1. Introduction

Petrol stations in Saudi Arabia play a crucial role in the country's economic and transportation networks, enhancing mobility and facilitating access to energy amidst rapid urbanization and elevated living standards fueled by oil wealth. These stations do more than distribute fuel; they are integral to the broader economic landscape. Proper management and Rehabiliation are essential for their optimal performance and longevity.

Currently, petrol stations in Saudi Arabia are overseen by seven different government agencies, each employing its own stand-alone management system. This fragmented approach has led to significant integration challenges and a lack of transparency, resulting in conflicting decisions and disputes among station owners and regulators. Some stations have exploited these regulatory gaps to continue operating under unsafe conditions, increasing the risk of fires and workplace hazards (Ahmed et al., 2012; Ahmad & Rehan, 2016; Argaam, 2018). This lead to numerous fire incidents in some staions, posing significant risks to lives and property. Civil Defense reports document several events, including fires at petrol stations on the Makkah-Jeddah expressway (2021), in Madinah (2023), Tabuk (2024), and Hafr Al Batin (2024). These incidents highlight the ongoing safety challenges in the sector and highlights the need for more effective integrated management systems to predict manage and prevent such incidents.

A recent report by KAPSARC (2021) further revealed that 440 out of 1,219 petrol stations along highways were closed due to non-compliance and substandard operating conditions. These closure decisions were often disputed because they were issued by different agencies whose directives contradicted each other, due to the absence of any integrated platform for managing decisions among these agencies.

This situation highlights the urgent need for a unified, transparent framework to evaluate the overall performance of petrol stations in Saudi Arabia. Such a framework should align with Saudi Vision 2030 and ensure compliance with both international and local standards, as current petrol station operation, management, and rehabilitation programs lack these essential elements (Khalafalla et al., 2023).

To address these challenges, this study has developed a condition rating index model (CRI) using the analytical hierarchy process (AHP) integrated with multi-attribute utility theory (MAUT). The AHP is effective given the limited and inconsistent quality of data available for evaluating petrol station performance. The AHP's capability to incorporate both qualitative and quantitative data types enhance the decision-making process (Aldeeb, O., & Qasem, A. (2022). Consequently, the CRI will function as a comprehensive, transparent decision support system for the operation and management decisions for petrol stations among all stakeholders. The developed CRI will not only enhance transparent and effective management of petrol stations but also aligns with key United Nations Sustainable Development Goals (SDGs) such as SDG 7 (affordable and clean energy), SDG 9 (industry, innovation, and infrastructure), SDG 11 (sustainable cities and communities), and SDG 12 (responsible consumption and production). This alignment demonstrates a commitment to sustainable economic growth and responsible practices across Saudi Arabia, contributing to global sustainability efforts (Global Bioenergy Partnership, 2022; International Renewable Energy Agency, 2022; Chian, 2021; Olabi et al., 2022).

2. Background and Motivation

Petrol stations are critical components of urban infrastructure, serving as essential amenities and fuel points within cities and along highways that connect urban centers. These stations are crucial for maintaining urban connectivity and functionality. These facilities, categorized based on their location and service types, mostly adhere to local guidelines to ensure operational efficiency and safety, as opposed to the globally recognized frameworks that other facilities might follow.

They typically operate under local best practice guidelines rather than the universal standards that govern other sectors of asset management (Smith et al., 2022). In contrast, buildings and utilities often benefit from advanced, condition-based maintenance and rehabilitation systems that are bolstered by comprehensive decision-support tools (Johnson et al., 2021; Lee et al., 2022). This discrepancy underscores the need for management strategies specifically tailored to meet the unique operational and safety challenges faced by petrol stations (Baker & Liu, 2023).

Throughout the years, petrol stations mainly on highways connecting cities have transformed from simple fuel selling points to complex service-based commercial entities, necessitating a broad range of management, operational, and environmental strategies for effective management (Beckman, 2011; Purohit & Jain, 2020). Modern asset management trends emphasize safety and risk frameworks, crucial for station activities, including hazard identification and assessments (Ahmed et al., 2011; Abrahim et al., 2016; Eftekhari, 2017). Effective management of these facilities requires an amalgamation of technical, operational, environmental, and managerial competencies, supported by safety protocols and service quality standards that align with the UN Sustainable Development Goals (Pan et al., 2021; Kahraman et al., 2020; Tsekouras et al., 2018). The necessity for specialized attention in managing petrol stations, which are strategically placed and vital assets, is evident.

Current asset management strategies employ standardized techniques to sustain and govern a variety of assets effectively. However, petrol stations tend to adhere to local best practices rather than the more sophisticated, condition-based systems that are prevalent in sectors such as buildings and utilities, which benefit from robust rehabilitation and maintenance decision-support systems (Dejaco et al., 2017; Nawel, 2023). While research like Cranston (2018) showcases how different sectors aim to optimize benefits and reduce risks, it also underscores the critical need for specialized decision management tools tailored for the operation and rehabilitation of petrol stations. This need highlights a significant research gap, previously identified by studies such as those by Sarkis (2018), Sun et al. (2018), and Leung et al. (2017), which emphasize the necessity for such tools.

These studies, along with current management practices in the operation and oversight of petrol stations, clearly highlight the need for a standardized, comprehensive management tool. This management a tool would be essential for effectively managing these critical facilities from various perspectives, ensuring their rehabilitation at optimal performance levels in terms of safety, sustainability, and operational efficiency. This gap highlights the need for more focused research to develop effective tools that integrate environmental, safety, and operational factors.

Therefore, the main objective of this study is to develop an integrated Condition Rating Index (CRI) specifically for petrol stations, which will serve as the backbone of a comprehensive decision-support system for managing and operating these facilities efficiently and sustainably.

3. Methodology

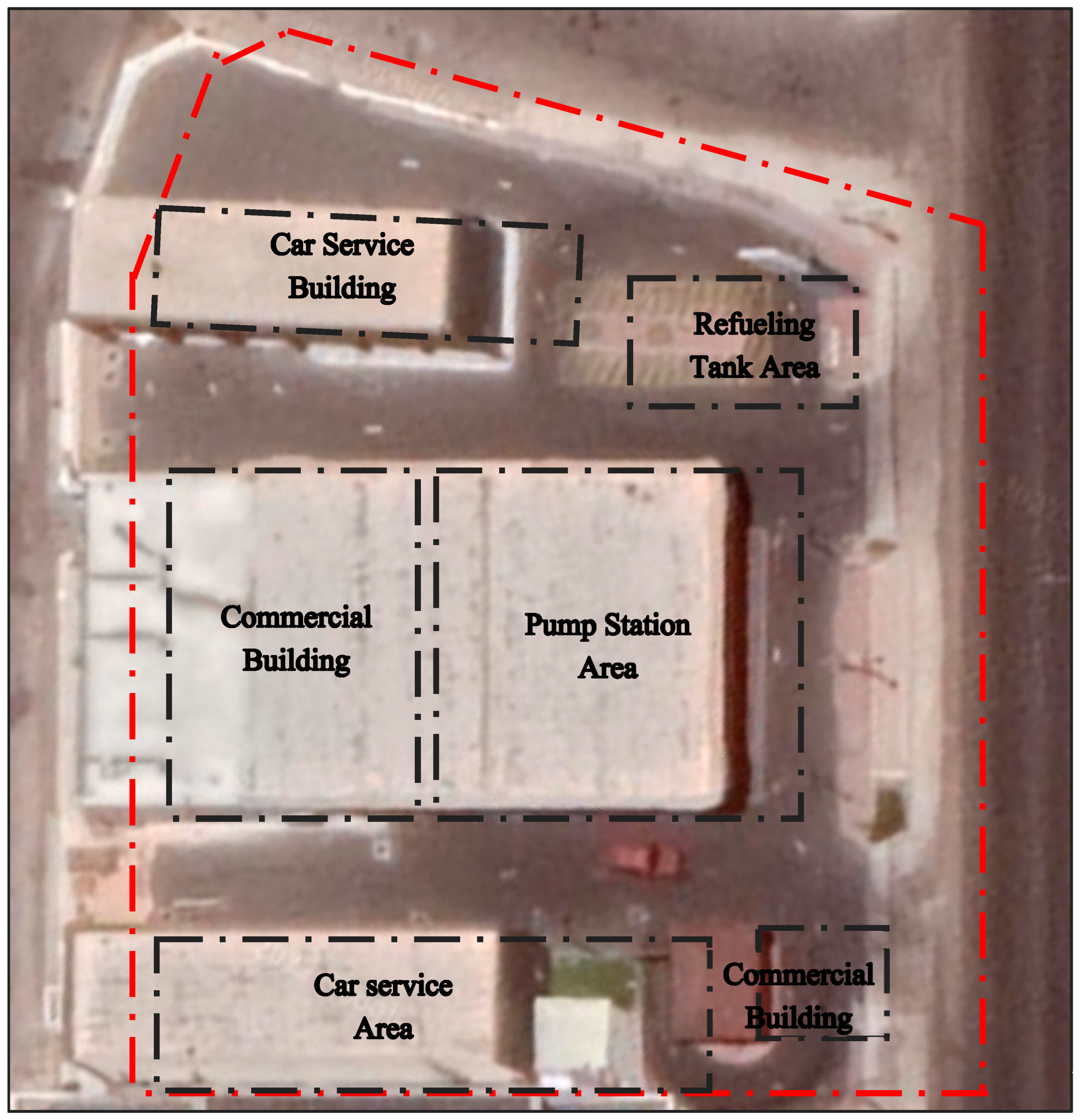

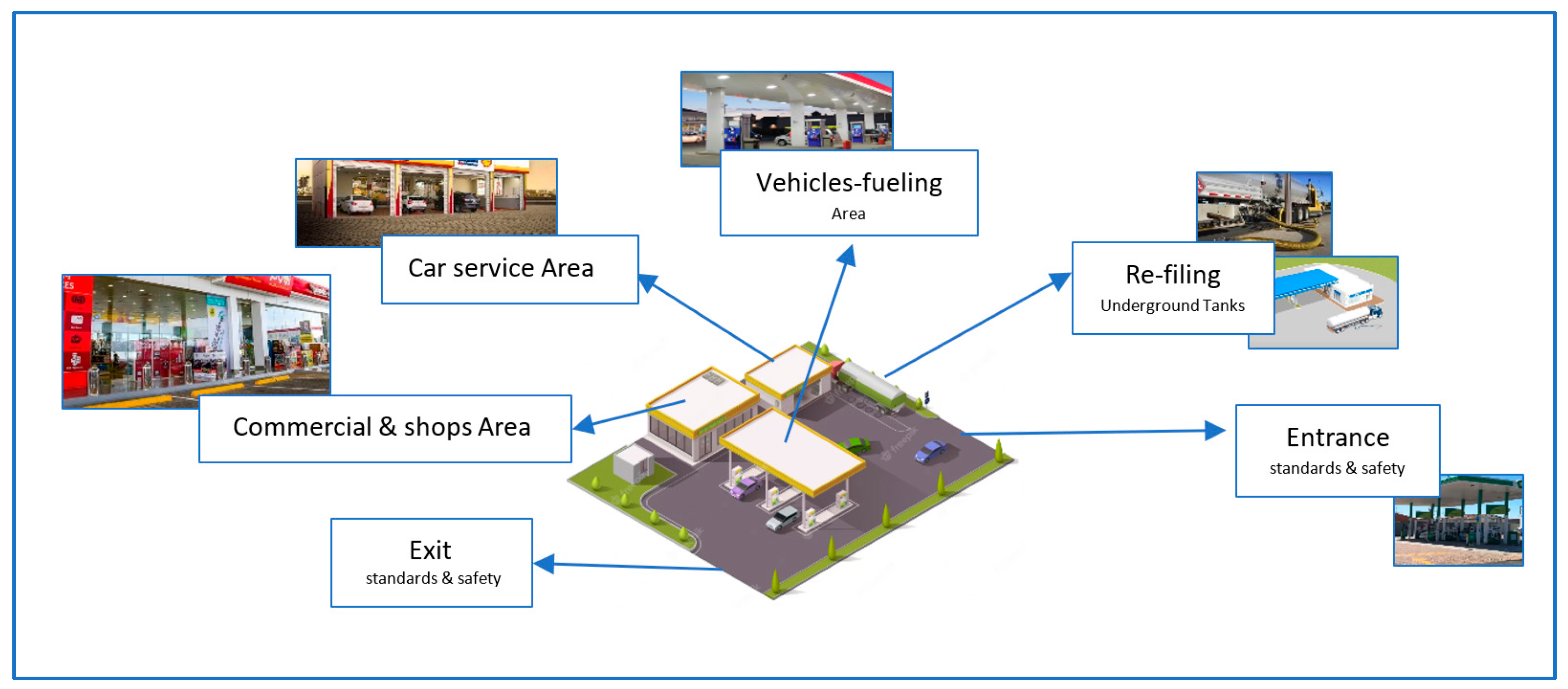

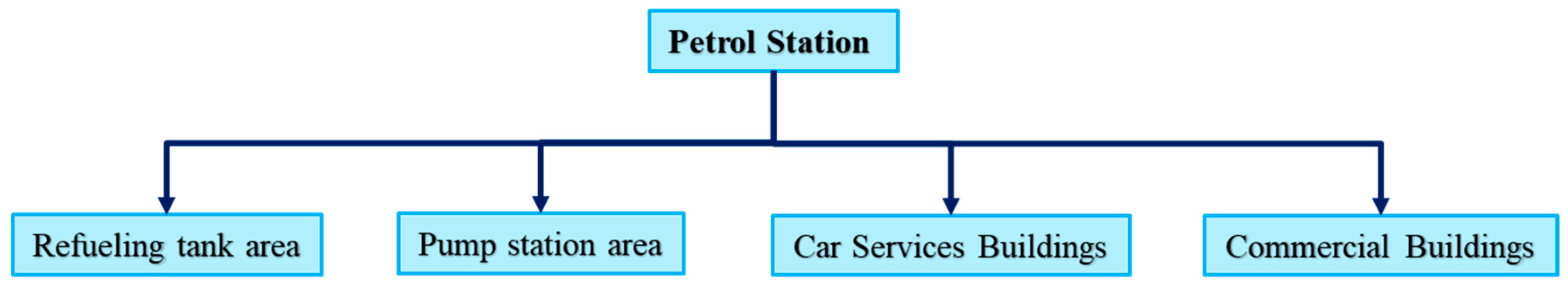

Petrol stations are complex facilities composed of four main spaces: pump station areas, refueling tank areas, commercial buildings, and car service buildings (Sun et al., 2018; Sarkis, 2018; Leung et al., 2017). Each space has unique functions and requirements, and effective management is essential for safe and efficient operation (

Figure 1). The study will focus on developing a condition rating model for each space. This will provide decision makers and stakeholders with a transparent, comprehensive understanding of these assets, enabling them to make effective, optimized operational and rehabilitation decisions within their budget constraints.

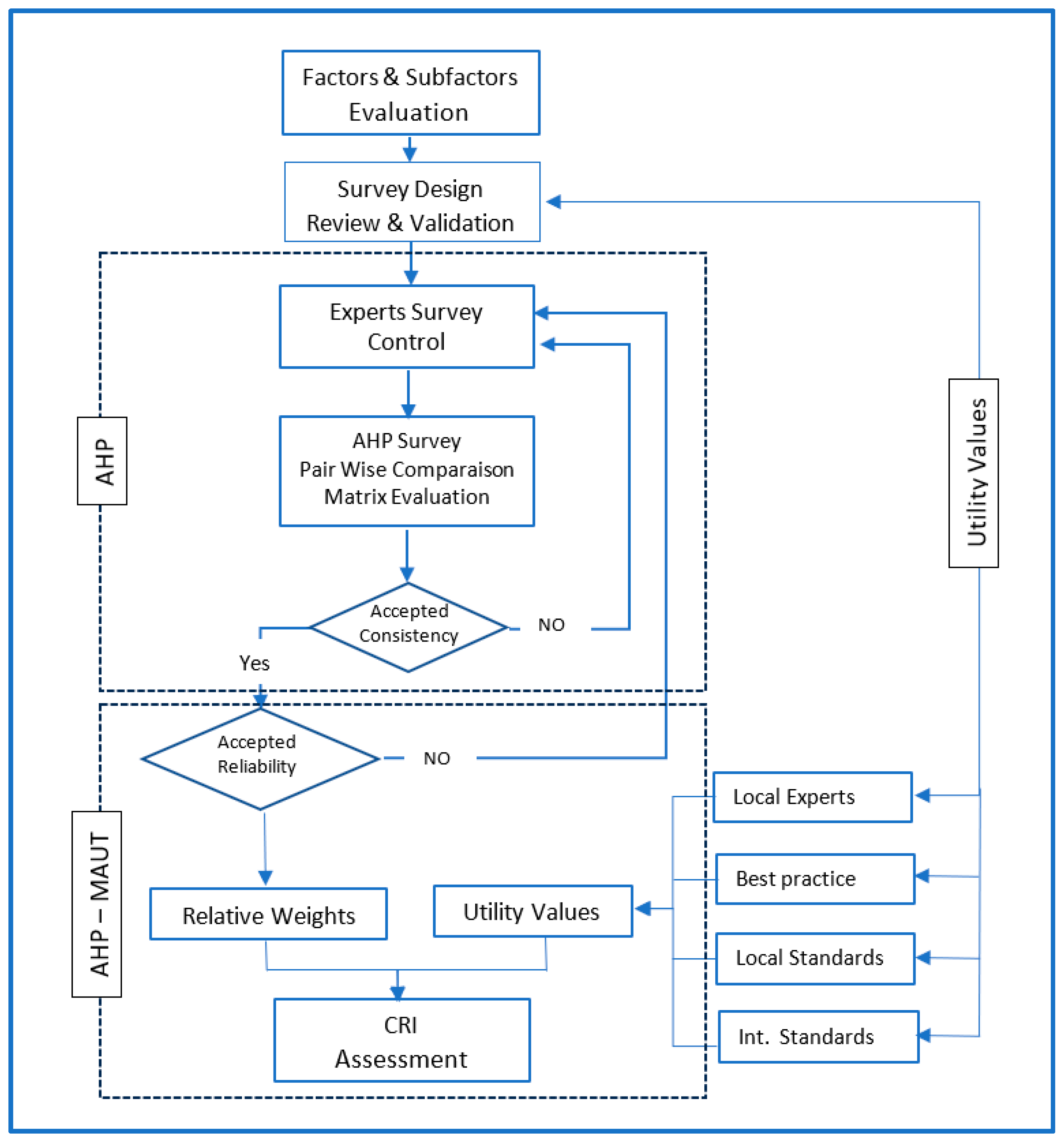

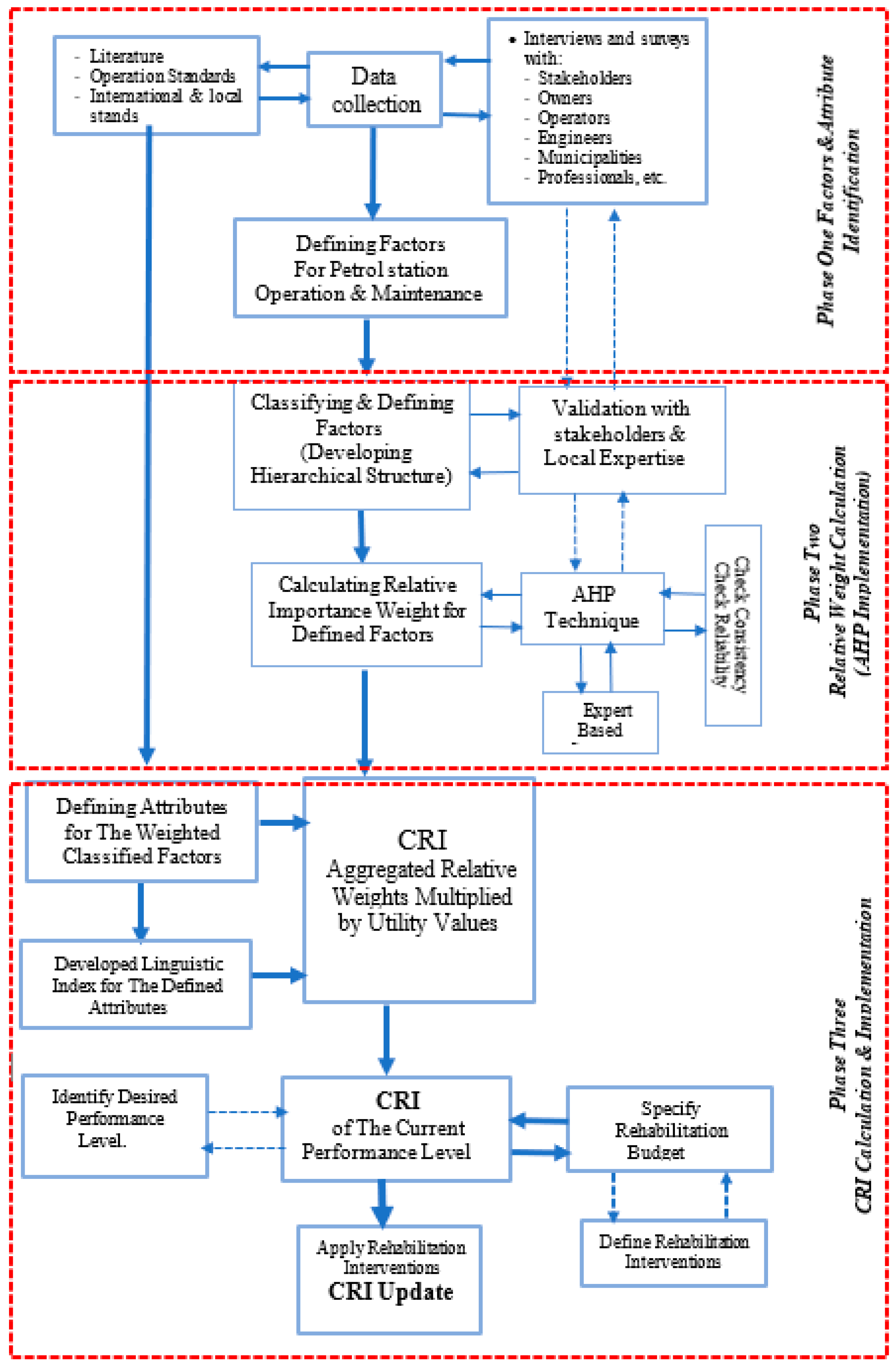

The research methodology of this study is divided into three phases as illustrated in

Figure 2.

Identify factors affecting petrol station operation and maintenance: This phase will involve a comprehensive review of local and international standards, as well as consultation with experts in the field. The goal is to identify all of the factors that can have a significant impact on the operation and maintenance of petrol stations.

Organize factors into a hierarchical order: Once all of the factors have been identified, they will be organized into a hierarchical order. This will involve grouping similar factors together and creating a hierarchy of main criteria and sub-factors. The goal of this phase is to develop a structured framework for evaluating the overall performance of petrol stations.

Extract attributes and calculate CRI: In the final phase, attributes will be extracted for each factor identified in Phase 1. These attributes will be based on petrol station operation standards, best practices, and expert input.

The attributes will then be aggregated with their weighted factors to calculate the integrated condition rating index (CRI) for each petrol station. The CRI will provide a comprehensive measure of the overall condition of a petrol station.

3.1. Data Collection & Analysis for Phase One

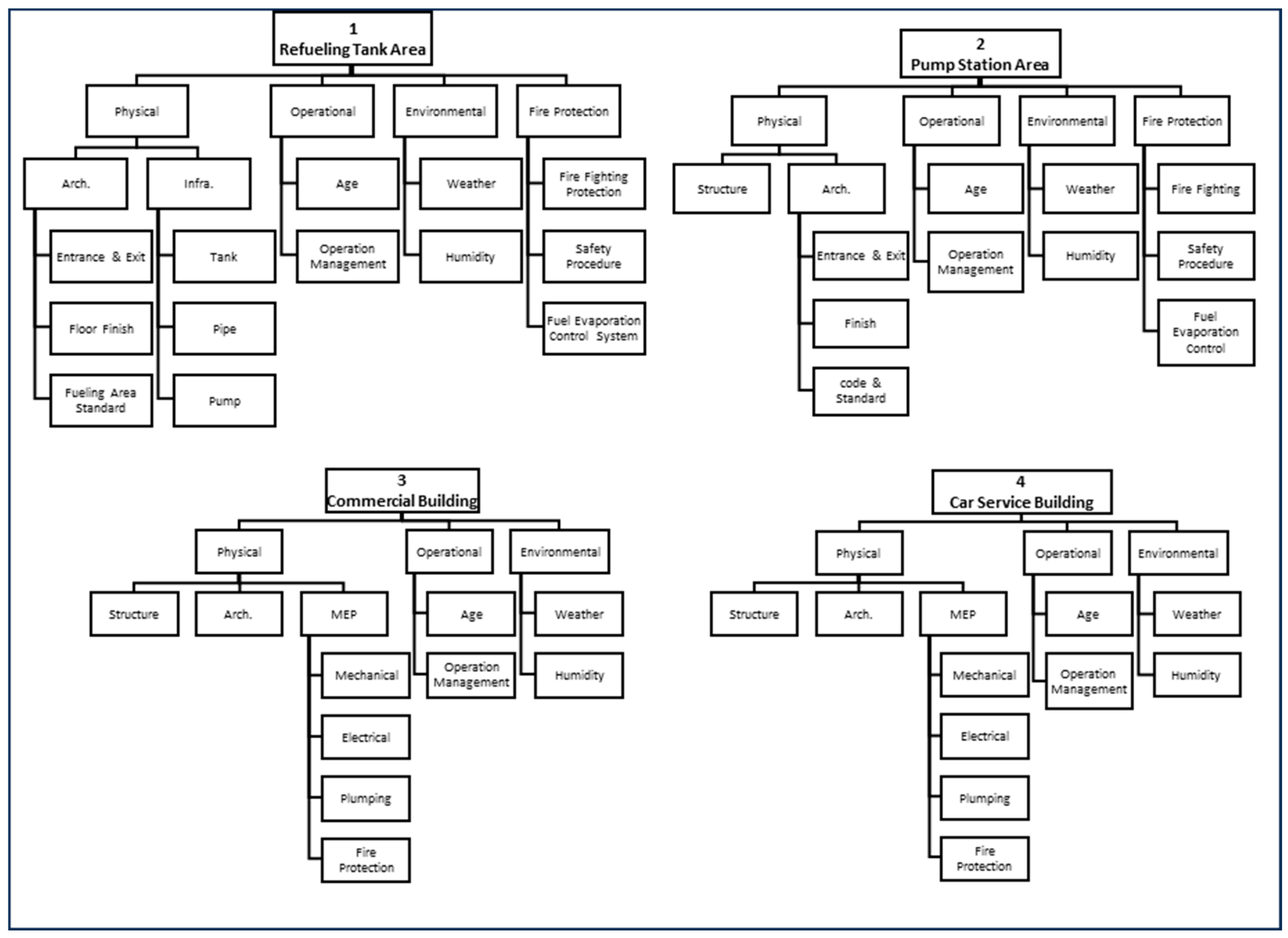

The initial phase involved an extensive and comprehensive data collection effort to identify different factors affecting the performance of petrol stations. Through this comprehensive examination, the primary factors influencing petrol station performance were systematically identified thorough literature, best practices, safety standards, and local and international operation and maintenance norms in addition to the Ministry of Municipal and Rural Affairs standards and guidelines. To ensure a robust foundation, local experts and stakeholders meticulously analyzed and categorized these factors into main and sub-main categories. The hierarchy for these factors for each space is illustrated in

Figure 3.

The data collection for this phase was done through a three-parts survey involving 200 experienced stakeholders, including owners, safety engineers, maintenance engineers, and experienced operators. After organizing and confirming this factor hierarchy, their relative weights were assessed through surveys using AHP. Despite applying revised survey modifications, conducting personal interviews, and engaging in extensive phone calls to aid data collection, the evolving survey complexity limited considered survey responses to 120, who met the reliability and consistency standards ensuring all considered responds had a consistency index below 10%.

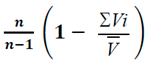

Data reliability using Cronbach's alfa (Cα) was calculated along with the coefficient of variance for all factors and subfactors. Cronbach's Alpha is a number between 0 and 1 that shows data reliability calculated using Eq. (1); the higher values indicate more dependable data. The typical Cα values and their interpretation are shown in

Table 1. The coefficient of variation (CoV) evaluates relative variability through standard deviation compared to mean. In calculated relative importance weights, it measures data stability and dispersion for each factor, revealing variability and consistency. Higher CoV signifies more variability, while lower suggests greater consistency relative to the mean. The relative weights of main Factors and subfactors along with their reliability and CoV are presented in

Table 2

| Cα = |

|

……………………. 1 |

where:

| Cα |

: |

Is the Cronbach’s Alpha |

| n |

: |

Is the number of points |

| Vi |

: |

Is the variance of scores for each point |

The relative importance weights for these spaces were calculated using the first part of the survey using the eigen vector AHP technique and listed in

Table 2. The relative importance weights showed that the Refueling tank tare has the highest relative importance weight of 54% followed by the pump station area with 26% which reflect the importance of these two spaces in the functionality of the se petrol stations, compared to the care service are and commercial buildings with relative weights 12% and 8% respectively as shown in

Table 2.

3.2. Data Collection & Analysis for the Second Two

In the second phase, the factors and subfactors affecting the performance of each space were organized in the hierarchy shown in

Figure 4. Factors for the four spaces considered in this study were classified into physical, operational, environmental, and fire protection factors for the refueling tanks and pumping stations areas. Meanwhile, for the commercial buildings and car services areas, they were categorized as physical, operational, and environmental factors, with fire protection systems evaluated under electromechanical factors.

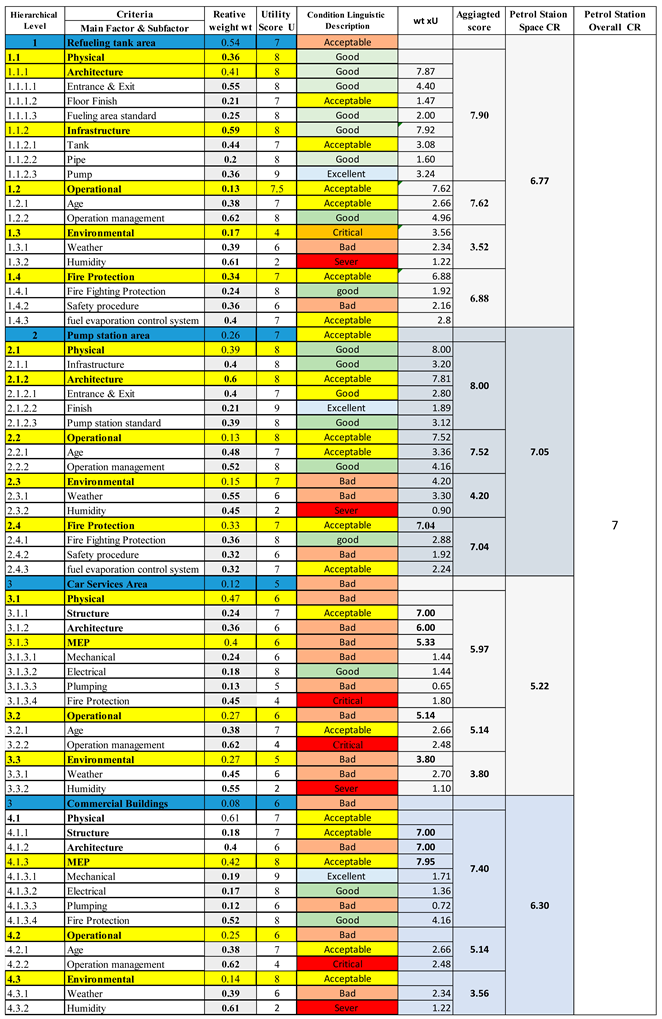

The relative weights for main factors and sub factors in addition to the relative importance weight for each space in identified spaces within the petrol station were identified, as presented in

Table 3. The relative importance weights for the main factors and sub factors for each space were obtained using AHP through the pairwise comparison matrix. The data was collected through the second part of the survey designed to collect the relative importance weights for different factors of the four spaces identified for the petrol station.

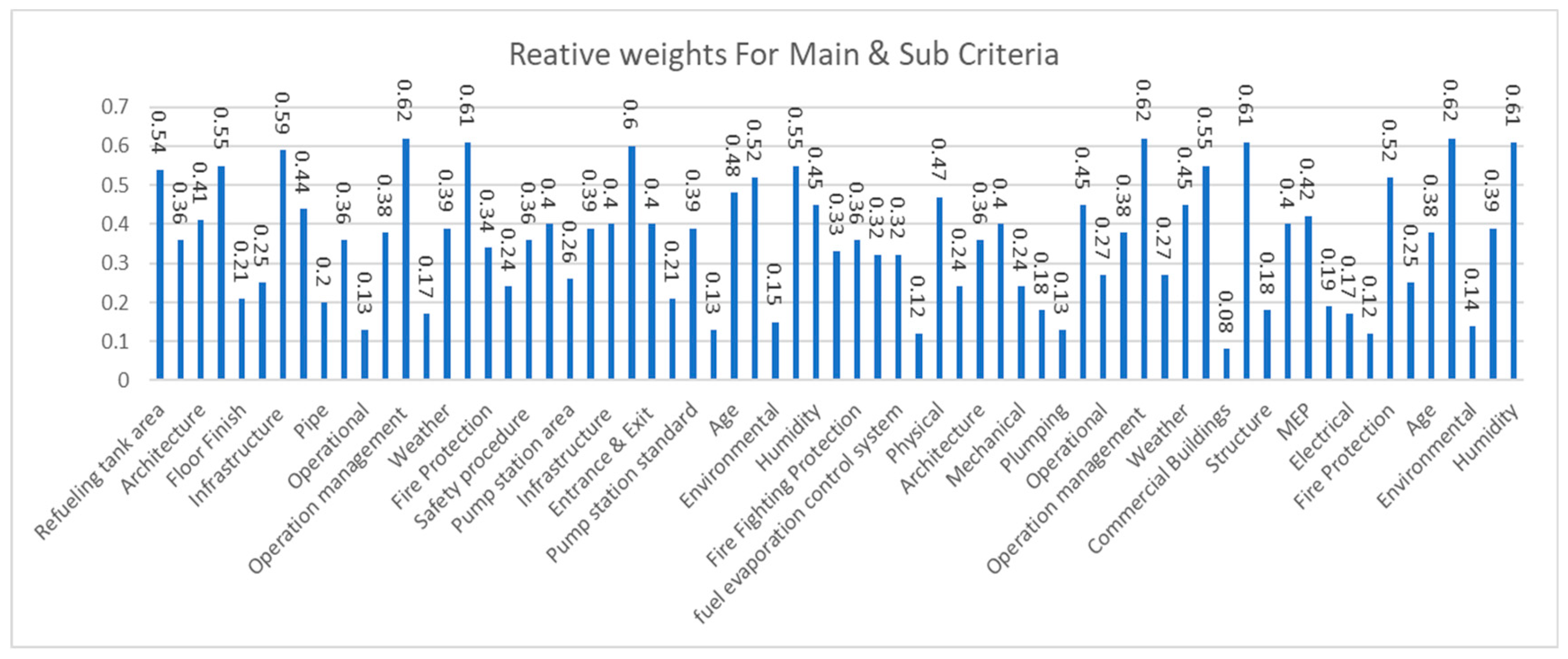

The relative weights for main criteria and sub criteria are represented in

Figure 5. It shows that the factors of petrol stations are categorized into main and sub-factors for each of the four spaces examined. The table indicates the following impact values: The Refueling Tank Area (0.54), central to the station, is influenced by the Physical Layout (0.36) and Architecture (0.41), highlighting the need for an efficient and appealing design. Infrastructure (0.59) emphasizes aesthetic, functional, and durable components, while Entrance & Exit (0.55) emphasizes smooth vehicle movement. Operational aspects (0.13) are less prioritized compared to Operation Management (0.62), indicating an emphasis on managerial oversight.

The environmental concerns are mainly represented by General Environmental Impact (0.17), suggesting a lesser direct focus on environmental issues. Nonetheless, the role of Weather (0.39) and especially Humidity (0.61) indicates its effect on fuel storage, particularly affecting surface structures. Safety Protocols are characterized by Fire Protection (0.34), Fire Fighting Protection (0.24), and Fuel Evaporation Control System (0.4), emphasizing safety and fuel quality. The Pump Station Area (0.26), although less prioritized than the refueling tank, is predominantly affected by Operation Management (0.52) and Humidity (0.45). In the Car Services Area (0.12), the major influencing factors are Operation Management (0.62) and Humidity (0.55). Commercial Buildings (0.08) have a subsidiary role in petrol stations. When present, they are chiefly influenced by Physical aspects (0.61), Operation Management (0.62), and Humidity (0.61). The results shows that operational management and humidity are consistently paramount across different station areas. However, the significance of other factors fluctuates. This reveals the complex nature of station performance and the necessity for tailored management strategies.

3.3. Data Collection & Analysis for Phase Three

The data collection for the third phase was to employ the Multi attribute utility (MAUT) technique that quantifies the performance level of each factor by its utility score resembling its performance level within an identified utility system for each factor. In this phase all factors identified for all identified spaces are linked with specific utility scoring systems obtained from operation standards, best practices and operation manuals in addition to and experts. These utility values provide a comprehensive systematic and consistent tool to evaluate diverse attributes and alternatives utility scores for each identified factor. The utility values are interpreted to actual performance level of which when aggerated with other factors with their relative importance weight provide an overall performance score reflecting the performance of each space within the petrol station in addition to the overall performance of the whole petrol station.

3.4. Assigning Utility Scores

The utility values for different factors of the main four paces considered in this study for petrol stations were of two main types: functional utility attributes derived from standards, literature, and best practice guidelines, and expert-based utility values obtained through the third part of the survey. The MAUT approach was used owing to its advantage of handling both quantitative and qualitative values to evaluate and quantify the status of each factor, allowing for the accommodation of continuous future upgrades. The Utility value score U serves as a reflection of the status of each factor, and when combined with its relative importance, contributes to the computation of the overall Condition Rating Index (CRI). In expert-based Utility value U, experts were requested to provide preference utility values on a 1-10 scale for various attributes affecting each factor, while standard Utility values are based on standard performance level. A utility value of 10 indicates the highest performance and best preference score. The utility values and their interpretation for different factors along with their scores are presented in Table 4.

Table 4a.

Utility Values for Architecture Factors.

Table 4a.

Utility Values for Architecture Factors.

| Factor |

Sub factor |

Utility score |

Utility Description |

| Architectural Factors |

Entrance & exit |

8 - 10 |

Efficient flow, clear signs, safety measures, vehicle access for all |

| 6 - 8 |

Modest Efficient flow, clear signs, safety measures, vehicle access for all |

| 4 - 6 |

Acceptable Efficient flow, clear signs, safety measures, vehicle access for all |

| 2 - 4 |

inefficient flow, No clear signs, No or bad safety measures, restricted vehicle access |

| Floor Finish |

8 - 10 |

Highly Durable, slip-resistant, chemically resistant, and compliant for easy maintenance |

| 6 - 8 |

Moderate Durable, slip-resistant, chemically resistant, and compliant for easy maintenance |

| 4 - 6 |

Acceptable Durable, slip-resistant, chemically resistant, and compliant for easy maintenance |

| 2 - 4 |

Non-Durable, slip-resistant, chemically resistant, and compliant for easy maintenance |

| Fueling Area Design & Standards |

8 - 10 |

Fully Available functioning safety measures, fuel pump integrity, environmental protection, and certified operational requirements. |

| 6 - 8 |

Available functioning safety measures, acceptable fuel pump integrity, environmental protection available systems, and certified operational requirements. |

| 4 - 6 |

Available functioning safety measures withy minor incidence, acceptable fuel pump integrity records, semi functional environmental protection available systems, and certified operational requirements. |

| 2 - 4 |

Available functioning safety measures with many incidents, Bad fuel pump integrity, Semi functional environmental protection systems, and operational requirements violations. |

Table 4b.

Utility Values for Infrastructure Factors.

Table 4b.

Utility Values for Infrastructure Factors.

| Factor |

Sub factor |

Utility score |

Utility Description |

| Infrastructure |

Tanks |

8 - 10 |

Available leak detection and prevention systems; excellent structural integrity; available installation records; available corrosion protection measures. |

| 6 - 8 |

Available leak detection and prevention systems; Good structural integrity; available installation records; available corrosion protection measures. |

| 4 - 6 |

Available leak detection and prevention systems; acceptable structural integrity; Semi available installation & maintenance records; available corrosion protection measures. |

| 2 - 4 |

Available but defected leak detection and prevention systems; bad to critical structural integrity; messy or unavailable maintenance records ; visible corrosion in the tanks. |

| Pipes |

8 - 10 |

Excellent pipe material with no corrosion, full compliance with safety and environment standards, pressure and flow are satisfied, available maintenance records with updates. |

| 6 - 8 |

Excellent pipe material with no corrosion, partial compliance with safety and environment standards , pressure and flow are satisfied with minor down time , partially updated maintenance records with updates. |

| 4 - 6 |

Acceptable pipe material with minor corrosion, low compliance with safety and environment standards , pressure and flow are satisfied with clear down time , Un- updated maintenance |

| 2 - 4 |

Clearly Visible pipe corrosion, low compliance with safety and environment standards, pressure and flow are satisfied with clear down time , Un- updated maintenance |

| Pumps |

8 - 10 |

Calibrated flow rate, ensure no leaks, compliance with safety and environmental standards, updated maintenance records. |

| 6 - 8 |

Calibrated flow rate with minor errors, ensure no leaks, no down time, Acceptable compliance with safety and environmental standards, semi available maintenance records. |

| 4 - 6 |

Calibrated flow rate with clear errors, ensure no leaks, some down time, Acceptable compliance with safety and environmental standards, incomplete maintenance records. |

| 2 - 4 |

Major flow rate calibration errors , Some leak, non-acceptable down time, questioned compliance with safety and environmental standards, incomplete maintenance records. |

Table 4c.

Utility Values for Operational Factors.

Table 4c.

Utility Values for Operational Factors.

| Factor |

Sub factor |

Utility score |

Utility Description |

| Operational |

Age |

8 - 10 |

0 - 5 (New units fully Operation Conditions) |

| 6 - 8 |

5 - 10 ( Good Operating Condition & Proper Maintenance) |

| 4 - 6 |

10 - 15 (Aging Units in acceptable operating conditions) |

| 2 - 4 |

15- 20 (Approaching End of Service Life with faulty operation) |

| 1 |

> 20 end of service life (Depends on the Units Useful life) |

| Operation Management Standards |

8 - 10 |

Fully trained workers, full compliance with safety regulations, standard customer service and marketing practices, excellent equipment condition and maintenance records, applying fuel quality control and inventory management, continuous employee training and upgrades programs |

| 6 - 8 |

Good level of trained workers, full compliance with safety regulations, standard customer service and marketing practices, good equipment condition and maintenance records, applying fuel quality control and inventory management, available employee training and upgrades programs |

| 4 - 6 |

Acceptable level of trained workers, good compliance with safety regulations, local customer service and marketing practices, acceptable equipment condition and maintenance records, applying acceptable fuel quality control and inventory management, weak employee training and upgrades programs |

| 2 - 4 |

Unacceptable Level of trained workers, Barely compliance with safety regulations, local customer service and marketing practices, Non-acceptable equipment condition and maintenance records, missing good fuel quality control and inventory management, non-employee training and upgrades programs |

Table 4d.

Utility Values for Environment & Fire Protection Factors.

Table 4d.

Utility Values for Environment & Fire Protection Factors.

| Factor |

Sub factor |

Utility score |

Utility Description |

| Environmental |

Weather |

8 - 10 |

Moderate Weather all year have mild or no influence petrol station performance which depends on demand, footfall, operations, infrastructure, and safety |

| 6 - 8 |

Moderate to severe weather yearly cycles have noticeable impact and needs proper maintenance programs to keep good performance not to affect , operations, safety, and supply chain |

| 4 - 6 |

Moderate to severe weather almost all year have noticeable impact on petrol stations infrastructure, personnel safety, operation disruption of and failing supply chain operations |

| 2 - 4 |

Extreme Weather can influence petrol station performance by affecting fuel demand, footfall, operations, infrastructure, safety, and supply chain management. |

| Humidity |

8 - 10 |

Mild to low humidity in weather has minimal impact on fuel quality, and low impact on equipment corrosion, and has no impact of the safety procedures nor it affects the operation practices. |

| 6 - 8 |

Seasonal Humidity cycles in weather remarkable affects fuel quality, accelerates equipment corrosion, raises safety concerns, and has impacts on vapor recovery systems. |

| 4 - 6 |

Daily Humidity cycles and high temperature with salty in the weather severely affects equipment's, accelerates equipment corrosion, raises safety concerns, and jeopardize vapor recovery systems, and affects fuel quality |

| 2 - 4 |

Sever high humidity in weather including temperature daily and seasonal cycles in addition to vapors sever salty affects fuel quality, accelerates equipment corrosion, raises safety concerns, damage vapor recovery systems |

| Fire Protection & Safety |

8 - 10 |

Petrol stations is fully equipped for safety measures like fire extinguishers, automatic fire suppression systems, and emergency shutdown systems to mitigate fire risks. In addition, there are good records for regular inspections, maintenance, and staff training for compliance and preparedness. |

| 6 - 8 |

Petrol stations is fully equipped for safety measures like fire extinguishers, automatic fire suppression systems, and emergency shutdown systems to mitigate fire risks. In addition, there are some records for regular inspections, maintenance, and acceptable staff training |

| 4 - 6 |

Petrol stations is partially equipped for some safety measures like fire extinguishers, however automatic fire suppression systems are missing , and emergency shutdown systems are manually operated only and lack inspection and maintenance records, in addition to primitive staff training |

| 2 - 4 |

Petrol stations is partially equipped for some safety measures like fire extinguishers, however automatic fire suppression systems are missing , and no emergency shutdown systems neither recodes of inspection maintenance and no staff training program |

3.5. The AHP-MAUT CRI Model

To determine the Condition Rating Index (CRI) for each space, the scores of all factors and sub-factors were aggregated, considering their corresponding utility values that represent the status of each space as shown in Figure 6. The integration of AHP and MAUT strengthened the decision-making process, ensuring a thorough and objective evaluation of the factors and sub-factors that are significantly impacted by petrol station performance within the proposed CRI. The overall CRI for the petrol station was obtained by aggregating the CRIs of individual spaces, considering their respective relative importance weights. This comprehensive approach ensures a robust evaluation of the petrol station's condition. The CRI vales were computed using Eq. (2),

In which

: relative weight of each main factor (criterion)

i,: relative weight of each sub-factor

: criterion j within factor i, and

: the sub-factor preference utility value scored out of 10.

Figure 6.

The Integrated AHP- MAUT Technique.

Figure 6.

The Integrated AHP- MAUT Technique.

The calculated CRI was then reviewed by operators, stakeholders, and managers to assess current facility performance to identify necessary interventions and alternatives according to the desired performance level and available maintenance budget. The interpretation of the CRI for petrol stations is presented in

Table 5.

4. CRI Implementation

The developed CRI was implemented on a real petrol station as a case study. As mentioned earlier, seven authorities are currently responsible for the management and control of petrol stations in Saudi Arabia. Applying the developed CRI on a real case study to quantify its performance and pinpoint the level of performance for each unit within the petrol station will ensure that all these authorities will have same vision about the petrol station and these authorities will be able to understands and quantify the performance of this petrol stations based on its four spaces discussed earlier.

The case study was a selected petrol station located in the Eastern Province. The name of this petrol station is kept confidential, and the collected data was assured to be used for demonstration and academic purposes only. This petrol station was selected because it has the four spaces system followed in this study these spaces are: refueling tank area, pump station, car service area, and commercial building. It was built in 2015. The breakdown of areas for the petrol station is the following: 3200 m2 for the total station; the refueling tank area is about 120 m2; the pump station area is 480 m2; the car service building is about 450 m2 (including car wash and changing tires and oil); and the commercial building is 415 m2 (including supermarket, coffee shop, and restaurant). The remaining 1700 m2 represents the fenced area, which includes pathways for cars and the parking area, as illustrated in Figure 6.

Figure 6.

Petro Station Spaces.

Figure 6.

Petro Station Spaces.

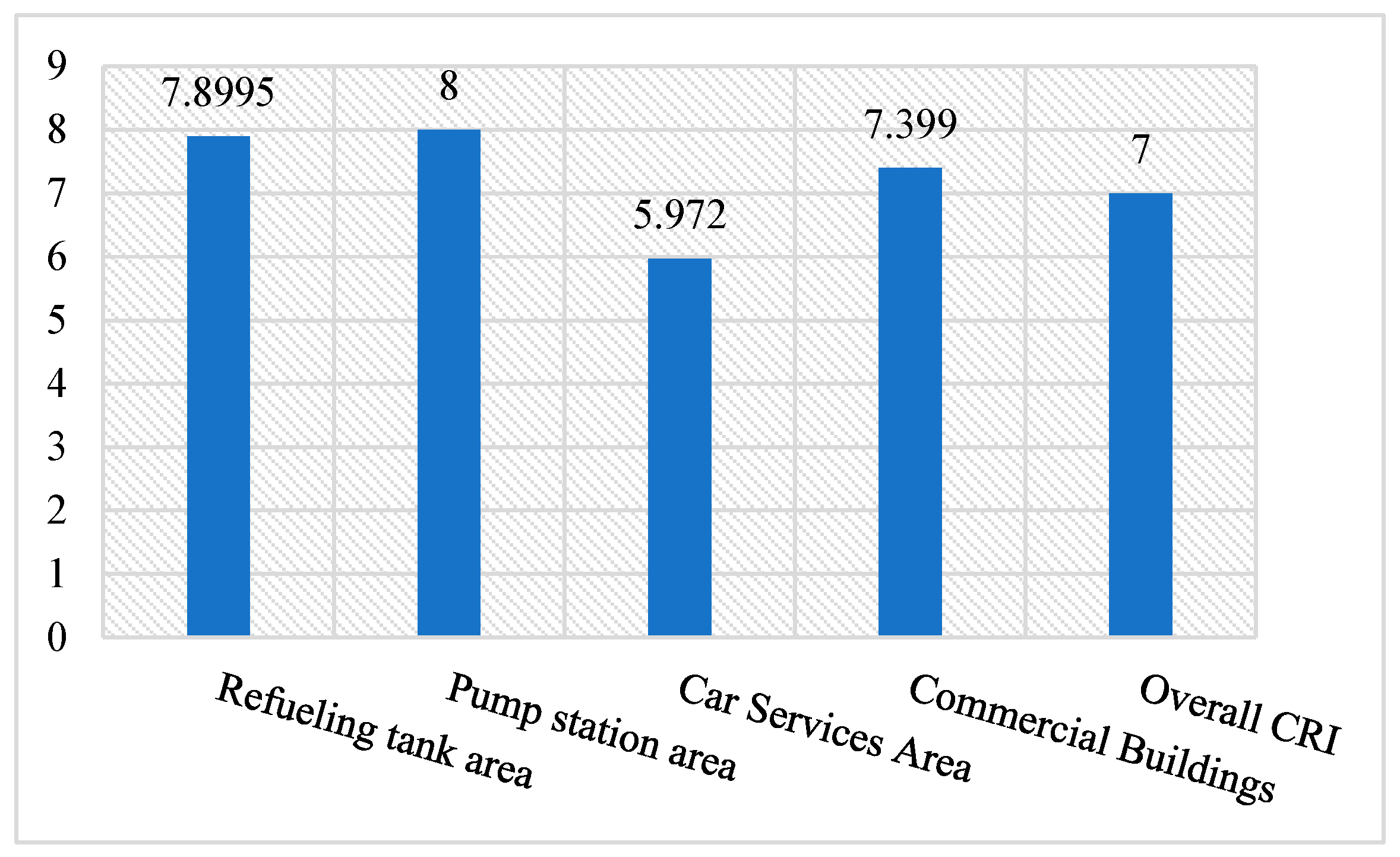

The developed condition rating index was implemented on the petrol station four spaces outlined in the study. The application revealed the ability to discern the performance level of each space using its specific parameters, enabling precise fault detection and evaluation, which in turn facilitates the prioritization of essential operation and maintenance interventions. The CRI for the petrol spaces and main criteria used in this study are shown in

Table 6 and plotted in

Figure 7. The utility score of each criterion was assessed for each space based on the utility level scoring system shown in Table 4.

Applying the developed CRI on the selected petrol station gave a comprehensive evaluation of its current performance and rehabilitation needs derived from this model as shown in

Table 6. The CRI for each space in the studied petrol station where are follows: Refueling tank area scored and pump station areas which are the most important spaces in the petrol’s station spaces scored 8 which is good performance according to the developed scale model shown in Table5. While the car service area scored 6 which is bad on the developed scale. The overall performance of the studied petrol station is 7 which is a satisfactory good performance. The detailed score for all factors is shown in table 6 which reveals the following:

The refueling tank area, especially the entrance, exit, and fueling zones, was well-designed. The infrastructure, especially the pumps, stood out in terms of quality and efficiency. Despite its age, the tank area's operation was satisfactory. Challenges posed by environmental conditions, especially to surface equipment such as fuel dispensers were identified, which pinpoint the importance of frequent preventive maintenance to overcome sever weather conditions. However, buried infrastructures like the tank and pipes are less affected by severe weather. In the area of fire protection for the refueling zone, the efficacy of the firefighting and fuel evaporation control systems was validated. Yet, a need for enhancement in safety protocols was pinpointed and showed that workers need to be trained and training programs and certification must be considered to keep up with the required standards and better prevent possible incidents and better management of these incidents if it occurs.

The pump station was in good shape, with its infrastructure rated highly. Its above-ground parts are more exposed to environmental wear than underground ones. Improved fire safety measures are also required here. The car services area showed some weaknesses, especially in architecture and mechanical and electrical works (MEP). It needs better upkeep due to weather exposure. The station's commercial buildings had mixed results. While some parts like the heating and cooling system (HVAC) worked well, the buildings' design and operational management could be improved. Buildings exposed to the environment, like roofs, need special attention. The implementation of the developed CRI revealed critical safety concerns, emphasized the urgency to reinforce outdoor structures against adverse environmental conditions, and highlighted the significance of enhancing MEP systems. Furthermore, potential avenues to refine the station's architectural design were identified. Collectively, this model provides a blueprint for reinforcing petrol station's performance and operational efficiency.

5. Discussion

Asset management for petrol stations aims to optimize asset performance, minimize downtime and disruptions, ensure safety and environmental compliance, and maximize the value and lifespan of assets. It requires a holistic and proactive approach that integrates various aspects of operational, safety, and regulatory considerations to achieve efficient and sustainable operations. These stations are considered one of the vital infrastructures for cities efficient transportation systems needed for sustainable economy. To keep these stations functioning effectively, they are challenged to meet not only local and international operation and maintenance standards. Effective asset management for petrol stations encompasses key elements such as asset inventory and condition assessment, maintenance and repair programs, asset performance monitoring, compliance with regulatory requirements, and financial planning for asset replacement.

The present study addresses the lack of comprehensive performance evaluation methods for petrol stations, proposing a condition rating model as the DSS backbone for station operation and maintenance. Many studies addressed maintenance issues from the safety and fires protections aspect mostly at pump dispensers; for example, Agyemang et al. (2022), Zhang et al. (2023) and many other studies addressed fire safety issues and other safety impacts on petrol stations workers and users. However, the significance of tools that accurately assess the state and performance of petrol stations has been a focal point in recent scholarly endeavors. Afolabi et al. (2019) explored the complexities of managing assets in petrol stations, particularly in a fast-changing industry. In another study Adeyemi et al. (2019) explored the complexities of managing assets in petrol stations, particularly in a fast-changing industry. Their focus was on asset management in fluctuating economic conditions but omitted maintenance aspects. Their focus was on asset management in fluctuating economic conditions but omitted maintenance aspects. Highlighting this, Adeyemi et al. (2023) delved into the merits of condition-based maintenance (CBM) for these establishments, detailing its benefits like decreased costs and heightened safety. However, their focus was mainly on reviewing CBM literature, also pointing out its implementation challenges. Meanwhile, Oladiran et al. (2023) emphasized the vital role of integrating maintenance management systems with other operational processes, suggesting it boosts efficiency and reduces expenses in petrol stations. Adeyemi et al. (2023) introduced a maintenance framework for petrol stations grounded in a risk-based approach. This framework was designed to allocate resources judiciously and prioritize maintenance tasks based on associated risks. Conversely, Mohammed et al. (2020) underscored the importance of asset management in boosting petrol station efficiency. They proposed a framework to address challenges in system development. Their research pointed out the role of asset management in profitably extending petrol station assets' lifespan. They also identified challenges like a shortage of skilled staff and the disconnect between asset management and other petrol station systems. Numerous studies have highlighted the link between maintenance and petrol station productivity. Adeoye et al. (2021) showcased the influence of Total Productive Maintenance (TPM) on station operations and introduced a targeted framework. They identified preventive maintenance as crucial for reliability, despite challenges in its implementation. Importantly, they pointed out the lack of performance evaluation tools, essential for decision-making in the operation and maintenance of these assets.

Recent research has begun to explore the integration of performance modeling and artificial intelligence (AI) in asset management, notably in petrol station operations. Mohammed et al. (2020) highlighted AI's transformative capabilities for optimizing petrol station asset management, presenting a relevant AI deployment framework. Concurrently, Hassan et al. (2022) delved into IoT-enabled sensors' role in station maintenance. These sensors, while enhancing efficiency, precision, and promptness in maintenance, face challenges like data security and system integration, leading to the development of a tailored framework. Taking it a notch higher, Hassan et al. (2022) explored the potential of digital twins in refining maintenance practices. They demonstrated simulating asset behaviors and maintenance scenarios with digital twin aids in pinpointing and addressing issues, streamlining schedules, and elevating maintenance quality. Yet, they emphasized the need for more advanced tools for effective simulation representation.

The CRI developed in this study is grounded in best practice standards, amalgamating various factors influencing petrol station space performance. This hierarchical model discerns each factor's specific impact, arranging them in a root cause hierarchy. This method quantifies both surface and subsurface unit performance in each space, assigning them distinct importance weights. This aids in prioritizing rehabilitation efforts and fosters transparent communication among stakeholders. In essence, the CRI introduced in this research is highlighted as a crucial advancement and need, firmly supported by previous academic studies. The condition rating model developed in this research is an expert-based model, employing the analytical hierarchy process (AHP) integrated with the multi-attribute utility theory (MAUT) technique. This approach is adopted due to limited availability or varying formats and qualities of data required for evaluating the performance of petrol stations. The AHP technique proves advantageous in accommodating diverse qualitative and quantitative data types, providing a robust framework for better assessment and decision-making in such data-constrained scenarios.

The adopted factors and their utility score system adopted in the study complies with the united stations sustainability development goals UNSDGs. These practices promote SDG 3 through user safety, SDG 6 (Clean Water and Sanitation) by safeguarding the environment, and SDG 7 (Affordable and Clean Energy) by ensuring safe fuel storage and distribution. They also align with Goal 9 (Industry, Innovation, and Infrastructure) through advanced safety measures. These spaces significantly contribute UNSDGs. They promote Goal 8: Decent Work and Economic Growth through job creation and development. Goal 9: Industry, Innovation, and Infrastructure are advanced with modern equipment and sustainable materials. Goal 11: Sustainable Cities and Communities is supported by proper waste management. Emphasizing efficient resource use aligns with Goal 12: Responsible Consumption and Production. Lastly, collaborations with third-party partners foster Goal 17: Partnerships for the Goals.

6. Conclusion

The study adopted factors and utility values to quantify their performance and contribution within petrol stations. This study developed a comprehensive CRI for petrol stations by dividing these assets into four standard spaces. The relative weight for each space is identified in this study. For each space all major factors affecting the performance of each space is identified and organized in a hierarchal order organized in main -sub main factors. The relative importance weight for each factor and sub factor were identified in this study using the AHP approach. Moreover, the utility value for each factor was also identified in this study, which makes it a comprehensive transparent tool that can be used by different stakeholders, especially if each space within the petrol station is managed by different stakeholders.

In Saudi Arabia, there are seven authorities responsible for managing the operations and performances of petrol stations. A transparent and unified decision support system (DSS) among these authorities empowers petrol stations to identify deficiencies, optimize resource allocation, and enhance overall performance. The development of a condition rating index for petrol stations serves as the backbone of a structured decision support system. This index plays a pivotal role in quantifying the performance of key units within petrol stations, as well as providing an overall assessment of station performance, it can be used as the backbone for such DSS. The implementation of the CRI on the case study showed that it can easily pinpoint the performance of different units and parameters affecting the performance of different operating units in different spaces within the petrol station. This not only will identify the performance level but each unit and each space but also it can facilitate addressing responsibilities among decision makers and stakeholders. An effective decision support system for asset management in petrol stations should provide essential information on assets inventory, value, condition rating, costs of rehabilitation interventions, prioritization of interventions, cost optimization, and the consequences of deferring maintenance interventions. The developed CRI can be improved by adopting more specific experimental tools and techniques to better describe the utility score of different impacts. This continuous improvement will provide more realistic prediction models that will help in better planning for maintenance interventions and budget allocations.

References

- Abrahim, A.; El-Sayed, M.; Al-Fadl, Y. Hazard Identification and Risk Assessment in Petrol Stations: A Review. Journal of Loss Prevention in the Process Industries 2016, 39, 123–145. [Google Scholar]

- Adeoye, A.; Oladiran, O.; Adeyemi, A. Total Productive Maintenance for Petrol Stations: A Case Study of Nigeria. Journal of Maintenance and Reliability 2021, 23, 123–145. [Google Scholar]

- Adeyemi, A.; Oladiran, O.; Afolabi, O. Asset Management in Petrol Stations: A Case Study of Nigeria. Journal of Asset Management 2019, 14, 123–145. [Google Scholar]

- Adeyemi, A.; Oladiran, O.; Afolabi, O. Condition-Based Maintenance for Petrol Stations: A Review of Recent Advances. Journal of Building Engineering 2023, 10, 123456. [Google Scholar]

- Afolabi, O.; Adeyemi, A.; Oladiran, O. Asset Management in Petrol Stations: A Review of Current Practices and Challenges. Journal of Asset Management 2019, 15, 123–145. [Google Scholar]

- Agyemang, K.; Agyei-Mensah, S.; Amoah, A. Fire Safety Management in Petrol Stations: A Case Study of Ghana. Journal of Safety Research 2022, 52, 123–134. [Google Scholar]

- Ahmad, N.; Rehan, M.A. Fire Safety Management in Petroleum Industry: A Case Study of Saudi Arabia. International Journal of Engineering Research & General Science 2016, 4, 187–191. [Google Scholar]

- Ahmed, A.; Al-Zahrani, A.M.; Al-Olayan, A.A. Safety Management Systems in Petroleum Industry: A Case Study of Saudi Arabia. International Journal of Industrial Ergonomics 2012, 42, 42–52. [Google Scholar]

- Ahmed, S.; Khan, A.; Ali, M. Safety Risk Assessment in Petrol Stations: A Comparative Study. Journal of Safety Research 2011, 42, 123–134. [Google Scholar]

- Aldeeb, O., & Qasem, A. (2022). Decision support system (DSS) for facilities rehabilitation and management (part 1): Development of integrated AHP-MAUT performance assessment model (PAM). Facilities 40(13/14), 845-861.

- Argaam, 2018. Saudi Arabia's Ministry of Commerce and Industry Issues Guidelines for Petrol Stations. Retrieved from: https://www.argaam.com/en/article/articledetail/id/1692566.

- Baker, J.; Liu, Y. The Unique Challenges of Asset Management in Petrol Stations. Asset Management Journal 2023, 17, 34–56. [Google Scholar]

- Beckman, D. The Evolution of Petrol Stations: From Fuel Points to Service Centers. Journal of Retailing 2011, 87, 456–478. [Google Scholar]

- Chian, S. Sustainable Development Goals and the Energy Transition. Nature Energy 2021, 6, 981–983. [Google Scholar]

- Cranston, J. Optimizing Benefits and Reducing Risks in Asset Management: A Comparative Study. Journal of Asset Management 2018, 13, 123–145. [Google Scholar]

- Dejaco, M.; Schleich, S.; Sonderegger, M. Asset Management Strategies for Buildings: A Comparative Analysis. Journal of Building Engineering 2017, 3, 123–145. [Google Scholar]

- Eftekhari, A. Risk Management in the Oil and Gas Industry: A Focus on Petrol Stations. Journal of Risk Management 2017, 12, 123–145. [Google Scholar]

- Global Bioenergy Partnership, 2022. Sustainable Bioenergy: A Framework for Action. Retrieved from: https://www.fao.org/in-action/global-bioenergy-partnership/en.

- Hassan, M.; Mohammed, A.; El-Sayed, M. Digital Twins for Asset Management in Petrol Stations: A Feasibility Study. Journal of Asset Management 2022, 18, 123–145. [Google Scholar]

- Hassan, M.; Mohammed, A.; El-Sayed, M. The Role of IoT in Asset Management for Petrol Stations: A Review. Journal of Asset Management 2022, 17, 123–145. [Google Scholar]

- International Renewable Energy Agency, 2022. Renewable Energy Statistics 2022. Retrieved from: https://www.irena.org/publications/2022/Jul/Renewable-Energy-Statistics-2022.

- Johnson, R.; Lee, S.; Baker, J. Condition-Based Maintenance for Buildings: A Review of Recent Advances. Building and Environment 2021, 103, 123456. [Google Scholar]

- Kahraman, A.; Oztaysi, B.; Ruan, D. A Multi-Criteria Decision-Making Approach for Assessing the Performance of Petrol Stations. International Journal of Sustainable Energy 2020, 12, 123–145. [Google Scholar]

- KAPSARC, 2021. Saudi Arabia's Petrol Stations: A Comprehensive Assessment. Retrieved from: https://www.kapsarc.org/.

- Khalafalla, M.; Al-Zahrani, A.; Al-Olayan, A. Assessing the Performance of Petrol Stations in Saudi Arabia: A Condition Rating Index Model. Journal of Petroleum Exploration and Production 2023, 13, 1–18. [Google Scholar]

- Lee, S.; Kim, J.; Park, H. Decision Support Systems for Asset Management: A Comparative Analysis. International Journal of Asset Management 2022, 15, 78–95. [Google Scholar]

- Leung, H.; Chan, A.; Wong, K. Integrated Asset Management for Petrol Stations: A Framework. Journal of Asset Management 2017, 12, 123–145. [Google Scholar]

- Mohammed, A.; Hassan, M.; El-Sayed, M. Asset Management in Petrol Stations: A Framework for Implementation. Journal of Asset Management 2020, 16, 123–145. [Google Scholar]

- Nawel, A. Condition-Based Maintenance for Utilities: A Review of Recent Advances. Utilities Policy 2023, 85, 123456. [Google Scholar]

- Olabi, A.G.; Al-Hammadi, A.M.; Al-Sulaiman, O.A. Sustainable Energy Development in Saudi Arabia: Challenges and Opportunities. Journal of Cleaner Production 2022, 342, 128538. [Google Scholar]

- Oladiran, O.; Adeyemi, A.; Afolabi, O. Integrated Maintenance Management Systems for Petrol Stations: A Case Study of Nigeria. Journal of Maintenance and Reliability 2023, 25, 123–145. [Google Scholar]

- Pan, Y.; Liu, Z.; Chen, X. Sustainable Development Goals and the Petrol Station Industry. Journal of Sustainable Development 2021, 14, 123–145. [Google Scholar]

- Purohit, R.; Jain, A. Environmental Management in Petrol Stations: A Case Study of India. Journal of Environmental Management 2020, 261, 110123. [Google Scholar]

- Sarkis, J. Decision Support Systems for Asset Management in the Oil and Gas Industry: A Review. International Journal of Energy Economics and Policy 2018, 8, 123–145. [Google Scholar]

- Smith, J.; Jones, M.; Williams, A. Asset Management in the Petrol Station Industry: A Review of Current Practices and Challenges. Journal of Asset Management 2022, 12, 123–140. [Google Scholar]

- Sun, Y.; Li, Z.; Zhang, W. Asset Management for Petrol Stations: A Case Study of China. Journal of Asset Management 2018, 14, 123–145. [Google Scholar]

- Tsekouras, G.; Papazoglou, I.; Psarras, J. The Role of Service Quality in Petrol Stations: A Customer Perspective. Journal of Retailing 2018, 94, 123–145. [Google Scholar]

- Zhang, Y.; Li, Z.; Wang, X. Risk Assessment and Prevention of Fires in Petrol Stations: A Review. Journal of Loss Prevention in the Process Industries 2023, 85, 123456. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).