Submitted:

25 February 2025

Posted:

26 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

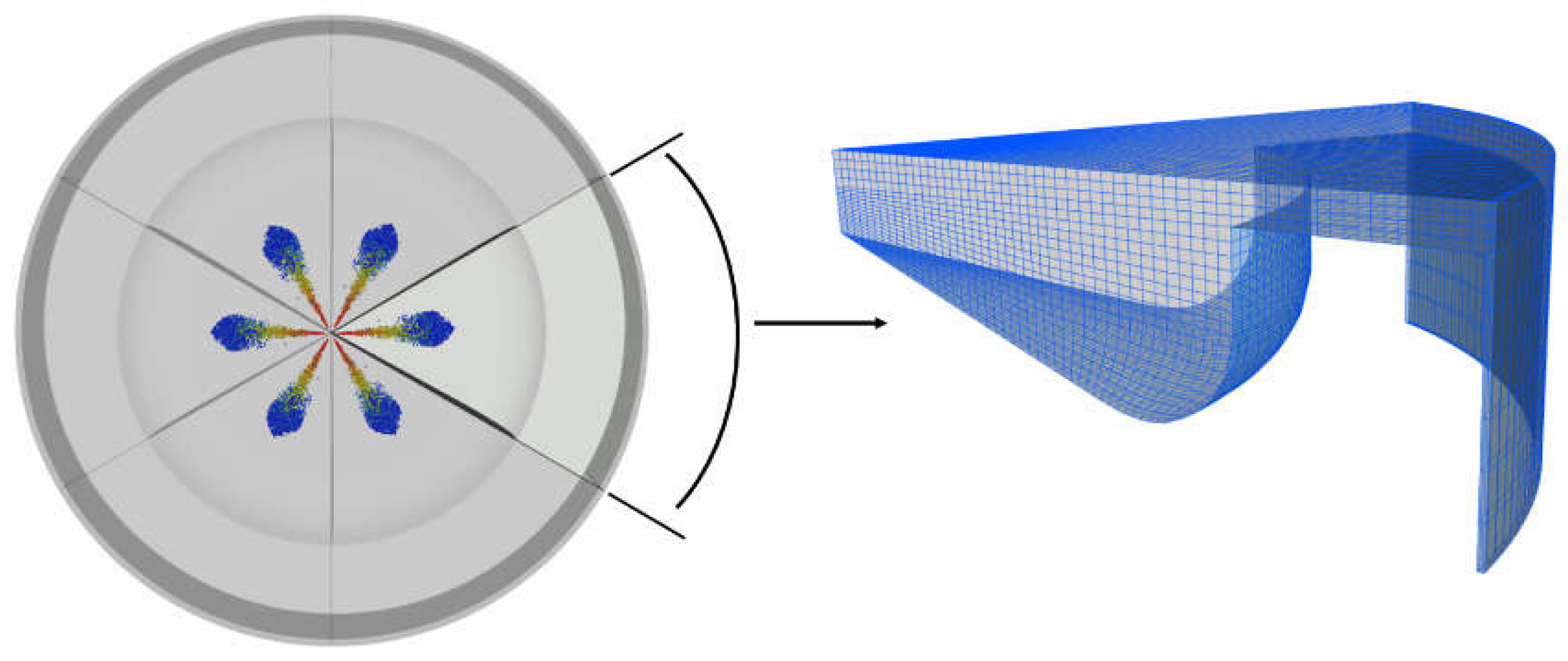

2. Simulation Methodology and Matrix

2.1. Numerical Model of Engine

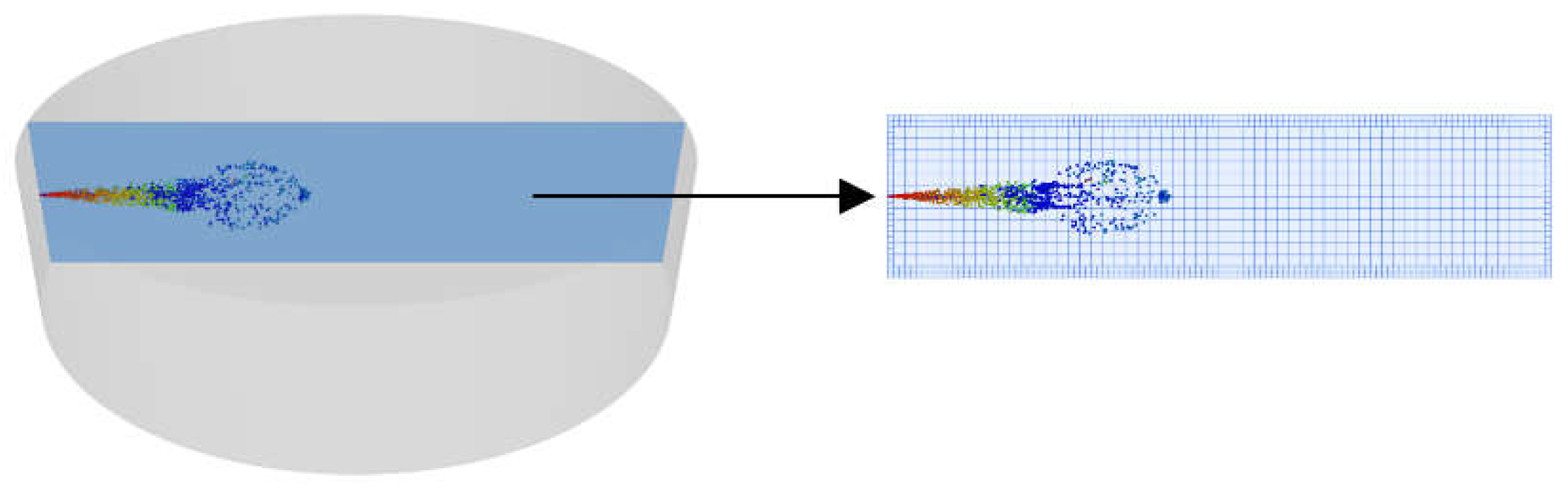

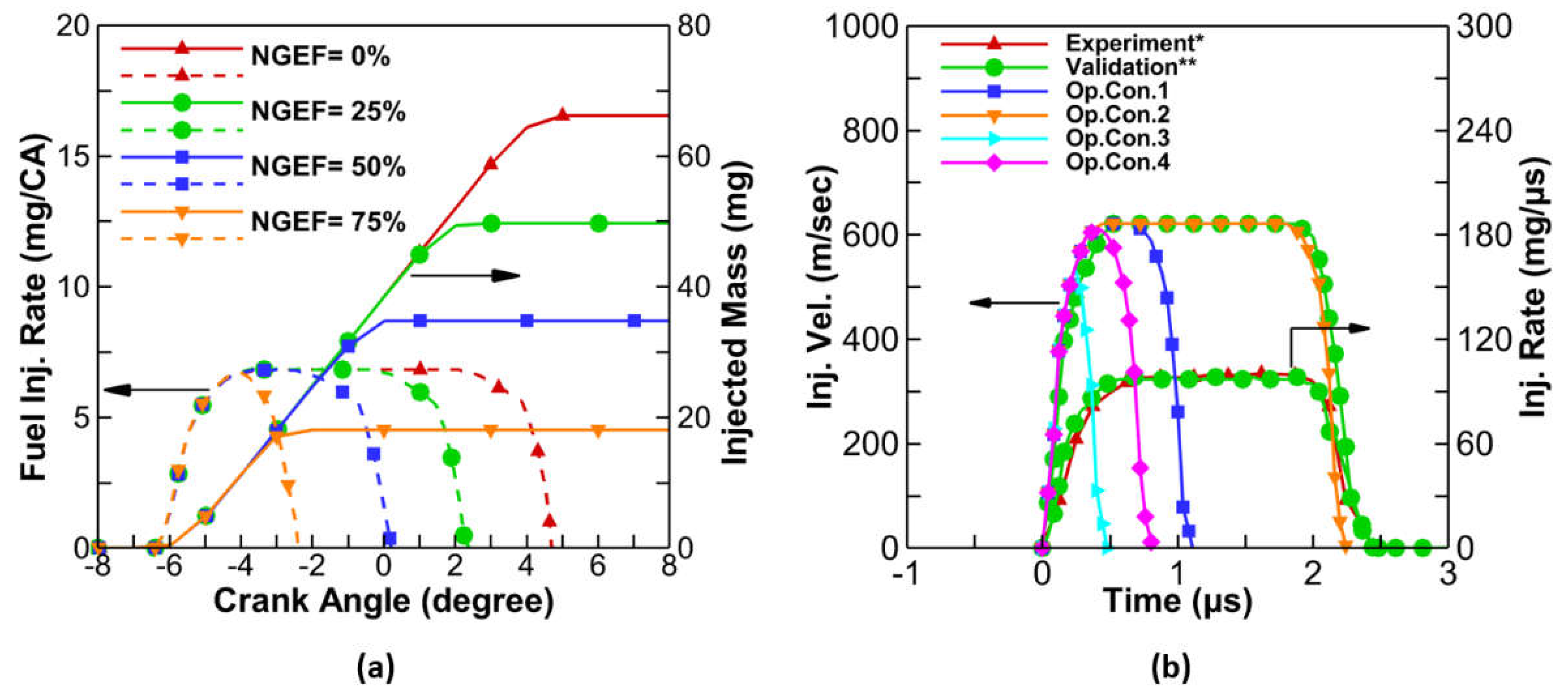

2.2. Numerical Model of Spray Box

2.3. Simulation Matrix

3. Results and Discussions

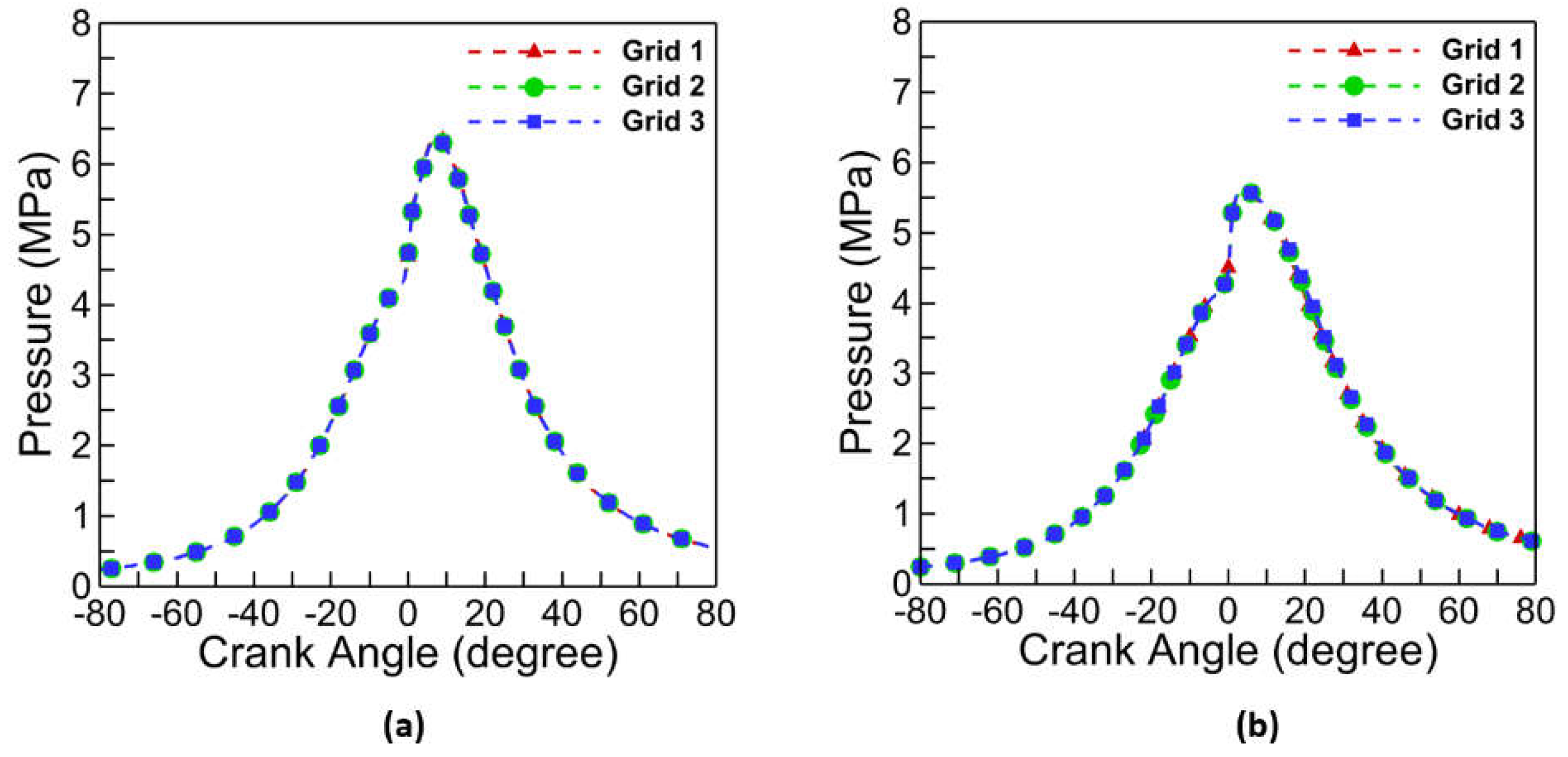

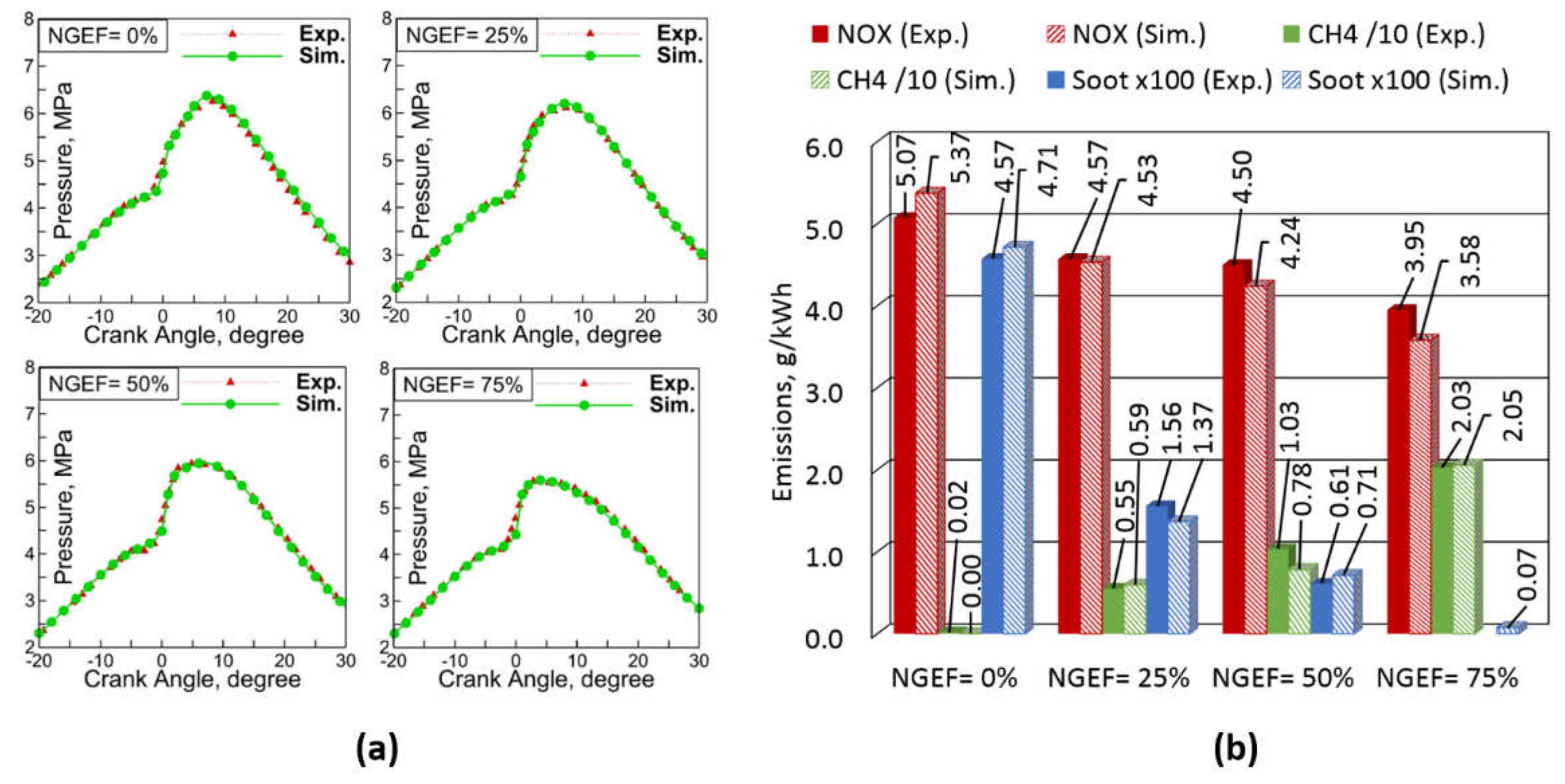

3.1. Validation of the Numerical Models

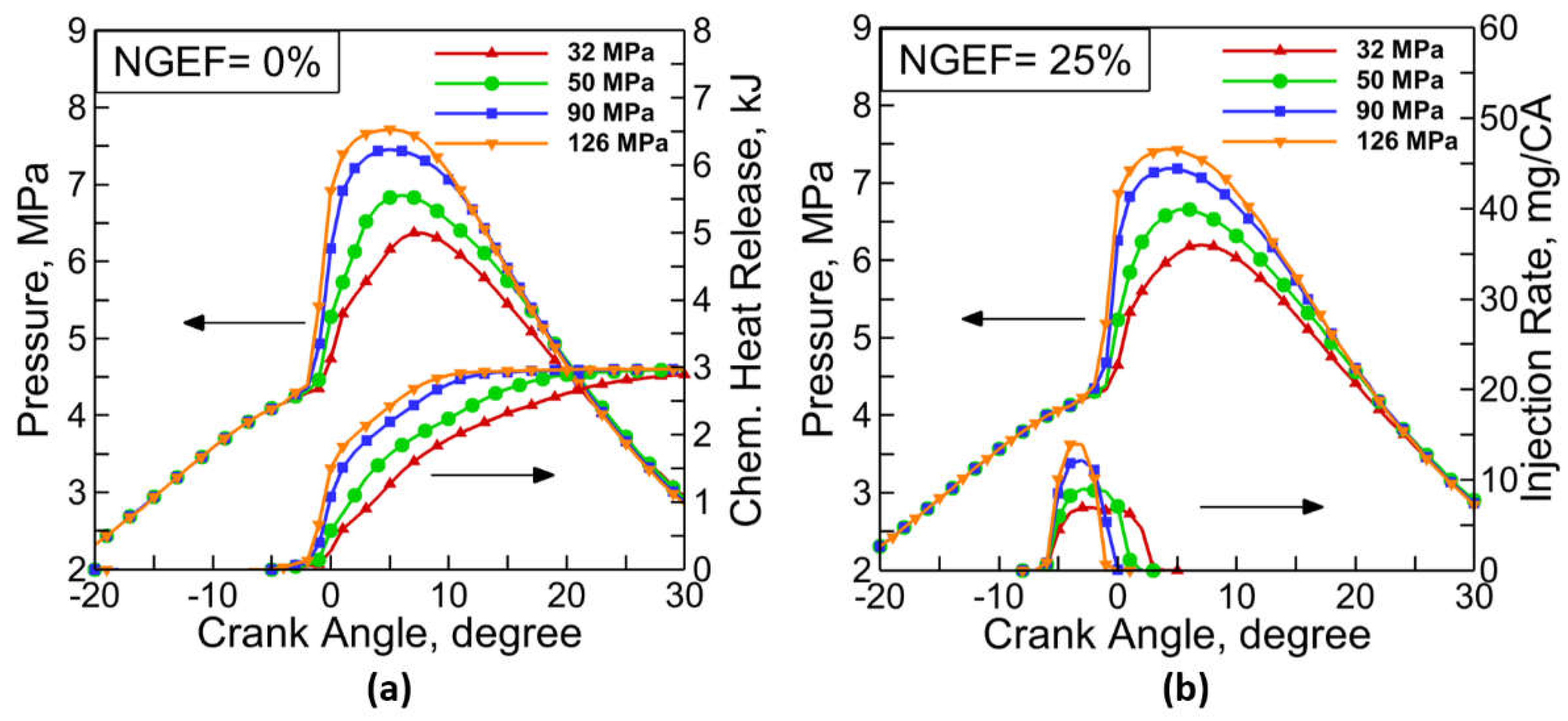

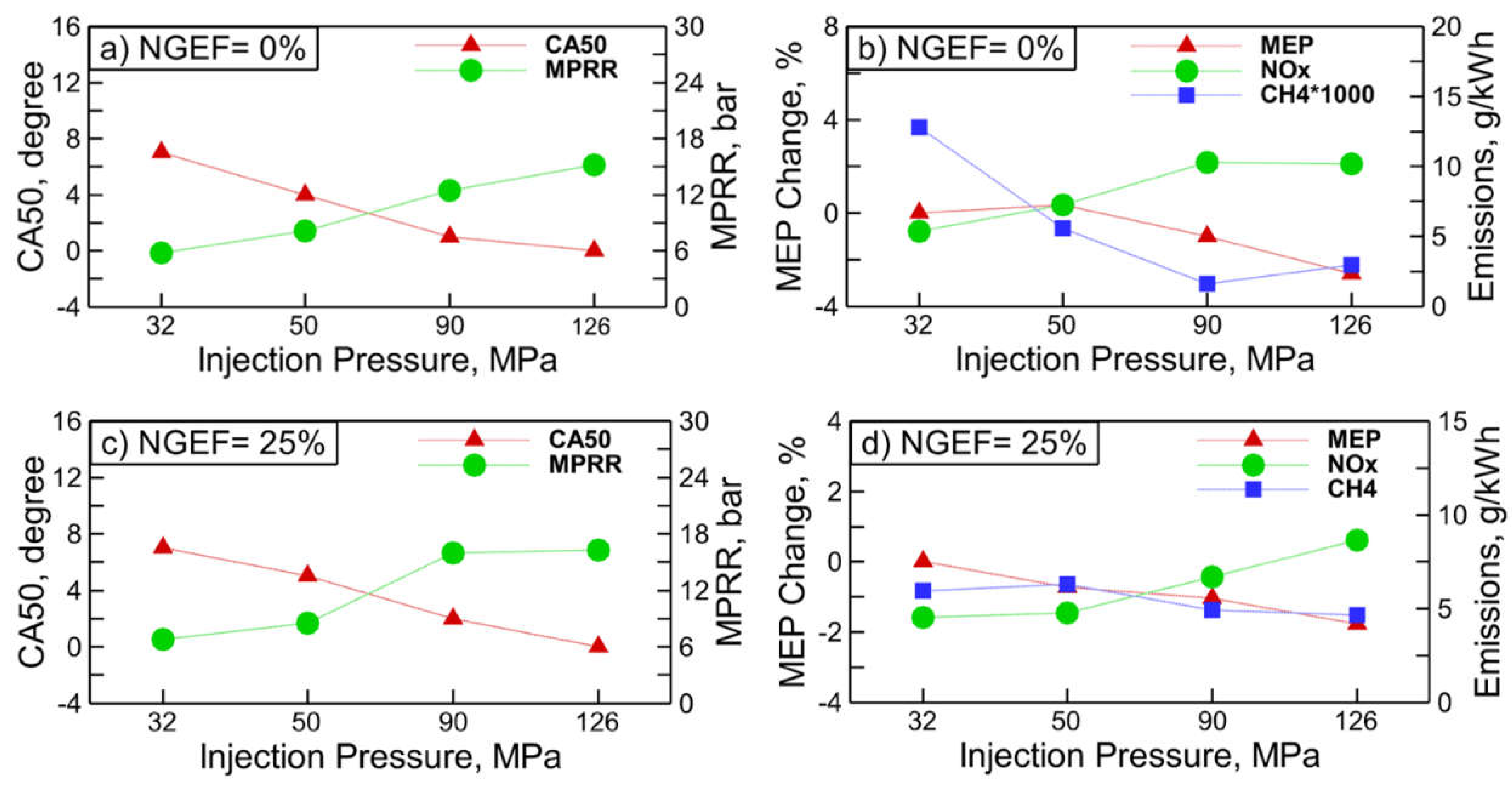

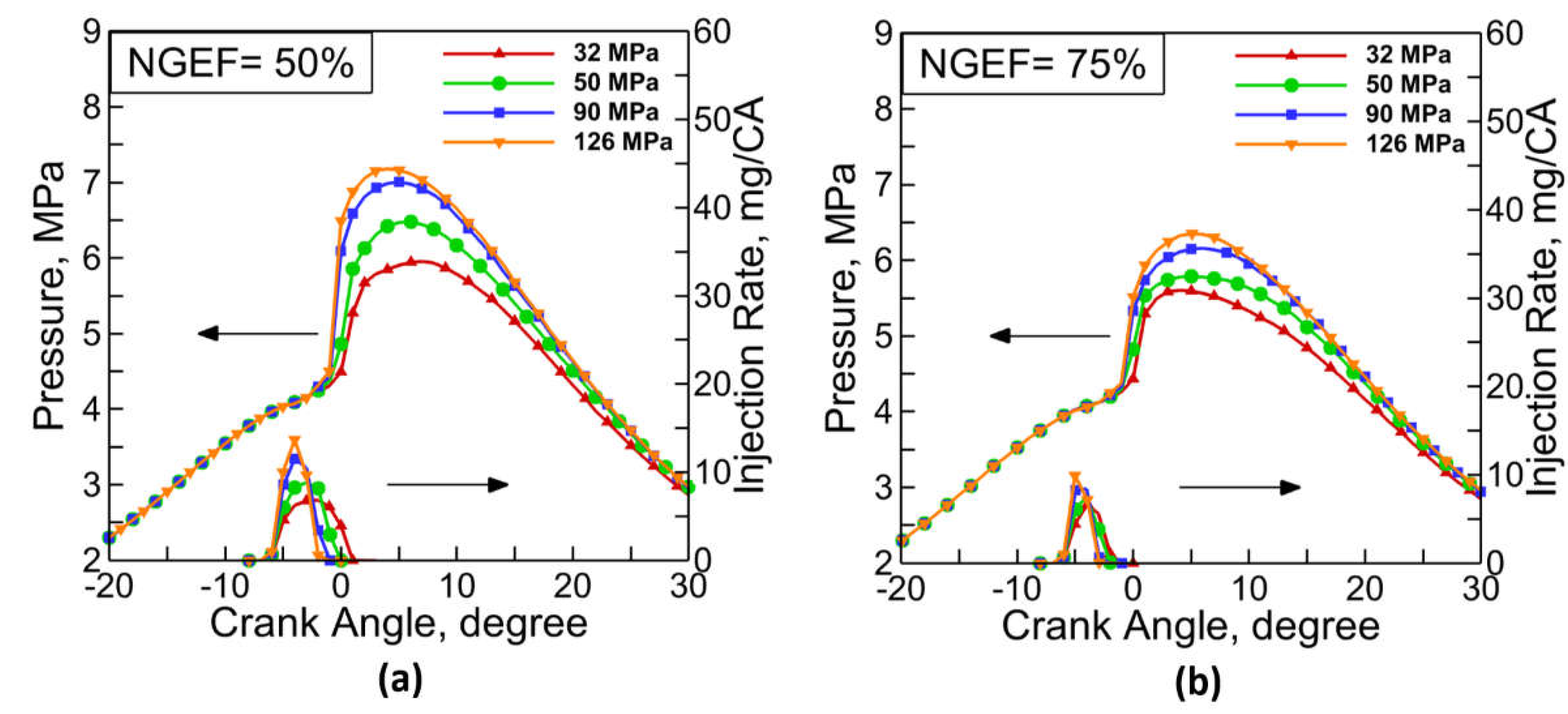

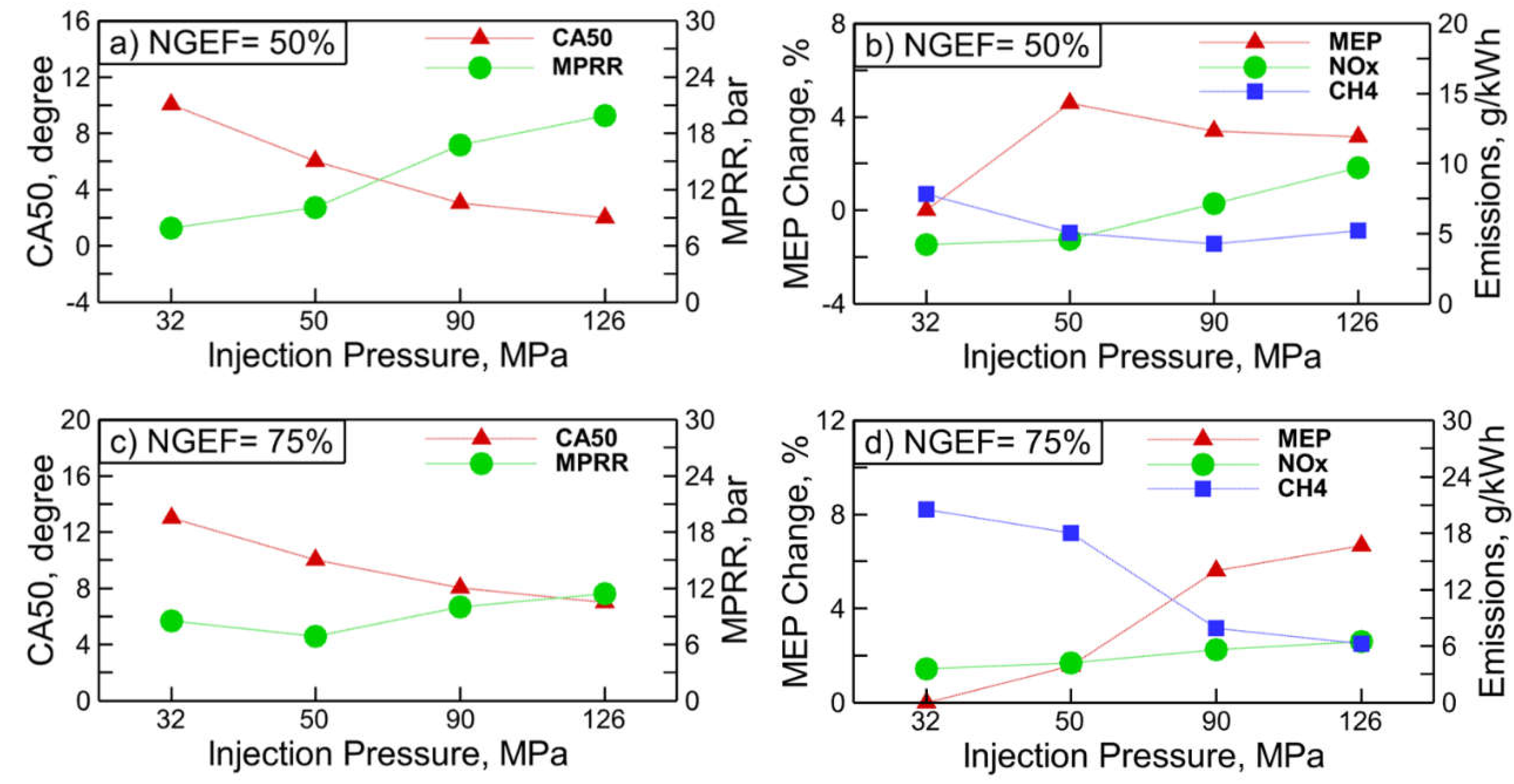

3.2. Effects of Injection Pressure

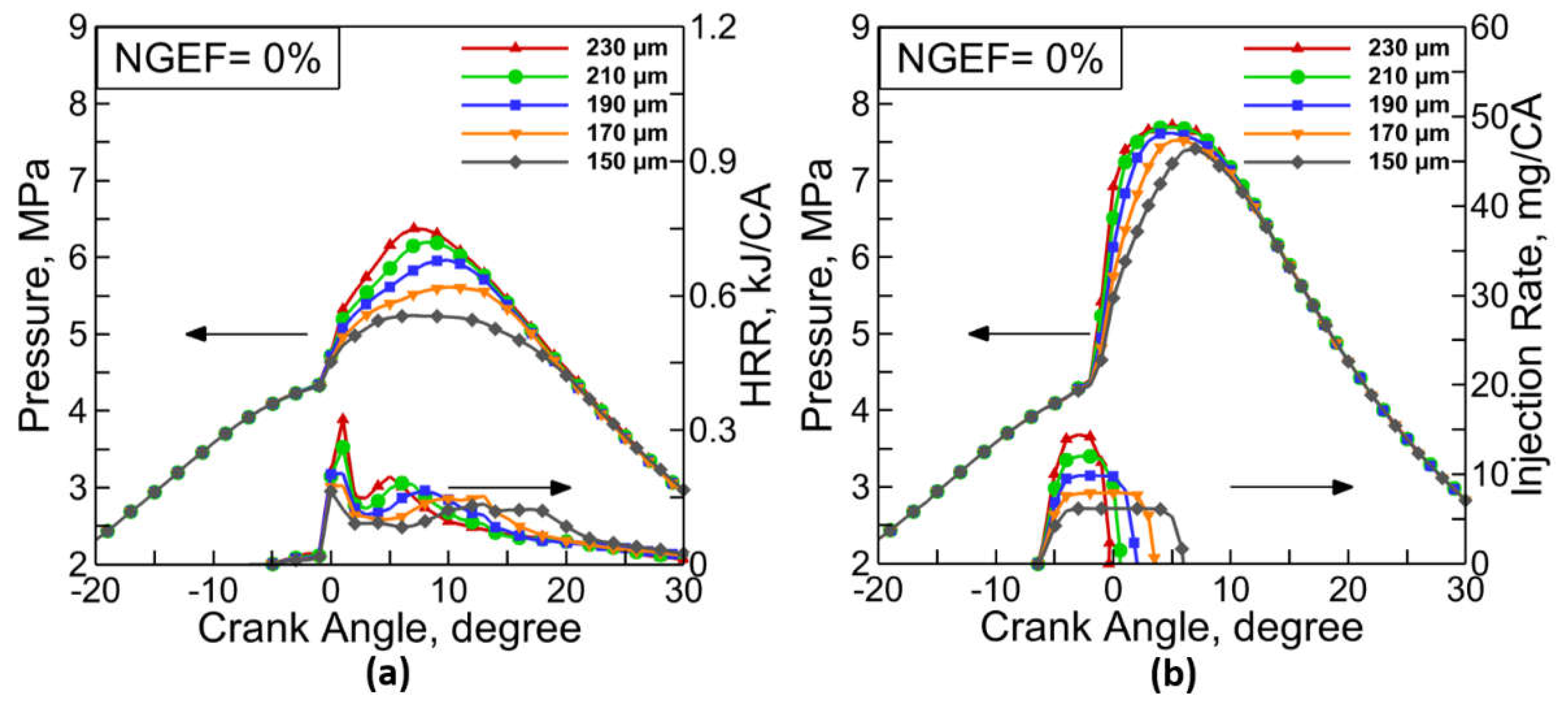

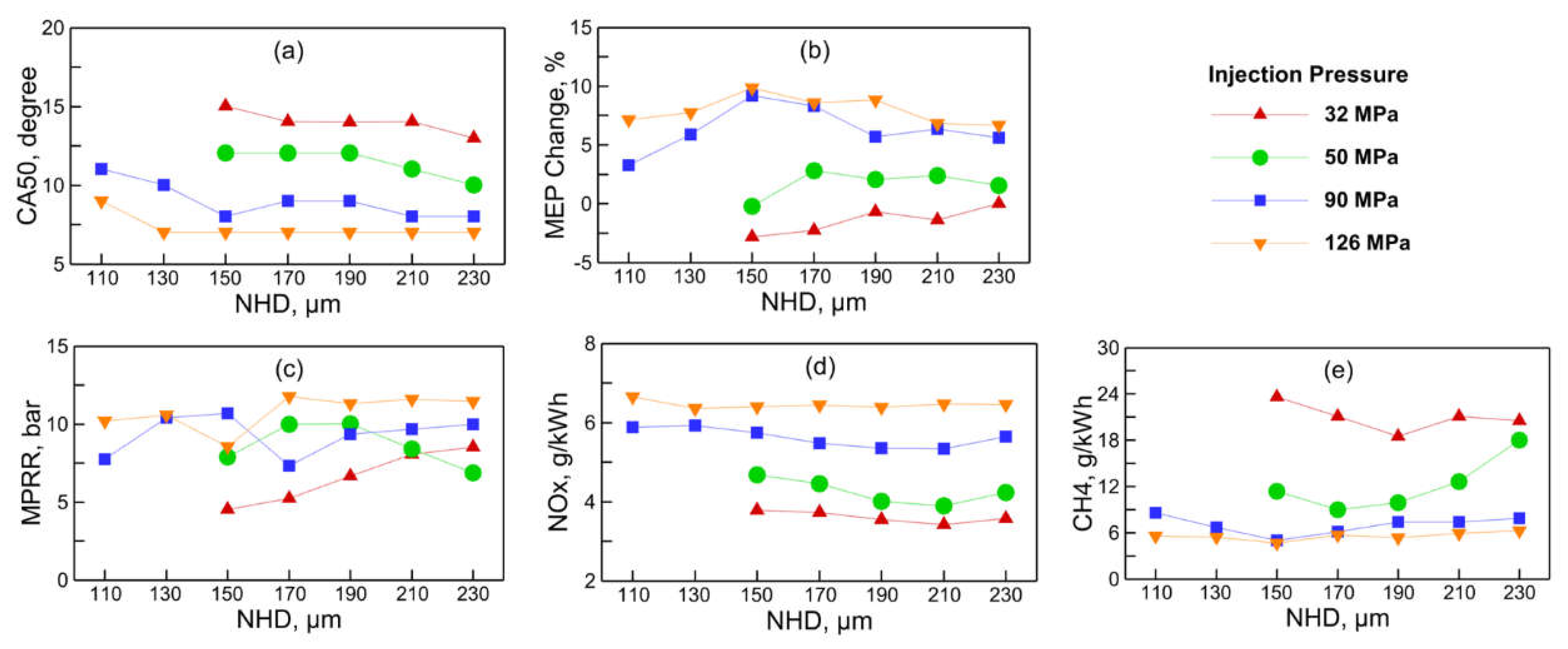

3.3. Effects of NHD Variations

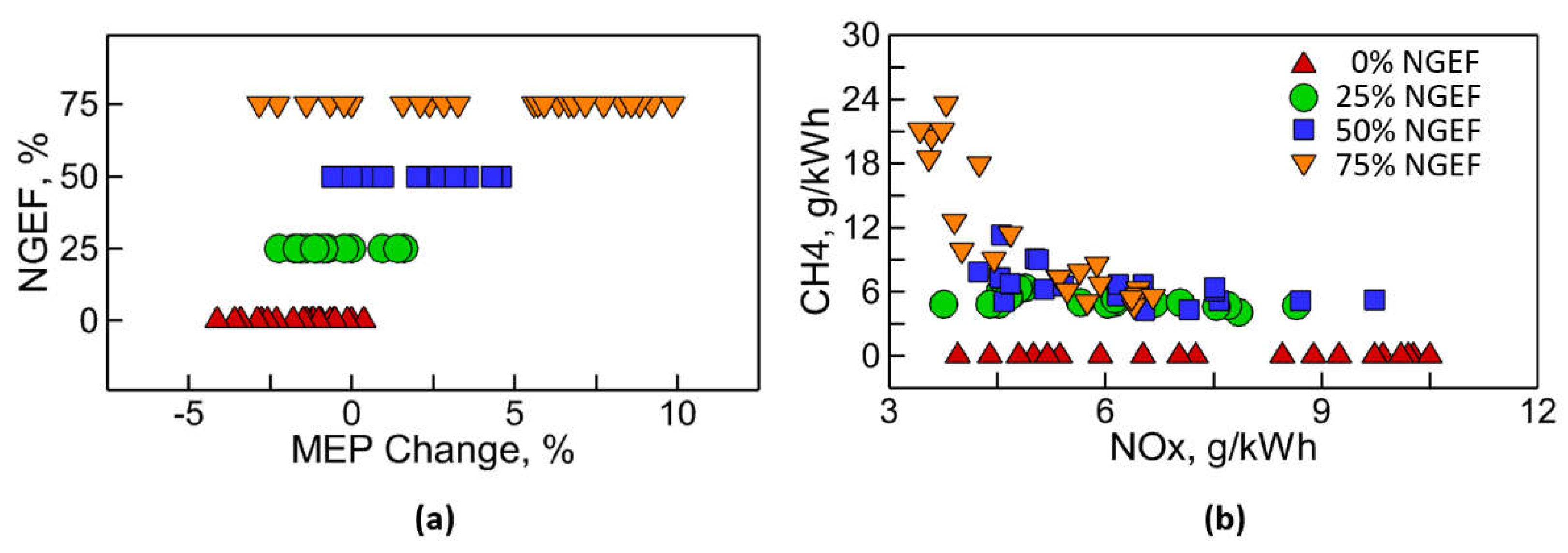

3.4. Evaluation of Simulated Matrix

4. Conclusions

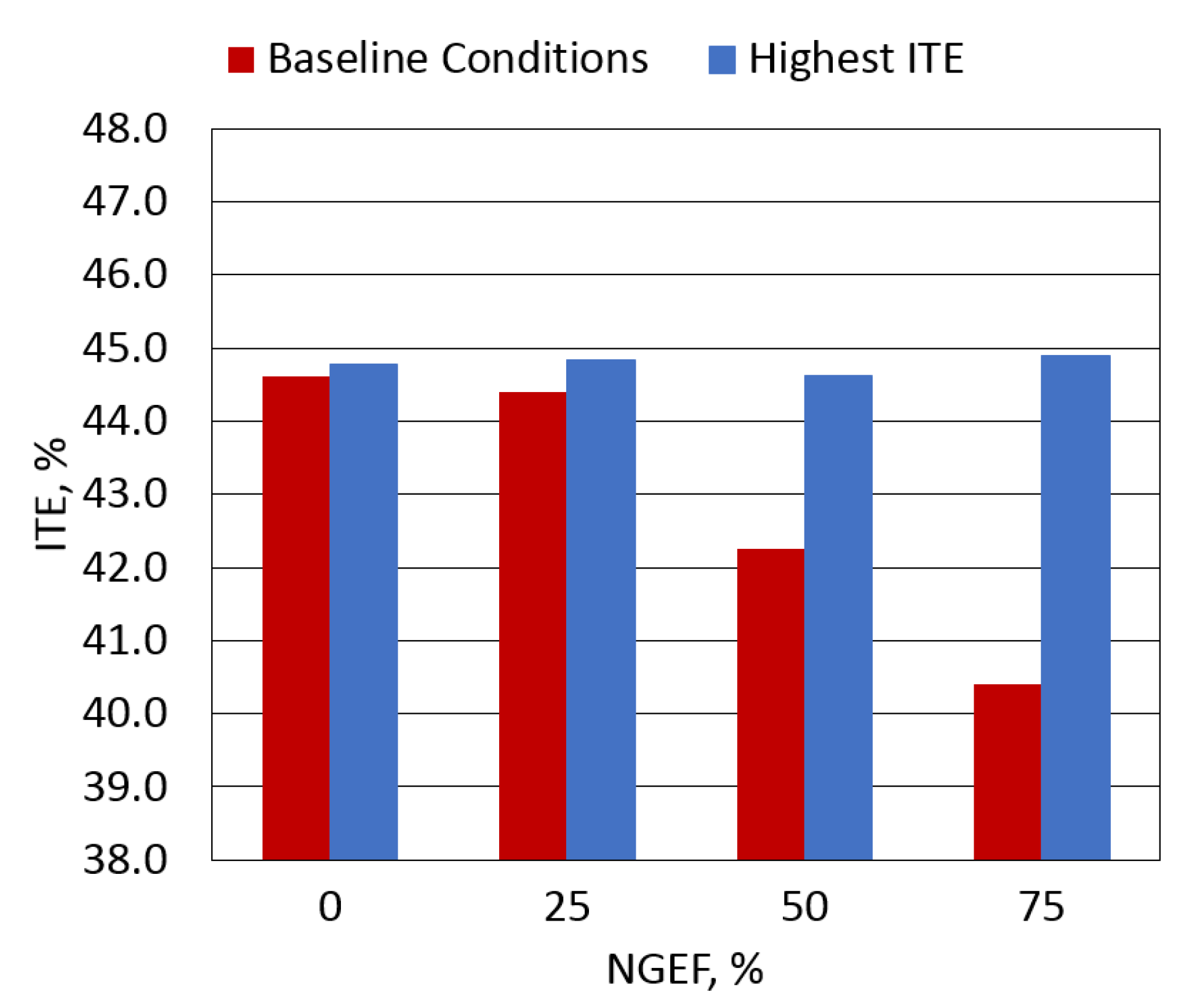

- An increase in injection pressure causes a decrease in MEP values because of excessively advanced combustion under 0% and 25% NGEF conditions. Additionally, a reduction in NHD from 230 μm to 150 μm does not improve MEP values. Although a substantial improvement in engine performance is not observed, optimal values of injection pressure and NHD can provide significant reductions in MPRR values, NOX, and soot emissions.

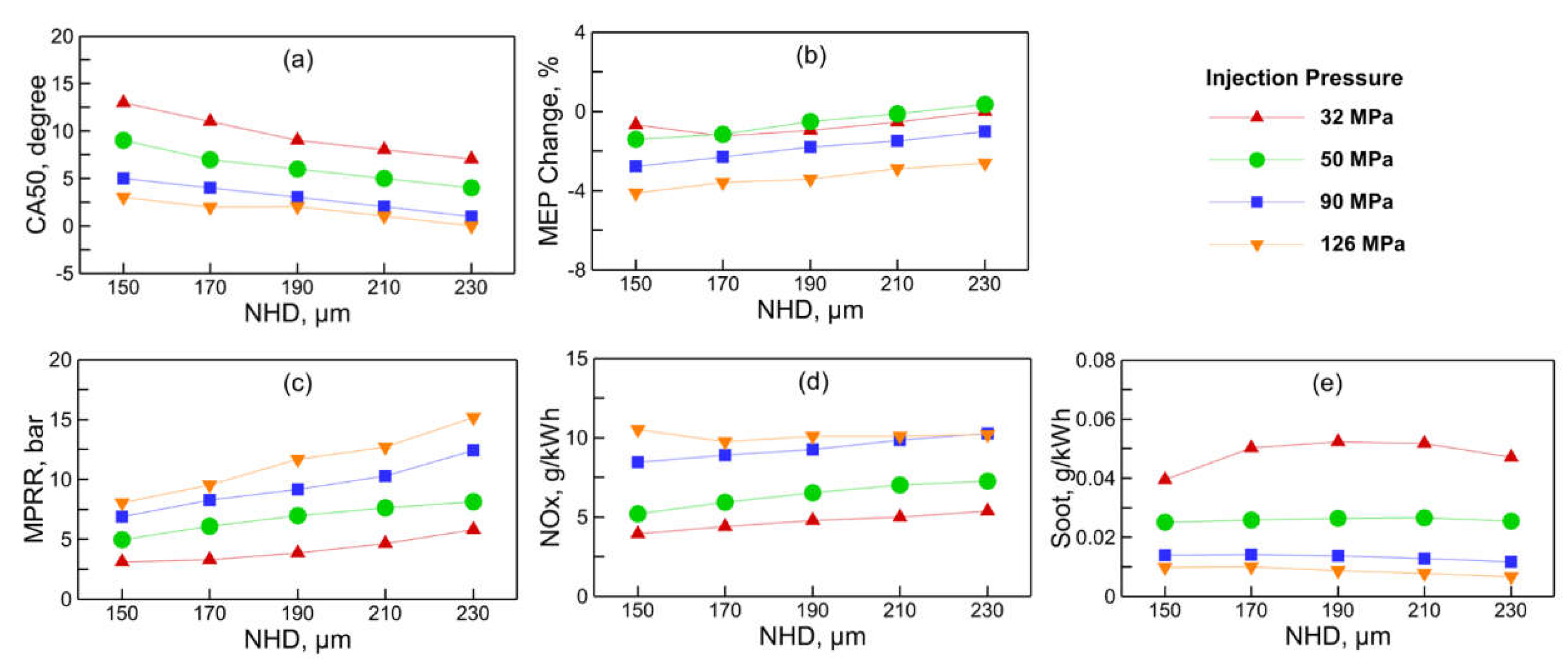

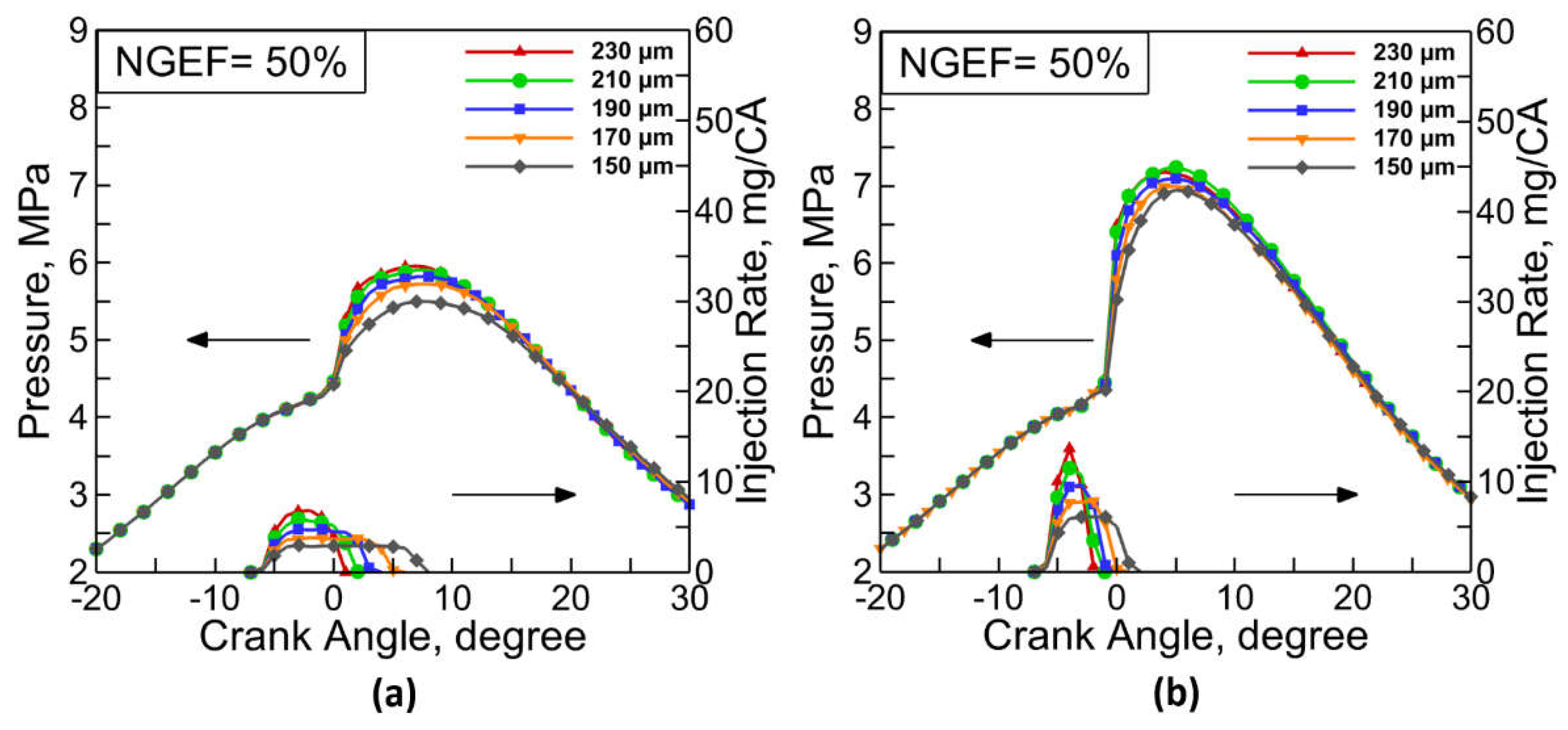

- Unlike at 0% and 25%, MEP improves by up to 4.6% under 50% NGEF conditions. MEP values increase with a rise in injection pressures. However, no additional improvement is observed as NHD decreases. The highest MPRR levels are observed under 50% NGEF conditions. At higher injection pressures and larger NHD values, MPRR exceeds the allowable limit. Therefore, a combination of higher injection pressures and smaller NHD values is preferable. In this way, compliance with MPRR limit and soot regulations can be achieved.

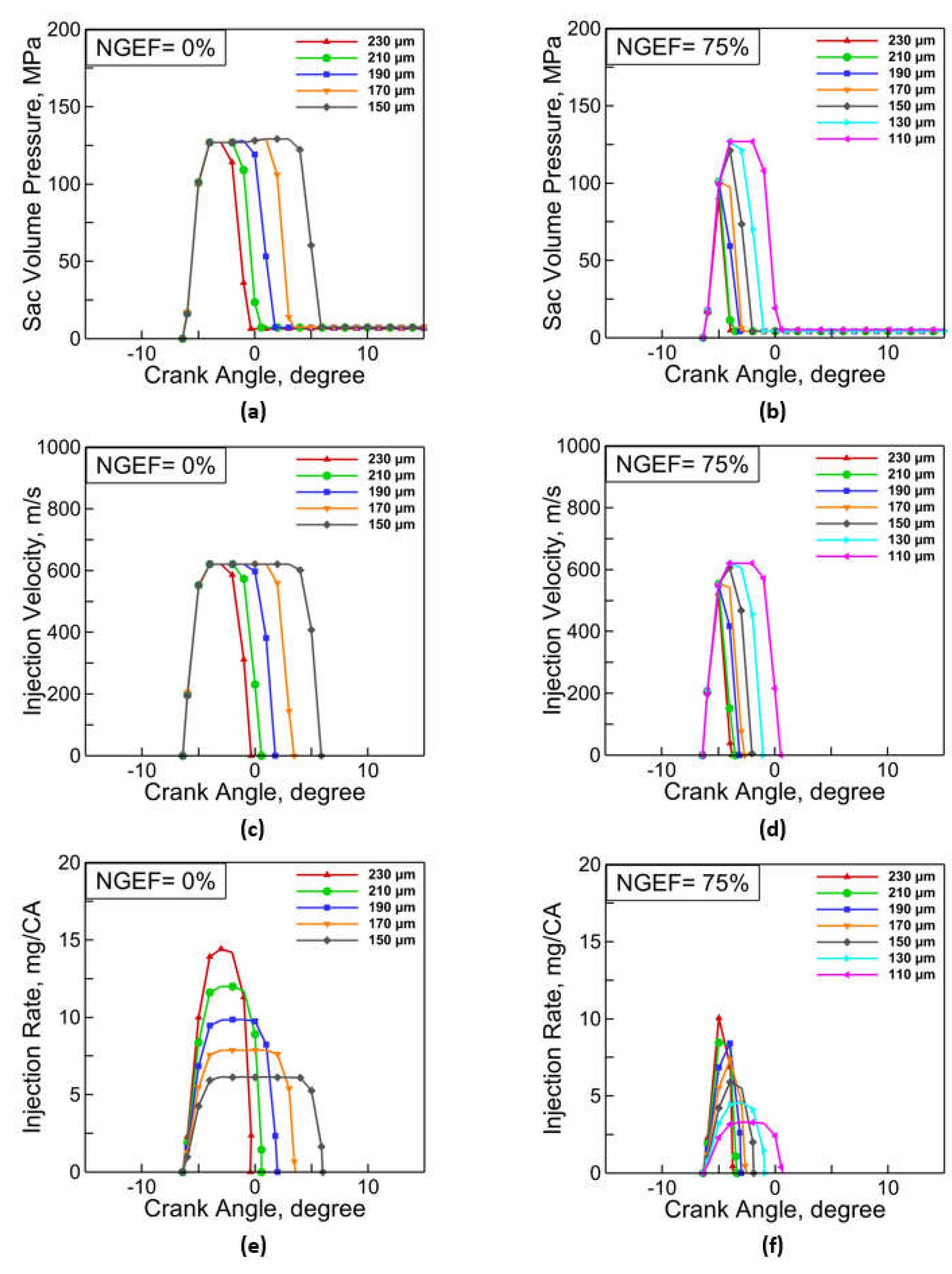

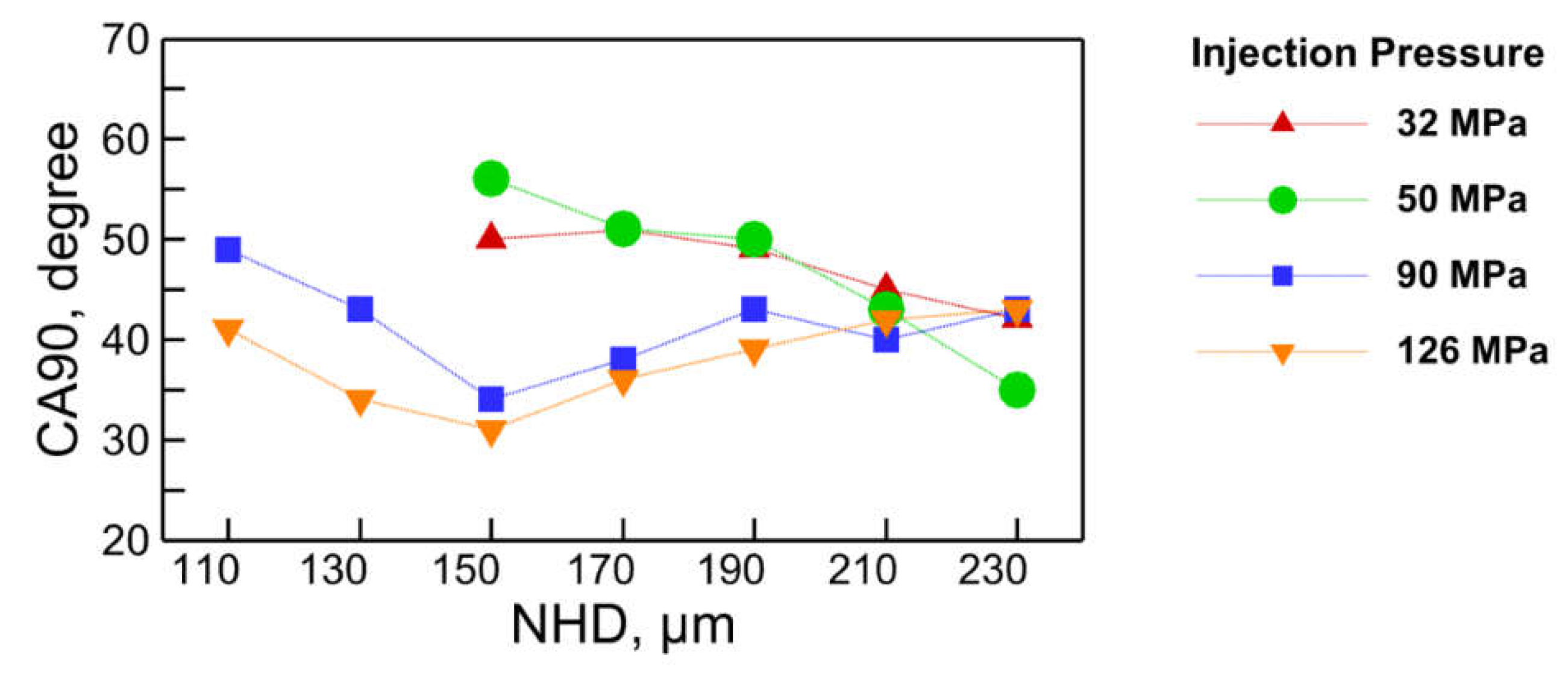

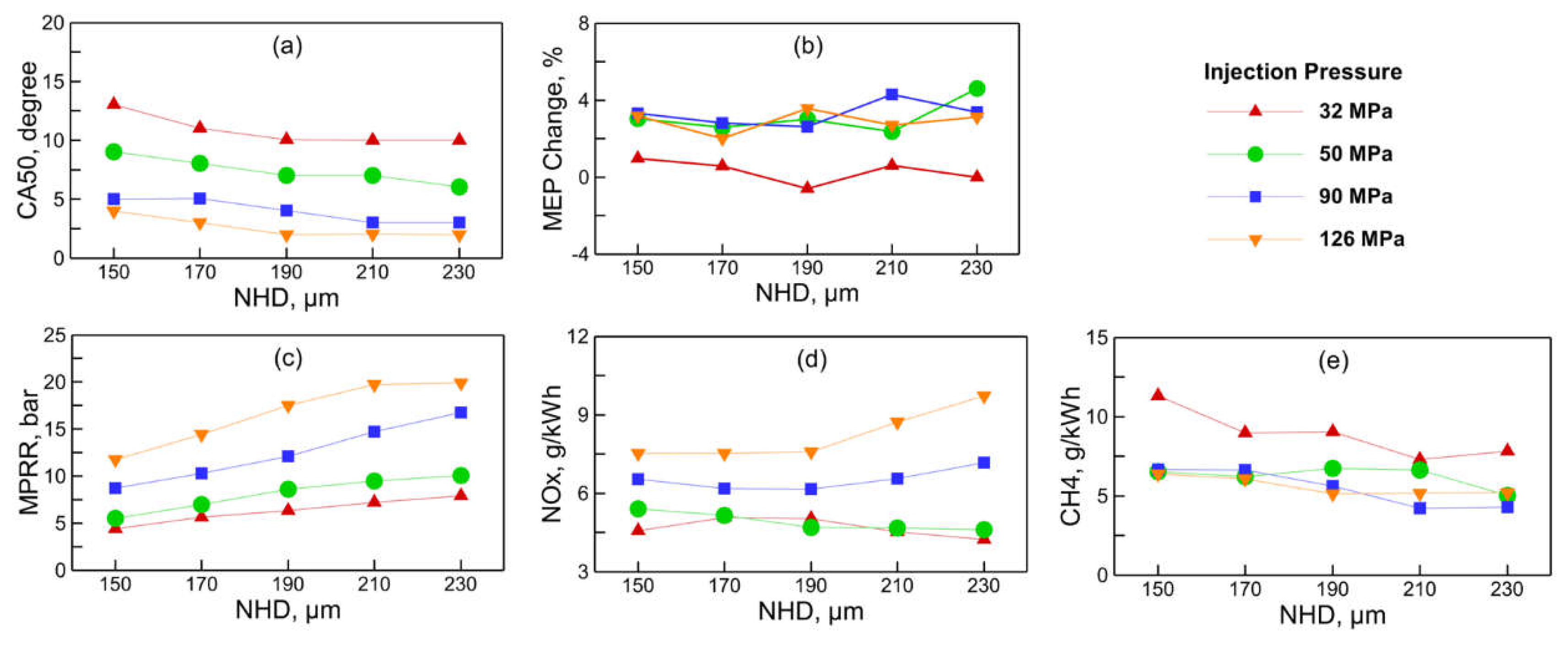

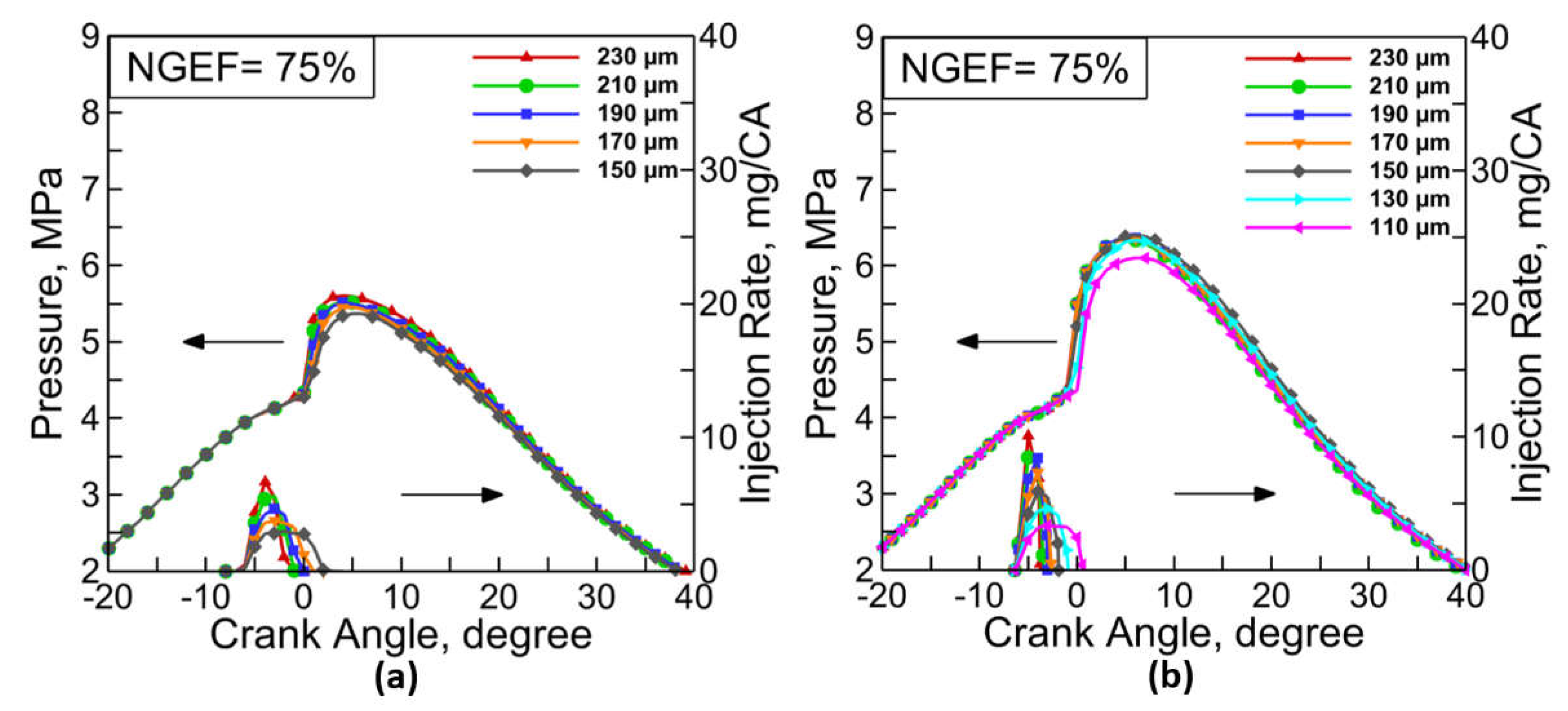

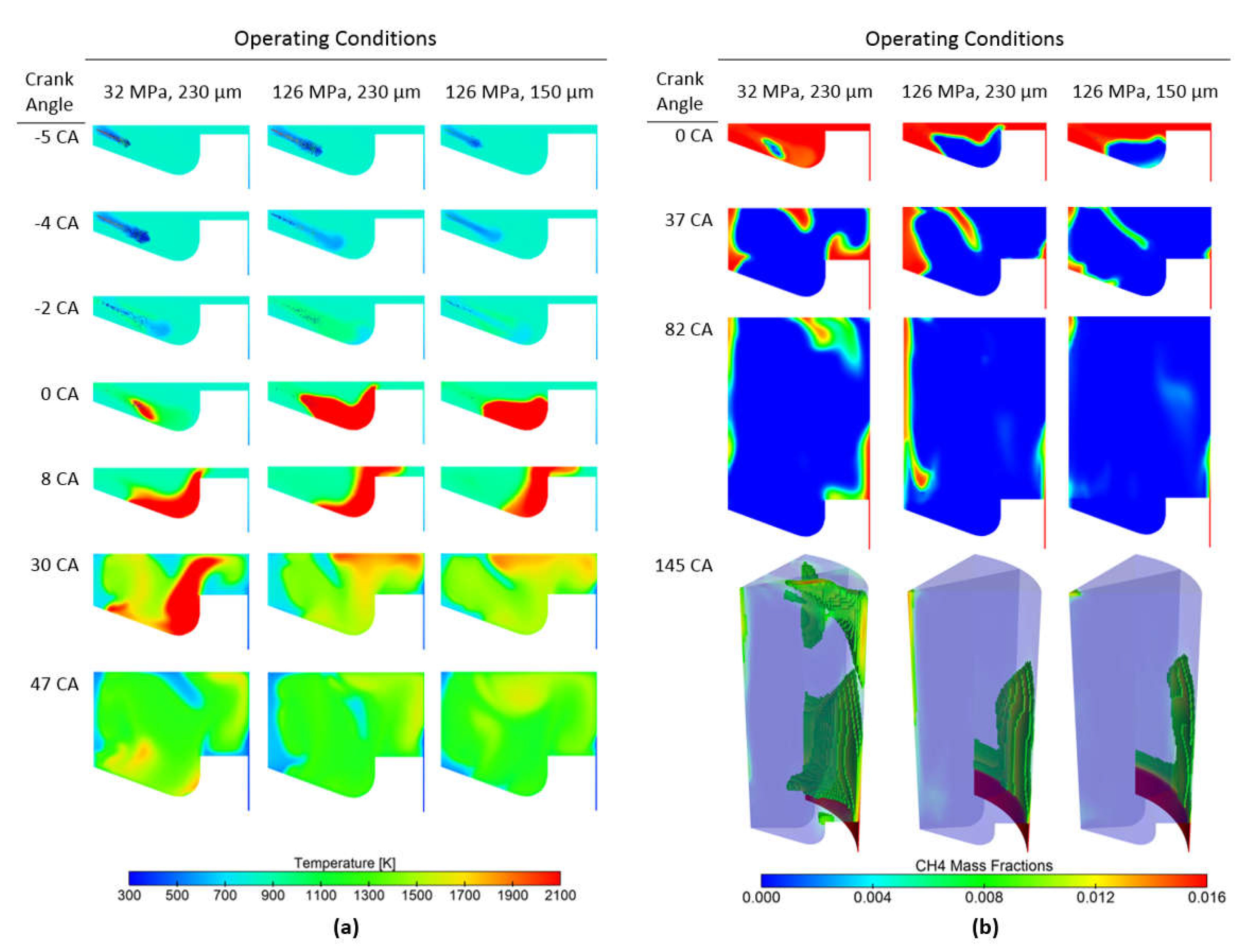

- The effects of injection pressure and NHD variation differ between 75% NGEF and others. The baseline CA50 value is delayed significantly at 75% NGEF depending on reduced combustion rates. An increase in injection pressure substantially improves the combustion rates, MEP values, and efficiency at 75% NGEF. When injection pressure increases from 32 MPa to 126 MPa, MEP increases by 6.7%. However, injection durations are further shortened under high NGEF, high injection pressure, and larger NHD conditions. These shortened injection durations introduce challenges in combustion control and stability.

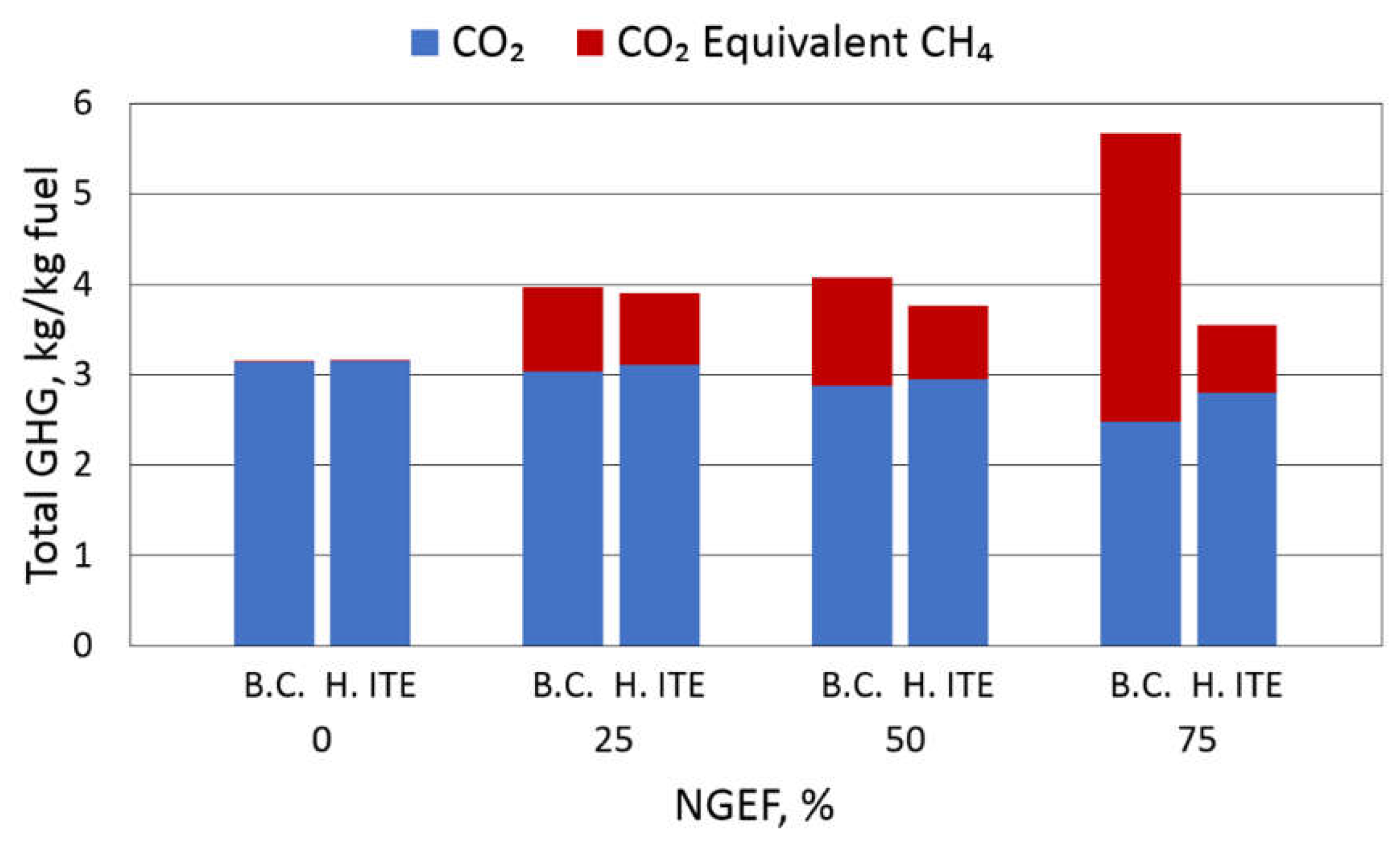

- At 75% NGEF and injection pressures of 90 and 126 MPa, reducing NHD values increases injection duration and velocity. This improves the mixing between premixed natural gas-air and diesel spray. As a result, reducing NHD from 230 μm, further enhances engine performance. MEP increases with decreasing NHD up to a certain point, then it declines. The highest MEP is achieved with the combination of 126 MPa and 150 μm. Improvement in MEP reaches 9.8% compared to baseline. Under these conditions, the thermal efficiency is equivalent to that of a diesel engine. This improvement also results in a 77% reduction in CH4 emissions. This value is equivalent to 2.7% of fuel mass and it is lower than Fuel EU methane slip value of 3.1%. Moreover, PM emission regulations are met without requiring a DPF system. Additionally, MPRR values are lower than the limit. Finally, this condition results in the lowest total GHG emissions among the NDDF cases considered in this study.

- Finally using smaller NHD values at 75% NGEF enhances combustion control and stability. CA90 values and CH4 mass fraction images indicate that combustion rates are more stable at lower NHD values. Additionally, relative MEP changes indicate that combustion performance is highly sensitive to injection parameters under high NGEF conditions. Therefore, results indicate the need for more precise injector control to achieve stable operation. The use of smaller NHD is also advantageous in this regard as it increases injection durations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Reşitoğlu, İ.A.; Altinişik, K.; Keskin, A. The Pollutant Emissions from Diesel-Engine Vehicles and Exhaust Aftertreatment Systems. Clean Technol. Environ. Policy 2015, 17, 15–27. [Google Scholar] [CrossRef]

- Endresen, Ø.; Eide, M.; Dalsøren, S.; Isaksen, I.; Sørgård, E.; Corbett, J.; Winebrake, J. International Maritime Shipping: Environmental Impacts of Increased Activity Levels. In Globalisation, Transport and the Environment; 2010; pp. 161–184. ISBN 978-92-64-07919-9. [Google Scholar]

- Corbett, J.J.; Fischbeck, P.S.; Pandis, S.N. Global Nitrogen and Sulfur Inventories for Oceangoing Ships. J. Geophys. Res. Atmospheres 1999, 104, 3457–3470. [Google Scholar] [CrossRef]

- Sydbom, A.; Blomberg, A.; Parnia, S.; Stenfors, N.; Sandström, T.; Dahlén, S.E. Health Effects of Diesel Exhaust Emissions. Eur. Respir. J. 2001, 17, 733–746. [Google Scholar] [CrossRef] [PubMed]

- Dornoff, J.; Rodríguez, F. Euro 7: The New Emission Standard for Light- and Heavy-Duty Vehicles in the European Union. 2024. [Google Scholar]

- Ni, P.; Wang, X.; Li, H. A Review on Regulations, Current Status, Effects and Reduction Strategies of Emissions for Marine Diesel Engines. Fuel 2020, 279, 118477. [Google Scholar] [CrossRef]

- Fuel EU Maritime. REGULATION (EU) 2023/1805 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 13 September 2023 on the Use of Renewable and Low-Carbon Fuels in Maritime Transport, and Amending Directive 2009/16/EC. 2009; Vol. 188. [Google Scholar]

- Tolley, A. Heavy-Duty Vehicles and Powertrains: Future Internal Combustion Engine Systems and Technologies. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; Elsevier; pp. 291–351. ISSN 978-0-323-90979-2.

- Curran, S.; Onorati, A.; Payri, R.; Agarwal, A.K.; Arcoumanis, C.; Bae, C.; Boulouchos, K.; Dal Forno Chuahy, F.; Gavaises, M.; Hampson, G.J.; et al. The Future of Ship Engines: Renewable Fuels and Enabling Technologies for Decarbonization. Int. J. Engine Res. 2024, 25, 85–110. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K. Evolution, Challenges and Path Forward for Low Temperature Combustion Engines. Prog. Energy Combust. Sci. 2017, 61, 1–56. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of High Efficiency and Clean Reactivity Controlled Compression Ignition (RCCI) Combustion in Internal Combustion Engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- AEsoy, V.; Magne Einang, P.; Stenersen, D.; Hennie, E.; Valberg, I. LNG-Fuelled Engines and Fuel Systems for Medium-Speed Engines in Maritime Applications; 30 August 2011; pp. 2011-01–1998.

- Karim, G.A. Dual-Fuel Diesel Engines, 1st ed.; Taylor & Francis Group: London, UK, 2015; ISBN 978-1-4987-0309-3. [Google Scholar]

- Cui, Z.; Liu, Y.; Zhang, X.; Zhou, Q.; Yang, H.; Lu, M.; Tian, J. Visualization Study on the Ignition and Combustion Characteristics of Methane/Hydrogen Ignited by Diesel. Fuel 2024, 372, 132215. [Google Scholar] [CrossRef]

- Tripathi, G.; Dhar, A. Performance, Emissions, and Combustion Characteristics of Methane-Diesel Dual-Fuel Engines: A Review. Front. Therm. Eng. 2022, 2, 870077. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, W.; Zhang, X.; Ji, Q.; Ma, H.; Sun, P.; Wang, P. Optimizing Combustion and Emissions in Natural Gas/Diesel Dual-Fuel Engine with Pilot Injection Strategy. Therm. Sci. Eng. Prog. 2024, 48, 102418. [Google Scholar] [CrossRef]

- Lee, S.; Kim, C.; Lee, S.; Lee, J.; Kim, J. Diesel Injector Nozzle Optimization for High CNG Substitution in a Dual-Fuel Heavy-Duty Diesel Engine. Fuel 2020, 262, 116607. [Google Scholar] [CrossRef]

- Wei, L.; Geng, P. A Review on Natural Gas/Diesel Dual Fuel Combustion, Emissions and Performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Liu, J.; Yao, A.; Yao, C. Effects of Diesel Injection Pressure on the Performance and Emissions of a HD Common-Rail Diesel Engine Fueled with Diesel/Methanol Dual Fuel. Fuel 2015, 140, 192–200. [Google Scholar] [CrossRef]

- Yalong, L.; Bo, W.; Cong, W.; Zhi, J.; Binyang, W. The Effect of Ignition Diesel Injection Conditions on the Combustion Process of Natural Gas Engine. Appl. Therm. Eng. 2023, 235, 121452. [Google Scholar] [CrossRef]

- Bonfochi Vinhaes, V.; McTaggart-Cowan, G.; Munshi, S.; Shahbakhti, M.; Naber, J.D. Experimental Studies of Low-Load Limit in a Stoichiometric Micro-Pilot Diesel Natural Gas Engine. Energies 2022, 15, 728. [Google Scholar] [CrossRef]

- Baumgarten, C. Mixture Formation in Internal Combustion Engines; Heat and mass transfer; Springer: Berlin, Germany, 2006; ISBN 978-3-540-30835-5. [Google Scholar]

- Wang, X.; Li, H.; Li, G.; Fan, J.; Bai, H.; Gao, Y.; Huo, H. Effect of Injection Pressure on Low-Temperature Fuel Atomization Characteristics of Diesel Engines under Cold Start Conditions. Int. J. Multiph. Flow 2024, 172, 104712. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M.; Liko, B. On Greenhouse Gas Emissions and Thermal Efficiency of Natural Gas/Diesel Dual-Fuel Engine at Low Load Conditions: Coupled Effect of Injector Rail Pressure and Split Injection. Appl. Energy 2019, 242, 216–231. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, C. Study on Influencing Factors and Laws of Fuel Injection Consistency of Common Rail Injector. J. Phys. Conf. Ser. 2021, 2097, 012001. [Google Scholar] [CrossRef]

- Yoon, M.; Choi, M.; Kang, K.; Oh, C.; Park, Y.; Choi, G. Effects of N-Heptane/Methane Blended Fuel on Ignition Delay Time in Pre-Mixed Compressed Combustion. Energies 2022, 15, 4081. [Google Scholar] [CrossRef]

- Zheng, J.; Hao, Z.; Wang, D.; Di, Y.; Peng, H.; Wu, T.; Miao, X. Effect of Double-Layer Hole Nozzle with Narrow Spray Angle on Combustion and Emissions in Dual-Fuel Natural Gas Engine. Fuel 2022, 314, 123090. [Google Scholar] [CrossRef]

- Hariharan, D.; Rajan Krishnan, S.; Kumar Srinivasan, K.; Sohail, A. Multiple Injection Strategies for Reducing HC and CO Emissions in Diesel-Methane Dual-Fuel Low Temperature Combustion. Fuel 2021, 305, 121372. [Google Scholar] [CrossRef]

- Guo, H.; Neill, W.S.; Liko, B. An Experimental Investigation on the Combustion and Emissions Performance of a Natural Gas–Diesel Dual Fuel Engine at Low and Medium Loads. In Proceedings of the Volume 1: Large Bore Engines; Fuels; Advanced Combustion; American Society of Mechanical Engineers, Houston, TX, USA, 8 November 2015; p. V001T03A005. [Google Scholar]

- Li, Y.; Li, H.; Guo, H.; Li, Y.; Yao, M. A Numerical Investigation on Methane Combustion and Emissions from a Natural Gas-Diesel Dual Fuel Engine Using CFD Model. Appl. Energy 2017, 205, 153–162. [Google Scholar] [CrossRef]

- ANSYS®Academic Research Forte Theory Manual.

- Healy, D.; Kalitan, D.M.; Aul, C.J.; Petersen, E.L.; Bourque, G.; Curran, H.J. Oxidation of C1−C5 Alkane Quinternary Natural Gas Mixtures at High Pressures. Energy Fuels 2010, 24, 1521–1528. [Google Scholar] [CrossRef]

- Wang, H.; Jiao, Q.; Yao, M.; Yang, B.; Qiu, L.; Reitz, R.D. Development of an N-Heptane/Toluene/Polyaromatic Hydrocarbon Mechanism and Its Application for Combustion and Soot Prediction. Int. J. Engine Res. 2013, 14, 434–451. [Google Scholar] [CrossRef]

- Gao, Z.; Li, G.; Xu, C.; Li, H.; Wang, M. A Calculation Method and Experiment Study of High-Pressure Common Rail Injection Rate with Solenoid Injectors. Sci. Prog. 2021, 104, 00368504211026157. [Google Scholar] [CrossRef]

- Salvador, F.J.; Gimeno, J.; De La Morena, J.; Carreres, M. Using One-Dimensional Modeling to Analyze the Influence of the Use of Biodiesels on the Dynamic Behavior of Solenoid-Operated Injectors in Common Rail Systems: Results of the Simulations and Discussion. Energy Convers. Manag. 2012, 54, 122–132. [Google Scholar] [CrossRef]

- Xu, J.; Fan, L.; Chen, C.; Lu, G.; Li, B.; Tu, T. Study on Fuel Injection Stability Improvement in Marine Low-Speed Dual-Fuel Engines. Appl. Therm. Eng. 2024, 253, 123729. [Google Scholar] [CrossRef]

- Kang, S.; Lee, S.; Hong, D.; Bae, C. Effects of Nozzle Orifice Diameter and Hole Number on Diesel Combustion and Engine Performance. Int. J. Automot. Technol. 2022, 23, 481–494. [Google Scholar] [CrossRef]

- Tanner, F.X.; Reitz, R.D. Scaling Aspects of the Characteristic Time Combustion Model in the Simulation of Diesel Engines. March 1 1999; pp. 1999-01–1175.

- Yousefi, A. A Numerical Study of the Combustion of a Natural Gas/Diesel Dual-Fuel Engine under Low to High Load Conditions. 2018.

- Soruşbay, C.; Ergeneman, M.; İmren, A.; Çalık, A.T. Experimental and Numerical Air Flow and Spray Dynamics Investigation in Internal Combustion Engines; İstanbul, Türkiye, 2008; p. 38.

- İmren, A. THE FULL OPERATING CYCLE MODELING OF HEAVY-DUTY DIESEL ENGINES. Ph.D. Thesis, Istanbul Technical University, İstanbul, Türkiye, 2010. [Google Scholar]

- Chan, M.; Das, S.; Reitz, R.D. Modeling Multiple Injection and EGR Effects on Diesel Engine Emissions. 1 October 1997; 972864. [Google Scholar]

- Baek, H.-M.; Jung, G.-S.; Vuong, Q.D.; Lee, J.-U.; Lee, J.-W. Effect of Performance by Excessive Advanced Fuel Injection Timing on Marine Diesel Engine. Appl. Sci. 2023, 13, 9263. [Google Scholar] [CrossRef]

- Dallmann, T.R.; Onasch, T.B.; Kirchstetter, T.W.; Worton, D.R.; Fortner, E.C.; Herndon, S.C.; Wood, E.C.; Franklin, J.P.; Worsnop, D.R.; Goldstein, A.H.; et al. Characterization of Particulate Matter Emissions from On-Road Gasoline and Diesel Vehicles Using a Soot Particle Aerosol Mass Spectrometer. Atmospheric Chem. Phys. 2014, 14, 7585–7599. [Google Scholar] [CrossRef]

- U.S. EPA Importance of Methane. Available online: https://www.epa.gov/gmi/importance-methane (accessed on 31 January 2025).

- Sagot, B.; Giraudier, G.; Decuniac, F.; Lefebvre, L.; Miquel, A.; Thomas, A. On-Board Measurement of Emissions on a Dual Fuel LNG Powered Cruise Ship: A Sea Trial Study. Atmospheric Environ. X 2025, 25, 100313. [Google Scholar] [CrossRef]

| Engine Specification and Operation Conditions | Value |

|---|---|

| Engine speed, rpm | 910 |

| Compression ratio | 16.25 |

| Nozzle hole number | 6 |

| Nozzle hole diameter, μm | 230 |

| Inlet valve closure, CA degrees | -147 |

| Exhaust valve opening, CA degrees | 145 |

| NGEF (%) | 0, 25, 50, 75 |

| Injection Pressure, MPa | NHD, μm |

|---|---|

| 32 | 150, 170, 190, 210, 230 |

| 50 | 150, 170, 190, 210, 230 |

| 90 | 150, 170, 190, 210, 230 |

| 126 | 150, 170, 190, 210, 230 |

| Injection Pressure, MPa | 0% NGEF | 25% NGEF | 50% NGEF | 75% NGEF |

|---|---|---|---|---|

| 32 | 4.7E-02 | 1.4E-02 | 7.1E-03 | 7.5E-04 |

| 50 | 2.5E-02 | 5.1E-03 | 1.8E-03 | 2.5E-04 |

| 90 | 1.2E-02 | 1.8E-03 | 5.7E-04 | 1.6E-04 |

| 126 | 6.6E-03 | 9.1E-04 | 2.5E-04 | 1.5E-04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).