Submitted:

28 September 2023

Posted:

03 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Present status and challenges in the avenue of AM-based HEAs

3. Trends in AM-based fabrication of HEAs

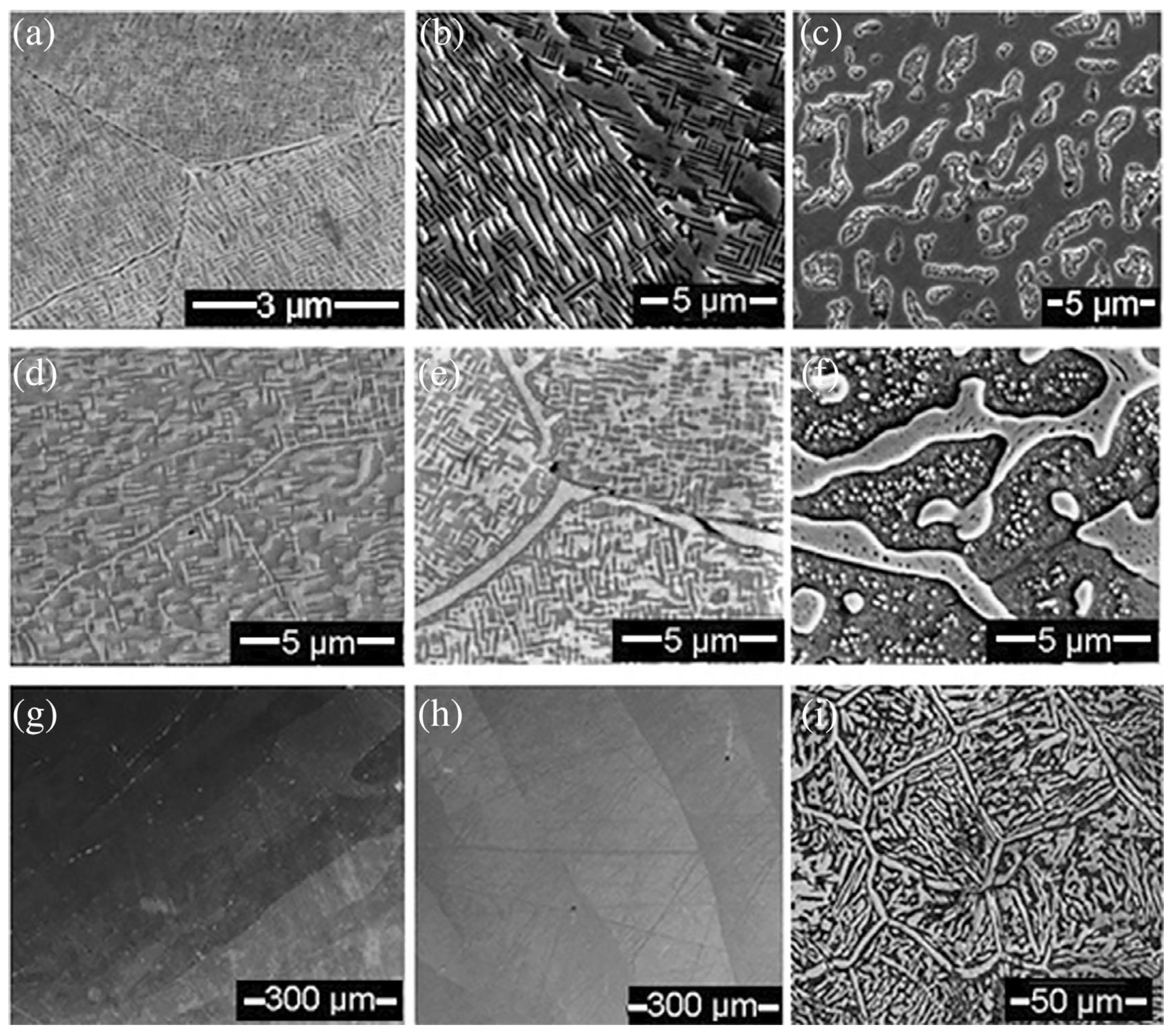

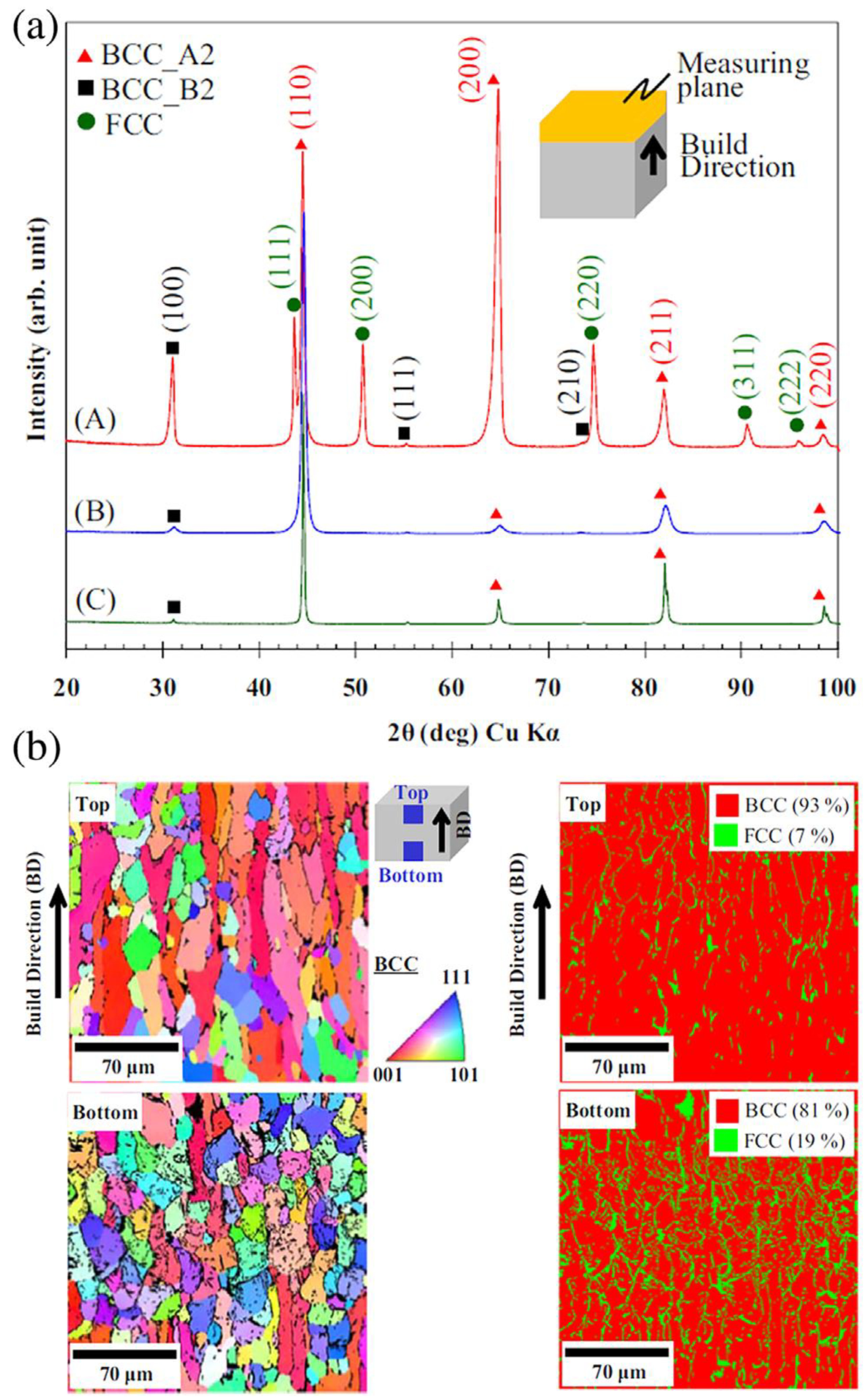

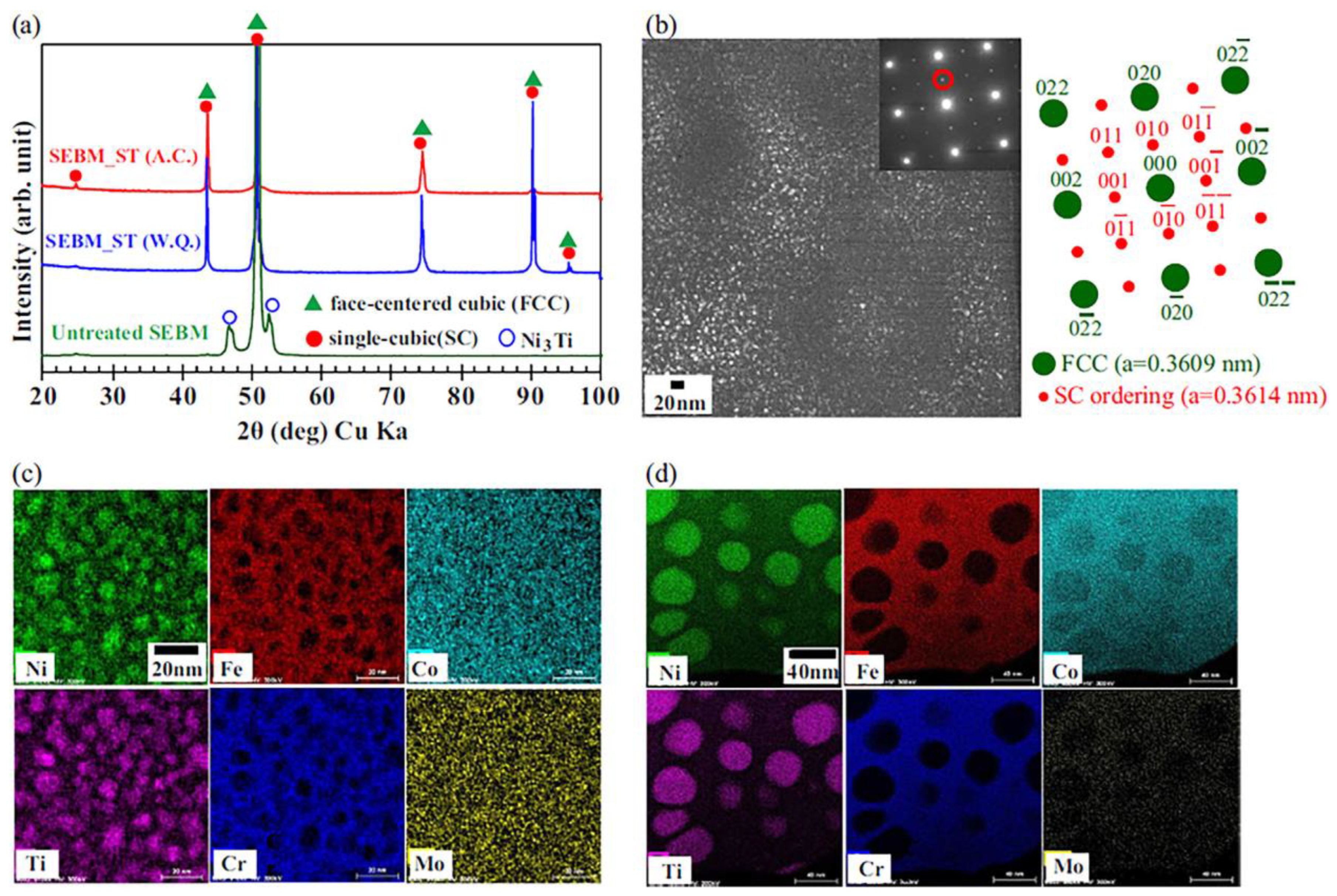

3.1. From the viewpoint of microstructural features and mechanical properties

3.1.1. Design of interstitial HEAs

3.1.2. Core-shell structure

3.1.3. HEA-based composites

3.2. From the viewpoint of HEA fabrication

3.2.1. Non-beam AM techniques

4. AM of HEAs: future perspectives

5. Conclusions

References

- S. Luo, P. Gao, H. Yu, J. Yang, Z. Wang, and X. Zeng, “Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical behavior,” J Alloys Compd, vol. 771, pp. 387–397, Jan. 2019. [CrossRef]

- P. Wang et al., “Additively manufactured CoCrFeNiMn high-entropy alloy via pre-alloyed powder,” Mater Des, vol. 168, Apr. 2019. [CrossRef]

- H. Dobbelstein, E. L. Gurevich, E. P. George, A. Ostendorf, and G. Laplanche, “Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends,” Addit Manuf, vol. 25, pp. 252–262, Jan. 2019. [CrossRef]

- N. Li et al., “Progress in additive manufacturing on new materials: A review,” J Mater Sci Technol, vol. 35, no. 2, pp. 242–269, Feb. 2019. [CrossRef]

- M. Saha, “3D printing of nanoceramics: Present status and future perspectives,” Sep. 2022. [CrossRef]

- M. Saha, “On the advanced microstructural characterisation of additively manufactured alumina-zirconia based eutectic ceramics: Overview and outlook,” Dec. 2022. [CrossRef]

- M. Saha and M. Mallik, “Additive Manufacturing and Characterisation of Biomedical Materials,” Advanced Materials for Biomechanical Applications, pp. 29–57, May 2022. [CrossRef]

- M. Saha and M. Mallik, “Additive manufacturing of ceramics and cermets: present status and future perspectives,” Sādhanā 2021 46:3, vol. 46, no. 3, pp. 1–35, Aug. 2021. [CrossRef]

- B. Gwalani, V. Soni, O. A. Waseem, S. A. Mantri, and R. Banerjee, “Laser additive manufacturing of compositionally graded AlCrFeMoVx (x = 0 to 1) high-entropy alloy system,” Opt Laser Technol, vol. 113, pp. 330–337, May 2019. [CrossRef]

- M. Saha, “A brief discussion on the tensile creep deformation behaviour of wrought single-phase γ-TiAl,” Mater Today Proc, Jan. 2021. [CrossRef]

- M. Saha, “Understanding the role of Al2O3 formed during isothermal oxidation in a dual phase AlCoCrFeNi2.1 Eutectic High-Entropy Alloy,” Journal of Materials NanoScience, vol. 7, no. 2, pp. 68–72, Nov. 2020, [Online]. Available: http://thesciencein.org/journal/index.php/jmns/article/view/119.

- M. Saha and M. Mallik, “3D printing of nanoceramics for biomedical applications,” Advanced Ceramic Coatings for Biomedical Applications, pp. 111–135, Jan. 2023. [CrossRef]

- M. Saha and M. Mallik, “Metal-based conducive nano-inks: synthesis and characterization techniques,” Smart Multifunctional Nano-Inks, pp. 27–52, Jan. 2023. [CrossRef]

- H. Diao, X. Xie, F. Sun, K. A. Dahmen, and P. K. Liaw, “Mechanical properties of high-entropy alloys,” High-Entropy Alloys: Fundamentals and Applications, pp. 181–236, Jan. 2016. [CrossRef]

- Amar et al., “Additive manufacturing of high-strength CrMnFeCoNi-based High Entropy Alloys with TiC addition,” Intermetallics (Barking), vol. 109, pp. 162–166, Jun. 2019. [CrossRef]

- S. Chen, X. Chen, L. Wang, J. Liang, and C. Liu, “Laser cladding FeCrCoNiTiAl high entropy alloy coatings reinforced with self-generated TiC particles,” J Laser Appl, vol. 29, no. 1, p. 012004, Feb. 2017. [CrossRef]

- Y. He, J. Zhang, H. Zhang, and G. Song, “Effects of different levels of boron on microstructure and hardness of CoCrFeNiAl x Cu 0.7 Si 0.1 B y high-entropy alloy coatings by laser cladding,” Coatings, vol. 7, no. 1, Jan. 2017. [CrossRef]

- V. Ocelík, N. Janssen, S. N. Smith, and J. T. M. de Hosson, “Additive Manufacturing of High-Entropy Alloys by Laser Processing,” JOM, vol. 68, no. 7, pp. 1810–1818, Jul. 2016. [CrossRef]

- C. Zhang, G. J. Chen, and P. Q. Dai, “Evolution of the microstructure and properties of laser-clad FeCrNiCoBx high-entropy alloy coatings,” Materials Science and Technology (United Kingdom), vol. 32, no. 16, pp. 1666–1672, Nov. 2016. [CrossRef]

- M. Saha, “Grain boundary segregation in steels: Towards engineering the design of internal interfaces,” Feb. 2022. [CrossRef]

- M. Saha, “New frontiers in characterising ZrB$_2$-MoSi$_2$ ultra-high temperature ceramics,” Feb. 2022. [CrossRef]

- M. Saha, “ɤ-TiAl alloy: revisiting tensile creep deformation behaviour and creep life at 832 °C,” Advances in Materials and Processing Technologies, 2021. [CrossRef]

- M. Saha, “Fly ash composites: A review,” Feb. 2022. [CrossRef]

- M. Saha and M. Mallik, “Surface engineering of nanomaterials : Processing and applications,” Surface Engineering, pp. 95–119, Dec. 2022. [CrossRef]

- M. Saha et al., “An Insight Into Cyclic Oxidation behavior of ZrB2-20 Vol.% MoSi2 Based Ultrahigh Temperature Ceramic Matrix Composite,” Modern Manufacturing Systems, pp. 149–163, Dec. 2022. [CrossRef]

- M. Mallik and M. Saha, “Carbon-Based Nanocomposites: Processing, Electronic Properties and Applications,” Springer, Singapore, 2021, pp. 97–122. [CrossRef]

- M. Zhang, W. Zhang, F. Liu, Y. Peng, S. Hu, and Y. Liu, “Effect of binding and dispersion behavior of high-entropy alloy (HEA) powders on the microstructure and mechanical properties in a novel HEA/diamond composite,” Entropy, vol. 20, no. 12, Dec. 2018. [CrossRef]

- J. Kim, A. Wakai, and A. Moridi, “Materials and manufacturing renaissance: Additive manufacturing of high-entropy alloys,” J Mater Res, vol. 35, no. 15, pp. 1963–1983, Aug. 2020. [CrossRef]

- S. Chen, Y. Tong, and P. K. Liaw, “Additive manufacturing of high-entropy alloys: A review,” Entropy, vol. 20, no. 12, Dec. 2018. [CrossRef]

- X. Li, “Additive Manufacturing of Advanced Multi-Component Alloys: Bulk Metallic Glasses and High Entropy Alloys,” Adv Eng Mater, vol. 20, no. 5, May 2018. [CrossRef]

- Ostovari Moghaddam, N. A. Shaburova, M. N. Samodurova, A. Abdollahzadeh, and E. A. Trofimov, “Additive manufacturing of high entropy alloys: A practical review,” J Mater Sci Technol, vol. 77, pp. 131–162, Jun. 2021. [CrossRef]

- X. Li, “Additive Manufacturing of Advanced Multi-Component Alloys: Bulk Metallic Glasses and High Entropy Alloys,” Adv Eng Mater, vol. 20, no. 5, p. 1700874, May 2018. [CrossRef]

- J. Joseph, T. Jarvis, X. Wu, N. Stanford, P. Hodgson, and D. M. Fabijanic, “Comparative study of the microstructures and mechanical properties of direct laser fabricated and arc-melted AlxCoCrFeNi high entropy alloys,” Materials Science and Engineering: A, vol. 633, pp. 184–193, May 2015. [CrossRef]

- H. R. Sistla, J. W. Newkirk, and F. Frank Liou, “Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of AlxFeCoCrNi2−x (x = 0.3, 1) high entropy alloys,” Mater Des, vol. 81, pp. 113–121, Sep. 2015. [CrossRef]

- V. Ocelík, N. Janssen, S. N. Smith, and J. Th. M. de Hosson, “Additive Manufacturing of High-Entropy Alloys by Laser Processing,” JOM 2016 68:7, vol. 68, no. 7, pp. 1810–1818, Apr. 2016. [CrossRef]

- H. Dobbelstein, M. Thiele, E. L. Gurevich, E. P. George, and A. Ostendorf, “Direct Metal Deposition of Refractory High Entropy Alloy MoNbTaW,” Phys Procedia, vol. 83, pp. 624–633, Jan. 2016. [CrossRef]

- T. Fujieda et al., “First demonstration of promising selective electron beam melting method for utilizing high-entropy alloys as engineering materials,” Mater Lett, vol. 159, pp. 12–15, Nov. 2015. [CrossRef]

- H. Shiratori et al., “Relationship between the microstructure and mechanical properties of an equiatomic AlCoCrFeNi high-entropy alloy fabricated by selective electron beam melting,” Materials Science and Engineering: A, vol. 656, pp. 39–46, Feb. 2016. [CrossRef]

- T. Fujieda, H. Shiratori, K. Kuwabara, and T. Kato, “First demonstration of promising selective electron beam melting method for utilizing high-entropy alloys as engineering materials,” Mater Lett, vol. 159, pp. 12–15, 2015. [CrossRef]

- T. Fujieda et al., “CoCrFeNiTi-based high-entropy alloy with superior tensile strength and corrosion resistance achieved by a combination of additive manufacturing using selective electron beam melting and solution treatment,” Mater Lett, vol. 189, pp. 148–151, Feb. 2017. [CrossRef]

- Y. Brif, M. Thomas, and I. Todd, “The use of high-entropy alloys in additive manufacturing,” Scr Mater, vol. 99, pp. 93–96, Apr. 2015. [CrossRef]

- T. Fujieda, H. Shiratori, K. Kuwabara, M. Hirota, and T. Kato, “CoCrFeNiTi-based high-entropy alloy with superior tensile strength and corrosion resistance achieved by a combination of additive manufacturing using selective electron beam melting and solution treatment,” Mater Lett, vol. 189, no. September 2016, pp. 148–151, 2017. [CrossRef]

- Z. G. Zhu et al., “Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy,” http://mc.manuscriptcentral.com/tmrl, vol. 7, no. 11, pp. 453–459, Nov. 2019. [CrossRef]

- J. G. Kim et al., “Nano-scale solute heterogeneities in the ultrastrong selectively laser melted carbon-doped CoCrFeMnNi alloy,” Materials Science and Engineering: A, vol. 773, p. 138726, Jan. 2020. [CrossRef]

- D. B. Miracle, “High entropy alloys as a bold step forward in alloy development,” Nat Commun, vol. 10, no. 1, Dec. 2019. [CrossRef]

- J. M. Park et al., “Superior tensile properties of 1%C-CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting,” http://mc.manuscriptcentral.com/tmrl, vol. 8, no. 1, pp. 1–7, Jan. 2019. [CrossRef]

- R. Zhou et al., “Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting,” Intermetallics (Barking), vol. 94, pp. 165–171, Mar. 2018. [CrossRef]

- M. Song, R. Zhou, J. Gu, Z. Wang, S. Ni, and Y. Liu, “Nitrogen induced heterogeneous structures overcome strength-ductility trade-off in an additively manufactured high-entropy alloy,” Appl Mater Today, vol. 18, p. 100498, Mar. 2020. [CrossRef]

- H. Zhang, W. Wu, Y. He, M. Li, and S. Guo, “Formation of core–shell structure in high entropy alloy coating by laser cladding,” Appl Surf Sci, vol. 363, pp. 543–547, Feb. 2016. [CrossRef]

- Y. He, J. Zhang, H. Zhang, and G. Song, “Effects of Different Levels of Boron on Microstructure and Hardness of CoCrFeNiAlxCu0.7Si0.1By High-Entropy Alloy Coatings by Laser Cladding,” Coatings 2017, Vol. 7, Page 7, vol. 7, no. 1, p. 7, Jan. 2017. [CrossRef]

- Amar et al., “Additive manufacturing of high-strength CrMnFeCoNi-based High Entropy Alloys with TiC addition,” Intermetallics (Barking), vol. 109, pp. 162–166, Jun. 2019. [CrossRef]

- J. Li et al., “Additive manufacturing of high-strength CrMnFeCoNi high-entropy alloys-based composites with WC addition,” J Mater Sci Technol, vol. 35, no. 11, pp. 2430–2434, Nov. 2019. [CrossRef]

- B. Li, L. Zhang, Y. Xu, Z. Liu, B. Qian, and F. Xuan, “Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: Process, particle behavior and effects,” Powder Technol, vol. 360, pp. 509–521, Jan. 2020. [CrossRef]

- P. F. Jiang, C. H. Zhang, C. L. Wu, S. Zhang, J. B. Zhang, and A. O. Abdullah, “Microstructure and Properties of CeO2-Modified FeCoCrAlNiTi High-Entropy Alloy Coatings by Laser Surface Alloying,” Journal of Materials Engineering and Performance 2020 29:2, vol. 29, no. 2, pp. 1346–1355, Feb. 2020. [CrossRef]

- S. Chen, X. Chen, L. Wang, J. Liang, and C. Liu, “Laser cladding FeCrCoNiTiAl high entropy alloy coatings reinforced with self-generated TiC particles,” J Laser Appl, vol. 29, no. 1, p. 012004, Nov. 2016. [CrossRef]

- C. Kenel, N. P. M. Casati, and D. C. Dunand, “3D ink-extrusion additive manufacturing of CoCrFeNi high-entropy alloy micro-lattices,” Nat Commun, vol. 10, no. 1, Dec. 2019. [CrossRef]

- J. U. Surjadi, L. Gao, K. Cao, R. Fan, and Y. Lu, “Mechanical Enhancement of Core-Shell Microlattices through High-Entropy Alloy Coating,” Scientific Reports 2018 8:1, vol. 8, no. 1, pp. 1–10, Apr. 2018. [CrossRef]

- T. Wohlers, “Rapid Prototyping & Tooling State of the Industry Annual Worldwide Progress Report Rapid Prototyping & Tooling State of the Industry Annual Worldwide Progress Report TERRY WOHLERS 2 0 0 2”.

- J. P. Kruth, L. Froyen, J. van Vaerenbergh, P. Mercelis, M. Rombouts, and B. Lauwers, “Selective laser melting of iron-based powder,” J Mater Process Technol, vol. 149, no. 1–3, pp. 616–622, Jun. 2004. [CrossRef]

- X. P. Li, M. P. Roberts, S. O’Keeffe, and T. B. Sercombe, “Selective laser melting of Zr-based bulk metallic glasses: Processing, microstructure and mechanical properties,” Mater Des, vol. 112, pp. 217–226, Dec. 2016. [CrossRef]

- M. Saha, “A Brief Discussion on High-Entropy Alloys vs Compositionally Complex Alloys,” Oct. 2021. [CrossRef]

- Saha, M. (2022). Densification and characterization of pressureless sintered ZrB2-20 vol% MoSi2 ultra high temperature ceramic composites. M. Mallik et al. Densification and characterization of pressureless sintered ZrB2-20 vol% MoSi2 ultra high temperature ceramic composites, 47, 77-82. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).