Submitted:

12 February 2025

Posted:

14 February 2025

You are already at the latest version

Abstract

The purpose of this article is to use a numerical model to match the experimental results in case of steel frames with infilled masonry with or without rubber bricks at the corners (SISBRICK) under cyclic loading. The analysis are performed with opensees software using for preprocessing and postprocessing matlab. In this model the beam and column made of steel are modelled with displacement based elements and using section fiber models at each fiber the Giuffre Menegotto Pinto is used, to model the infill masonry with or without SISBRICK the concrete model based on Thorenfeldt curve is used to model the diagonals with high strength under compression and low under tension.

Keywords:

1. INTRODUCTION NUMERICAL MODEL PARAMETERS

1.1. Constitutive Curves:

1.1.1. To Model Steel:

| Material | Fy | E0 | b | R0 | R1 | R2 |

| Steel | 275 | 210000 | 0.001 | 20 | 0.925 | 0.15 |

- Fy yield strength

- E0 initial elastic tangent

- b strain-hardening ratio (ratio between post-yield tangent and initial elastic tangent)

- R0 R1 R2 parameters to control the transition from elastic to plastic branches.

- Recommended values: R0=between 10 and 20, R1=0.925, R2=0.15

1.1.2. To Model the Infill Walls Masonry and SISBRICK:

| Fc | E0 | n | k | Alpha1 | fcr | ecr | b | Alpha2 | |

| Masonry | -2 | -0.0025 | 2 | 1 | 0.32 | 0.2 | 0.00014 | 4 | 0.08 |

| SISBRICK | -2 | -0.0012 | 2 | 1 | 0.32 | 0.2 | 0.00014 | 4 | 0.08 |

- fc concrete compressive strength (compression is negative)

- e0 strain at compressive strength

- n compressive shape factor

- K post-peak compressive shape factor

- alpha1 parameter for compressive plastic strain definition

- Fcr tensile strength

- Ecr tensile strain at peak stress ($fcr)

- B exponent of the tension stiffening curve

- alpha2 parameter for tensile plastic strain definition

1.2. Area of the Equivalent Diagonal (Strut):

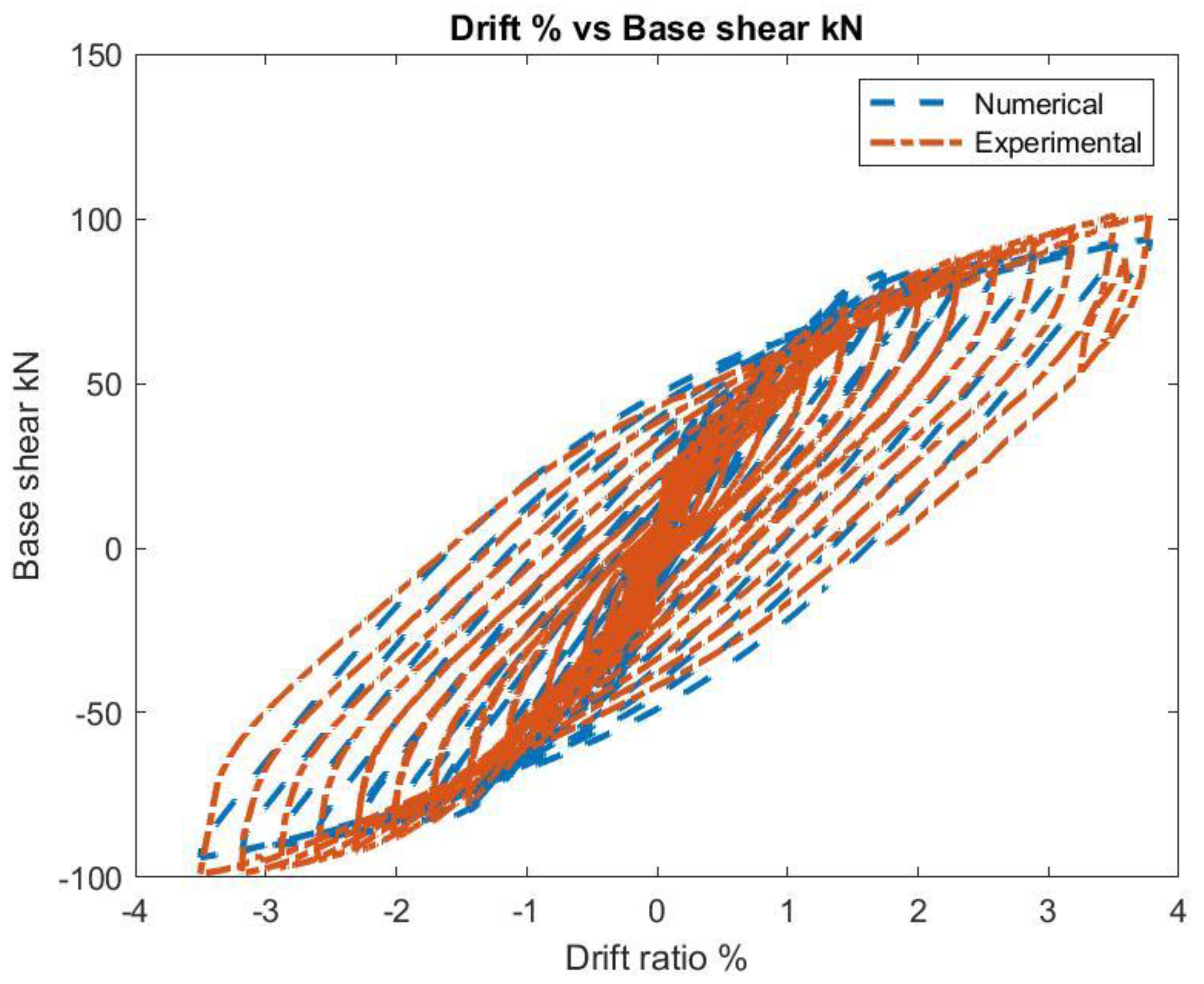

2. VALIDATION. Plots Comparison Between Experiments and Numerical.

- -

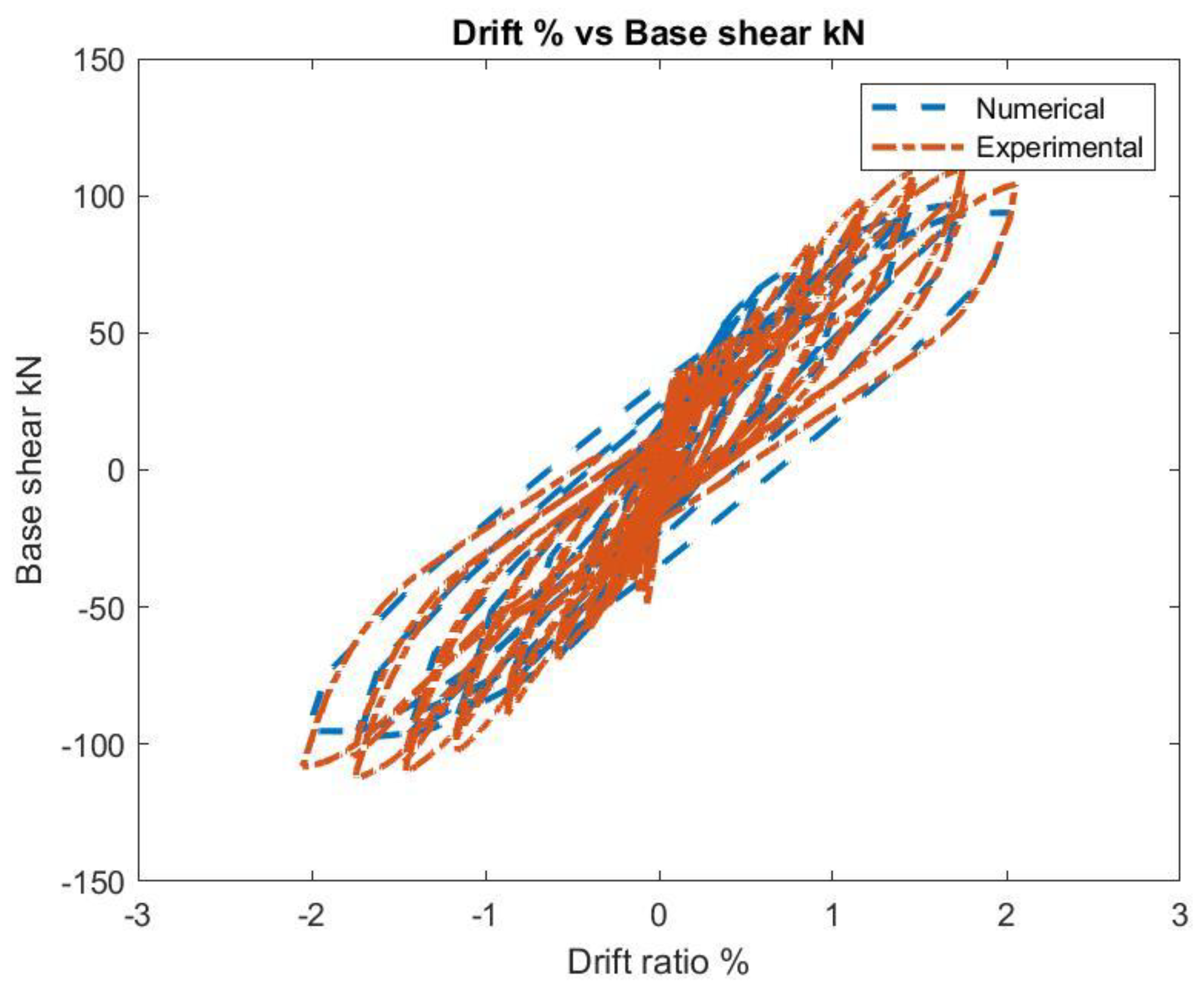

- Drift vs Base Shear Figure 1

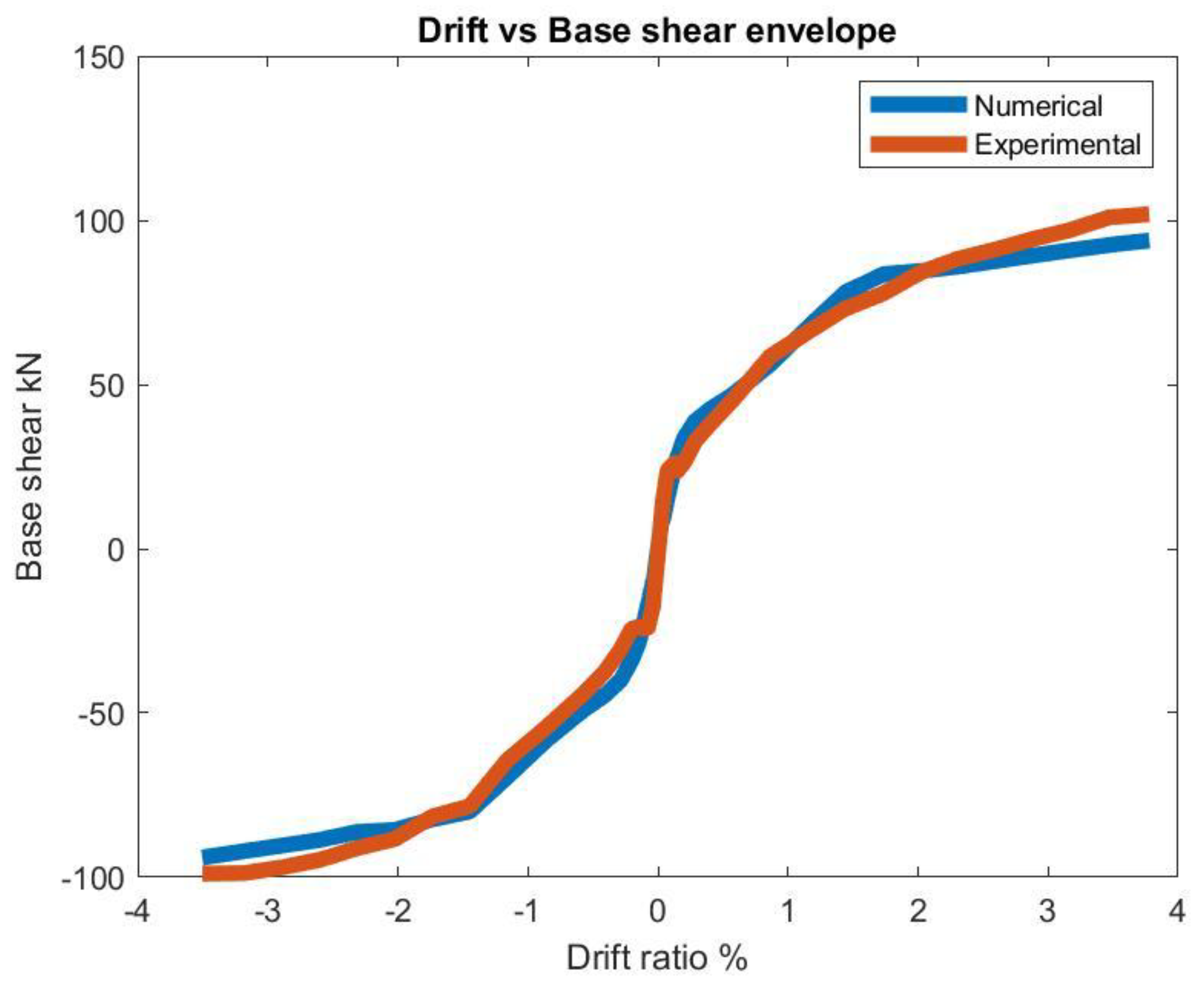

- -

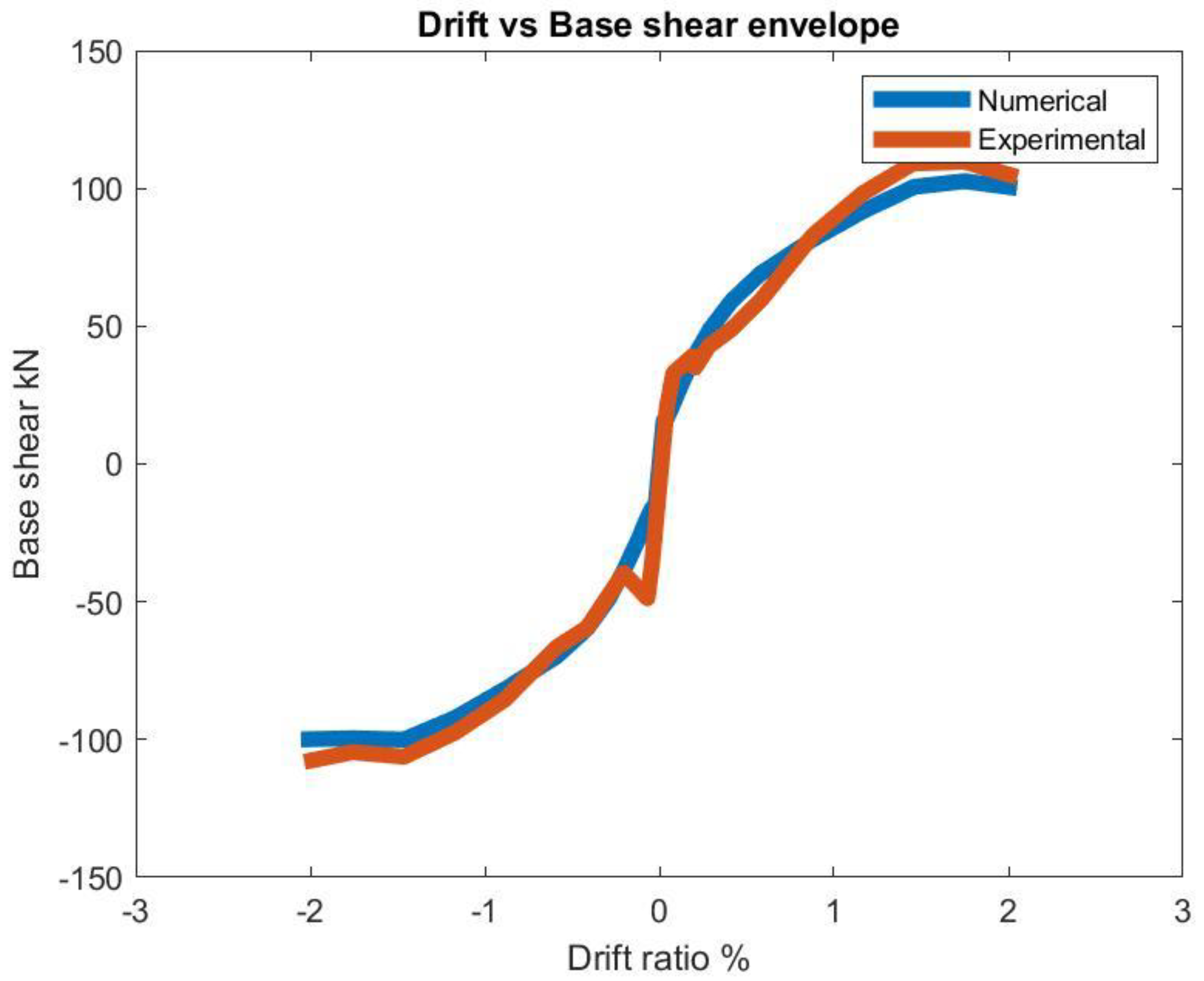

- Drift vs base shear envelope Figure 2

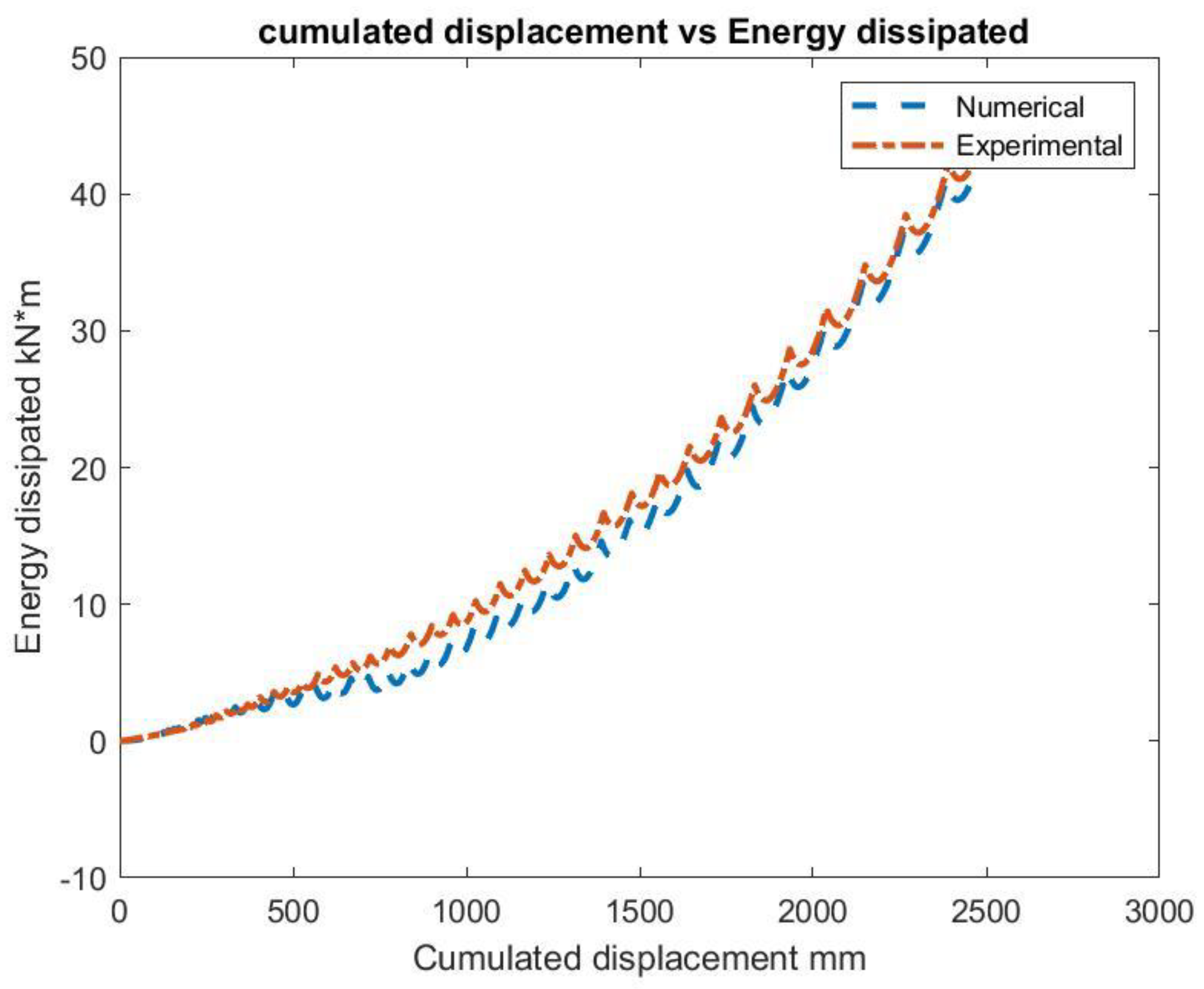

- -

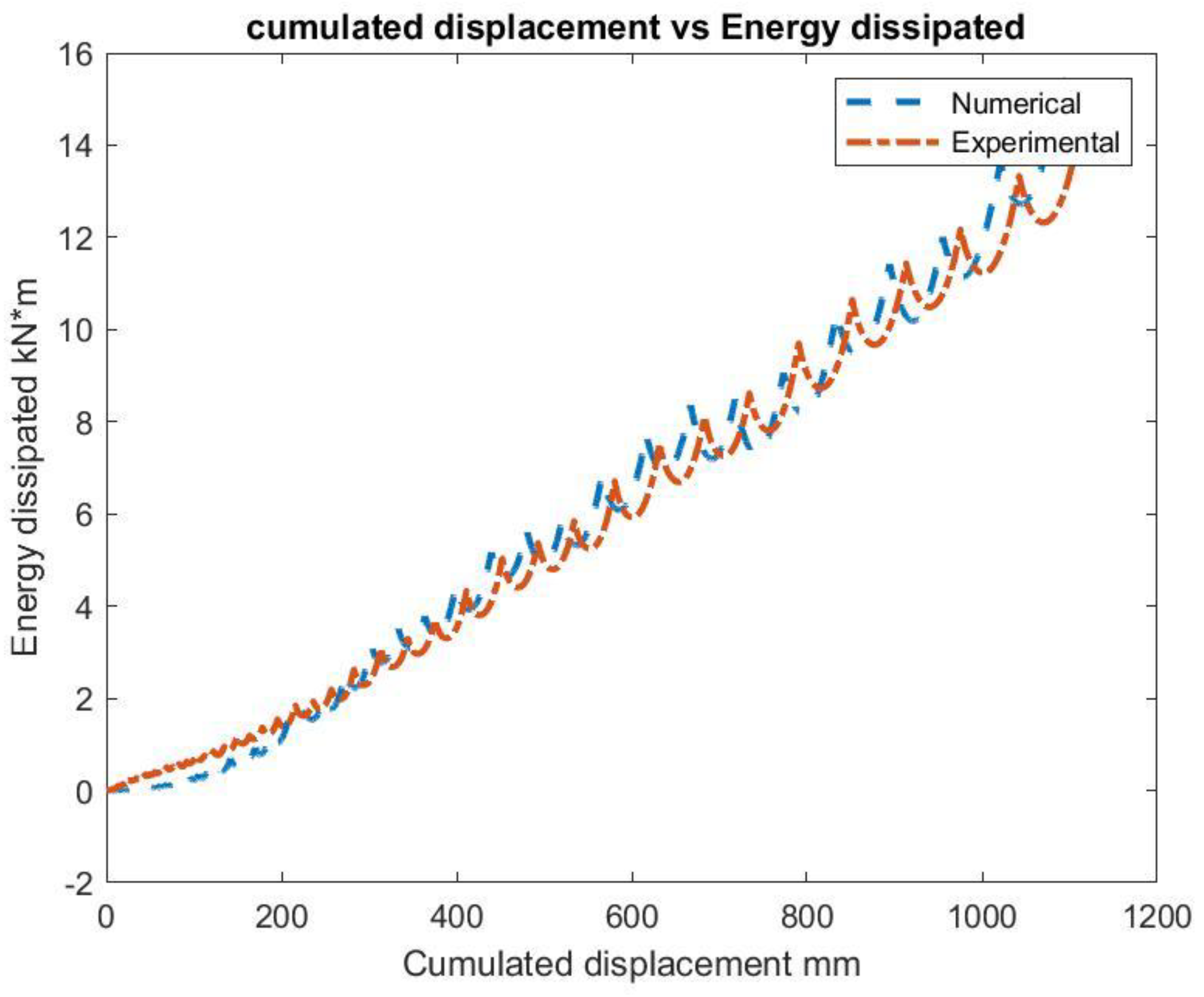

- Cumulated displacement vs energy dissipated Figure 3

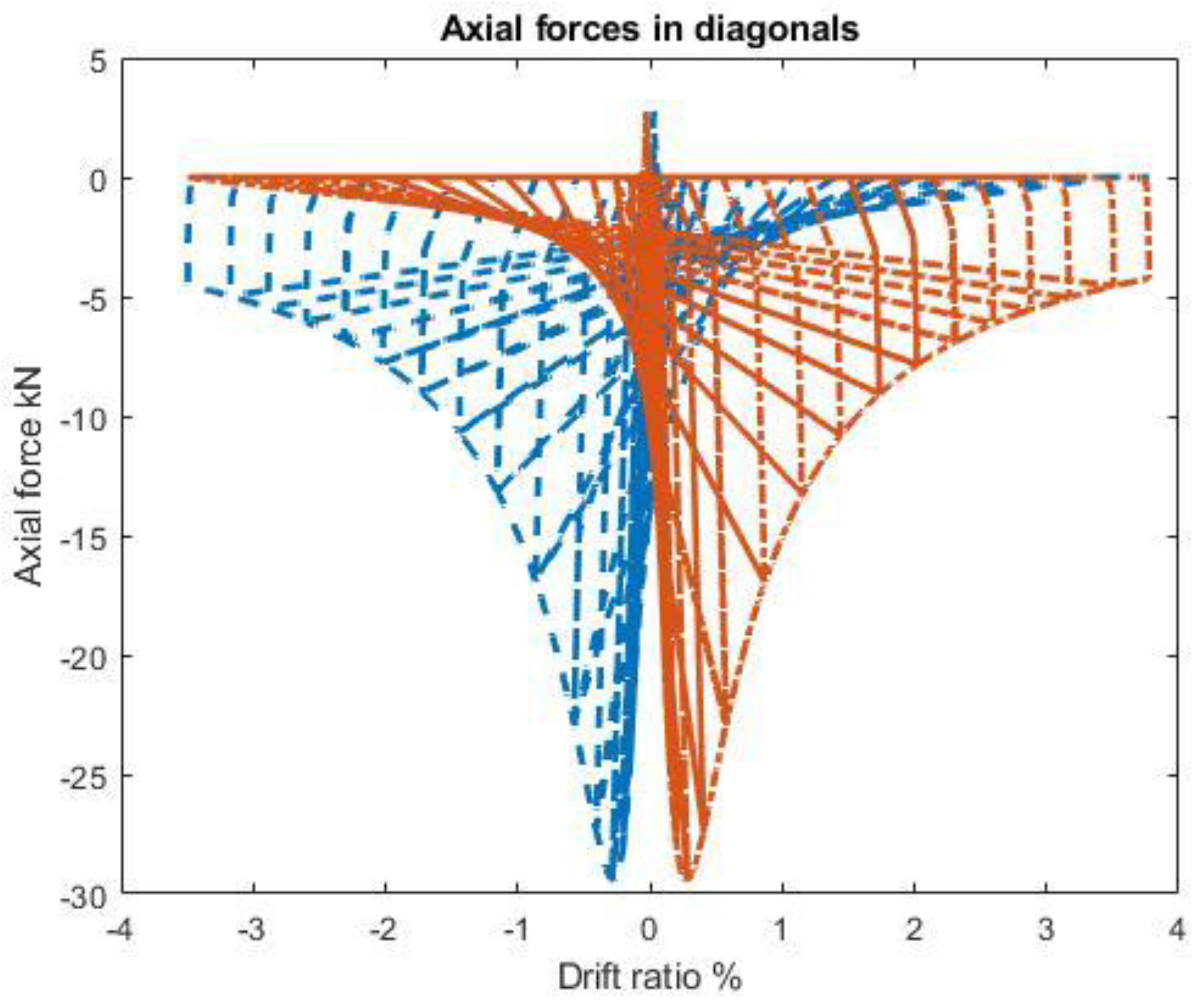

- -

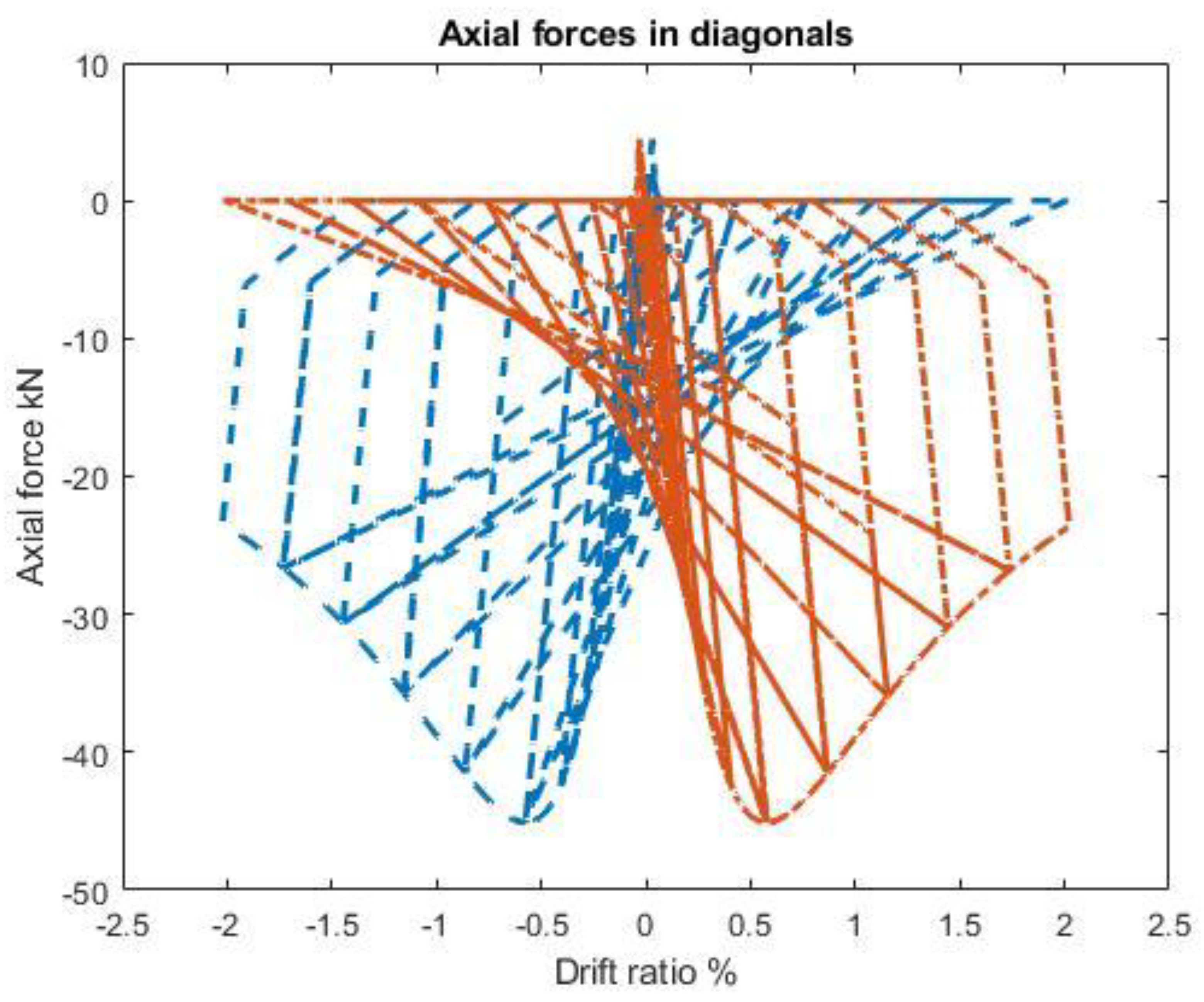

- Equivalent diagonals axial forces Figure 4

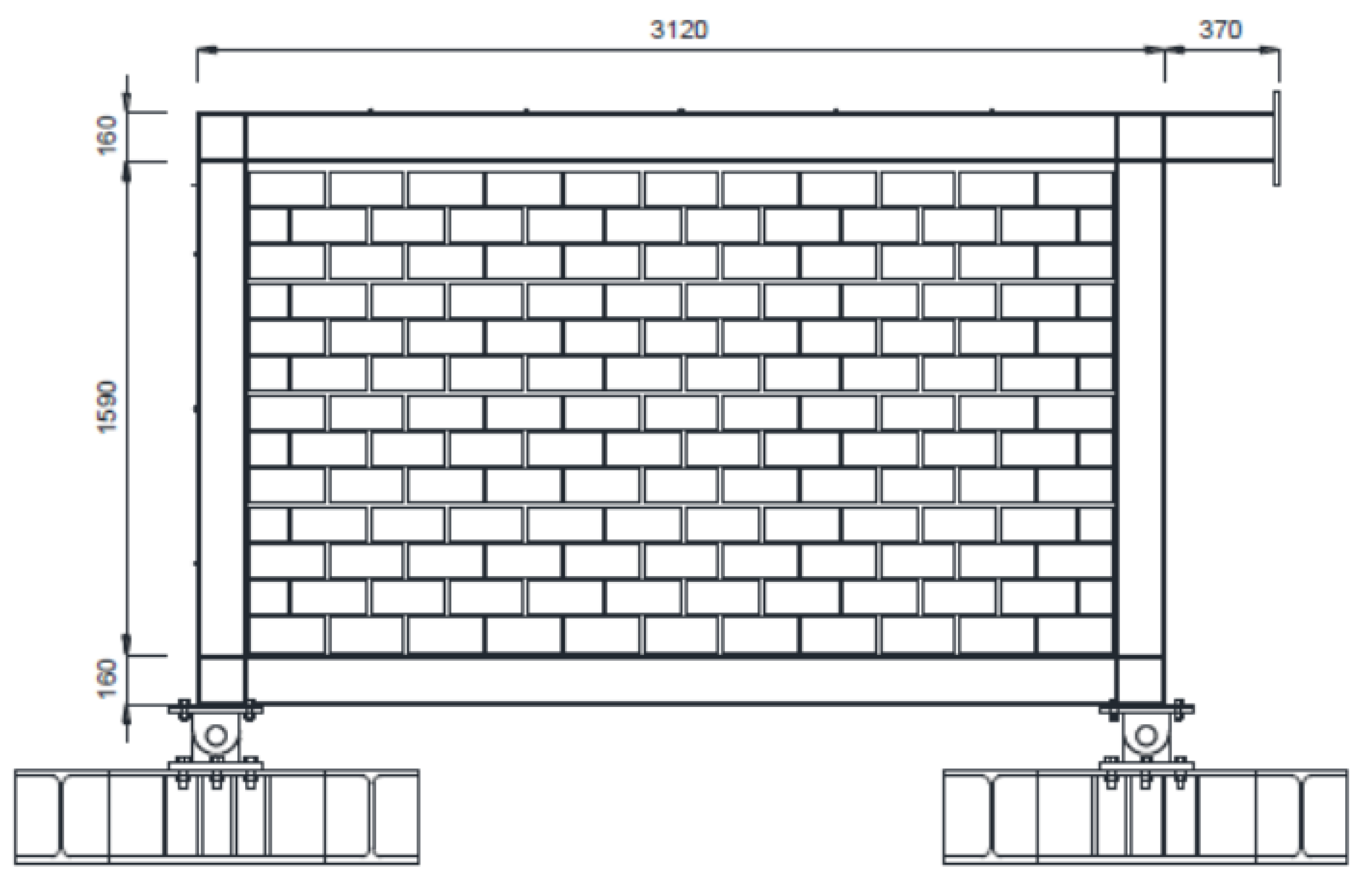

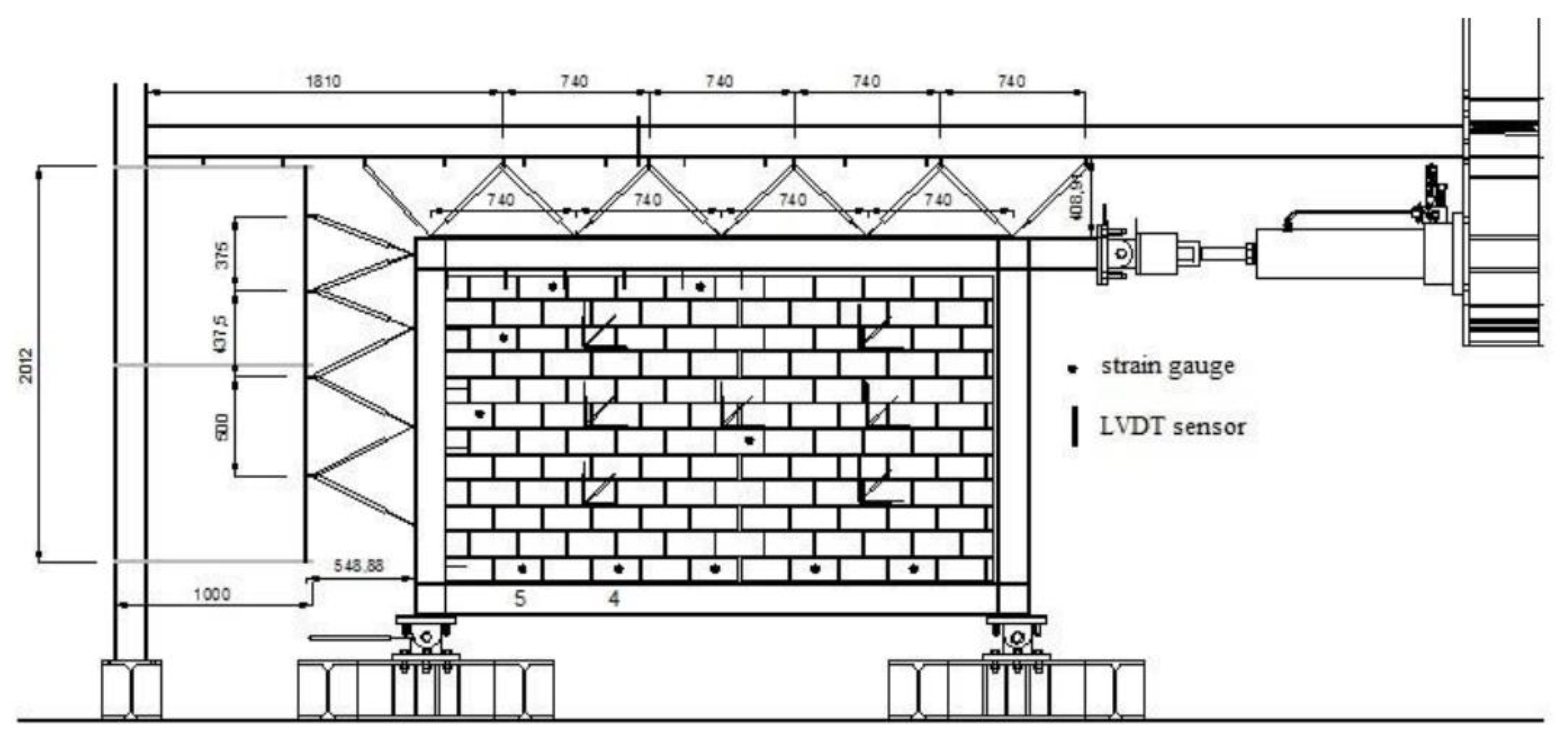

3. Test Definition

4. Conclusions

Nomenclature

References

- Agüero. https://es.mathworks.com/matlabcentral/fileexchange/124635-steel-frame-masonry-wall-dynamic.

- Agüero. https://es.mathworks.com/matlabcentral/fileexchange/124570-cyclic-analysis-of-steel-frames-with-masonry-infilled-wall?s_tid=prof_contriblnk.

- Francisco J. Pallarés, Luis Pallarés, Experimental study on the response of seismically isolated masonry infilled steel frames during the initial stages of a seismic movement, Engineering Structures, Volume 129, 2016, Pages 44-53. [CrossRef]

- Agüero. https://www.mathworks.com/matlabcentral/fileexchange/124570-cyclic-analysis-of-steel-frames-with-masonry-infilled-wall.

- Agüero. https://es.mathworks.com/matlabcentral/fileexchange/125030-concrete-frame-masonry-wall-dynamic-opensees?s_tid=prof_contriblnk.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).