1. Introduction

Multi-material additive manufacturing, process of joining multiple materials for numerous tiny melting pool continuously to make heterogeneous parts from 3D model data, usually layer upon layer, as opposed to traditional subtractive manufacturing and formative manufacturing methodologies. It provides significant advantages in fabricating continuously real-time variable composition and structural gradients for metallic materials [

1,

2,

3]. Especially, directed energy deposition (DED) using a laser beam, where powder-feeding ratios and other parameters can be manipulated in real time during processing, is more suitable for fabricating the heterogeneous alloy [

4,

5,

6]. However, the real-time variable composition deposition has a huge challenge, how to achieve the continuous uniformly and variably feeding multiple powders.

In the last decade, most researchers focused on the graded metals noncontinuous variable metals. Hofmann et al. [

7,

8,

9] provided an overview of multi-material additive manufacturing, with emphasis on compositionally graded metals designed with the help of phase diagrams. W. Li et al. [

10,

11] control the metallurgical quality of interfaces between dissimilar materials by DED. According to these results, the different critical metallurgical incompatibilities between metals have been identified as preventing their sound combination by additive manufacturing. To circumvent such incompatibilities, various studies proved the use of appropriate intermediate material layers to be an effective solution. For instance, Eliseeva et al. [

12,

13] proposed an algorithm for automatic optimization of the multi-metallic gradient transition between incompatible metals, based on equilibrium phase calculations, and followed by manufacturing via DED. Current works [

14,

15,

16] have presented the multi-powder mixer details and verified the mixer’s stability and uniformity utilized directed energy deposition. However, these studies haven’t gave a real-time variable composition and structural gradients for metallic materials. A dynamic composition adjusting approach is still urgent for multi-material directed energy deposition.

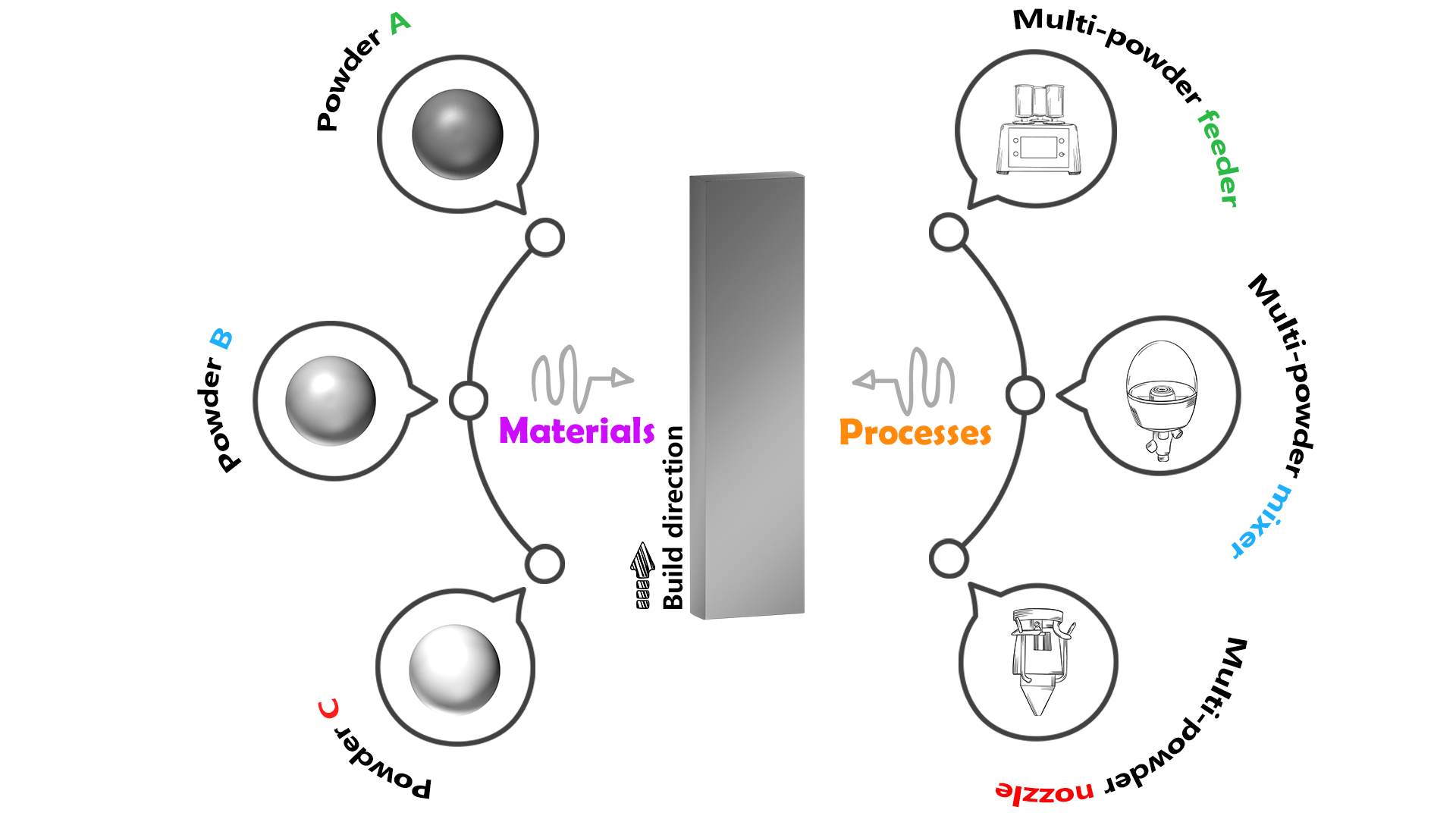

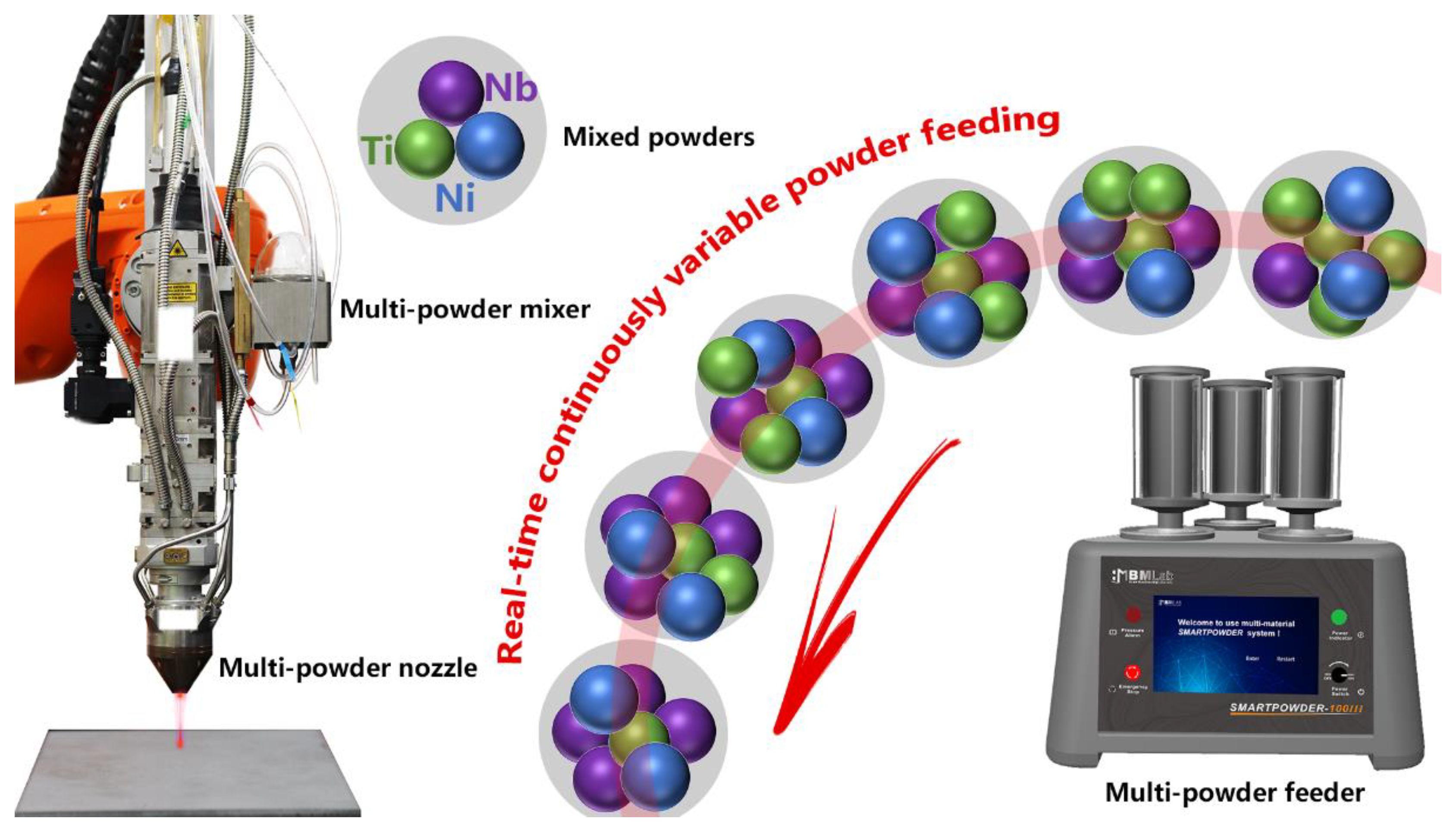

This work presents a novel additive manufacturing approach utilized a multi-powder feeder with real-time continuously variable composition function, a multi-powder mixer and a multi-powder nozzle to fabricate the Ti-Ni-Nb variable composition single-track deposited layer. This study also paves the way for future development of multi-material additive manufacturing.

2. Materials and Methods

The self-designed novel additive manufacturing powder feeding system is composed of a three-channel powder feeder with real-time variable composition function, a three-channel powder mixer and a circle coaxial multi-powder nozzle.

Figure 1 shows the schematic diagram of the novel real-time continuously variable composition directed energy deposition.

Previous research results have proved that these mixed powders perform an excellent in-situ alloying characteristics among the pure titanium powder, pure nickel powder and pure niobium powder under the laser irradiation. Therefore, pure titanium powder, pure nickel powder and pure niobium powder with a particle size of titanium is 15~53 μm, nickel is 53~105 μm, and niobium is 15~53 μm, and a purity of 99.99 wt.% are selected as raw powder materials. A pure titanium plate with a size of 150.0×150.0×4.0 mm as the build platform was machined in this work. The argon with a purity of 99.99 wt.% is used for powder feeding carried gas and preventing the melting pool from being oxidated. This optimal depositing process parameters with a laser power of 600 W, a laser scanning speed of 10 mm/s, and a laser spot diameter of about 1.0 mm with a uniform energy distribution.

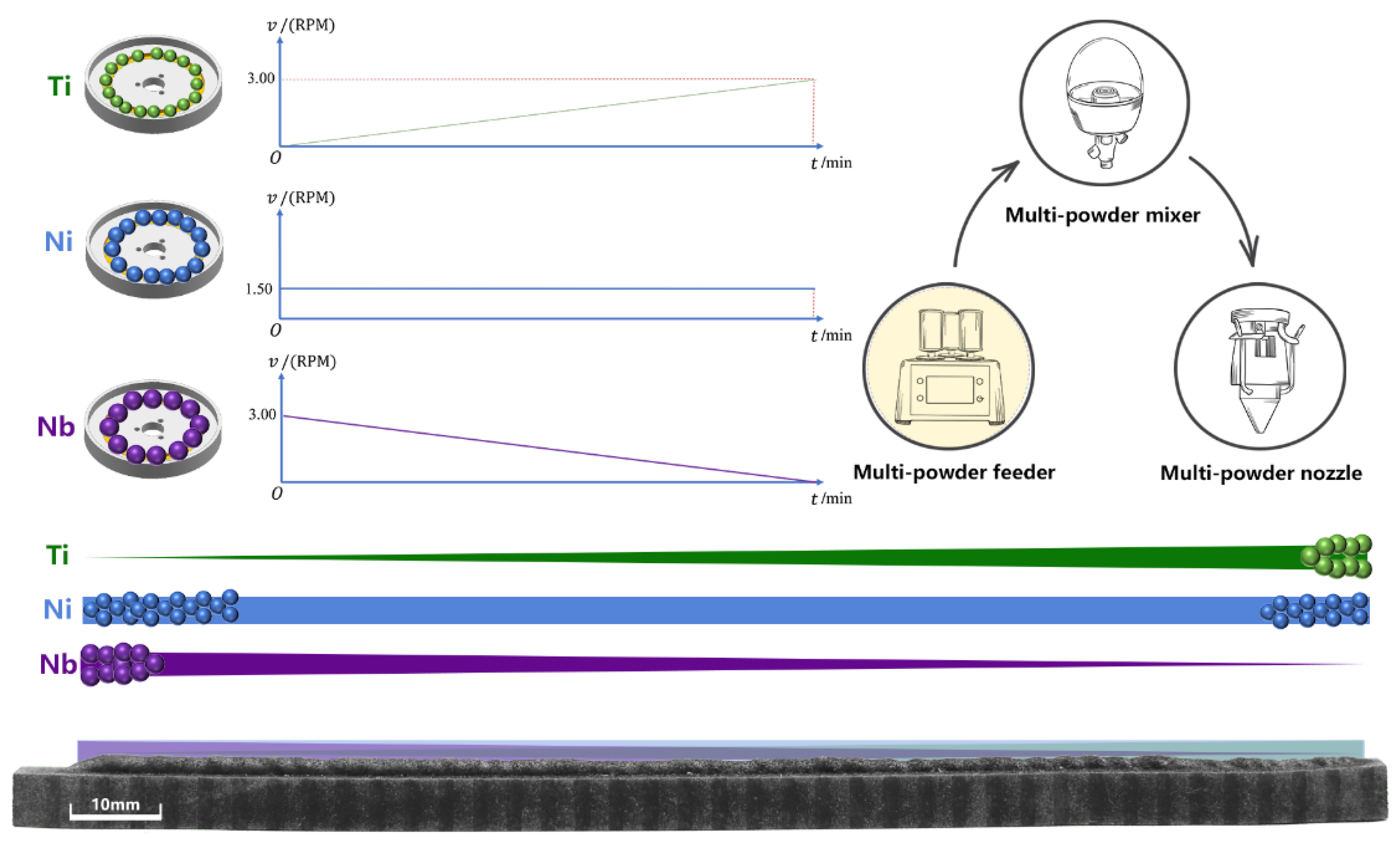

In

Figure 2, the titanium powder feeding rate is increased linearly from 0 RPM to 3.00 RPM, the nickel powder feeding rate is constant as 1.50 RPM and the niobium powder feeding rate is decreased linearly from 3.00 RPM to 0 RPM. This means that the powder feeding mass of titanium powder is increased linearly from zero to a maximum value, nickel powder as a constant value and niobium powder is decreased linearly from a certain value to zero. In the building process, the three channel powder feeders are open at the same time and the duration time for mixing is all set for 10 s, respectively. Thus, a length of 100 mm deposited layer in the build platform was acquired at the laser scanning speed of 10 mm/s. The deposited layer sample was divided into 10 units every 10.00 mm along the laser scanning speed direction. The energy dispersing spectrum (EDS) element analysis based on a 45 sampling points random strategy, and the X-ray diffraction (XRD) phase constitution based on a representative sampling strategy was implemented for verifying the reliability of this unique approach presented in this work.

3. Results and Discussions

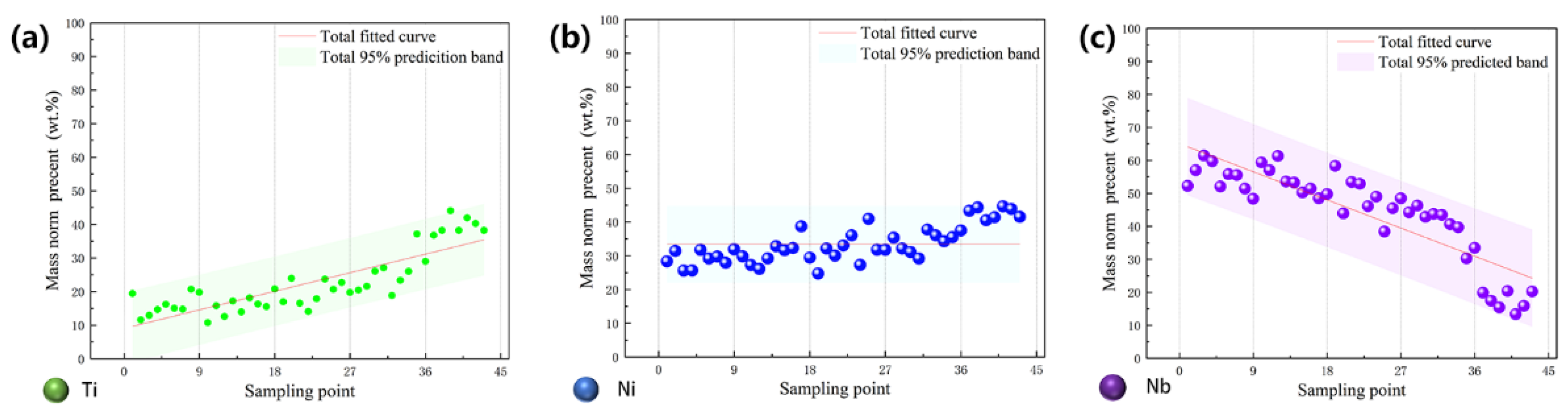

Figure 3 presents the EDS analysis results of a single-track deposited layer under the real-time continuously variable powder feeding rate. From

Figure 3a, the mass norm precent of titanium element gradually continuously increase along the scanning speed direction. In

Figure 3b, the mass norm precent of nickel element basically doesn’t change. In

Figure 3c, the mass norm precent of niobium element gradually continuously decrease. These results reveal that the mass norm precent of titanium, nickel and niobium is real-time variable along the laser scanning direction. It is interesting that the trends are consistent with the experimental expectation due to the three powders in accordance with the linear speed change trends. We can also find that the absolute value of the slope between the mass norm precent curve of titanium element and the mass norm precent curve of niobium element resulting from the loose packing density when the volume of the three elements is equal. The slope of mass norm precent curve of nickel element is approximate zero. These phenomena indicates that a real-time continuously variable composition directed energy deposition strategy is reliable.

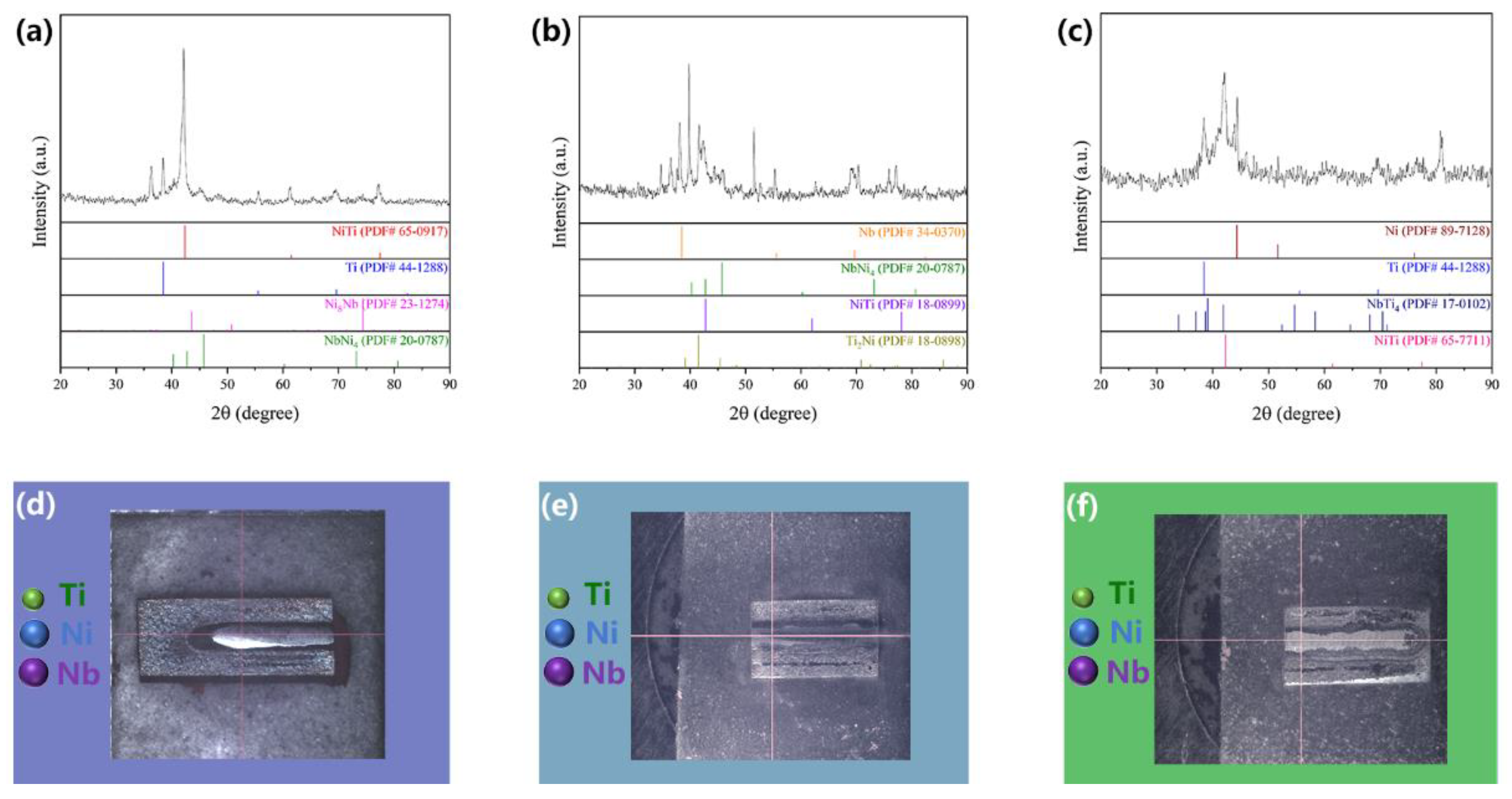

In order to further probe the phase evolution of the Ti-Ni-Nb deposited layer along the scanning direction with change of the three channels’ powder feeding rate,

Figure 4 demonstrates the XRD micro-regions’ phase constitution diagram of the representative samples. From

Figure 4a, the XRD results of the sample in the

Figure 4d sampled at the laser starting scanning position, there are four main phases including NiTi, Ti, Ni

8Nb and NiNb

4. From Figure. 4b, the XRD results of the sample in the

Figure 4e sampled in the middle of the deposited layer, there are four main phases include NiTi, Nb, Ti

2Ni and NbNi

4. From

Figure 4c, the XRD results of the sample in the

Figure 4f sampled at the laser ending scanning position, there are also four main phases including NiTi, Ni, Ti and NbTi

4. Interestingly, these results indicates that the NiTi phase is more easily generated than any other phases among titanium, nickel, and niobium elements under the laser beam irradiation. The number of phases containing niobium element decreases with the decrease of niobium element. Moreover, the titanium-rich phase increase with the increase of titanium element. These results also reveal that the NiTi phase is easily formed no matter the content of titanium. According to these data, we can infer that the additive manufacturing approach named directed energy deposition with real-time continuously variable composition is suitable to adopt for verifying the rapid alloy design strategies.

4. Conclusions

In summary, the multi-material laser directed energy deposition of Ti-Ni-Nb alloy at a real-time continuously variable composition has been achieved. The mass norm precent of titanium element continuously increases along the laser beam traversing direction, nickel element essentially unchanged and niobium element continuously decrease. The different phases generate from the laser start scanning position to the end of the deposited layer. The NiTi phase is more easily generated than any other phases among titanium, nickel, and niobium elements under the laser beam irradiation. And the novel approach is efficient to verify the different powder alloying capacity by a dynamic composition, rapid selection of alloy composition designs from actual fabricating. It also paves the way for future development of multi-material additive manufacturing.

Author Contributions

Jinlong Li: Methodology, Investigation, Resources, Data curation, Visualization, Formal analysis, Validation, Writing-original draft, Writing-review & editing. Xiaowei Zhang: Supervision, Conceptualization, Investigation, Resources, Software, Methodology, Data curation, Visualization, Formal analysis, Funding acquisition, Project administration, Validation, Writing-original draft, Writing-review & editing. Zhe An: Methodology, Investigation, Formal analysis. Biqiang Li: Methodology, Investigation, Formal analysis. Yizheng Wang: Methodology, Investigation, Formal analysis. Yaoyuan Yang: Methodology, Investigation, Formal analysis. Kexin Tong: Methodology, Investigation, Formal analysis. Yingze Zhu: Methodology, Investigation, Formal analysis.

Funding

This work was supported by Ten Thousand Talent Plans for Young Top-notch Talents of Yunnan Province (YNWR-QNBJ-2020–007), Projects of Yunnan Provincial Science and Technology Department (202401AT070331) and Major Science and Technology Projects of Yunnan Province (KKAU202351005, 202302AG050006–2).

Data Availability Statement

Data will be made available on request.

Acknowledgments

This work was supported by Ten Thousand Talent Plans for Young Top-notch Talents of Yunnan Province (YNWR-QNBJ-2020–007), Projects of Yunnan Provincial Science and Technology Department (202401AT070331) and Major Science and Technology Projects of Yunnan Province (KKAU202351005, 202302AG050006–2). We also appreciate the meaningful discussions of Mr. Peng Song, Taihong Huang and Chengxi Wang working at the Kunming University of Science and Technology.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Tomar, B.; Shiva, S.; Nath, T. A Review on Wire Arc Additive Manufacturing: Processing Parameters, Defects, Quality Improvement and Recent Advances. Materials Today Communications 2022, 31, 103739. [CrossRef]

- Yang, Z.; Sun, H.; Liu, Z.-K.; Beese, A.M. Design Methodology for Functionally Graded Materials: Framework for Considering Cracking. Additive Manufacturing 2023, 73, 103672. [CrossRef]

- Kim, E.S.; Park, J.M.; Karthik, G.M.; Kim, K.T.; Yu, J.-H.; Lee, B.-J.; Kim, H.S. Local Composition Detouring for Defect-Free Compositionally Graded Materials in Additive Manufacturi. [CrossRef]

- Hu, Z.; Ma, Z.; Yu, L.; Liu, Y. Functionally Graded Materials with Grain-Size Gradients and Heterogeneous Microstructures Achieved by Additive Manufacturing. Scripta Materialia 2023, 226, 115197. [CrossRef]

- Wu, Y.; Chen, S.; Cao, Y.; Yu, J.; Zhou, S.; Zhu, D.; Yang, H. Corrosion Behavior of Laser Directed Energy Deposited SS316L/Inconel718 Functionally Graded Materials. Materials Today Communications 2024, 40, 110038. [CrossRef]

- Ouyang, L.; Xie, X.; Wang, X.; Li, H.; Wang, J.; Wang, Z.; Feng, L.; Gui, Y.; Pan, F. Heterogeneous Structure Formation of Mg Alloy during Direct Laser Deposition with Dissimilar Alloy. Materials Today Communications 2024, 41, 111071. [CrossRef]

- Hofmann, D.C.; Kolodziejska, J.; Roberts, S.; Otis, R.; Dillon, R.P.; Suh, J.-O.; Liu, Z.-K.; Borgonia, J.-P. Compositionally Graded Metals: A New Frontier of Additive Manufacturing. J. Mater. Res. 2014, 29, 1899–1910. [CrossRef]

- Wei, C.; Liu, L.; Gu, Y.; Huang, Y.; Chen, Q.; Li, Z.; Li, L. Multi-Material Additive-Manufacturing of Tungsten - Copper Alloy Bimetallic Structure with a Stainless-Steel Interlayer and Associated Bonding Mechanisms. Additive Manufacturing 2022, 50, 102574. [CrossRef]

- Feenstra, D.R. Critical Review of the State of the Art in Multi-Material Fabrication via Directed Energy Deposition. Materials Science 2021. [CrossRef]

- Li, W.; Liou, F.; Newkirk, J.; Taminger, K.M.B.; Seufzer, W.J. Investigation on Ti6Al4V-V-Cr-Fe-SS316 Multi-Layers Metallic Structure Fabricated by Laser 3D Printing. Sci Rep 2017, 7, 7977. [CrossRef]

- Zhao, J.; Wang, G.; Wang, X.; Luo, S.; Wang, L.; Rong, Y. Multicomponent Multiphase Modeling of Dissimilar Laser Cladding Process with High-Speed Steel on Medium Carbon Steel. International Journal of Heat and Mass Transfer 2020. [CrossRef]

- Eliseeva, O.V. Functionally Graded Materials through Robotics-Inspired Path Planning. Materials and Design 2019. [CrossRef]

- Jacquier, V.; Zollinger, J.; Zeller, P.; Schuster, F.; Maskrot, H.; Pacquentin, W. Directed Energy Deposition with a Graded Multi-Material Compatibility Interface Enables Deposition of W on Cu. Materials & Design 2024, 244, 113114. [CrossRef]

- Han, Y. Structural Design, Numerical Examination and Experimental Approach of the Multi-Powder Mixer for Directed Energy Deposition. Powder Technology 2022. [CrossRef]

- Zhang, X.; Rao, J.H.; Wang, M.; Cai, B.; Liu, H. Structural Design of a Novel Fume Hood for Vapor and Spatter Removal in Direct Energy Deposition via Numerical Investigation. Additive Manufacturing 2021, 37, 101704. [CrossRef]

- Gao, G.; Zhang, X.; Han, Y.; Xu, M.; Liu, H.; Ao, J.; Cai, Y.; Wang, J.; Wang, M. Structural Design of a Coaxial-Jet Vortex Powder Mixer for Multi-Material Directed Energy Deposition. Powder Technology 2023, 425, 118586. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).