, 611–616. [Google Scholar] [CrossRef]

- Baudino, M.; Gil-Costa, V.; Giubergia, A.; Guerrero, R.; Printista, M. Modelos de Simulación: Selección y Reemplazo de Equipos Para Proyectos Mineros. 2012.

- Mesa, D.; Ortiz, Y.; Pinzón, M. La Confiabilidad, La Disponibilidad, y La Mantenibilidad, Disciplinas Modernas Aplicadas La Mantenimiento. 2006.

- Nakajima, S. Introduction to TPM. 1988.

- Amendola, L. INDICADORES DE CONFIABILIDAD PROPULSORES EN LA GESTIÓN DEL MANTENIMIENTO.

- Gavrilov, L.A.; Gavrilova, N.S. Reliability Theory of Aging and Longevity. 2011.

- Misra, K.B. Reliability Optimization of a Series-Parallel System; 1972; Vol. 21.

- Romero, J. Análisis de Criticidad y Estudio RCM Del Equipo de Máxima Criticidad de Una Planta Desmotadora de Algodón. 2013.

- Saez, M.; Barton, K.; Maturana, F.; Tilbury, D.M. Modeling Framework to Support Decision Making and Control of Manufacturing Systems Considering the Relationship between Productivity, Reliability, Quality, and Energy Consumption. J Manuf Syst 2022, 62, 925–938. [Google Scholar] [CrossRef]

- Gong, H. Optimization and Simulation-Based Verification of near Face Stockpile Mining Method; 2023.

- Raychaudhuri, S. INTRODUCTION TO MONTE CARLO SIMULATION. ACM Digital Library, 2013; ISBN 9781424427086. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).