Submitted:

20 December 2024

Posted:

20 December 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

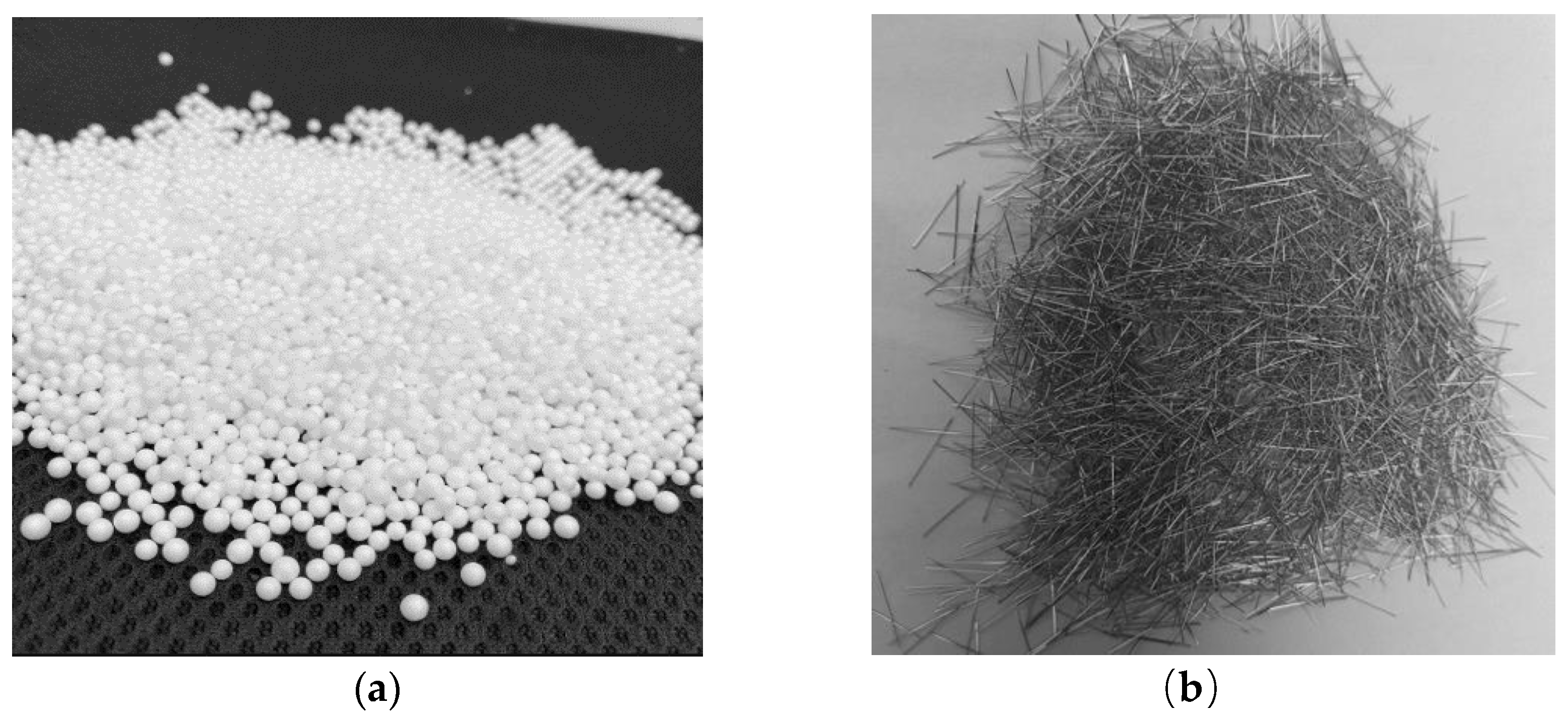

2.1. Test Materials

2.2. Experimental Plan

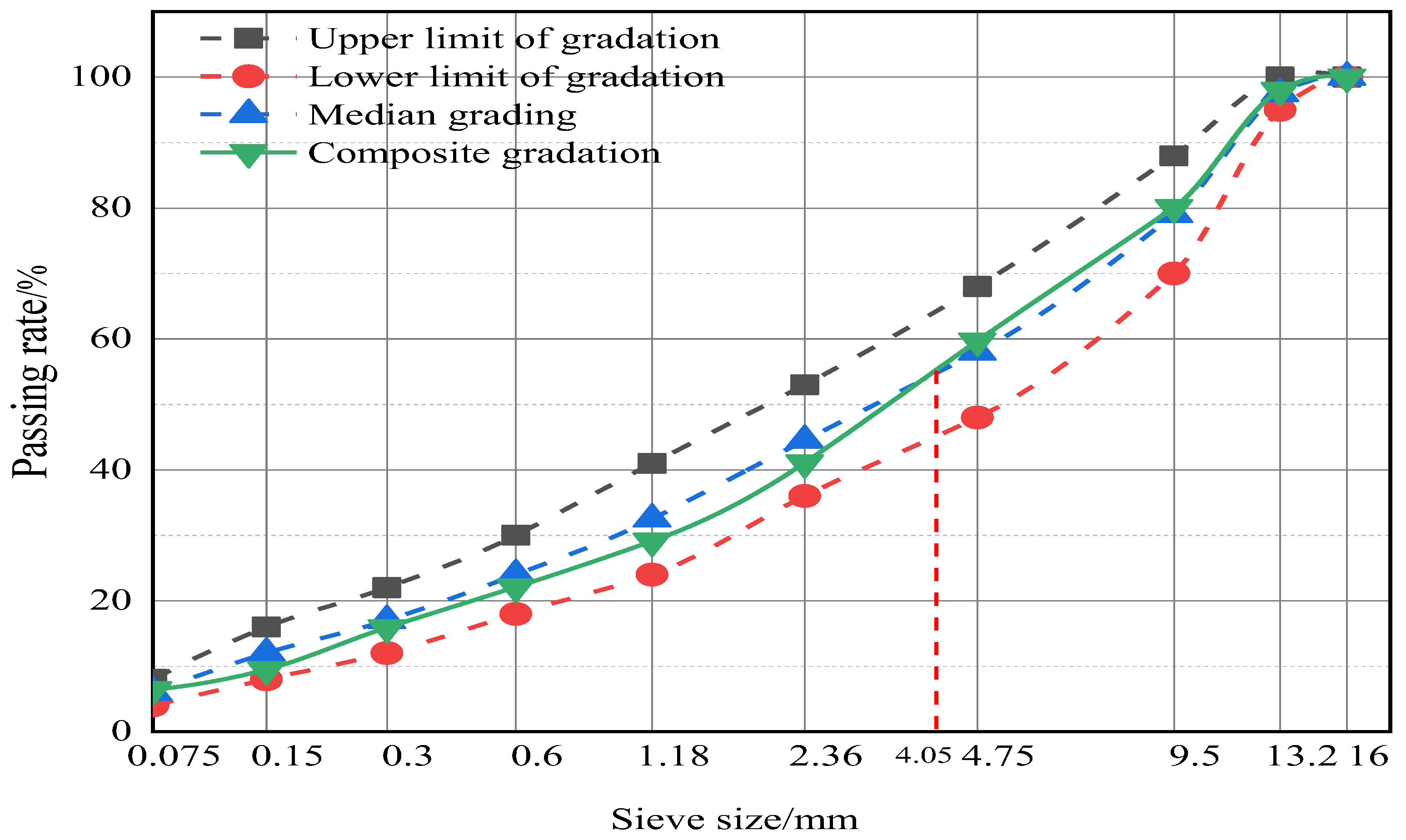

2.3. Material Grading Curve

2.4. Mix Design

3. Analysis of Experimental Phenomena and Results

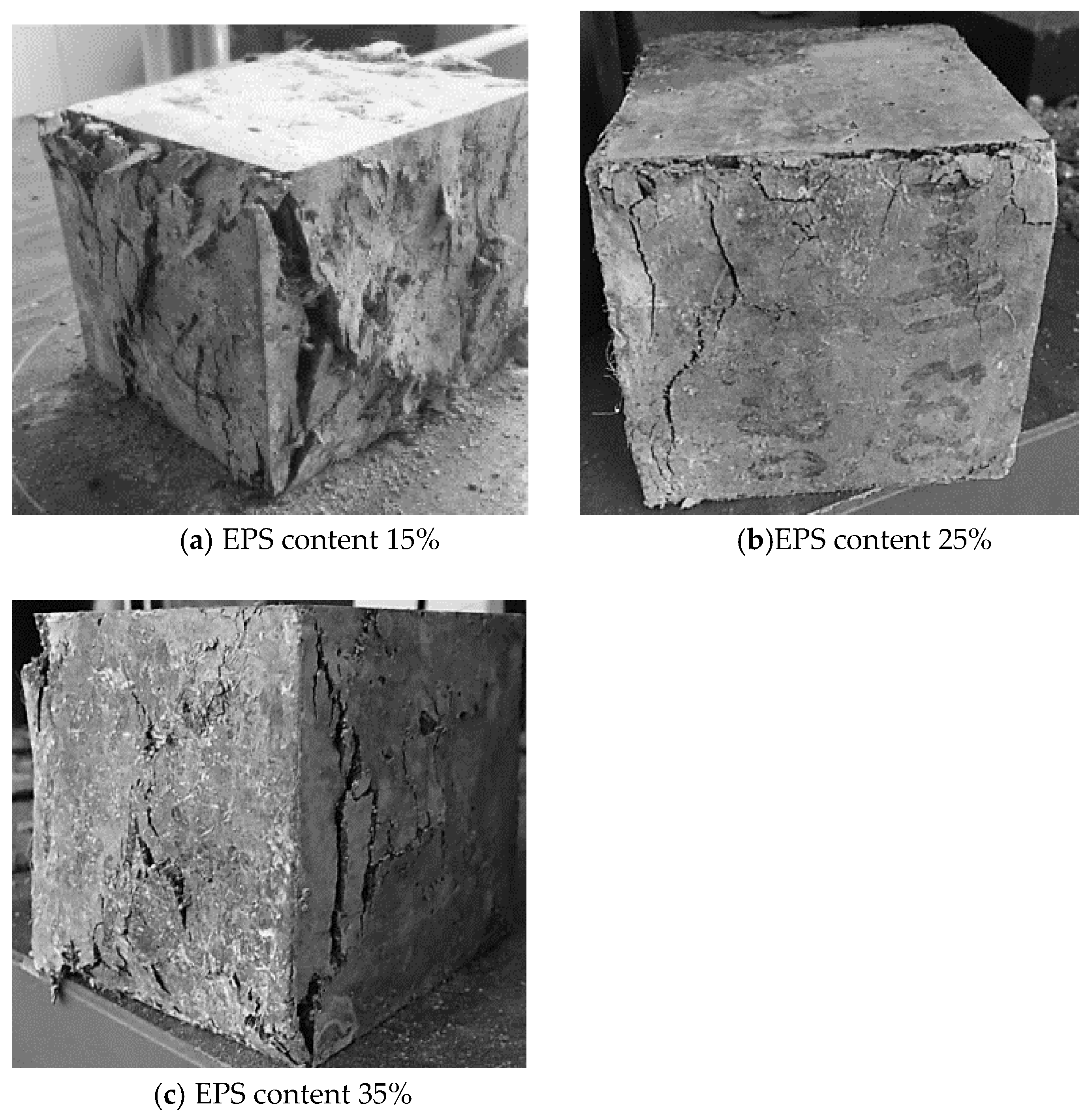

3.1. Failure Mode of Compression Test Specimens

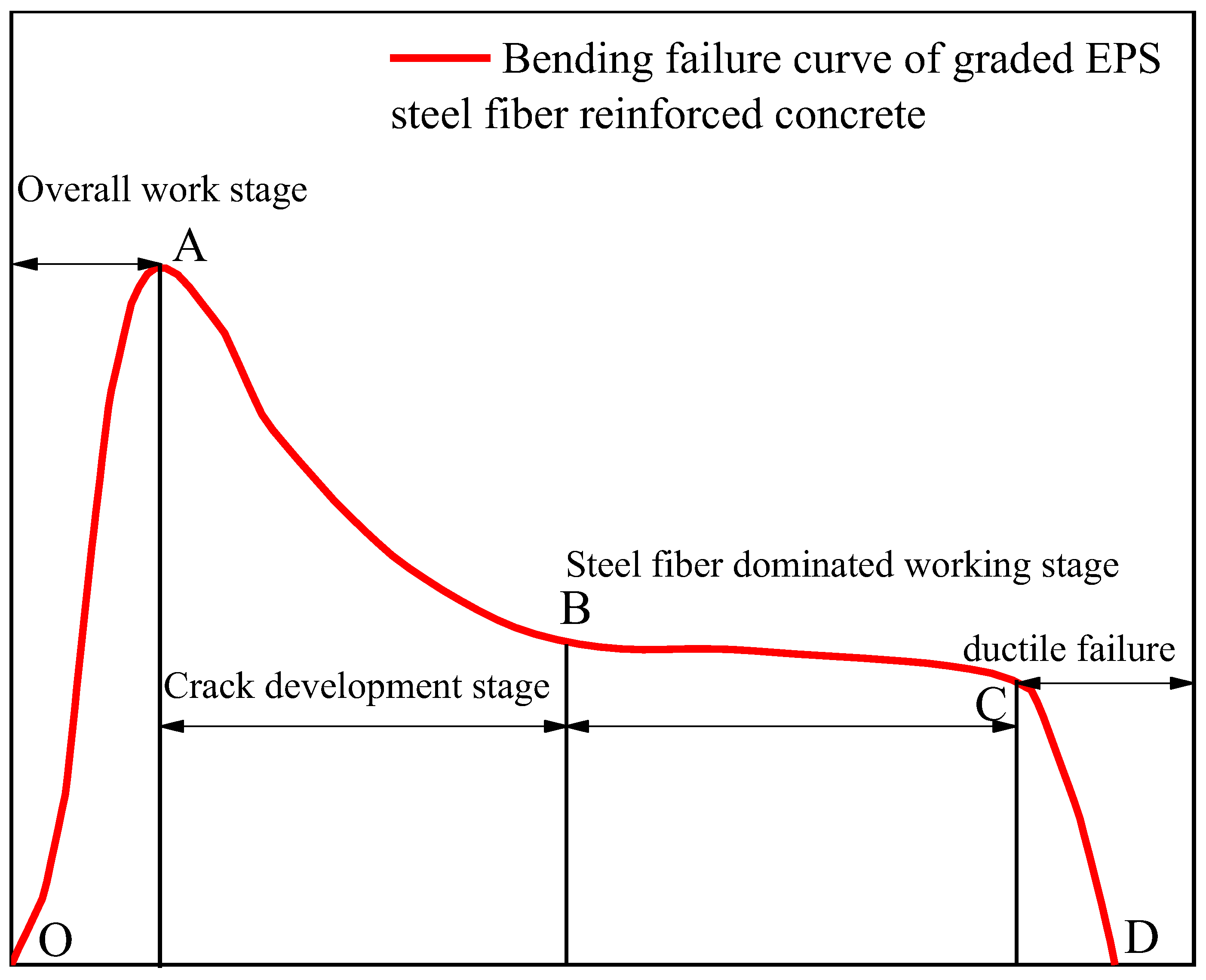

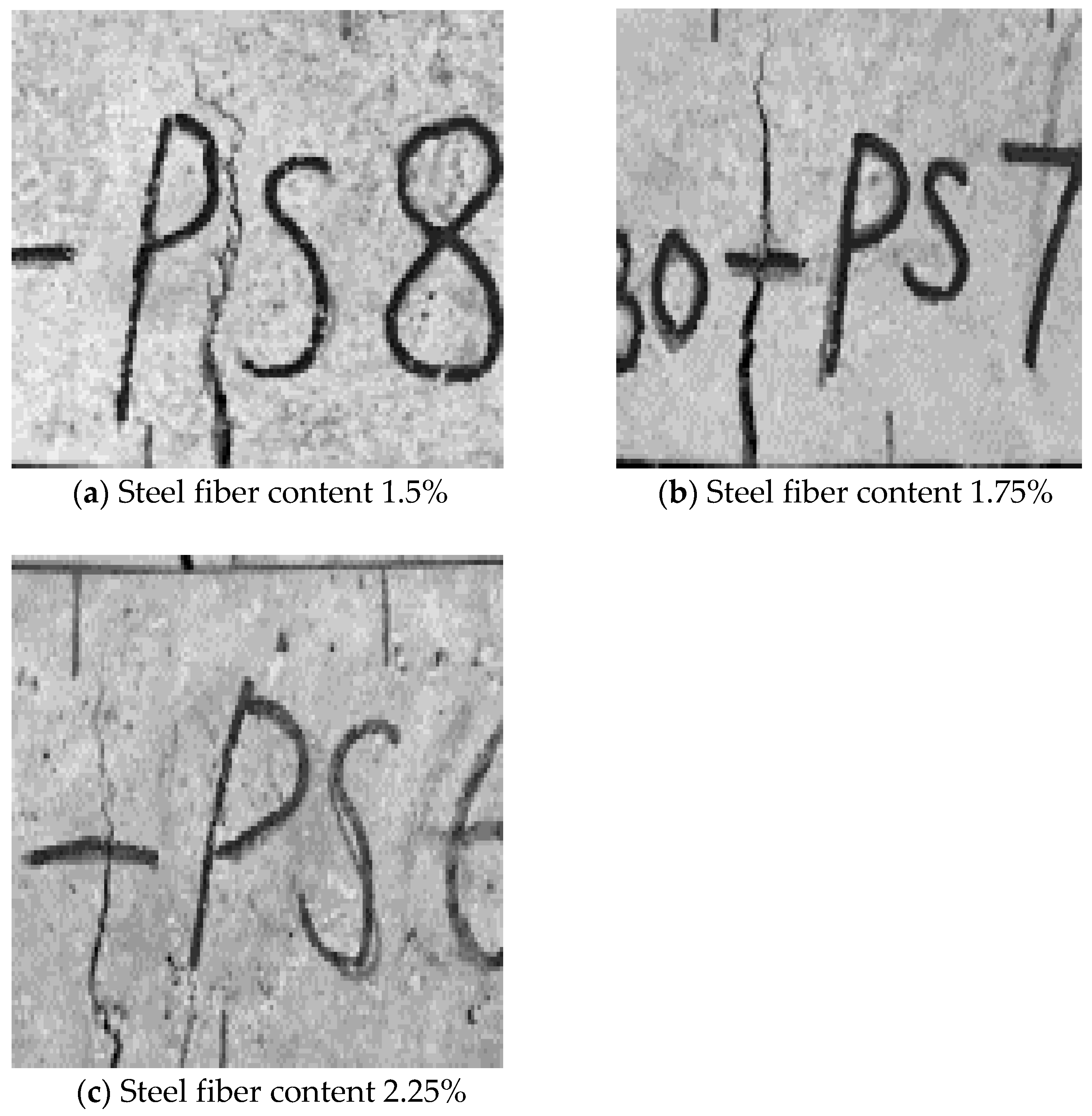

3.2. Failure Mode of Flexural Test Specimen

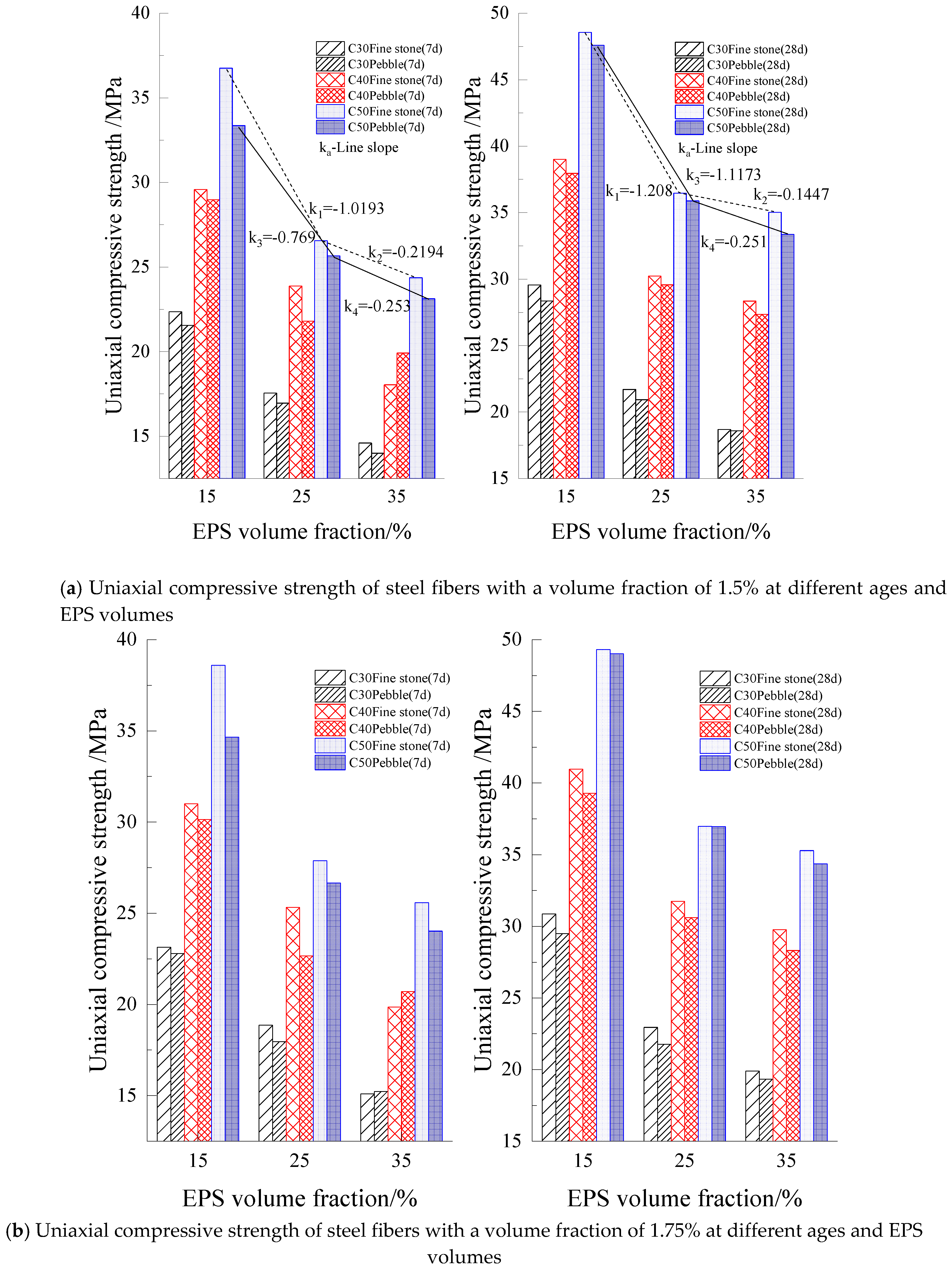

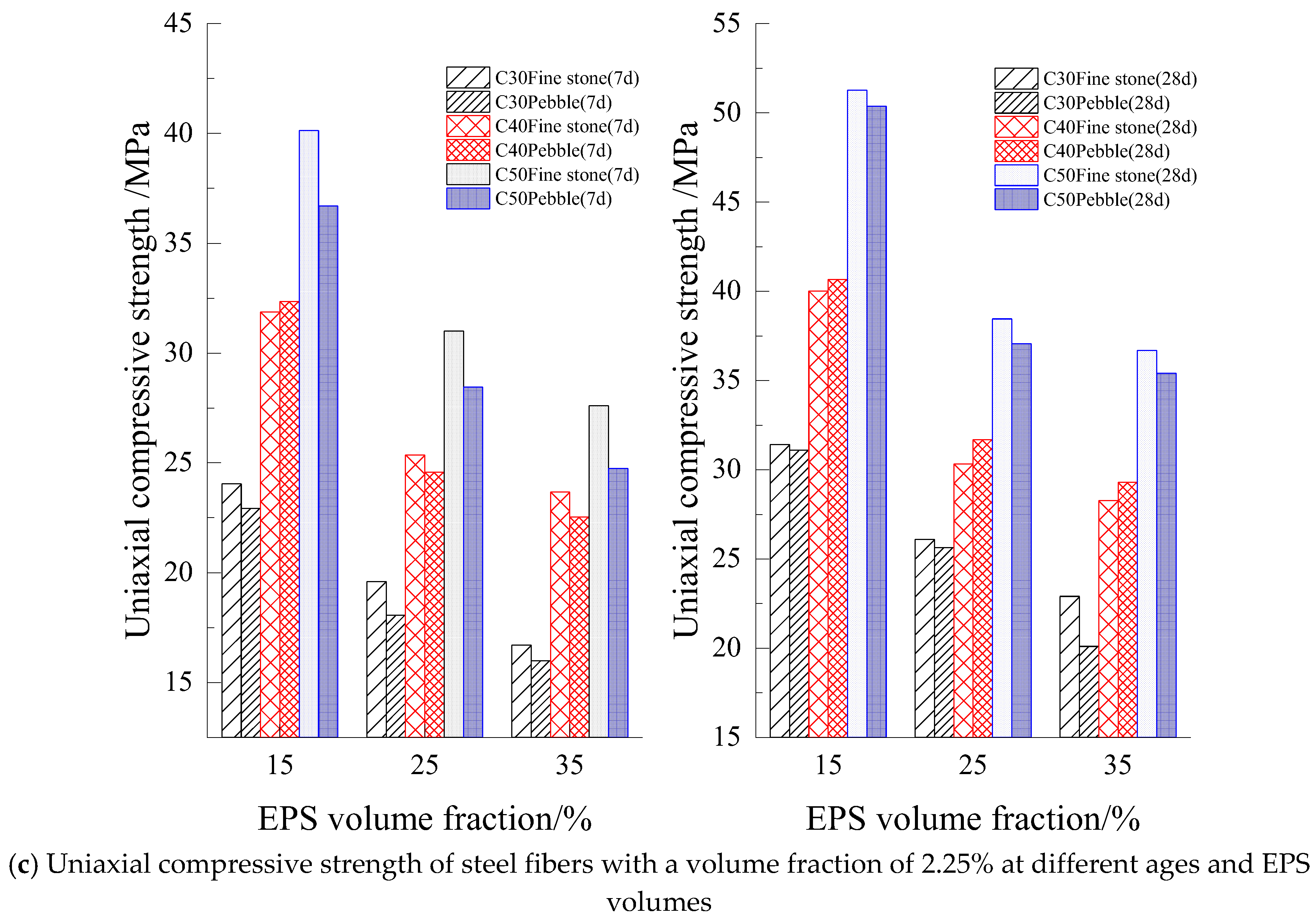

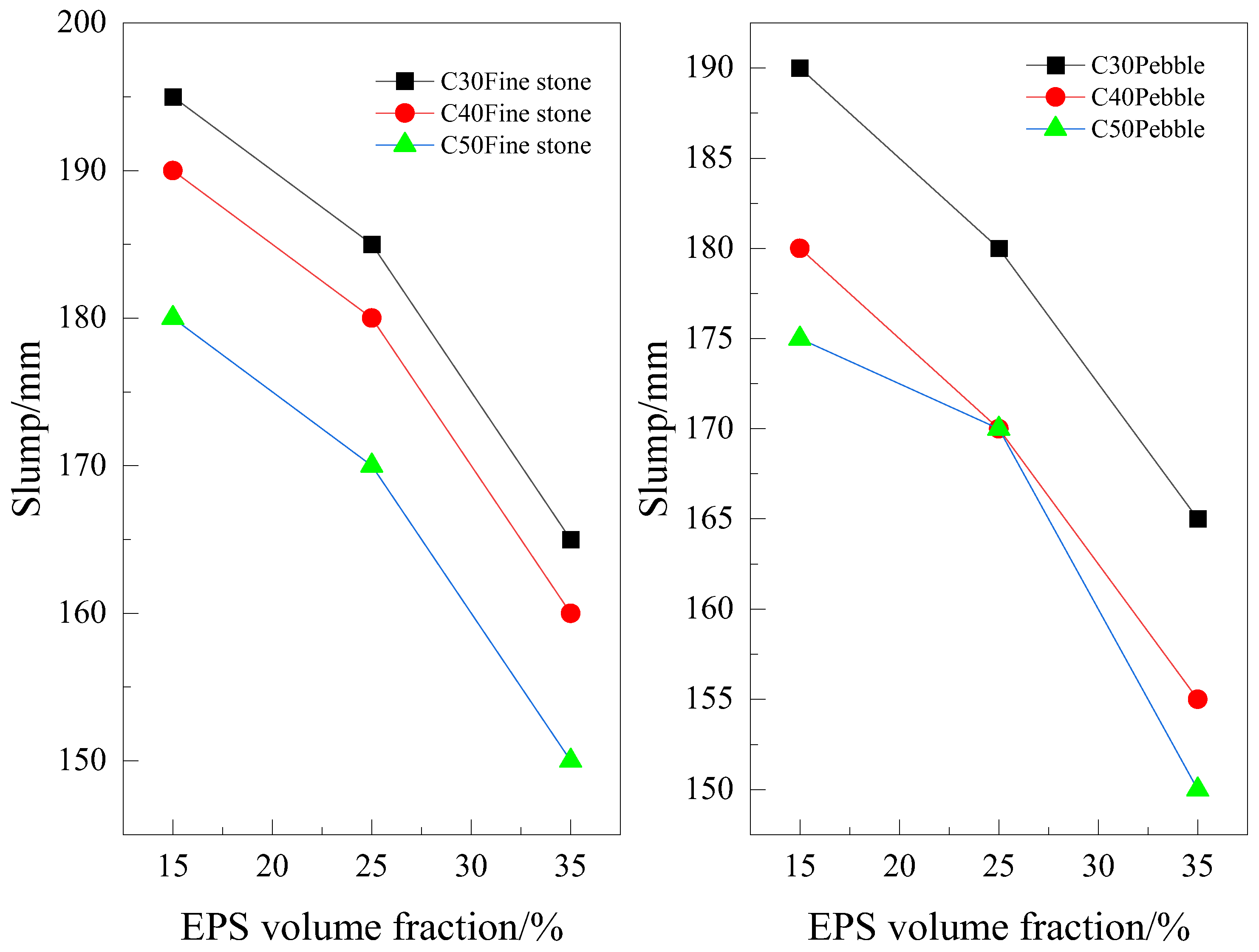

3.3. Evaluation of Compressive Strength and Flowability

- Aggregate replacement: The 5 mm particles in graded EPS replace some coarse aggregates, and the 1 mm particles replace part of the fine aggregates. This improves the embedding effect of the concrete matrix structure, increases frictional resistance, and at the same time, the lower density of EPS particles compared to aggregates reduces the vertical and diagonal component forces from the weight of the concrete matrix during the slump test, leading to a decrease in the slump (positive effect).

- Reduced water content: The incorporation of graded EPS reduces the amount of water required for concrete [26], increasing the consistency and reducing the slump (positive effect).

- Hydrophobic nature of EPS particles: EPS particles are hydrophobic, preventing the retention of free water on their surfaces. As a result, there is no liquid bridge connection between EPS particles and fine aggregate particles. According to the Young-Laplace theory, the absence of capillary suction between the two types of particles leads to an increase in the concrete slump (negative effect).

- Steel fiber length: The length of steel fibers is much greater than the diameter of the aggregates. When steel fibers are incorporated, they consume more cement paste to surround them. Additionally, steel fibers may anchor the matrix, improving particle integrity and reducing the concrete slump (positive effect).

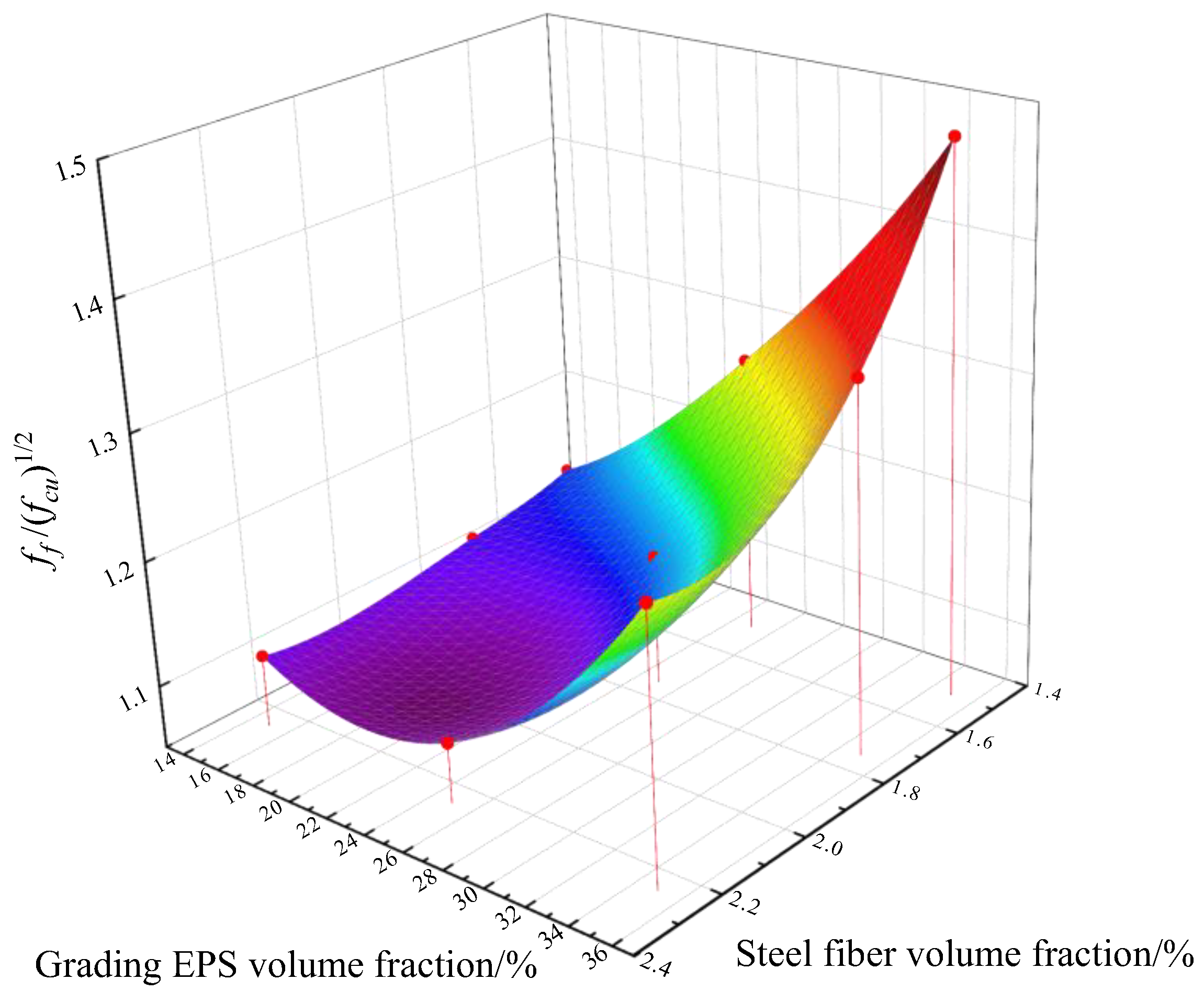

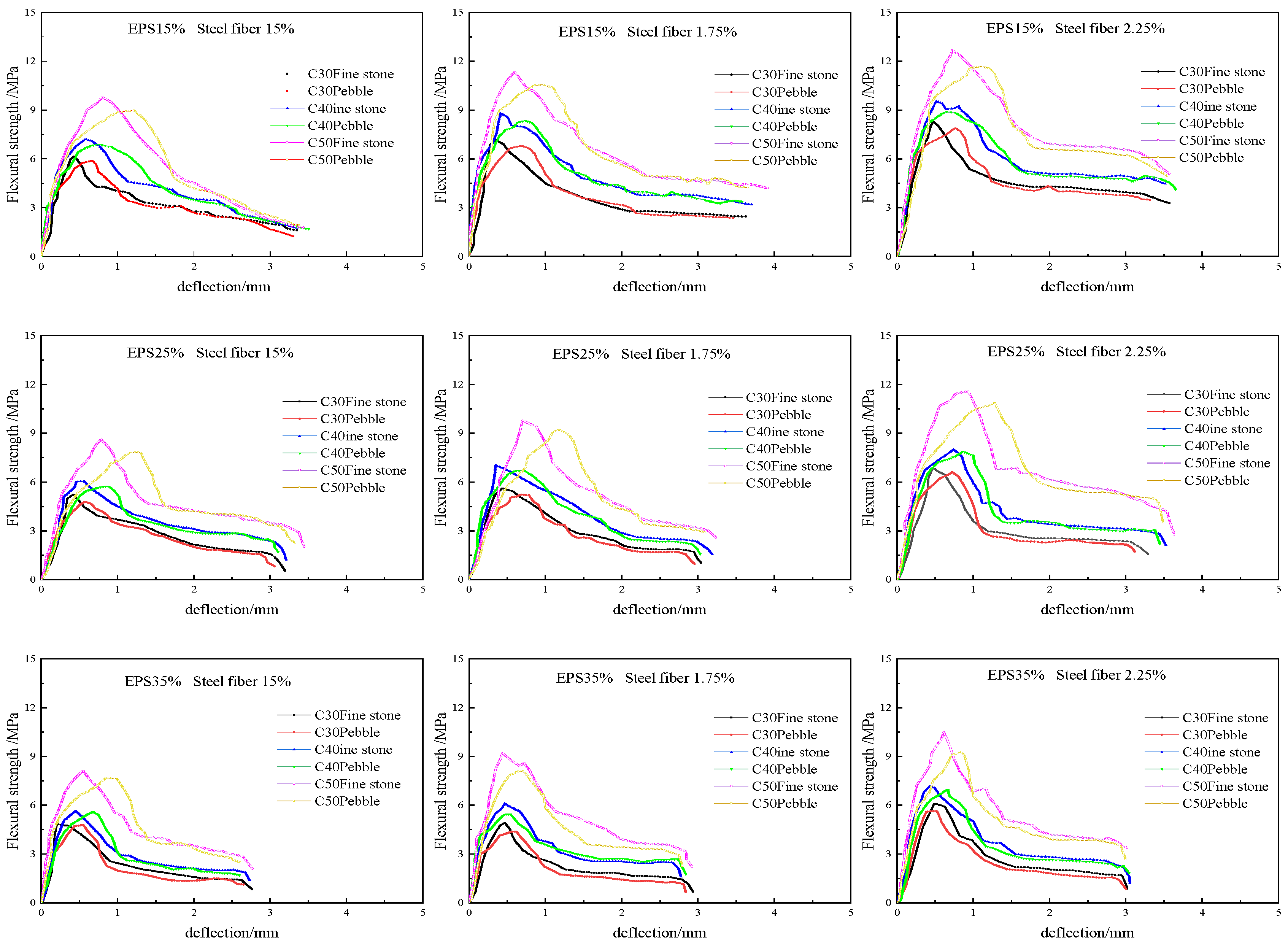

3.4. Flexural Strength and Failure Mechanism

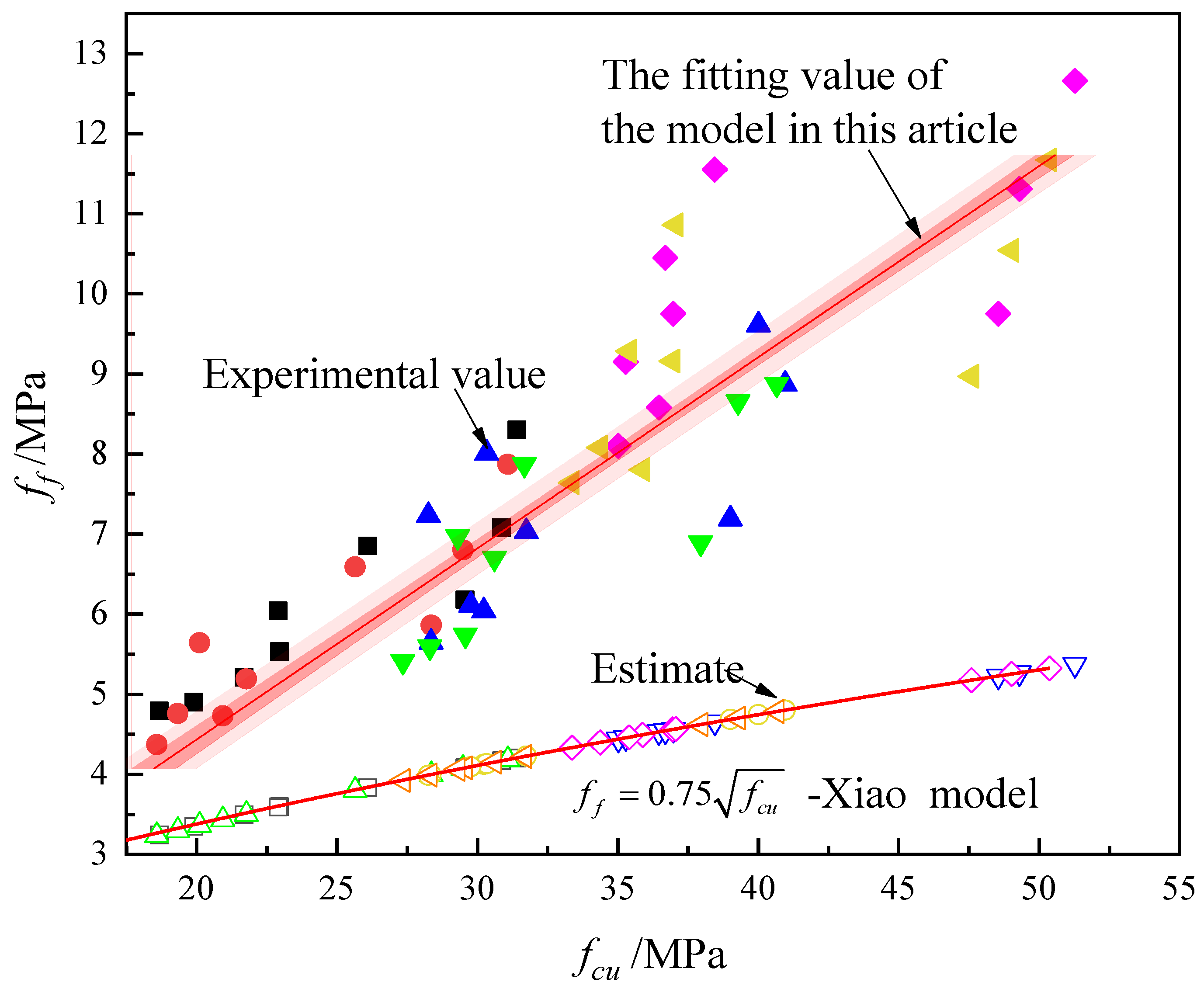

3.5. Conversion Formula and Accuracy of Compression Ratio

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Zhang, W.H., Lv, Y.J., Liu, P.Y. (2019). Review on the research progress of EPS concrete. Materials Review, 33(13), 2214-2228.

- Scioti, A., & Fatiguso, F. (2024). Performance characterization and evaluation of innovative cement mortars and concretes made with recycled EPS. Applied Sciences, 14, 1583.

- Subhani, K., Prasad, K., Hameed, N., Nikzad, M., & Salim, N.V. (2024). Expanded polystyrene/tyre crumbs composites as promising aggregates in mortar and concrete. Polymers, 16, 3207.

- Qu, L.L., & Zhang, D.W. (2022). Rheological properties and corrosion resistance analysis of recycled EPS plastic/concrete composites. Plastic Science and Technology, 50(01), 31-35.

- Li, J.H., Tian, Z.J., Tang, T.Y., et al. (2021). Effect of spherical SAP aggregates and EPS aggregates on the mechanical properties of concrete. Concrete, 2021(04), 70-73+77.

- Zhao, D.L., Hu, C.Y., Bo, D.S., et al. (2015). Building energy conservation. 43(3), 116 (in Chinese).

- Srinivas, K., Akula, K.R., & Mahesh, V. (2021). Experimental investigation on lightweight concrete by replacing coarse aggregate with coconut shell and expanded polystyrene beads and using polypropylene fiber. Materials Today: Proceedings, 46, 838-842.

- Patricia, F.B.B., Carmeane, E., & Adilson, S. (2022). Lightweight thermal insulating coating mortars with aerogel, EPS, and vermiculite for energy conservation in buildings. Cement and Concrete Composites, 125, 104283.

- Yu, Z.P., Yang, W.J., Huang, D.K., et al. (2022). Effect of fiber on the mechanical properties of polystyrene particle concrete.Concrete, 2022(11), 68-72+76.

- Li, Q.R., Wei, T., Liu, K.N. (2021). Compressive constitutive model and bending toughness test of steel fiber reinforced recycled concrete.Concrete, 2021(10), 31-35.

- Gao, D.Y., Zhao, L.P., Feng, H., et al. (2014). Bending toughness and evaluation methods of steel fiber concrete. Journal of Building Materials, 17(05), 783-789.

- Cook, D.J. (1973). Expanded polystyrene beads as lightweight aggregate for concrete.Precast Concrete, 4, 691-693.

- Zhang, W.H., Lv, Y.J., Liu, P.Y. (2019). Review on the research progress of EPS concrete. Materials Review, 33(13), 2214-2228.

- Luo, T.T., Liu, W.S., Guo, Y.J., et al. (2021). Review on the application of recycled polystyrene in concrete. Bulletin of the Chinese Ceramic Society, 40(01), 133-145.

- Liu, Y.C., Zhang, L.X., Zhan, J.P., et al. (2013). Strength model of EPS lightweight concrete. Concrete, 2013(02), 36-37+45.

- Zhou, K.K., Chen, B., Chen, L.Z. (2010). Effect of EPS particle gradation on the mechanical properties of EPS concrete. Journal of Harbin Engineering University, 31(02), 195-201.

- Yang, Y.M., Ge, Z.S. (2024). Impact test study on the full lightweight concrete beams with different steel fiber contents. Building Structures, 54(03), 59-64.

- Wu, D.Y., Yao, Q.S., Diao, F., et al. (2023). Bending toughness and impact resistance of steel fiber reinforced recycled concrete. Concrete, 2023(12), 141-144.

- Anjaney, A., Dix, I.T., Sung, H.K. (2019). Lightweight structural cement composites with expanded polystyrene (EPS) for enhanced thermal insulation. Cement and Concrete Composites, 102, 185-197.

- Zhou, K.K., Chen, B., Chen, L.Z. (2010). Effect of EPS particle gradation on the mechanical properties of EPS concrete. Journal of Harbin Engineering University, 31(02), 195-201.

- National Standardization Management Committee of China. (2013). Pre-mixed concrete (GB/T14902-2012) [S]. Beijing: China Standard Press.

- Ministry of Housing and Urban-Rural Development of the People's Republic of China. (2019). Standard for physical and mechanical property testing methods of concrete (GB/T 50081-2019) [S]. Beijing: China Building Industry Press.

- China Engineering Construction Standardization Association. (2010). Test method standards for fiber concrete (CECS 13-2009) [S]. Beijing: China Planning Press.

- Zhang, X.N., Guo, Z.X., Wu, K.H. (1995). Design of asphalt mixtures by volume method. Journal of Harbin University of Architecture, 1995(02), 28-36.

- Standard for performance test methods of common concrete mixes (GB/T 50080-2002) [S]. Beijing: China Building Industry Press.

- Pan, W.L., Deng, D.H., Yuan, T.P., et al. (2006). Effect of EPS lightweight concrete mix ratio on its flowability and mechanical properties. Concrete, 2006(02), 63-65+69.

- Ministry of Transport of the People's Republic of China. (2002). Specification for highway cement concrete pavement design (JTG D40-2002).

- Xiao, J.Z., Lin, Z.B., Zhu, J. (2014). Effect of recycled aggregate gradation on the compressive strength of concrete. Journal of Sichuan University (Engineering Science Edition), 46(04), 154-160.

- Zhang, X.G., Kuang, X.M., Zhang, X.X., et al. (2018). Study on the flexural and compressive strength conversion relationship of lightweight shale aggregate concrete. Bulletin of the Chinese Ceramic Society, 37(07), 2264-2269.

| Material Composition (%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

| P.O 42.5 | 21.85 | 4.75 | 3.15 | 61.50 | 0.95 | 7.5 |

| Nominal particle size (mm) | The cumulative sieve residue on the sieve (%) | Mineral aggregate proportion (%) | |||||||||

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | ||

| 11-22 | 100 | 95.3 | 69.1 | 33.1 | 18.0 | 10.0 | 3.01 | 0.90 | 0.39 | 0.15 | 35.6 |

| 6-11 | 100 | 98.2 | 71.1 | 42.2 | 25.6 | 14.2 | 7.10 | 3.10 | 1.35 | 0.68 | 19.2 |

| 3-6 | 100 | 100 | 77.3 | 47.2 | 35.1 | 22.3 | 15.1 | 9.5 | 4.10 | 1.95 | 3.7 |

| 0.075-3 | 100 | 100 | 92.5 | 89.9 | 61.2 | 41.9 | 33.3 | 20.4 | 8.10 | 2.21 | 33.5 |

| <0.075 | 100 | 100 | 100 | 100 | 100 | 100 | 99.7 | 98.4 | 77.5 | 56.5 | 8.0 |

| Upper gradation limit | 100 | 100 | 88 | 68 | 53 | 41 | 30 | 22 | 16 | 8 | / |

| Lower gradation limit | 100 | 95 | 70 | 48 | 36 | 24 | 18 | 12 | 8 | 4 | / |

| Median gradation | 100 | 97.5 | 79 | 58 | 44.5 | 32.5 | 24 | 17 | 12 | 6 | / |

| Combined gradation | 100 | 98.0 | 80.1 | 59.7 | 41.1 | 29.1 | 22.1 | 15.9 | 9.5 | 5.5 | / |

| Type | (%) | Superplasticizer | (%) | Experimental environment | ||||||||

| kg/m3 | ||||||||||||

| C30Gravel | 0.49 | 0.13 | 5.0 | 28 | 318 | 147 | 542 | 1388 | 5 | 0.8 | 0.46 | Class IIb |

| C30Fine Aggregate | 0.53 | 0.20 | 5.0 | 33 | 367 | 176 | 604 | 1228 | 5 | 0.5 | 0.48 | |

| C40Gravel | 0.49 | 0.13 | 5.0 | 29 | 349 | 150 | 561 | 1369 | 5 | 0.7 | 0.43 | |

| C40Fine Aggregate | 0.53 | 0.20 | 5.0 | 35 | 368 | 169 | 643 | 1192 | 5 | 0.9 | 0.46 | |

| C50Gravel | 0.49 | 0.13 | 6.0 | 27 | 345 | 145 | 521 | 1408 | 5 | 0.7 | 0.42 | |

| C50Fine Aggregate | 0.53 | 0.20 | 6.0 | 34 | 365 | 164 | 640 | 1230 | 5 | 0.6 | 0.45 | |

| EPS(%) | "steel fiber (%) | stress peak value (MPa) | growth rate (%) | ||||||||||||

| C30A | C30a | C40B | C40b | C50C | C50c | A | a | B | b | C | c | ||||

| 15 | 1.5 | 6.18 | 5.86 | 7.19 | 6.89 | 9.75 | 8.97 | / | / | / | / | / | / | ||

| 1.75 | 7.08 | 6.80 | 8.87 | 8.65 | 11.31 | 10.54 | 14.53 | 16.01 | 23.32 | 25.48 | 15.99 | 17.48 | |||

| 2.25 | 8.30 | 7.87 | 9.61 | 8.87 | 12.66 | 11.67 | 17.25 | 15.66 | 8.33 | 2.55 | 11.93 | 10.74 | |||

| 25 | 1.5 | 5.21 | 4.73 | 6.04 | 5.74 | 8.58 | 7.80 | / | / | / | / | / | / | ||

| 1.75 | 5.53 | 5.19 | 7.03 | 6.70 | 9.75 | 9.16 | 6.23 | 9.89 | 16.33 | 17.39 | 13.71 | 17.38 | |||

| 2.25 | 6.85 | 6.59 | 8.01 | 7.87 | 11.55 | 10.86 | 23.92 | 26.83 | 13.9 | 17.46 | 18.36 | 18.64 | |||

| 35 | 1.5 | 4.79 | 4.37 | 5.65 | 5.41 | 8.10 | 7.64 | / | / | / | / | / | / | ||

| 1.75 | 4.90 | 4.76 | 6.11 | 5.59 | 9.15 | 8.08 | 2.43 | 8.89 | 8.21 | 8.40 | 12.91 | 5.75 | |||

| 2.25 | 6.04 | 5.64 | 7.23 | 6.97 | 10.45 | 9.28 | 23.21 | 18.51 | 18.3 | 24.66 | 14.25 | 14.81 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).