1. Introduction

Portugal, with its magnificent history and culture, is rich in traditional buildings that reflect its identity and architectural heritage. Wattle and daub walls, commonly found in constructions up to the mid-20th century in historic centres and many Portu-guese villages, are significant examples of this architectural legacy, both vernacular and urban.

Tabique constructions, as they are known in Portugal, have been used in Europe, the Americas, and Asia, and are referred to as pau-a-pique in Brazil, torchis in France, wattle and daub in the United Kingdom and the United States, quincha in Argentina, Chile, Peru, and Spain, bahareque in Colombia, Venezuela, and El Salvador, cuje in Cuba, tsuchikabe in Japan, and lehmbewurf in Germany, [

1].

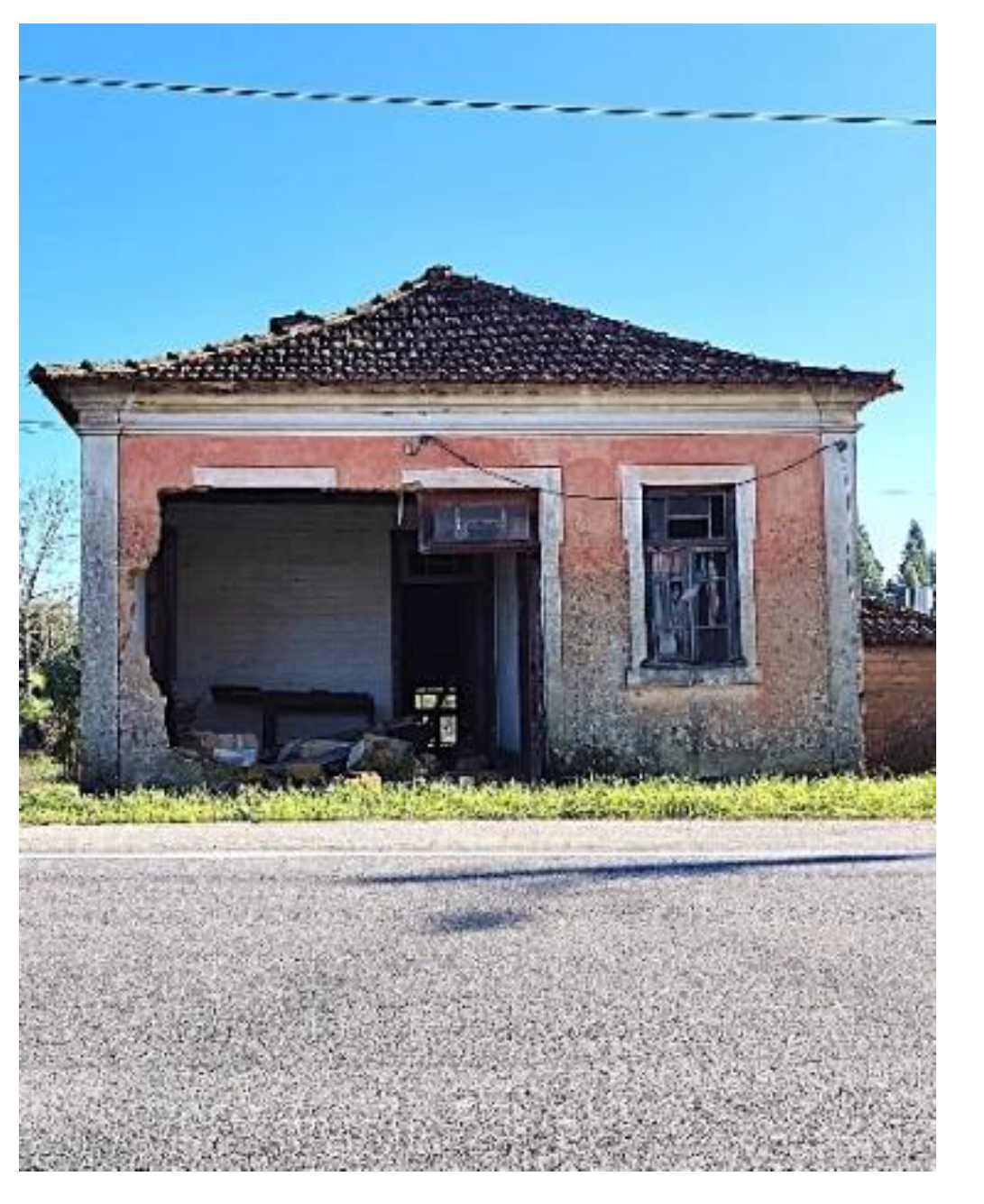

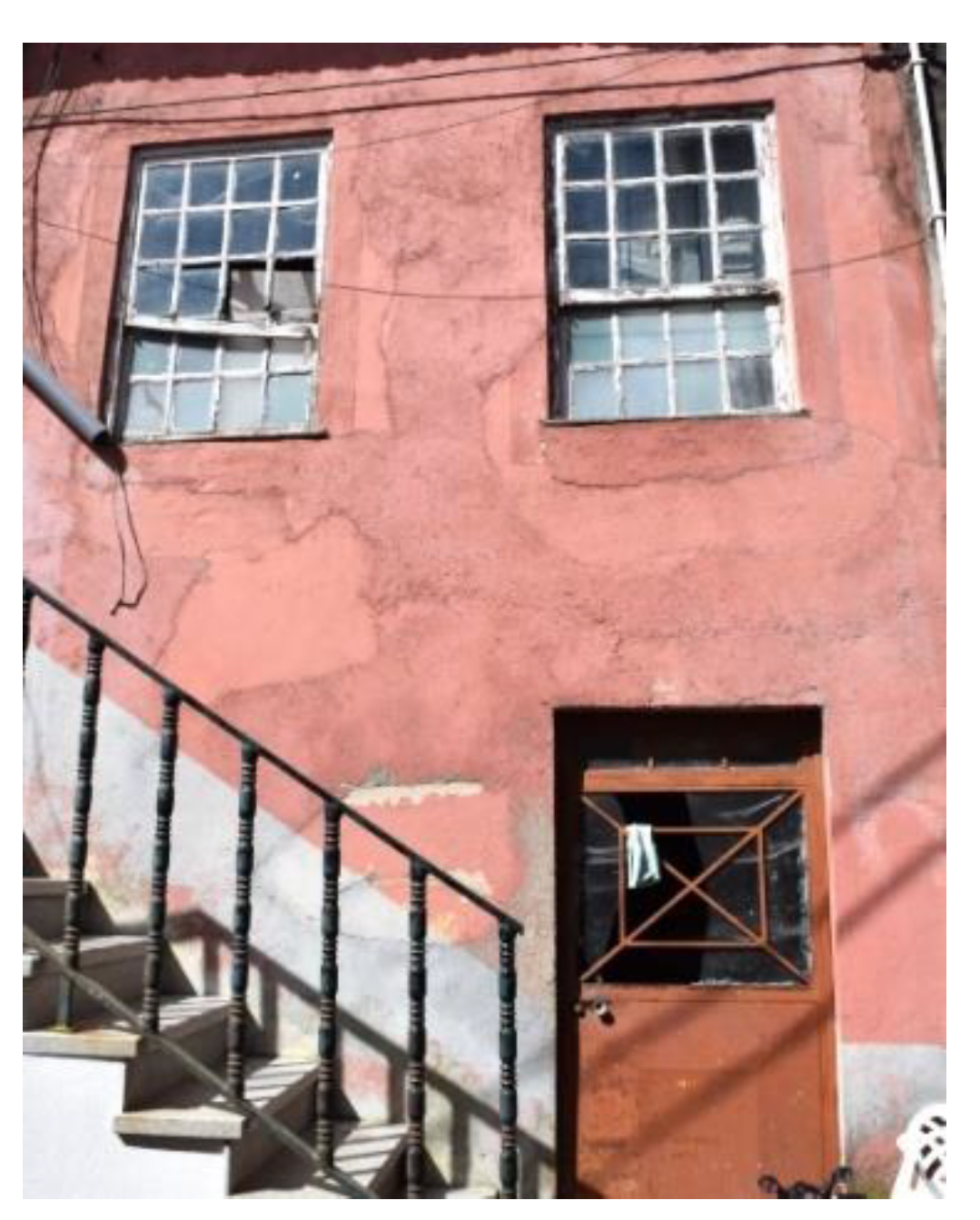

The rehabilitation of wattle and daub constructions emerges as a relevant solution in the current context, both due to the extent of its use and the risks currently associ-ated with it. It is a fact that a significant portion of the wattle and daub-built heritage in Portugal is in a state of degradation. This scenario is mainly due to the lack of regu-lar maintenance actions or the complete abandonment of these structures, particularly regarding rendering mortars. These mortars serve the primary function of protecting and ensuring the durability of the surfaces to which they are applied, while also con-tributing to the comfort and healthiness of the buildings. Additionally, it is evident that insufficient importance is given to this constructive element, as it often becomes a target for demolition, even when in good condition.

In a study that analysed 127 external wattle-and-daub walls, [

22] observed that approximately 40% of the constructions exhibited detachment of rendering mortars, while around 83% showed cracks. Humidity stains were also frequent, affecting ap-proximately 74.8% of the constructions analysed.

Despite the identified pathologies, it is important to highlight that the existence of buildings with wattle and daub walls in good condition proves that this construction system has durability compatible with modern standards. The rehabilitation of such constructions, in addition to helping reduce the housing deficit with minimal envi-ronmental impact, would promote the appreciation of heritage and the urban land-scape, as well as the preservation and dissemination of this cultural legacy for future generations.

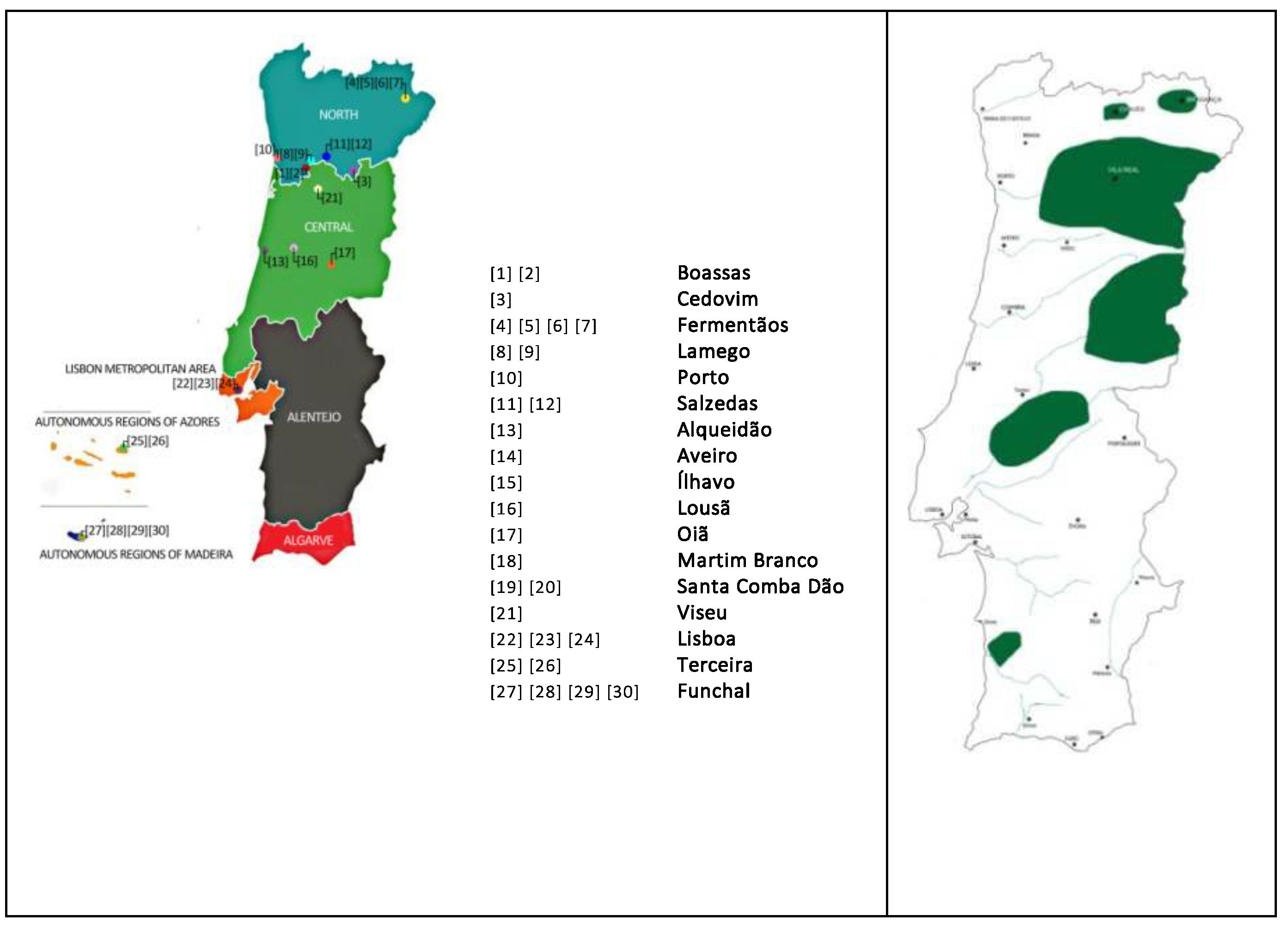

Over the past 20 years, research into wattle-and-daub constructions in Portugal has intensified. Regarding the study of construction typologies, the published litera-ture has predominantly focused on the northern region of mainland Portugal, encom-passing the sub-regions of Douro, Porto Metropolitan Area, Alto Tâmega, Terras de Trás-os-Montes, and Tâmega e Sousa [

1,

3,

4,

7,

8,

10,

11]. In addition, studies have been highlighted in the central region, specifically in the Viseu Dão Lafões sub-region [

14,

15], and the Lisbon Metropolitan Area [

20,

21].

Despite the progress made, Portugal comprises 25 sub-regions, of which approx-imately 70% still lack systematic records on wattle and daub constructions. This sce-nario reinforces the need to expand research areas to include underexplored regions. It is therefore proposed to extend studies on the construction typologies of wattle and daub walls to other areas of central and southern mainland Portugal, as well as to the Autonomous Regions of the Azores and Madeira.

Another proposal of this article aims to expand the scientific knowledge about wattle and daub walls in Portugal by providing detailed information to the academic and technical communities and society at large. This information, which includes the pre-existing characteristics of materials and construction processes, is fundamental for promoting the preservation of this tangible and cultural heritage. Such preservation is not limited to the production of literary records but also aims to support interventions in the built heritage. A comprehensive understanding of the structural and functional behaviour of wattle and daub walls is crucial to inform choices regarding intervention processes and repair materials. This synthesis of information is an indispensable pre-requisite to ensuring compatibility between pre-existing and new elements, thereby promoting the durability of the constructions.

Through a thorough scientific analysis, this study highlights the importance of preserving the sustainable character of this construction typology in architectural her-itage rehabilitation. This approach not only addresses the practical demand for inte-grating tradition and innovation but also honours the history and cultural identity of the community.

The other objective of this study is to emphasise the intrinsic sustainable nature of this construction typology, particularly in interventions aimed at rehabilitating archi-tectural heritage. This approach is grounded in the need to balance technical perfor-mance criteria, such as energy efficiency and durability, with the conservation of his-torical and cultural values. Moreover, the integration of traditional construction prac-tices with innovative solutions not only meets contemporary demands for sustainabil-ity and functionality but also safeguards the authenticity and cultural identity of the communities associated with this heritage.

2. General Characterization of Portuguese Wattle and Daub Walls

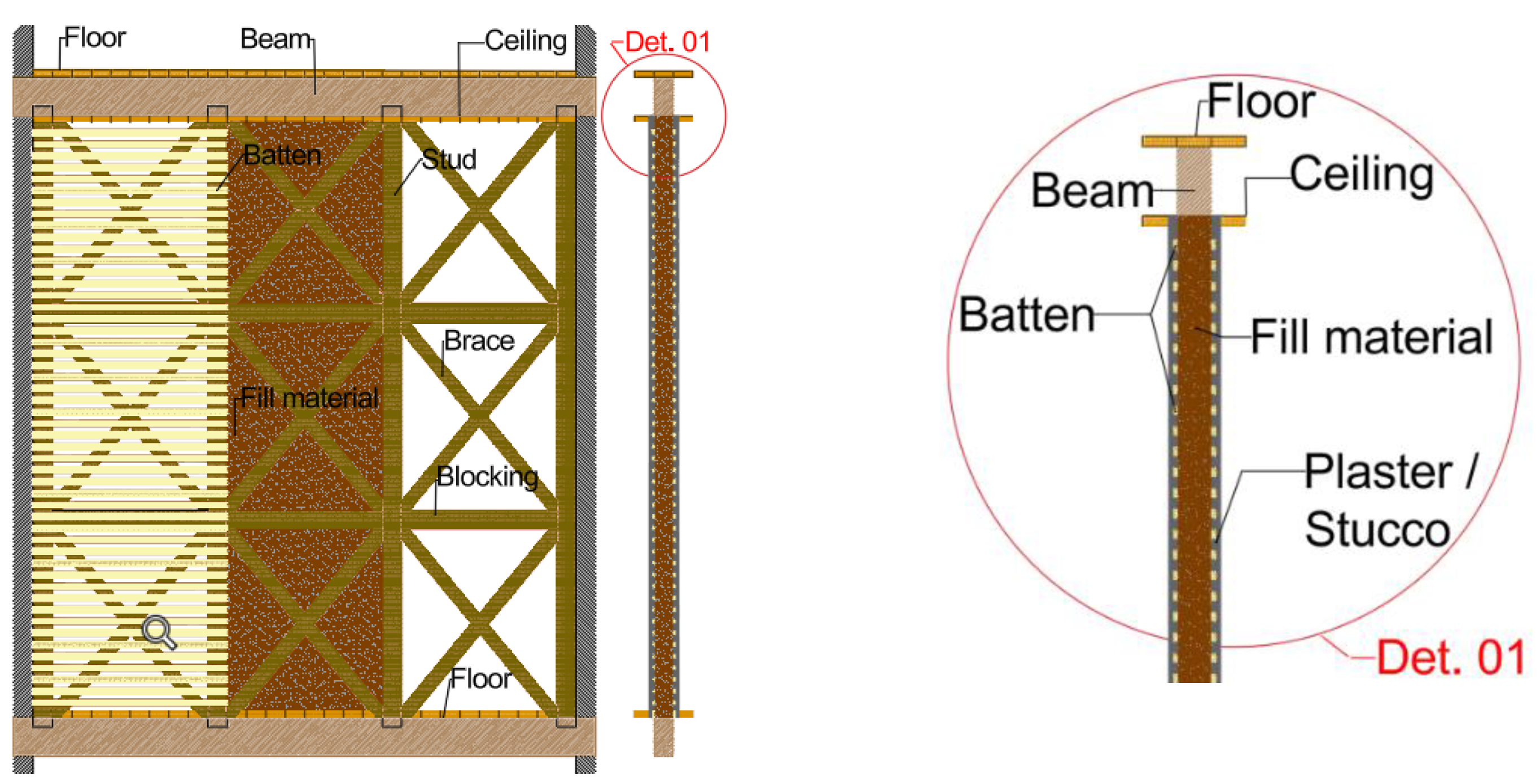

In Portugal, the wattle and daub technique was predominantly used for interior partitions, less frequently for external walls, ceilings, and, in more limited cases, chimneys. These constructions did not adhere to rigid normative standards, resulting in significant variability in both the materials used for the timber structural compo-nents and the arrangement of these elements. The structure typically comprised a framework with an essentially load-bearing function, consisting of boards, uprights, beams, and wooden slats joined by metal connectors.

The infill materials for the fasquios – set of wood battens - and the coatings varied widely, although earth-based mortars and, in some cases, sand mortars with added lime were most common. These coatings served an essential role in protecting the timber structure, acting as a barrier against biological agents and fire, thereby contrib-uting to the durability and preservation of wattle and daub constructions [

1].

Wattle and daub constructions exhibit distinct characteristics even in regions with similar conditions or within the same locality. This diversity can be attributed to the interplay of factors such as the availability of local natural resources, the technical knowledge of builders, the financial capacity of owners, the intended use of the build-ing, its structural function, and local climatic conditions. Such factors encouraged the incorporation of animal and plant fibres in both the infill and coating materials, com-monly including onion stalks, wood shavings, rye or wheat straw, maize cobs, horse-hair, ceramic tile fragments, stone pieces, vegetable oils and whale oil.

The primary function of adding plant or animal fibres was to mitigate shrinkage in the mortars, thereby reducing the occurrence of cracks. Oils were primarily incor-porated to enhance the water-repellent properties of the mortars. As for the infill ma-terials, these were used to facilitate application, reduce mortar consumption, and, in some cases, provide additional structural strength. From a contemporary perspective, the incorporation of local and recyclable materials in wattle and daub constructions represents a sustainable and economical solution, as it promotes the reuse of locally available resources [

1,

2,

3,

4].

Wattle and daub constructions stand out for their sustainable and economical na-ture, offering numerous environmental and functional advantages. These buildings predominantly use natural and local materials, characterised by low greenhouse gas emissions. Furthermore, their construction does not require specialised equipment or highly skilled labour, thereby reducing costs and the environmental impact of the building process. The continued existence of wattle and daub buildings in good condi-tion today confirms their durability.

Research by [

5] comparing the properties of pre-existing wattle and daub mortars with current normative values and bibliographic references, indicates that these con-structions meet contemporary performance standards, particularly regarding capillary water absorption, drying index, open porosity, and compressive strength. The results corroborate the durability and viability of these buildings, demonstrating that the wat-tle and daub construction system remains suitable for current conservation and func-tionality standards.

Focusing on the northern region of Portugal, studies on the characterisation of wattle and daub walls have been conducted over the past two decades. These investi-gations revealed that wattle and daub is most used in one or two storey dwellings, where the ground floor is generally allocated to storage or commercial purposes. In most of these buildings, the ground-floor walls are built of stone masonry, while the external and internal walls of the upper floor are wattle and daub. Another identified solution involves the use of stone masonry for external walls, reserving wattle and daub for partitions walls [

1].

The external wattle and daub walls were usually coated with lime-based mortar and, in some cases, protected with materials such as slate tiles or zinc sheets, as de-scribed by [

6,

7,

8,

9,

10,

11].

Regarding the types of wood used in structural elements, research in the northern region identified the use of native species such as maritime pine (Pinus pinaster), sweet chestnut (Castanea sativa), poplar (Populus sp), and linden (Tilia cordata), [

4]. In the Au-tonomous Region of Madeira, some of the identified wood species were also native, including sweet chestnut (Castanea sativa), maritime pine (Pinus pinaster Aiton), and the Madeira cedar or Canary Islands juniper (Juniperus cedrus) [

12]. Although bamboo (Bambusa vulgaris) is not a wood species, it was used as lath in Funchal, originating from Asia. In the Azores, maritime pine (Pinus pinaster Aiton) and Azorean cedar (Juni-perus brevifolia) were predominant [

13].

The laths exhibited four main types of cross-sections: rectangular with double bevel, rectangular with single bevel, regular rectangular, and irregular rectangular. As for the uprights, their cross-sections varied between square, square with rounded edg-es, and rectangular. The boards could have regular or irregular rectangular sections, in addition to waney-edge boards [

1].

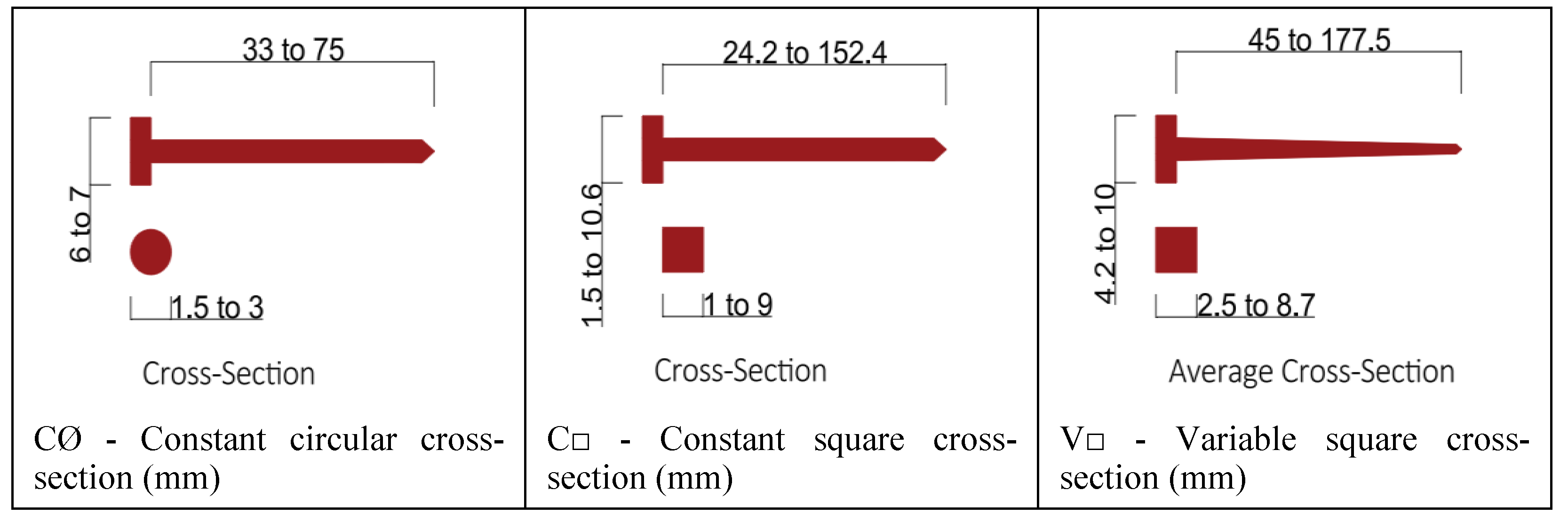

The research also revealed that nails used in the construction of wattle and daub walls acted as mechanical connectors, predominantly made of iron. The coatings ap-plied to these walls played a fundamental role in protecting and preserving the prop-erties of the materials used.

Figure 1 illustrates the three geometric types of nails identified in these studies: nails with constant circular cross-section (CØ), nails with constant square cross-section (C□), and nails with variable square cross-section (V□), [

1,

14,

15].

Finally, it was found that natural earth, or earth mixed with a lime-based binder, was widely used in the preparation of mortars [

9]. A study conducted by [

16] showed that 74.07% of the examined mortars contained lime content ranging between 22% and 26%.

3. Methodology

The methodology employed in this scientific research is based on two main approaches: Bibliographic Research and Exploratory Research.

In the bibliographic research phase, relevant published works were identified to understand and analyse the topic of wattle and daub construction methodologies in Portugal. This involved consulting books, scientific articles, theses, dissertations, yearbooks, journals, legislation, and other types of written sources. At the conclusion of this phase, gaps in the existing knowledge were mapped, guiding the subsequent actions in the exploratory phase.

The purpose of the exploratory research was to refine and update the knowledge previously gathered. It aimed to answer the following questions:

- ➢

What is the geographical distribution of the wattle and daub construction typology in Portugal? Is this typology predominantly concentrated in the northern region, with sporadic occurrences in other regions of mainland Portugal? How prevalent is it in the autonomous islands of Madeira and the Azores?

- ➢

Do the typical construction typologies differ across regions? If so, how are these differences manifested? Are there any construction-specific characteristics that remain uncatalogued?

Following the identification of relevant buildings—with support from Municipal Councils as well as other public and private institutions in Portugal—details of their construction were recorded using both qualitative and quantitative approaches. The procedures involved visual observation, measurement of sections, and photographic documentation. The data collected to characterise construction typologies and related information were organised into descriptive records, spreadsheets, sketches, and maps.

Finally, a deductive approach was employed to formulate conclusions, based on a descending chain of reasoning that moved from general analysis to specific analysis.

4. Location of the Samples

Figure 2 shows the locations of the buildings analysed in this research, while Figure 3 displays the geographic distribution of the regions in mainland Portugal where wattle and daub constructions were studied by [

18]. Comparing the data from the two figures reveals an expansion of the study area for wattle and daub constructions in mainland Portugal, now including areas to the west of the northern and central re-gions, as well as the Lisbon Metropolitan Area.

It is worth noting that no wattle and daub constructions were identified in the Algarve region.

Regarding the prevalence of areas with wattle and daub constructions in main-land Portugal, it can be said that the Northern, Central, and Lisbon Metropolitan re-gions are prominent, with the Alentejo region featuring to a lesser extent and no nota-ble presence in the Algarve. Additionally, in the Autonomous Regions of the Azores and Madeira, the presence of wattle and daub buildings is not significant.

Figure 2.

Places of builds.

Figure 2.

Places of builds.

Figure 3. Places of wattle and daub Portugal, [

18].

5. Characteristics of the Studied Buildings

The wattle and daub construction systems are versatile and can be used in various types of buildings. However, their use is not recommended in locations with direct contact with the ground or where there is no assurance of adequate ventilation renew-al.

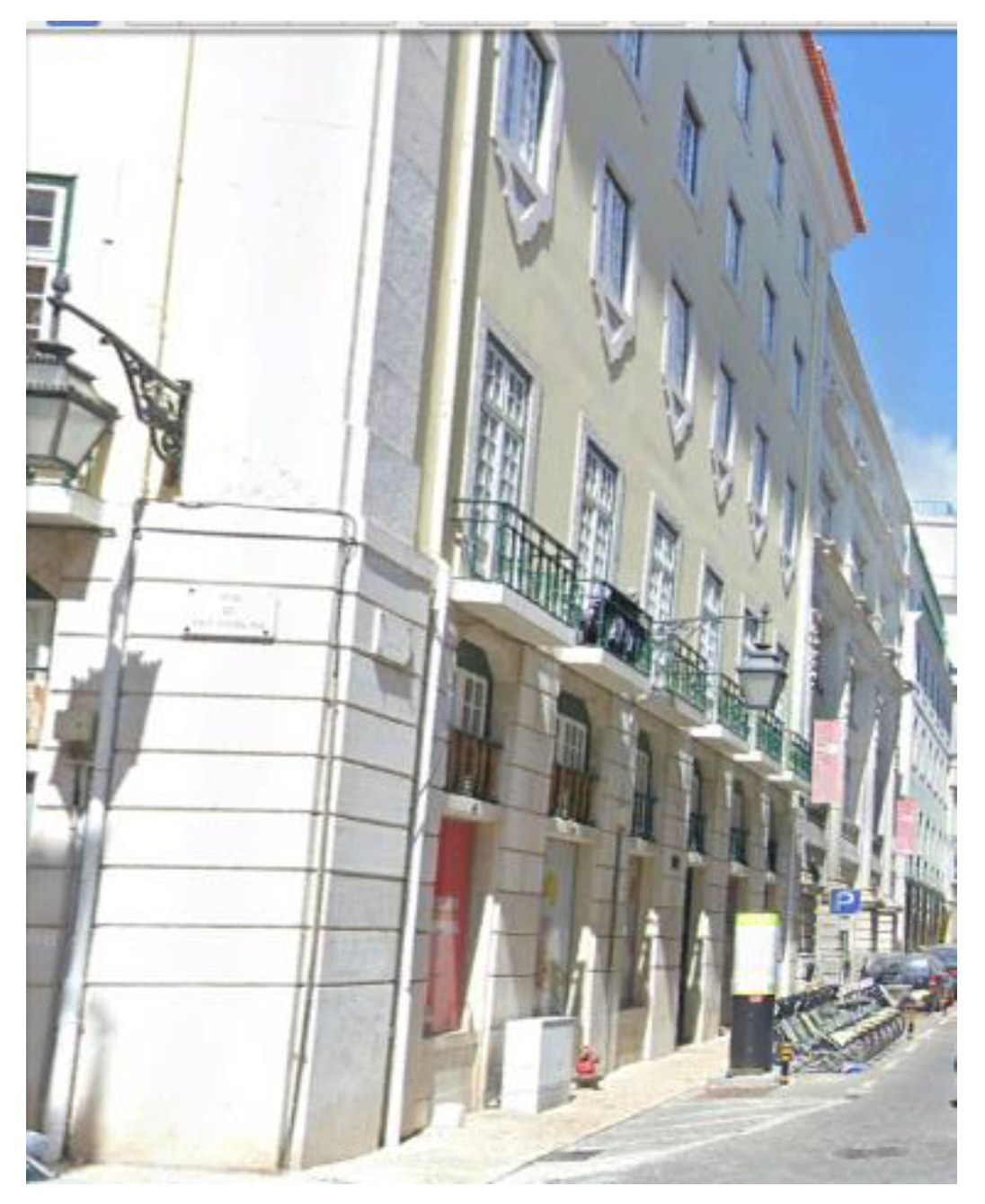

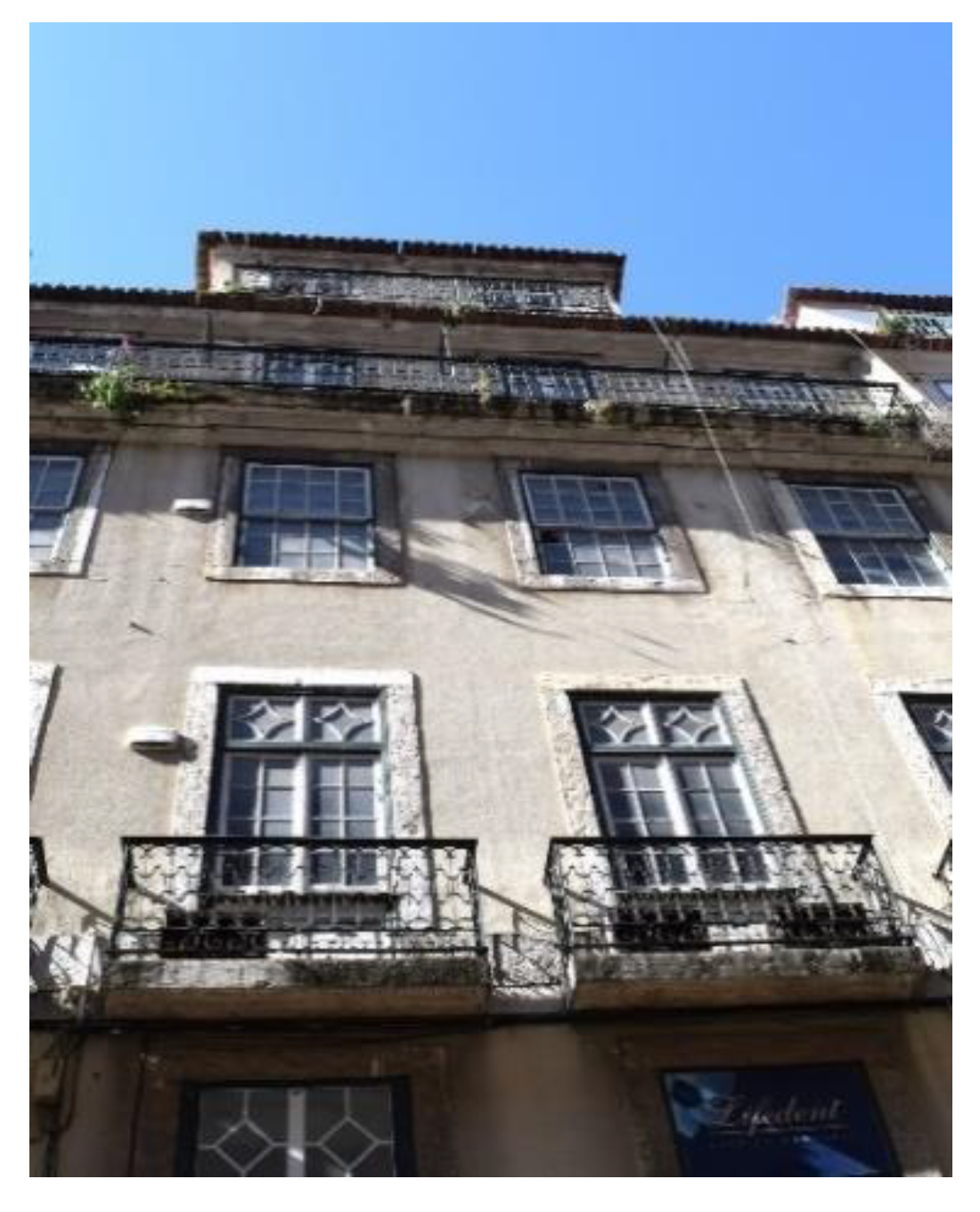

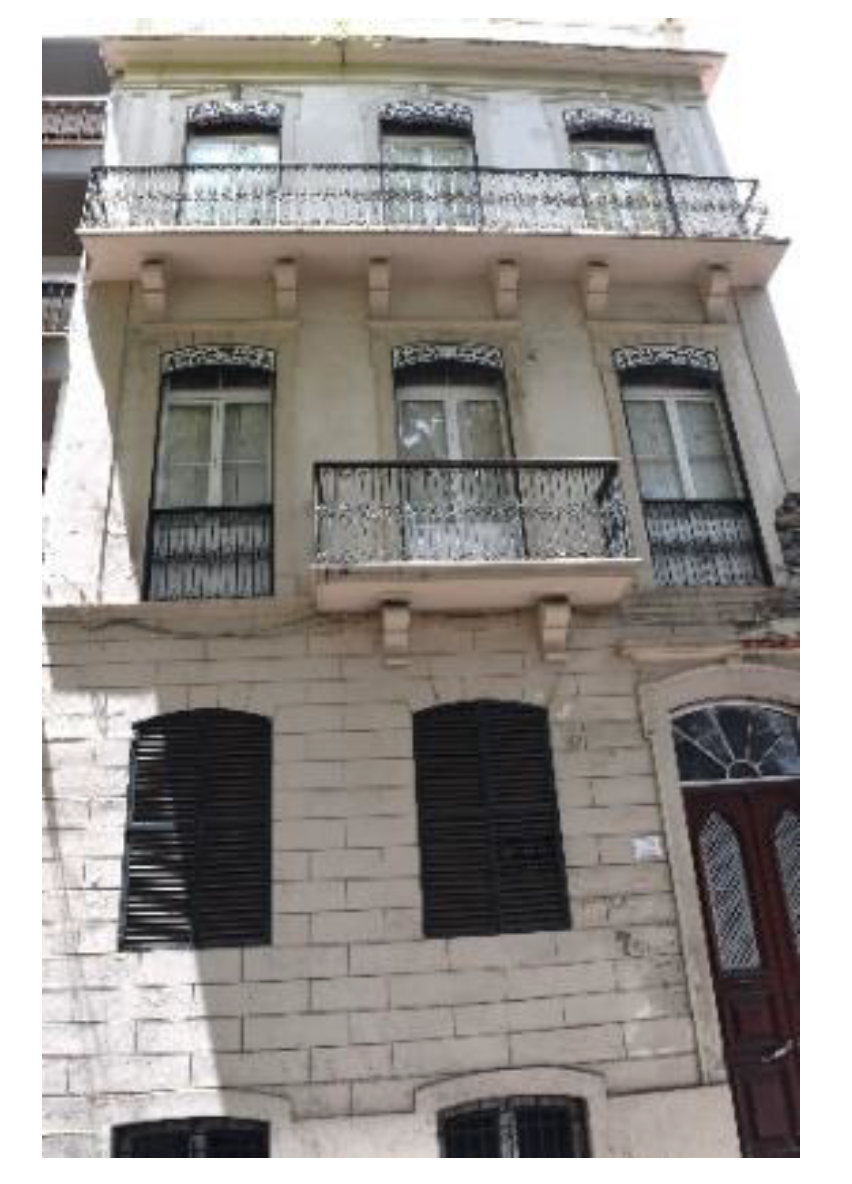

Table 1 lists the types of buildings featuring wattle and daub walls, along with their usage and the region where they are located.

In

Table 2, the types of coatings used on wattle and daub walls and their areas of occurrence are presented.

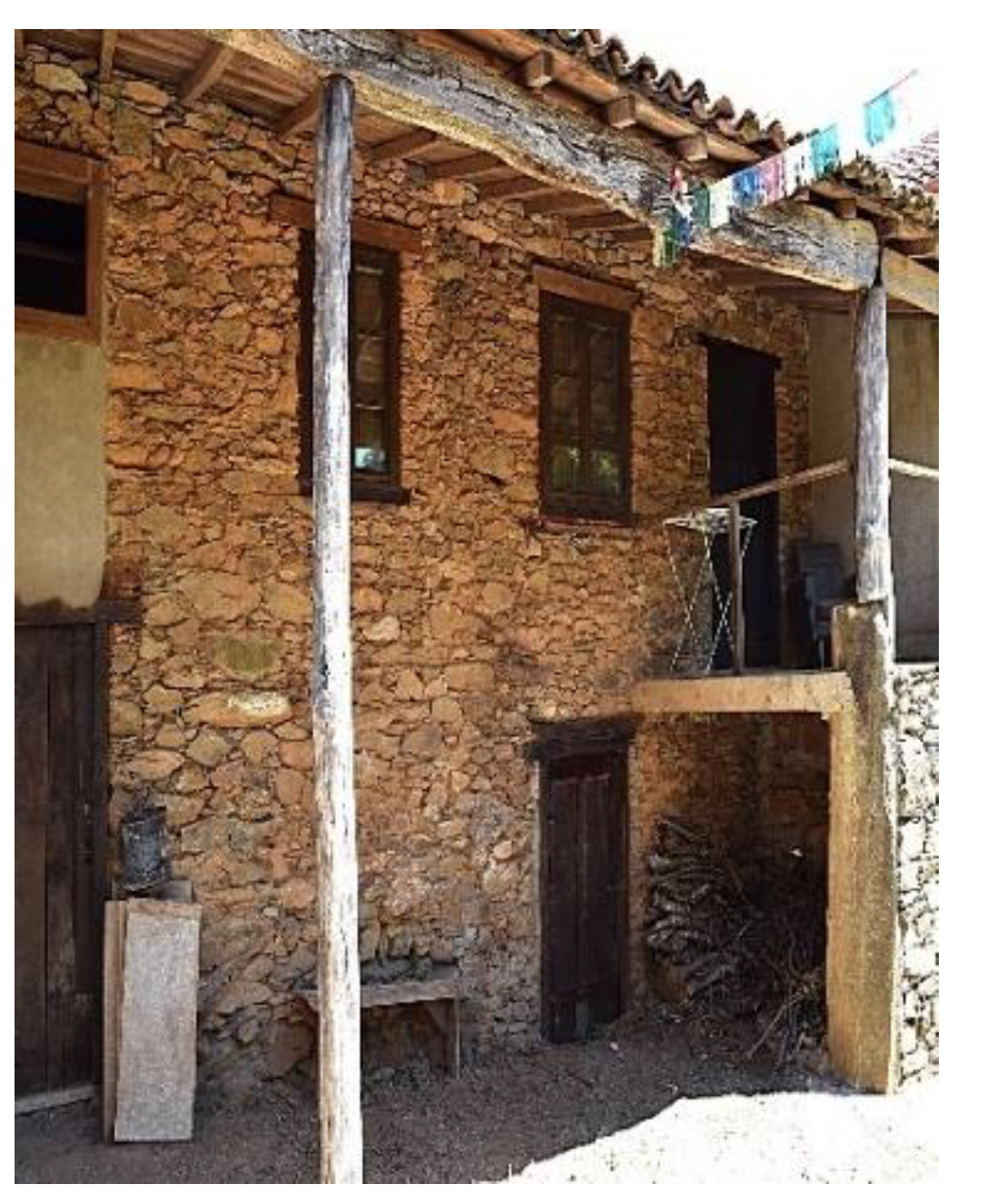

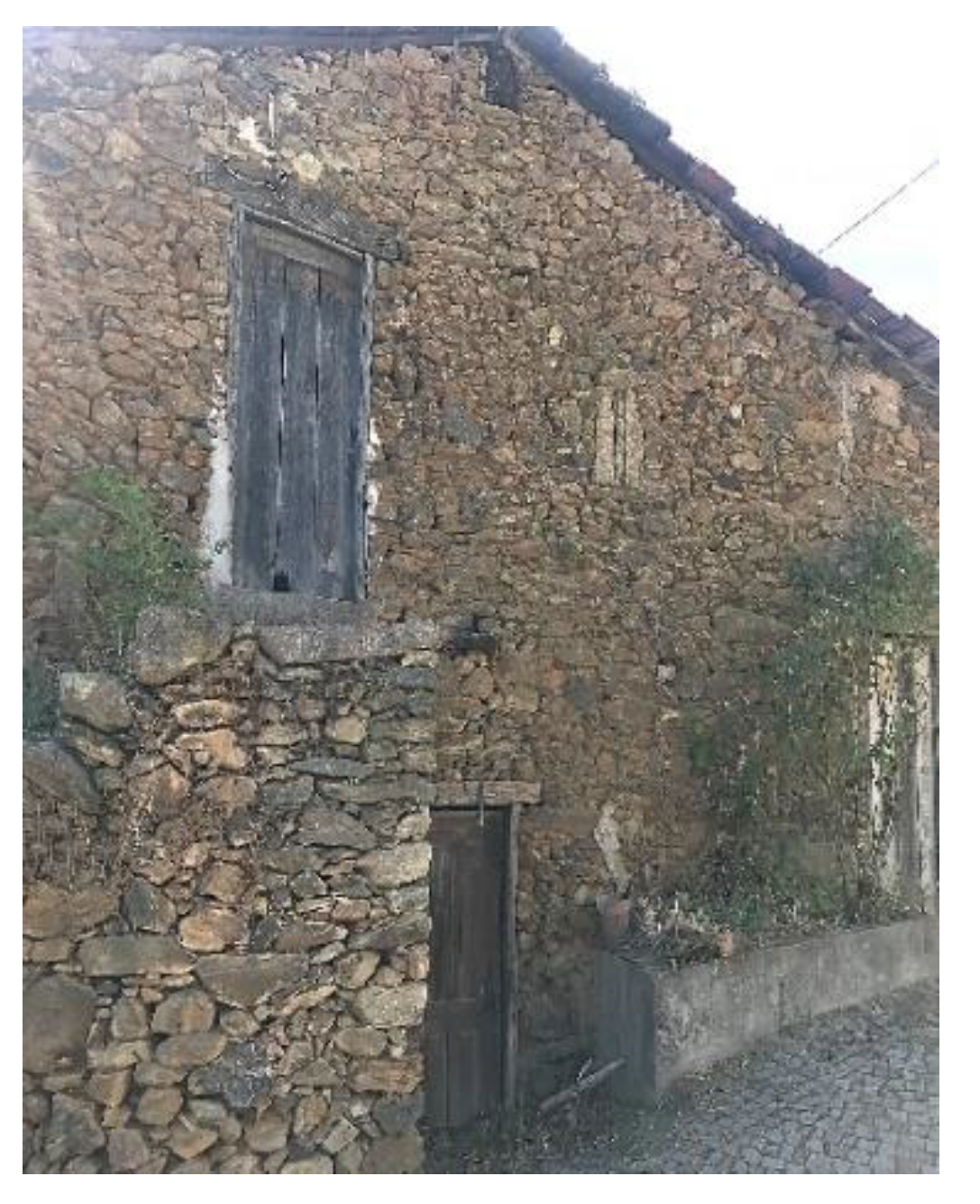

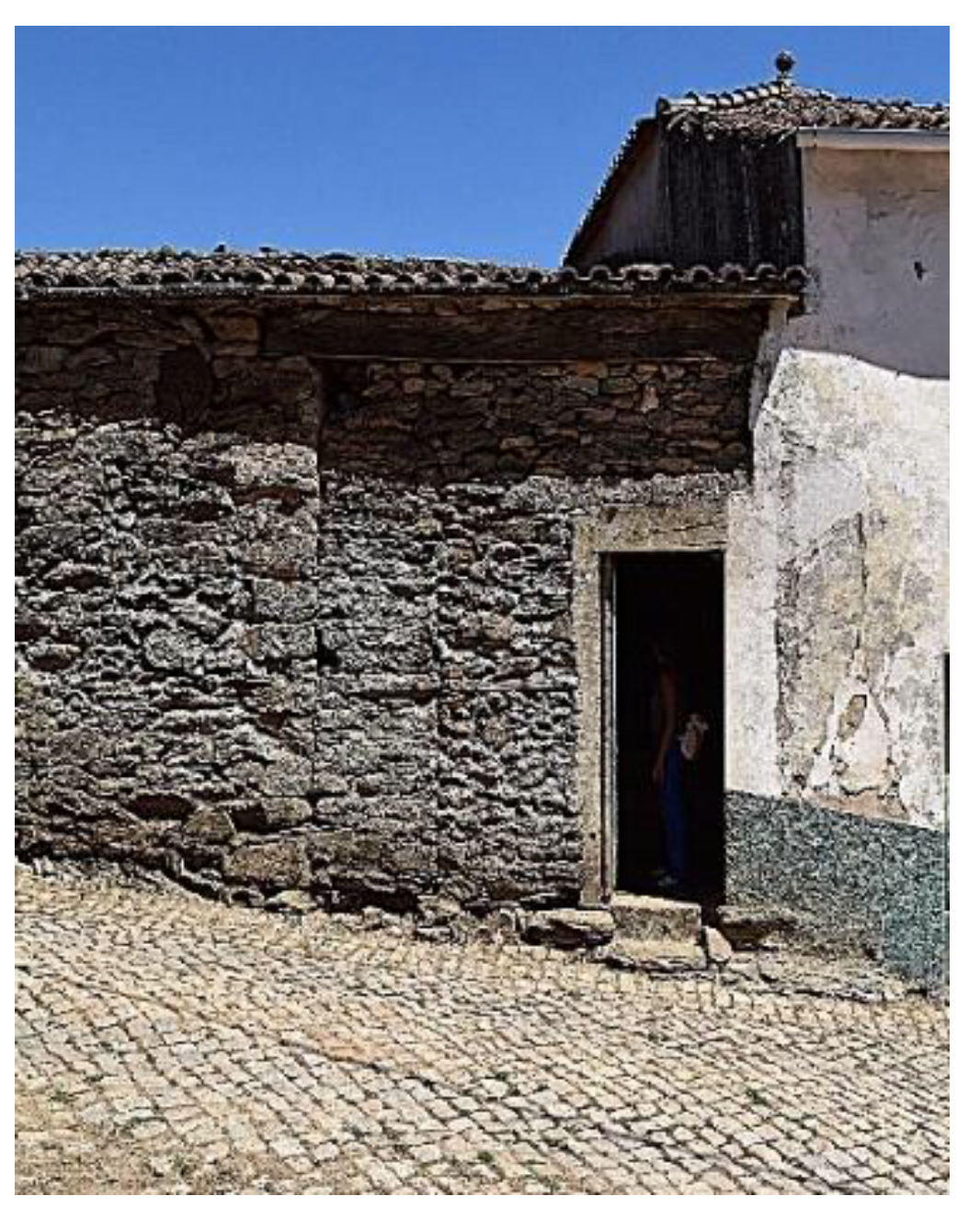

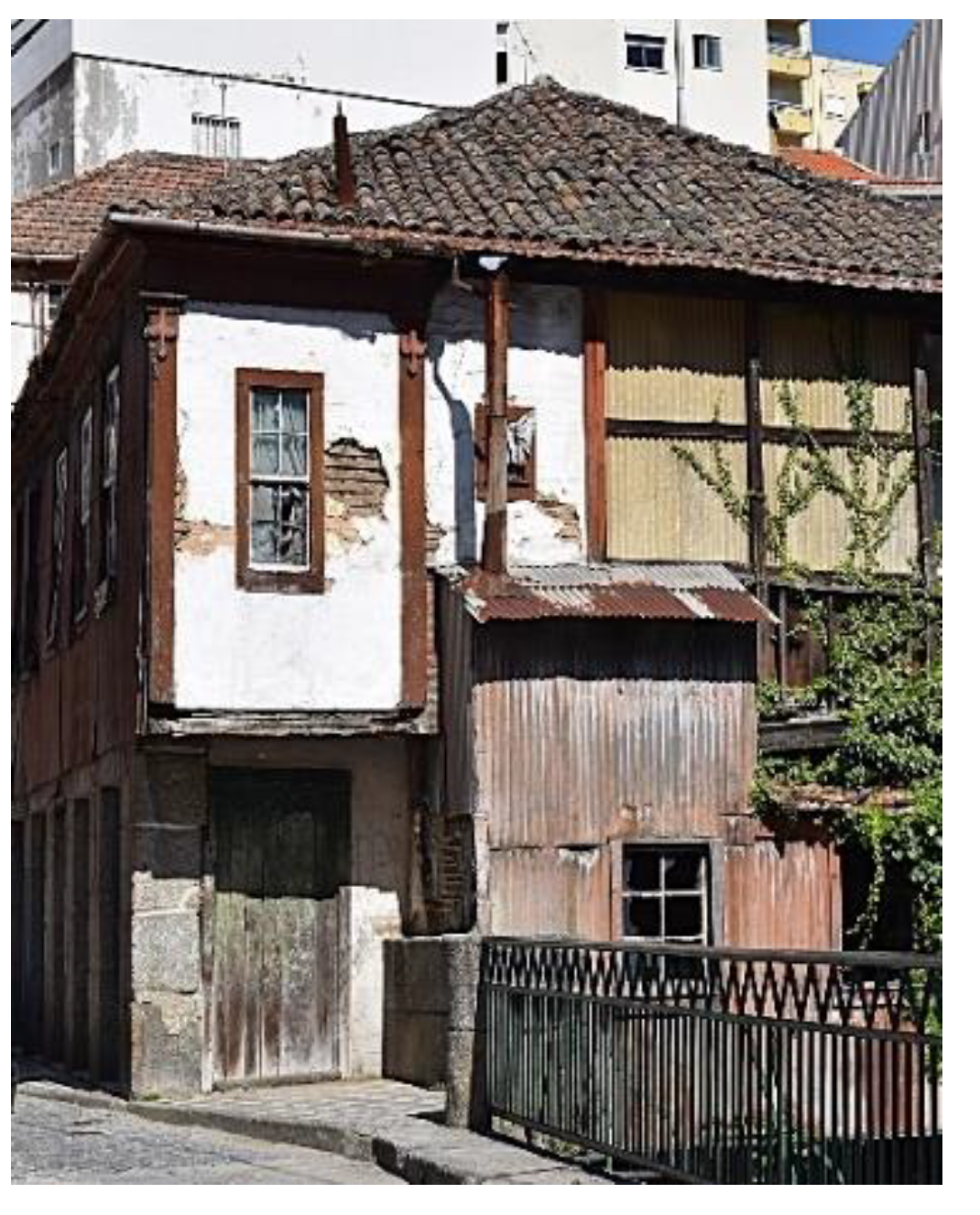

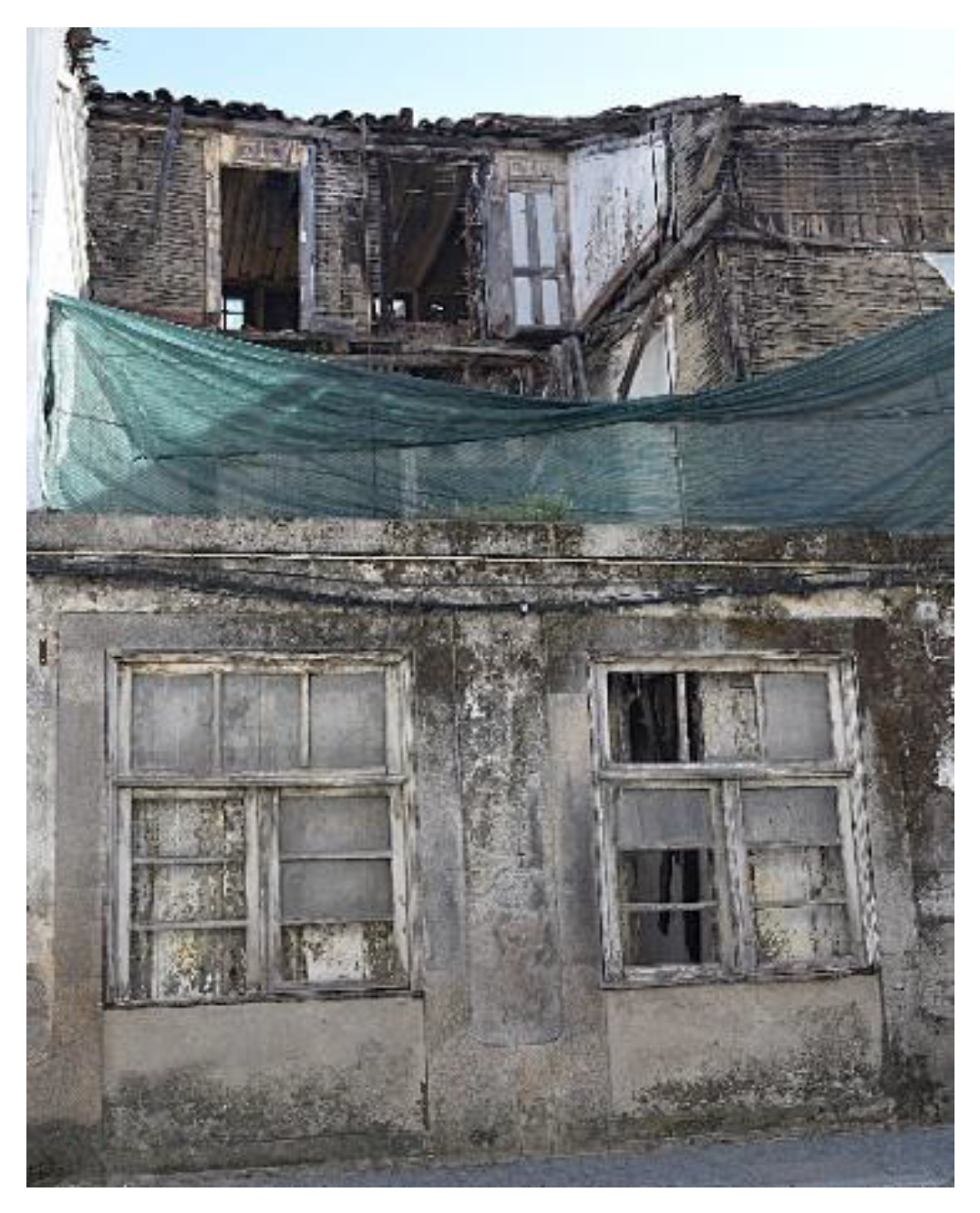

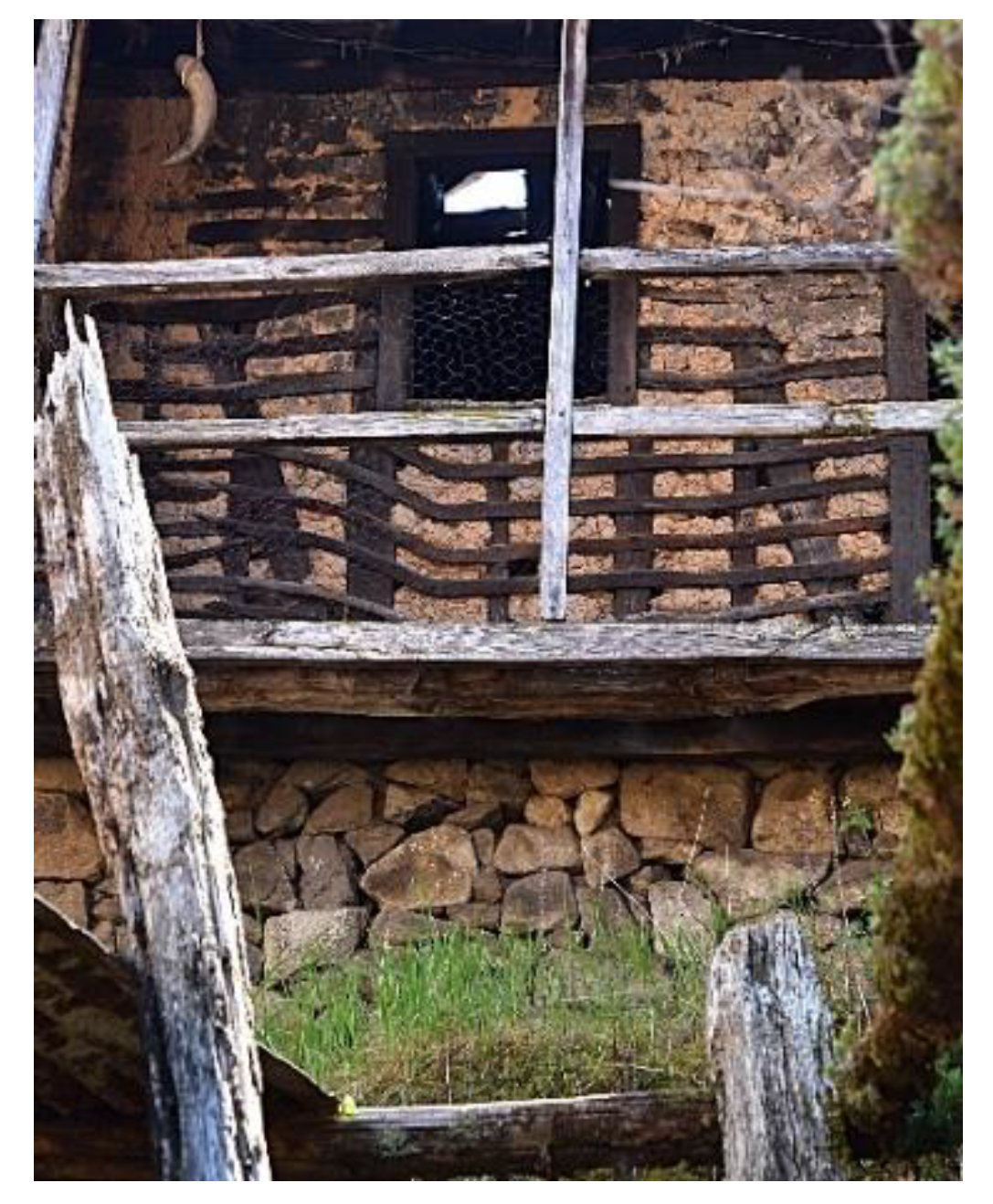

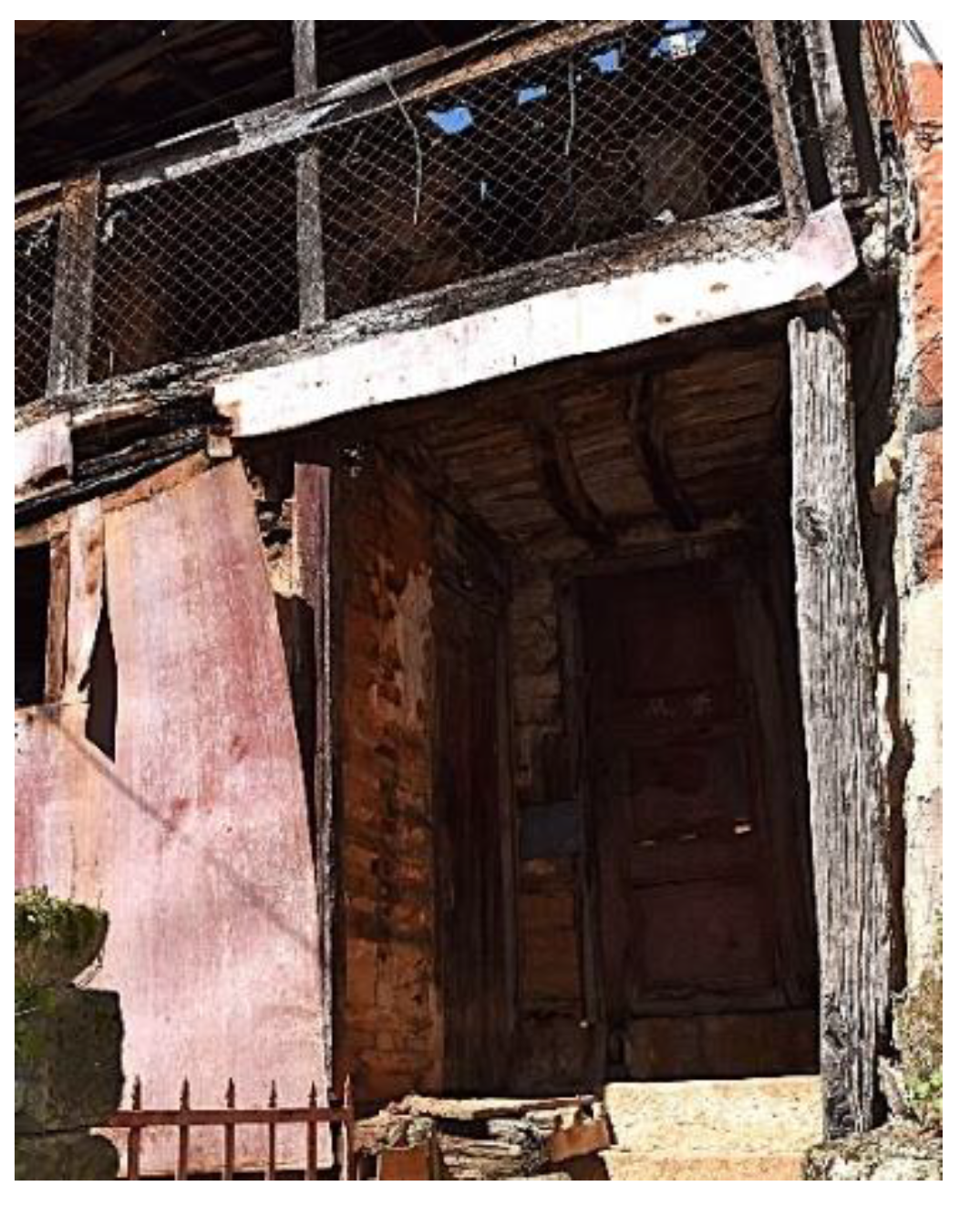

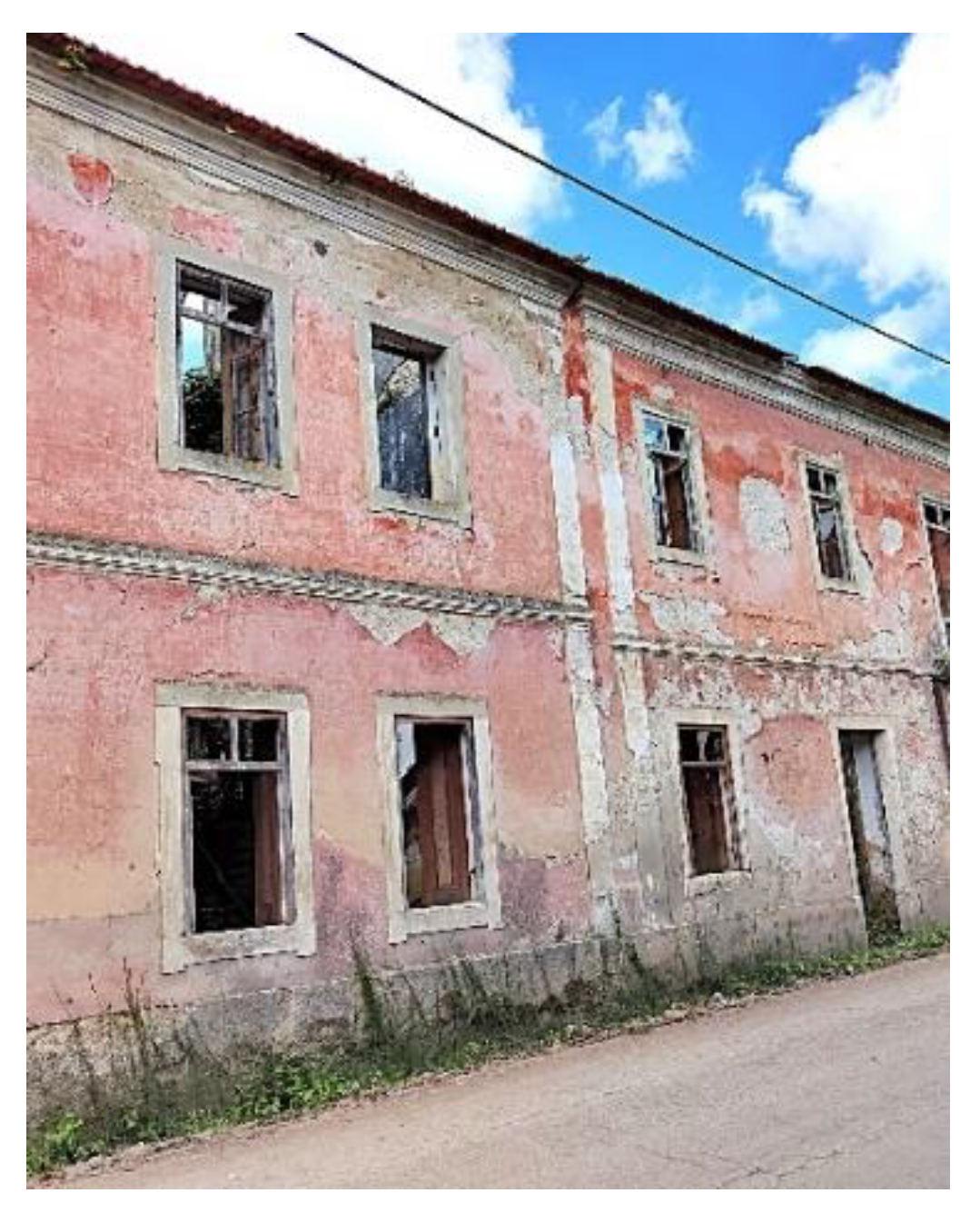

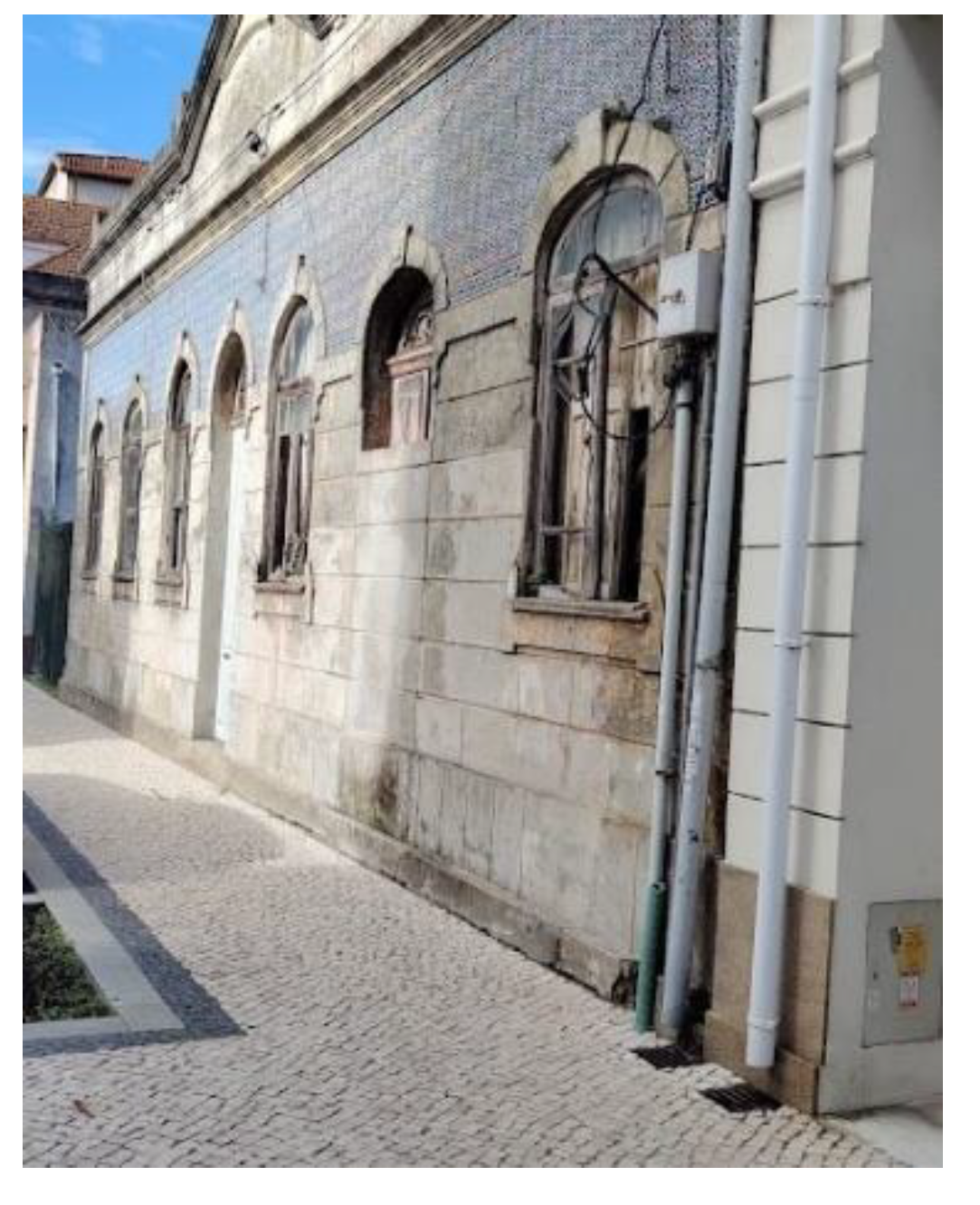

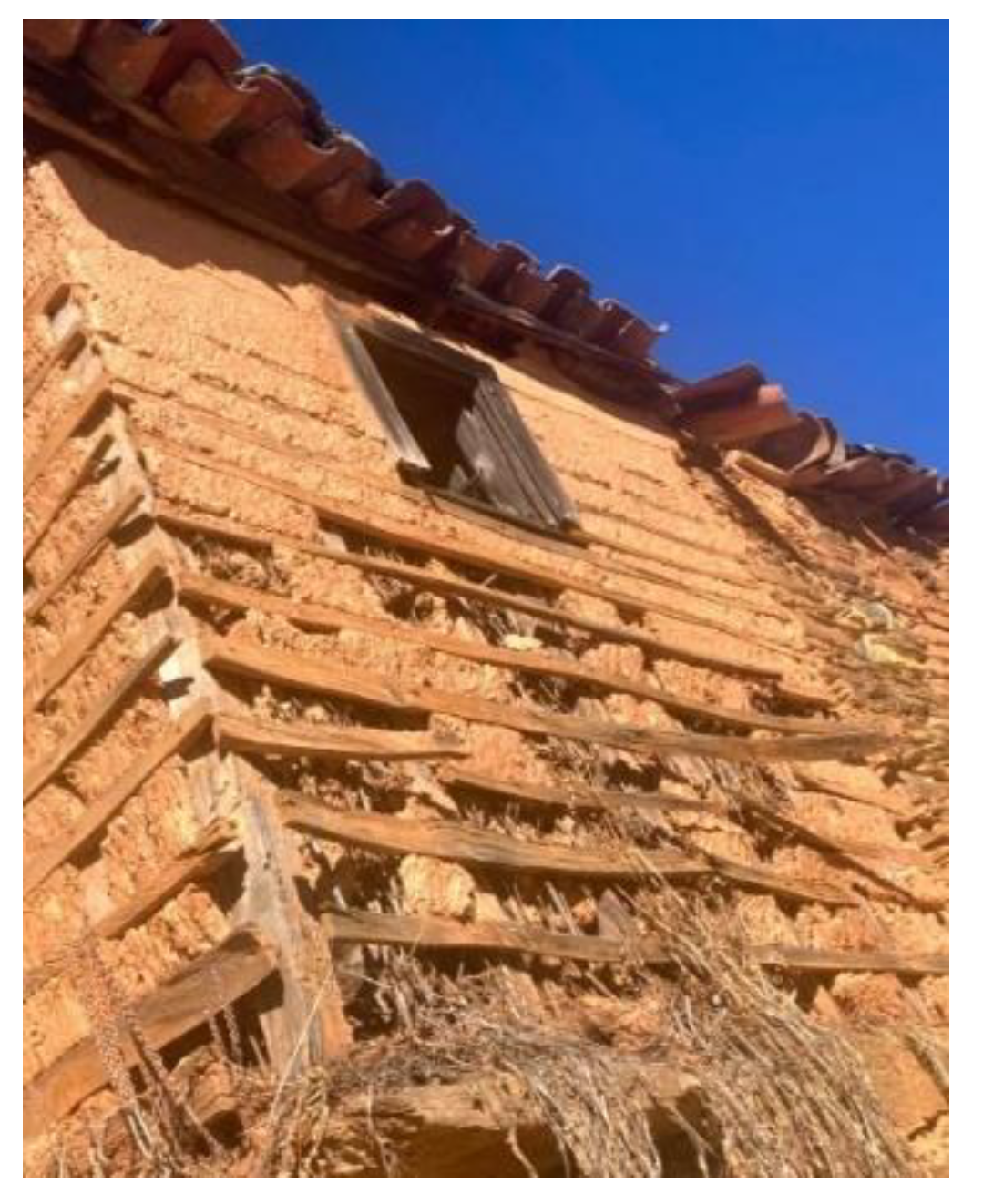

In

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25,

Figure 26,

Figure 27,

Figure 28,

Figure 29,

Figure 30,

Figure 31,

Figure 32 and

Figure 33, the buildings studied in this research are presented and exemplify the constructive diversity found in Portugal with the incorporation of wattle and daub.

6. Constructional Characterisation of Wattle and Daub Walls

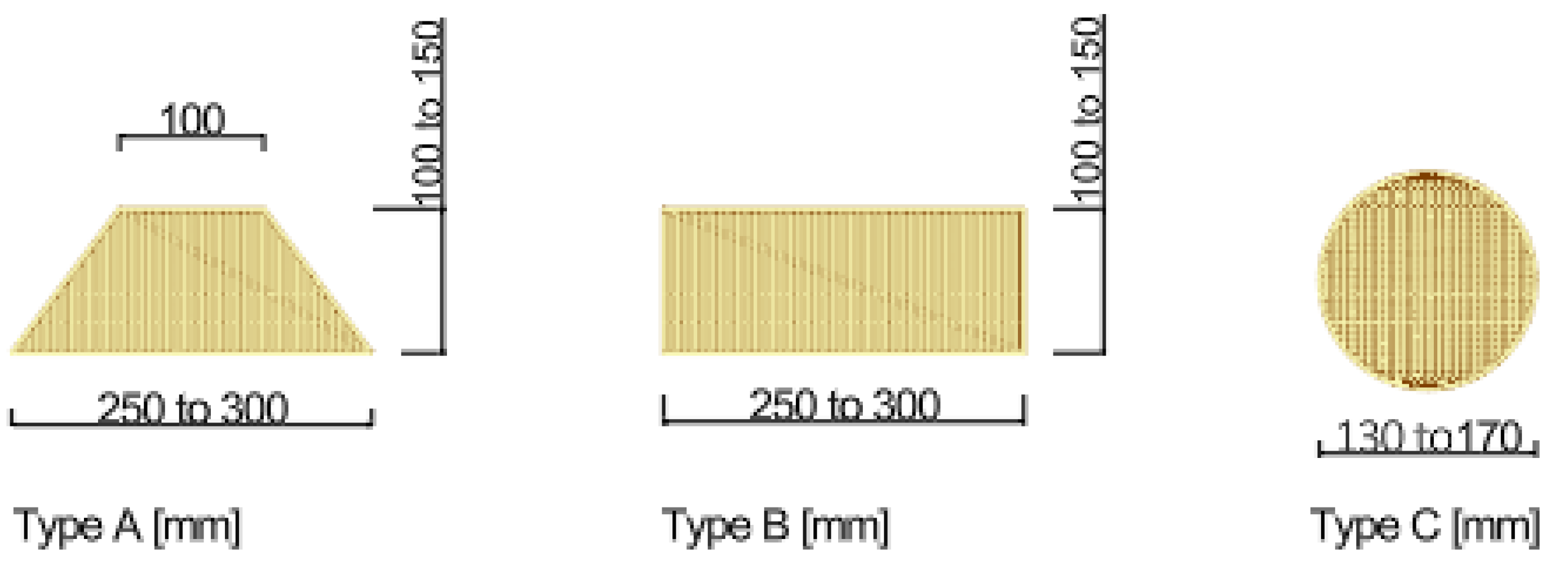

6.1. The Fasquio

The fasquio is a set of wooden laths or bamboo rods arranged horizontally, with a rough surface and no final finishing. The sections and arrangements of the laths do not require construction precision, even within a single wall.

Figure 34 presents the typical cross-sections of the laths comprising the

fasquio in the studied samples:

Type A: Rectangular cross-section with a double chamfer.

Type B: Rectangular cross-section.

Type C: Circular cross-section.

6.2. Wattle and Daub Structure

Depending on the width of the walls, they were referred to as wattle and daub or frontal. The wattle and daub forming secondary partitions in relation to the frontals. According to [

17], the frontals were subdivided into French frontal, Galician frontal, and Fabric frontal, while the wattle and daub were classified as Single wattle and daub, Double-Faced wattle and daub, Lightened wattle and daub, and Light wattle and daub.

The following sections detail the constructional characteristics of the frontals and wattle and daub found in the studied buildings. Where applicable, the terminology used aligns with [

17].

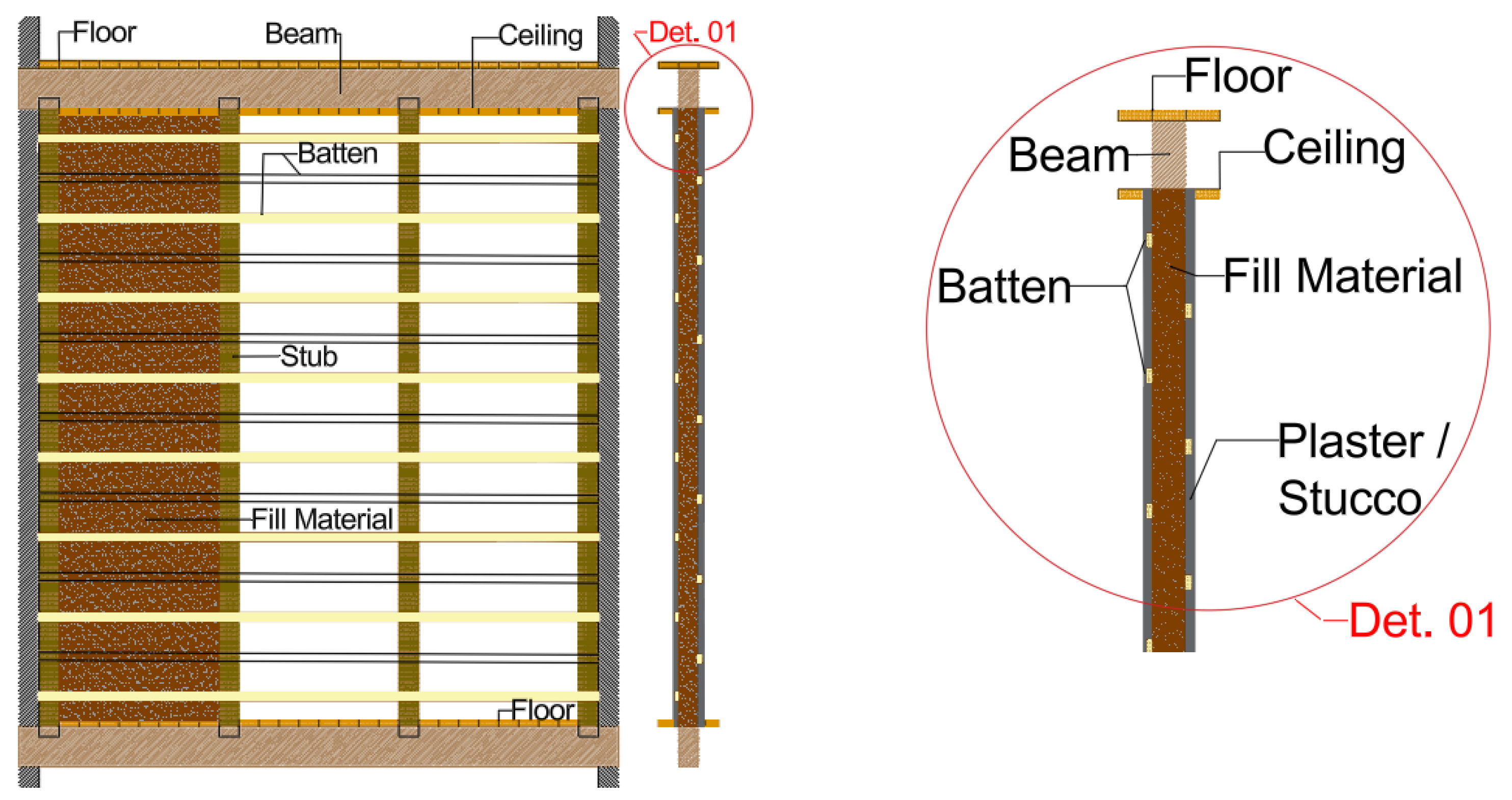

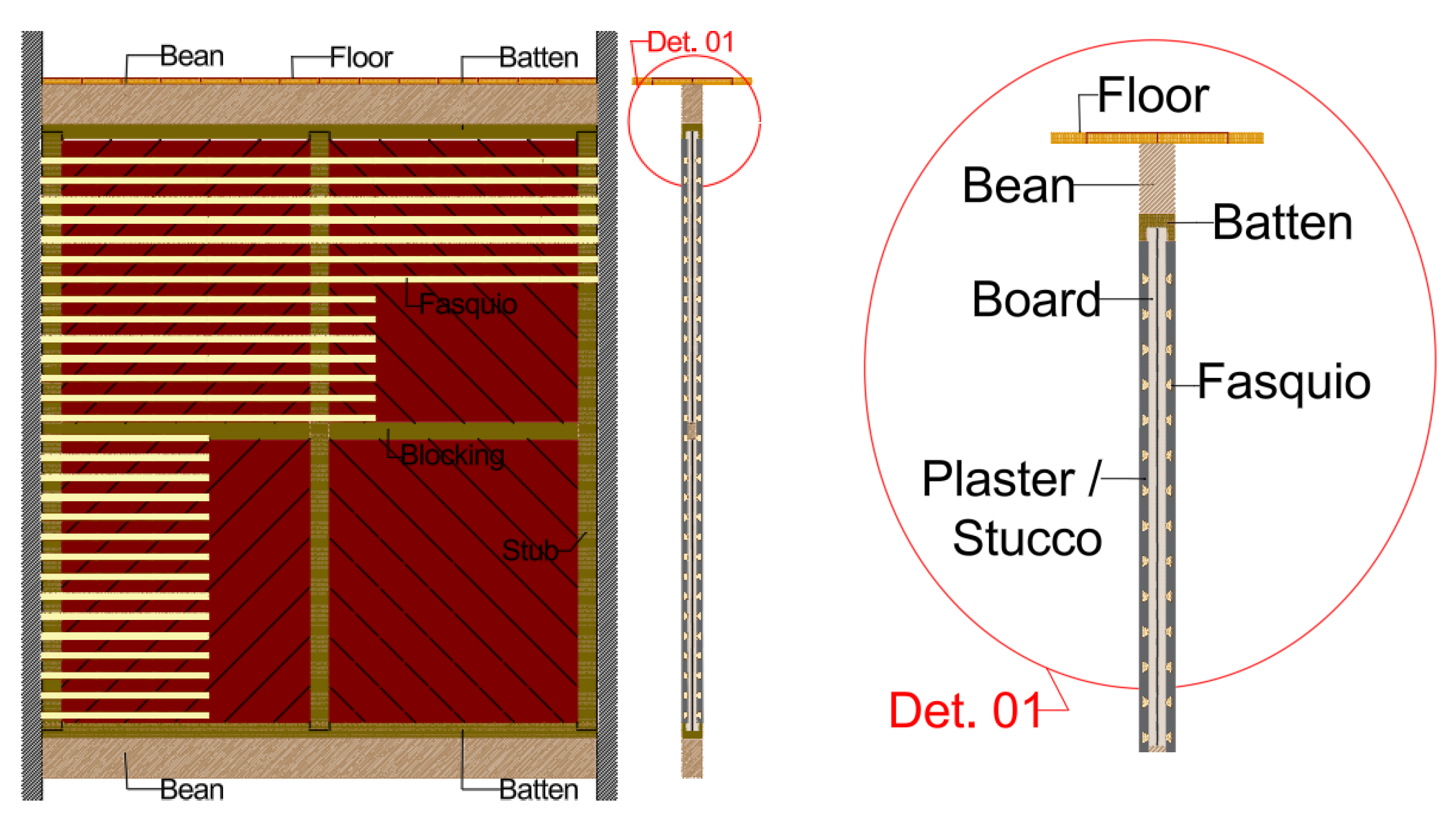

6.2.1. Frontal of Galician

In

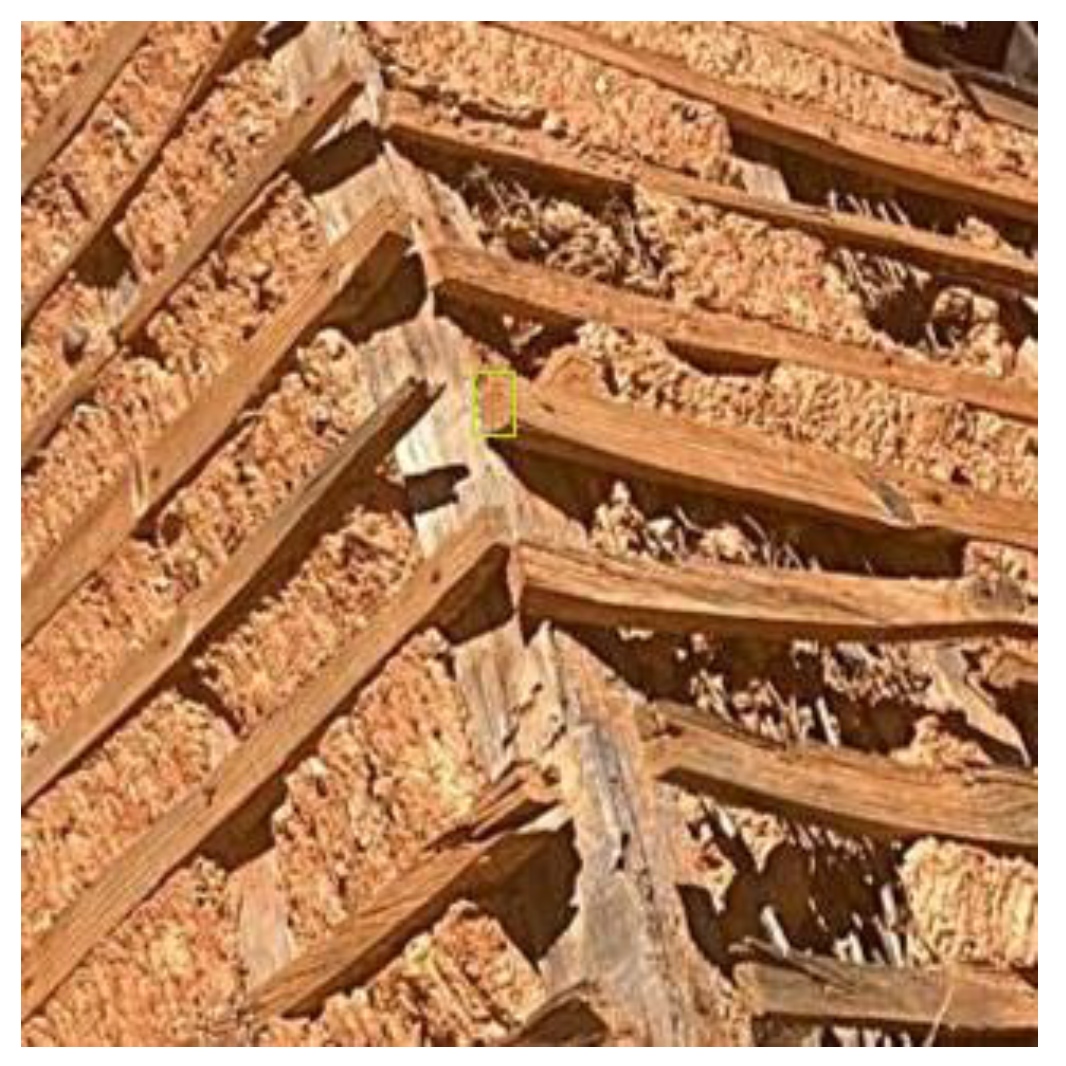

Figure 38, a schematic drawing of the Frontal of Galician, commonly found in exterior walls, is presented.

The framework of the Frontal of Galician has an approximate width of 15 cm. Its construction begins with the placement of vertical posts, width in these cases had cross-sections of approximately 8x8 cm and 10x10 cm. These posts are erected on the floor beams and connected to the ceiling beams. Once the posts are in place, fasquios is installed. In the studied cases, the laths varied significantly in size, with average dimensions of approximately 4 to 6 cm in which and 2.5 cm in thickness, type B. The laths were spaced 20 to 40 cm apart and arranged alternately between the two faces of the wall.

The voids between posts and laths were filled with an earthen mortar mixed with vegetable fibres. According to [

17], other materials such as brick fragments and small stones could also be incorporated into the infill mortar. Although the analysed Frontals were not plastered, the usual practice is to apply plaster once the infill is thoroughly dry, using the same mortar to cover the wattle and daub faces completely.

Figure 39,

Figure 40 and

Figure 41 correspond to exterior walls of dwellings located in the Northern region of Portugal. The walls shown in

Figure 39 and

Figure 40 belong to type 1 dwellings located in Salzedas. The wall in

Figure 41 belongs to a type 3 dwelling located in Martim Branco.

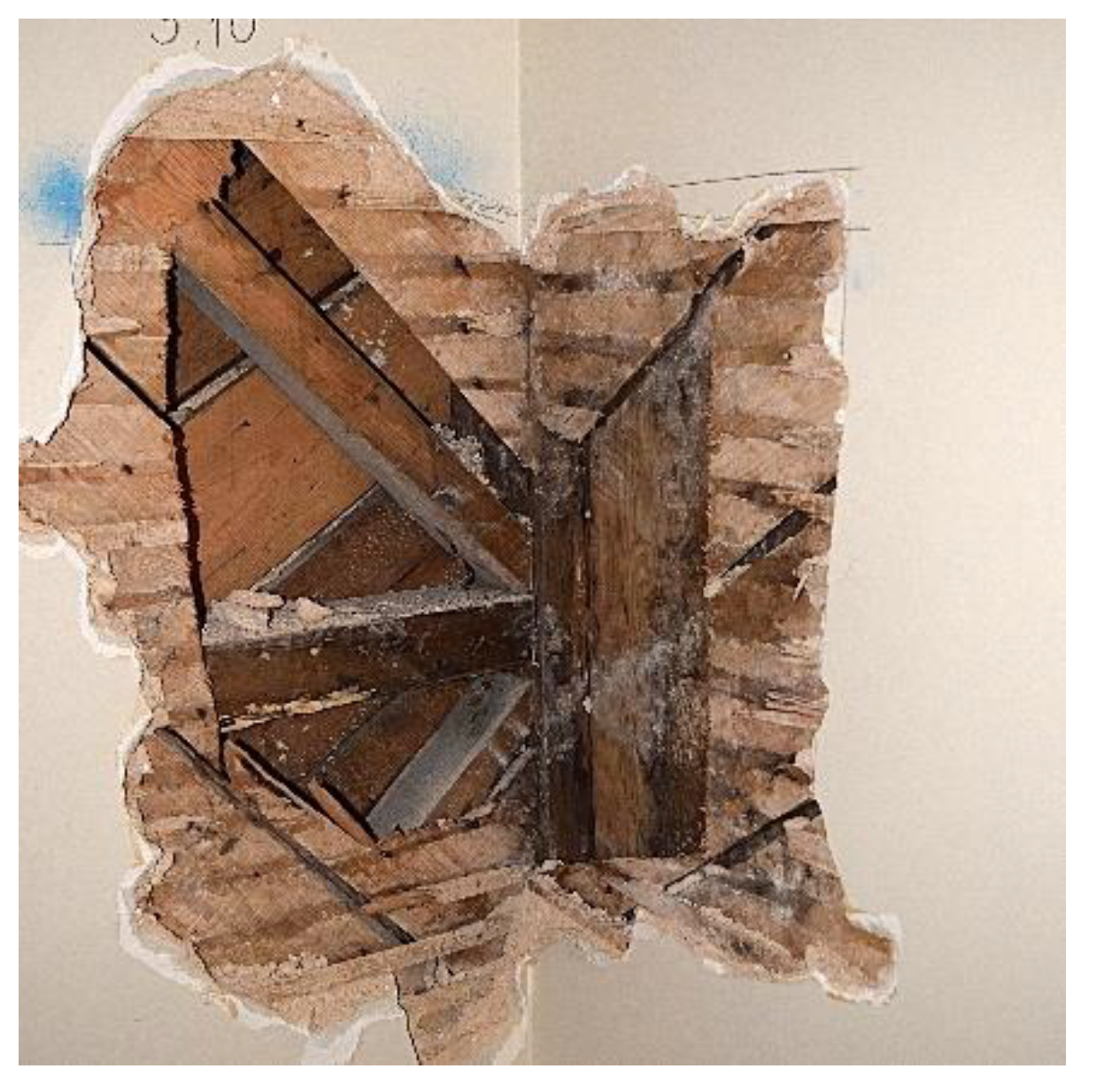

6.2.2. Frontal of Fabric

The Frontal of Fabric, also known as the Pombaline Cage, is an earthquake-resistant construction system inspired by shipbuilding techniques. It was extensively used in the reconstruction of the Baixa Pombalina in Lisbon after the 1755 earthquake.

Figure 42 presents a schematic drawing of the Frontal of Fabric. Like the Frontal of Galician, the width of the framework is around 15 cm. For the study of these Frontals, small windows were opened in the walls, and it was not possible to obtain measurements of the spacing between vertical posts, crossbeams, and diagonals. Therefore, studies by [

19,

20,

21] were used to create the description and construction scheme.

According to these researchers, the length of the frontal is divided into sections approximately 1 metre wide, using posts with a section of ±10x10 cm, nailed to the floor beams below and to the ceiling beams above. The height of the ceiling is then divided into equal parts, with horizontal crossbeams placed between the posts. In the rectangles formed between the posts and crossbeams, diagonal braces are placed –

Figure 42.

The laths are then fixed between each side of the framework, spaced approximately 3 to 4 cm apart. Once the wooden framework is built, it is filled up to the outer faces with earthen mortar, incorporating or not fragments of brick or small stones. After this infill is thoroughly dry, the plastering is applied with the same mortar to cover the faces of the fasquio.

In the specific cases studied, the sections of the posts and the spacing between the laths were like the literature. The laths presented sections of type A and type B. It was noted that in some cases, before the wattle and daub were fixed, seam boards were placed –

Figure 45, positioned as explained for the Double wattle and daub (Item 4.2.4). In the case of the infill and plaster mortars, they are sandy and do not contain fragments of brick or stone.

Both walls shown in

Figure 43,

Figure 44 and

Figure 45 correspond to the partition walls of type 9 dwellings located in the city of Lisbon.

Figure 42.

Scheme Frontal of Fabric.

Figure 42.

Scheme Frontal of Fabric.

Figure 43.

Frontal of Fabric – Lisbon .

Figure 43.

Frontal of Fabric – Lisbon .

Figure 44.

Frontal of Fabric - Lisbon.

Figure 44.

Frontal of Fabric - Lisbon.

Figure 45.

Frontal of Fabric - Lisbon.

Figure 45.

Frontal of Fabric - Lisbon.

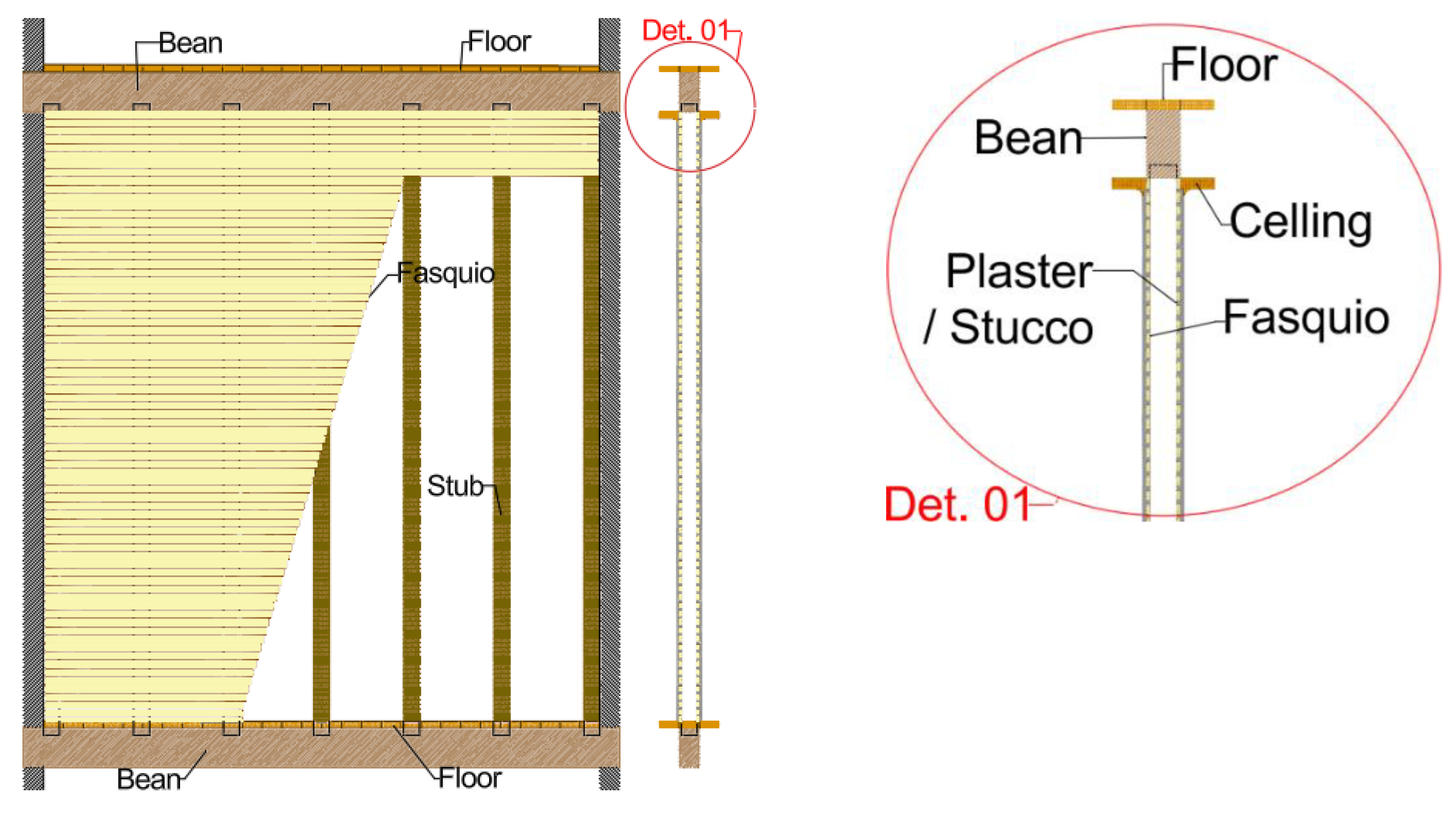

6.2.3. Single Wattle and Daub

The structure of the Single wattle and daub,

Figure 46, is made up of a series of seams boards nailed to auxiliary beams that are fixed to the beams that structure the floor and ceiling. These auxiliary beams support the vertical placement of the seaming boards and are about 4 cm high, with an overhang of about 2.5 cm. Once the wall structure has been assembled, with a width of around ±10 cm, the

fasquio are fixed on both sides of the structure.

In the buildings analysed, the laths were of Type A and Type B, arranged horizontally and spaced about 2 to 3 cm apart. When the partitions are of considerable length, they are reinforced with crossbeams from one side to the other, or, in some cases, uprights are added to provide greater robustness, with struts used to reduce weight [

17].

In the case of

Figure 47, depicting an external wall of a type 5 dwelling located in Cedovim, in the northern region, sandy mortars were used.

Figure 48 shows a partition wall of a type 5 dwelling, used for housing animals and storing agricultural products, located in Fermentãos, northern region, where earthen mortars were used, incorporating plant fibres such as straw and maize cobs. Finally,

Figure 49 refers to a partition wall on the first floor of a type 6 dwelling located in Alqueidão, in the central region, where earthen mortars were used for plastering and for infilling between the laths.

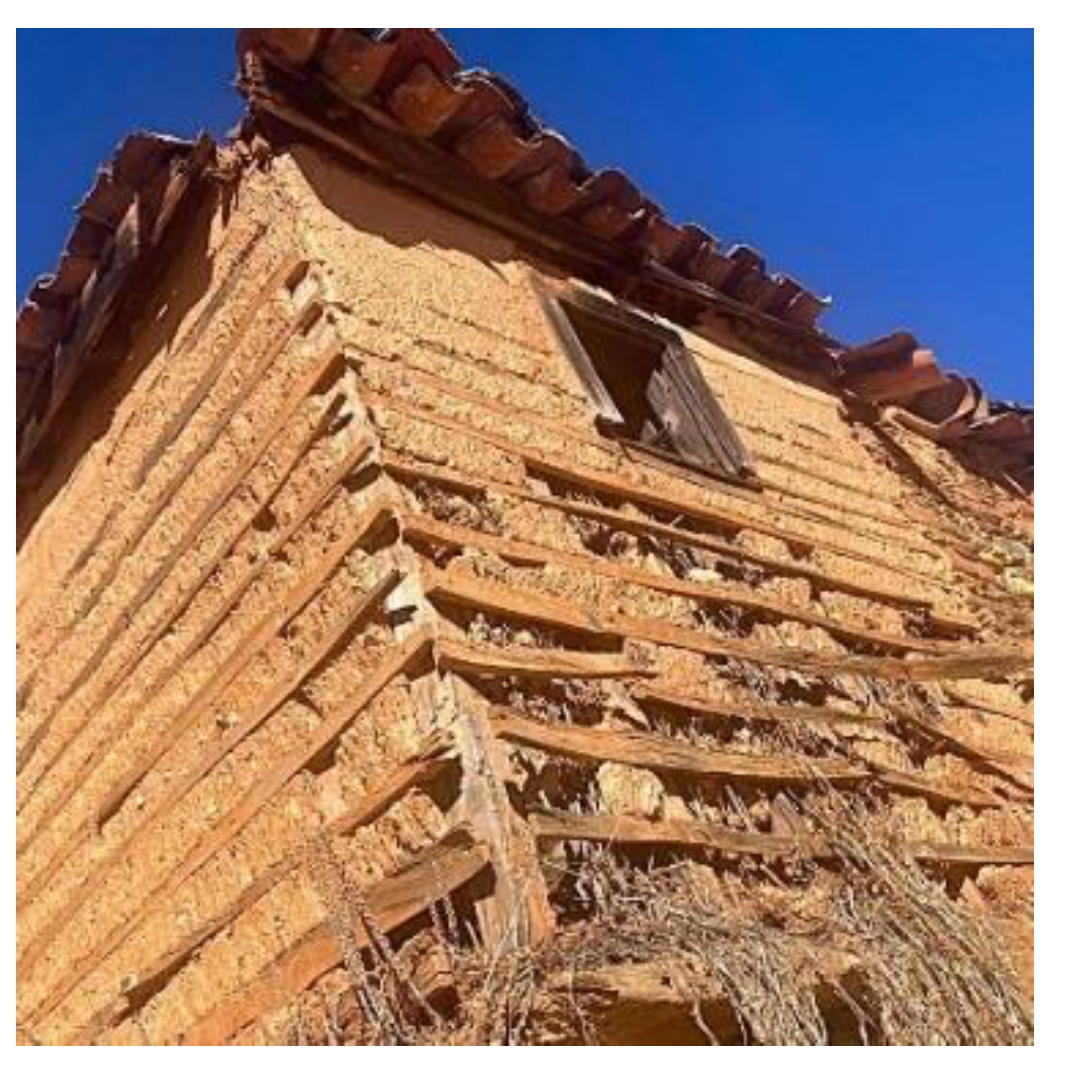

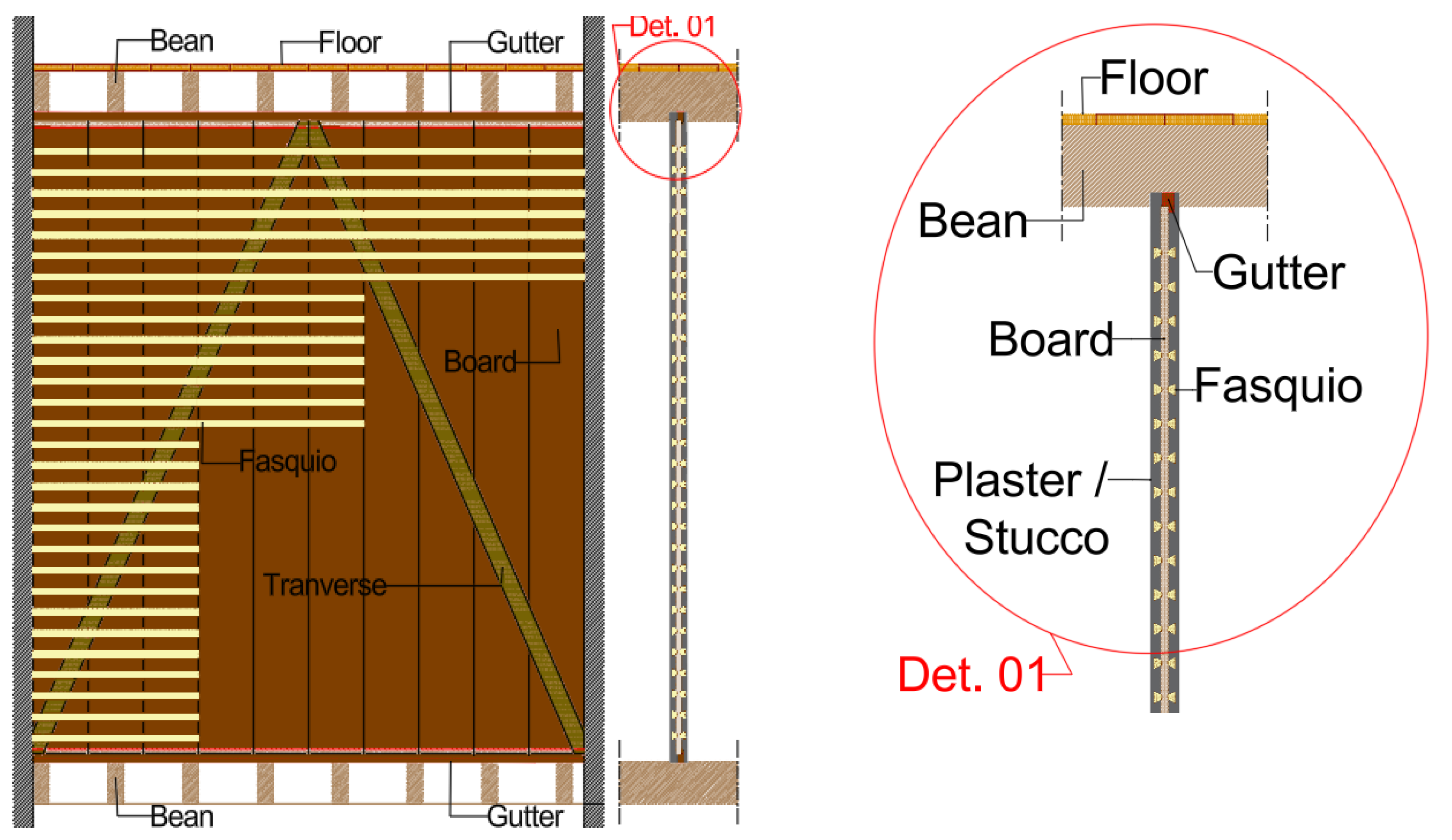

6.2.4. Double Wattle and Daub

The Double wattle and daub,

Figure 50, also known as Double-faced, is structured with two layers of seam boards or, sometimes, floorboards. The structure of upright and crossbeams is first built. Then the seam boards are nailed diagonally, on either side, in opposite directions, for instance, diagonally from left to right on one side and from right to left on the other. The width of the wood framework is approximately 10 cm.

Figure 51 and

Figure 52 correspond to partitions walls of a type 2 dwelling located in Santa Comba Dão, in the central region, where the system was also supported by struts diagonal braces. The slats forming the

fasquio were type A, spaced 3 to 4 cm apart. The infill mortar was sandy with straw incorporated, while the rendering mortar did not include fibres or other elements.

6.2.5. Lath Wattle and Daub

Figure 53 represents the structure of the Lath wattle and daub, with width of the framework of about 10 cm. In this type of wattle and daub, the posts are erected, with an approximate section of 10x8 cm, placed on each of the floor beams, which will connect to the ceiling beams. After the posts are set, the laths of type B are placed side by side, with no spacing between them. After the

fasquio assembly, the plastering is applied.

The walls shown in

Figure 54 and

Figure 55 are located on the island of Terceira, in the Autonomous Region of the Azores. Both are partitions walls of type 11 dwellings. The wall shown in

Figure 54, located in Porto Judeu, has a sandy plaster, while the wall shown in

Figure 55, located in Biscoito, also has a sandy plaster with the incorporation of animal hair.

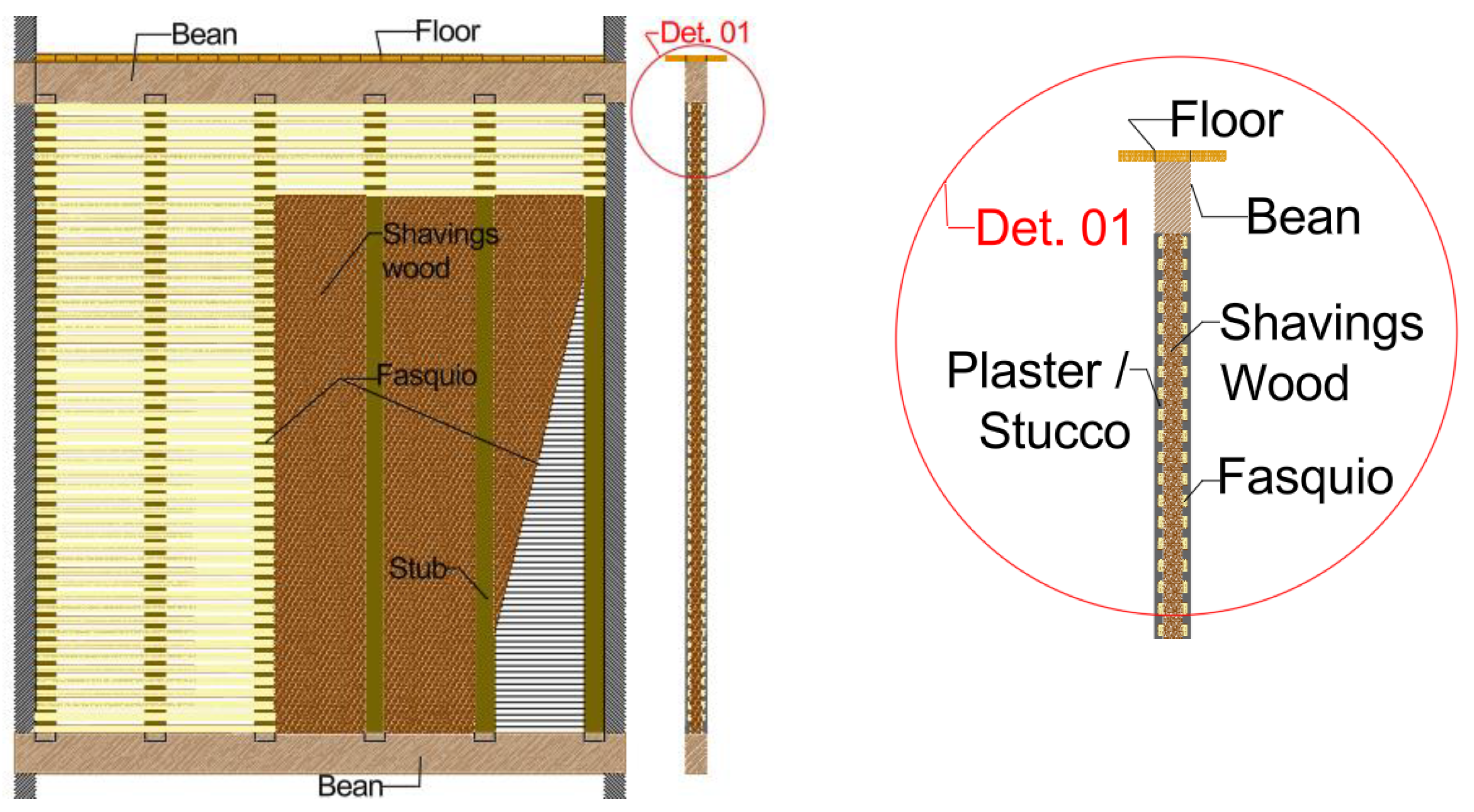

6.2.6. Wood Shavings Wattle and Daub

The structure of the Wood shavings wattle and daub is shown in

Figure 56, and has a width of the framework of about 10 cm. In this type of wattle and daub, the posts, with an approximate section of 10x8 cm, are erected between each of the floor and ceiling beams. After the posts are set, the laths of Type B –

Figure 57 and

Figure 58, spaced approximately 3.0 cm apart, or type C (bamboo) –

Figure 59, with spaces between 1.5 and 2.0 cm, are installed. In all the cases studied, the gaps between the posts were filled with wood shavings. The plasters used do not incorporate fibres or other elements. All the walls are partitions walls, of type 10 dwellings, located in Funchal, in the Autonomous Region of Madeira.

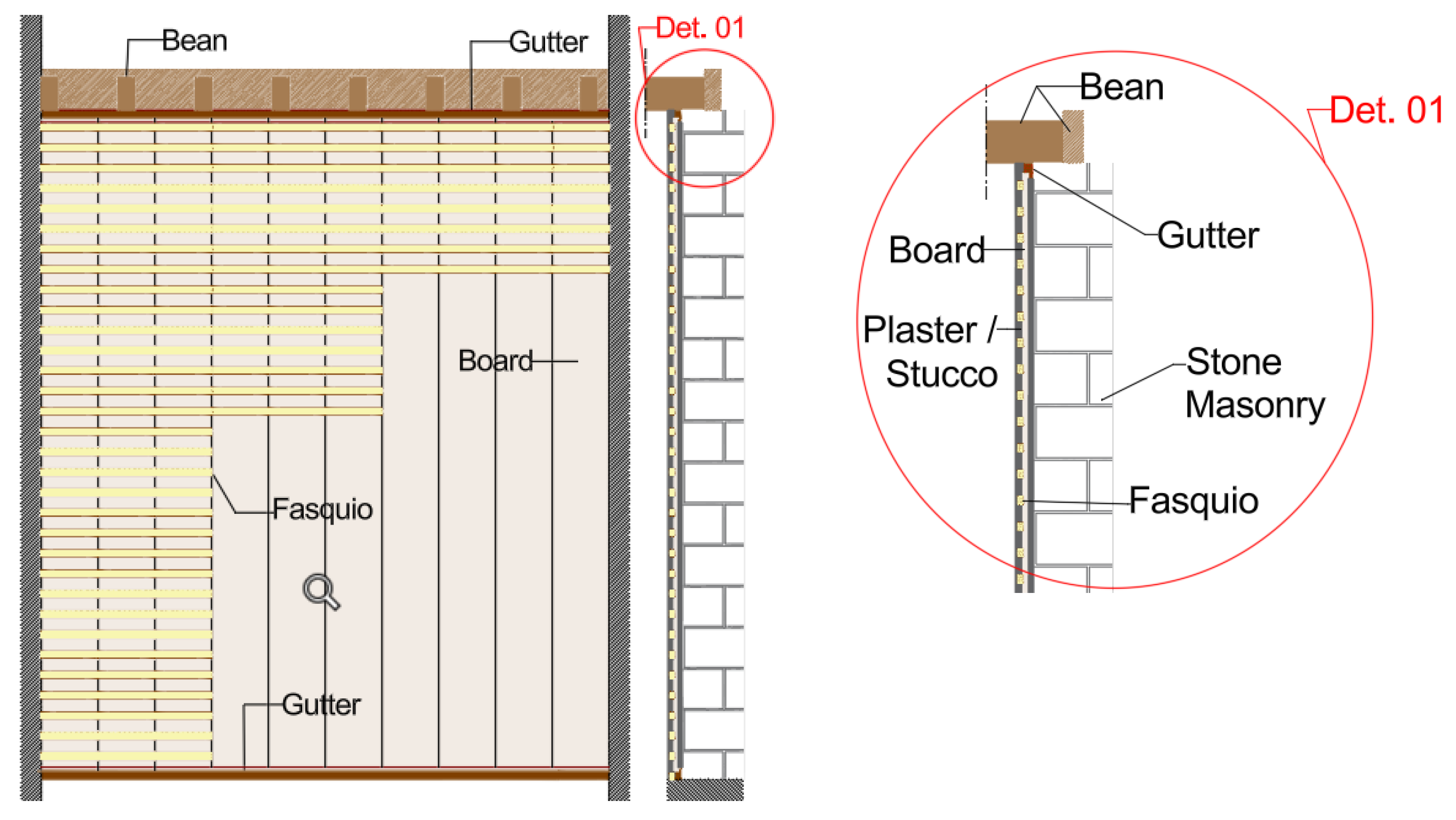

6.2.7. Insulating Wattle and Daub

The Insulating wattle and daub structure is shown in

Figure 60. Not very common, it was identified in the city of Boassas, in the North region, internally covering an exterior stone wall of a type 4 dwelling –

Figure 61.

It differs from the simple wattle and daub by having laths on the side of the seam boards facing the interior of the dwelling. The width of the framework of the insulating wattle and daub is approximately 8 cm. The infill between the posts and between the slats were filled with sandy mortar, incorporated with vegetable fibres straw.

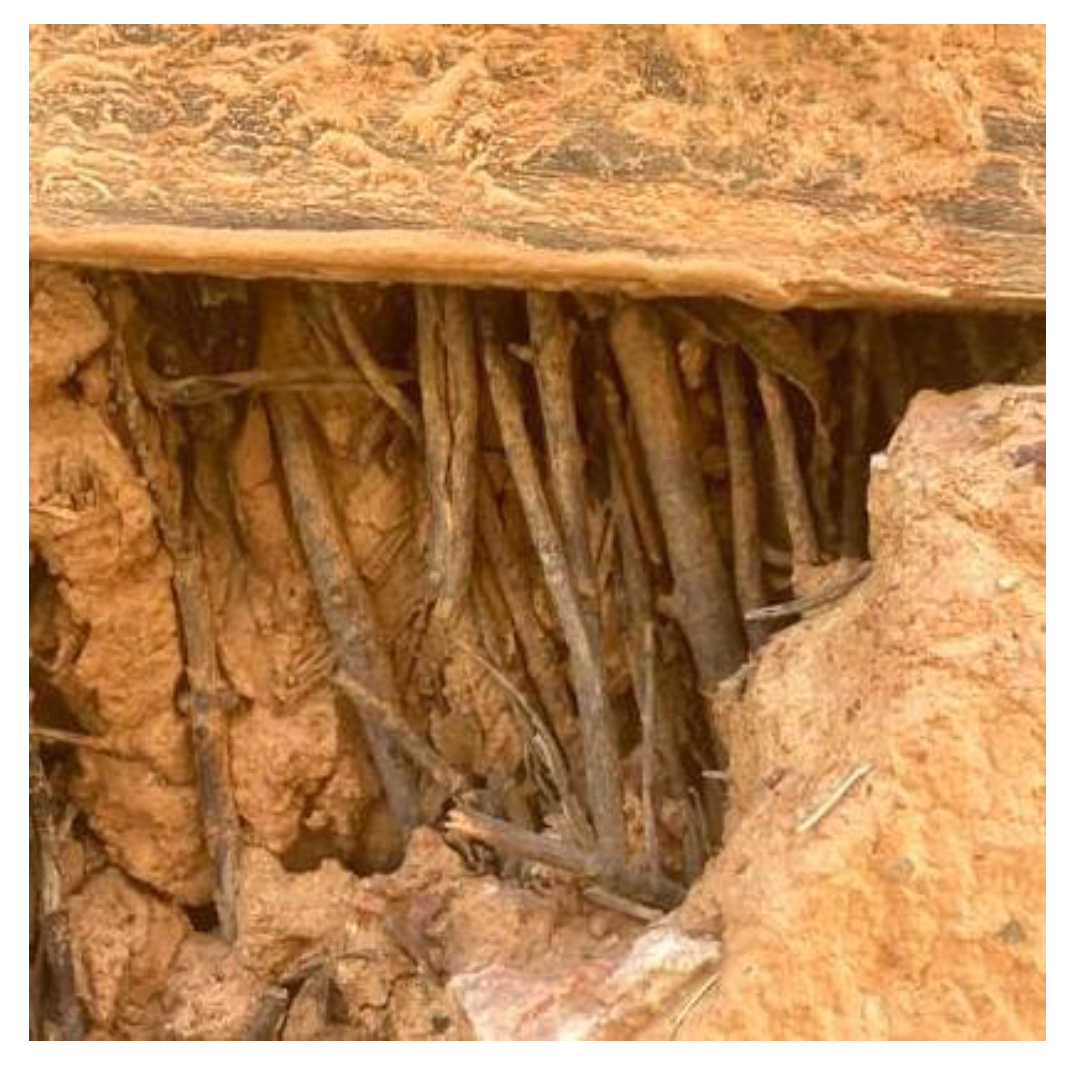

6.2.8. The Mortars

During the fieldwork, it was also possible to quickly assess the type of filling material used in the various wattle and daub walls. This analysis revealed that, in addition to the use of earth-based mortar, sandy lime mortar was also employed. In both types, situations were found with and without the incorporation of vegetable fibres, animal hairs, fragments of bricks, stones, among others.

Figure 62,

Figure 63,

Figure 64,

Figure 65,

Figure 66 and

Figure 67 illustrate the presence of these incorporated elements.

7. Conclusions

The aim of this investigation, which sought to expand studies on wattle and daub walls in mainland Portugal as well as in the Autonomous Regions of Madeira and the Azores, has been achieved.

The study encompassed, in the northern region, the sub-regions of the Porto Metropolitan Area, Alto Tâmega e Sousa, Douro, and Terras de Trás-os-Montes. In the central region, it included the sub-regions of Aveiro, Coimbra, Viseu Dão Lafões, and Beira Baixa. Additionally, it covered the sub-regions of the Lisbon Metropolitan Area and the Autonomous Regions of the Azores and Madeira, totalling 50% of Portugal's 23 sub-regions.

With this broad geographical coverage, it can be concluded that the prevalence of constructions with wattle-and-daub walls is extensive in the northern, central, and Lisbon Metropolitan Area regions. In contrast, it is far less common in the Alentejo region and negligible in the Algarve. The presence of this construction typology is also not significant in the Autonomous Regions of the Azores and Madeira.

Regarding the objective of expanding scientific knowledge about wattle-and-daub walls in Portugal by providing detailed information to the academic and technical communities and society at large, this goal has also been achieved. Particularly noteworthy is the documentation of the construction methods for walls in the Autonomous Regions of Madeira and the Azores, as well as the analysis of the use of wattle and daub as a component contributing to thermal insulation.

Wattle and daub walls exhibit remarkable construction variability due to the absence of rigid standards, which is reflected in the diversity of materials and the arrangement of wooden structural elements. In addition to the use of earth-based mortar for filling the laths and rendering, lime mortars with sand were also applied, often incorporating vegetable fibres, animal hairs, and fragments of bricks and stones.

The versatility and accessibility of this technique, which uses local materials and does not require highly skilled labour, favoured its adoption in various types of buildings, consolidating a significant architectural legacy in Portugal. Through in-depth scientific analysis, the importance of preserving the sustainable nature of wattle and daub constructions in architectural heritage rehabilitation initiatives is emphasised, ensuring the continuation of this tradition, which holds both cultural and environmental value.

Author Contributions

Conceptualization, K.S., I.T. and A.V.; Methodology, K.S., I.T. and A.V.; Validation, I.T. and A.V.; Formal Analysis, K.S..; Investigation, K.S.; Data Curation, K.S.; Writing Original Draft Preparation, K.S.; Writing Review & Editing, K.S., I.T. and A.V..; Supervision, I.T. and A.V..; Project Administration, I.T. and A.V..; Funding Acquisition, I.T. and A.V..

Funding

FCT (Fundação para a Ciência e a Tecnologia), grant number 2022.13467.BD.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The author is grateful for the Foundation for Science and Technology's support through funding UIDB/04625/2020 from the research unit CERIS.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cardoso, R. (2013) – "Characterisation of Wattle and Daub Construction in Lamego and Alto Douro". PhD Thesis, Department of Civil Engineering, University of Beira Interior, Covilhã.

- Lopes, W.; Ino, A. (2003) – "Mixed Earth Construction Techniques". PROTERRA, Project XIV.6. Latin American Science and Technology for Development Programme – CYTED 2003. ISBN 85-904015-1-0. pp.15-35.

- Teixeira, J. (2004). "Descriptions of the Constructions System of the Bourgeois House of Porto Between the 17TH and 19TH Centuries - Contribution to a History of Architectural Construction in Portugal" – Evidence of pedagogical aptitude and scientific capacity. University of Porto, Porto - https://hdl.handle.net/10216/39475.

- Pinto, J.; Cardoso, R.; Paiva, A.; Cunha, S.; Cruz, D.; Vieira, B.; Louzada, J.; Varum, H. (2011) – "Characterisation of Traditional Wattle and Daub Walls". Article from the Institutional Repository of the University of Aveiro under the record http://hdl.handle.net/10773/8010, Aveiro.

- Soares, K.; Torres, I.; Velosa, A. (2024) – "Characterisation of Traditional Mortars Used in Wattle and Daub in Portugal". Conference Paper. Rehabend: Construction Pathology, Rehabilitation Technology, and Heritage Management, May 07-10, 2024. Code 112. Gijón, Spain.

- Carvalho, J.; Pinto, J.; Varum, H.; Jesus, A.; Lousada, J.; Morais, L. (2008) – "Study of Earth Material Used in Wattle and Daub Constructions in the Trás-os-Montes and Alto Douro Region". TERRABRASIL 2008, 7th Ibero-American Seminar on Earth Construction, State University of Maranhão, São Luiz, MA, Brazil, Ed. UEMAS/Proterra, ISBN 978-85-86036-41-5.

- Martinho, J.; Gonçalves, C.; Magalhães, F.; Lousada, J.; Vieira, J.; Varum, H.; Tavares, P.; Pinto, J. (2009) – "Wattle and Daub Construction in the Southern Douro Valley". CD of the 8th Ibero-American Earth Construction Seminar (VIII SIACOT) and the 2nd Argentine Seminar on Architecture and Earth Construction (II SAACT). Editor: CRIATIAC – FAU – UNT. June 2009, Tucumán, Argentina. ISBN IN PROCESS. pp. 514-521.

- Martinho, J.; Pinto, J.; Vieira, J.; Silva, P.; Tavares, P.; Fernandes, L.; Lousada, J.; Varum, H. (2010) – "Wattle and Daub Construction in the Municipalities Association of Terra Fria do Nordeste Transmontano". 7th International Earth Architecture Congress: Tradition and Innovation – Tierra Group, University of Valladolid, Valladolid 25-26 September 2010. Published in Construcción con Tierra. Tecnología y Arquitectura. Earth Architecture Congress in Cuenca de Campos 2010/2011. ISBN 978-84-694-8107-3, September 2011, pp. 141-150, Spain.

- Cepeda, A.; Lousada, J.; Vieira, J.; Varum, H.; Tavares, P.; Fernandes, L.; Pinto, J. (2010) – "Study of Earth Material Used in Existing Wattle and Daub Construction in Alto Tâmega". Article 6th ATP / 9th SIACOT. http://hdl.handle.net/10773/7181. Coimbra, Portugal.

- Gonçalves, C.; Martinho, J.; Pinto, J.; Vieira, J.; Silva, P.; Tavares, P.; Fernandes, L.; Lousada, J.; Varum, H. (2010) – "Wattle and Daub Construction in the Municipal Associations of Terra Fria do Nordeste Transmontano and Terra Quente Transmontana". Institutional Repository of the University of Aveiro, URI http://hdl.handle.net/10773/7160, Aveiro.

- Gonçalves, C.; Pinto, J.; Vieira, J.; Silva, P.; Paiva, A.; Ramos, L.; Tavares, P.; Fernandes, L.; Lousada, J.; Varum, H. (2010) – "Wattle and Daub Construction in the Municipalities Association of Terra Quente Transmontana". Latest Trends on Cultural Heritage and Tourism (CUHT-36). ISSN: 1792-4308. ISBN: 978-960-474-205-9. pp 235-240.

- Gouveia, J. (2017) – "Requalification of Traditional Madeira Buildings – Study and Reflection on Casa da Quinta Grande". Master's Dissertation in Architecture, University of Porto, University of Porto, Porto.

- Leite, J. (2019) – "Wood Architecture in the Azores Archipelago". Master's Dissertation, Faculty of Architecture, Instituto Superior Técnico, Technical University of Lisbon, Lisbon.

- Padrão, J.; Guedes, J.; Pinto, J.; Arêde, A. (2020) – "Wattle and Daub Walls in Viseu – Construction Details and Material Characterisation". Portuguese Journal of Structural Engineering. Ed. LNEC. Series III, No. 14, pp. 71-84, ISSN 2183-8488.

- Rodrigues, M. (2022) – "Characterisation of Metal Connections in the Rehabilitation of Wattle and Daub Walls in Historic Buildings in Viseu". Master's Dissertation, Polytechnic Institute of Viseu, School of Technology and Management of Viseu, Viseu.

- Costa, A. (2021) – "Plasters for Wattle and Saub Walls in Northern Portugal ". Master's Dissertation. University of Aveiro, Aveiro.

- Costa, F. (1930-1939) – "Practical Encyclopaedia of Civil Construction – Interiors and Exteriors", Notebook 26, pp 1-5, Lisbon, Portugal.

- Jorge, F.; Fernandes, M.; Correia, M. (2005) – "Earth Architecture in Portugal". 1st Edition. Lisbon, Argumentum ISBN 972-8479-36-0. Portugal.

- Florido, F. (2010). "Typification of Rehabilitation Solution for Wooden Walls in Old Buildings". Master's Dissertation, Department of Civil Engineering, University of Porto, Porto.

- Mira, D. (2007) – "Analysis of the Pombaline Construction System and the Rehabilitation of a Building". Master's Dissertation, Faculty of Architecture, Instituto Superior Técnico, Technical University of Lisbon, Lisbon.

- Santos, V. (1994) – "The Pombaline Construction System in Lisbon". Master's Dissertation, Faculty of Architecture, Instituto Superior Técnico, Technical University of Lisbon, Lisbon.

- Pinto, T. (2015) – “Study of Building Pathologies in Tabique: Survey, Characterization and Repair”. Master's Thesis, Department of Engineering, School of Science and Technology, University of Trás-os-Montes and Alto Douro, Vila Real.

Figure 1.

Typical types of nails.

Figure 1.

Typical types of nails.

Figure 20.

Martim Branco.

Figure 20.

Martim Branco.

Figure 22.

Santa Comba Dão.

Figure 22.

Santa Comba Dão.

Figure 23.

Santa Comba Dão.

Figure 23.

Santa Comba Dão.

Figure 34.

Typical sections of the batten that make up the laths.

Figure 34.

Typical sections of the batten that make up the laths.

Figure 35.

Fasquio type A - Lamego.

Figure 35.

Fasquio type A - Lamego.

Figure 36.

Fasquio type B – Martim Branco.

Figure 36.

Fasquio type B – Martim Branco.

Figure 37.

Fasquio type C - Funchal.

Figure 37.

Fasquio type C - Funchal.

Figure 38.

Scheme frontal of Galician, (adapted from [

17]).

Figure 38.

Scheme frontal of Galician, (adapted from [

17]).

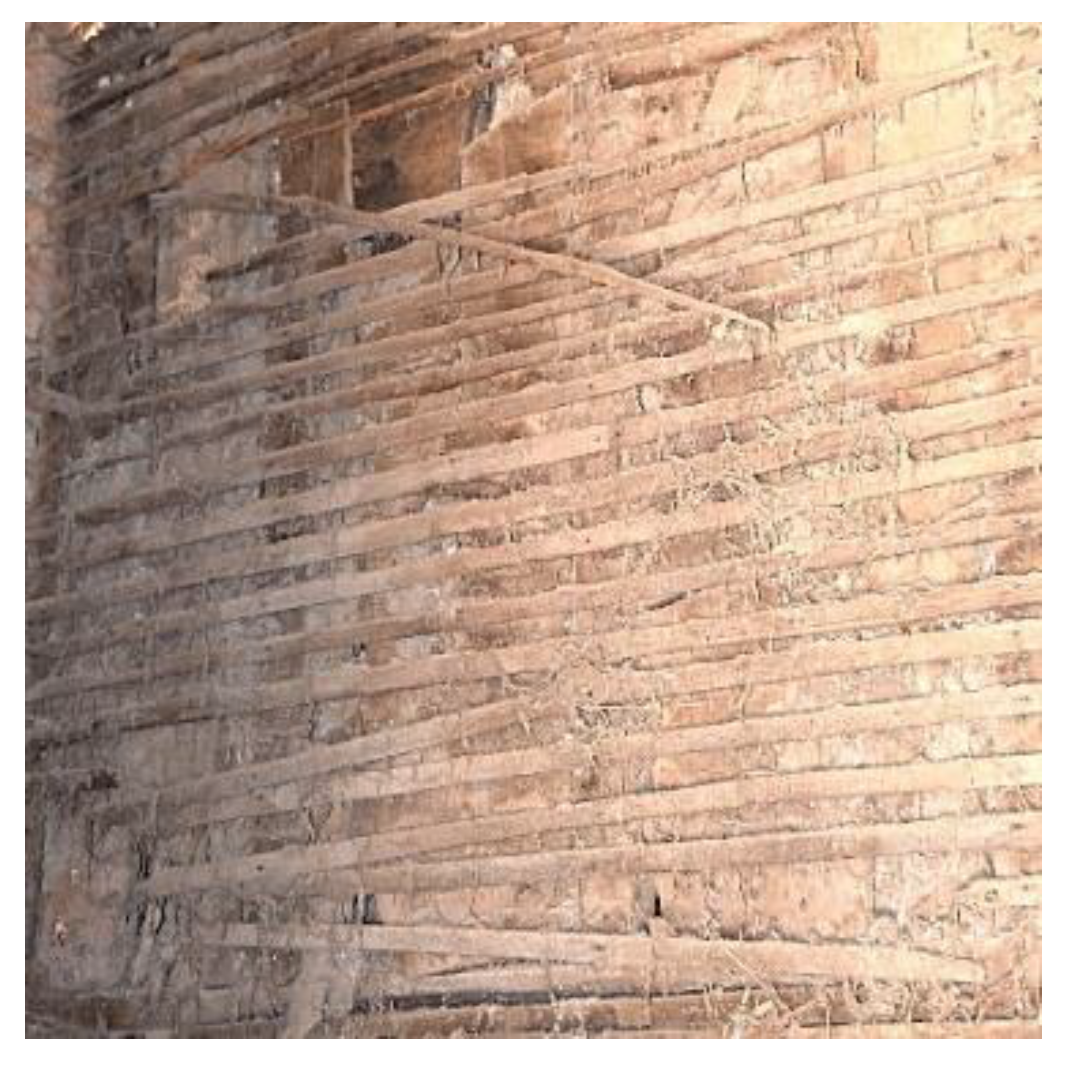

Figure 39.

Frontal of Galician – Salzedas.

Figure 39.

Frontal of Galician – Salzedas.

Figure 40.

Frontal of Galician - Salzedas.

Figure 40.

Frontal of Galician - Salzedas.

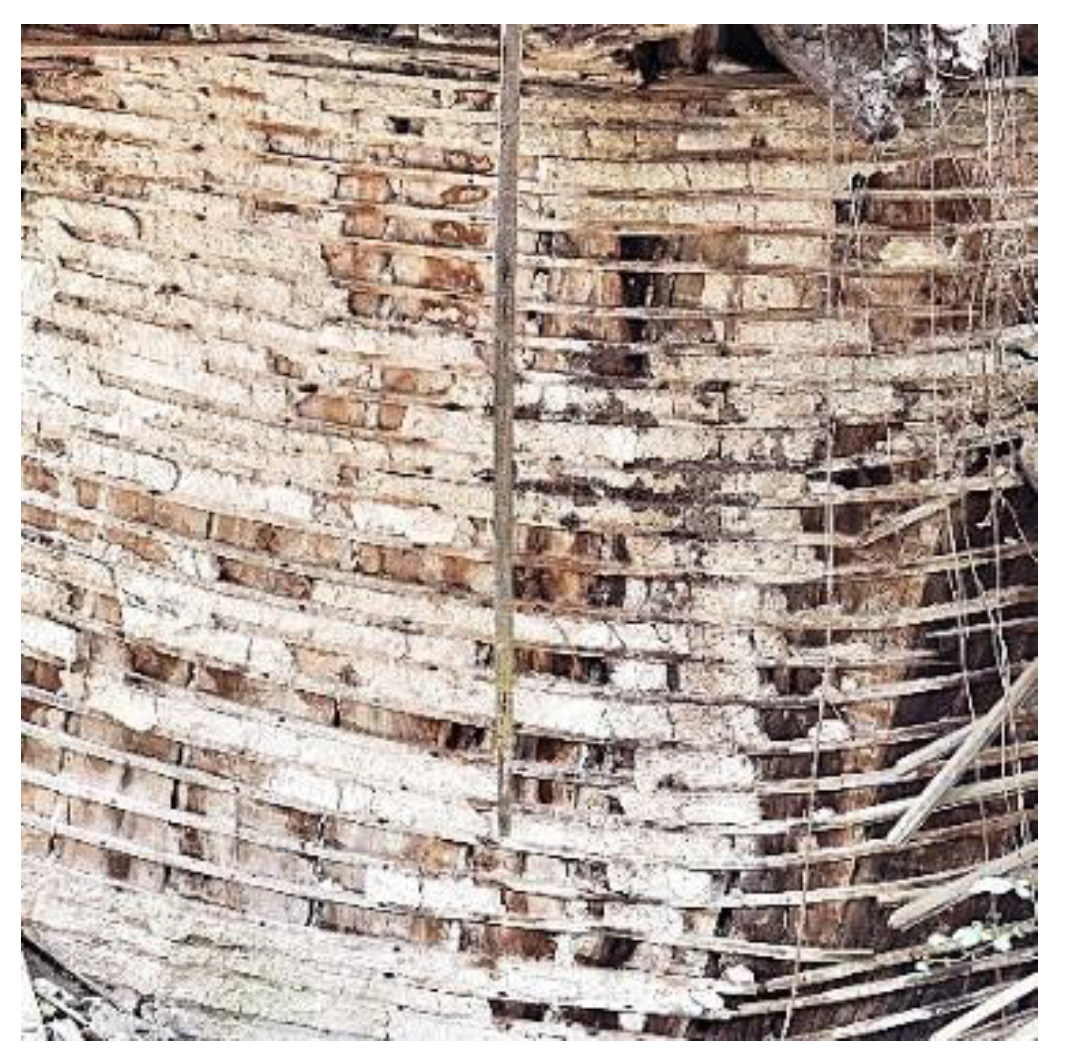

Figure 41.

Frontal of Galician - Lamego.

Figure 41.

Frontal of Galician - Lamego.

Figure 46.

Scheme Simples wattle and daub , (adapted from [

17]).

Figure 46.

Scheme Simples wattle and daub , (adapted from [

17]).

Figure 47.

Simple wattle and daub - Cedovim.

Figure 47.

Simple wattle and daub - Cedovim.

Figure 48.

Simple wattle and daub - Fermentãos.

Figure 48.

Simple wattle and daub - Fermentãos.

Figure 49.

Simple wattle and daub - Alqueidão.

Figure 49.

Simple wattle and daub - Alqueidão.

Figure 50.

Scheme Double wattle and daub – ( adapted from [

17]).

Figure 50.

Scheme Double wattle and daub – ( adapted from [

17]).

Figure 51.

Double wattle and daub - Santa Comba Dão.

Figure 51.

Double wattle and daub - Santa Comba Dão.

Figure 52.

Double wattle and daub - Santa Comba Dão.

Figure 52.

Double wattle and daub - Santa Comba Dão.

Figure 53.

Scheme - Batten wattle and daub.

Figure 53.

Scheme - Batten wattle and daub.

Figure 54.

Batten wattle and daub - Third Island - Biscoito.

Figure 54.

Batten wattle and daub - Third Island - Biscoito.

Figure 55.

Batten wattle and daub - Third Island – Porto Judeu.

Figure 55.

Batten wattle and daub - Third Island – Porto Judeu.

Figure 56.

Scheme Wood shavings wattle and daub.

Figure 56.

Scheme Wood shavings wattle and daub.

Figure 57.

Wood shavings wattle and daub - Funchal.

Figure 57.

Wood shavings wattle and daub - Funchal.

Figure 58.

Wood shavings wattle and daub - Funchal.

Figure 58.

Wood shavings wattle and daub - Funchal.

Figure 59.

Wood shavings wattle and daub - Funchal.

Figure 59.

Wood shavings wattle and daub - Funchal.

Figure 60.

Scheme Insulating wattle and daub.

Figure 60.

Scheme Insulating wattle and daub.

Figure 61.

Insulating wattle and daub - Boassas.

Figure 61.

Insulating wattle and daub - Boassas.

Figure 62.

Onion stalks - Guiães.

Figure 62.

Onion stalks - Guiães.

Figure 63.

Plant fiber - Martim Branco.

Figure 63.

Plant fiber - Martim Branco.

Figure 64.

Corn straw - Oteiro.

Figure 64.

Corn straw - Oteiro.

Figure 65.

Hair - Azores.

Figure 65.

Hair - Azores.

Figure 66.

Corn cob – Fermentãos.

Figure 66.

Corn cob – Fermentãos.

Figure 67.

Wood shavings - Funchal.

Figure 67.

Wood shavings - Funchal.

Table 1.

Types of buildings with battle and daub walls.

Table 1.

Types of buildings with battle and daub walls.

| Item |

Description |

Region of Portugal |

Figure |

| Type 1 |

Two-floor buildings. The external walls and ground-floor partitions are made of stone masonry, while the partitions on the upper floor are constructed of wattle and daub. These buildings may be used as housing, or the ground floor may serve as shelter for animals, storage for agricultural products, or commercial space. |

North

Central |

5,14,23 |

| Type 2 |

Two-floor buildings. All external walls are made of stone masonry, while the partitions are constructed of wattle and daub. These buildings may be used as housings, or the ground floor may serve as shelter for animals, storage for agricultural products, or commercial space. |

North

Central |

7, 8, 9, 19, 22, 24 |

| Type 3 |

Two-floor buildings. All walls, both external and internal partitions, are con-structed of wattle and daub. These buildings may be used as housings, or the ground floor may serve as shelter for animals, storage for agricultural products, or commercial space. |

North

Central |

11, 12, 15, 20 |

| Type 4 |

Single-floor buildings. The external walls are made of stone masonry, while the partitions are constructed of wattle and daub. These buildings are generally used as housings or shelters for animals. |

North |

4 |

| Type 5 |

Single-floor buildings. Both the external walls and partitions are constructed of wattle and daub. These buildings are generally used as housings or shelters for animals. |

North

Central |

6,10 |

| Type 6 |

Two-storey buildings. The external walls are made of adobe masonry, while the partitions are constructed of wattle and daub. These buildings are generally used as housings. |

Central -

Region of Aveiro |

16, 18 |

| Type 7 |

Single-floor buildings. The external walls are made of adobe masonry, while the partitions are constructed of wattle and daub. These buildings are generally used as housings. |

Central -

Region of Aveiro |

17, 21 |

| Type 8 |

Multi-floor buildings. The external walls are made of ceramic brick masonry, while the partitions are constructed of wattle and daub. These buildings are generally used as housings. |

North -

Porto city |

13 |

| Type 9 |

Multi-floor buildings. The external walls are made of stone masonry, and the partitions are of the “Pombaline cage” type. In some of these buildings, the ground floor is used for commercial purposes, while the upper floors are used as housings or offices. |

Lisbon

Metropolitan Area |

25, 26, 27 |

| Type 10 |

Two- or multi-floor buildings. The external walls are made of stone masonry, while the partitions are constructed of wattle and daub. In some of these buildings, the ground floor is used for commercial purposes, while the upper floors are used as housings or offices. |

Autonomous

Region of Madeira - Funchal |

28, 29, 30, 31 |

| Type 11 |

One- or two-floor buildings. With a sim-ple and rigorous geometry, the external walls are made of volcanic stone mason-ry, and the partitions are constructed of wattle and daub. These buildings are generally used as housings. |

Autonomous

Region of Azores – Third Island |

32, 33 |

Table 2.

Types of coatings for wattle and daub walls.

Table 2.

Types of coatings for wattle and daub walls.

| Item |

Description |

Wall |

Figure |

| Cover 1 |

Plaster |

External

Internal |

6, 7, 12, 13, 16, 17, 18, 19, 20, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33 |

| Cover 2 |

Slate roofs. |

External |

5 |

| Cover 3 |

Zinc sheets |

External |

11 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).