Submitted:

29 January 2025

Posted:

03 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

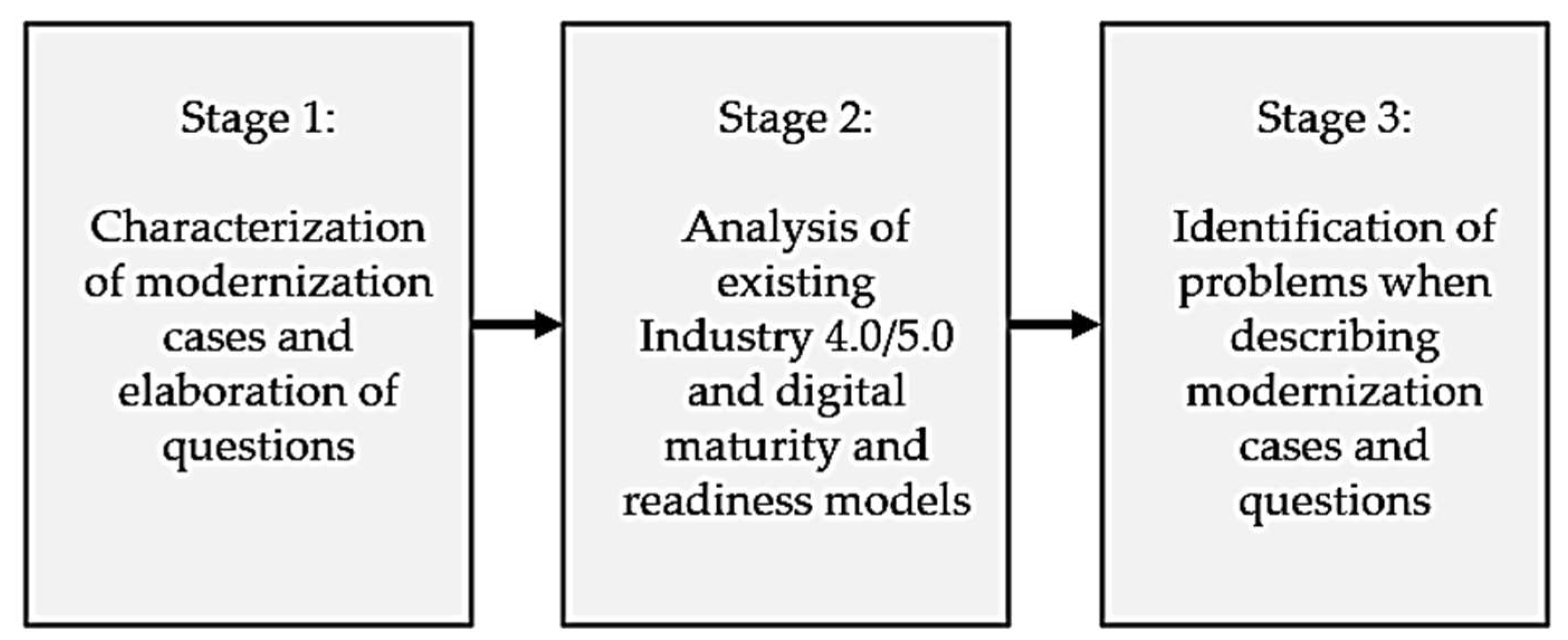

2. Materials and Methods

2.1. Characterization of Proposed Contexts for Concept Testing

2.2.1. Industrial Process

2.2.2. Laboratory Process

2.2.3. Artisanal Process

2.2.4. Office Process

3. Results

3.1. Analysis of Potential Solutions Provided by Industry 4.0/5.0 Maturity and Readiness Models

3.1.1. Analysis of Potential Solutions Provided by SMSRL

3.1.2. Analysis of Potential Solutions Provided by Impuls Industry 4.0 Readiness Model

3.1.3. Analysis of Potential Solutions Provided by MOM Manufacturing Operations Management Capability Maturity Level

3.1.4. Analysis of Potential Solutions Provided by DREAMY Digital Readiness and Maturity Model

3.1.5. Analysis of Potential Solutions Provided by Other Digital Maturity Models

3.1.6. Analysis of Potential Solutions Provided by Industry 5.0 Readiness Level

4. Discussion

4.1. Applying the Concepts of Industry 4.0/5.0 and Digital Maturity Models to Cases and Questions

4.1.1. Problems Identified When Describing Industrial Production Processes

4.1.2. Problems Identified When Describing Laboratory Processes

4.1.3. Problems Identified When Describing Artisanal Production Processes

4.1.4. Problems Identified When Describing Office Processes

4.2. Literature Discussion

4.3. Overall Analysis and Final Remarks

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kagermann, H.; Wahlster, W.; Helbig, J.; Hellinger, A.; Stumpf, M.A.V.; Treugut, L.; Blasco, J.; Galloway, H.; Findeklee, U. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; 2013. [Google Scholar]

- Noor Hasnan, N.Z.; Yusoff, Y.M. Short Review: Application Areas of Industry 4.0 Technologies in Food Processing Sector. In Proceedings of the 2018 IEEE 16th Student Conference on Research and Development, SCOReD 2018; Institute of Electrical and Electronics Engineers Inc, 2 July 2018. [Google Scholar]

- Hassoun, A.; Aït-Kaddour, A.; Abu-, A.M.; Bhojraj Rathod, N.; Bader, F.; Barba, F.J.; Biancolillo, A.; Cropotova, J.; Galanakis, C.M.; Jambrak, R.; et al. The Fourth Industrial Revolution in the Food Industry-Part I: Industry 4.0 Technologies 2.

- Konur, S.; Lan, Y.; Thakker, D.; Morkyani, G.; Polovina, N.; Sharp, J. Towards Design and Implementation of Industry 4.0 for Food Manufacturing. Neural Comput Appl 2023, 35, 23753–23765. [Google Scholar] [CrossRef]

- Sarker, I.H. AI-Based Modeling: Techniques, Applications and Research Issues Towards Automation, Intelligent and Smart Systems. SN Comput Sci 2022, 3. [Google Scholar] [CrossRef] [PubMed]

- Romero, M.; Guédria, W.; Panetto, H.; Barafort, B. Towards a Characterisation of Smart Systems: A Systematic Literature Review. Comput Ind 2020, 120, 103224. [Google Scholar] [CrossRef]

- Kishor, A.; Chakraborty, C. Artificial Intelligence and Internet of Things Based Healthcare 4.0 Monitoring System. Wirel Pers Commun 2022, 127, 1615–1631. [Google Scholar] [CrossRef]

- Osama, M.; Ateya, A.A.; Sayed, M.S.; Hammad, M.; Pławiak, P.; Abd El-Latif, A.A.; Elsayed, R.A. Internet of Medical Things and Healthcare 4.0: Trends, Requirements, Challenges, and Research Directions. Sensors 2023, 23. [Google Scholar] [CrossRef] [PubMed]

- Aziz Hussin, A. Education 4.0 Made Simple: Ideas For Teaching. International Journal of Education and Literacy Studies 2018, 6, 92. [Google Scholar] [CrossRef]

- Azah Mansor, N.; Abdullah, N.; Abd Rahman, H. Towards Electronic Learning Features in Education 4.0 Environment: Literature Study. Indonesian Journal of Electrical Engineering and Computer Science 2020, 19, 442. [Google Scholar] [CrossRef]

- Rifkin, J. The Third Industrial Revolution: How Lateral Power Is Transforming Energy, the Economy, and The; Carleton, E., Ed.; Palgrave Macmillan: New York, 2011; ISBN 978-0-230-11521-7. [Google Scholar]

- Moll, I. Why There Is No Technological Revolution, Let Alone a ‘Fourth Industrial Revolution’. S Afr J Sci 2023, 119. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J Manuf Syst 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union, 2021; ISBN 9789276253082. [Google Scholar]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11. [Google Scholar] [CrossRef]

- Nagy, L.; Abonyi, J.; Ruppert, T. Knowledge Graph-Based Framework to Support Human-Centered Collaborative Manufacturing in Industry 5.0. Applied Sciences (Switzerland) 2024, 14. [Google Scholar] [CrossRef]

- Introna, V.; Santolamazza, A.; Cesarotti, V. Integrating Industry 4.0 and 5.0 Innovations for Enhanced Energy Management Systems. Energies (Basel) 2024, 17, 1222. [Google Scholar] [CrossRef]

- Panza, L.; Bruno, G.; Lombardi, F. Integrating Absolute Sustainability and Social Sustainability in the Digital Product Passport to Promote Industry 5.0. Sustainability 2023, 15, 12552. [Google Scholar] [CrossRef]

- Brozzi, R.; D’Amico, R.D.; Pasetti Monizza, G.; Marcher, C.; Riedl, M.; Matt, D. Design of Self-Assessment Tools to Measure Industry 4.0 Readiness .A Methodological Approach for Craftsmanship SMEs. In Proceedings of the IFIP Advances in Information and Communication Technology, Springer New York LLC, 2018; Vol. 540, pp. 566–578. [Google Scholar]

- Hatzichronoglou, T. Revision of the High-Technology Sector and Product Classification; 1997. [Google Scholar]

- Alcácer, V.; Rodrigues, C.; Carvalho, H.; Cruz-Machado, V. Tracking the Maturity of Industry 4.0: The Perspective of a Real Scenario. The International Journal of Advanced Manufacturing Technology 2021, 116, 2161–2181. [Google Scholar] [CrossRef] [PubMed]

- De Carolis, A.; Macchi, M.; Negri, E.; Terzi, S.; Terzi, S.A. A Maturity Model for Assessing the Digital Readiness of Manufacturing Companies. 2017, 13–20. [CrossRef]

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readiness Assessment.; 2011; p. 1.

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readiness Assessment. In Proceedings of the IFIP Advances in Information and Communication Technology, Springer New York LLC, 2016; Vol. 488, pp. 705–712. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (SMEs). J Manuf Syst 2018, 49, 194–214. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. In Proceedings of the Procedia CIRP, Elsevier B.V., 2016; Vol. 52, pp. 161–166. [Google Scholar]

- Castor, N.; Damberg, D.; Sjöborg, E. MESA MOM Capability Maturity Level; 2016. [Google Scholar]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Schmitt, K.; Schmitz, E.; Schröter, M. Industrie 4.0 Readiness; Aachen, 2015. [Google Scholar]

- Martell, F.; López, J.M.; Sánchez, I.Y.; Paredes, C.A.; Pisano, E. Evaluation of the Degree of Automation and Digitalization Using a Diagnostic and Analysis Tool for a Methodological Implementation of Industry 4.0. Comput Ind Eng 2023, 177, 109097. [Google Scholar] [CrossRef]

- Lowendahl, B. Strategic Management of Professional Service Firms; Copenhagen Business School Press, 2005. [Google Scholar]

- Kronblad, C.; Pregmark, J.E.; Berggren, R. Difficulties to Digitalize: Ambidexterity Challenges in Law Firms. Journal of Service Theory and Practice 2023, 33, 217–236. [Google Scholar] [CrossRef]

- Sahebi, F. Application of Large Language Models in the Industry. International Journal of Sustainable Applied Science and Engineering 2024.

- Wang, F.Y.; Yang, J.; Wang, X.; Li, J.; Han, Q.L. Chat with ChatGPT on Industry 5.0: Learning and Decision-Making for Intelligent Industries. IEEE/CAA Journal of Automatica Sinica 2023, 10, 831–834. [Google Scholar] [CrossRef]

- Liu, Y.; Han, T.; Ma, S.; Zhang, J.; Yang, Y.; Tian, J.; He, H.; Li, A.; He, M.; Liu, Z.; et al. Summary of ChatGPT-Related Research and Perspective Towards the Future of Large Language Models. 2023. [Google Scholar] [CrossRef]

- Thirunavukarasu, A.J.; Ting, D.S.J.; Elangovan, K.; Gutierrez, L.; Tan, T.F.; Ting, D.S.W. Large Language Models in Medicine. Nat Med 2023, 29, 1930–1940. [Google Scholar] [CrossRef]

- Alem, S.; Espes, D.; Nana, L.; Martin, E.; De Lamotte, F. A New Normative Approach to Intrusion Detection in Manufacturing 4.0. IFAC-PapersOnLine 2023, 56, 3692–3697. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Kulvatunyou, B.; Brundage, M.P.; Terzi, S.; Maturity, S.T. Maturity Models and Tools for Enabling Smart Manufacturing Systems: Comparison and Reflections for Future Developments. In Proceedings of the In Product Lifecycle Management and the Industry of the Future: 14th IFIP WG 5.1 International Conference, PLM 2017; Springer International Publishing: Seville, Spain, 10 July 1 2017; pp. 23–35. [Google Scholar]

- Acerbi, F.; Spaltini, M.; De Carolis, A.; Taisch, M. Developing a Roadmap Towards the Digital Transformation of Small & Medium Companies: A Case Study Analysis in the Aerospace & Defence Sector. In Proceedings of the IFIP Advances in Information and Communication Technology, Springer Science and Business Media Deutschland GmbH, 2023; Vol. 667 IFIP, pp. 284–293. [Google Scholar]

- Azizan, S.; Ismail, R.; Baharum, A.; Hidayah Mat Zain, N. Exploring the Factors That Influence the Success of Digitalization in An Organization’s IT Department. In Proceedings of the 2021 6th IEEE International Conference on Recent Advances and Innovations in Engineering, ICRAIE 2021; Institute of Electrical and Electronics Engineers Inc., 14 February 2022. [Google Scholar]

- Berghaus, S.; Back, A. Stages in Digital Business Transformation: Results of an Empirical Maturity Study. In Proceedings of the MCIS 2016 Proceeding; Mediterranean Conference on Information Systems (MCIS) at AIS Electronic Library (AISeL); 2016. [Google Scholar]

- Valdez-De-Leon, O. A Digital Maturity Model for Telecommunications Service Providers; 2016; Vol. 6. [Google Scholar]

- Ifenthaler, D.; Egloffstein, M. Development and Implementation of a Maturity Model of Digital Transformation. TechTrends 2020, 64, 302–309. [Google Scholar] [CrossRef]

- Kljajić Borštnar, M.; Pucihar, A. Multi-Attribute Assessment of Digital Maturity of SMEs. Electronics (Basel) 2021, 10, 885. [Google Scholar] [CrossRef]

- Haryanti, T.; Rakhmawati, N.A.; Subriadi, A.P. Assessing the Digital Transformation Landscapes of Organization: The Digital Transformation Self-Assessment Maturity Model (DX-SAMM). In Proceedings of the Procedia Computer Science, Elsevier B.V., 2024; Vol. 234, pp. 1561–1569. [Google Scholar]

- Thordsen, T.; Murawski, M.; Bick, M. How to Measure Digitalization? A Critical Evaluation of Digital Maturity Models. In Proceedings of the Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), Springer, 2020; Vol. 12066 LNCS, pp. 358–369. [Google Scholar]

- Hein-Pensel, F.; Winkler, H.; Brückner, A.; Wölke, M.; Jabs, I.; Mayan, I.J.; Kirschenbaum, A.; Friedrich, J.; Zinke-Wehlmann, C. Maturity Assessment for Industry 5.0: A Review of Existing Maturity Models. J Manuf Syst 2023, 66, 200–210. [Google Scholar] [CrossRef]

- Madhavan, M.; Sharafuddin, M.A.; Wangtueai, S. Measuring the Industry 5.0-Readiness Level of SMEs Using Industry 1.0–5.0 Practices: The Case of the Seafood Processing Industry. Sustainability 2024, 16, 2205. [Google Scholar] [CrossRef]

- Alarcon, C.; Shene, C. Fermentation 4.0, a Case Study on Computer Vision, Soft Sensor, Connectivity, and Control Applied to the Fermentation of a Thraustochytrid. Comput Ind 2021, 128. [Google Scholar] [CrossRef]

- Popkova, E.G.; Yulia; Ragulina, V.; Bogoviz Editors, A.V. Industry 4.0: Industrial Revolution of the 21st Century; Popkova, E.G., Ragulina, Y.V., Bogoviz, A.V., Eds.; Studies in Systems, Decision and Control; Springer International Publishing: Cham, 2019; Vol. 169, ISBN 978-3-319-94309-1. [Google Scholar]

- Kunst, R.; Avila, L.; Binotto, A.; Pignaton, E.; Bampi, S.; Rochol, J. Improving Devices Communication in Industry 4.0 Wireless Networks. Eng Appl Artif Intell 2019, 83, 1–12. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0 -Systematic Review, Challenges and Outlook. IEEE Access 2020. [Google Scholar] [CrossRef]

- Elhoone, H.; Zhang, T.; Anwar, M.; Desai, S. Cyber-Based Design for Additive Manufacturing Using Artificial Neural Networks for Industry 4.0. Int J Prod Res 2020, 58, 2841–2861. [Google Scholar] [CrossRef]

- Saiki, R.K.; Scharf, S.; Faloona, F.; Mullis, K.B.; Horn, G.T.; Erlich, H.A.; Arnheim, N. Enzymatic Amplification of β-Globin Genomic Sequences and Restriction Site Analysis for Diagnosis of Sickle Cell Anemia. Science (1979) 1985, 230, 1350–1354. [Google Scholar] [CrossRef]

- Alarcon, C.; Shene, C. Arduino Soft Sensor for Monitoring Schizochytrium Sp. Fermentation, a Proof of Concept for the Industrial Application of Genome-Scale Metabolic Models in the Context of Pharma 4.0. Processes 2022, 10. [Google Scholar] [CrossRef]

- Kishor, A.; Chakraborty, C. Artificial Intelligence and Internet of Things Based Healthcare 4.0 Monitoring System. Wirel Pers Commun 2022, 127, 1615–1631. [Google Scholar] [CrossRef]

- Martín-Gómez, A.M.; Agote-Garrido, A.; Lama-Ruiz, J.R. A Framework for Sustainable Manufacturing: Integrating Industry 4.0 Technologies with Industry 5.0 Values. Sustainability (Switzerland) 2024, 16. [Google Scholar] [CrossRef]

- Zhironkin, S.; Ezdina, N. Review of Transition from Mining 4.0 to Mining 5.0 Innovative Technologies. Applied Sciences (Switzerland) 2023, 13. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Business and Information Systems Engineering 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Vinitha, K.; Ambrose Prabhu, R.; Bhaskar, R.; Hariharan, R. Review on Industrial Mathematics and Materials at Industry 1.0 to Industry 4.0. In Proceedings of the Materials Today: Proceedings, Elsevier Ltd, 2020; Vol. 33, pp. 3956–3960. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).