Submitted:

25 February 2025

Posted:

26 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

3. Materials and Methods

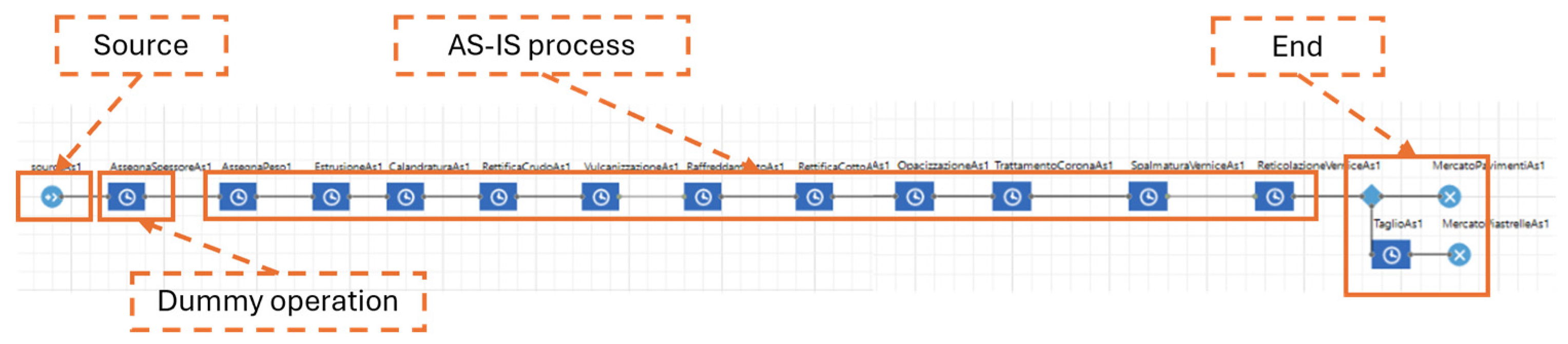

3.1. “As-Is” Scenario

3.1.1. Linear Process

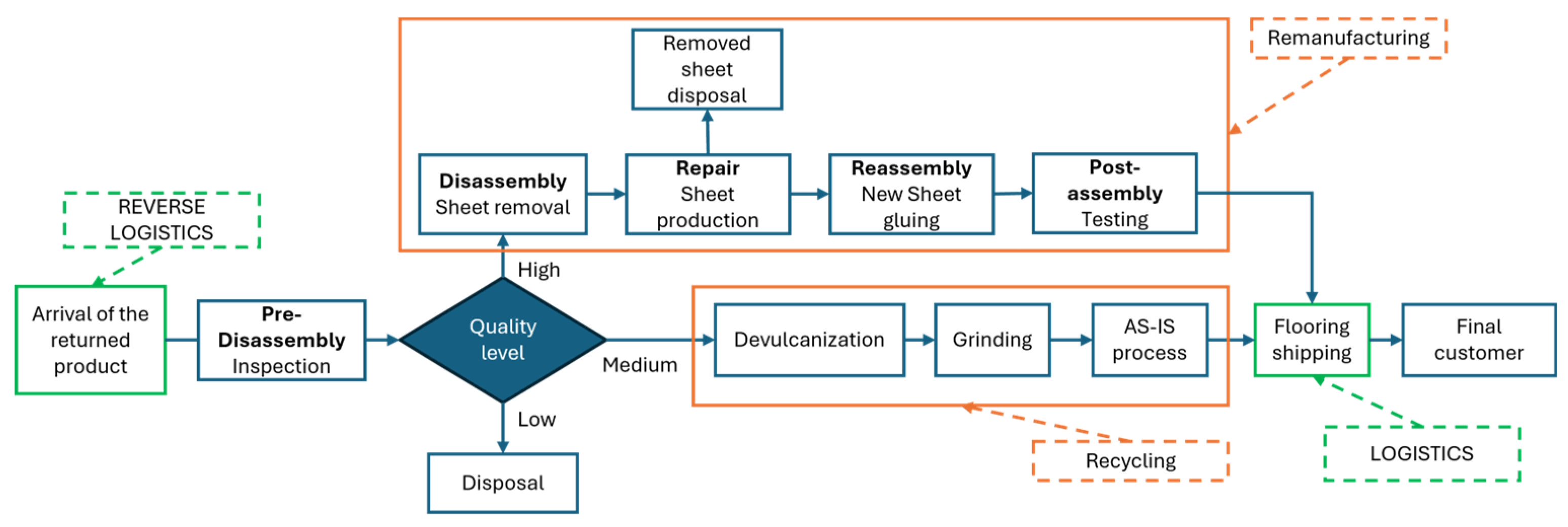

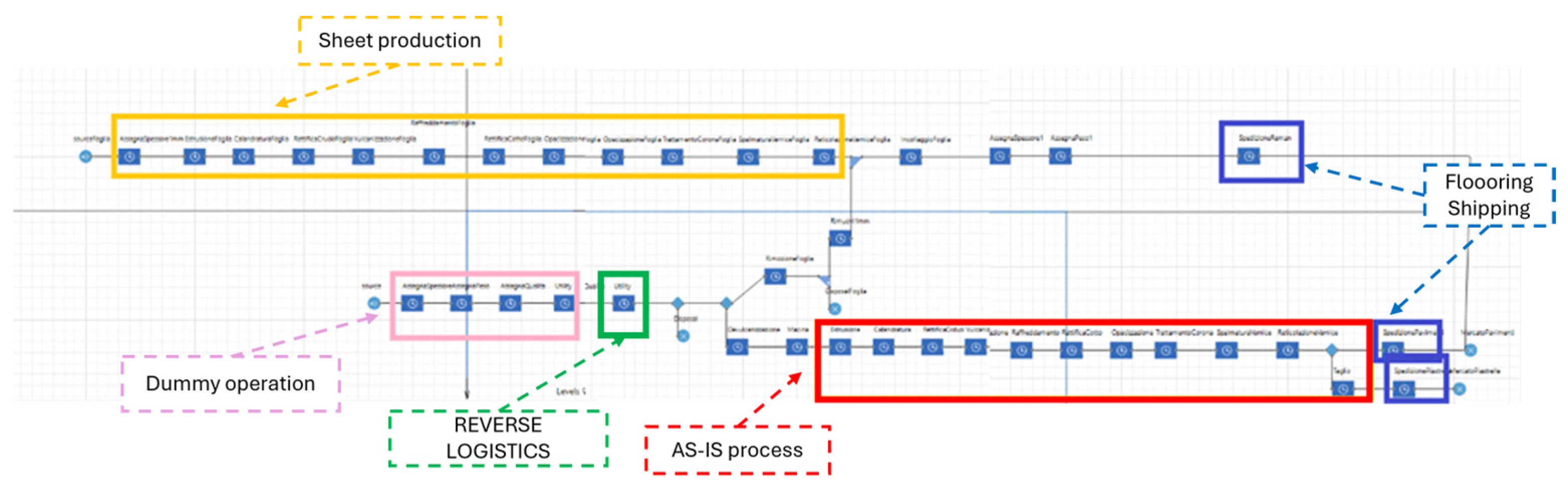

3.1.2. From Linear to Circular

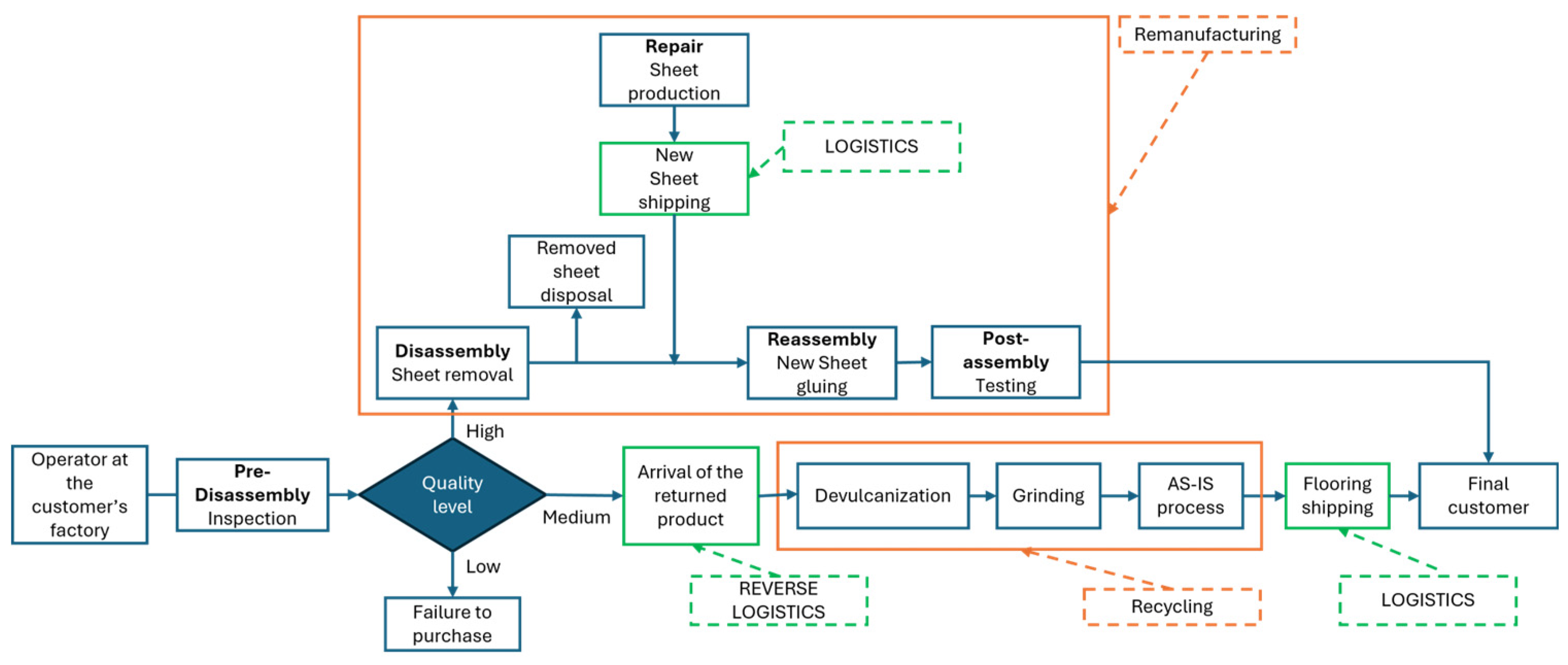

3.2. “To-Be” Scenarios

3.2.1. To-Be 1: Inspection at the Manufacturer’s Facility

3.2.2. To-Be 2: Inspection at the Customer’s Location

3.2.3. Design of Experiment

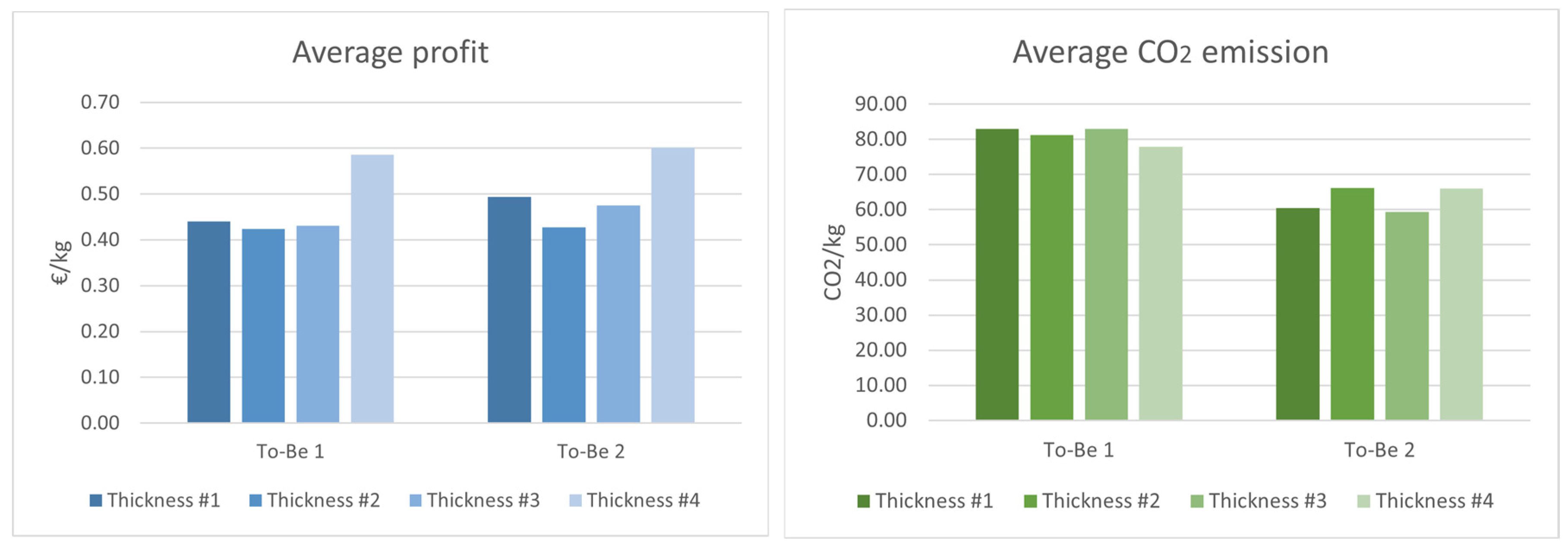

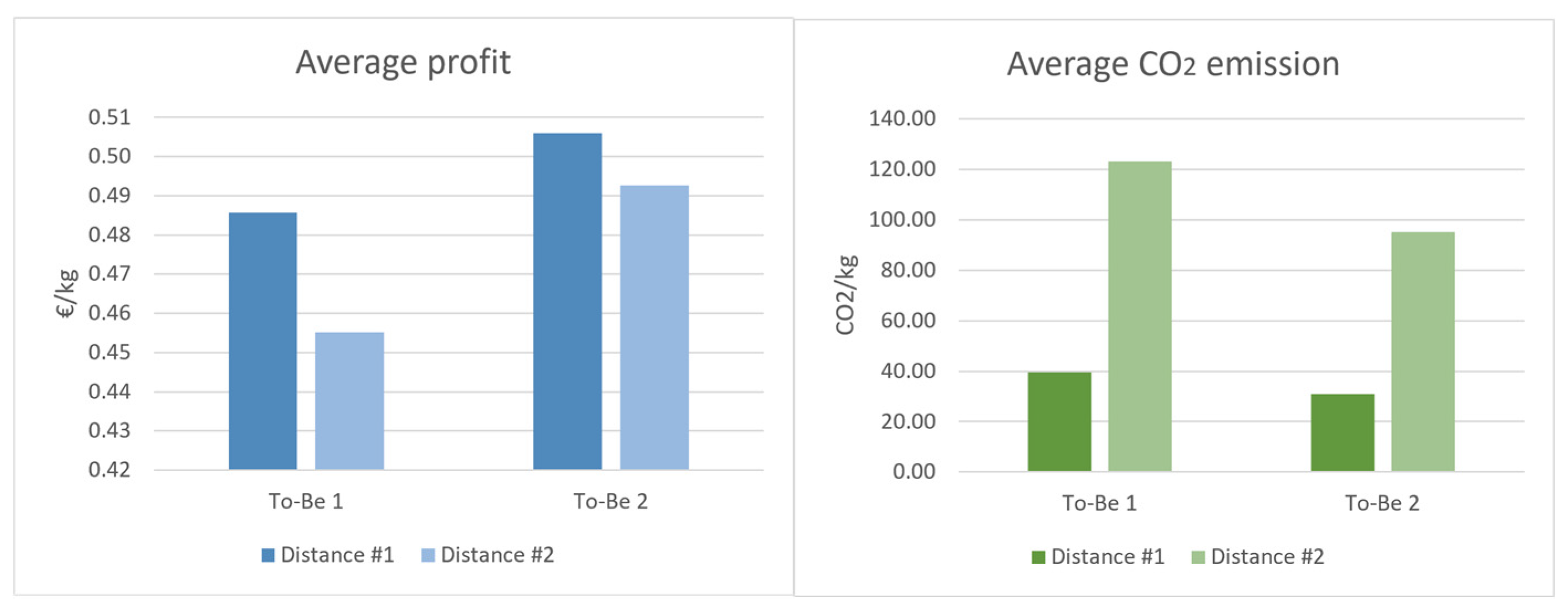

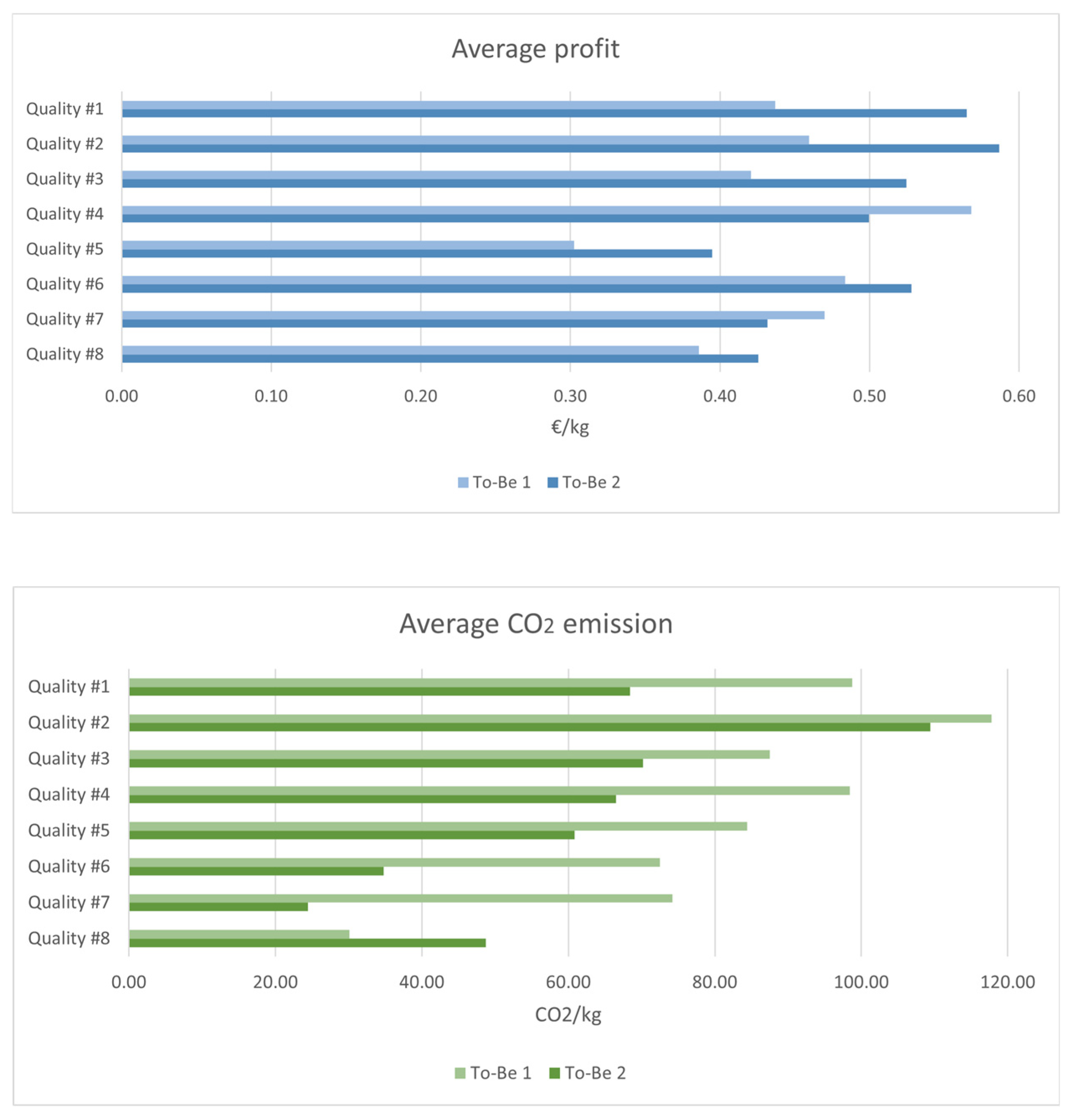

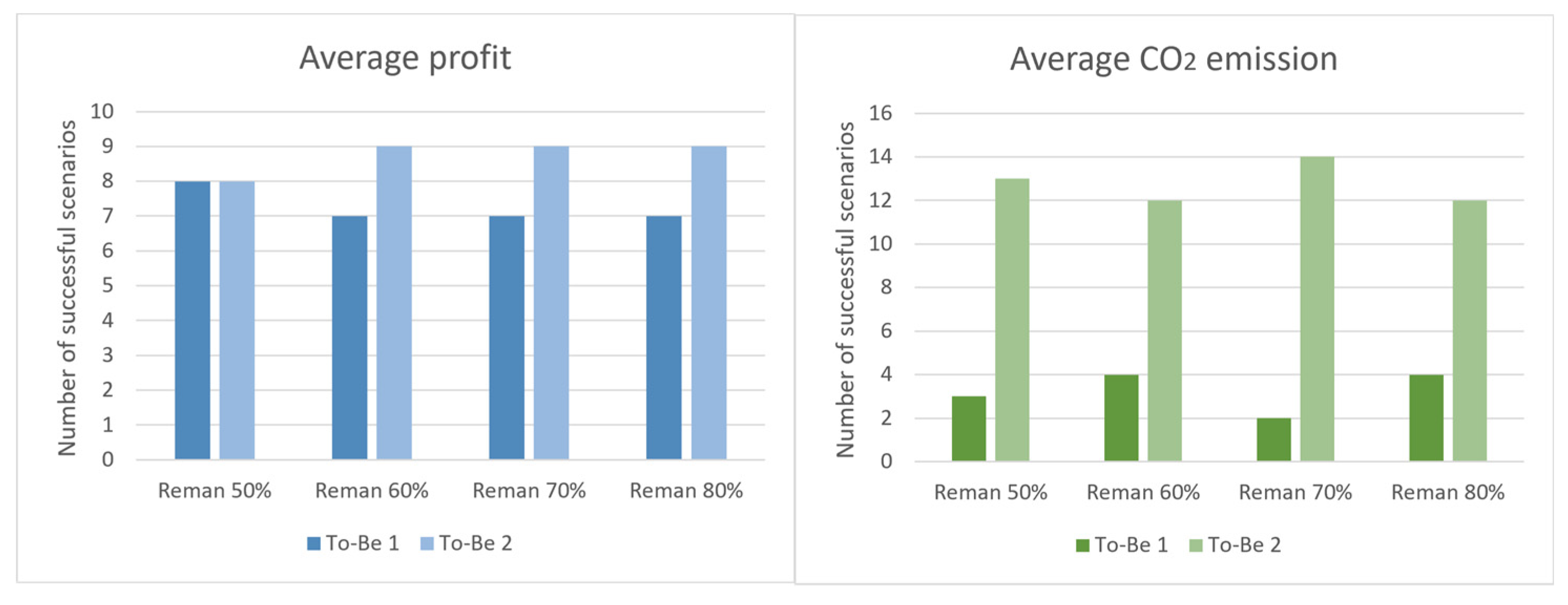

- Average profit [€/kg]

- Average CO2 emissions [kgCO2/kg]

4. Results

5. Discussion

5.1. Main Findings

5.2. Final Remarks and Practical Implications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agreement, P. (2015, December). Paris agreement. In report of the conference of the parties to the United Nations framework convention on climate change (21st session, 2015: Paris). Retrived December (Vol. 4, No. 2017, p. 2). Getzville, NY, USA: HeinOnline.

- Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 establishing the framework for achieving climate neutrality and amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’).

- Fantozzi, I.C.; Di Luozzo, S.; Schiraldi, M.M. The Impact of University Challenges on Students’ Attitudes and Career Paths in Industrial Engineering: A Comparative Study. Sustainability 2024, 16, 1600. [Google Scholar] [CrossRef]

- Neves, S.A.; Marques, A.C. Drivers and barriers in the transition from a linear economy to a circular economy. J. Clean. Prod. 2022, 341, 130865. [Google Scholar] [CrossRef]

- Gharfalkar, M.; Ali, Z.; Hillier, G. Clarifying the disagreements on various reuse options: Repair, recondition, refurbish and remanufacture. Waste Manag. Res. J. a Sustain. Circ. Econ. 2016, 34, 995–1005. [Google Scholar] [CrossRef] [PubMed]

- Manco, P.; Caterino, M.; Rinaldi, M.; Macchiaroli, R. A sustainability-oriented methodology to compare production strategies: The case of AM-based remanufacturing. J. Clean. Prod. 2023, 423, 138594. [Google Scholar] [CrossRef]

- Arnold, M.; Palomäki, K.; Le Blévennec, K.; Koop, C.; Geerken, T.; Jensen, P.; Colgan, S. Contribution of remanufacturing to circular economy. Eionet Report-ETC/WMGE, 10, 2021. Eionet Report-ETC/WMGE 2021, 10, 2021. [Google Scholar]

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2020, 243, 118360. [Google Scholar] [CrossRef]

- Han, F.; Sun, M.; Jia, X.; Klemeš, J.J.; Shi, F.; Yang, D. Agent-based model for simulation of the sustainability revolution in eco-industrial parks. Environ. Sci. Pollut. Res. 2021, 29, 23117–23128. [Google Scholar] [CrossRef]

- de Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L. A. Simulation in industry 4.0: A state-of-the-art review. Computers & Industrial Engineering 2020, 149, 106868. [Google Scholar]

- Caterino, M.; Greco, A.; D’ambra, S.; Manco, P.; Fera, M.; Macchiaroli, R.; Caputo, F. Simulation Techniques for Production Lines Performance Control. Procedia Manuf. 2020, 42, 91–96. [Google Scholar] [CrossRef]

- Leoni, L.; Cantini, A.; BahooToroody, F.; Khalaj, S.; De Carlo, F.; Abaei, M.M.; BahooToroody, A. Reliability Estimation under Scarcity of Data: A Comparison of Three Approaches. Math. Probl. Eng. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Leoni, L.; De Carlo, F.; Abaei, M.M.; BahooToroody, A.; Tucci, M. Failure diagnosis of a compressor subjected to surge events: A data-driven framework. Reliab. Eng. Syst. Saf. 2023, 233. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Caterino, M.; Fera, M.; Macchiaroli, R.; Pham, D.T. Cloud remanufacturing: Remanufacturing enhanced through cloud technologies. J. Manuf. Syst. 2022, 64, 133–148. [Google Scholar] [CrossRef]

- Panagou, S., La Cava, G., Fruggiero, F., & Mancusi, F. (2023, September). Selective complexity determination at cost based alternatives to re-manufacture. In IFIP International Conference on Advances in Production Management Systems (pp. 215-228). Cham: Springer Nature Switzerland.

- Leoni, L. , De Carlo, F., Sgarbossa, F., & Paltrinieri, N. (2020). Comparison of risk-based maintenance approaches applied to a natural gas regulating and metering station.

- Guide, V.D.R., Jr. Production planning and control for remanufacturing: industry practice and research needs. Journal of Operations Management 2000, 18, 467–483. [Google Scholar] [CrossRef]

- Jakowczyk, M.; Neto, J.Q.F.; Gibson, A.; Van Wassenhove, L.N. Understanding the market for remanufactured products: what can we learn from online trading and Web search sites? Int. J. Prod. Res. 2016, 55, 3465–3479. [Google Scholar] [CrossRef]

- Mallick, P.K.; Salling, K.B.; Pigosso, D.C.; McAloone, T.C. Closing the loop: Establishing reverse logistics for a circular economy, a systematic review. J. Environ. Manag. 2022, 328, 117017. [Google Scholar] [CrossRef] [PubMed]

- Dat, L.Q.; Linh, D.T.T.; Chou, S.-Y.; Yu, V.F. Optimizing reverse logistic costs for recycling end-of-life electrical and electronic products. Expert Syst. Appl. 2012, 39, 6380–6387. [Google Scholar] [CrossRef]

- Errington, M.; Childe, S.J. A business process model of inspection in remanufacturing. J. Remanufacturing 2013, 3, 7. [Google Scholar] [CrossRef]

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Appl. Energy 2022, 331, 120437. [Google Scholar] [CrossRef]

- Smith, S.; Hsu, L.-Y.; Smith, G.C. Partial disassembly sequence planning based on cost-benefit analysis. J. Clean. Prod. 2016, 139, 729–739. [Google Scholar] [CrossRef]

- Guevara-Rivera, E., Osorno-Hinojosa, R., & Zaldívar-Carrillo, V. H. (2020, September). A simulation methodology for circular economy implementation. In 2020 10th International Conference on Advanced Computer Information Technologies (ACIT) (pp. 43-48). IEEE.

- Guevara-Rivera, E.; Osorno-Hinojosa, R.; Zaldivar-Carrillo, V.; Perez-Ortiz, H. Dynamic simulation methodology for implementing circular economy: A new case study. J. Ind. Eng. Manag. 2021, 14, 850–862. [Google Scholar] [CrossRef]

- Charnley, F.; Tiwari, D.; Hutabarat, W.; Moreno, M.; Okorie, O.; Tiwari, A. Simulation to Enable a Data-Driven Circular Economy. Sustainability 2019, 11, 3379. [Google Scholar] [CrossRef]

- Goodall, P.; Sharpe, R.; West, A. A data-driven simulation to support remanufacturing operations. Comput. Ind. 2018, 105, 48–60. [Google Scholar] [CrossRef]

- Okorie, O.; Charnley, F.; Ehiagwina, A.; Tiwari, D.; Salonitis, K. Towards a simulation-based understanding of smart remanufacturing operations: a comparative analysis. J. Remanufacturing 2020, 14, 45–68. [Google Scholar] [CrossRef]

- He, P. Optimization and Simulation of Remanufacturing Production Scheduling under Uncertainties. Int. J. Simul. Model. 2018, 17, 734–743. [Google Scholar] [CrossRef]

- Li, J.; González, M.; Zhu, Y. A hybrid simulation optimization method for production planning of dedicated remanufacturing. Int. J. Prod. Econ. 2009, 117, 286–301. [Google Scholar] [CrossRef]

- Zhang, R.; Ong, S.; Nee, A. A simulation-based genetic algorithm approach for remanufacturing process planning and scheduling. Appl. Soft Comput. 2015, 37, 521–532. [Google Scholar] [CrossRef]

- Huster, S.; Glöser-Chahoud, S.; Rosenberg, S.; Schultmann, F. A simulation model for assessing the potential of remanufacturing electric vehicle batteries as spare parts. J. Clean. Prod. 2022, 363, 132225. [Google Scholar] [CrossRef]

- Li, X.; Mu, D.; Du, J.; Cao, J.; Zhao, F. Game-based system dynamics simulation of deposit-refund scheme for electric vehicle battery recycling in China. Resour. Conserv. Recycl. 2020, 157, 104788. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.A.; Rashid, A. Towards Circular Economy implementation: an agent-based simulation approach for business model changes. Auton. Agents Multi-Agent Syst. 2017, 31, 1377–1402. [Google Scholar] [CrossRef]

- https://cordis.europa.eu/project/id/101003893.

- https://circulareconomy.europa.eu/platform/en/good-practices/iobac-adhesive-free-flooring-tiles-which-can-be-readily-reused-and-recycled.

- https://circulareconomy.europa.eu/platform/en/good-practices/circular-flooring-partnership-tarkett-ikea.

- Parvaresh, F.; Amini, M.H. Application of circular economy for sustainable waste management in the carpet industry. International Journal of Research in Industrial Engineering 2024, 13, 188–206. [Google Scholar]

- Wiesinger, H., Bleuler, C., Christen, V., Favreau, P., Hellweg, S., Langer, M., ... & Wang, Z. (2023). Legacy and Emerging Plasticizers and Stabilizers in PVC Floorings: Impacts of an Industrial Transition and Recycling.

| Scenario | Distance [km] |

|---|---|

| Scenario 1 | 300 |

| Scenario 2 | 1000 |

| Scenario | High quality [%] | Medium quality [%] | Low quality [%] |

|---|---|---|---|

| Scenario 1 | 50% | 30% | 20% |

| Scenario 2 | 50% | 40% | 10% |

| Scenario 3 | 60% | 20% | 20% |

| Scenario 4 | 60% | 30% | 10% |

| Scenario 5 | 70% | 20% | 10% |

| Scenario 6 | 70% | 10% | 20% |

| Scenario 7 | 80% | 10% | 10% |

| Scenario 8 | 80% | 15% | 5% |

| Scenario | Low Thickness [%] | Medium Thickness [%] | High Thickness [%] |

|---|---|---|---|

| Scenario 1 | 33,3% | 33,3% | 33,3% |

| Scenario 2 | 60% | 20% | 20% |

| Scenario 3 | 20% | 60% | 20% |

| Scenario 4 | 20% | 20% | 60% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).