Submitted:

26 November 2024

Posted:

27 November 2024

You are already at the latest version

Abstract

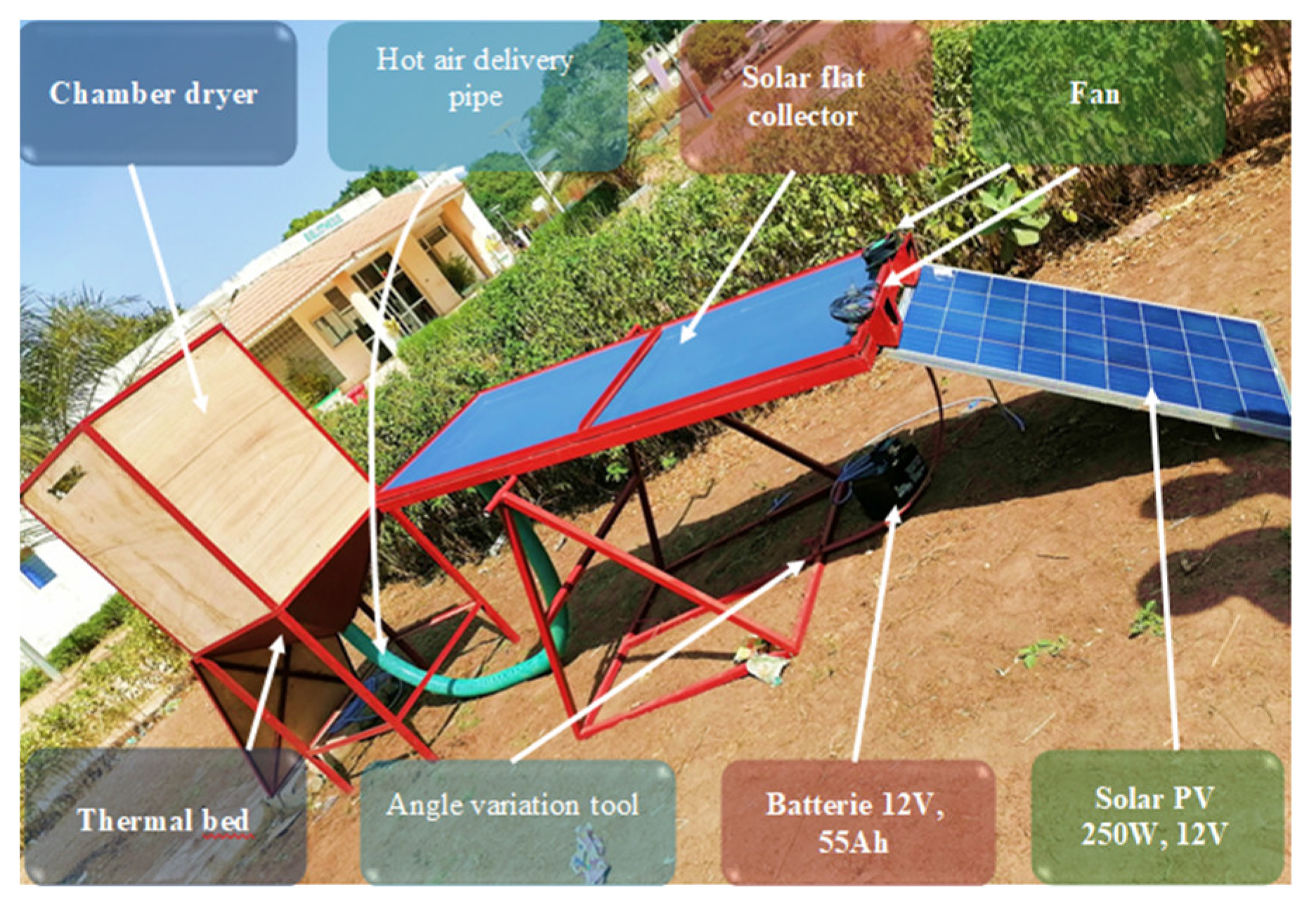

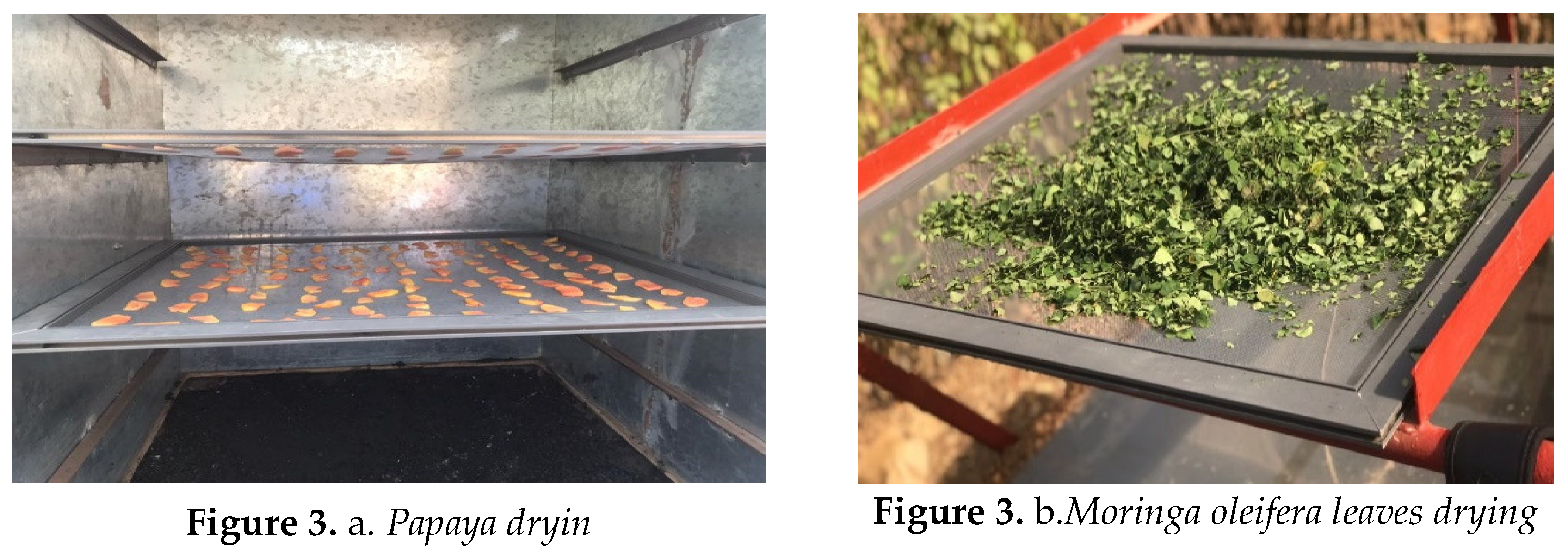

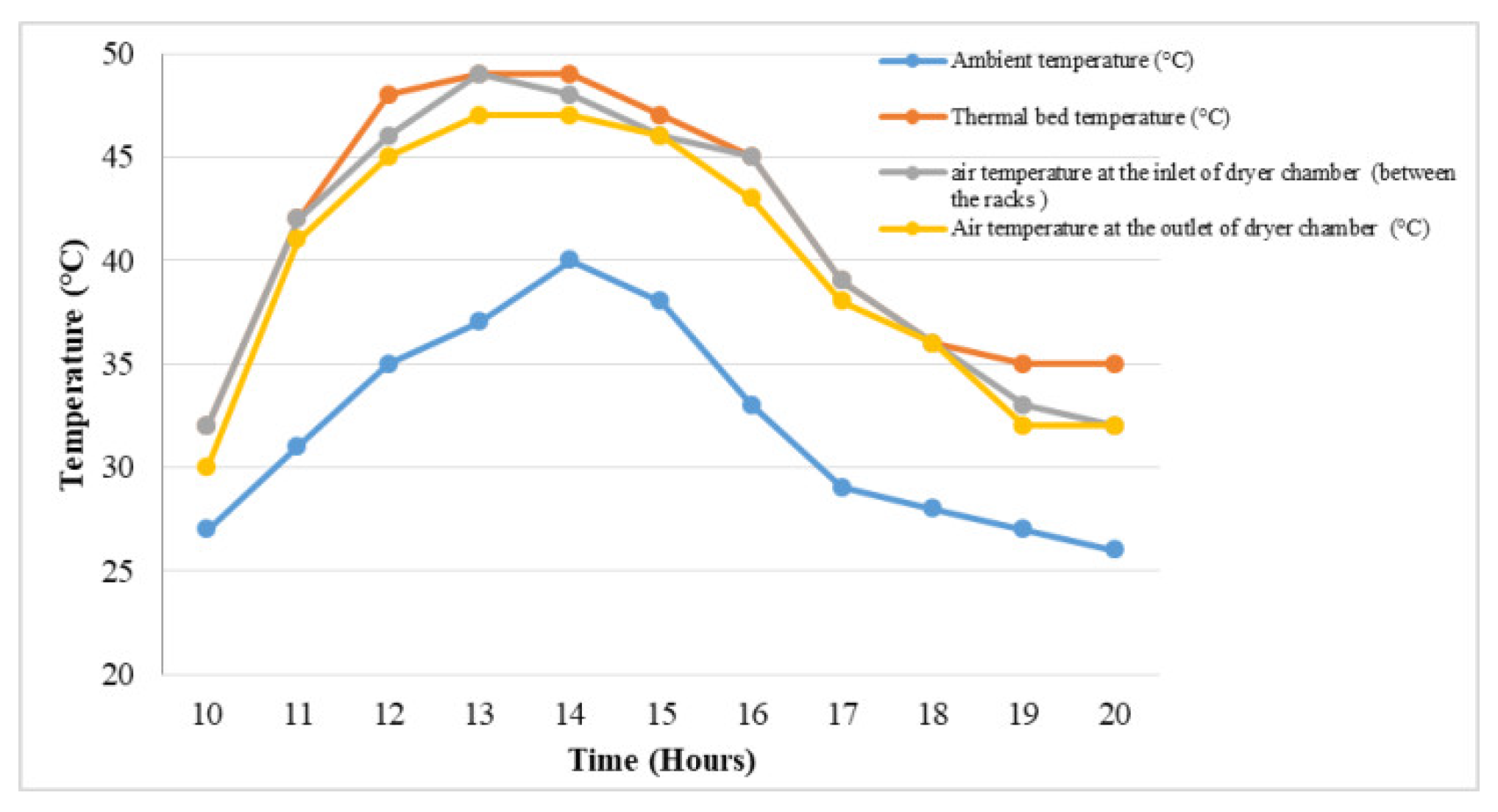

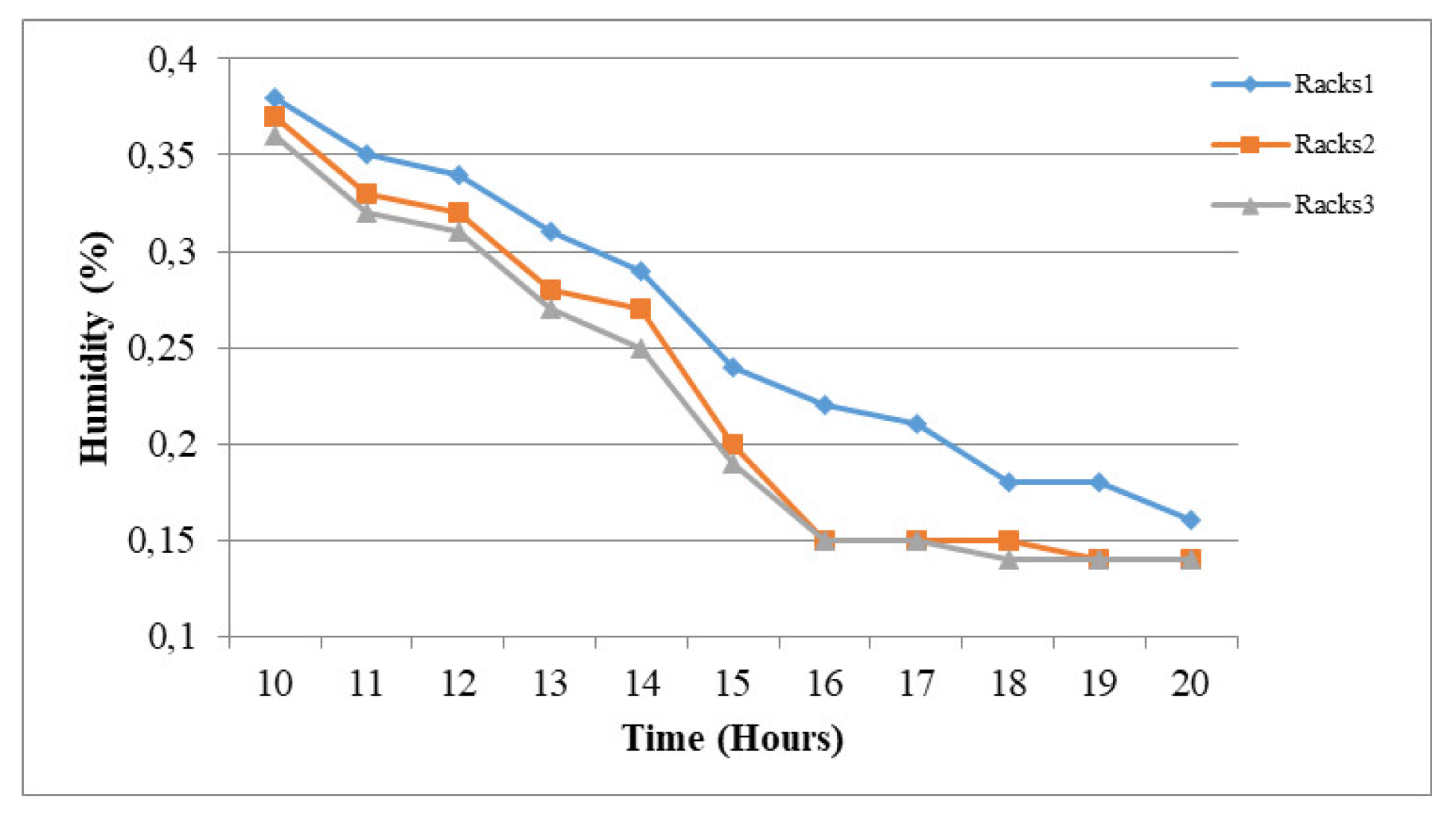

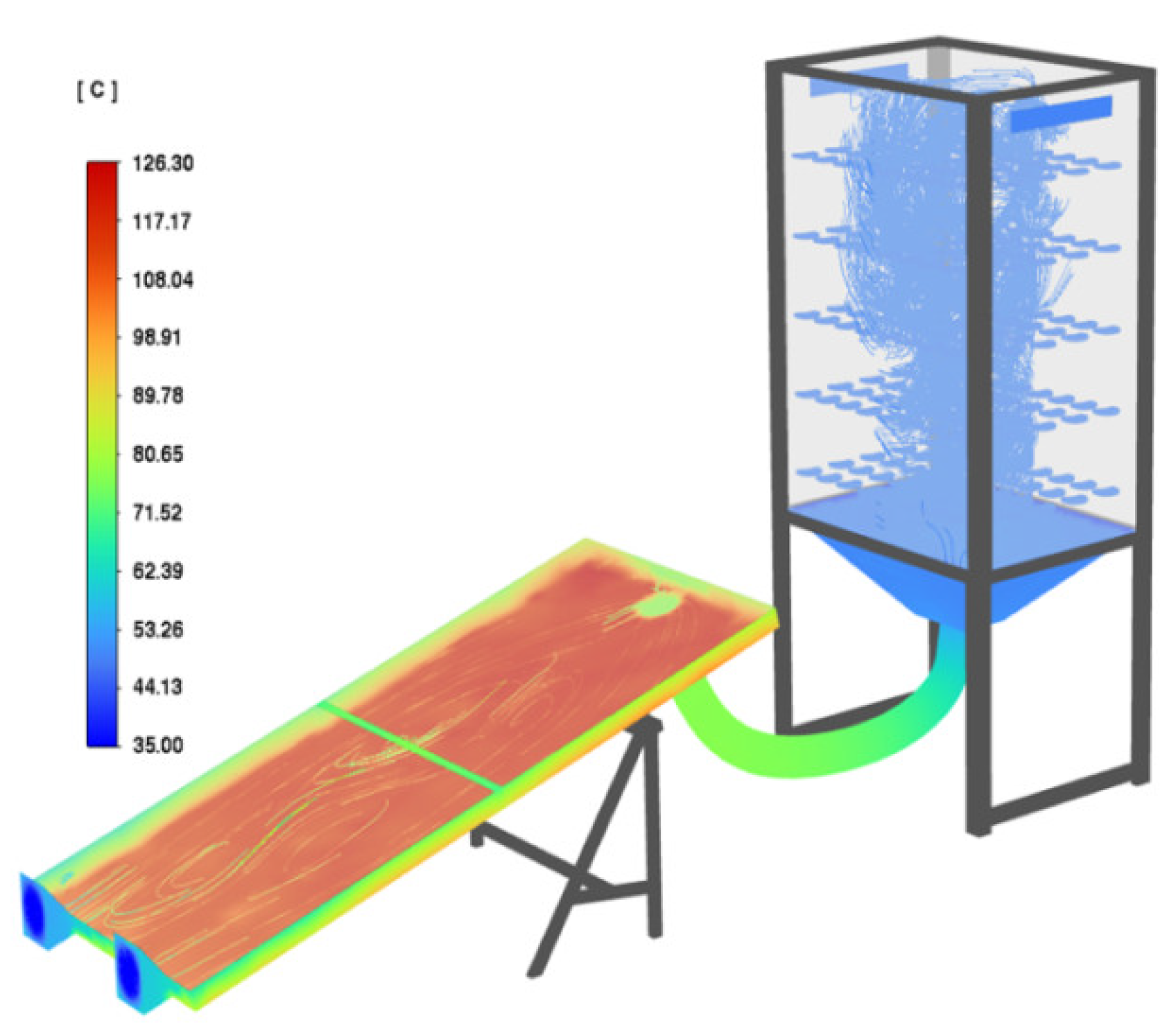

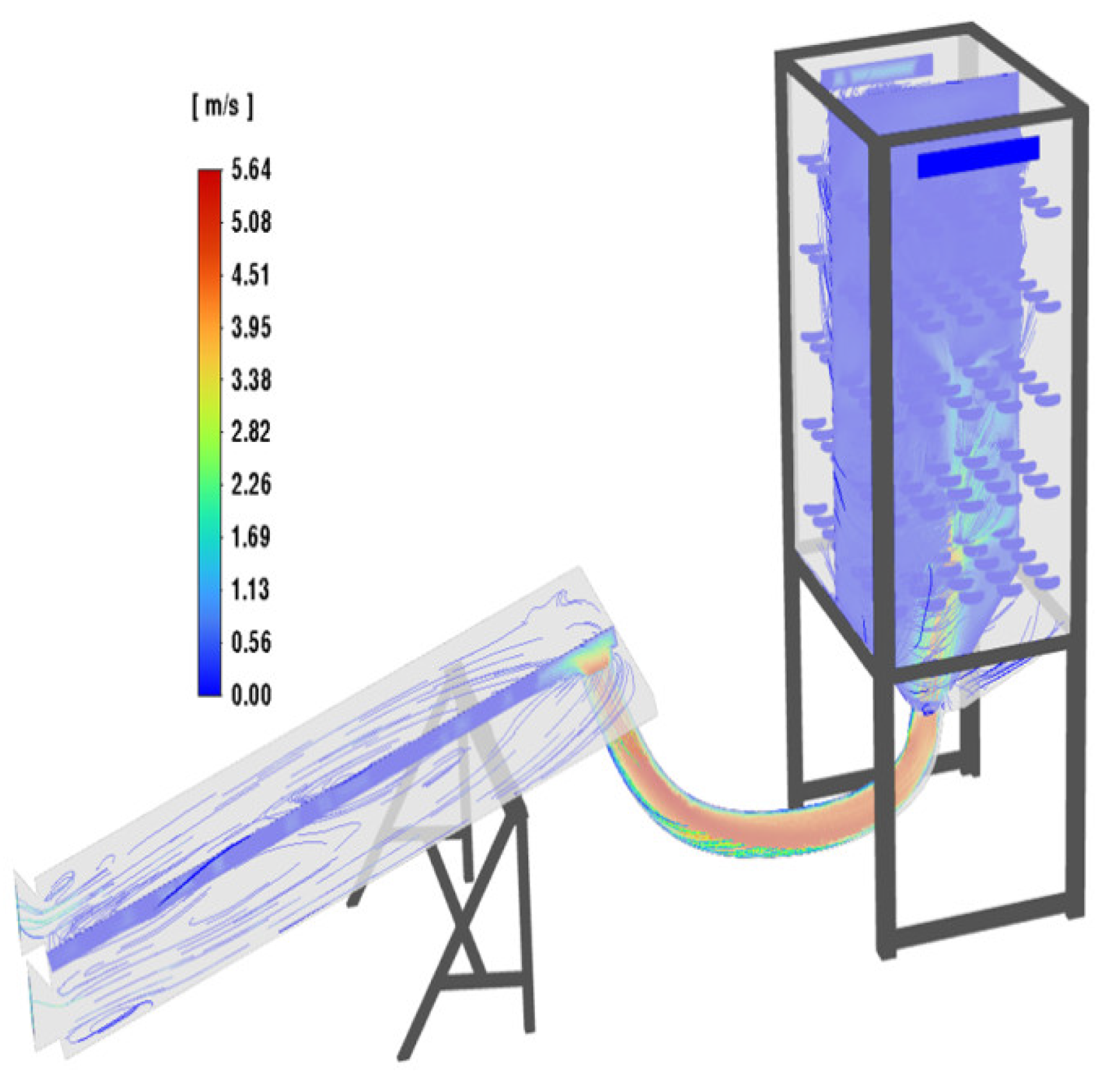

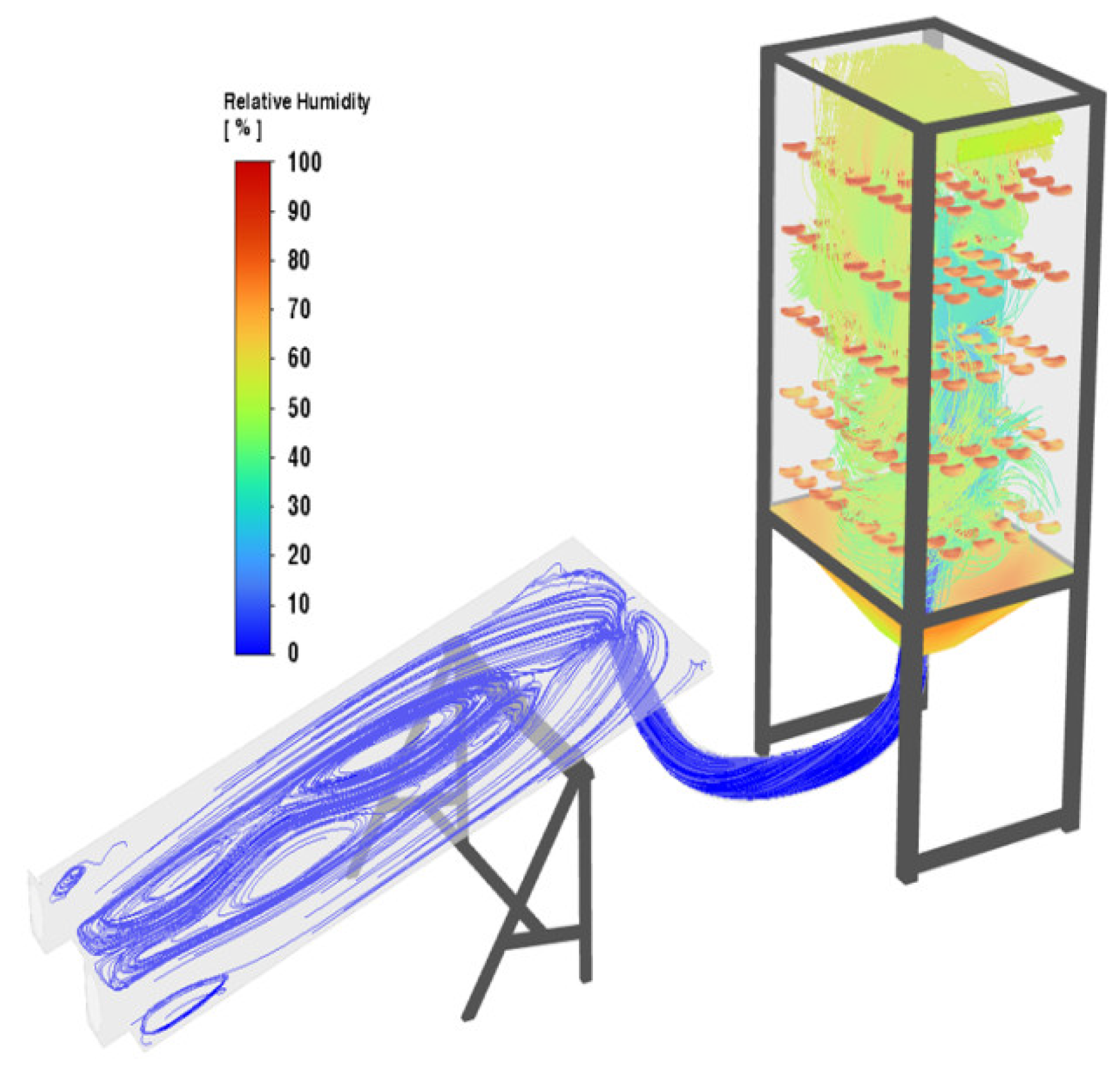

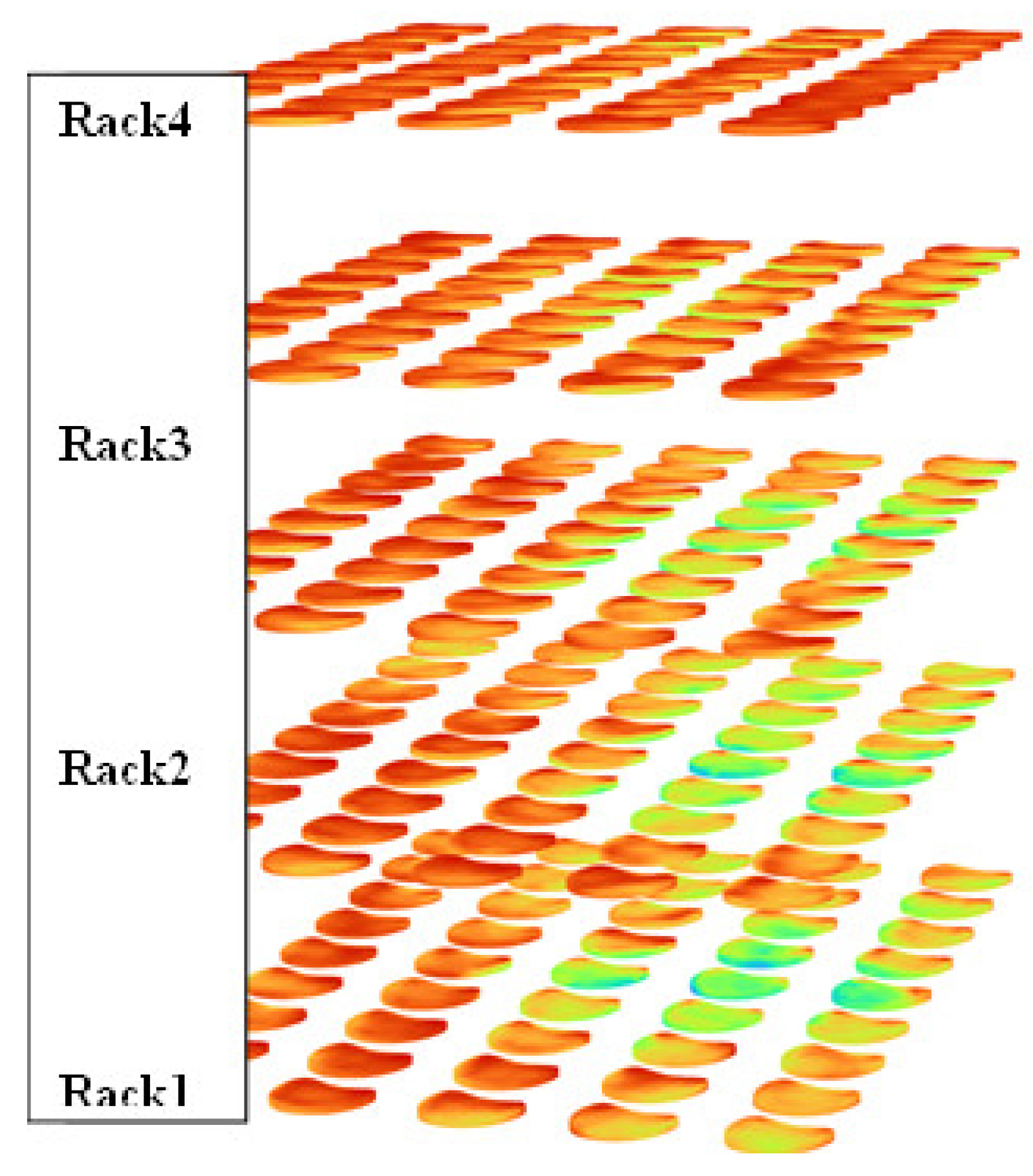

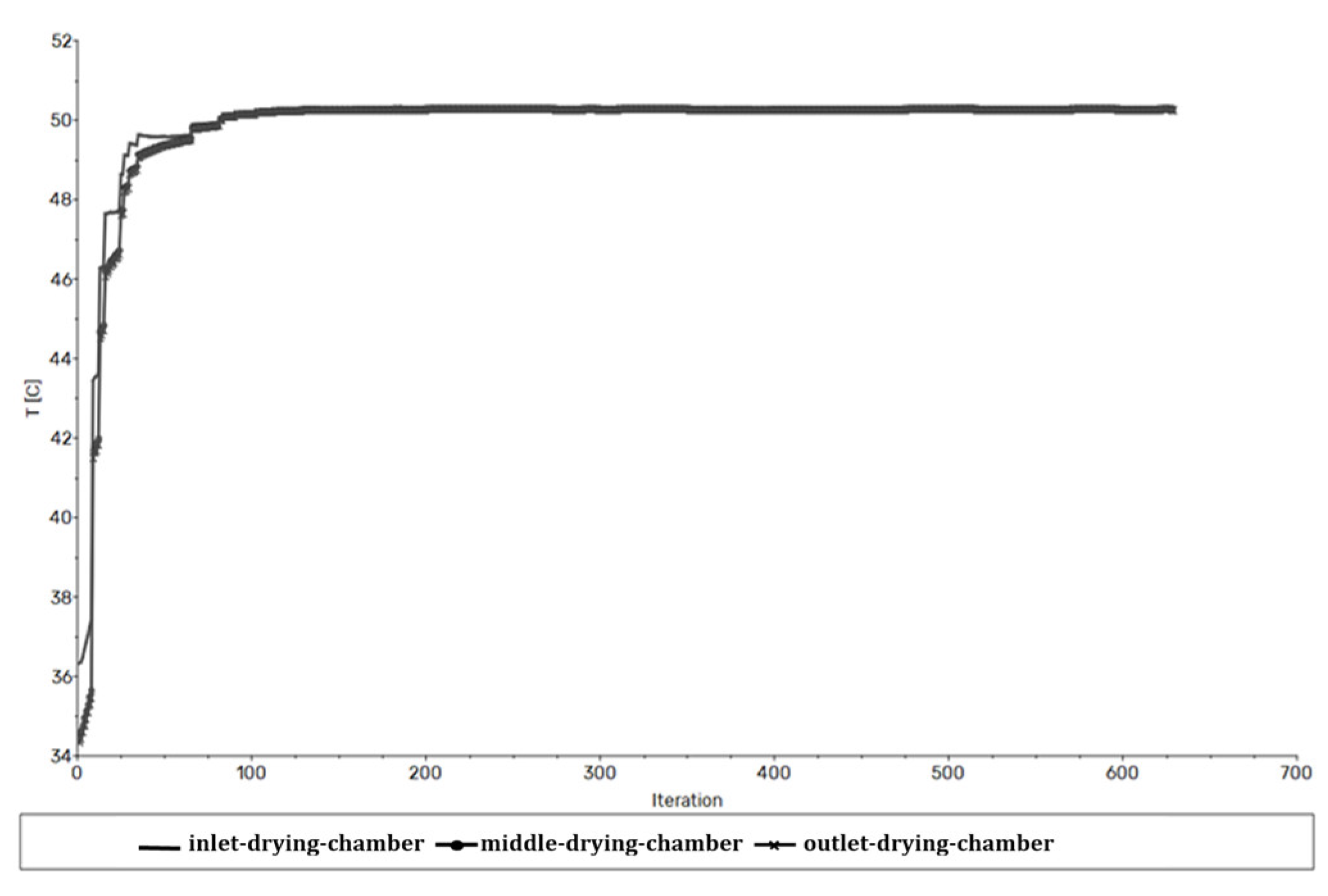

Solar thermal energy is available in abundance in a country like Senegal where direct solar radiation is on average 1950 kWh/m2 per year. Solar drying is the most popular method to preserve food in our country. However, it is limited by the intermittent nature of the sun. The objective of this paper is to overcome the intermittency of the sun by integrating a thermal bed into the solar dryer. The thermal bed is made of basalt and biochar for heat storage and humidity absorption respectively. An experimental study was done using papaya and moringa leaves. The results obtained show that the thermal bed stores heat at the temperature of 39 °C at 10 p.m. Papaya is dried in two days and moringa leaves are dried in one day. For papaya slices, water content is 15% and was reached at the second day of drying. Also, moringa dry leaves water content is 8%. This value begins to be reached from 3 p.m. in the afternoon. Thus, the thermal bed temperature, the air temperature between the drying racks and the drying chamber outlet air temperature are respectively an average of 48.67°C, 48°C and 47.22° C compared to 34.33°C of the ambient temperature, a difference of more than 4°C. The experimental study is supported by a Computational fluid dynamic (CFD) analysis.

Keywords:

1. Introduction

2. Theoretical Modeling

2.1. Modeling of the Thermal Bed

2.2. Governing Equations

2.2.1. Balance Equation at the Air Flow

2.2.2. Balance Equation on the Racks

3. Measurement and Experimentation Equipment

4. Results and Discussions

4.1. Experimental Results

4.2. Numerical Results

5. Conclusion

Abbrevation

| Turbulent Kinetic Energy, | |

| Dissipation of Turbulent Kinetic Energy, | |

| Density, | |

| Viscosity, Pa.s | |

| Turbulent Dynamic Viscosity, | |

| Turbulence Model Constants | |

| , | Velocity, m.s-1 |

| P | Pressure, Bar |

| Constant Pressure Specific Heat, kJ.kg-1 K-1 | |

| Inertial Resistance Factor | |

| Temperature, K | |

| Inertial Resistance Factor, | |

| Particle Diameter, m | |

| Gravitational Acceleration, | |

| Thermal Conductivity, W.m-1 K-1 | |

| Turbulence Model Constant | |

| Source Term | |

| , , | Constants Involved in the Model |

| , , | Empirically Coefficients |

| Porosity | |

| Prandtl Number | |

| Coefficient of Expansion | |

| Solid Phase in the Thermal Bed | |

| Fluid Phase in the Thermal Bed | |

| Blend |

Acknowledgments

Conflicts of Interest

Nomenclature

References

- Cliquet, R. and Thienpont, K. (1995). Population and Development: a Message from The Cairo Conference. London: Kluwer Academic Publishers), ISBN: 0792337638.

- Dyson, T. (1996). Population and Food: Global Trends and Future Prospects. Global Environmental Change Series. London: Routledge. 231.

- Dwivedi, A.; Goel, V.; Pathak, S.K.; Kumar, A. Prioritization of potential barriers to the implementation of solar drying techniques using MCDM tools: A case study and mapping in INDIA. Sol. Energy 2023, 253, 199–218. [Google Scholar] [CrossRef]

- Suresh, B.V.; Shireesha, Y.; Kishore, T.S.; Dwivedi, G.; Haghighi, A.T.; Patro, E.R. Natural energy materials and storage systems for solar dryers: State of the art. Sol. Energy Mater. Sol. Cells 2023, 255. [Google Scholar] [CrossRef]

- Mugi, V.R.; Das, P.; Balijepalli, R.; Vp, C. A review of natural energy storage materials used in solar dryers for food drying applications. J. Energy Storage 2022, 49. [Google Scholar] [CrossRef]

- Abdel-Rahman, G.N.; Saleh, E.M.; Hegazy, A.; Fouzy, A.S.; Embaby, M.A. Safety improvement of the open sun dried Egyptian Siwi dates using closed solar dryer. Heliyon 2023, 9, e22425. [Google Scholar] [CrossRef]

- Ndukwu, M.; Ibeh, M.; Okon, B.B.; Akpan, G.; Kalu, C.; Ekop, I.; Nwachukwu, C.C.; Abam, F.; Lamrani, B.; Simo-Tagne, M.; et al. Progressive review of solar drying studies of agricultural products with exergoeconomics and econo-market participation aspect. Clean. Environ. Syst. 2023, 9. [Google Scholar] [CrossRef]

- Barbosa, E.G.; de Araujo, M.E.V.; de Oliveira, A.C.L.; Martins, M.A. Thermal energy storage systems applied to solar dryers: Classification, performance, and numerical modeling: An updated review. Case Stud. Therm. Eng. 2023, 45. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; El-Seesy, A.I.; Hu, Z.; Li, Y. Recent developments in solar drying technology of food and agricultural products: A review. Renew. Sustain. Energy Rev. 2022, 157, 112070. [Google Scholar] [CrossRef]

- Kreetachat, T.; Imman, S.; Suwannahong, K.; Wongcharee, S.; Muangthong-On, T.; Suriyachai, N. Dataset on the optimization by response surface methodology for dried banana products using greenhouse solar drying in Thailand. Data Brief 2023, 49, 109370. [Google Scholar] [CrossRef]

- Denise, H.M.; Álvarez-Sánchez, F.; Ortiz-Rodríguez, N.; Flores-Prieto, J. Solar drying modes of saladette tomatoes slices on phytochemicals and functional properties. Sol. Energy 2023, 262. [Google Scholar] [CrossRef]

- Usama, M.; Ali, Z.; Ndukwu, M.C.; Sathyamurthy, R. The energy, emissions, and drying kinetics of three-stage solar, microwave and desiccant absorption drying of potato slices. Renew. Energy 2023, 219. [Google Scholar] [CrossRef]

- Prajapati, C.; Sheorey, T. Exploring the efficacy of natural convection in a cabinet type solar dryer for drying gooseberries: An experimental analysis. J. Agric. Food Res. 2023, 14. [Google Scholar] [CrossRef]

- Mongi, R.J. Physicochemical properties, microbial loads and shelf life prediction of solar dried mango (Mangifera indica) and pineapple (Ananas comosus) in Tanzania. J. Agric. Food Res. 2023, 11. [Google Scholar] [CrossRef]

- M. Emamjome Kashan et al., (2023) Insulated concrete form foundation wall as solar thermal energy storage for Cold-Climate building heating system, Energy Conversion and Management: X 19,100391, Energy Conversion and Management: X 19 (2023) 100391.). [CrossRef]

- Arefian, A.; Hosseini-Abardeh, R.; Rahimi-Larki, M.; Torkfar, A.; Sarlak, H. A comprehensive analysis of time-dependent performance of a solar chimney power plant equipped with a thermal energy storage system. Renew. Sustain. Energy Rev. 2023, 189. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, Y.; Li, J.; Ma, X.; Li, Q.; Yang, M.; Zhao, X.; Zhu, Y. Simulation and economic analysis of an innovative indoor solar cooking system with energy storage. Sol. Energy 2023, 263. [Google Scholar] [CrossRef]

- Hassan, A.; Nikbakht, A.M.; Fawzia, S.; Yarlagada, P.K.; Karim, A. Transient analysis and techno-economic assessment of thermal energy storage integrated with solar air heater for energy management in drying. Sol. Energy 2023, 264. [Google Scholar] [CrossRef]

- Ellis, J.; Opoku, R.; Sekyere, C.K.; Arkoh, A.K. Solar crop dryer with thermal energy storage as backup heater. Sol. Compass 2023, 8. [Google Scholar] [CrossRef]

- Ong, T.-C.; Sarvghad, M.; Bell, S.; Will, G.; Steinberg, T.A.; Yin, Y.; Andersson, G.; Lewis, D. Review on the challenges of salt phase change materials for energy storage in concentrated solar power facilities. Appl. Therm. Eng. 2023, 238. [Google Scholar] [CrossRef]

- Svobodova-Sedlackova, A.; Palacios, A.; Jiang, Z.; Renna, A.I.F.; Ding, Y.; Navarro, H.; Barreneche, C. Thermal stability and durability of solar salt-based nanofluids in concentrated solar power thermal energy storage: An approach from the effect of diverse metal alloys corrosion. J. Energy Storage 2023, 75. [Google Scholar] [CrossRef]

- Serigne, T, Omar, D, Awa, M, Lat Grand, N, Issakha, Y. Experimental and Numerical CFD Analysis of A Solar Dryer with Integration of Basalt Thermal Bed for Heat Storage. 12. Eur. Conf. Ren. Energy Sys. 17 May.

- Pelay, U.; Luo, L.; Fan, Y.; Stitou, D.; Rood, M. Thermal energy storage systems for concentrated solar power plants. Renew. Sustain. Energy Rev. 2017, 79, 82–100. [Google Scholar] [CrossRef]

- Palacios, A.; Barreneche, C.; Navarro, M.; Ding, Y. Thermal energy storage technologies for concentrated solar power – A review from a materials perspective. 156 2019, 156, 1244–1256. [Google Scholar] [CrossRef]

- Barnetche, M.; González-Portillo, L.F.; Abbas, R. Optimum integration of latent heat storage in a solar thermal system for industrial processes: In series or in parallel? Appl. Therm. Eng. 2023, 232. [Google Scholar] [CrossRef]

- Divyangkumar, N.; Jain, S.; Panwar, N. Influences of latent heat storage heat sink integrated with solar dryer to enhance drying period. Energy Nexus 2022, 8. [Google Scholar] [CrossRef]

- Muhammad, Y.; Saini, P.; Knobloch, K.; Frandsen, H.L.; Engelbrecht, K. Rock bed thermal energy storage coupled with solar thermal collectors in an industrial application: Simulation, experimental and parametric analysis. J. Energy Storage 2023, 67. [Google Scholar] [CrossRef]

- Gilago, M.C.; Mugi, V.R.; V.p., C. Performance assessment of passive indirect solar dryer comparing without and with heat storage unit by investigating the drying kinetics of carrot. Energy Nexus 2023, 9. [Google Scholar] [CrossRef]

- Embiale, D.T.; Gunjo, D.G. Investigation on solar drying system with double pass solar air heater coupled with paraffin wax based latent heat storage: Experimental and numerical study. Results Eng. 2023, 20. [Google Scholar] [CrossRef]

- Rehman, H.U.; Naseer, F.; Ali, H.M. An experimental case study of solar food dryer with thermal storage using phase change material. Case Stud. Therm. Eng. 2023, 51. [Google Scholar] [CrossRef]

- Majeed, A.H.; Faraj, J.J.; Hussien, F.M. Enhancing Solar Drying Efficiency Through Indirect Solar Dryers Integrated with Phase Change Materials. Int. J. Heat Technol. 2024, 42, 121–131. [Google Scholar] [CrossRef]

- Jaworski, M., Rusowicz, A., Grzebielec, A., & Szelągowski, A. (2023). Experimental Investigation of PCM Based Thermal Energy Storage Unit with Finned Tubes. In 11. EUROPEAN CONFERENCE on RENEWABLE ENERGY SYSTEMS. Turchia., 2023.

- Thaker, A.S.; Hussien, F.M.; Faraj, J.J. Numerical Simulation of an Indirect Solar Dryer Equipped with Thermal Conduction Enhancer Augmented Phase Change Materials (PCMs) for Banana Drying. Int. J. Heat Technol. 2023, 41, 1158–1166. [Google Scholar] [CrossRef]

- Madhankumar, S.; Viswanathan, K.; Taipabu, M.I.; Wu, W. A review on the latest developments in solar dryer technologies for food drying process. Sustain. Energy Technol. Assessments 2023, 58. [Google Scholar] [CrossRef]

- Lad, P.; Kumar, R.; Saxena, R.; Patel, J. Numerical investigation of phase change material assisted indirect solar dryer for food quality preservation. Int. J. Thermofluids 2023, 18. [Google Scholar] [CrossRef]

- Fertahi, S.E.-D.; Belhadad, T.; Kanna, A.; Samaouali, A.; Kadiri, I. CFD Investigation of Fin Design Influence on Phase Change Material Melting for Solar Thermal Energy Storage. e-Prime 2023, 6. [Google Scholar] [CrossRef]

- Petros, Demissie; et al. Design, development and CFD modeling of indirect solar food dryer, Energy Procedia 2019, 158,1128–1134, http://creativecommons.org/licenses/by-nc-nd/4.

- Rakshamuthu, S.; Jegan, S.; Benyameen, J.J.; Selvakumar, V.; Anandeeswaran, K.; Iyahraja, S. Experimental analysis of small size solar dryer with phase change materials for food preservation. J. Energy Storage 2020, 33, 102095. [Google Scholar] [CrossRef]

- Sengar, M.; Singhania, R.R.; Singh, D.; Mishra, P.K.; Singh, D.; Kumar, M.; Giri, B.S. Drying kinetics, thermal and morphological analysis of starchy food material: Experimental investigation through an induced type solar dryer. Environ. Technol. Innov. 2023, 31, 103221. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).