Submitted:

13 February 2025

Posted:

13 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. State of the Art

3. Materials and Methods

- Materials Science Multidisciplinary;

- Engineering Biomedical;

- Engineering Electrical Electronic;

- Engineering Manufacturing;

- Engineering Multidisciplinary;

- Orthopedics;

- Robotics;

- Engineering aerospace;

- Engineering Industrial.

- to provide original content;

- to observe connections and similitudes among the article;

- to guide to specific content the researcher highlighting the novel path in the area;

- to explore the evolution of a certain theme in time.

4. Theoretical Analysis

4.1. Classification after the Generalized Main Objective

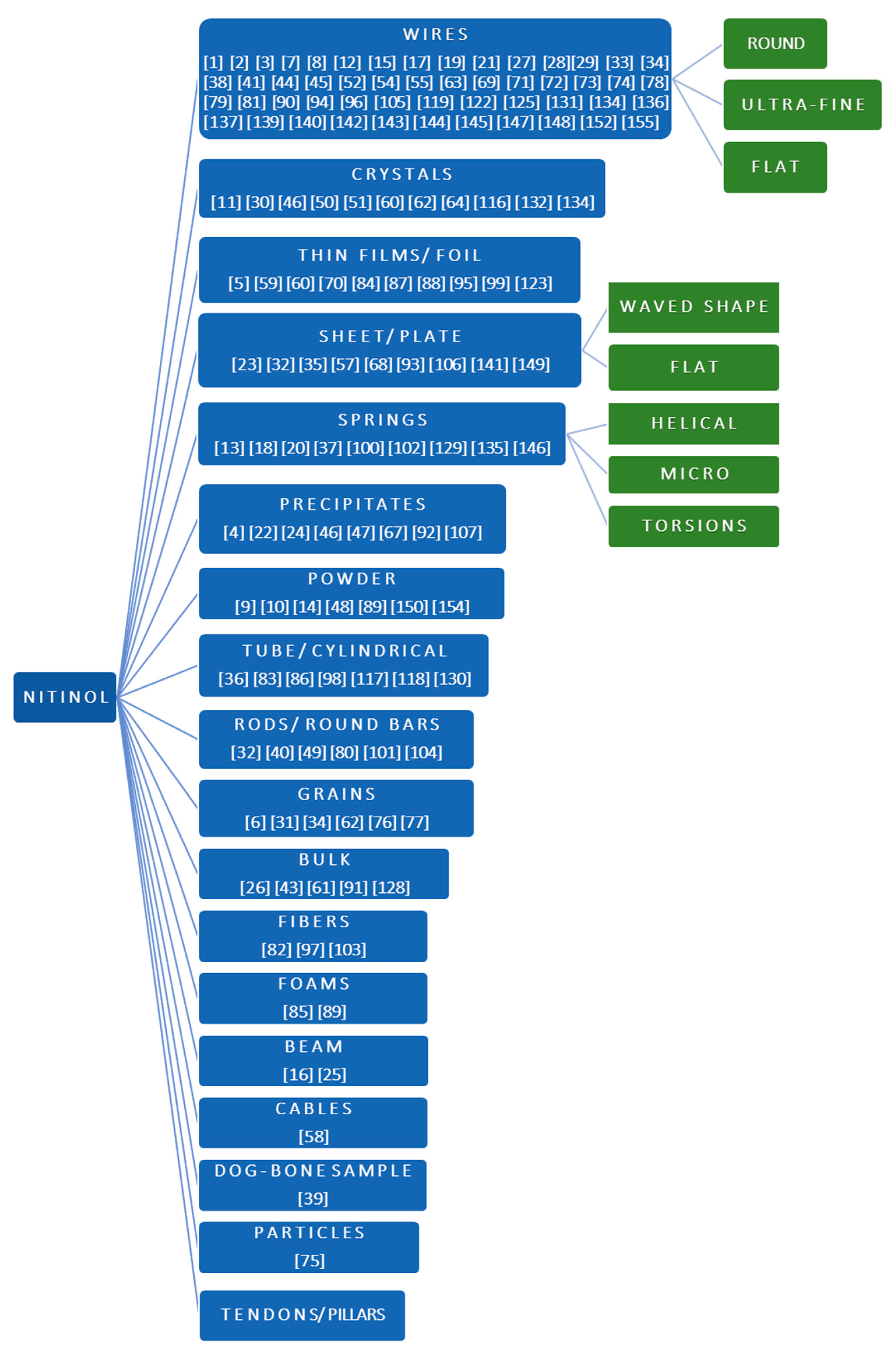

4.2. Classification After the Nitinol form

4.3. Classification After the Application Domain

-

Medical:

- ◾

- Blood pressure sensors on the head of a pin;

- ◾

- Root canal files;

- ◾

- Arches, stents;

- ◾

- Spinal and dental implants;

- ◾

- Vascular stent;

- ◾

- Eyeglass frame;

- ◾

- Micro-stent;

- ◾

- Bone implant;

- ◾

- Orthodontic wires;

- ◾

- Minimally invasive surgical devices;

- ◾

- Robotic needle insertion;

- ◾

- Stents;

- ◾

- Valves;

- ◾

- Muscles.

-

Engineering:

- ◾

- Rotary actuator;

- ◾

- Actuator;

- ◾

- Aerospace gas turbine engines;

- ◾

- Dynamic actuators

- ◾

- Actuators used for helicopter active rotor blade control;

- ◾

- Thermal bimorph actuators;

- ◾

- Sensor-less actuator.

-

Civil Engineering Industry:

- ◾

- High damping materials;

- ◾

- Thin-wall structures;

- ◾

- Grate;

- ◾

- Micro-lattice;

- ◾

- NiTi foil for welding.

-

Robotics:

- ◾

- Artificial muscle;

- ◾

- Micro-actuators;

- ◾

- Bionic manipulator.

-

Automotives:

- ◾

- Actuators;

- ◾

- Motors;

- ◾

- MEMS.

-

Seismology:

- ◾

- Innovative SC brace;

- ◾

- Seismic retrofit applications.

- Constructions: Cement mortar beams.

- Mechanical: Pressure sensors.

5. Bibliometric Simulation Analysis

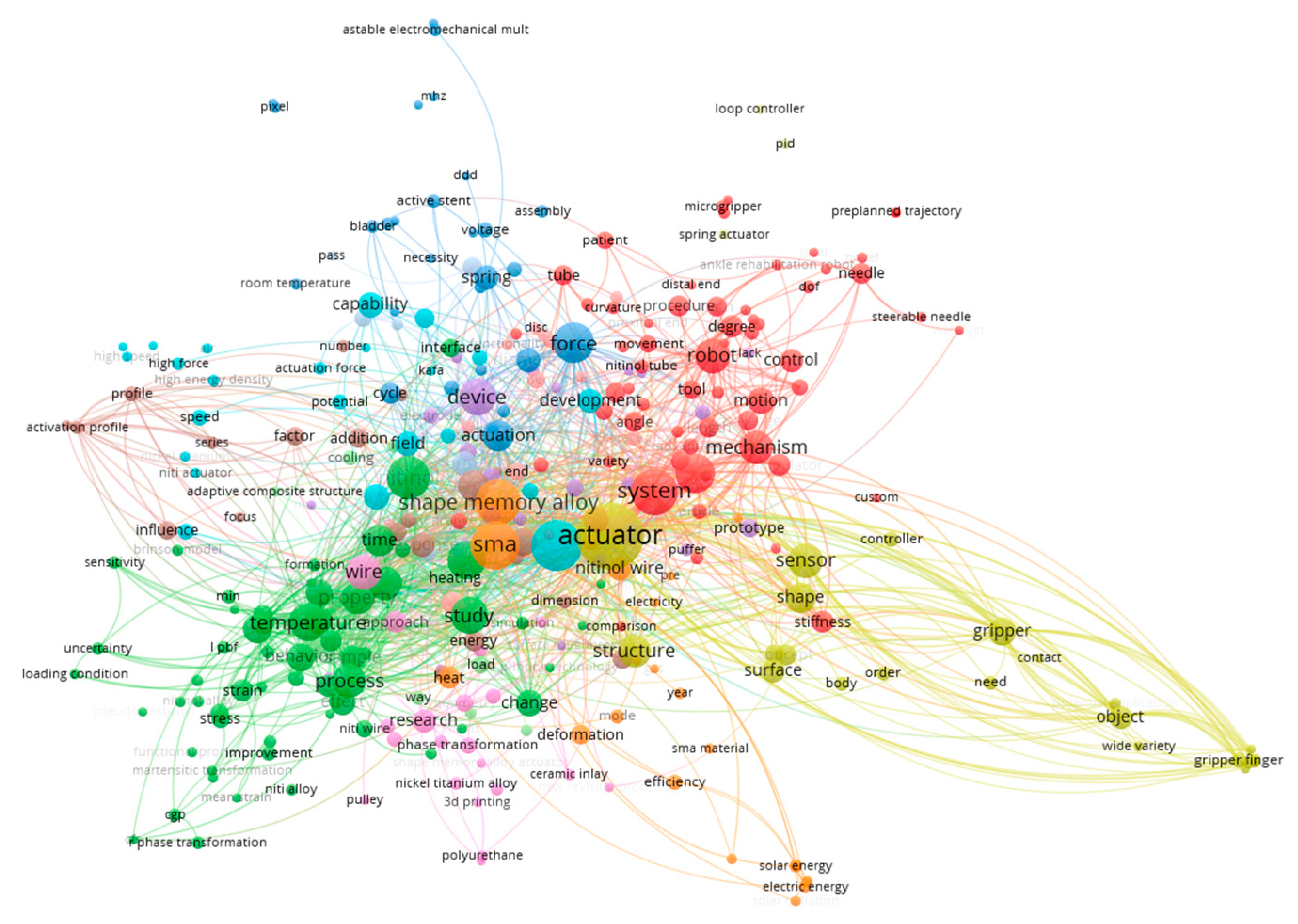

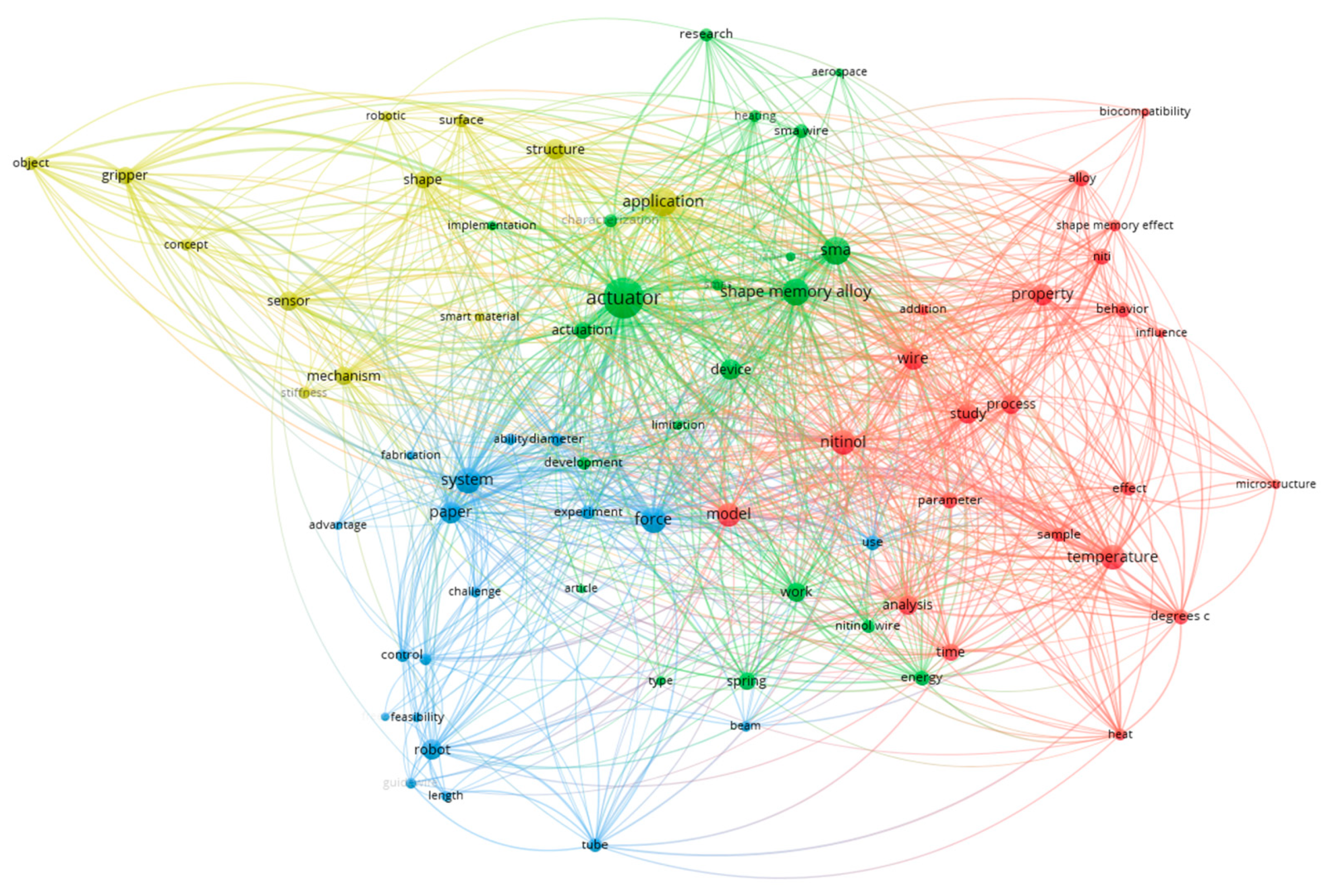

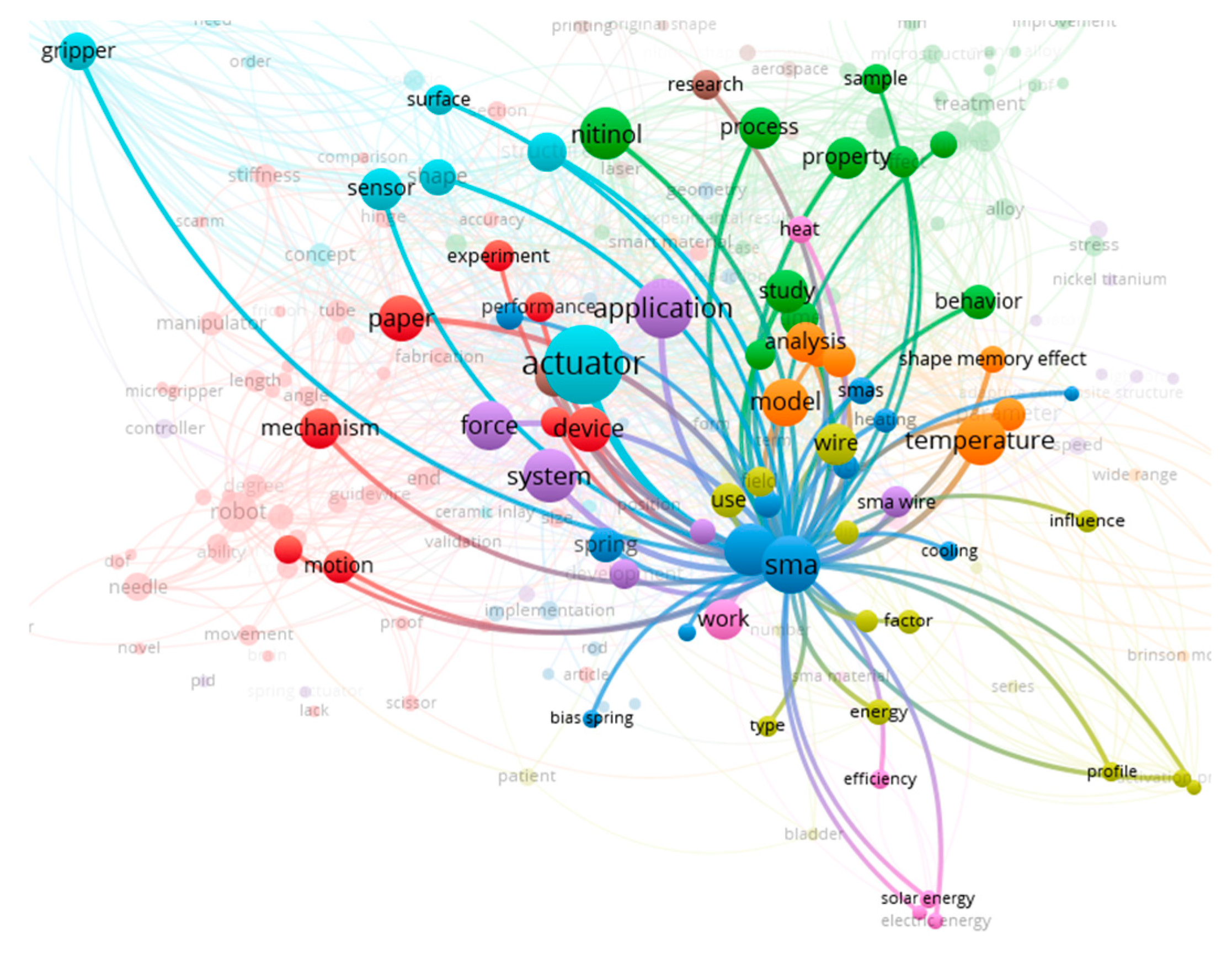

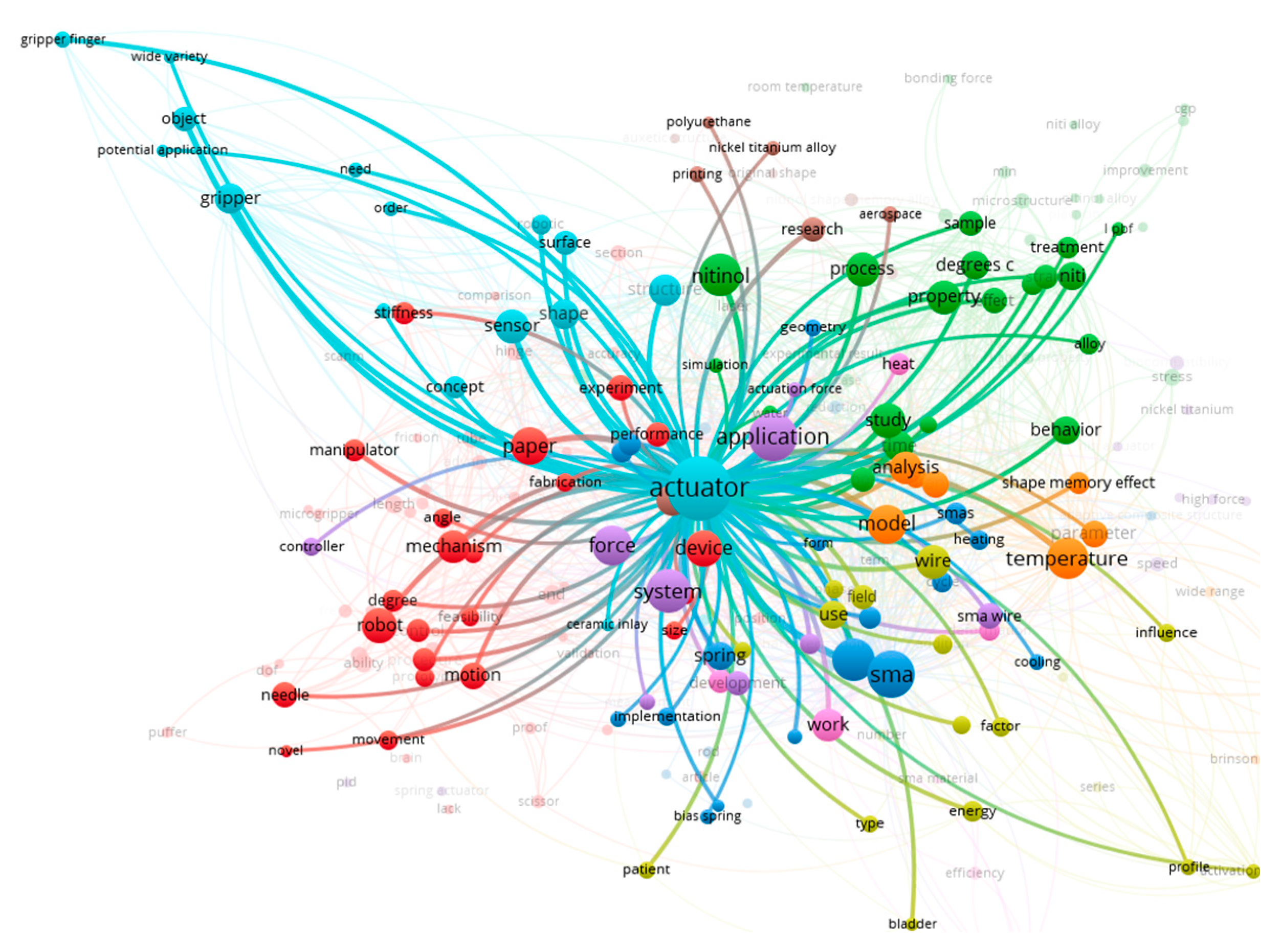

5.1. Network Visualization

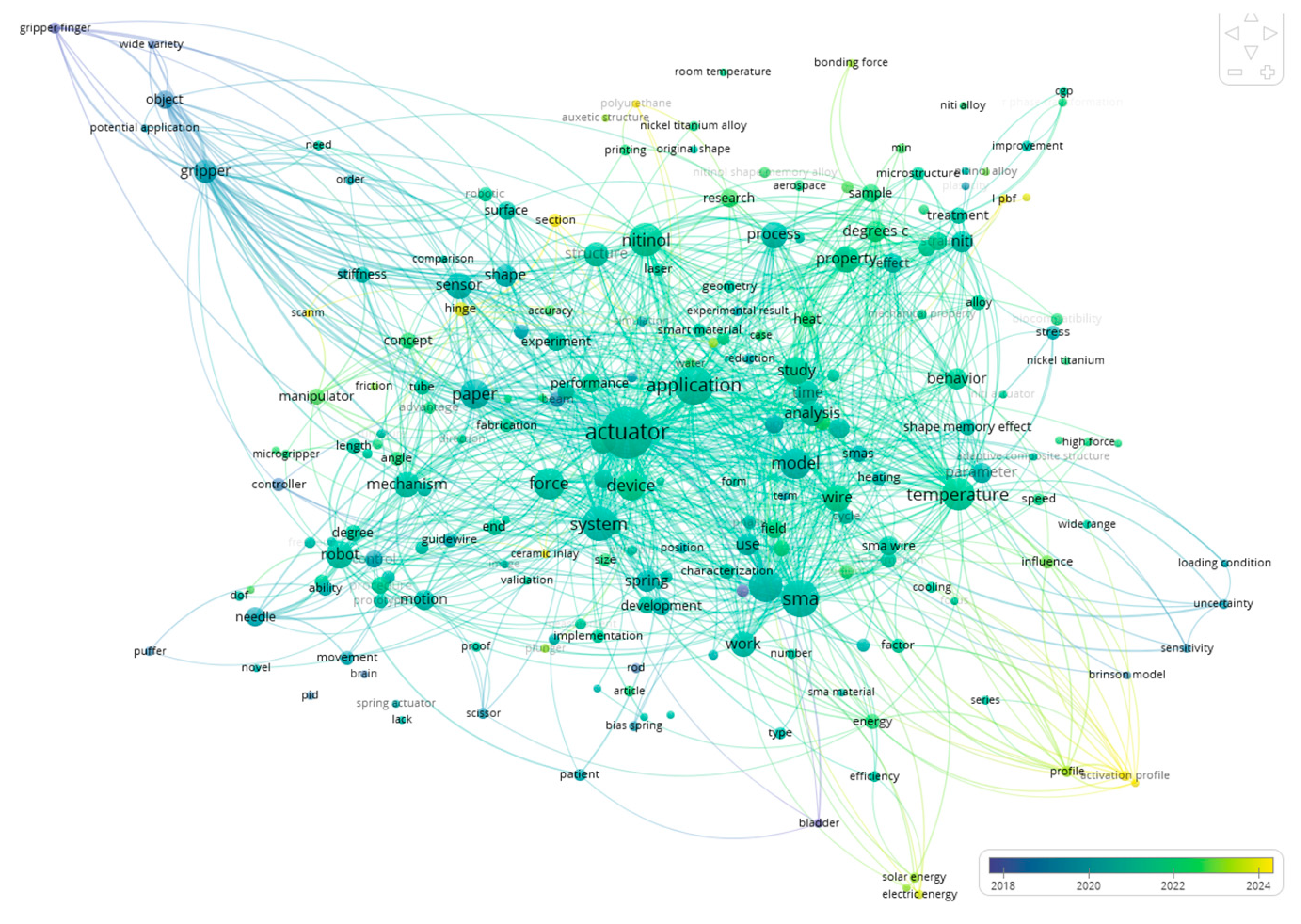

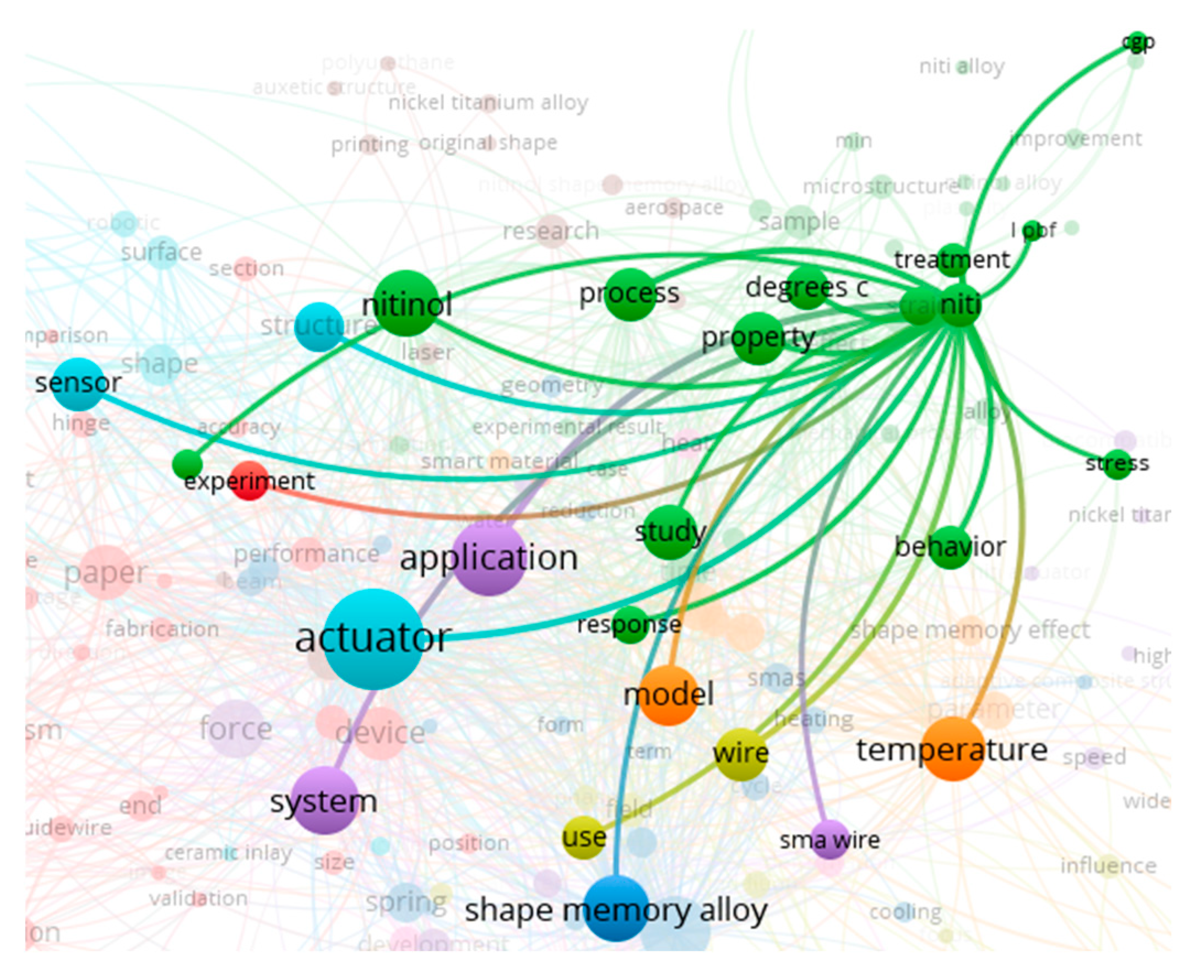

5.2. Temporal Analysis

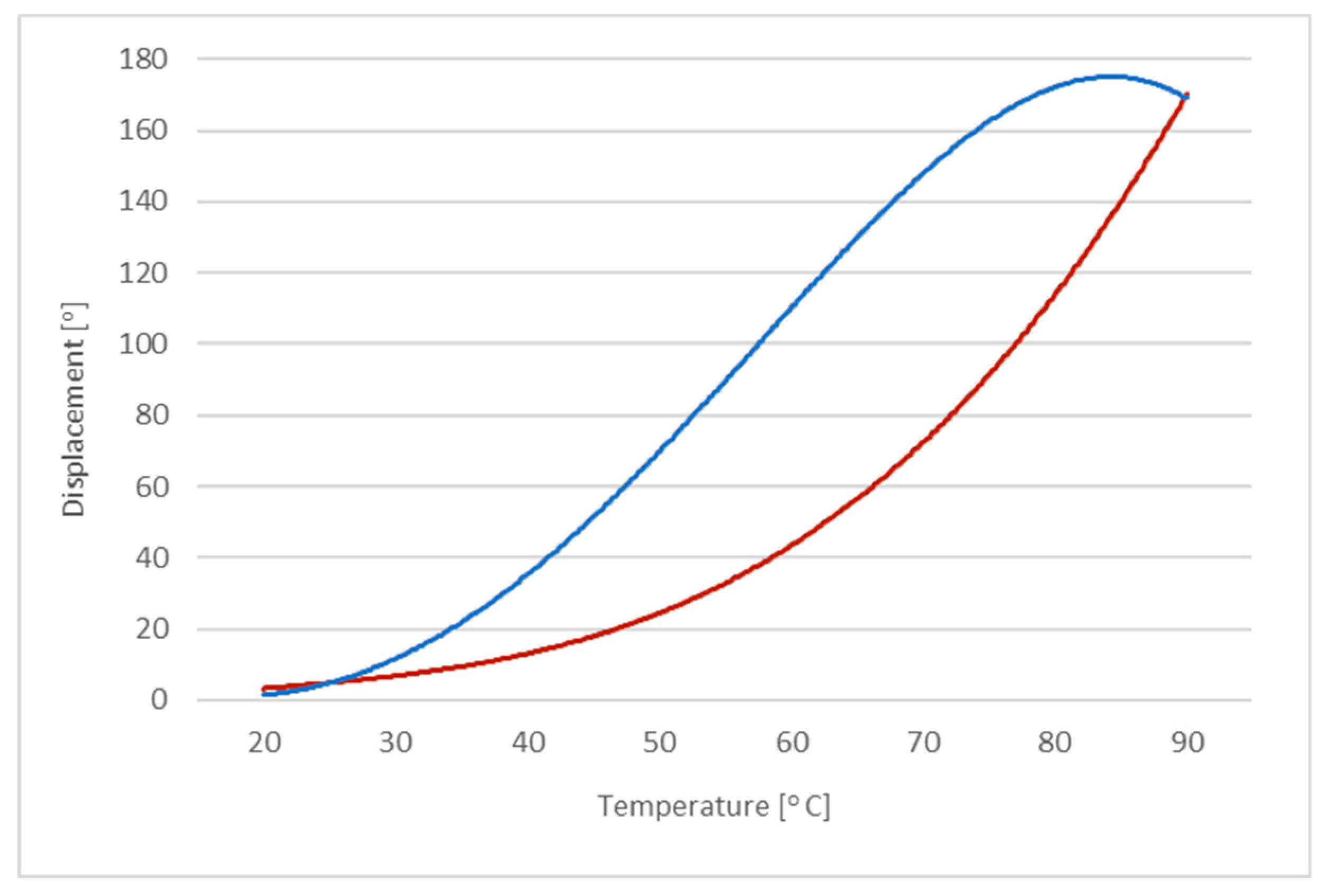

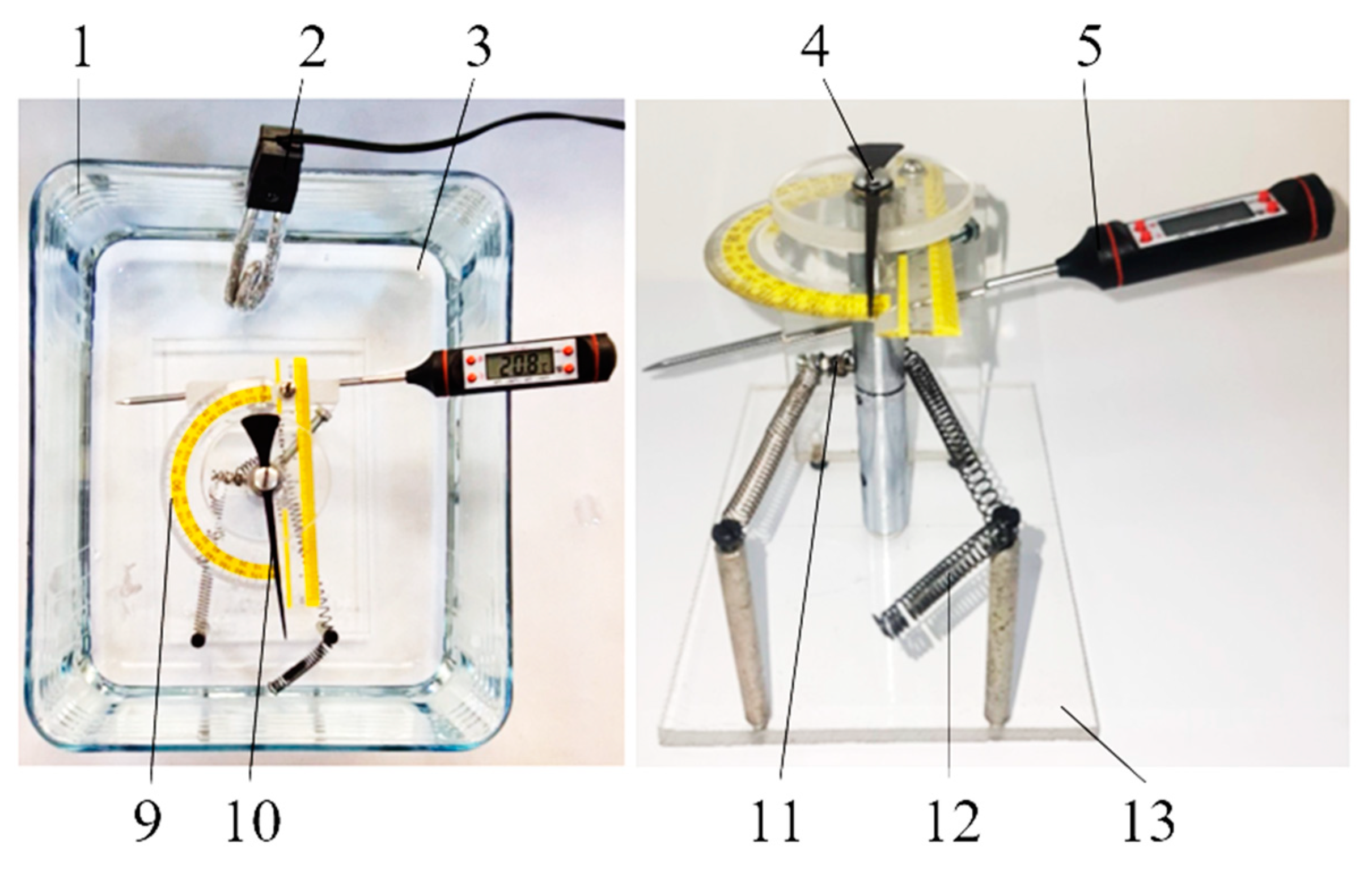

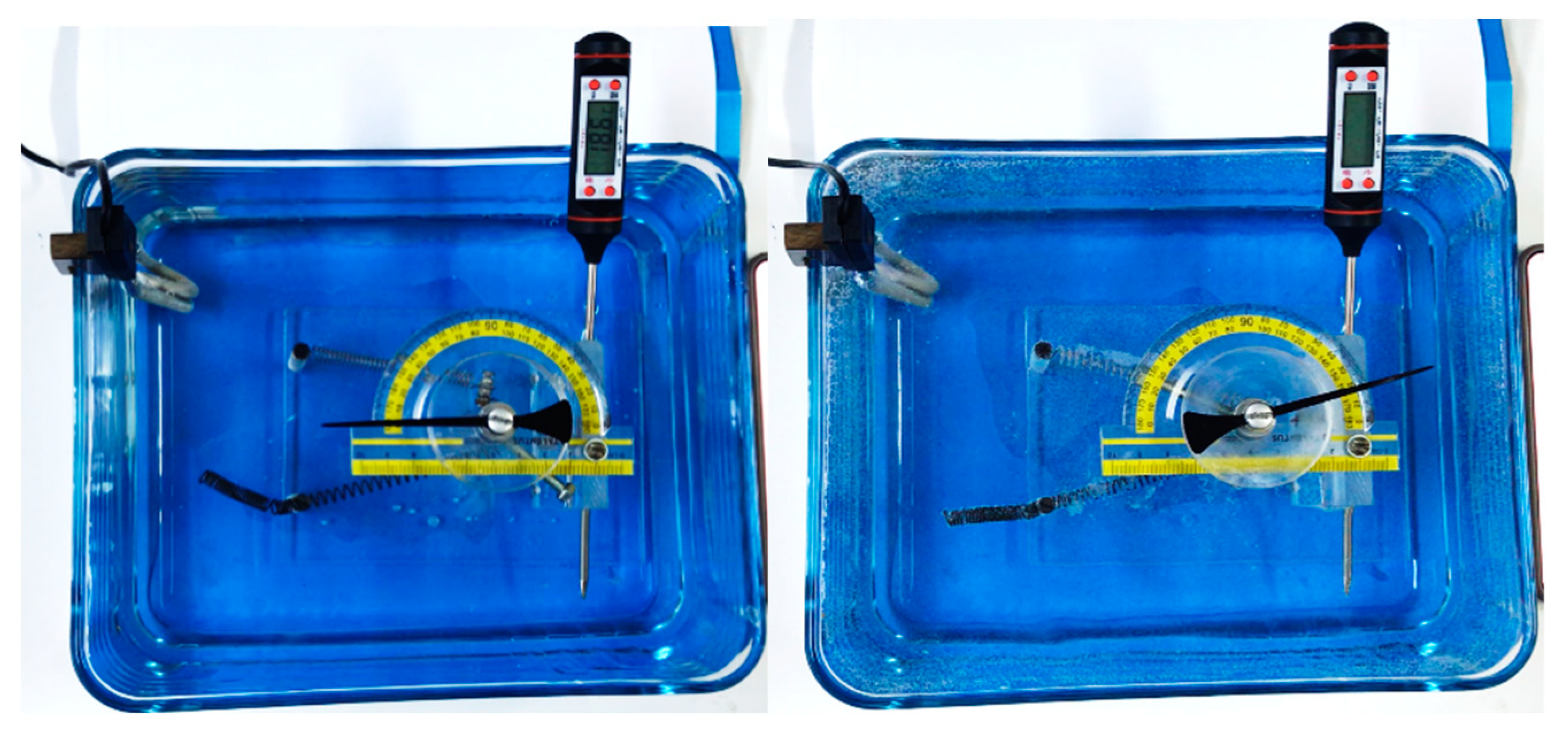

6. Practical Application. Nitinol Spring Angular Actuator

6.1. Methodology

- ♣

- Wire diameter: 1 mm;

- ♣

- Diameter of the coil: 6 mm;

- ♣

- Total length: 76,2 mm;

- ♣

- Stretching capacity: x 4

- ♣

- Transition temperature: 45 ⁰C.

6.2. Constructive Description

6.3. Description of Actuator’s Operation

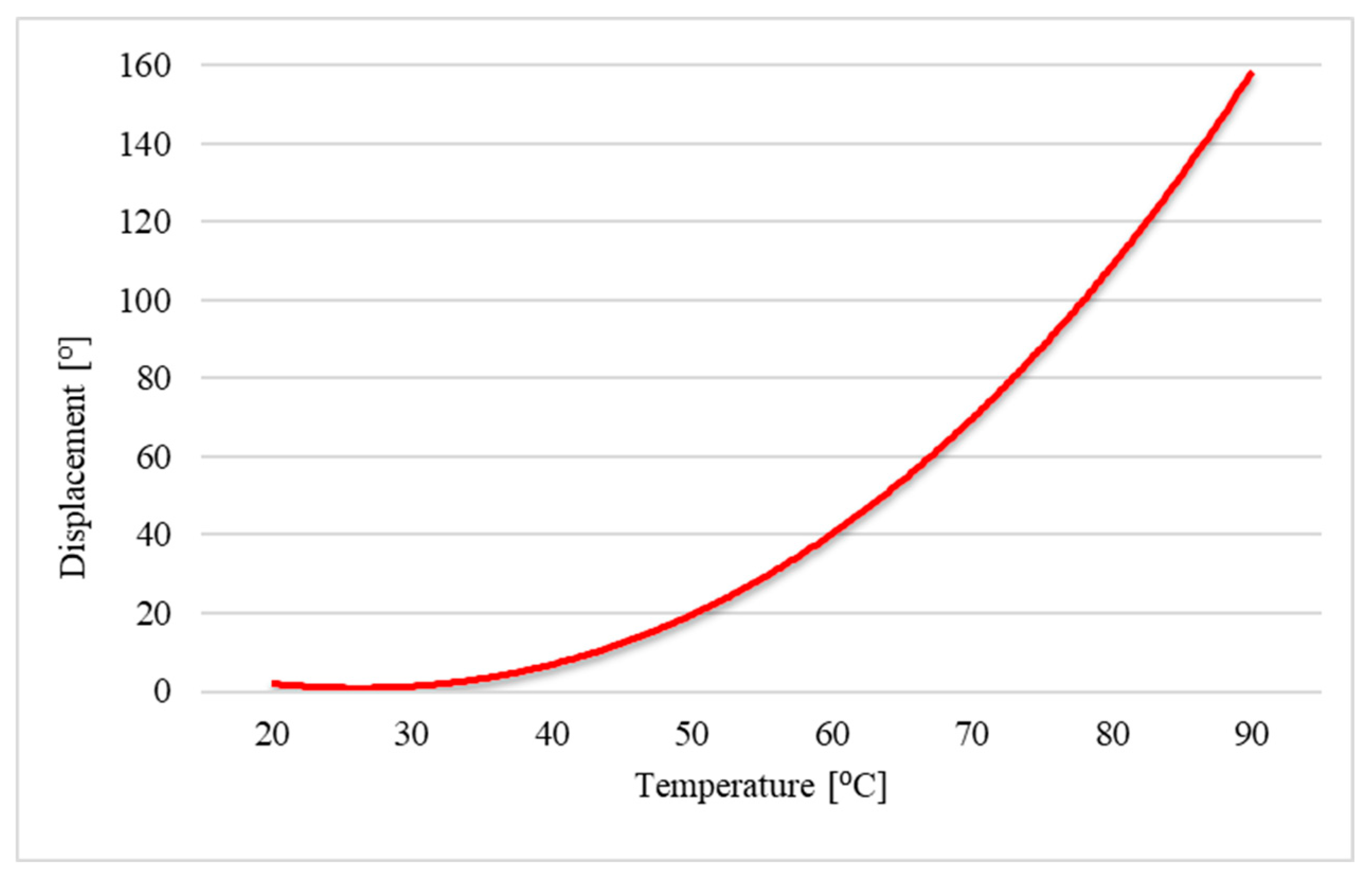

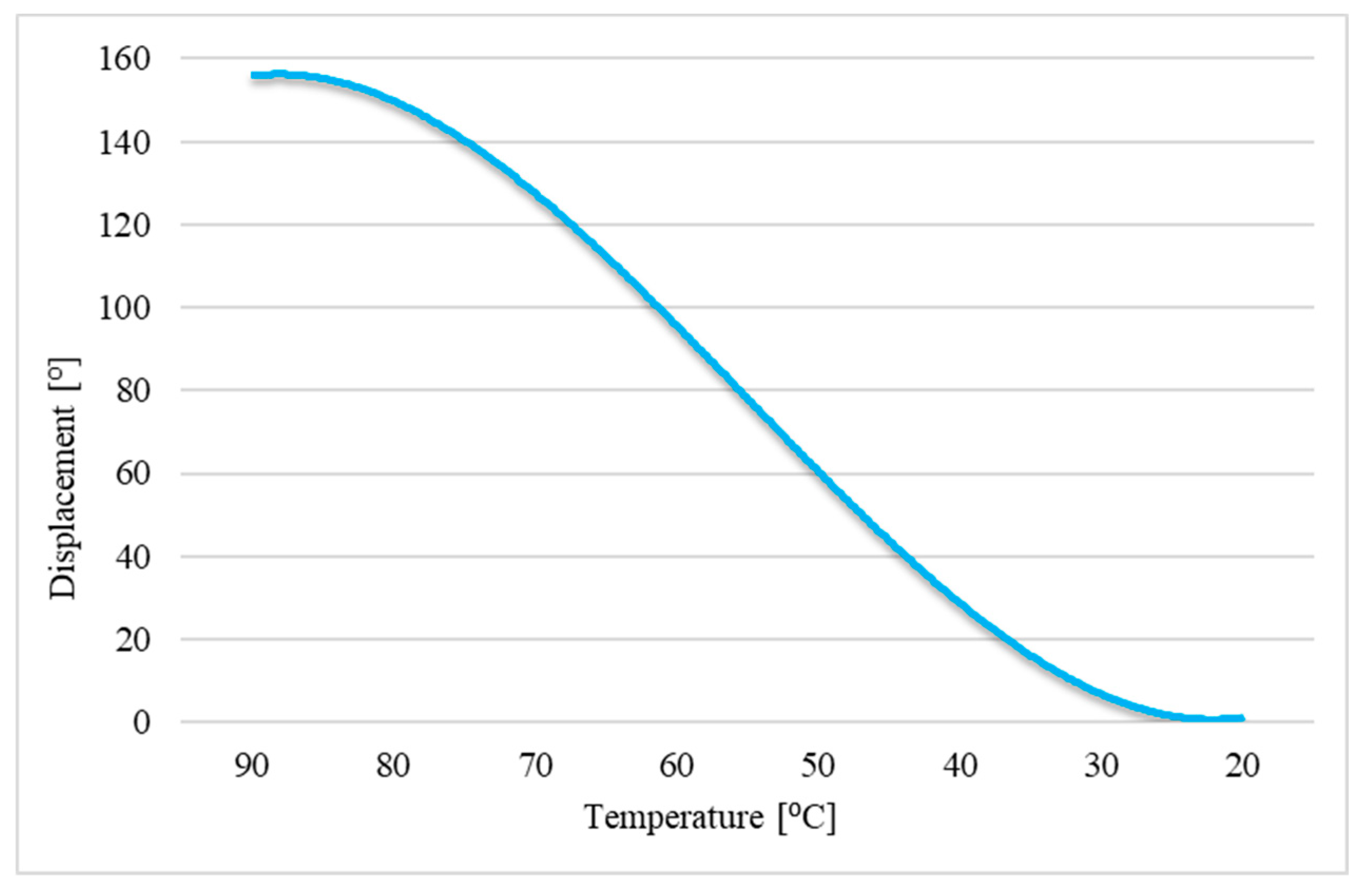

7. Experimental Data Collection

8. Discussions and Conclusions

8. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dezaki, M.L.; Bodaghi, M.; Serjouei, A.; Afazov, S.; Zolfagharian, A. Adaptive reversible composite-based shape memory alloy soft actuators. Sensors Actuators A: Phys. 2022, 345. [Google Scholar] [CrossRef]

- Karimi, S.; Konh, B. Kinematics modelling and dynamics analysis of an SMA-actuated active flexible needle for feedback-controlled manipulation in phantom. Med Eng. Phys. 2022, 107, 103846–103846. [Google Scholar] [CrossRef] [PubMed]

- Chaudhari, R.; Prajapati, P.; Khanna, S.; Vora, J.; Patel, V.K.; Pimenov, D.Y.; Giasin, K. Multi-Response Optimization of Al2O3 Nanopowder-Mixed Wire Electrical Discharge Machining Process Parameters of Nitinol Shape Memory Alloy. Materials 2022, 15, 2018. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, Z.; Li, Y.; Cong, W. Excellent damping properties and their correlations with the microstructures in the NiTi alloys fabricated by laser-directed energy deposition. J. Manuf. Process. 2022, 84, 965–976. [Google Scholar] [CrossRef]

- Sahu, A.; Palani, I.; Singh, V. Investigation on fabrication of NiTi based strain gauge using laser decal transfer based µ-3D printing. Manuf. Lett. 2022, 32, 49–53. [Google Scholar] [CrossRef]

- Cui, Y.; Zeng, X.; Tan, V.B.; Zhang, Z. Experimental and numerical studies of NiTi dynamic fracture behaviors under the impact loading. Int. J. Mech. Sci. 2022, 235. [Google Scholar] [CrossRef]

- Britz, R.; Motzki, P. Analysis and evaluation of bundled SMA actuator wires. Sensors Actuators A: Phys. 2022, 333. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, Y.; Fang, X.; Zhang, H.; Jiao, G.; Li, Y.; Huang, K. Tailoring the superelasticity of NiTi alloy fabricated by directed energy deposition through the variation of residual stress. Mater. Des. 2022, 224. [Google Scholar] [CrossRef]

- Chekotu, J.C.; Kinahan, D.; Goodall, R.; Brabazon, D. Influence of Structural Porosity and Martensite Evolution on Mechanical Characteristics of Nitinol via In-Silico Finite Element Approach. Materials 2022, 15, 5365. [Google Scholar] [CrossRef]

- Kannan, R.R.; Sivabharathy, M.; Lenin, N. Shape memory effect of Cu Al1-nitinol/MWCNT nanocomposites for actuators in MEMS. Sensors Actuators A: Phys. 2021, 334, 113327. [Google Scholar] [CrossRef]

- Liu, S.; Ke, C.; Cao, S.; Ma, X.; Zhao, Z.; Li, Y.; Zhang, X. An atomistic study of self-accommodation martensite morphologies and microstructure evolution during forward and reverse martensitic transformations in single crystal and bicrystal NiTi alloys. Comput. Mater. Sci. 2022, 210. [Google Scholar] [CrossRef]

- Kong, X.; Hao, S.; Ren, Y.; Yang, Y.; Feng, B.; Guo, F.; Yang, Q.; Huang, B.; Cui, L. Interactions between martensitic NiTi shape memory alloy and Nb nanowires in composite wire during tensile deformation. Compos. Part B: Eng. 2022, 234. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Zhu, Y.; Kan, Q.; Kang, G. Thermo-mechanically coupled deformation of pseudoelastic NiTi SMA helical spring. Int. J. Mech. Sci. 2022, 236. [Google Scholar] [CrossRef]

- Safaei, K.; Nematollahi, M.; Bayati, P.; Kordizadeh, F.; Andani, M.T.; Abedi, H.; Poorganji, B.; Elahinia, M. On the crystallographic texture and torsional behavior of NiTi shape memory alloy processed by laser powder bed fusion: Effect of build orientation. Addit. Manuf. 2022, 59. [Google Scholar] [CrossRef]

- Sun, G.; Liu, H.; Liu, W.; Yang, W. Development, simulation, and validation of sliding self-centering steel brace with NiTi SMA wires. Eng. Struct. 2022, 256, 114069. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, X.; Leng, J.; Yan, Z.; Yan, X. Design methodology of the Ni50Ti50 shape memory alloy beam actuator: Heat treatment, training and numerical simulation. Mater. Des. 2022, 217. [Google Scholar] [CrossRef]

- Hau, C.T.; Gouwanda, D.; Gopalai, A.A.; Low, C.Y.; Hanapiah, F.A. Gamification and Control of Nitinol Based Ankle Rehabilitation Robot. Biomimetics 2021, 6, 53. [Google Scholar] [CrossRef]

- Dumitru, C.; Milici, L.D.; Pentiuc, R.D.; Atănăsoae, P.; Ungureanu, C.; Hopulele, E. Experimental Analysis on the Impact of Current on the Strength and Lifespan of a Ni-Ti Element. Appl. Sci. 2022, 12, 3185. [Google Scholar] [CrossRef]

- Pu, Z.; Du, D.; Wang, K.; Liu, G.; Zhang, D.; Zhang, H.; Xi, R.; Wang, X.; Chang, B. Study on the NiTi shape memory alloys in-situ synthesized by dual-wire-feed electron beam additive manufacturing. Addit. Manuf. 2022, 56. [Google Scholar] [CrossRef]

- Wang, J.; Huang, B.; Gu, X.; Zhu, J.; Zhang, W. Actuation performance of machined helical springs from NiTi shape memory alloy. Int. J. Mech. Sci. 2022, 236. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, G.; Miao, H.; Yu, C. Cyclic degeneration of elastocaloric effect for NiTi shape memory alloy: Experimental observation and constitutive model. Int. J. Solids Struct. 2022, 248. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, H.; Yang, H.; Yang, Y.; Liu, Y.; Cui, L.; Li, X.; Masseling, L.; Shen, L.; Hao, S. Micro laser powder bed fusion of NiTi alloys with superior mechanical property and shape recovery function. Addit. Manuf. 2022, 57. [Google Scholar] [CrossRef]

- Li, X.; Cheng, S.; Sun, Q. A compact NiTi elastocaloric air cooler with low force bending actuation. Appl. Therm. Eng. 2022, 215. [Google Scholar] [CrossRef]

- Lu, H.; Ma, H.; Cai, W.; Luo, X.; Qu, S.; Wang, J.; Lupoi, R.; Yin, S.; Yang, C. Altered phase transformation behaviors and enhanced bending shape memory property of NiTi shape memory alloy via selective laser melting. J. Mech. Work. Technol. 2022, 303. [Google Scholar] [CrossRef]

- Gangwar, K.; Jayachandran, S.; Sahu, A.; Singh, A.; Palani, I. Influence of pre-strain on attributes of Ni-rich NiTi/ Kapton polyimide bimorph for flexible mirrors. Sensors Actuators A: Phys. 2022, 341. [Google Scholar] [CrossRef]

- Fazeli, S.; Izadifar, M.; Dolado, J.S.; Ramazani, A.; Sadrnezhaad, S.K. Atomistic study of the effect of crystallographic orientation on the twinning and detwinning behavior of NiTi shape memory alloys. Comput. Mater. Sci. 2022, 203. [Google Scholar] [CrossRef]

- Maimani, F.; Calderón, A.A.; Yang, X.; Rigo, A.; Ge, J.Z.; Pérez-Arancibia, N.O. A 7-mg miniature catalytic-combustion engine for millimeter-scale robotic actuation. Sensors Actuators A: Phys. 2022, 341. [Google Scholar] [CrossRef]

- Rajoriya, S.; Mishra, S.S. Size, length, temperature and loading range effects on deformation response of NiTi SMA wire: an analytical study. Innov. Infrastruct. Solutions 2022, 7, 1–15. [Google Scholar] [CrossRef]

- Jiang, H.M.; Yu, C.; Kan, Q.; Xu, B.; Ma, C.; Kang, G. Effect of hydrogen on super-elastic behavior of NiTi shape memory alloy wires: Experimental observation and diffusional-mechanically coupled constitutive model. J. Mech. Behav. Biomed. Mater. 2022, 132, 105276. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Zhao, G.; Guo, K. Transformation yield surface of nanocrystalline NiTi shape memory alloy. Int. J. Mech. Sci. 2022, 222. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Ojha, M.; Garudapalli, A.; Gupta, A.K. Microstructural, mechanical and strain hardening behaviour of NiTi alloy subjected to constrained groove pressing and ageing treatment. J. Mech. Work. Technol. 2021, 294, 117132. [Google Scholar] [CrossRef]

- McCue, I.D.; Valentino, G.M.; Trigg, D.B.; Lennon, A.M.; Hebert, C.E.; Seker, D.P.; Nimer, S.M.; Mastandrea, J.P.; Trexler, M.M.; Storck, S.M. Controlled shape-morphing metallic components for deployable structures. Mater. Des. 2021, 208, 109935. [Google Scholar] [CrossRef]

- Singh, S.; Resnina, N.; Belyaev, S.; Jinoop, A.; Shukla, A.; Palani, I.; Paul, C.; Bindra, K. Investigations on NiTi shape memory alloy thin wall structures through laser marking assisted wire arc based additive manufacturing. J. Manuf. Process. 2021, 66, 70–80. [Google Scholar] [CrossRef]

- Tyc, O.; Molnárová, O.; Šittner, P. Effect of microstructure on fatigue of superelastic NiTi wires. Int. J. Fatigue 2021, 152, 106400. [Google Scholar] [CrossRef]

- Liu, W.; Sun, G.; Chen, L.; Kong, J. Experimental investigation into NiTi shape memory alloy panels under cyclic shear loading. Eng. Struct. 2021, 245, 112958. [Google Scholar] [CrossRef]

- Safaei, K.; Nematollahi, M.; Bayati, P.; Dabbaghi, H.; Benafan, O.; Elahinia, M. Torsional behavior and microstructure characterization of additively manufactured NiTi shape memory alloy tubes. Eng. Struct. 2021, 226. [Google Scholar] [CrossRef]

- Shayanfard, P.; Heller, L.; Šandera, P.; Šittner, P. Numerical analysis of NiTi actuators with stress risers: The role of bias load and actuation temperature. Eng. Fract. Mech. 2021, 244. [Google Scholar] [CrossRef]

- Eyer, P.; Dittus, J.; Trauth, A.; Coutandin, S.; Fleischer, J.; Weidenmann, K. Improvement of the adhesion in functional NiTi wire/polymer composites made by additive manufacturing. Compos. Struct. 2021, 275. [Google Scholar] [CrossRef]

- Jape, S.; Young, B.; Haghgouyan, B.; Hayrettin, C.; Baxevanis, T.; Lagoudas, D.; Karaman, I. Actuation-Induced stable crack growth in near-equiatomic nickel-titanium shape memory alloys: Experimental and numerical analysis. Int. J. Solids Struct. 2021, 221, 165–179. [Google Scholar] [CrossRef]

- Oliveira, J.; Shen, J.; Escobar, J.; Salvador, C.; Schell, N.; Zhou, N.; Benafan, O. Laser welding of H-phase strengthened Ni-rich NiTi-20Zr high temperature shape memory alloy. Mater. Des. 2021, 202. [Google Scholar] [CrossRef]

- Karna, P.; Prabu, S.S.M.; Karthikeyan, S.; Mithun, R.; Jayachandran, S.; Resnina, N.; Belyaev, S.; Palani, I. Investigations on laser actuation and life cycle characteristics of NiTi shape memory alloy bimorph for non-contact functional applications. Sensors Actuators A: Phys. 2021, 321. [Google Scholar] [CrossRef]

- Cissé, C.; Zaeem, M.A. Design of NiTi-based shape memory microcomposites with enhanced elastocaloric performance by a fully thermomechanical coupled phase-field model. Mater. Des. 2021, 207. [Google Scholar] [CrossRef]

- Ko, W.-S.; Jeon, J.B. Atomistic simulations on orientation dependent martensitic transformation during nanoindentation of NiTi shape-memory alloys. Comput. Mater. Sci. 2021, 187. [Google Scholar] [CrossRef]

- Sedlák, P.; Frost, M.; Ševčík, M.; Seiner, H. 3D spatial reconstruction of macroscopic austenite–martensite transition zones in NiTi wires induced by tension and twisting using diffraction/scattering computed tomography. Int. J. Solids Struct. 2021, 228. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, Z.; Shen, B.; Wu, M.; Yuan, Z.; Wang, C.; Zhang, L. Graded functionality obtained in NiTi shape memory alloy via a repetitive laser processing strategy. J. Mech. Work. Technol. 2021, 296. [Google Scholar] [CrossRef]

- Liu, S.; Lin, Y.; Han, L.; Wang, X.; Zhao, G.; Wang, G. Atomistic simulation of microstructure evolution of NiTi single crystals in bending deformation. Comput. Mater. Sci. 2021, 199. [Google Scholar] [CrossRef]

- Guo, S.; Wu, T.; Kwak, M.; Lu, W.; Ma, W.; Liu, Q.; Liu, H.; Meng, Q.; Liu, G.; Cheng, X.; et al. Achieving a combination of decent biocompatibility and large near-linear-elastic deformation behavior in shell-core-like structural TiNb/NiTi composite. J. Mech. Behav. Biomed. Mater. 2021, 123, 104789. [Google Scholar] [CrossRef]

- Islam, M.; Bayati, P.; Nematollahi, M.; Jahadakbar, A.; Elahinia, M.; Haghshenas, M. Strain rate dependent micromechanical properties of NiTi shape memory alloys: Laser powder bed fusion versus casting. Forces Mech. 2021, 5. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Lavvafi, H.; Dehghanghadikolaei, Darafsheh, A. Chapter 8 - Laser welding of nickel-titanium (Ni-Ti) shape memory alloys, Editor(s): J. Paulo Davim, Kapil Gupta, Kapil Gupta, J. Paulo Davim, In Handbooks in Advanced Manufacturing, Advanced Welding and Deforming 2021, Elsevier, Pages 203-230.

- Lv, C.; Wang, G.; Zhang, X.; Luo, B.; Luo, N.; Wu, F.; Wu, H.-A.; Tan, F.; Zhao, J.; Liu, C.; et al. Spalling modes and mechanisms of shocked nanocrystalline NiTi at different loadings and temperatures. Mech. Mater. 2021, 161. [Google Scholar] [CrossRef]

- Owusu-Danquah, J.; Saleeb, A.; Soudah, M. Cyclic pseudoelastic training and two-way shape memory behavior of a NiTi alloy with small irrecoverable plastic strains:numerical modeling. Int. J. Solids Struct. 2021, 217-218, 178–192. [Google Scholar] [CrossRef]

- Varughese, K.; El-Hacha, R. Experimental free vibrations test of steel braced frames reinforced with NiTi shape memory alloy wires. Structures 2021, 29, 1165–1172. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, H.; Chen, Y.; Liu, Q.; Wu, R.; Ma, W.; Liu, H.; Meng, Q.; Liu, G.; Cheng, X.; et al. A sandwich-structured Nb/NiTi composite with good bio-compatibility, near-linear-elastic deformation and large elastic admissible strain. Compos. Part B: Eng. 2021, 207. [Google Scholar] [CrossRef]

- Marandi, L.; Sen, I. In-vitro mechanical behavior and high cycle fatigue characteristics of NiTi-based shape memory alloy wire. Int. J. Fatigue 2021, 148. [Google Scholar] [CrossRef]

- Khan, S.; Pydi, Y.S.; Prabu, S.M.; Palani, I.; Singh, P. Development and actuation analysis of shape memory alloy reinforced composite fin for aerodynamic application. Sensors Actuators A: Phys. 2021, 331. [Google Scholar] [CrossRef]

- Sibirev, A.; Belyaev, S.; Resnina, N. The influence of counter-body stiffness on working parameters of NiTi actuator. Sensors Actuators A: Phys. 2021, 319. [Google Scholar] [CrossRef]

- LePage, W.S.; Shaw, J.A.; Daly, S.H. Effects of texture on the functional and structural fatigue of a NiTi shape memory alloy. Int. J. Solids Struct. 2021, 221, 150–164. [Google Scholar] [CrossRef]

- Chen, J.; Fang, C.; Wang, W.; Liu, Y. Variable-friction self-centering energy-dissipation braces (VF-SCEDBs) with NiTi SMA cables for seismic resilience. J. Constr. Steel Res. 2020, 175. [Google Scholar] [CrossRef]

- Cavaleiro, A.J.; Ramos, A.S.; Fernandes, F.M.B.; Schell, N.; Vieira, M.T. Follow-up structural evolution of Ni/Ti reactive nano and microlayers during diffusion bonding of NiTi to Ti6Al4V in a synchrotron beamline. J. Mater. Process. Technol. 2020, 275, 116354. [Google Scholar] [CrossRef]

- Zhao, W.; Lin, P.; Lin, T.; He, P.; Liu, Y.; Long, W.; Li, J. Low temperature joining of NiTi shape memory alloy with Au-Si isothermal solidification. J. Manuf. Process. 2020, 58, 1034–1038. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, H.; Huang, Y.; Ye, X.; Li, J.; Zhang, C.; Li, H.; Pang, B.; Tian, Y.; Huang, C.; et al. Strain rate dependent mechanical response for monoclinic NiTi shape memory alloy: Micromechanical decomposition and model validation via neutron diffraction. Mater. Des. 2020, 191. [Google Scholar] [CrossRef]

- Zhou, T.; Yu, C.; Kang, G.; Kan, Q.; Fang, D. A crystal plasticity based constitutive model accounting for R phase and two-step phase transition of polycrystalline NiTi shape memory alloys. Int. J. Solids Struct. 2020, 193-194, 503–526. [Google Scholar] [CrossRef]

- Varughese, K.; El-Hacha, R. Design and behaviour of steel braced frame reinforced with NiTi SMA wires. Eng. Struct. 2020, 212. [Google Scholar] [CrossRef]

- Xie, X.; Kang, G.; Kan, Q.; Yu, C. Phase-field theory based finite element simulation on thermo-mechanical cyclic deformation of polycrystalline super-elastic NiTi shape memory alloy. Comput. Mater. Sci. 2020, 184. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Liu, J.; Chen, L.; Yang, Q.; Wei, H.; Sun, J.; Wang, Z.; Zhang, Z.; Zhao, G.; et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting. Addit. Manuf. 2020, 36, 101545. [Google Scholar] [CrossRef]

- Lu, B.; Cui, X.; Jin, G.; Dong, M.; Fang, Y.; Wen, X.; Ma, W. Effect of La2O3 addition on mechanical properties and wear behaviour of NiTi alloy fabricated by direct metal deposition. Opt. Laser Technol. 2020, 129. [Google Scholar] [CrossRef]

- Fu, J.; Hu, Z.; Song, X.; Zhai, W.; Long, Y.; Li, H.; Fu, M. Micro selective laser melting of NiTi shape memory alloy: Defects, microstructures and thermal/mechanical properties. Opt. Laser Technol. 2020, 131. [Google Scholar] [CrossRef]

- Ao, S.; Li, K.; Liu, W.; Qin, X.; Wang, T.; Dai, Y.; Luo, Z. Electrochemical micromachining of NiTi shape memory alloy with ethylene glycol–NaCl electrolyte containing ethanol. J. Manuf. Process. 2020, 53, 223–228. [Google Scholar] [CrossRef]

- Belyaev, S.; Resnina, N.; Rakhimov, T.; Andreev, V. Martensite stabilisation effect in Ni-rich NiTi shape memory alloy with different structure and martensitic transformations. Sensors Actuators A: Phys. 2020, 305. [Google Scholar] [CrossRef]

- Askari-Naeini, F.G.; Taghizadeh, M.; Mohri, M.; Nili-Ahmadabadi, M. On the microstructure and mechanical properties of a two-way shape memory NiTi/NiTiCu bi-layer diaphragm. Mater. Des. 2020, 188, 108464. [Google Scholar] [CrossRef]

- Racek, J.; Šittner, P. Environmental fatigue of superelastic NiTi wire with two surface finishes. J. Mech. Behav. Biomed. Mater. 2020, 111, 104028. [Google Scholar] [CrossRef]

- Ruvinov, I.; Zamani, N.; Zhou, N.Y.; Khan, M.I. Novel laser processed shape memory alloy actuator design with an embedded strain gauge sensor using dual resistance measurements. Part II: Recurrent neural network-based position and force estimation. Sensors Actuators A: Phys. 2020, 313, 112188. [Google Scholar] [CrossRef]

- Rodrigues, P.F.; Fernandes, F.B.; Magalhães, R.; Camacho, E.; Lopes, A.; Paula, A.; Basu, R.; Schell, N. Thermo-mechanical characterization of NiTi orthodontic archwires with graded actuating forces. J. Mech. Behav. Biomed. Mater. 2020, 107, 103747. [Google Scholar] [CrossRef] [PubMed]

- Barros, C.D.d.R.; Gomes, J.A.d.C.P. Strain induced localized corrosion of NiTi, NiTiCo and NiTiCr alloys in 0.9% NaCl. J. Mech. Behav. Biomed. Mater. 2020, 112, 104015. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, J.; Guo, K.; Sivalingam, V.; Sun, J. Study on chip formation characteristics in turning NiTi shape memory alloys. J. Manuf. Process. 2020, 58, 787–795. [Google Scholar] [CrossRef]

- Polatidis, E.; Šmíd, M.; Kuběna, I.; Hsu, W.-N.; Laplanche, G.; Van Swygenhoven, H. Deformation mechanisms in a superelastic NiTi alloy: An in-situ high resolution digital image correlation study. Mater. Des. 2020, 191. [Google Scholar] [CrossRef]

- Ebrahimi, P.; Arghavani, J.; Naghdabadi, R.; McGarry, J.P. On the effect of detwinning-induced plasticity in compressive cyclic loading of NiTi shape memory alloys. Mech. Mater. 2020, 148, 103451. [Google Scholar] [CrossRef]

- Zeng, Z.; Oliveira, J.; Ao, S.; Zhang, W.; Cui, J.; Yan, S.; Peng, B. Fabrication and characterization of a novel bionic manipulator using a laser processed NiTi shape memory alloy. Opt. Laser Technol. 2020, 122. [Google Scholar] [CrossRef]

- Schuleit, M.; Theren, B.; Maack, P.; Kuhlenkötter, B.; Esen, C. Investigation of minimal strokes of NiTi shape memory wires using laser activation. Procedia CIRP 2020, 94, 542–545. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, I. Tool wear progression of PCD and PCBN cutting tools in high speed machining of NiTi shape memory alloy under various cutting speeds. Diam. Relat. Mater. 2020, 105, 107810. [Google Scholar] [CrossRef]

- Schuleit, M.; Becher, M.; Franke, F.; Maaß, B.; Esen, C. Development of form-fit connection for NiTi shape memory wire actuators using laser processing. Procedia CIRP 2020, 94, 546–550. [Google Scholar] [CrossRef]

- Mingear, J.; Zhang, B.; Hartl, D.; Elwany, A. Effect of process parameters and electropolishing on the surface roughness of interior channels in additively manufactured nickel-titanium shape memory alloy actuators. Addit. Manuf. 2019, 27, 565–575. [Google Scholar] [CrossRef]

- Wassel, E.; Dietze, M.; Laghrissi, A.; Klöhn, F.; Weyrich, T.; Es-Souni, M. Processing of nanotubes on NiTi-shape memory alloys and their modification with photografted anti-adhesive polymer brushes. Towards smart implant surfaces. Mater. Des. 2019, 182. [Google Scholar] [CrossRef]

- Lin, H.-C.; Chang, Y.-L.; Han, Y.-Y.; Yang, K.-C.; Chen, M.-C. Atomic Layer Deposited Al2O3 Films on NiTi Shape Memory Alloys for Biomedical Applications. Procedia Manuf. 2019, 37, 431–437. [Google Scholar] [CrossRef]

- A. , T.; N., M.; G., M.; J., M.; Th., B.; D., L. A numerical study of “functional fatigue” of closed-cell NiTi shape memory foams. Mech. Mater. 2019, 131, 11–21. [Google Scholar] [CrossRef]

- Dhala, S.; Mishra, S.; Tewari, A.; Alankar, A. Modeling of finite deformation of pseudoelastic NiTi shape memory alloy considering various inelasticity mechanisms. International Journal of Plasticity 2018, 115, 216–237. [Google Scholar] [CrossRef]

- Jayachandran, S.; Akash, K.; Prabu, S.M.; Manikandan, M.; Muralidharan, M.; Brolin, A.; Palani, I. Investigations on performance viability of NiTi, NiTiCu, CuAlNi and CuAlNiMn shape memory alloy/Kapton composite thin film for actuator application. Compos. Part B: Eng. 2019, 176. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Zhang, C.; Luo, J. Preparation of self-lubricating NiTi alloy and its self-adaptive behavior. Tribol. Int. 2019, 130, 43–51. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, L. Processing and damping capacity of NiTi foams with laminated pore architecture. J. Mech. Behav. Biomed. Mater. 2019, 96, 108–117. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Costanza, G.; Tata, M.E. Shape Memory Activated Self-Deployable Solar Sails: Small-Scale Prototypes Manufacturing and Planarity Analysis by 3D Laser Scanner. Actuators 2019, 8, 38. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Xiao, B.; Zheng, Q.; Gao, Y.; Zhao, S.; Wang, Z. First-principles calculation on the adhesion strength, fracture mechanism, interfacial bonding of the NiTi (111)//α-Al2O3 (0001) interfaces. Mater. Des. 2019, 183. [Google Scholar] [CrossRef]

- Panton, B.; Michael, A.; Zhou, Y.; Khan, M. Effects of post-processing on the thermomechanical fatigue properties of laser modified NiTi. Int. J. Fatigue 2019, 118, 307–315. [Google Scholar] [CrossRef]

- Lesota, A.; Sibirev, A.; Rubanik, V.; Resnina, N.; Belyaev, S. Initiation of the shape memory effect by temperature variation or ultrasonic vibrations in the NiTi shape memory alloy after different preliminary deformation. Sensors Actuators A: Phys. 2019, 286, 1–3. [Google Scholar] [CrossRef]

- Chen, Y.; Tyc, O.; Kadeřávek, L.; Molnárová, O.; Heller, L.; Šittner, P. Temperature and microstructure dependence of localized tensile deformation of superelastic NiTi wires. Mater. Des. 2019, 174. [Google Scholar] [CrossRef]

- Knick, C.R.; Smith, G.L.; Morris, C.J.; Bruck, H.A. Rapid and low power laser actuation of sputter-deposited NiTi shape memory alloy (SMA) MEMS thermal bimorph actuators. Sensors Actuators A: Phys. 2019, 291, 48–57. [Google Scholar] [CrossRef]

- Heller, L.; Šittner, P.; Sedlák, P.; Seiner, H.; Tyc, O.; Kadeřávek, L.; Sedmák, P.; Vronka, M. Beyond the strain recoverability of martensitic transformation in NiTi. Int. J. Plast. 2019, 116, 232–264. [Google Scholar] [CrossRef]

- Fazeli, S.; Sadrnezhaad, S.K. Molecular dynamics simulation of plastic deformation and interfacial delamination of NiTi/Ag bilayer by cyclic-nanoindentation: Effects of crystallographic orientation of substrate. Comput. Mater. Sci. 2019, 168, 229–245. [Google Scholar] [CrossRef]

- Ponikarova, I.; Belyaev, S.; Resnina, N. Degradation of two-way shape memory effect due to the relaxation of internal oriented stress in NiTi alloy on holding at 640÷700 K. Mech. Mater. 2019, 138, 103174. [Google Scholar] [CrossRef]

- Ainslie, K.; Knick, C.; Smith, G.; Li, J.; Troxel, C.; Mehta, A.; Kukreja, R. Controlling shape memory effects in NiTi thin films grown on Ru seed layer. Sensors Actuators A: Phys. 2019, 294, 133–139. [Google Scholar] [CrossRef]

- Gédouin, P.-A.; Pino, L.; Chirani, S.A.; Calloch, S.; Delaleau, E.; Bourgeot, J.-M. R-phase shape memory alloy helical spring based actuators: Modeling and experiments. Sensors Actuators A: Phys. 2019, 289, 65–76. [Google Scholar] [CrossRef]

- . Prabu, S.M.; Perugu, C.S.; H.C., M.; Jangde, A.; Khan, S.; Jayachandran, S.; Manikandan, M.; Kumar, P.A.; Kailas, S.V.; Palani, I. Exploring the functional and corrosion behavior of friction stir welded NiTi shape memory alloy. J. Manuf. Process. 2019, 47, 119–128. [Google Scholar] [CrossRef]

- Cernusca, D.; Milici, D.L.; Poienar, M. Development of special actuators using smart materials. 2016 International Conference and Exposition on Electrical and Power Engineering (EPE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 567–570.

- Lee, K.-J.; Lee, J.-H.; Jung, C.-Y.; Choi, E. Crack-closing performance of NiTi and NiTiNb fibers in cement mortar beams using shape memory effects. Compos. Struct. 2018, 202, 710–718. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Elahinia, M. Laser welding of NiTi shape memory alloy: A review. J. Manuf. Process. 2018, 31, 162–186. [Google Scholar] [CrossRef]

- Ammar, O.; Dieng, L.; Haddar, N. Modeling of strain rate effect on the pseudoelastic behavior of NiTi SMA using a simple thermomechanical coupling model. Mech. Mater. 2018, 124, 7–17. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Brotzu, A.; Natali, S. Laser welding of NiTi shape memory sheets using a diode laser. Opt. Laser Technol. 2018, 108, 142–149. [Google Scholar] [CrossRef]

- Solomou, A.; Zhao, G.; Boluki, S.; Joy, J.K.; Qian, X.; Karaman, I.; Arróyave, R.; Lagoudas, D.C. Multi-objective Bayesian materials discovery: Application on the discovery of precipitation strengthened NiTi shape memory alloys through micromechanical modeling. Materials & Design 2018, 160, 810–827. [Google Scholar] [CrossRef]

- Toader, V.E.; Milici, L.D.; Ungureanu, C.; Bejenar, C.; Grosu, O.V. Analysis of a Low-Speed Drive System Using Intelligent Materials. Actuators 2021, 11, 10. [Google Scholar] [CrossRef]

- Toader, V.E.; Poienar, M.; Cernușcă, D. ; Study of smart materials used in the development of new types of electro and thermomechanical actuators, Conferinţa tehnico-ştiinţifică a studenţilor, masteranzilor şi doctoranzilor 2019, Pages 134-137, Moldova.

- Romanescu, A.N.; Poienar, M.; Cenusa, M.; Nitan, I. Performance analysis of a linear heliothermic actuator. 2017 International Conference on Modern Power Systems (MPS). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 1–4.

- Cernusca, D.; Milici, L.D.; Poienar, M. Researches on the Realization of a Electromechanical Micropump. 2018 International Conference and Exposition on Electrical And Power Engineering (EPE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 0270–0273.

- Cernusca, D.; Milici, D.L.; Ungureanu, C. Theoretical and experimental contribution of using special actuators and materials with shape memory. 2016 International Conference and Exposition on Electrical and Power Engineering (EPE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 171–174.

- Cernusca, D.; Milici, D.L.; Pentiuc, R.D.; Hopulele, E. Research on the Realization of a Nitinol Clutch Type Thermocouple. 2020 International Conference and Exposition on Electrical And Power Engineering (EPE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 078–081.

- Toader, V.E.; Bejenar, C.; Paval, M.; Cernusca, D.; Grosu, O.V. Considerations Regarding a Nitinol (Ni-Ti)-operated Micropump. 2021 International Conference on Applied and Theoretical Electricity (ICATE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 1–4.

- Cernusca, D.; Milici, D.L.; Paval, M.; Hopulele, E.; Toader, E.V.; Cernusca, P. Design, Implementation and Testing of a Locking System. 2021 International Conference on Applied and Theoretical Electricity (ICATE). LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE; pp. 1–4.

- Wu, Z.; Liu, B.; Wei, J.; Yang, Y.; Zhang, X.; Deng, J. Design of Porous Shape Memory Alloys with Small Mechanical Hysteresis. Crystals 2022, 13, 34. [Google Scholar] [CrossRef]

- Khan, L.A.; McCarthy, E.; Muilwijk, C.; Ahad, I.U.; Brabazon, D. Analysis of nitinol actuator response under controlled conductive heating regimes. Results Eng. 2023, 18. [Google Scholar] [CrossRef]

- Sibirev, A.V.; Belyaev, S.P.; Resnina, N.N. Influence of temperature range on NiTi SMA actuator performance during thermal cycling, Material Science 2023, 13, 3. [CrossRef]

- Singh, S.; Palani, I.; Dehgahi, S.; Paul, C.; Prashanth, K.; Qureshi, A. Influence of the interlayer temperature on structure and properties of CMT wire arc additive manufactured NiTi structures. J. Alloy. Compd. 2023, 966. [Google Scholar] [CrossRef]

- Sibirev, A.; Belyaev, S.; Resnina, N. Improvement of the NiTi actuator performance stability by decreasing its operating temperature range. Sensors Actuators A: Phys. 2023, 363. [Google Scholar] [CrossRef]

- Fuaad, M.R.A.; Hasan, M.N.; Asri, M.I.A.; Ali, M.S.M. Microactuators technologies for biomedical applications. Microsyst. Technol. 2023, 29, 953–984. [Google Scholar] [CrossRef]

- Chen, P.; Liu, Y.; Min, N.; Wang, M.; Cai, X.; Jin, M.; Jin, X. Enhanced two way shape memory effect in nanocrystalline NiTi shape memory alloy wires. Scr. Mater. 2023, 236. [Google Scholar] [CrossRef]

- Kim, S.; Bergbreiter, S. 3D-Printed Adaptive Microgripper Driven by Thin-Film NiTi Actuators. 2023 IEEE International Conference on Robotics and Automation (ICRA). LOCATION OF CONFERENCE, United KingdomDATE OF CONFERENCE; pp. 5445–5451.

- Nicholson, D.E.; Benafan, O.; Bigelow, G.S.; Pick, D.; Demblon, A.; Mabe, J.H.; Karaman, I.; Van Doren, B.; Forbes, D.; Sczerzenie, F.; et al. Standardization of Shape Memory Alloys from Material to Actuator. Shape Mem. Superelasticity 2023, 9, 353–363. [Google Scholar] [CrossRef]

- Hartwich, J.; Sławski, S.; Kciuk, M.; Duda, S. Determination of Thin NiTi Wires’ Mechanical Properties during Phase Transformations. Sensors 2023, 23, 1153. [Google Scholar] [CrossRef] [PubMed]

- Sibirev, A.V.; Belyaev, S.P.; Resnina, N.N. Influence of temperature range on NiTi SMA actuator performance during thermal cycling. Letters on materials 2023, 13(3). [CrossRef]

- Thüsing, K.; Hofer, A.; Pagel, K.; Weck, C.; Drossel, W.-G. High Load NiTi Shape Memory Alloy Actuators: A Study of Cyclic Behavior. ASME 2023 Conference on Smart Materials, Adaptive Structures and Intelligent Systems. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE;

- Muniraj, L.; Ardron, M.; Reuben, R.L.; Hand, D.P. Laser-Induced Forward Transfer of Ni-rich NiTi Alloys for Shape Memory Applications. J. Laser Micro/Nanoengineering 2023, 18, 94–99. [Google Scholar] [CrossRef]

- Shukla, S.; Barjibhe, R. Experimental and numerical Comparison of traditional spring DVA and shape memory alloy actuated DVA for fixed beam vibration control. Mater. Today: Proc. 2023. [Google Scholar] [CrossRef]

- Li, C.; Zhang, L.; Zhang, X.; Liu, G.; Zhao, J. A compliant actuator for steering the needle within tissue with feedback of FBG-based shape sensing. Sensors Actuators A: Phys. 2023, 356. [Google Scholar] [CrossRef]

- Oguntosin, V. Design of a color changing shape memory actuator. Sci. Talks 2023, 5. [Google Scholar] [CrossRef]

- Dang, P.; Zhou, Y.; Pang, J.; Ding, X.; Sun, J.; Lookman, T.; Xue, D. Achieving stable actuation response and elastocaloric effect in a nanocrystalline Ti50Ni40Cu10 alloy. Scr. Mater. 2022, 226. [Google Scholar] [CrossRef]

- Liu, Q.; Ghodrat, S.; Huisman, G.; Jansen, K.M. Shape memory alloy actuators for haptic wearables: A review. Mater. Des. 2023, 233. [Google Scholar] [CrossRef]

- Kennedy, S.; Shougat, R.E.U.; Perkins, E. Robust self-sensing shape memory alloy actuator using a machine learning approach. Sensors Actuators A: Phys. 2023, 354. [Google Scholar] [CrossRef]

- Shukla, S.; Barjibhe, R. An experimental and numerical comparison of traditional spring DVA in parallel and shape memory alloy actuated DVA in series and parallel for fixed beam vibration control. Mater. Today: Proc. 2023. [Google Scholar] [CrossRef]

- Durante, F.; Raparelli, T.; Zobel, P.B. Three-Degree-of-Freedom Cable-Driven Parallel Manipulator with Self-Sensing Nitinol Actuators. Robotics 2024, 13, 93. [Google Scholar] [CrossRef]

- Islam, N.; Gonzalez, M.B.; Tabassum, S.; Billah, K.M.M. 3D Printed Shape Memory Alloy Wire Embedded Actuator. 2024 IEEE 17th Dallas Circuits and Systems Conference (DCAS). LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; pp. 1–5.

- Hedrick, A.; Kabutz, H.; Smith, L.; MacCurdy, R.; Jayaram, K. Femtosecond Laser Fabricated Nitinol Living Hinges for Millimeter-Sized Robots. IEEE Robot. Autom. Lett. 2024, 9, 5449–5455. [Google Scholar] [CrossRef]

- Zuo, Z.; He, X.; Wang, H.; Shao, Z.; Liu, J.; Zhang, Q.; Pan, F.; Wen, L. A Nitinol-Embedded Wearable Soft Robotic Gripper for Deep-Sea Manipulation: A Wearable Device for Deep-Sea Delicate Operation. IEEE Robot. Autom. Mag. 2024, 31, 96–107. [Google Scholar] [CrossRef]

- Satpute, S.N.; Sake, S.A.; Sardesai, P.P.; Sawant, P.S.; Sarode, A.V.; Sadegaonkar, V.G.; Iwaniec, M.; Narina, R.; Dombale, A.; Kulkarni, N.S. Nitinol Based heat Engine for Solar Energy Harvesting. 2024 IEEE 19th International Conference on the Perspective Technologies and Methods in MEMS Design (MEMSTECH). LOCATION OF CONFERENCE, UkraineDATE OF CONFERENCE; pp. 97–101.

- Ryu, C.; Prabu, S.M.; Palani, I.; Nguyen, A.P.; Bin In, J. Improving the actuation behavior of nitinol shape memory alloys by nanosecond laser surface texturing. Opt. Laser Technol. 2024, 176. [Google Scholar] [CrossRef]

- Liu, Q.; Ghodrat, S.; Jansen, K.M. Design and modelling of a reversible shape memory alloy torsion hinge actuator. Mater. Des. 2023, 237. [Google Scholar] [CrossRef]

- Pathan, M.; Devaramani, R.; Adinarayanappa, S.M. Modelling, simulation, and experiments of 4D printed twisting actuator. Mater. Today: Proc. 2023, 101, 43–50. [Google Scholar] [CrossRef]

- Fischer, M.; Santoro, L.A.; Bruk, S.; Henkel, K.; Hüttner, R.; Körbitz, R.; Brinkmann, F.; Spickenheuer, A.; Kühnert, I.; Hampe, J.; et al. Friction testing of tube-guided electrically heated Nitinol shape-memory alloy wires. Tribol. Int. 2023, 191. [Google Scholar] [CrossRef]

- Copaci, D.; Palenzuela, A.L.; Moreno, L.; Martínez, S.; Balaguer, C. Characterization and control of Shape Memory Alloy-based actuators for heavy payloads displacement. Results Eng. 2024, 24. [Google Scholar] [CrossRef]

- Almeida, D.I.R.; Rodríguez, L.F.M. Experimental oscillation and regulation control strategy for 1-DOF mechanical rotational systems with an antagonistic SMA actuator. Results Eng. 2024, 23. [Google Scholar] [CrossRef]

- Zuñiga, S.; Bravo, D.; Rengifo, C. Design and construction of a servomechanism using a memory alloy linear actuator. HardwareX 2024, 20, e00587. [Google Scholar] [CrossRef] [PubMed]

- Shihora, N.; Simaan, N. The friction-limited end-effector motion resolution of tendon-actuated and continuum robots. Mech. Mach. Theory 2024, 203. [Google Scholar] [CrossRef]

- Boni, C.; Galuppi, L. A kinematics-based single-actuator setup for constant-curvature bending tests in extremely large deformations. Extreme Mech. Lett. 2024, 73. [Google Scholar] [CrossRef]

- Bertolini, R.; Khademzadeh, S.; Ghiotti, A.; Bruschi, S. Machining Effect On The Surface Integrity And SE Of Additively Manufactured And Heat-Treated Nitinol. Procedia CIRP 2024, 123, 47–52. [Google Scholar] [CrossRef]

- Rodinò, S.; Maletta, C. Design considerations and applications of shape memory alloy-based actuation in morphing structures: A systematic review. Prog. Eng. Sci. 2024, 1. [Google Scholar] [CrossRef]

- Singh, A.J.; Wala, S.; Ladakhan, S.H.; Sreesha, R.B.; Adinarayanappa, S.M. Design and fabrication of shape memory alloy based 4D-printed actuator for FWMAV: A performance study. Mater. Today: Proc. 2023, 101, 22–29. [Google Scholar] [CrossRef]

- Wei, L.; Ma, D.; Xie, D.; Jing, P.; Leng, Y. The performance and stability of NiTi photoactuator utilizing photothermal effect of TiN films with tilted columnar structure. Sensors Actuators A: Phys. 2024, 368. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D.J. Additive manufacturing of NiTi shape memory alloy and its industrial applications. Heliyon 2023, 10, e23369. [Google Scholar] [CrossRef]

- Leal, M.L.; Pino, L.; Barati, M.; Saint-Sulpice, L.; Daniel, L.; Chirani, S.A. Modeling of functional fatigue of SMA-based actuators under thermomechanical loading and Joule heating. Int. J. Fatigue 2023, 179. [Google Scholar] [CrossRef]

- VOSviewer software official web page. https://www.vosviewer.c.

| Generalized main objective | Reference |

|---|---|

| To improve the device fabrication | [5,153] |

| To fabricate new NiTi alloys | [4,23,150,154] |

| To test models/ strategies on a device based on Nitinol | [9,21,27,44,143,144,148,149,155] |

| To build a new device/ equipment/ application/ model | [17,18,32,33,70,81,82,85,105,131,136,139,140,147,151,152] |

| To improve the characteristics of an already existing device/ equipment/ application/ model/ process | [1,2,3,7,8,10,15,20,28,31,38,59,63,72,80,104,106,107,121,127,130,132,134,135,137,141,142,146] |

| To study/ test device/ equipment/ applications | [22,25,29,37,39,40,41,42,53,54,68,75,83,87,90,94,95,96,98,101,102,103,117,118,121,122,123,126,129,138,145] |

| To study/ test the NiTi alloy | [6,11,12,13,14,16,19,24,26,30,34,35,36,43,45,46,47,48,49,50,51,52,55,56,57,58,60,61,62,64,65,66,67,69,71,73,74,76,77,78,79,84,86,88,89,91,92,93,97,99,100,116,119,120,125,128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).