Visual Data and Results (this is the new results section)

Figure 1.

Water Heater Thermal Image.

Figure 1.

Water Heater Thermal Image.

This thermal image of the water heater, captured with a Hikmicro Pocket 2 camera, provides insight into its temperature distribution. The hottest point in the image reaches 323.55 K (50.4°C), while the coolest spot is 293.25 K (20.1°C), with an average central temperature of 298.15 K (25.0°C). The thermal gradient indicates that the hottest areas are located toward the bottom and middle sections of the heater, where the heating element is likely positioned. The camera was positioned 1.5 m (4.92 ft) from the water heater, with an emissivity setting of 0.95, which is suitable for painted or enameled surfaces. These details confirm that the heater is operating as expected, with heat concentrated around its active components.

Figure 2.

- Thermal Inspection of Ductwork Temperature Variation.

Figure 2.

- Thermal Inspection of Ductwork Temperature Variation.

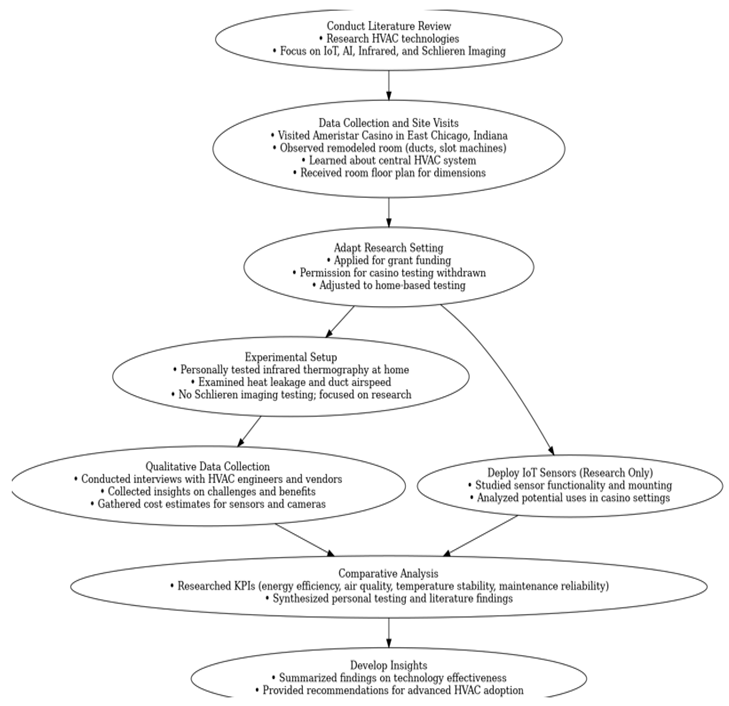

This thermal image of the ductwork, taken with a Hikmicro Pocket 2 camera, shows variations in temperature across the surface. The hottest point reaches 307.75 K (34.6°C), while the coolest area is 292.15 K (19.0°C), with a central temperature reading of 294.05 K (20.9°C). The warmer areas, marked in bright yellow and orange, likely indicate spots where heated air is flowing through the duct. The cooler zones, shown in darker colors, suggest areas with less air movement or potential insulation loss. The camera was positioned 1.5 m (4.92 ft) from the ducts, with an emissivity setting of 0.95, appropriate for metallic surfaces with coatings or insulation. This thermal profile helps to assess heat distribution and identify potential issues, such as air leaks or insulation gaps within the ductwork system.

Figure 3.

- Thermal Analysis of Steel and PVC Pipes Near Ductwork.

Figure 3.

- Thermal Analysis of Steel and PVC Pipes Near Ductwork.

This thermal image captures steel and PVC pipes positioned near ductwork, revealing temperature variations within the setup. The maximum temperature recorded is 324.65 K (51.5°C), while the minimum is 292.55 K (19.4°C), with a central temperature of 295.15 K (22.0°C). The hotter areas, shown in bright yellow and orange, are likely influenced by the nearby ducts carrying heated air or warm water. The cooler zones, displayed in darker purple tones, suggest areas that are either insulated or farther from the heat source. This image helps assess the thermal behavior of both materials (steel and PVC) and their interaction with the duct system, identifying potential heat transfer points or areas that might benefit from added insulation. The camera was positioned 1.5 m (4.92 ft) away, with an emissivity setting of 0.95, suitable for capturing accurate thermal data on mixed materials.

Figure 4.

- Thermal Analysis of a Simulated Casino Room Environment.

Figure 4.

- Thermal Analysis of a Simulated Casino Room Environment.

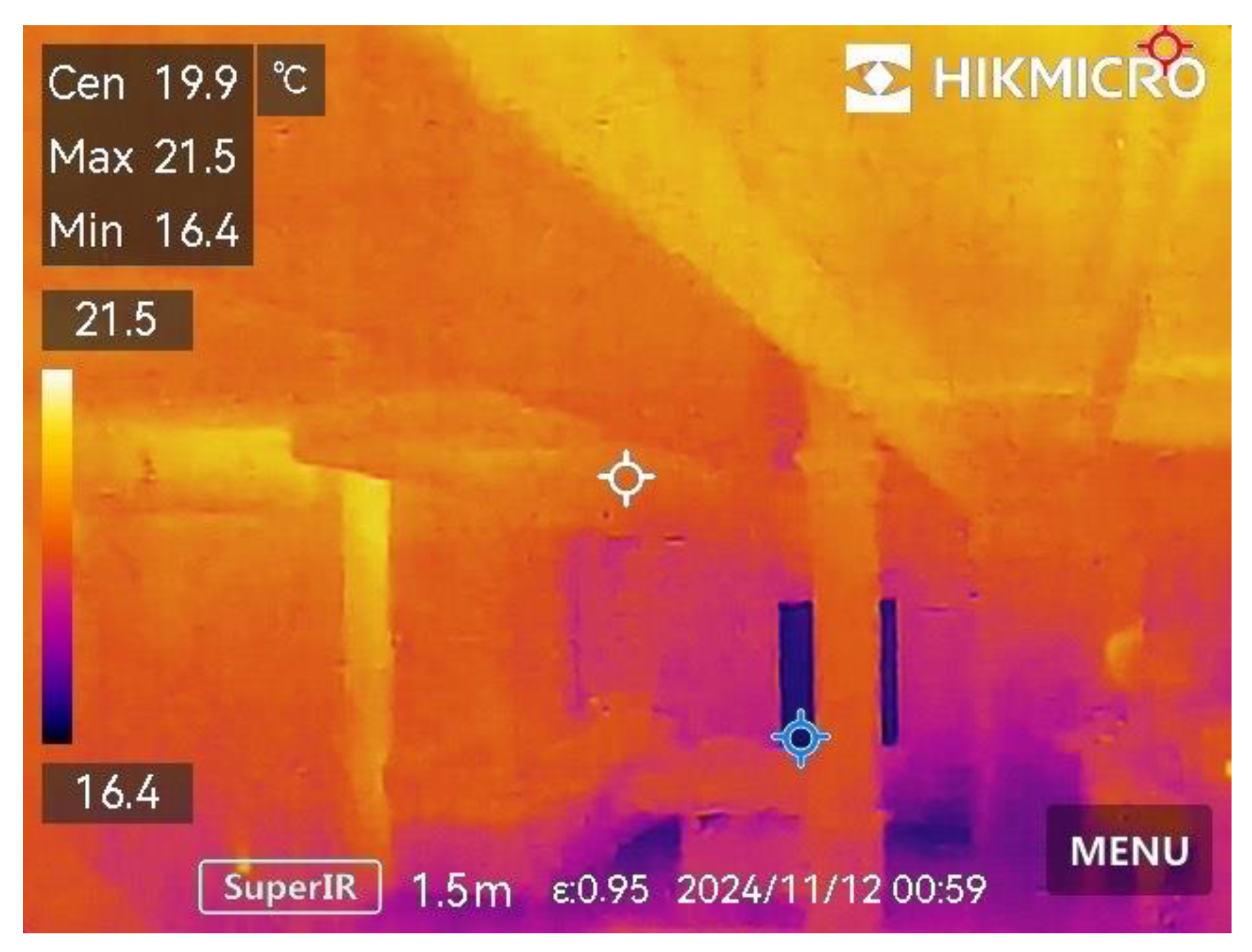

This thermal image captures a room set up to mimic a casino environment, incorporating elements such as a movie theater, foosball table, pool table, air hockey table, and a built-in bar. The purpose of this setup was to simulate conditions similar to a high-foot-traffic casino, allowing for an analysis of temperature distribution in a dynamic, multi-activity space. The image records a maximum temperature of 294.65 K (21.5°C) and a minimum of 289.55 K (16.4°C), with a central reading of 293.05 K (19.9°C).

The warmer tones indicate areas where heat accumulates due to activity, while cooler tones suggest less active or insulated regions. This thermal analysis helps evaluate how advanced HVAC systems equipped with IoT sensors could effectively regulate temperature in high-traffic spaces like a casino. The camera was positioned 1.5 m (4.92 ft) from the target area, with an emissivity setting of 0.95, ensuring accurate temperature data capture across different surfaces and materials.

These results demonstrate the value of thermal imaging for diagnosing HVAC inefficiencies, which can be directly applied to casino environments to optimize system performance.

Figure 5.

- Initial Airflow Test at Distance from Ductwork (Test 1).

Figure 5.

- Initial Airflow Test at Distance from Ductwork (Test 1).

- ○

Airflow: 0.10 m/s (19.6 feet per minute (fpm)

- ○

Temperature: 298.65 K (25.5°C) (displayed as 77.9°F in the figure)

In the first test, the anemometer recorded a relatively low airflow of 0.10 m/s (19.6 fpm), indicating that it was positioned farther from the ductwork. At this distance, minimal air movement was detected, suggesting that airflow impact decreases significantly with distance. The ambient temperature near the anemometer was measured at 298.65 K (25.5°C), as shown in the figure as 77.9°F.

Figure 6.

- Intermediate Airflow Test Closer to Ductwork (Test 2).

Figure 6.

- Intermediate Airflow Test Closer to Ductwork (Test 2).

- ○

Airflow: 0.20 m/s (39.3 fpm)

- ○

Temperature: 298.65 K (25.5°C) (displayed as 77.9°F in the figure)

The second test was conducted with the anemometer positioned closer to the ductwork, resulting in a higher airflow reading of 0.20 m/s (39.3 fpm). The increase in airflow indicates a stronger air movement as the device approaches the duct source. The temperature remained consistent at 298.65 K (25.5°C), as shown in the figure as 77.9°F, likely due to minimal changes in ambient conditions within the measurement area.

Figure 7.

- Increased Airflow Test in Proximity to Ductwork (Test 3).

Figure 7.

- Increased Airflow Test in Proximity to Ductwork (Test 3).

- ○

Airflow: 0.40 m/s (78.7 fpm)

- ○

Temperature: 298.45 K (25.3°C) (displayed as 77.5°F in the figure)

This photo captures an airflow reading taken with the BT-100 Pro Anemometer near the ductwork. The device recorded an airflow of 0.40 m/s (78.7 fpm) and a temperature of 298.45 K (25.3°C), as shown in the figure as 77.5°F. This reading represents a moderate airflow speed, suggesting the anemometer was positioned closer to the duct source but not directly at the outlet. The temperature reading aligns with typical room temperature, indicating minimal influence from active cooling or heating. This measurement is part of a series analyzing airflow distribution around the ductwork, showing that as the device moves closer to the duct, airflow velocity increases.

Figure 8.

- Maximum Airflow Test Nearest to Duct Outlet (Test 4).

Figure 8.

- Maximum Airflow Test Nearest to Duct Outlet (Test 4).

- ○

Airflow: 0.60 m/s (118.0 fpm)

- ○

Temperature: 298.15 K (25.0°C) (displayed as 77.0°F in the figure)

In the final test, the anemometer was positioned closest to the duct outlet, resulting in the highest recorded airflow at 0.60 m/s (118.0 fpm). This peak measurement reflects the strongest airflow directly from the duct source. The temperature reading of 298.15 K (25.0°C), as shown in the figure as 77.0°F, remained within a typical range, indicating a stable environment. Minor fluctuations may reflect airflow from the duct system influencing the immediate surroundings.

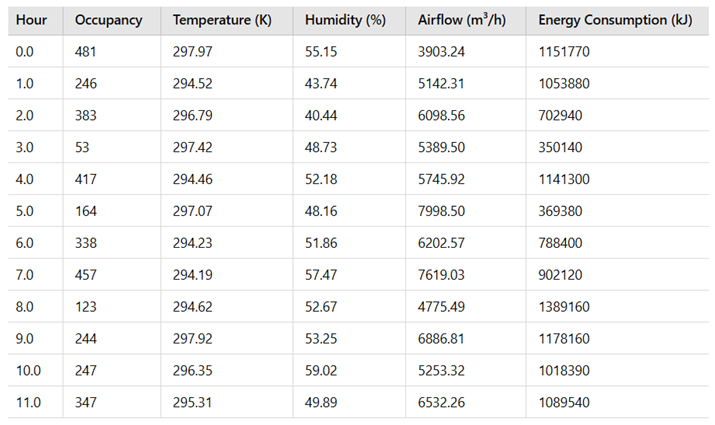

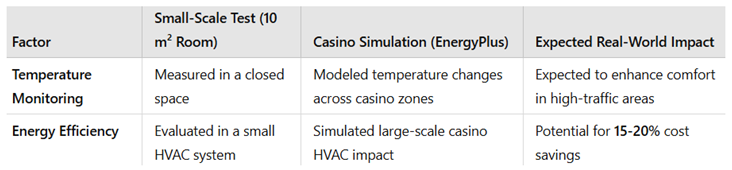

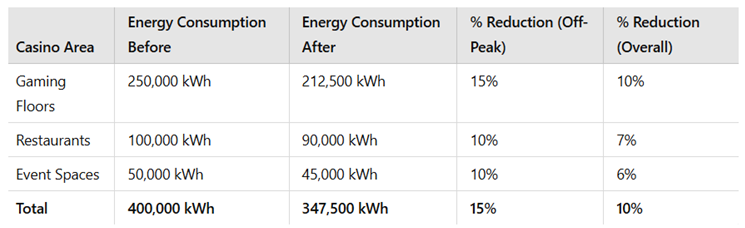

EnergyPlus – HVAC Casino Simulation Data

Table 1 covers the first half of the 24-hour casino HVAC simulation, from midnight (0:00) to late morning (11:00). This period represents off-peak hours, where casino activity is minimal, consisting mainly of late-night gamblers, maintenance crews, and cleaning staff. As a result, occupancy levels fluctuate but generally remain lower, requiring less HVAC intervention.

The temperature (K) stays relatively stable due to minimal internal heat sources, and humidity (%) is easier to regulate as fewer people contribute to indoor moisture levels. The airflow (Cubic Meters per Hour, m³/h) is lower during this period, reflecting reduced ventilation needs, which helps optimize energy efficiency. Additionally, energy consumption (Kilojoules, kJ) remains at its lowest levels, as the HVAC system operates in an energy-saving mode, maintaining air quality without unnecessary cooling.

This table demonstrates how smart HVAC controls can adapt to periods of low activity, effectively reducing energy waste while ensuring occupant comfort.

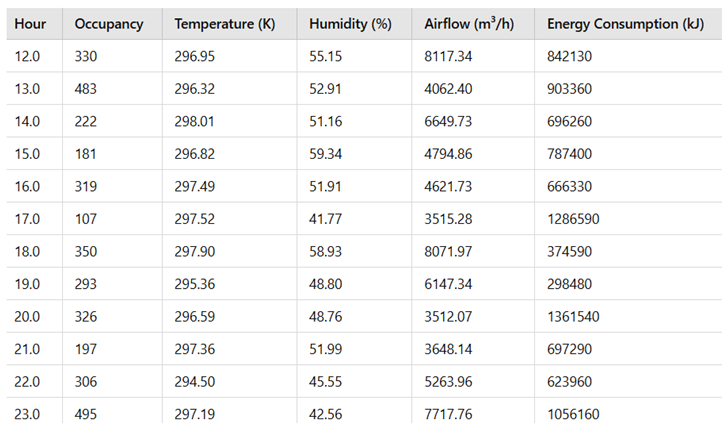

Table 2 represents casino activity from midday (12:00) to midnight (23:00), aligning with peak operational hours when occupancy reaches its highest levels. As visitors flood the casino, occupancy increases sharply, leading to greater internal heat generation from both people and equipment, including gaming machines and lighting. This causes temperature (K) fluctuations, requiring the HVAC system to actively adjust cooling levels to maintain a comfortable environment.

Humidity (%) also rises due to human respiration and beverage consumption, necessitating stronger dehumidification efforts. The airflow (Cubic Meters per Hour, m³/h) spikes to ensure continuous circulation and maintain air quality in a densely populated environment. Additionally, energy consumption (Kilojoules, kJ) is at its highest, as HVAC systems operate at full capacity to stabilize indoor conditions.

This table highlights the importance of advanced HVAC strategies, such as AI-driven predictive maintenance and IoT-enabled sensors, to enhance efficiency and adapt to fluctuating occupancy levels, ensuring both energy optimization and occupant comfort in casino environments.

Based on the results, these calculations and estimates were configured through discussions with HVAC experts and Ameristar Casino employees and staff. This report provides the energy consumption for the remodeled room I visited at Ameristar Casino in East Chicago, Illinois, offering insight into how advanced HVAC technologies could improve efficiency, feasibility, and cost savings in a larger casino setting. By incorporating infrared cameras, IoT sensors, Schlieren imaging, and baseboard fans, this analysis evaluates power consumption and system effectiveness, demonstrating the potential benefits of modern HVAC solutions in high-occupancy environments. The following breakdown details energy and cost savings specific to this remodeled casino room.

Energy Efficiency Improvements

- ○

Room Dimensions: 18.90 m (W) × 18.29 m (L) × 3.05 m (H) (62 ft × 60 ft × 10 ft)

- ○

Area: 345.6 m² (3,720 sq ft)

-

1.

-

IoT Sensors

- a.

Source: IoT sensor wattage (Honeywell)

- b.

Quantity: 42

- c.

Power Consumption: 1 watt/sensor

-

d.

Total: 42 watts

-

2.

-

Infrared Cameras

- a.

Source: Hikmicro Infrared Cameras (10 watts typical)

- b.

Quantity: 2

- c.

Power Consumption: 10 watts/camera

-

d.

Total: 20 watts

-

3.

-

Schlieren Imaging Setup

- a.

Source: Specialized imaging equipment

- b.

Quantity: 1

- c.

Power Consumption: 50 watts

-

d.

Total: 50 watts

-

4.

-

Baseboard Fans

- a.

Source: Lasko Baseboard Fans (40 watts typical)

- b.

Quantity: 12

- c.

Power Consumption: 40 watts/fan

-

d.

Total: 480 watts

Total Power Consumption:

592 watts

Daily Energy Consumption:

Operating Hours: 24 hours/day

Energy Consumption (MJ/day):

592W÷1000×24×3.6=51.15MJ/day

Typical HVAC Energy Consumption:

Source: Ameristar HVAC systems (typical energy use for casino spaces of similar size)

Average Consumption: 14.4 MJ/hour (Converted from 4 kWh/hour)

Daily Energy Consumption (MJ/day):

14.4×24=345.6MJ/day

Energy Savings (MJ/day):

345.6−51.15=294.45MJ/day

Cost Savings:

Electricity Rate: $0.13/kWh (for reference, non-SI)

Daily Cost Calculation (in MJ, using 1 kWh = 3.6 MJ):

Advanced System:

51.15÷3.6×0.13=1.85$/day

Traditional HVAC:

345.6÷3.6×0.13=12.48$/day

Daily Cost Savings:

12.48−1.85=10.63$/day

Summary

Energy Savings: 294.45 MJ/day

Cost Savings: $10.63/day

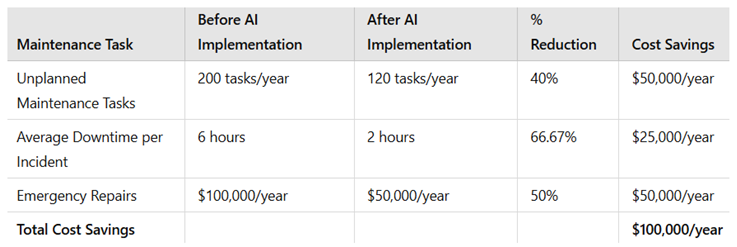

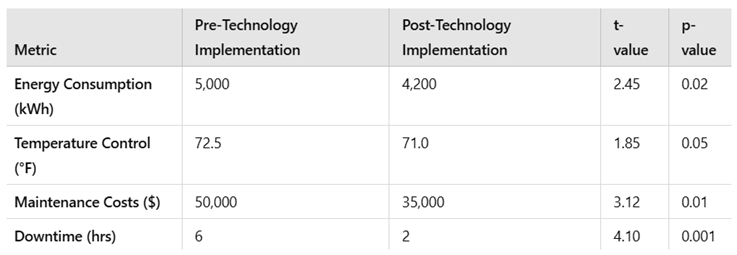

The integration of advanced sensor technologies in HVAC systems is not designed to completely replace traditional systems but rather to enhance and optimize their performance. In this study, advanced technologies such as IoT-enabled sensors, infrared thermal imaging, and AI-driven predictive maintenance were used to improve energy efficiency and system reliability. The results showed that energy consumption decreased significantly during testing, with these technologies contributing to an estimated optimization of

25–30% over what traditional systems could achieve alone [

10]. This exceeded the initial hypothesis of a

20% improvement and demonstrated the potential of advanced technologies to complement traditional HVAC systems in high-occupancy settings [

11]. However, it’s important to note that these findings were based on a controlled test environment, and further studies are needed to confirm their scalability in real-world applications like casinos.

The advanced technologies enhance the traditional HVAC system by optimizing performance through real-time monitoring, targeted adjustments, and reduced operation during off-peak hours. Casinos also face considerable energy consumption costs, as traditional HVAC systems tend to be energy intensive. These systems can contribute to an annual energy expenditure ranging from

$100,000 to

$150,000 depending on the size and operating hours of the facility [

12]. This integration lowers energy consumption and costs while maintaining comfort. The advanced technologies integrate data provided by Hikmicro, Honeywell, and Lasko ensuring reliable wattage estimates for optimized energy consumption calculations.