Submitted:

04 November 2024

Posted:

04 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

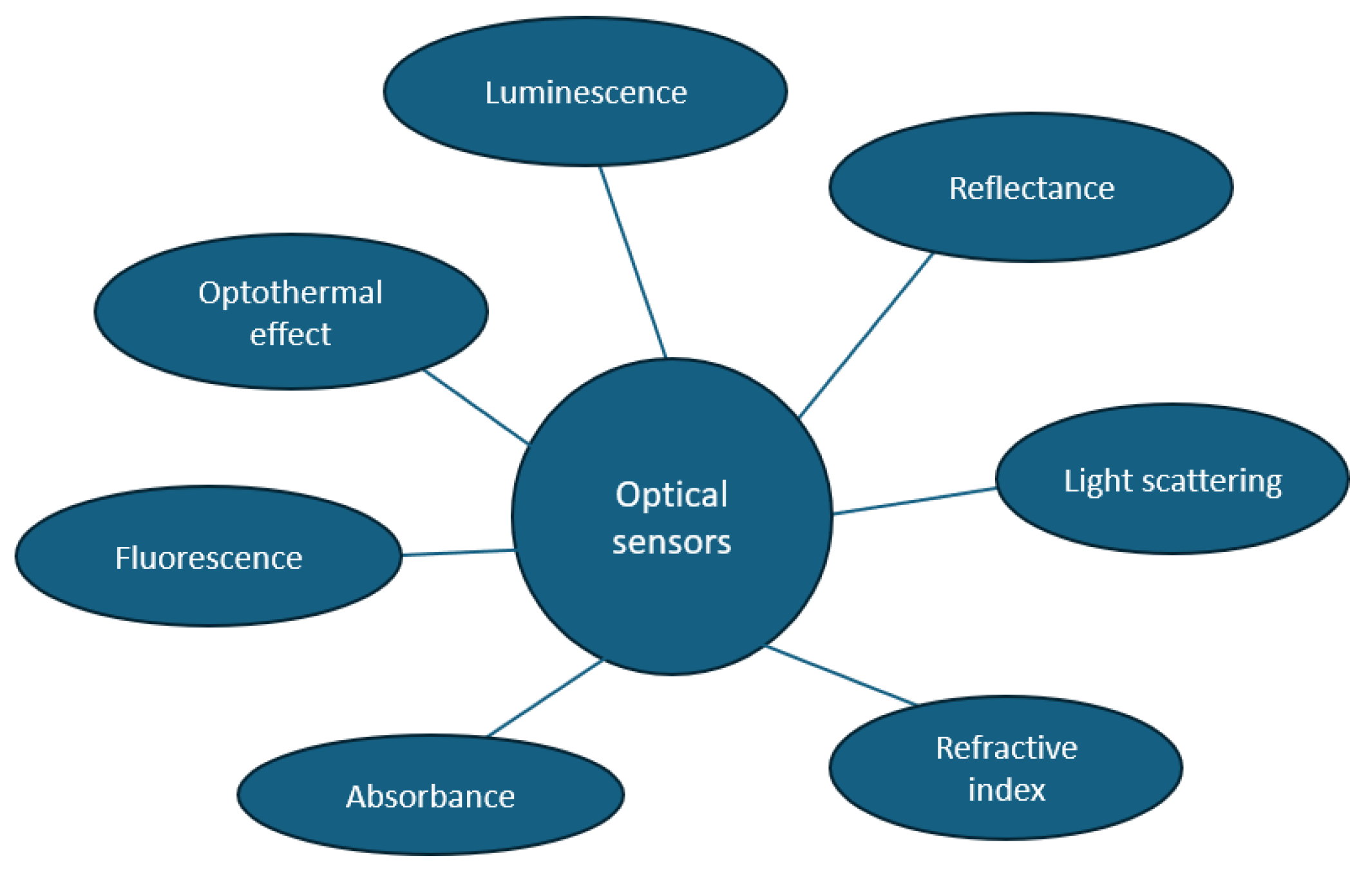

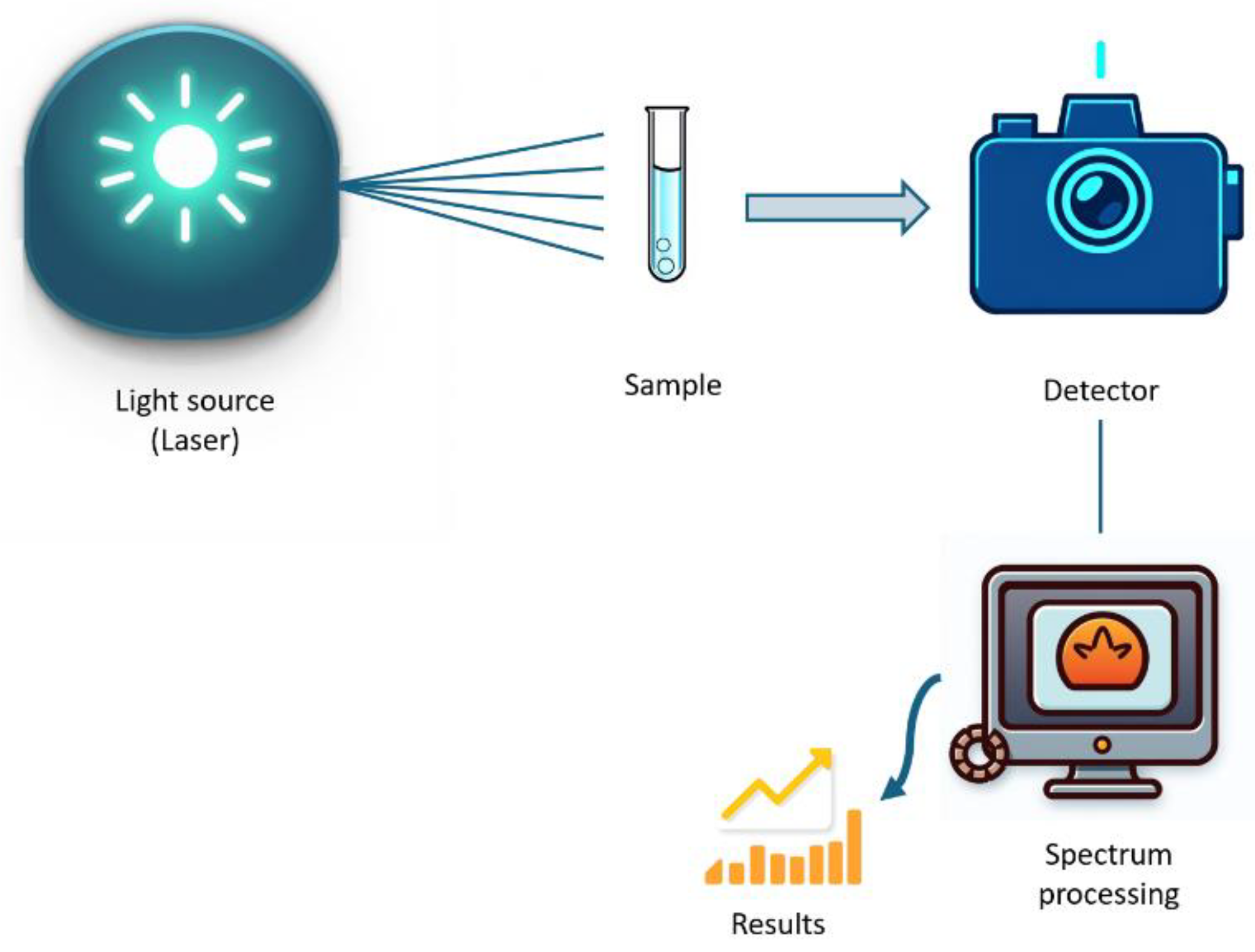

2. Spectroscopy Principles

2.1. Spectroscopy

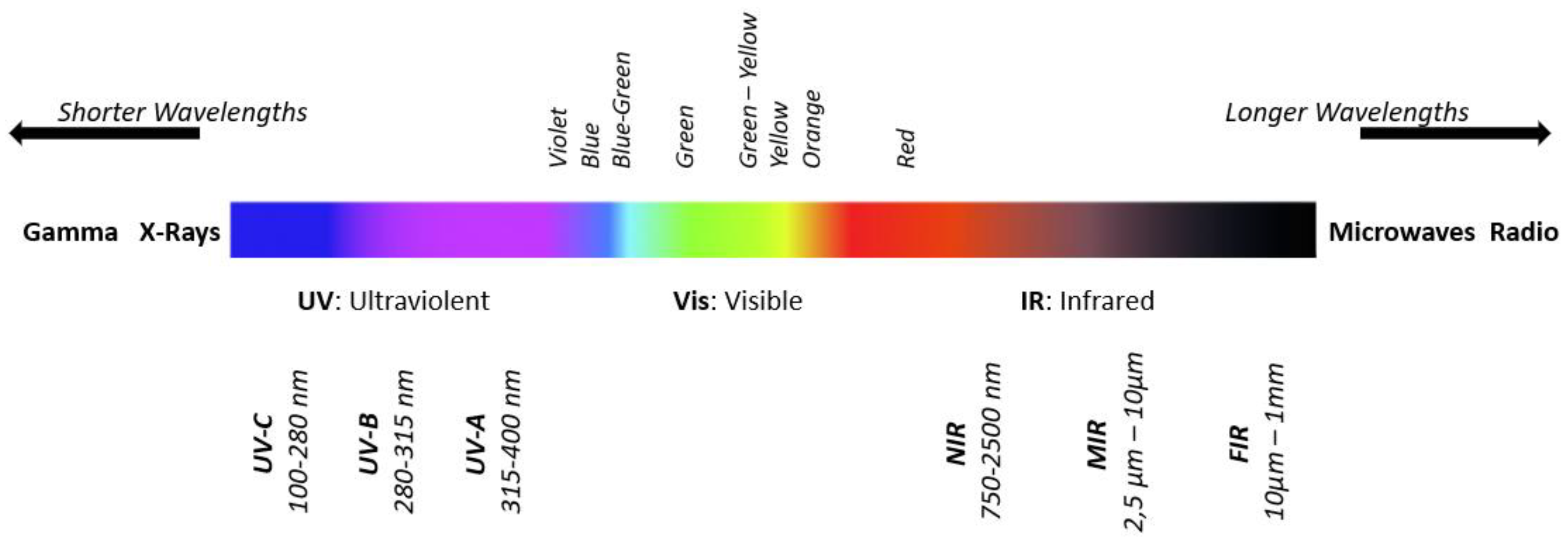

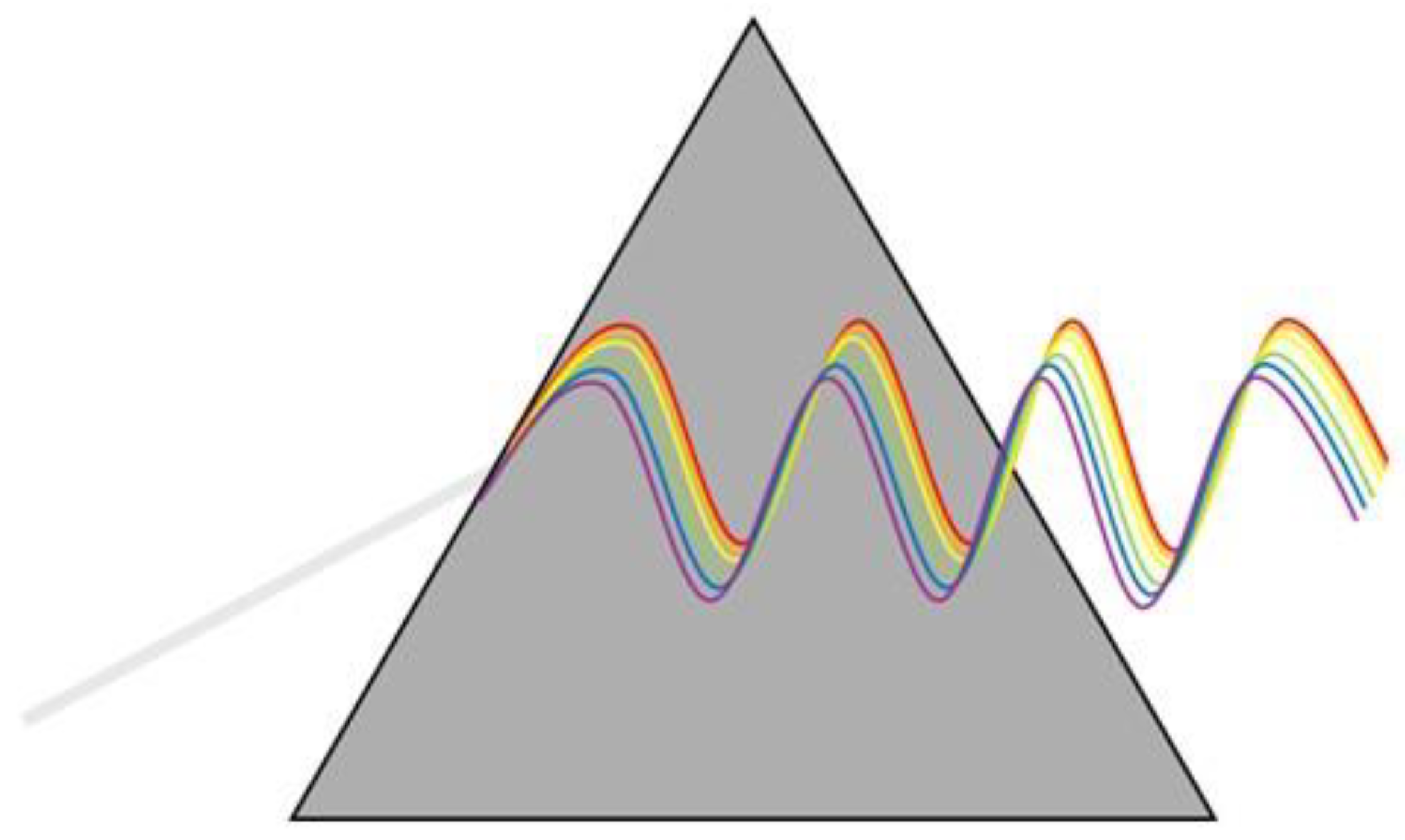

2.2. The Infrared Region of the Electromagnetic Spectrum

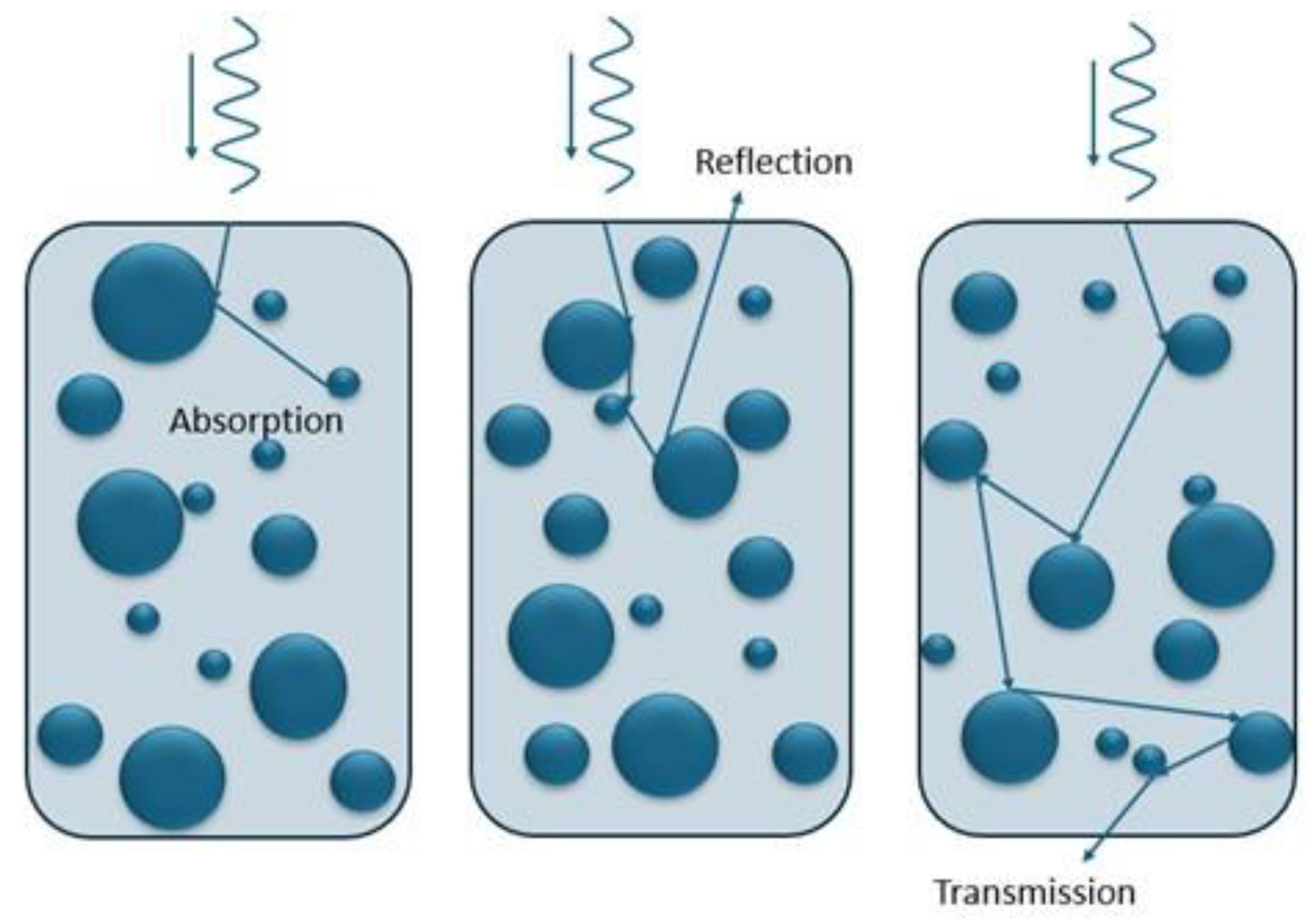

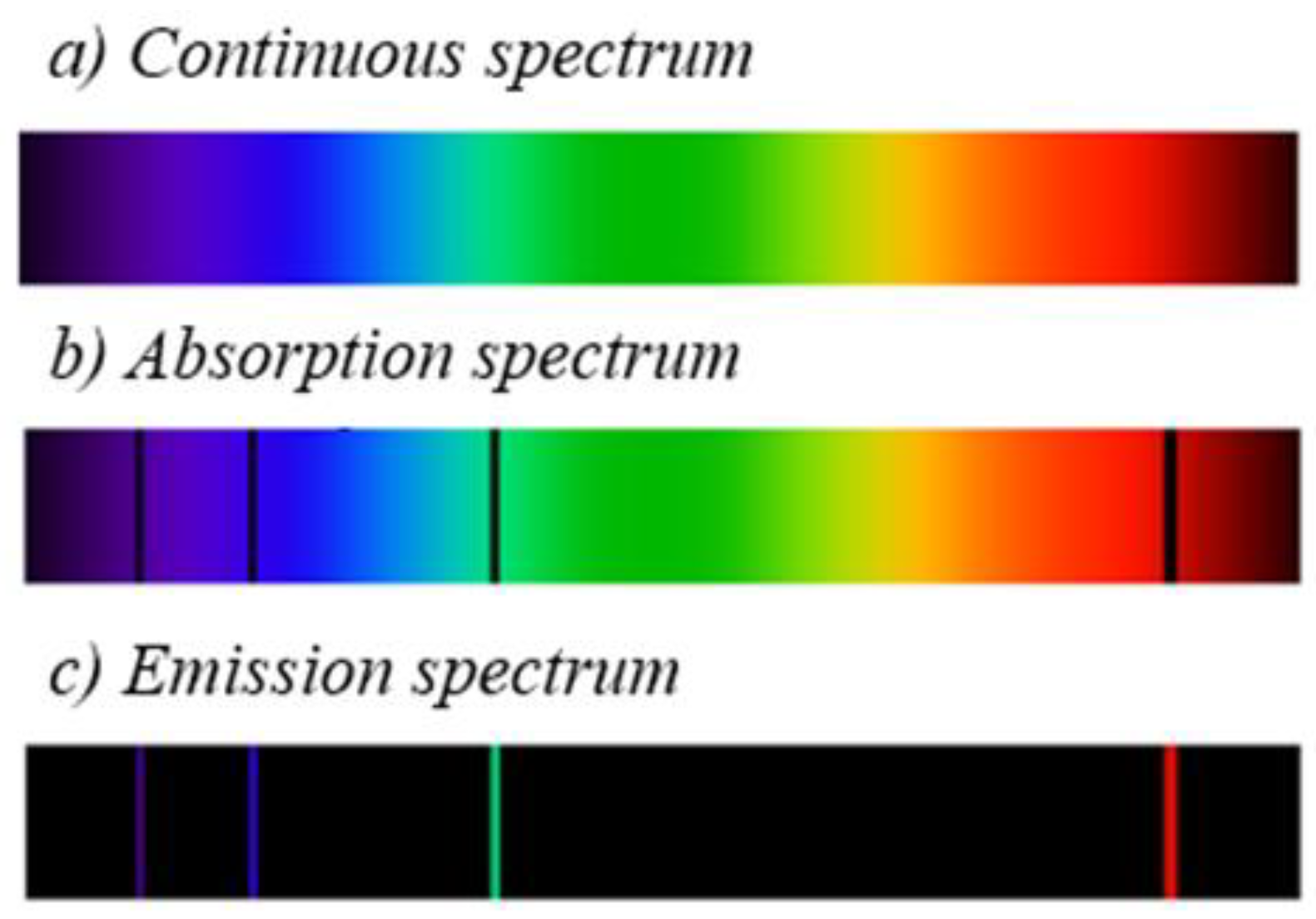

2.3. Transmittance, Reflectance, Absorption and Emission of Light

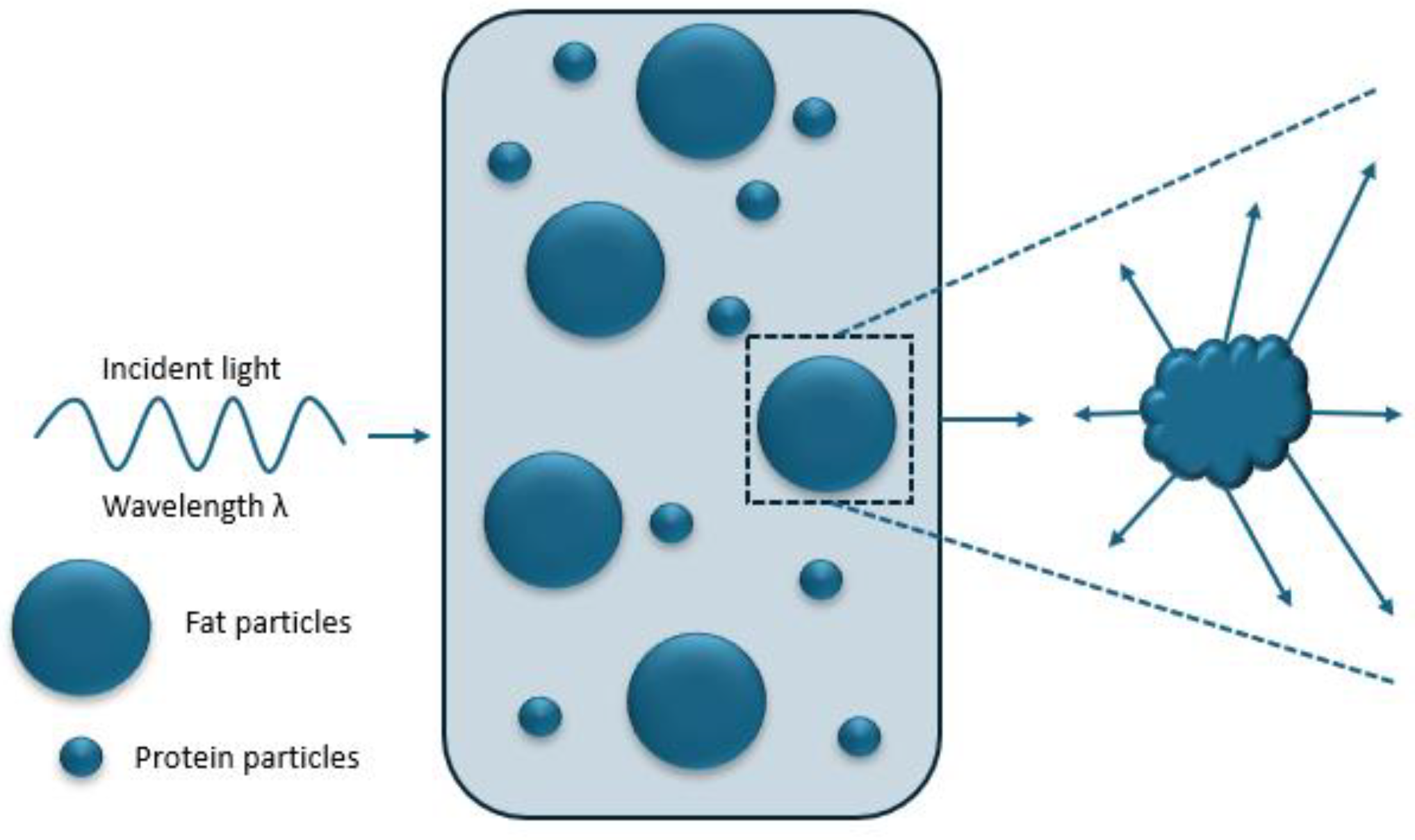

2.4. Light Scattering

2.5. Other Optical Properties

2.6. Optical Chemosensors

3. Milk Composition and Quantification Techniques

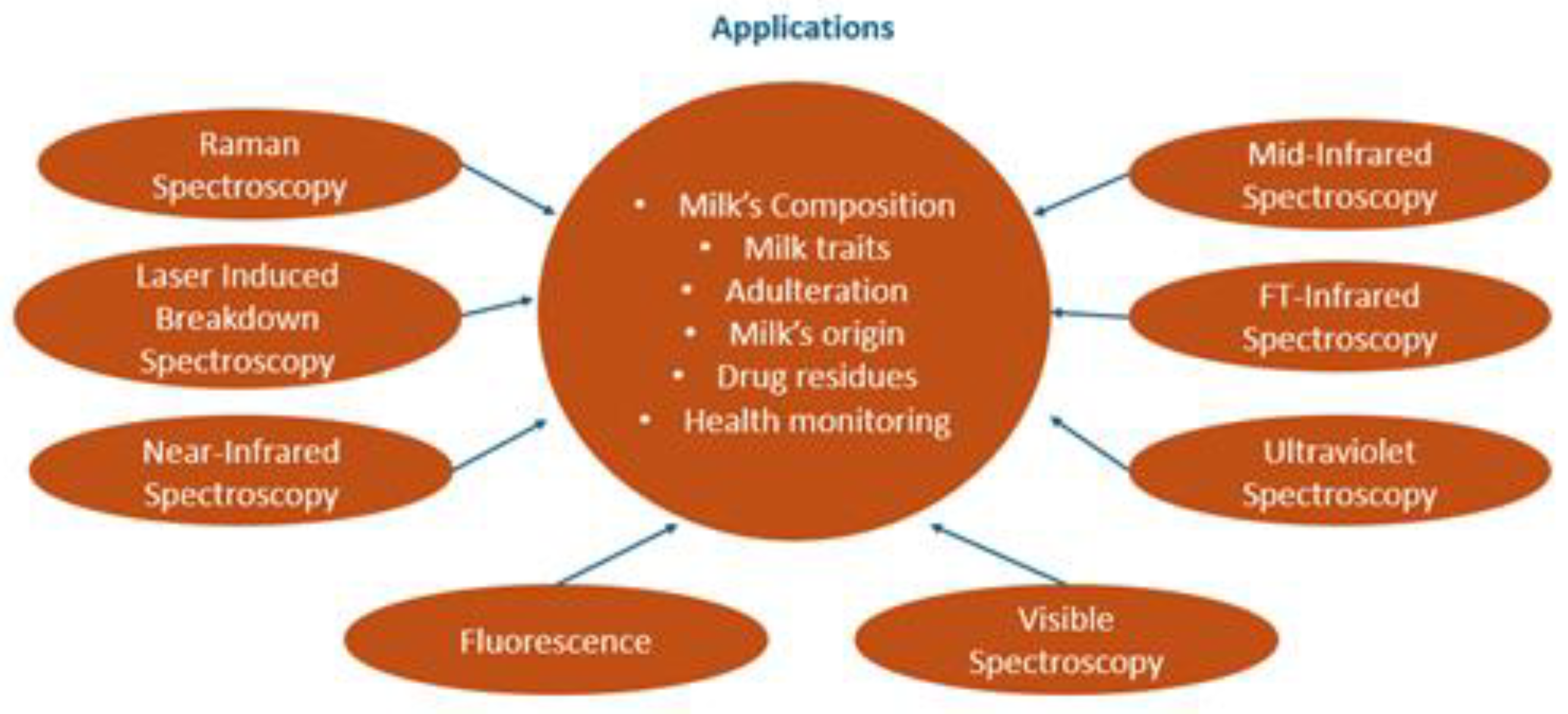

4. Spectroscopy Applications

4.1. Reflectance, Absorption, and Emission Spectroscopy

4.2. Raman Spectroscopy

4.3. Laser Induced Breakdown Spectroscopy (LIBS)

| Element | Wavelength (nm) |

|---|---|

| H | ) |

| N (I) | 742.4, 744.2, 746.8, 818.8, 821.6, 824.2, 862.9, 865.6 |

| N (II) | 500.5, 568.6 |

| O (I) | 715.6, 777.2, 777.4, 777.5, 844.6, 926.4 |

| C (I) | 247.8, 795.2, 906.2, 940.6 |

| Mg (II) | 279.8, 280.3 |

| Ca (I) | 422.6, 428.3*, 428.9*, 430.2*, 431.9*, 442.5*, 443.6*, 445.5*, 559.4*, 612.2*, 616.2*, 643.9*, 646.3*, 649.4* |

| Ca (II) | 315.9, 317.9, 393.3, 396.8 |

| Na (I) | 589.0 |

| K (I) | 766.5, 769.8 |

| Wavelength (nm) |

Type of milk sample | No of samples | Origin of milk | Application | RMSE/SEP | Accuracy (%) |

Ref. | |

| 534.9 766.5 285.2 |

powder | 23 | retail | Ca K Mg |

0.92 0.80 0.91 |

2614 mg kg-1 SEP 1549 mg kg-1 SEP 91 mg kg-1 SEP |

- |

[44] |

| Laser excitation: 1064 & 532 |

liquid, ashed L/ph powder |

ND | cowR, goatR, sheepR | major minerals† minor minerals†† |

- | - | - | [46] |

| 181 – 904 | powder | 5 | infant formula | Ca | 0.85 pr | 0.68 mg/g p | - | [52] |

| 200 – 700 | dried | 60 ND |

maternal infant formula |

composition quality (Mg, Ca, Fe, Na) |

- | - | - | [50] |

| 200 – 900 | liquid | 300 | cow | fat, protein, lactose, SNF, density, SCC |

- | - | - | [51] |

| 200 – 1000 | liquid L/ph powder |

1296 683 |

cow, goat, sheep | milk origin | - | - | 92.8 95.5 |

[47] |

| Mg, Ca, Na, K spectral lines | liquid L/ph powder |

1296 683 |

cow, goat, sheep | milk origin | - | - | 87.6 92.9 |

[47] |

| ≈ 185 – 1048 | powder | 50 | vetch root | milk origin | - | - | 73.1 | [53] |

| 190 – 450 | blended powder | 12 | cowR, goatR, sheepR | melamineA, p/b clss. |

0.99 (melamine) |

- | 98 (clss. rate) |

[48] |

| 540 – 900 | powder | 36 | cow | sweet wheyA acid wheyA |

0.981 0.985 |

- | - | [49] |

| 186 – 900 | gel | 13 13 14 |

cow goat sheep |

caprine adult. with bovine ovine adult. with bovine |

0.993 0.995 |

4.53 μg mL-1p 3.56 μg mL-1p |

- | [54] |

| 196 – 874 | powder | 25 | infant formula | exogenous protein | - | - | 93.9 (SVM) 97.8 (CNN) |

[55] |

4.4. Infrared (IR) Spectroscopy

4.4.1. Near-Infrared Spectroscopy (NIRS)

4.4.1.1. Applications of Near-Infrared Spectroscopy in the Dairy Industry

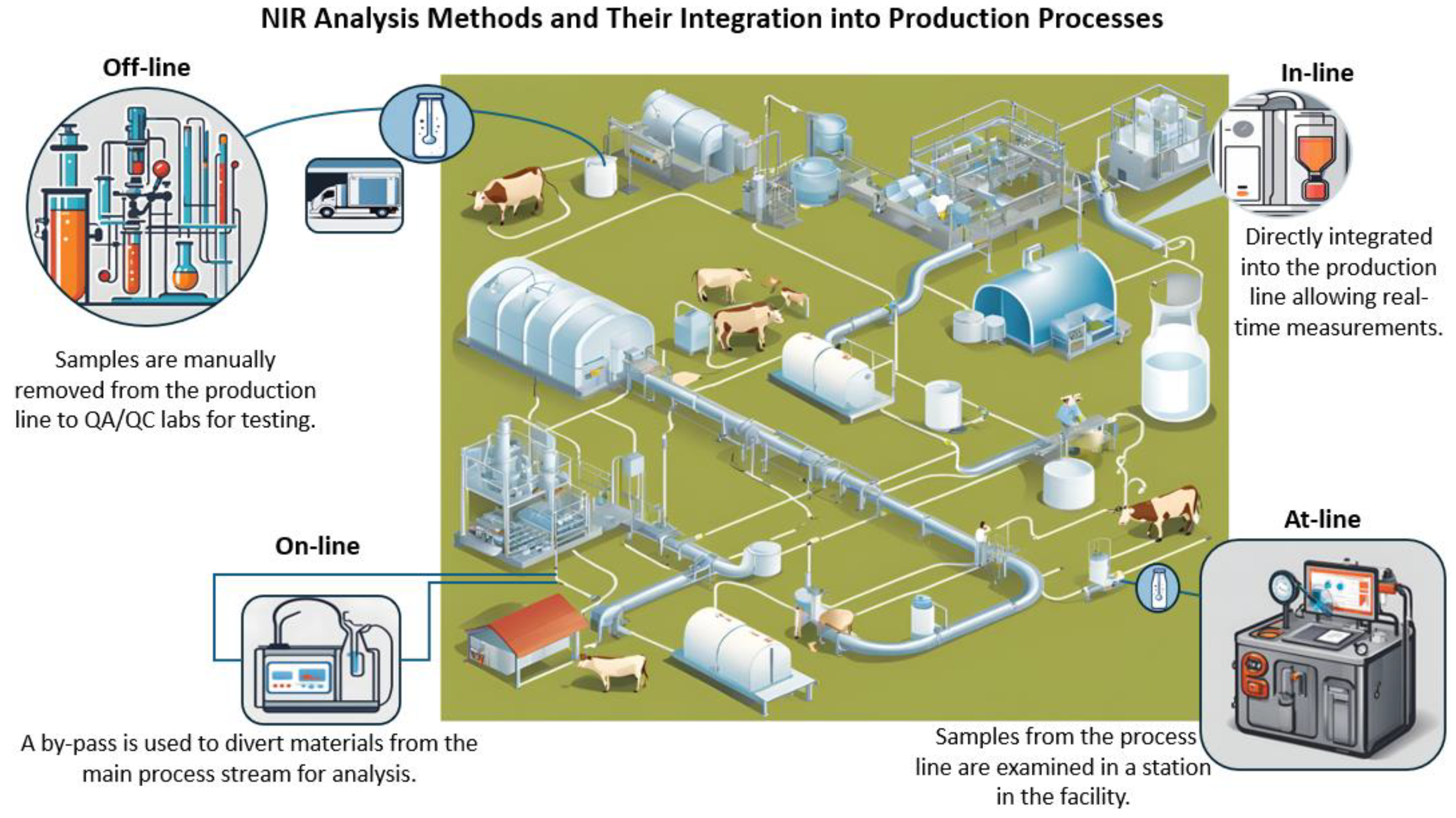

- Off-line: NIRS systems are located in quality assurance/quality control (QA/QC) labs; samples are manually collected from the production line for testing.

- At-line: Samples are collected from the milk-processing line and tested using NIRS systems which are positioned near the line.

- On-line: NIRS systems are located at the sampling point; a sample bypass is used to divert materials from the main process stream to be analyzed by the NIRS systems.

- In-line: NIRS system is directly incorporated into the production line, utilizing various sampling techniques that allow real-time measurements.

4.4.1.2. Near-Infrared Spectroscopy Systems for Milk Analysis

| Compound Assignment | Wavelength (nm) |

|---|---|

| N-H, protein | 904, 1014, 1031, 1720, 1758, 2196, 2296, 2334 [69,70] |

| O-H, C-H lipids | 2076, 2376 [69] |

| Carotenoids | 400 – 700 [69] |

| O-H, water | 1454, 1984, 1953 [71] |

| O-H, N-H | 1953, 2048 [71] |

| Attributed to high somatic cell count | 782, 788, 908, 980, 1068 [72] |

| Wavelength (nm) |

Type of milk sample |

No of samples |

Origin of milk |

Application | RMSE/SEP | Accuracy (%) |

Ref. | ||||

| 1000 – 1700refl 1000 – 2500tranms |

liquid | 300 | cow |

fat crude protein lactose urea |

refl 0.997 0.959 0.300 - |

tranms 0.997 0.927 0.768 - |

refl 0.047%p 0.099%p 0.282%p - |

tranms 0.043%p 0.133%p 0.162%p - |

- | [59] | |

| 1445 – 2348 | liquid HM liquid UM |

166 | goat | fat protein casein total solid SCC |

0.98HM, R 0.96HM, R 0.91HM, R 0.94HM, R 0.79 HM, R |

0.98 UM, R 0.95UM, R 0.92UM, R 0.95UM, R 0.74 UM, R |

- |

- | [66] | ||

| 851 – 1649 | liquid | 785 | cow | fat protein lactose urea SCClog |

0.998 0.98 0.92 0.82 0.85 |

0.09%SEP 0.05% SEP 0.06%SEP 19.3 mg/L SEP 0.18 SEP |

- | [27] | |||

| 1500 – 2500 | powder | 409 | retail | protein | 0.966 p | 0.547% p | - | [75] | |||

| 700 – 1100 | liquid | 384 | cow | SCC | 0.76 | - | - | [72] | |||

| 400 – 2500 | liquid | 242 | cow | carotenoids vitamins FAs |

0.09 – 0.63 0.01 – 0.69 0.07 – 0.96 |

0.01 – 0.15 μg/mL SEP 0.15 μg/mL – 611.82 pg/mL SEP 0.12 – 4.13 g/100g SEP |

- | [76] | |||

| 400 – 2498 refl | oven dried | 805 | goat | FAs | 0.80 – 0.47 | 0.06 – 2.99 g/100g SEP | - | [74] | |||

| 400 – 2498 trans | liquid oven dried |

220 220 |

goat | FAs | 0.11 – 0.79 0.23 – 0.78 |

0.05 – 2.81 g/100g SEP 0.05 – 3.35 g/100g SEP |

- | [74] | |||

| 400 – 2498 | liquid oven-dried |

468 | cow, bulk | FAs | 0.00 – 0.91 v 0.20 – 0.95 v |

0.11 – 3.93 g/100g SEP 0.03 – 3.25 g/100g SEP |

- | [73] | |||

| 400 – 2498 | liquid oven-dried |

215 | cow | FAs | 0.29 – 0.92 v 0.46 – 0.97 v |

0.08 – 2.34 g/100g SEP 0.05 – 1.00 g/100g SEP |

- | [77] | |||

| 600 – 1100 | liquid | ND | retail | pH | - | 0.031 pH unit | 88.0 – 93.0 | [70] | |||

| ≈1100 – 2500 | powder | 50 | vetch root | milk origin | - | - | 91.5 | [53] | |||

| 1100 – 2500 | liquid powder infant formula |

690 660 660 |

retail | melamineA | - | - | - | [78] | |||

| 1000 – 2500 | powder | 110 | infant formula | melamineA | - | 0.28 – 0.31 % p | - | [79] | |||

| 1000 – 2500 | liquid | 150 | cow | scattering in NIR absorption | - | - | - | [71] | |||

| 1100 – 2498 | liquid dried |

219 |

sheep |

summer milk winter milk |

- | - | liquid: 79.0 dried: 89.0 liquid: 78.0 dried: 93.0 |

[67] | |||

| 400 – 2498 | oven-dried | 486 | cow | cow feeding-type classification | - | - | 91.5 - 95.5 | [69] | |||

4.4.1.3. Handheld and Portable Near-Infrared Spectroscopy Systems

| Wavelength (nm) |

Type of milk sample |

No of samples |

Origin of milk | Application | RMSE/SEP | Diagnostic performance |

Ref. | |||

| 1600 – 2400 | liquid | 108 | cow | FAs | 0.01 – 0.92 | 0.01 – 1.57 g/100g SEP | - | [80] | ||

| 908 – 1676 | liquid | 87 | retail | O / NO classification |

- | - | Se: 59.0% Sp: 81.0% Acc: 73.0% |

[81] | ||

| 1600 – 2400 | liquid | 542 | cow | fat protein SNF |

0.971 0.758 0.612 |

0.126 % SEP 0.124 % SEP 0.221% SEP |

- | [82] | ||

| ≈ 1600 – 2400 | powder | 110 | infant formula | melamineA | - | 0.33 – 0.35 % p | - | [79] | ||

| ≈ 1100 – 2200 | powder | 110 | infant formula | melamineA | - | 0.27 – 0.30 % p | - | [79] | ||

| 960 – 1690 | liquid | 1270 | cow | fat protein lactose |

0.989 p_rl 0.894 p_rl 0.644 p_rl |

0.989 p_ph 0.947 p_ph 0.689 p_ph |

0.083p_rl* 0.110p_rl* 0.092p_rl* |

0.078p_ph* 0.080p_ph* 0.077p_ph* |

- | [83] |

| 800 – 1060 | liquid | 81 | cow | fat casein whey |

0.88 0.89 0.91 |

0.08 % wt p 0.13 % wt p 0.07 % wt p |

- | [84] | ||

4.4.2. Mid-Infrared Spectroscopy (MIRS)

| Wavelength () |

Type of milk sample |

No of samples |

Origin of milk | Application | RMSE/SEP | Accuracy (%) |

Ref. | |

| 1000 - 4000 | liquid | 235 | cow | protein | - | PLS: 0.22% NN: 0.08% |

- | [86] |

| 1470 – 1730 | L/ph powder | ND | cow | protein | 0.974 c | 0.765 mg mL-1cv | - | [87] |

| 400 – 4000 | powder | 409 | retail | protein | 0.990 pr | 0.294%p | - | [75] |

| All MIR excluding: 1600 – 1710 2990 – 3690 > 3822 |

liquid | 730 | cow | CMS pH protein traits RCT |

0.08 0.65 0.19 – 0.47 0.50 |

25.286 mm cv 0.061 pH unit cv 0.255 – 1.759 g/L cv 6.397 min cv |

0.62 0.80 0.41 – 0.48 0.75 |

[88] |

| 525 – 4000 | liquid | 242 | cow | carotenoids vitamins FAs |

– 0.50 0.02 – 0.40 0.01 – 0.34 |

0.01 – 0.19 μg/mL SEP 0.15 μg/mL – 907.3 pg/mL SEP 0.13 – 12.63 g/100g SEP |

- | [76] |

| 1000 – 5000 | liquid | 215 | cow | FAs | 0.33 – 0.94 v | 0.06 – 1.14 g/100g SEP | - | [77] |

| 900 – 4000 | liquid | 1064 | cow | RCT titratable acidity pH |

0.62 0.66 0.59 |

2.36 min cv 0.26 SHo/50 mLcv 0.08 Ph unit cv |

- | [89] |

| 500 – 4000 | liquid powder infant formula |

690 660 660 |

retail | melamineA | - | - | - | [78] |

| 1450 – 1600 | liquid | 310 | retail | (w, sm, su, u, hp) A | 0.96, 0.94, 0.98, 0.98, 0.90 | (2.33, 0.06, 0.41, 0.30, 0.01) g/L SEP | - | [85] |

4.5. Other Spectroscopy Methods

| Spectroscopy Method | Wavelength (nm) |

Type of milk sample |

No of samples |

Origin of milk | Application | RMSE | Accuracy (%) |

Ref. | |||

| FT-IR | liquid | 63 | cowR, goatR, sheepR |

composition | 0.92 0.93 0.96 |

6.40*p 5.61* p 3.98* p |

- | [93] | |||

| FT-IR | liquid | 23 | cowR, goatR, sheepR | fat content animal of origin |

- | - | 78.0 74.0 |

[95] | |||

| Ultraviolent | 220 – 400 | liquid | 23 | cowR, goatR, sheepR | fat content animal of origin |

- | - | 96.0 91.0 |

[95] | ||

| Fluorescence | 240 – 500 exc 290 – 750 em |

liquid | 23 | cowR, goatR, sheepR | fat content animal of origin |

- | - | 70.0 91.0 |

[95] | ||

| Fluorescence | 250 – 380 exc 280 – 640 em |

liquid | 40 | cow | milk origin clss. | - | - | 76.9† 70.4†† |

[101] | ||

| Fluorescence | 250 – 550 exc | liquid | 242 | cow | carotenoid vitamins FAs |

0.01– 0.54 0.03 – 0.17 0.01 – 0.50 |

0.01 – 0.17 μg/mL SEP 0.17 μg/mL – 918.32 pg/mL SEP 0.15 – 13.76 g/100g SEP |

- | [76] | ||

| Fluorescence | 240 – 260 exc 320 – 440 exc |

liquid | 12 | retail | melamineA | 0.97††† 0.95††† |

PARAFAC: 68.6 ppm p U-PLS/RBL: 81.9 ppm p |

- | [98] | ||

| Fluorescence | 330 exc 420 em |

liquid | 23 | ND | heat treatment discrimination |

> 0.95 | - | - | [102] | ||

| Fluorescence | 250 – 350 exc 260 – 500em |

liquid | 30 | cow | characterization of pasteurized milk | - | - | - | [103] | ||

| Visible | 400 – 1000 refl 400 – 1000 trans |

liquid | 300 | cow |

fat crude protein lactose urea |

refl 0.978 0.861 0.557 - |

trans 0.395 0.687 0.111 - |

refl 0.11%p 0.18%p 0.22%p - |

trans 0.629%p 0.274%p 0.317%p - |

- | [59] |

| Visible light scatter | 400 – 1000 | liquid | 21 | retail | fat protein |

0.973 0.964 |

0.047% 0.032% |

- | [99] | ||

| UV/Vis | 183 – 667 | liquid FR liquid HPH |

240 240 |

cow | fat, protein, lactose, TSC | - | Liquid FR 0.13%p – 0.46% p HPH FR 0.09%p – 0.27%p |

- | [100] | ||

| Fusion NIRS-LIBS |

≈ 185 – 2500 | powder | 50 | vetch root | milk origin | - | - | 95.8 | [53] | ||

4.6. Benchmarking of Spectroscopy Methods

5. Machine Learning Principles

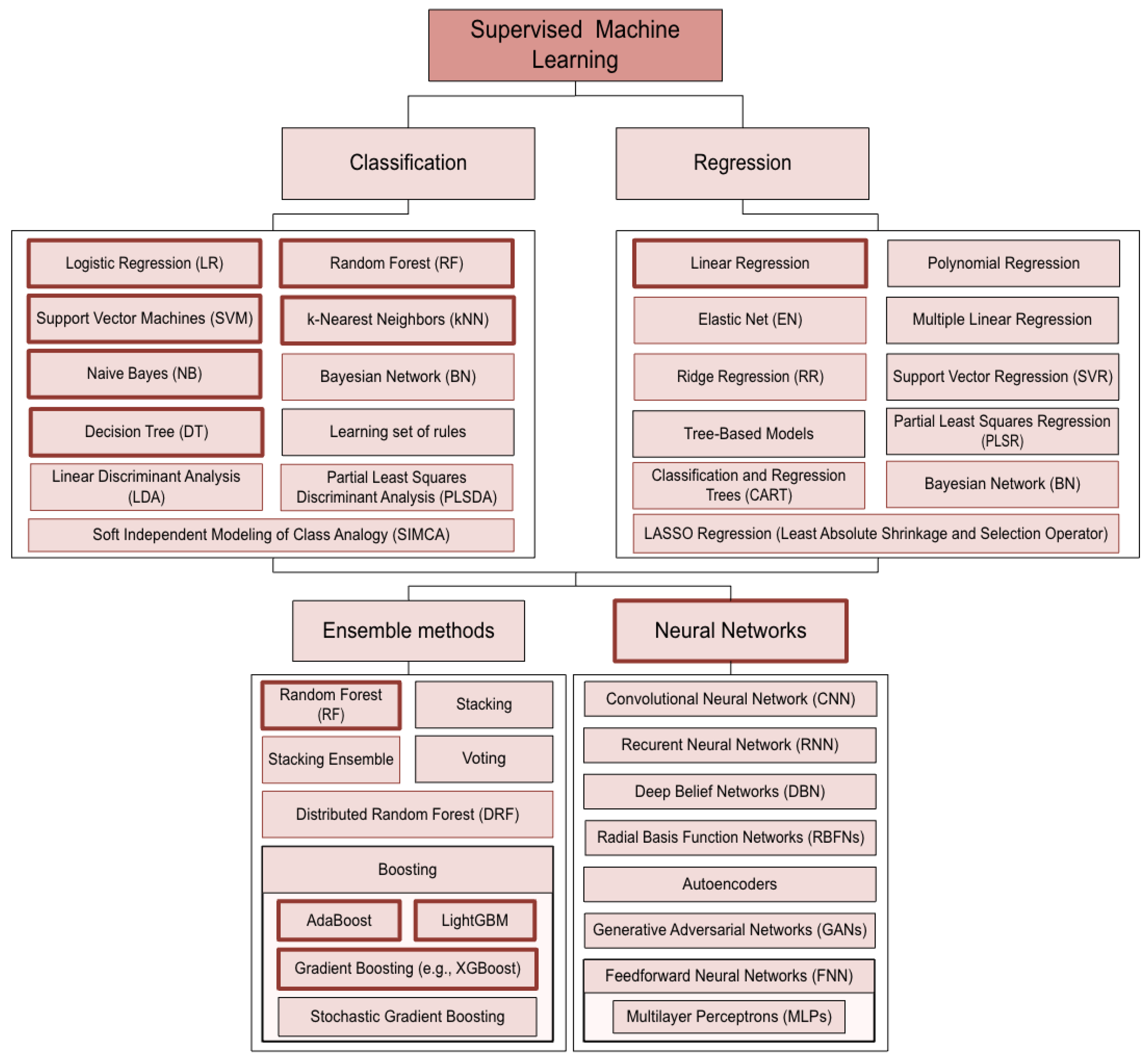

5.1. Logistic Regression (LR)

5.2. Decision trees (DTs)

5.3. Random Forest (RF)

5.4. Support Vector Machine (SVM)

5.5. k-Nearest Neighbor (k-NN)

5.6. Naïve Bayes (NB)

5.7. Linear Regression

5.8. Linear Discriminant Analysis (LDA)

5.9. Boosting

5.9.1. Adaptive Boosting/Adaboost

5.10. Gradient Boosting Machine (GBM)

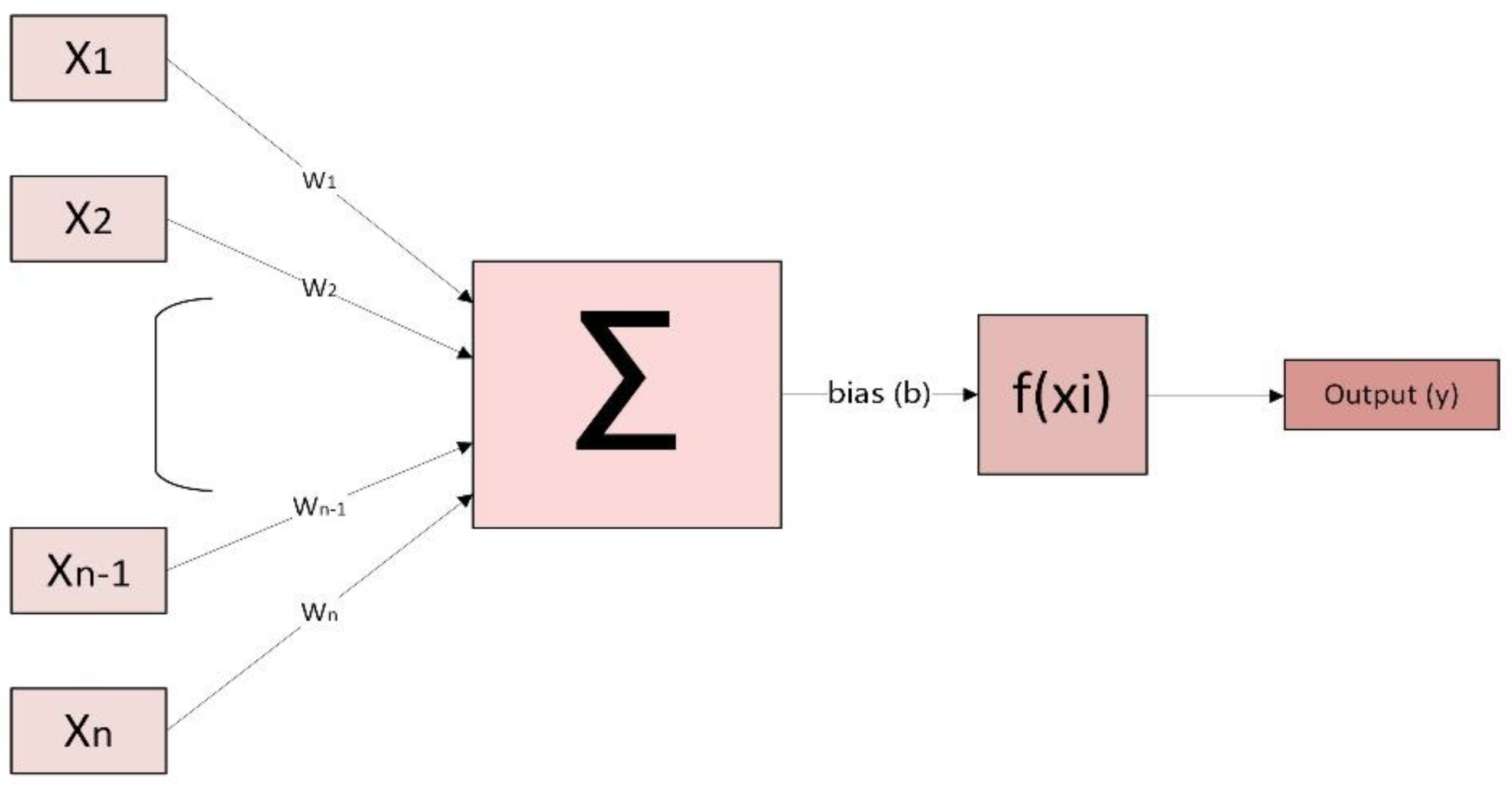

5.11. Neural Networks (NN)

5.12. Partial Least Square (PLS)

5.13. Partial Least Square Regression (PLSR)

6. Application of Machine Learning Methods in Milk Quality Assessment

6.1. Milk Quality and Composition Assessment

| ML | Tools | No and type of milk samples | Application | R2 | RMSE | Acc | Se | Sp | Ref. |

| NN | MIRS | 730 b | RCT k20 heat stability κ-CN |

0.50 0.36 0.45 0.42 |

(1) 6.397 min (1)2.770 min (1)5.464 min (1)1.095 g/L |

- | - | - | [88] |

| MFFANN | NIRS | 385 b | blood metabolites | - | - | - | - | - | [149] |

| ANN | NIRS | 499 b | milk technological properties (CFp, CYcurd, Recprotein etc) | 0.45 to 0.71 | (2) 0.02 % to 0.84 mm | - | - | - | [56] |

| FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.09 to 0.81 | 0.03 L/L to 80.59 U/L | - | - | - | [150] | |

| k-NN | sensors | 1059 ND | milk quality | - | - | 98.58% | - | - | [9] |

| PLS | FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.08 to 0.83 | 0.03 L/L to 106.37 U/L | - | - | - | [150] |

| FTIR | 471 b | κ-casein BCS BHB |

(3) 0.90 tr 0.77 v (3) 0.95 tr 0.57 v (3) 0.88 tr 0.76 v |

(1)1.41 g/L (1)0.35 (1)0.10 |

- | - | - | [147] | |

| PLS-DA | MIRS | 730 b | technological & protein properties of milk | - | - | 0.40 – 0.80 | 0.44 | - | [88] |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.968 | 0.977 | 0.962 | [148] | |

| LDA | MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.968 | 0.980 | 0.961 | [148] |

|

SVM |

MIRS |

730 b |

technological & protein properties of milk | - | - | 0.43 – 0.80 | 0.44 (overall) | 1.00 (overall) | [86] |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.947 | 0.962 | 0.938 | [148] | |

| Boosting | MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.754 | 0.587 | 0.842 | [148] |

| Boosting DT | MIRS | 730 b | coagulation | - | - | - | 0.50 | 0.98 | [88] |

| MB-DA | MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.964 | 0.972 | 0.959 | [148] |

| GBM | NIRS | 499 b | milk technological properties (CFp, CYcurd, Recprotein etc) | 0.45 to 0.70 | (2)0.02% to 0.87 mm | - | - | - | [56] |

| FTIR | 471 b | κ-casein BCS BHB |

(4) 0.97 tr 0.81 v (4) 0.91 tr 0.63 v (4) 0.90 tr 0.77 v |

(1)1.08 (1)0.25 (1)0.09 |

- | - | - | [147] | |

| FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc | 0.10 to 0.83 | 0.03 L/L to 75.69 U/L | - | - | - | [150] | |

| XGB | NIRS | 499 b | milk technological properties (CFp, CYcurd, Recprotein etc) | 0.43 to 0.63 | (2)0.02 % to 0.90 mm | - | - | - | [56] |

| FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.08 to 0.78 | 0.03 L/L to 80.23 U/L | - | - | - | [150] | |

| RF | MIRS | 730 b | αS1-CN, κ-CN |

- | - | 0.48 0.45 |

0.44 | - | [88] |

| FTIR | 471 b | κ-casein BCS BHB |

(3) 0.96 tr 0.80 v (3) 0.95 tr 0.61 v (3) 0.90 tr 0.79 v |

(1)1.18 (1)0.26 (1)0.10 |

- | - | - | [147] | |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.696 | 0.447 | 0.827 | [148] | |

| DRF | FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.09 to 0.79 | 0.03 L/L to 82.49 U/L | - | - | - | [150] |

| EN | NIRS | 499 b | milk technological properties (CFp, CYcurd, Recprotein etc) | 0.46 to 0.71 | (2) 0.02 % to 0.78 mm | - | - | - | [56] |

| FTIR | 471 b | κ-casein BCS BHB |

(3) 0.96 tr 0.79 v (3) 0.92 tr 0.59 v (3) 0.89 tr 0.78 v |

(1)1.25 (1)0.27 (1)0.10 |

- | - | - | [147] | |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.951 | 0.960 | 0.946 | [148] | |

| FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.12 to 0.87 | 0.03 L/L to 82.99 U/L | - | - | - | [150] | |

| LASSO | MIRS | 730 n | CMS, κ-CN |

0.08 0.42 |

(1)25.286 mm (1)1.095 g/L |

- | - | - | [88] |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.959 | 0.970 | 0.953 | [148] | |

| PC-LR | MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.667 | 0.117 | 0.956 | [148] |

| RR | MIRS | 730 b | a30, β-CN, β-LG A |

0.37 0.35 0.19 |

12.495 mm 1.759 g/L 1.050 g/L |

- | - | - | [88] |

| MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.880 | 0.779 | 0.933 | [148] | |

| Stacking Ensemble | NIRS | 385 b | blood metabolites | - | - | - | - | - | [149] |

| FTIR | 2701 b | blood metabolites (hematocrit, myeloperoxidase, globulins etc) | 0.13 to 0.87 | 0.03 L/L to 76.33 U/L | - | - | - | [150] | |

| VarSel-DA | MIRS | 4320 b | grass-fed/ non-grass-fed milk classification | - | - | 0.890 | 0.845 | 0.913 | [148] |

| PLS+ANN | MIRS | 6619 b | LF in milk | 0.60c 0.55cv 0.60v |

130.59c mg/L 139.01cv mg/L 162.17v mg/L |

- | - | - | [151] |

| PLSR | MIRS | 6619 b | LF in milk | 0.53c 0.51cv 0.61v |

140.94c mg/L 144.31cv mg/L 163.76v mg/L |

- | - | - | [151] |

| PLS+SVM | MIRS | 6619 b | LF in milk | 0.53c 0.53cv 0.63v |

144.32c mg/L 144.60cv mg/L 174.92v mg/L |

- | - | - | [151] |

| PLS+ Polynomial SVM | MIRS | 6619 b | LF in milk | 0.64c 0.56cv 0.62v |

125.89c mg/L 138.40cv mg/L 166.75v mg/L |

- | - | - | [151] |

6.2. Fraud Detection and Adulteration Identification

| ML | Tools | No and type of milk samples | Application | R2 | RMSE | Se (%) |

Sp (%) |

Accuracy | Ref. |

| NN | LIBS | 22 b, c, o | melamine in toddler milk powder | 0.999 | - | - | - | Acc: 100% | [48] |

| UV, Vis, IR | ND | adulterants in milk | - | - | - | - | Acc: 100% | [154] | |

| CNN | LIBS | 25 r | protein adulteration in milk powder | - | - | - | - | Acc: 97.8% | [55] |

| PLS-DA | NIRS | 600 b, c | fraud in goat milk: water urea bovine whey milk authentic |

- | - |

100 in all cases |

100 in all cases | - | [152] |

| PLSR | Fluorescence | 40 b | adulteration in milk | 0.99 | (1)1.16 (2)6.24 | - | - | - | [153] |

| NB | UV, Vis, IR | ND | adulterants in milk | - | - | - | - | 90% | [154] |

| DT | UV, Vis, IR | ND | adulterants in milk | - | - | - | - | 91.7% | [154] |

| LDA | UV, Vis, IR | ND | adulterants in milk | - | - | - | - | 88.1% | [154] |

| FTIR | ND | heat treatment to milk | - | - | - | - | 0.84 | [156] | |

| RF | FTIR | ND | heat treatment to milk | - | - | - | - | 0.92 | [156] |

| LIBS | 25 r | protein adulteration in milk powder | - | - | 0.886 (train) 0.871 (test) | [55] | |||

| k-NN | NIRS | 600 b, c | fraud in goat milk: water urea bovine whey milk authentic |

- | - |

76.0 80.0 96.0 80.0 99.0 |

96.6 95.4 100 100 88.0 |

- | [152] |

| FTIR | ND | heat treatment to milk | - | - | - | - | 0.86 | [156] | |

| LIBS | 25 r | protein adulteration in milk powder | - | - | - | - | 0.884 (train) 0.867 (test) | [55] | |

| SVM | UV, Vis, IR | ND | adulterants in milk | - | - | - | - | 90% | [154] |

| LIBS | 25 r | protein adulteration in milk powder | - | - | - | - | 0.961 (train) 0.938 (test) | [55] | |

| FTIR | ND | heat treatment to milk | - | - | - | - | 0.90 | [156] | |

| CART | FTIR | 520 b | fraud of cheese whey to milk | - | - | - | - | 96.2% (train), 97.2% (test) | [155] |

| MLP | FTIR | 520 b | fraud of cheese whey to milk | - | - | - | - | 97.8% | [155] |

6.3. Milk source and Origin Classification

| ML | Tools | No and type of milk samples |

Application | Accuracy (%) |

Ref. |

| NN | LIBS |

683 lyophilized 1296 liquid b, c, o |

animal origin: liquid milk powdered milk Mg, Ca, Na, K |

97.2 (train), 86.3 (test) 97.5 (train), 94.5 (test), 98.6 (train), 92.7 (test) |

[47] |

| ANN | UV-Vis/NIR, FT-NIR | 63 b | geographic origin of cow milk | 100 classification 95 train 92 validation |

[157] |

| SVM | LIBS |

683 lyophilized 1296 liquid b, c, o |

animal origin: liquid milk powdered milk |

96.6 (train), 91.3 (test) 96.2 (train), 93.1 (test) |

[47] |

| GBM | LIBS |

683 lyophilized 1296 liquid b, c, o |

animal origin: liquid milk powdered milk |

96.7 (train), 83.0 (test) 97.4 (train), 91.4 (test) |

[47] |

| RF | Raman | 602 b, c, o, h | classify milk (cow, human, buffalo, goat) | 93.63 | [40] |

7. Future Research

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McLeod, A. World Livestock 2011: Livestock in Food Security; FAO: Rome, 2011; ISBN 978-92-5-107013-0.

- Population Prospects 2019: Highlights.

- Neethirajan, S.; Kemp, B. Digital Livestock Farming. Sensing and Bio-Sensing Research 2021, 32, 100408. [CrossRef]

- Halachmi, I.; Guarino, M.; Bewley, J.; Pastell, M. Smart Animal Agriculture: Application of Real-Time Sensors to Improve Animal Well-Being and Production. Annu. Rev. Anim. Biosci. 2019, 7, 403–425. [CrossRef]

- Ochs, D.S.; Wolf, C.A.; Widmar, N.J.O.; Bir, C. Consumer Perceptions of Egg-Laying Hen Housing Systems. Poultry Science 2018, 97, 3390–3396. [CrossRef]

- Anestis, V.; Bartzanas, T.; Kittas, C. Life Cycle Inventory Analyis for the Milk Produced in a Greek Commercial Dairy Farm - The Link to Precision Livestock Farming. 7th European Conference on Precision Livestock Farming. ECPLF. 2015, 670-680.

- Pereira, P.C. Milk Nutritional Composition and Its Role in Human Health. Nutrition 2014, 30, 619–627. [CrossRef]

- Evangelista, C.; Basiricò, L.; Bernabucci, U. An Overview on the Use of Near Infrared Spectroscopy (NIRS) on Farms for the Management of Dairy Cows. Agriculture 2021, 11, 296. [CrossRef]

- Samad, A.; Taze, S.; Kürsad Uçar, M. Enhancing Milk Quality Detection with Machine Learning: A Comparative Analysis of KNN and Distance-Weighted KNN Algorithms. International Journal of Innovative Science and Research Technology (IJISRT) 2024, 2021–2029. [CrossRef]

- Tullo, E.; Finzi, A.; Guarino, M. Review: Environmental Impact of Livestock Farming and Precision Livestock Farming as a Mitigation Strategy. Science of The Total Environment 2019, 650, 2751–2760. [CrossRef]

- Helwatkar, A.; Riordan, D.; Walsh, J. Sensor Technology For Animal Health Monitoring. International Journal on Smart Sensing and Intelligent Systems 2014, 7, 1–6. [CrossRef]

- Neethirajan, S. Recent Advances in Wearable Sensors for Animal Health Management. Sensing and Bio-Sensing Research 2017, 12, 15–29. [CrossRef]

- Spectroscopy | Definition, Types, & Facts | Britannica Available online: https://www.britannica.com/science/spectroscopy (accessed on 12 September 2024).

- Pu, Y.-Y.; O’Donnell, C.; Tobin, J.T.; O’Shea, N. Review of Near-Infrared Spectroscopy as a Process Analytical Technology for Real-Time Product Monitoring in Dairy Processing. International Dairy Journal 2020, 103, 104623. [CrossRef]

- Agelet, L.E.; Hurburgh, C.R. A Tutorial on Near Infrared Spectroscopy and Its Calibration. Critical Reviews in Analytical Chemistry 2010, 40, 246–260. [CrossRef]

- Herschel, W. Investigation of the Powers of the Prismatic Colours to Heat and Illuminate Objects; With Remarks, That Prove the Different Refrangibility of Radiant Heat. To Which Is Added, an Inquiry into the Method of Viewing the Sun Advantageously, with Telescopes of Large Apertures and High Magnifying Powers. Philosophical Transactions of the Royal Society of London 1800, 90, 255 - 283.

- Gastélum-Barrios, A.; Soto-Zarazúa, G.M.; Escamilla-García, A.; Toledano-Ayala, M.; Macías-Bobadilla, G.; Jauregui-Vazquez, D. Optical Methods Based on Ultraviolet, Visible, and Near-Infrared Spectra to Estimate Fat and Protein in Raw Milk: A Review. Sensors 2020, 20, 3356. [CrossRef]

- Dispersion (Optics). Wikipedia 2024.

- Ma, W.; Ji, X.; Ding, L.; Yang, S.X.; Guo, K.; Li, Q. Automatic Monitoring Methods for Greenhouse and Hazardous Gases Emitted from Ruminant Production Systems: A Review. Sensors 2024, 24, 4423. [CrossRef]

- Fazio, E.; Spadaro, S.; Corsaro, C.; Neri, G.; Leonardi, S.G.; Neri, F.; Lavanya, N.; Sekar, C.; Donato, N.; Neri, G. Metal-Oxide Based Nanomaterials: Synthesis, Characterization and Their Applications in Electrical and Electrochemical Sensors. Sensors 2021, 21, 2494. [CrossRef]

- Hulanicki’, A.; Geab, S.; Ingman, F. O. L. K. E. Chemical sensors: definitions and classification. Pure and applied chemistry 1991, 63(9), 1247-1250.

- Kunes, R.; Bartos, P.; Iwasaka, G.K.; Lang, A.; Hankovec, T.; Smutny, L.; Cerny, P.; Poborska, A.; Smetana, P.; Kriz, P.; et al. In-Line Technologies for the Analysis of Important Milk Parameters during the Milking Process: A Review. Agriculture 2021, 11, 239. [CrossRef]

- He, H.; Sun, D.-W.; Pu, H.; Chen, L.; Lin, L. Applications of Raman Spectroscopic Techniques for Quality and Safety Evaluation of Milk: A Review of Recent Developments. Critical Reviews in Food Science and Nutrition 2019, 59, 770–793. [CrossRef]

- Pellegrino, L.; Cattaneo, S.; De Noni, I. Nutrition and Health: Effects of Processing on Protein Quality of Milk and Milk Products. Encyclopedia of dairy sciences Elsevier 2016, 1067-1074, ISBN 978-0-08-100596-5.

- Reference Material for Somatic Cell Counting - European Commission Available online: https://joint-research-centre.ec.europa.eu/jrc-news-and-updates/reference-material-somatic-cell-counting-2020-02-11_en (accessed on 1 October 2024).

- Gelasakis, A.I.; Mavrogianni, V.S.; Petridis, I.G.; Vasileiou, N.G.C.; Fthenakis, G.C. Mastitis in Sheep – The Last 10 Years and the Future of Research. Veterinary Microbiology 2015, 181, 136–146. [CrossRef]

- Melfsen, A.; Hartung, E.; Haeussermann, A. Accuracy of In-Line Milk Composition Analysis with Diffuse Reflectance near-Infrared Spectroscopy. Journal of Dairy Science 2012, 95, 6465–6476. [CrossRef]

- Numthuam, S.; Hongpathong, J.; Charoensook, R.; Rungchang, S. Method Development for the Analysis of Total Bacterial Count in Raw Milk Using Near-infrared Spectroscopy. Journal of Food Safety 2017, 37, e12335. [CrossRef]

- Nicolaou, N.; Goodacre, R. Rapid and Quantitative Detection of the Microbial Spoilage in Milk Using Fourier Transform Infrared Spectroscopy and Chemometrics. Analyst 2008, 133, 1424. [CrossRef]

- Pampoukis, G.; Lytou, A.E.; Argyri, A.A.; Panagou, E.Z.; Nychas, G.-J.E. Recent Advances and Applications of Rapid Microbial Assessment from a Food Safety Perspective. Sensors 2022, 22, 2800. [CrossRef]

- Blanco, M.; Villarroya, I. NIR Spectroscopy: A Rapid-Response Analytical Tool. TrAC Trends in Analytical Chemistry 2002, 21, 240–250. [CrossRef]

- User:Jhausauer English: Spectral Lines. Adapted from the Version in Italian.; 2007;

- Raman, C.V.; Krishnan, K.S. A new type of secondary radiation. Nature 1928, 121(3048), 501-502.

- Vaskova, H.; Buckova, M. Measuring the Lactose Content in Milk. MATEC Web Conf. 2016, 76, 05011. [CrossRef]

- Mazurek, S.; Szostak, R.; Czaja, T.; Zachwieja, A. Analysis of Milk by FT-Raman Spectroscopy. Talanta 2015, 138, 285–289. [CrossRef]

- El-Abassy, R.M.; Eravuchira, P.J.; Donfack, P.; Von Der Kammer, B.; Materny, A. Fast Determination of Milk Fat Content Using Raman Spectroscopy. Vibrational Spectroscopy 2011, 56, 3–8. [CrossRef]

- Rodrigues Júnior, P.H.; De Sá Oliveira, K.; Almeida, C.E.R.D.; De Oliveira, L.F.C.; Stephani, R.; Pinto, M.D.S.; Carvalho, A.F.D.; Perrone, Í.T. FT-Raman and Chemometric Tools for Rapid Determination of Quality Parameters in Milk Powder: Classification of Samples for the Presence of Lactose and Fraud Detection by Addition of Maltodextrin. Food Chemistry 2016, 196, 584–588. [CrossRef]

- Khan, K.M.; Krishna, H.; Majumder, S.K.; Gupta, P.K. Detection of Urea Adulteration in Milk Using Near-Infrared Raman Spectroscopy. Food Anal. Methods 2015, 8, 93–102. [CrossRef]

- McGoverin, C.M.; Clark, A.S.S.; Holroyd, S.E.; Gordon, K.C. Raman Spectroscopic Quantification of Milk Powder Constituents. Analytica Chimica Acta 2010, 673, 26–32. [CrossRef]

- Amjad, A.; Ullah, R.; Khan, S.; Bilal, M.; Khan, A. Raman Spectroscopy Based Analysis of Milk Using Random Forest Classification. Vibrational Spectroscopy 2018, 99, 124–129. [CrossRef]

- Noll, R. Laser-Induced Breakdown Spectroscopy: Fundamentals and Applications; Springer Berlin Heidelberg: Berlin, Heidelberg, 2012; ISBN 978-3-642-20667-2.

- Available online: https://www.sciaps.com/products/libs/what-is-libs (accessed on 12 September 2024).

- Musazzi, S.; Perini, U. Laser-Induced Breakdown Spectroscopy: Theory and Applications; Springer, 2014; ISBN 978-3-642-45085-3.

- Dos Santos Augusto, A.; Barsanelli, P.L.; Pereira, F.M.V.; Pereira-Filho, E.R. Calibration Strategies for the Direct Determination of Ca, K, and Mg in Commercial Samples of Powdered Milk and Solid Dietary Supplements Using Laser-Induced Breakdown Spectroscopy (LIBS). Food Research International 2017, 94, 72–78. [CrossRef]

- Markiewicz-Keszycka, M.; Cama-Moncunill, X.; Casado-Gavalda, M.P.; Dixit, Y.; Cama-Moncunill, R.; Cullen, P.J.; Sullivan, C. Laser-Induced Breakdown Spectroscopy (LIBS) for Food Analysis: A Review. Trends in Food Science & Technology 2017, 65, 80–93. [CrossRef]

- Nanou, E.; Stefas, D.; Couris, S. Milk’s Inorganic Content Analysis via Laser Induced Breakdown Spectroscopy. Food Chemistry 2023, 407, 135169. [CrossRef]

- Nanou, E.; Pliatsika, N.; Stefas, D.; Couris, S. Identification of the Animal Origin of Milk via Laser-Induced Breakdown Spectroscopy. Food Control 2023, 154, 110007. [CrossRef]

- Moncayo, S.; Manzoor, S.; Rosales, J.D.; Anzano, J.; Caceres, J.O. Qualitative and Quantitative Analysis of Milk for the Detection of Adulteration by Laser Induced Breakdown Spectroscopy (LIBS). Food Chemistry 2017, 232, 322–328. [CrossRef]

- Bilge, G.; Sezer, B.; Eseller, K.E.; Berberoglu, H.; Topcu, A.; Boyaci, I.H. Determination of Whey Adulteration in Milk Powder by Using Laser Induced Breakdown Spectroscopy. Food Chemistry 2016, 212, 183–188. [CrossRef]

- Abdel-Salam, Z.; Al Sharnoubi, J.; Harith, M.A. Qualitative Evaluation of Maternal Milk and Commercial Infant Formulas via LIBS. Talanta 2013, 115, 422–426. [CrossRef]

- Abdel-Salam, Z.; El-Saeid, R.; Abdelghany, S.; Abdel-Salam, S.; Radwan, M. Assessment of Milk Quality at Farm Level Using Laser Techniques. Egypt. J. Chem. 2022, 0, 0–0. [CrossRef]

- Cama-Moncunill, X.; Markiewicz-Keszycka, M.; Dixit, Y.; Cama-Moncunill, R.; Casado-Gavalda, M.P.; Cullen, P.J.; Sullivan, C. Feasibility of Laser-Induced Breakdown Spectroscopy (LIBS) as an at-Line Validation Tool for Calcium Determination in Infant Formula. Food Control 2017, 78, 304–310. [CrossRef]

- Eum, C.; Jang, D.; Kim, J.; Choi, S.; Cha, K.; Chung, H. Improving the Accuracy of Spectroscopic Identification of Geographical Origins of Agricultural Samples through Cooperative Combination of Near-Infrared and Laser-Induced Breakdown Spectroscopy. Spectrochimica Acta Part B: Atomic Spectroscopy 2018, 149, 281–287. [CrossRef]

- Sezer, B.; Durna, S.; Bilge, G.; Berkkan, A.; Yetisemiyen, A.; Boyaci, I.H. Identification of Milk Fraud Using Laser-Induced Breakdown Spectroscopy (LIBS). International Dairy Journal 2018, 81, 1–7. [CrossRef]

- Huang, W.; Guo, L.; Kou, W.; Zhang, D.; Hu, Z.; Chen, F.; Chu, Y.; Cheng, W. Identification of Adulterated Milk Powder Based on Convolutional Neural Network and Laser-Induced Breakdown Spectroscopy. Microchemical Journal 2022, 176, 107190. [CrossRef]

- Mota, L.F.M.; Giannuzzi, D.; Bisutti, V.; Pegolo, S.; Trevisi, E.; Schiavon, S.; Gallo, L.; Fineboym, D.; Katz, G.; Cecchinato, A. Real-Time Milk Analysis Integrated with Stacking Ensemble Learning as a Tool for the Daily Prediction of Cheese-Making Traits in Holstein Cattle. Journal of Dairy Science 2022, 105, 4237–4255. [CrossRef]

- Brandão, M. C. M. P.; Carmo, A. P.; Bell, M. J. V.; Anjos, V. C. Characterization of milk by infrared spectroscopy. Revista do Instituto de Laticínios Cândido Tostes 2010, 65(373), 30-33.

- Aernouts, B.; Van Beers, R.; Watté, R.; Huybrechts, T.; Lammertyn, J.; Saeys, W. Visible and Near-Infrared Bulk Optical Properties of Raw Milk. Journal of Dairy Science 2015, 98, 6727–6738. [CrossRef]

- Aernouts, B.; Polshin, E.; Lammertyn, J.; Saeys, W. Visible and Near-Infrared Spectroscopic Analysis of Raw Milk for Cow Health Monitoring: Reflectance or Transmittance? Journal of Dairy Science 2011, 94, 5315–5329. [CrossRef]

- Korelidou, V.; Simitzis, P.; Massouras, T.; Gelasakis, A.I. Infrared Thermography as a Diagnostic Tool for the Assessment of Mastitis in Dairy Ruminants. Animals 2024, 14(18), 2691.

- Swinehart, D.F. The Beer-Lambert Law. Journal of chemical education 1962, 39(7), 333.

- Givens, D.I.; De Boever, J.L.; Deaville, E.R. The Principles, Practices and Some Future Applications of near Infrared Spectroscopy for Predicting the Nutritive Value of Foods for Animals and Humans. Nutr. Res. Rev. 1997, 10, 83–114. [CrossRef]

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; Bazar, G. The Recent Advances of Near-Infrared Spectroscopy in Dairy Production—a Review. Critical Reviews in Food Science and Nutrition 2022, 62, 810–831. [CrossRef]

- 14:00-17:00 ISO 21543:2006 Available online: https://www.iso.org/standard/40318.html (accessed on 12 September 2024).

- Available online: https://www.iso.org/standard/77606.html (accessed on 13 September 2024).

- Albanell, E.; Caja, G.; Such, X.; Rovai, M.; Salama, A.A.K.; Casals, R. Determination of Fat, Protein, Casein, Total Solids, and Somatic Cell Count in Goat’s Milk by Near-Infrared Reflectance Spectroscopy. Journal of AOAC INTERNATIONAL 2003, 86, 746–752. [CrossRef]

- Revilla, I.; Escuredo, O.; González-Martín, M.I.; Palacios, C. Fatty Acids and Fat-Soluble Vitamins in Ewe’s Milk Predicted by near Infrared Reflectance Spectroscopy. Determination of Seasonality. Food Chemistry 2017, 214, 468–477. [CrossRef]

- Holroyd, S.E. The Use of near Infrared Spectroscopy on Milk and Milk Products. Journal of Near Infrared Spectroscopy 2013, 21, 311–322. [CrossRef]

- Coppa, M.; Martin, B.; Agabriel, C.; Chassaing, C.; Sibra, C.; Constant, I.; Graulet, B.; Andueza, D. Authentication of Cow Feeding and Geographic Origin on Milk Using Visible and Near-Infrared Spectroscopy. Journal of Dairy Science 2012, 95, 5544–5551. [CrossRef]

- Al-Qadiri, H.M.; Lin, M.; Al-Holy, M.A.; Cavinato, A.G.; Rasco, B.A. Monitoring Quality Loss of Pasteurized Skim Milk Using Visible and Short Wavelength Near-Infrared Spectroscopy and Multivariate Analysis. Journal of Dairy Science 2008, 91, 950–958. [CrossRef]

- Cattaneo, T.M.P.; Cabassi, G.; Profaizer, M.; Giangiacomo, R. Contribution of Light Scattering to near Infrared Absorption in Milk. Journal of Near Infrared Spectroscopy 2009, 17, 337–343. [CrossRef]

- Tsenkova, R.; Meilina, H.; Kuroki, S.; Burns, D.H. Near Infrared Spectroscopy Using Short Wavelengths and Leave-One-Cow-Out Cross-Validation for Quantification of Somatic Cells in Milk. Journal of Near Infrared Spectroscopy 2009, 17, 345–351. [CrossRef]

- Coppa, M.; Ferlay, A.; Leroux, C.; Jestin, M.; Chilliard, Y.; Martin, B.; Andueza, D. Prediction of Milk Fatty Acid Composition by near Infrared Reflectance Spectroscopy. International Dairy Journal 2010, 20, 182–189. [CrossRef]

- Núñez-Sánchez, N.; Martínez-Marín, A.L.; Polvillo, O.; Fernández-Cabanás, V.M.; Carrizosa, J.; Urrutia, B.; Serradilla, J.M. Near Infrared Spectroscopy (NIRS) for the Determination of the Milk Fat Fatty Acid Profile of Goats. Food Chemistry 2016, 190, 244–252. [CrossRef]

- Wu, D.; He, Y.; Feng, S.; Sun, D.-W. Study on Infrared Spectroscopy Technique for Fast Measurement of Protein Content in Milk Powder Based on LS-SVM. Journal of Food Engineering 2008, 84, 124–131. [CrossRef]

- Soulat, J.; Andueza, D.; Graulet, B.; Girard, C.L.; Labonne, C.; Aït-Kaddour, A.; Martin, B.; Ferlay, A. Comparison of the Potential Abilities of Three Spectroscopy Methods: Near-Infrared, Mid-Infrared, and Molecular Fluorescence, to Predict Carotenoid, Vitamin and Fatty Acid Contents in Cow Milk. Foods 2020, 9, 592. [CrossRef]

- Coppa, M.; Revello-Chion, A.; Giaccone, D.; Ferlay, A.; Tabacco, E.; Borreani, G. Comparison of near and Medium Infrared Spectroscopy to Predict Fatty Acid Composition on Fresh and Thawed Milk. Food Chemistry 2014, 150, 49–57. [CrossRef]

- Balabin, R.M.; Smirnov, S.V. Melamine Detection by Mid- and near-Infrared (MIR/NIR) Spectroscopy: A Quick and Sensitive Method for Dairy Products Analysis Including Liquid Milk, Infant Formula, and Milk Powder. Talanta 2011, 85, 562–568. [CrossRef]

- Henn, R.; Kirchler, C.G.; Grossgut, M.-E.; Huck, C.W. Comparison of Sensitivity to Artificial Spectral Errors and Multivariate LOD in NIR Spectroscopy – Determining the Performance of Miniaturizations on Melamine in Milk Powder. Talanta 2017, 166, 109–118. [CrossRef]

- Llano Suárez, P.; Soldado, A.; González-Arrojo, A.; Vicente, F.; De La Roza-Delgado, B. Rapid On-Site Monitoring of Fatty Acid Profile in Raw Milk Using a Handheld near Infrared Sensor. Journal of Food Composition and Analysis 2018, 70, 1–8. [CrossRef]

- Liu, N.; Parra, H.A.; Pustjens, A.; Hettinga, K.; Mongondry, P.; Van Ruth, S.M. Evaluation of Portable Near-Infrared Spectroscopy for Organic Milk Authentication. Talanta 2018, 184, 128–135. [CrossRef]

- De La Roza-Delgado, B.; Garrido-Varo, A.; Soldado, A.; González Arrojo, A.; Cuevas Valdés, M.; Maroto, F.; Pérez-Marín, D. Matching Portable NIRS Instruments for in Situ Monitoring Indicators of Milk Composition. Food Control 2017, 76, 74–81. [CrossRef]

- Diaz-Olivares, J.A.; Adriaens, I.; Stevens, E.; Saeys, W.; Aernouts, B. Online Milk Composition Analysis with an On-Farm near-Infrared Sensor. Computers and Electronics in Agriculture 2020, 178, 105734. [CrossRef]

- Kalinin, A.; Krasheninnikov, V.; Sadovskiy, S.; Yurova, E. Determining the Composition of Proteins in Milk Using a Portable near Infrared Spectrometer. Journal of Near Infrared Spectroscopy 2013, 21, 409–415. [CrossRef]

- Santos, P.M.; Pereira-Filho, E.R.; Rodriguez-Saona, L.E. Rapid Detection and Quantification of Milk Adulteration Using Infrared Microspectroscopy and Chemometrics Analysis. Food Chemistry 2013, 138, 19–24. [CrossRef]

- Etzion, Y.; Linker, R.; Cogan, U.; Shmulevich, I. Determination of Protein Concentration in Raw Milk by Mid-Infrared Fourier Transform Infrared/Attenuated Total Reflectance Spectroscopy. Journal of Dairy Science 2004, 87, 2779–2788. [CrossRef]

- Dabrowska, A.; David, M.; Freitag, S.; Andrews, A.M.; Strasser, G.; Hinkov, B.; Schwaighofer, A.; Lendl, B. Broadband Laser-Based Mid-Infrared Spectroscopy Employing a Quantum Cascade Detector for Milk Protein Analysis. Sensors and Actuators B: Chemical 2022, 350, 130873. [CrossRef]

- Frizzarin, M.; Gormley, I.C.; Berry, D.P.; Murphy, T.B.; Casa, A.; Lynch, A.; McParland, S. Predicting Cow Milk Quality Traits from Routinely Available Milk Spectra Using Statistical Machine Learning Methods. Journal of Dairy Science 2021, 104, 7438–7447. [CrossRef]

- De Marchi, M.; Fagan, C.C.; O’Donnell, C.P.; Cecchinato, A.; Dal Zotto, R.; Cassandro, M.; Penasa, M.; Bittante, G. Prediction of Coagulation Properties, Titratable Acidity, and pH of Bovine Milk Using Mid-Infrared Spectroscopy. Journal of Dairy Science 2009, 92, 423–432. [CrossRef]

- De Marchi, M.; Toffanin, V.; Cassandro, M.; Penasa, M. Invited Review: Mid-Infrared Spectroscopy as Phenotyping Tool for Milk Traits. Journal of Dairy Science 2014, 97, 1171–1186. [CrossRef]

- Ceniti, C.; Spina, A.A.; Piras, C.; Oppedisano, F.; Tilocca, B.; Roncada, P.; Britti, D.; Morittu, V.M. Recent Advances in the Determination of Milk Adulterants and Contaminants by Mid-Infrared Spectroscopy. Foods 2023, 12, 2917. [CrossRef]

- Fox, P.F.; Uniacke-Lowe, T.; McSweeney, P.L.H.; O’Mahony, J.A. Dairy Chemistry and Biochemistry; Springer International Publishing: Cham, 2015; ISBN 978-3-319-14891-5.

- Nicolaou, N.; Xu, Y.; Goodacre, R. Fourier Transform Infrared Spectroscopy and Multivariate Analysis for the Detection and Quantification of Different Milk Species. Journal of Dairy Science 2010, 93, 5651–5660. [CrossRef]

- Loudiyi, M.; Temiz, H.T.; Sahar, A.; Haseeb Ahmad, M.; Boukria, O.; Hassoun, A.; Aït-Kaddour, A. Spectroscopic Techniques for Monitoring Changes in the Quality of Milk and Other Dairy Products during Processing and Storage. Critical Reviews in Food Science and Nutrition 2022, 62, 3063–3087. [CrossRef]

- Fragkoulis, N.; Samartzis, P.C.; Velegrakis, M. Commercial Milk Discrimination by Fat Content and Animal Origin Using Optical Absorption and Fluorescence Spectroscopy. International Dairy Journal 2021, 123, 105181. [CrossRef]

- Andersen, C.M.; Mortensen, G. Fluorescence Spectroscopy: A Rapid Tool for Analyzing Dairy Products. J. Agric. Food Chem. 2008, 56, 720–729. [CrossRef]

- Shaikh, S.; O’Donnell, C. Applications of Fluorescence Spectroscopy in Dairy Processing: A Review. Current Opinion in Food Science 2017, 17, 16–24. [CrossRef]

- Barreto, M.C.; Braga, R.G.; Lemos, S.G.; Fragoso, W.D. Determination of Melamine in Milk by Fluorescence Spectroscopy and Second-Order Calibration. Food Chemistry 2021, 364, 130407. [CrossRef]

- Bogomolov, A.; Dietrich, S.; Boldrini, B.; Kessler, R.W. Quantitative Determination of Fat and Total Protein in Milk Based on Visible Light Scatter. Food Chemistry 2012, 134, 412–418. [CrossRef]

- Yang, B.; Guo, W.; Liang, W.; Zhou, Y.; Zhu, X. Design and Evaluation of a Miniature Milk Quality Detection System Based on UV/Vis Spectroscopy. Journal of Food Composition and Analysis 2022, 106, 104341. [CrossRef]

- Karoui, R.; Martin, B.; Dufour, É. Potentiality of Front-Face Fluorescence Spectroscopy to Determine the Geographic Origin of Milks from the Haute-Loire Department (France). Lait 2005, 85, 223–236. [CrossRef]

- Birlouez-Aragon, I.; Sabat, P.; Gouti, N. A New Method for Discriminating Milk Heat Treatment. International Dairy Journal 2002, 12, 59–67. [CrossRef]

- Hougaard, A.B.; Lawaetz, A.J.; Ipsen, R.H. Front Face Fluorescence Spectroscopy and Multi-Way Data Analysis for Characterization of Milk Pasteurized Using Instant Infusion. LWT - Food Science and Technology 2013, 53, 331–337. [CrossRef]

- Domingo, E.; Tirelli, A.A.; Nunes, C.A.; Guerreiro, M.C.; Pinto, S.M. Melamine Detection in Milk Using Vibrational Spectroscopy and Chemometrics Analysis: A Review. Food Research International 2014, 60, 131–139. [CrossRef]

- Vázquez-Diosdado, J.A.; Paul, V.; Ellis, K.A.; Coates, D.; Loomba, R.; Kaler, J. A Combined Offline and Online Algorithm for Real-Time and Long-Term Classification of Sheep Behaviour: Novel Approach for Precision Livestock Farming. Sensors 2019, 19, 3201. [CrossRef]

- Kaplan, A.; Haenlein, M. Siri, Siri, in My Hand: Who’s the Fairest in the Land? On the Interpretations, Illustrations, and Implications of Artificial Intelligence. Business Horizons 2019, 62, 15–25. [CrossRef]

- Niloofar, P.; Francis, D.P.; Lazarova-Molnar, S.; Vulpe, A.; Vochin, M.-C.; Suciu, G.; Balanescu, M.; Anestis, V.; Bartzanas, T. Data-Driven Decision Support in Livestock Farming for Improved Animal Health, Welfare and Greenhouse Gas Emissions: Overview and Challenges. Computers and Electronics in Agriculture 2021, 190, 106406. [CrossRef]

- Norton, T.; Berckmans, D. Developing Precision Livestock Farming Tools for Precision Dairy Farming. Animal Frontiers 2017, 7, 18–23. [CrossRef]

- VanderWaal, K.; Morrison, R.B.; Neuhauser, C.; Vilalta, C.; Perez, A.M. Translating Big Data into Smart Data for Veterinary Epidemiology. Front. Vet. Sci. 2017, 4, 110. [CrossRef]

- Benjamin, M.; Yik, S. Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners. Animals 2019, 9, 133. [CrossRef]

- Morota, G.; Ventura, R.V.; Silva, F.F.; Koyama, M.; Fernando, S.C. Big data analytics and precision animal agriculture symposium: Machine learning and data mining advance predictive big data analysis in precision animal agriculture. Journal of animal science 2018, 96(4), 1540-1550. [CrossRef]

- Southwest Jiaotong University, China; Muhammad, I.; Yan, Z.; Southwest Jiaotong University, China SUPERVISED MACHINE LEARNING APPROACHES: A SURVEY. ICTACT Journal on Soft Computing 2015, 05, 946–952. [CrossRef]

- Soofi, A.A.; & Awan, A. Classification techniques in machine learning: applications and issues. Journal of Basic & Applied Sciences 2017, 13, 459-465.112.

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer International Publishing: Cham, 2022; ISBN 978-3-030-89009-4.

- Nasir, N.; Kansal, A.; Alshaltone, O.; Barneih, F.; Sameer, M.; Shanableh, A.; Al-Shamma’a, A. Water Quality Classification Using Machine Learning Algorithms. Journal of Water Process Engineering 2022, 48, 102920. [CrossRef]

- Akalin, A. 5.13 Logistic Regression and Regularization | Computational Genomics with R;

- García, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodríguez, P. A Systematic Literature Review on the Use of Machine Learning in Precision Livestock Farming. Computers and Electronics in Agriculture 2020, 179, 105826. [CrossRef]

- Breiman, L.; Friedman, J.; Stone, C.J.; Olshen, R.A. Classification and Regression Trees; Taylor & Francis, 1984; ISBN 978-0-412-04841-8.

- Mu, F.; Gu, Y.; Zhang, J.; Zhang, L. Milk Source Identification and Milk Quality Estimation Using an Electronic Nose and Machine Learning Techniques. Sensors 2020, 20, 4238. [CrossRef]

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer International Publishing: Cham, 2022; ISBN 978-3-030-89009-4.

- Sun, S.; Huang, R. An Adaptive K-Nearest Neighbor Algorithm. In 2010 seventh international conference on fuzzy systems and knowledge discovery, IEEE: Yantai, China, August 2010, 1, 91–94.

- Japkowicz, N. Learning from imbalanced data sets: a comparison of various strategies. In AAAI workshop on learning from imbalanced data sets 2000, 68, 10-15.

- Tan, S. Neighbor-Weighted K-Nearest Neighbor for Unbalanced Text Corpus. Expert Systems with Applications 2005, 28, 667–671. [CrossRef]

- Zeng, Y.; Yang, Y.; Zhao, L. Pseudo Nearest Neighbor Rule for Pattern Classification. Expert Systems with Applications 2009, 36, 3587–3595. [CrossRef]

- Shinde, T.A.; Prasad, J.R. IoT based animal health monitoring with naive Bayes classification. IJETT 2017, 1(2).

- Rish, I. An empirical study of the naive Bayes classifier. In IJCAI 2001 workshop on empirical methods in artificial intelligence 2001, 3(22), 41-46.

- Rong, S.; Bao-wen, Z. The Research of Regression Model in Machine Learning Field. MATEC Web Conf. 2018, 176, 01033. [CrossRef]

- Sharma, A.; Paliwal, K.K. Linear Discriminant Analysis for the Small Sample Size Problem: An Overview. Int. J. Mach. Learn. & Cyber. 2015, 6, 443–454. [CrossRef]

- Tharwat, A.; Gaber, T.; Ibrahim, A.; Hassanien, A.E. Linear Discriminant Analysis: A Detailed Tutorial. AIC 2017, 30, 169–190. [CrossRef]

- Johnson, R.A.; Wichern, D.W. Applied Multivariate Statistical Analysis; 6th ed.; Pearson Prentice Hall: Upper Saddle River, N.J, 2007; ISBN 978-0-13-187715-3.

- Ferreira, A.J.; Figueiredo, M.A.T. Boosting Algorithms: A Review of Methods, Theory, and Applications. In Ensemble Machine Learning; Zhang, C., Ma, Y., Eds.; Springer New York: New York, NY, 2012; pp. 35–85 ISBN 978-1-4419-9325-0.

- Schapire, R.E. The Boosting Approach to Machine Learning: An Overview. In Nonlinear Estimation and Classification; Denison, D.D., Hansen, M.H., Holmes, C.C., Mallick, B., Yu, B., Eds.; Lecture Notes in Statistics; Springer New York: New York, NY, 2003; Vol. 171, pp. 149–171 ISBN 978-0-387-95471-4.

- Ganaie, M.A.; Hu, M.; Malik, A.K.; Tanveer, M.; Suganthan, P.N. Ensemble Deep Learning: A Review. Engineering Applications of Artificial Intelligence 2022, 115, 105151. [CrossRef]

- Freund, Y.; Schapire, R.E. A Decision-Theoretic Generalization of On-Line Learning and an Application to Boosting. Journal of Computer and System Sciences 1997, 55, 119–139. [CrossRef]

- Pence, I.; Kumaş, K.; Cesmeli, M.S.; Akyüz, A. Future Prediction of Biogas Potential and CH4 Emission with Boosting Algorithms: The Case of Cattle, Small Ruminant, and Poultry Manure from Turkey. Environ Sci Pollut Res 2024, 31, 24461–24479. [CrossRef]

- Bai, J.; Xue, H.; Jiang, X.; Zhou, Y. Recognition of Bovine Milk Somatic Cells Based on Multi-Feature Extraction and a GBDT-AdaBoost Fusion Model. MBE 2022, 19, 5850–5866. [CrossRef]

- Wang, F.; Li, Z.; He, F.; Wang, R.; Yu, W.; Nie, F. Feature Learning Viewpoint of Adaboost and a New Algorithm. IEEE Access 2019, 7, 149890–149899. [CrossRef]

- Sun, Y.; Kamel, M.; Wang, Y. Boosting for Learning Multiple Classes with Imbalanced Class Distribution. In Proceedings of the Sixth International Conference on Data Mining (ICDM) 2006, IEEE: Hong Kong, China, December 2006, 592–602.

- Çelik, A. Using Machine Learning Algorithms to Detect Milk Quality. Eurasian Journal of Food Science and Technology 2022, 6(2), 76-87.

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. The Annals of Statistics 2001, 29, 1189–1232.

- Otchere, D.A.; Ganat, T.O.A.; Ojero, J.O.; Tackie-Otoo, B.N.; Taki, M.Y. Application of Gradient Boosting Regression Model for the Evaluation of Feature Selection Techniques in Improving Reservoir Characterisation Predictions. Journal of Petroleum Science and Engineering 2022, 208, 109244. [CrossRef]

- Pirouz, D.M. An Overview of Partial Least Squares. SSRN Journal 2006. [CrossRef]

- Garthwaite, P.H. An Interpretation of Partial Least Squares. Journal of the American Statistical Association 1994, 89, 122–127. [CrossRef]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-Regression: A Basic Tool of Chemometrics. Chemometrics and Intelligent Laboratory Systems 2001, 58, 109–130. [CrossRef]

- Cheng, J.-H.; Sun, D.-W. Partial Least Squares Regression (PLSR) Applied to NIR and HSI Spectral Data Modeling to Predict Chemical Properties of Fish Muscle. Food Eng Rev 2017, 9, 36–49. [CrossRef]

- Meisel, S.; Stöckel, S.; Elschner, M.; Melzer, F.; Rösch, P.; Popp, J. Raman Spectroscopy as a Potential Tool for Detection of Brucella Spp. in Milk. Appl Environ Microbiol 2012, 78, 5575–5583. [CrossRef]

- Mota, L.F.M.; Pegolo, S.; Baba, T.; Peñagaricano, F.; Morota, G.; Bittante, G.; Cecchinato, A. Evaluating the Performance of Machine Learning Methods and Variable Selection Methods for Predicting Difficult-to-Measure Traits in Holstein Dairy Cattle Using Milk Infrared Spectral Data. Journal of Dairy Science 2021, 104, 8107–8121. [CrossRef]

- Frizzarin, M.; O’Callaghan, T.F.; Murphy, T.B.; Hennessy, D.; Casa, A. Application of Machine-Learning Methods to Milk Mid-Infrared Spectra for Discrimination of Cow Milk from Pasture or Total Mixed Ration Diets. Journal of Dairy Science 2021, 104, 12394–12402. [CrossRef]

- Giannuzzi, D.; Mota, L.F.M.; Pegolo, S.; Gallo, L.; Schiavon, S.; Tagliapietra, F.; Katz, G.; Fainboym, D.; Minuti, A.; Trevisi, E.; et al. In-Line near-Infrared Analysis of Milk Coupled with Machine Learning Methods for the Daily Prediction of Blood Metabolic Profile in Dairy Cattle. Sci Rep 2022, 12, 8058. [CrossRef]

- Giannuzzi, D.; Mota, L.F.M.; Pegolo, S.; Tagliapietra, F.; Schiavon, S.; Gallo, L.; Marsan, P.A.; Trevisi, E.; Cecchinato, A. Prediction of Detailed Blood Metabolic Profile Using Milk Infrared Spectra and Machine Learning Methods in Dairy Cattle. Journal of Dairy Science 2023, 106, 3321–3344. [CrossRef]

- Soyeurt, H.; Grelet, C.; McParland, S.; Calmels, M.; Coffey, M.; Tedde, A.; Delhez, P.; Dehareng, F.; Gengler, N. A Comparison of 4 Different Machine Learning Algorithms to Predict Lactoferrin Content in Bovine Milk from Mid-Infrared Spectra. Journal of Dairy Science 2020, 103, 11585–11596. [CrossRef]

- Teixeira, J.L.D.P.; Caramês, E.T.D.S.; Baptista, D.P.; Gigante, M.L.; Pallone, J.A.L. Vibrational Spectroscopy and Chemometrics Tools for Authenticity and Improvement the Safety Control in Goat Milk. Food Control 2020, 112, 107105. [CrossRef]

- Ullah, R.; Khan, S.; Ali, H.; Bilal, M. Potentiality of Using Front Face Fluorescence Spectroscopy for Quantitative Analysis of Cow Milk Adulteration in Buffalo Milk. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy 2020, 225, 117518. [CrossRef]

- Sowmya, N.; Ponnusamy, V. Development of Spectroscopic Sensor System for an IoT Application of Adulteration Identification on Milk Using Machine Learning. IEEE Access 2021, 9, 53979–53995. [CrossRef]

- Lima, J.S.; Ribeiro, D.C.S.Z.; Neto, H.A.; Campos, S.V.A.; Leite, M.O.; Fortini, M.E.D.R.; De Carvalho, B.P.M.; Almeida, M.V.O.; Fonseca, L.M. A Machine Learning Proposal Method to Detect Milk Tainted with Cheese Whey. Journal of Dairy Science 2022, 105, 9496–9508. [CrossRef]

- Wang, Y.-T.; Ren, H.-B.; Liang, W.-Y.; Jin, X.; Yuan, Q.; Liu, Z.-R.; Chen, D.-M.; Zhang, Y.-H. A Novel Approach to Temperature-Dependent Thermal Processing Authentication for Milk by Infrared Spectroscopy Coupled with Machine Learning. Journal of Food Engineering 2021, 311, 110740. [CrossRef]

- Behkami, S.; Zain, S.M.; Gholami, M.; Khir, M.F.A. Classification of Cow Milk Using Artificial Neural Network Developed from the Spectral Data of Single- and Three-Detector Spectrophotometers. Food Chemistry 2019, 294, 309–315. [CrossRef]

- Nychas, G.-J.E.; Panagou, E.Z.; Mohareb, F. Novel Approaches for Food Safety Management and Communication. Current Opinion in Food Science 2016, 12, 13–20. [CrossRef]

- Nychas, G.-J.; Sims, E.; Tsakanikas, P.; Mohareb, F. Data Science in the Food Industry. Annu. Rev. Biomed. Data Sci. 2021, 4, 341–367. [CrossRef]

- Knight, C.H. Review: Sensor Techniques in Ruminants: More than Fitness Trackers. Animal 2020, 14, s187–s195. [CrossRef]

| Wavelength ) |

Type of milk sample | No of samples | Origin of milk | Application | RMSE | Diagnostic performance |

Ref. | |

| 300 – 1700 | powder | ND | retail | lactose | 0.91 | - | - | [34] |

| 250 – 3500 | powder | 136 | retail | fat protein |

- | 0.21 – 0.31 % w/w p 0.14 – 0.35 % w/w p |

- | [39] |

| 800 – 3050 | liquid* liquid** powder* |

13 | retail | fat | 0.97 v 0.97 v 0.97 v |

0.16% v 0.06% v 0.18% v |

- | [36] |

| 8, 16, 32 | liquid | 75 | retail | fat protein carbohydrates dry matter |

- | 5.3 – 5.8% sp 5.6 – 6.1% sp 3.5 – 4.8% sp 3.4 – 4.8% sp |

- | [35] |

| 400 – 3500 | powder | 45 | retail | lactose high/low classification maltodextrin adulteration |

- | - | Se: 98.6% Sp: 100.0% Se: 88.6% Sp: 100.0% |

[37] |

| 750 – 1800 | liquid | 10 batches | retail | urea adulteration | > 0.95 | - | Acc+ 100mg/dl: > 97% 50-100mg/dl: 90-95% <50mg/dl: ≈ 60% |

[38] |

| 600 – 1800 | liquid | 602 | cow human buffalo goat |

milk origin | - | - | Se: 93.0% Sp: 97.0% Acc: 93.7% |

[40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).