Submitted:

26 October 2024

Posted:

28 October 2024

You are already at the latest version

Abstract

Keywords:

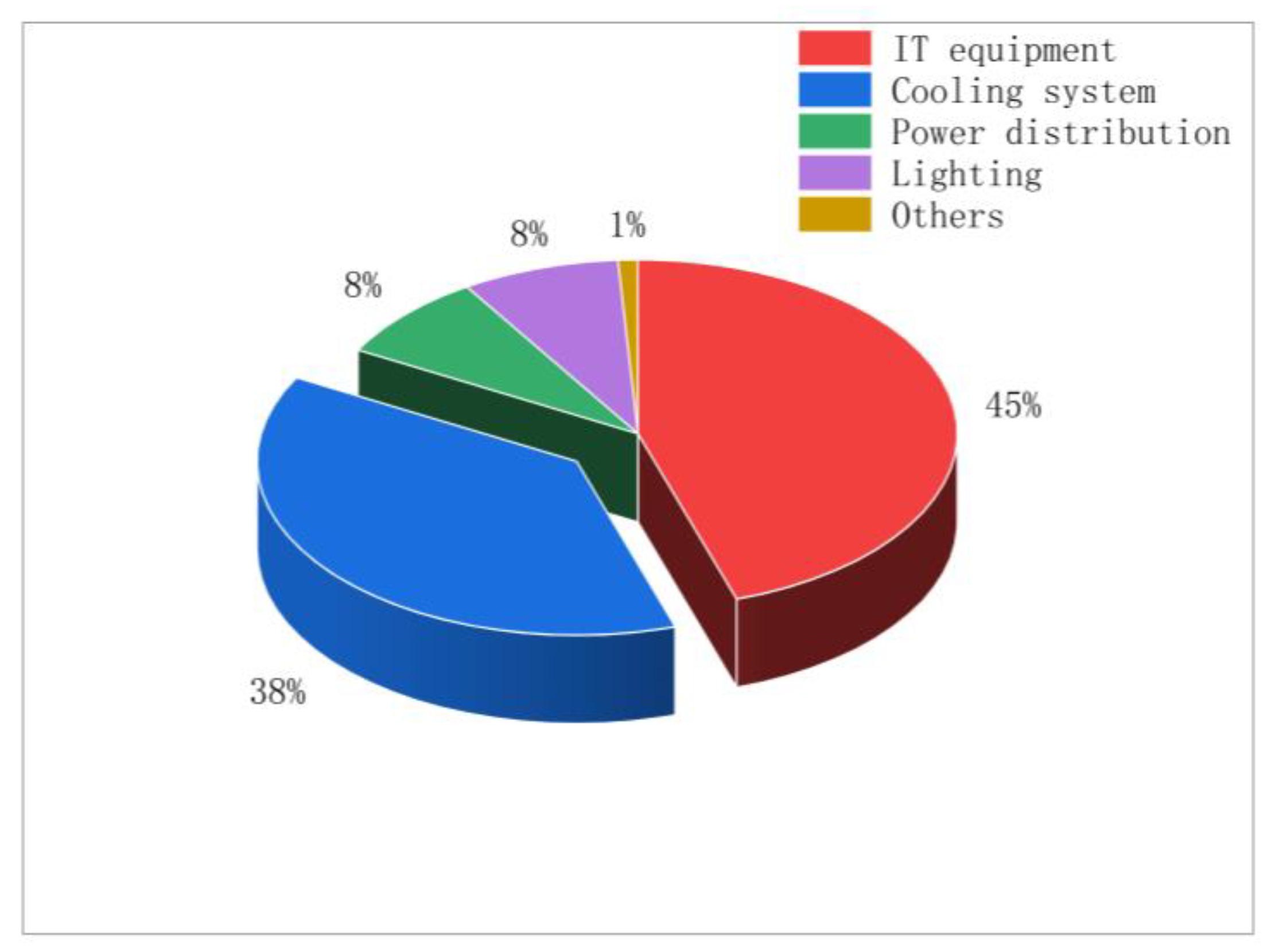

1. Introduction

2. Materials and Methods

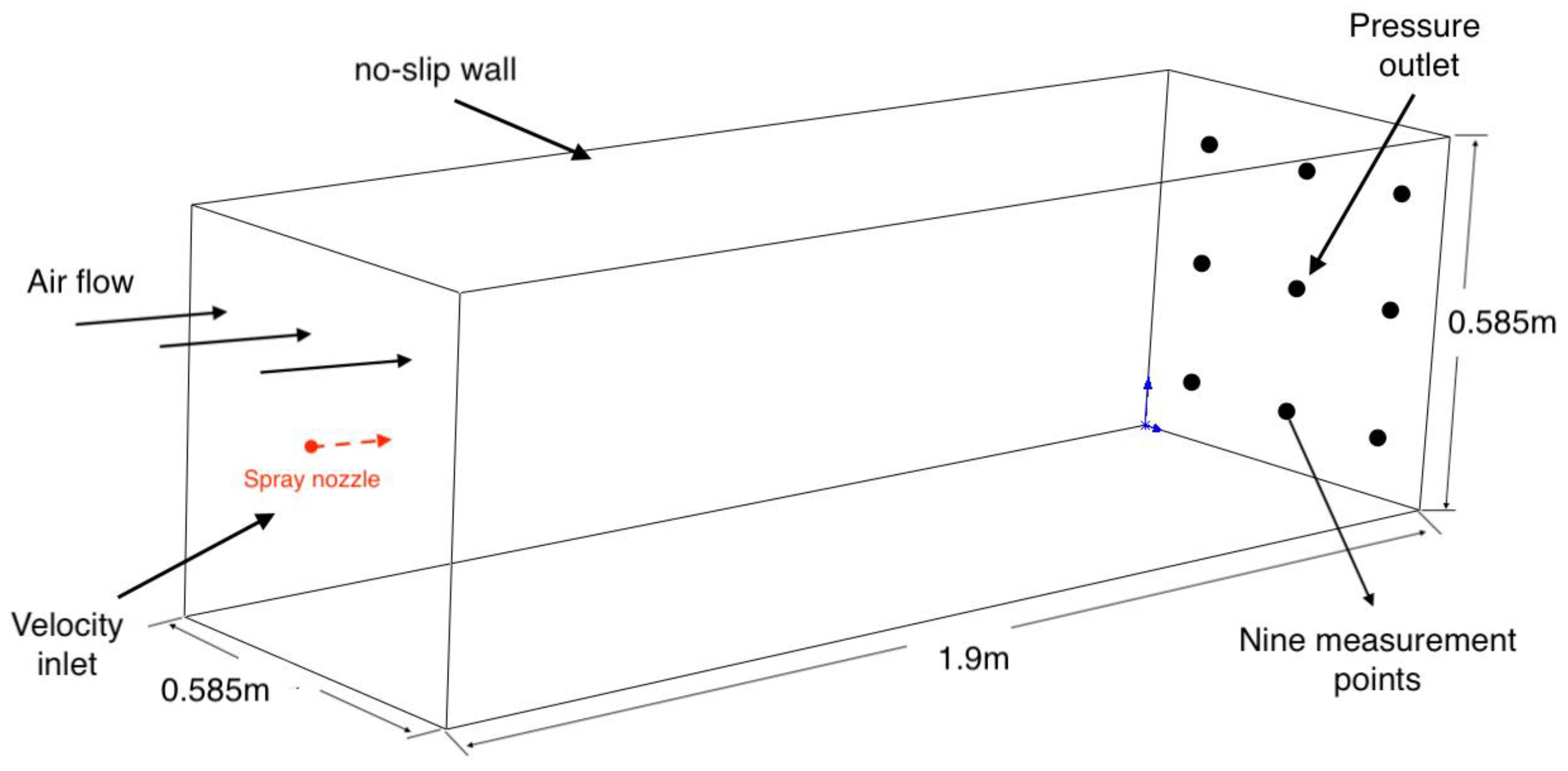

2.1. Computational Model

2.2. Governing Equations

2.3 Boundary Conditions

2.3. Discrete Phase Model

2.4. Droplet Distribution

2.5. Spray Nozzle Characteristics

2.6. Coefficient of Performance

3. Results and Discussion

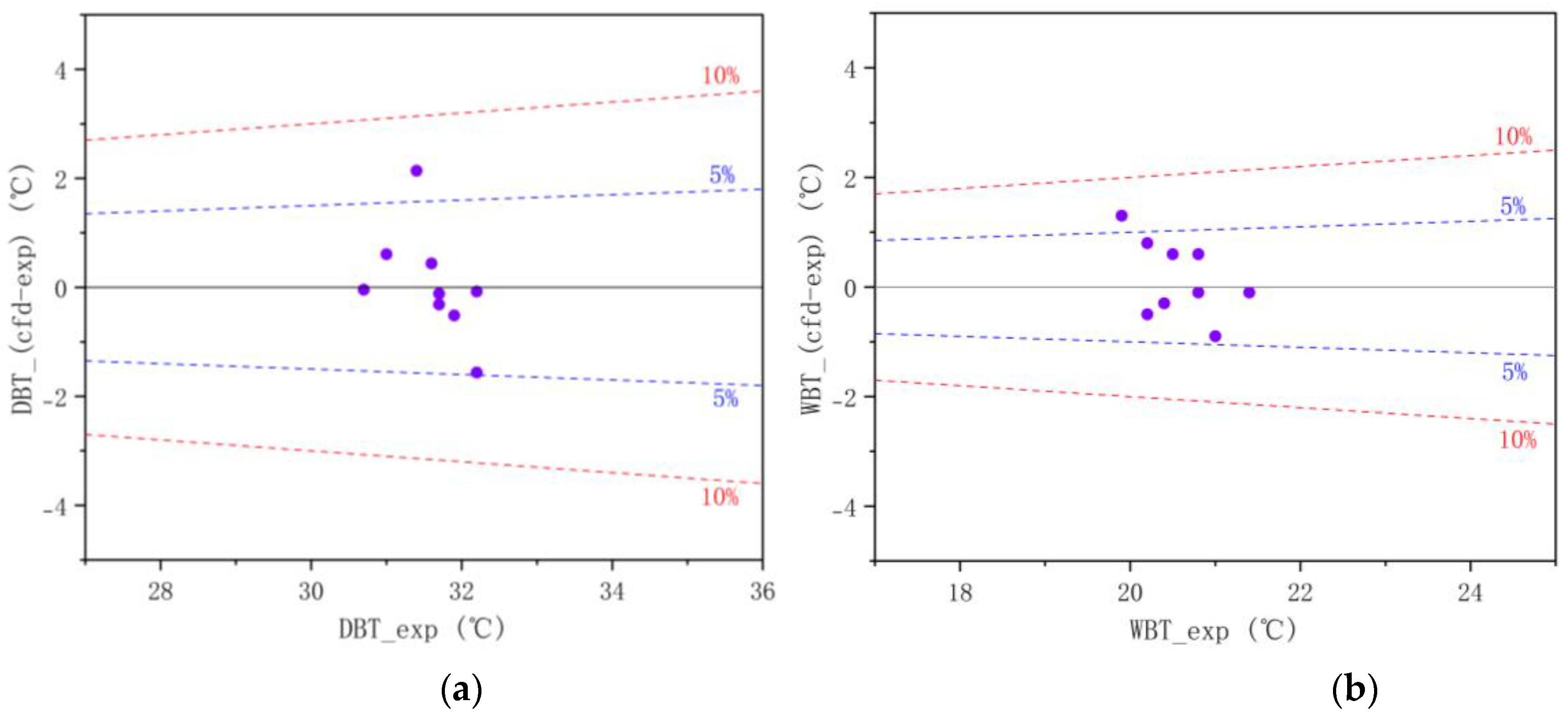

3.1. Validations

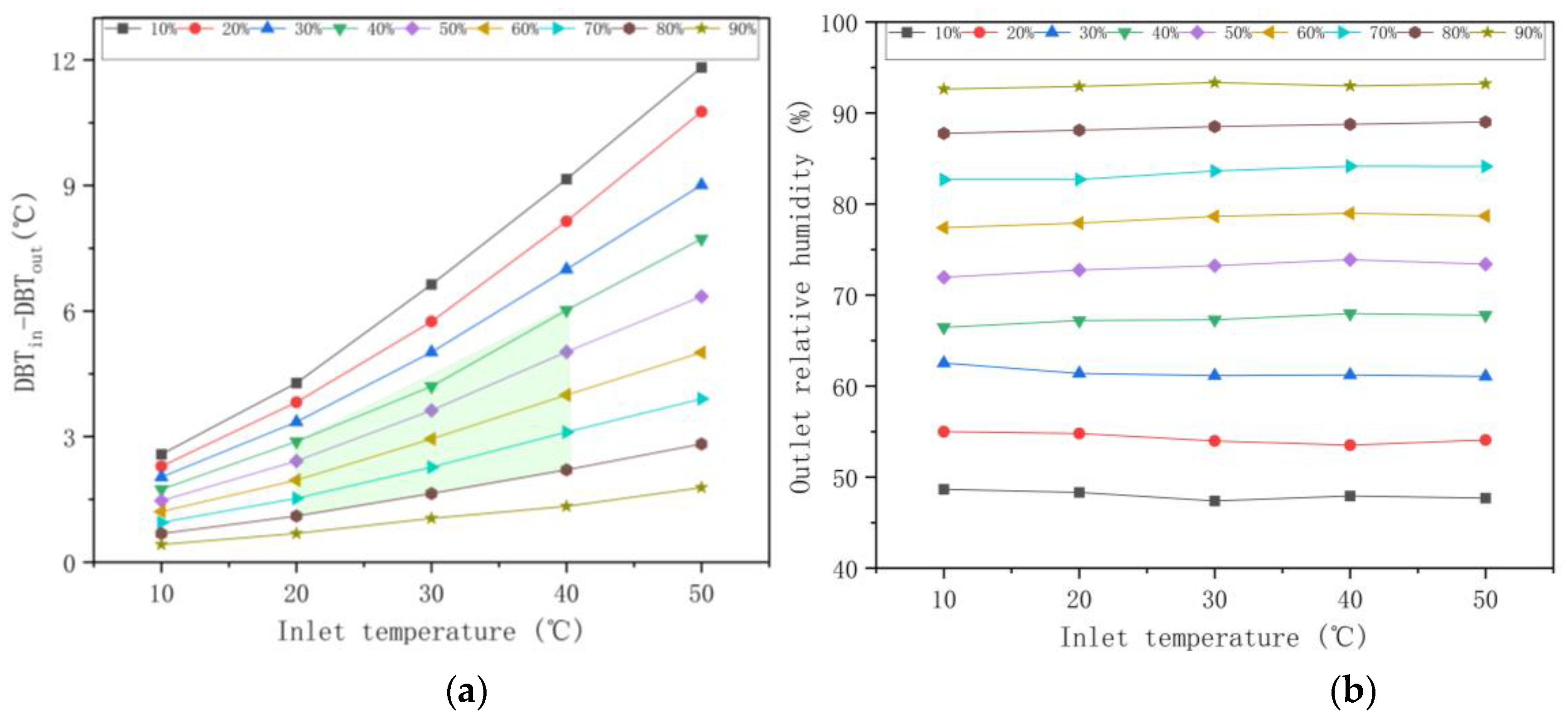

3.2. Impact of Different Geographical Conditions

3.3. Impact of Mass Flow Rate

3.4. Impact of the Length of the Domain

3.4. Average Droplet Size and Mass Flow Rate

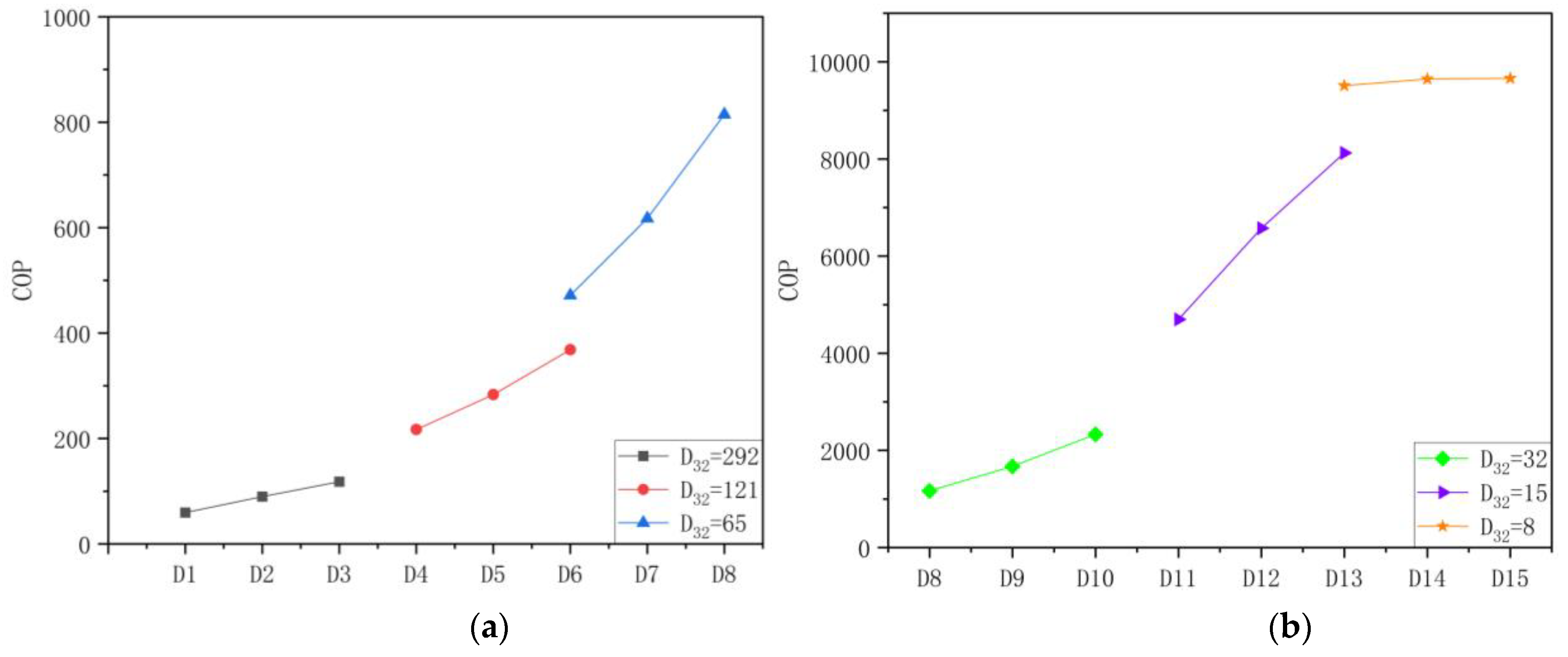

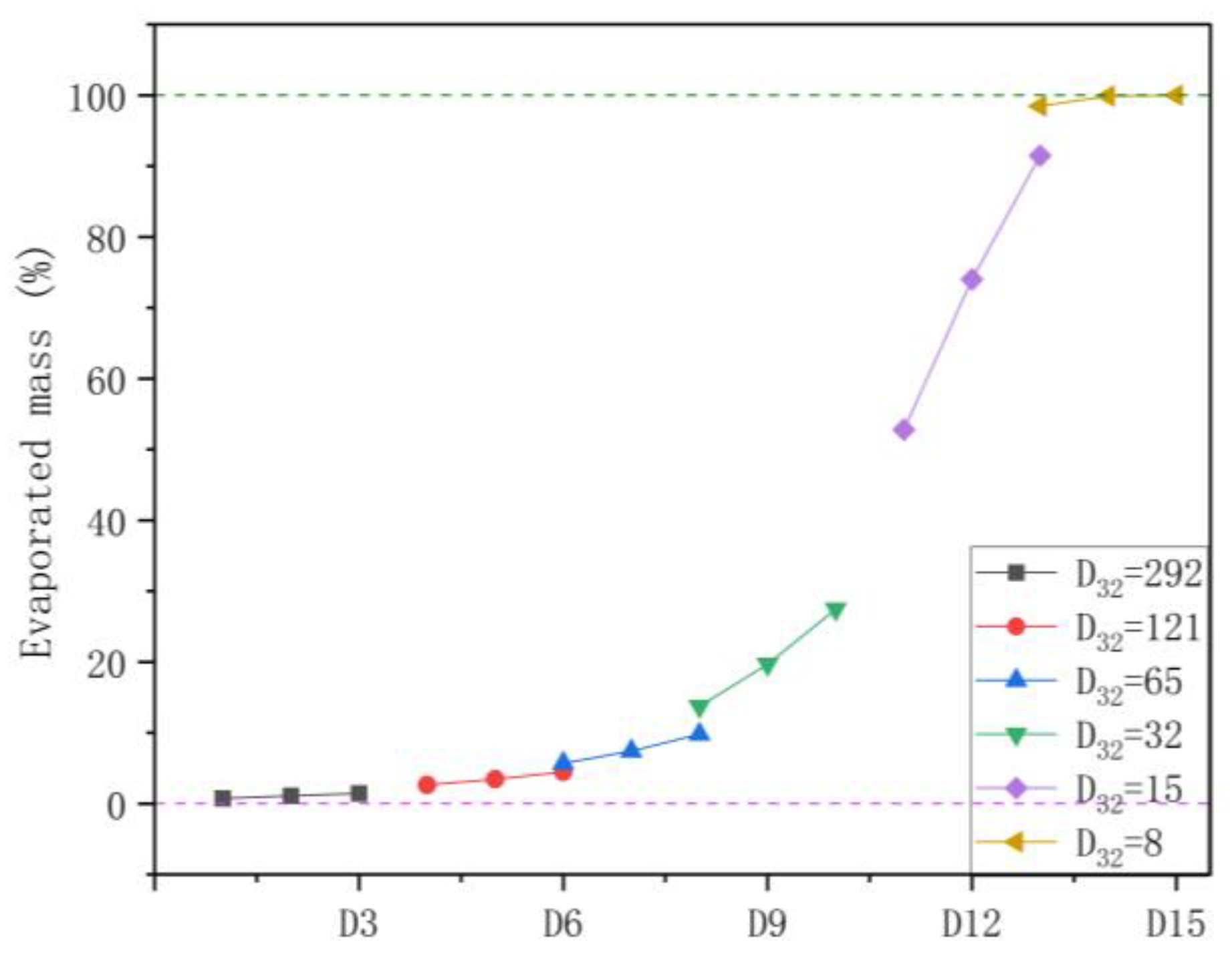

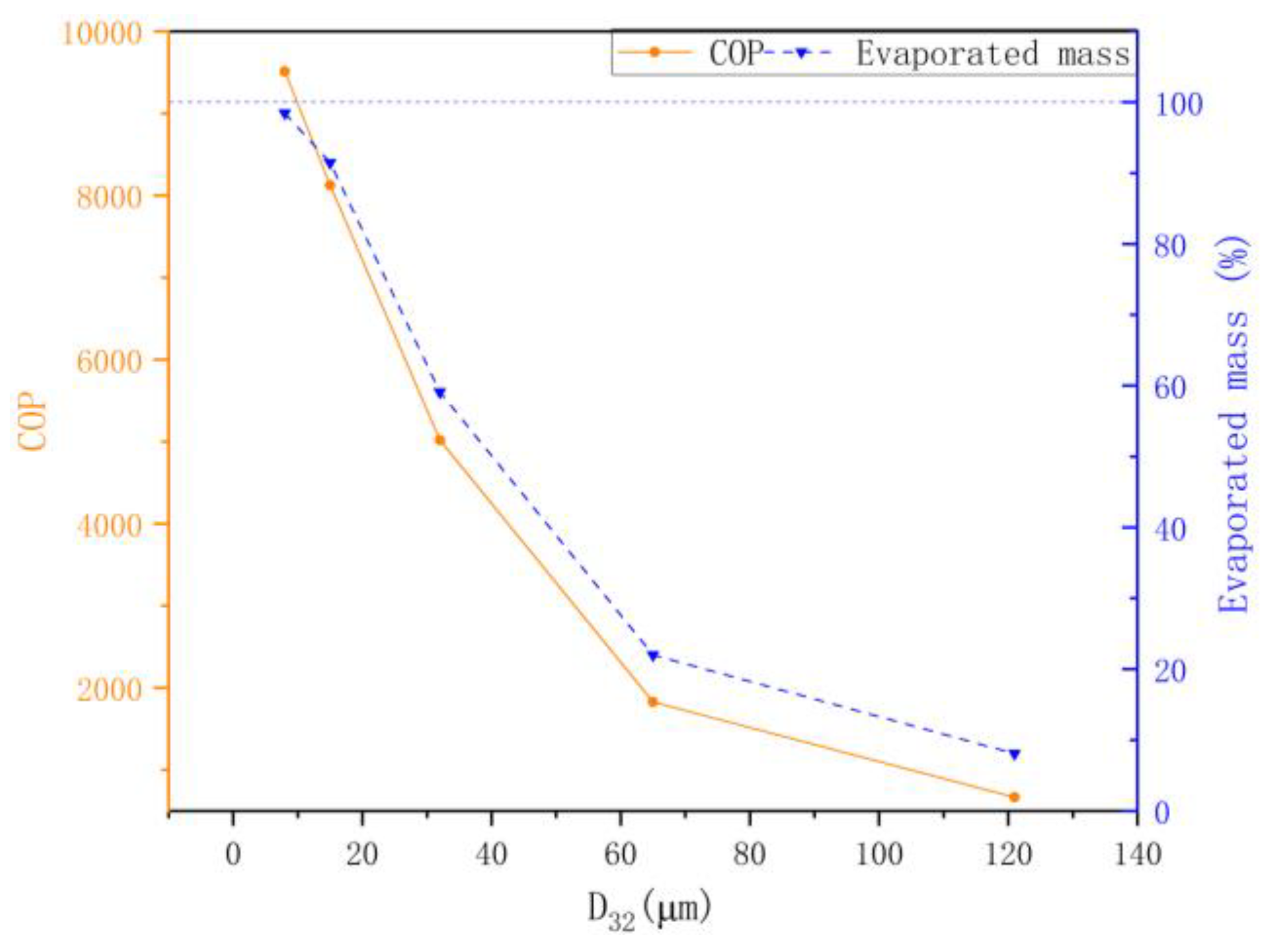

3.5. Optimization

- Fixing the upper limit of the droplet diameter and reducing the water mass flow rate in a geometric progression with ratio ½, and obtaining a relative humidity value close to 100 %.

- Reducing the droplet diameter in a geometric progression with ratio ½, repeating Step 1 until the 100 % relative humidity point is achieved.

5. Conclusions

- (1)

- The temperature and humidity of the air have a big influence on the evaporation system. Regions with high temperatures and low humidity experience the greatest cooling effect, with temperature drops of up to 12°C at 50°C and 10% humidity. Most regions fall within moderate temperature and humidity ranges, where evaporation systems typically reduce temperatures by 1.5 to 6°C for an average Sauter mean diameter (SMD) of 292 μm.

- (2)

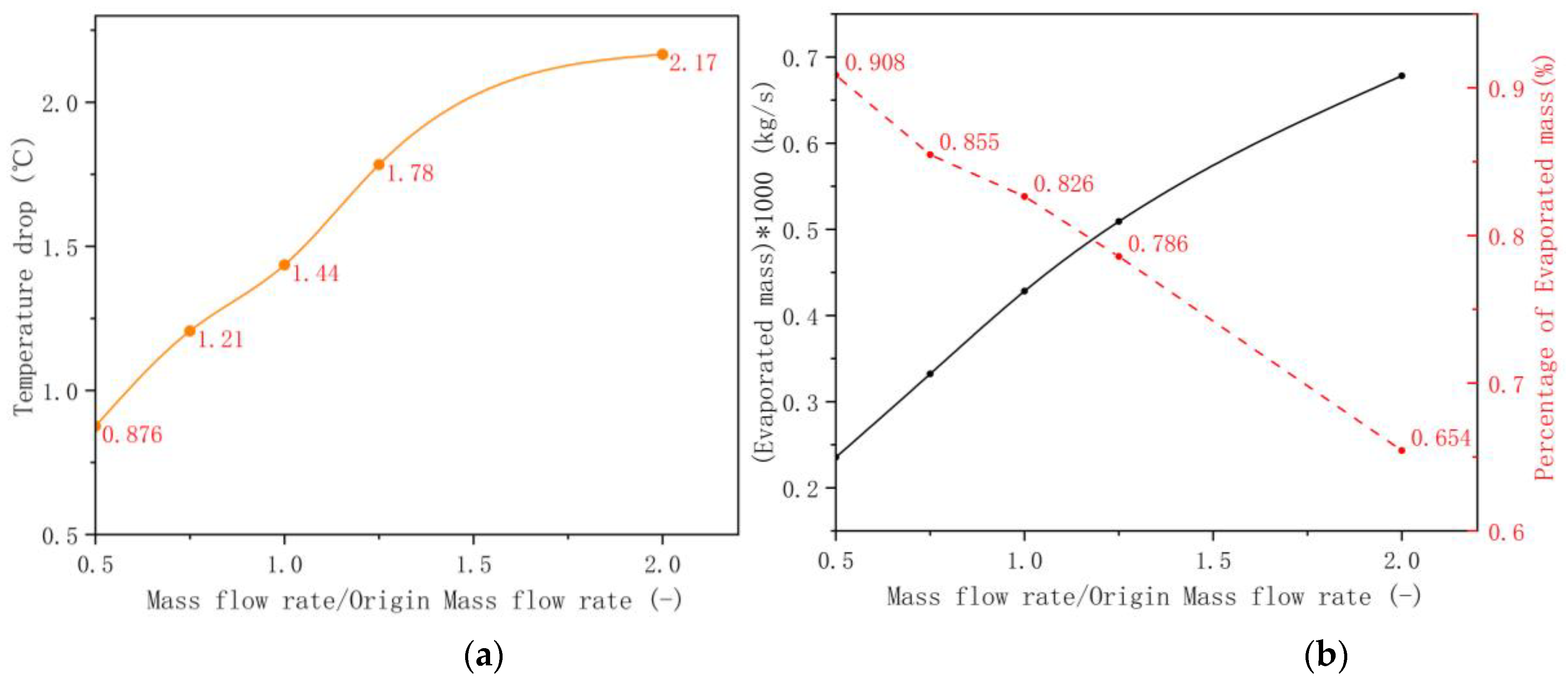

- Increasing mass flow rates in evaporation systems significantly enhances the temperature drop, with a 50.8% rise in ΔT as the flow rate increases from ṁ to 2ṁ. However, this is accompanied by a decrease in the percentage of evaporated mass reducing the overall system performance (COP) in terms of water consumption.

- (3)

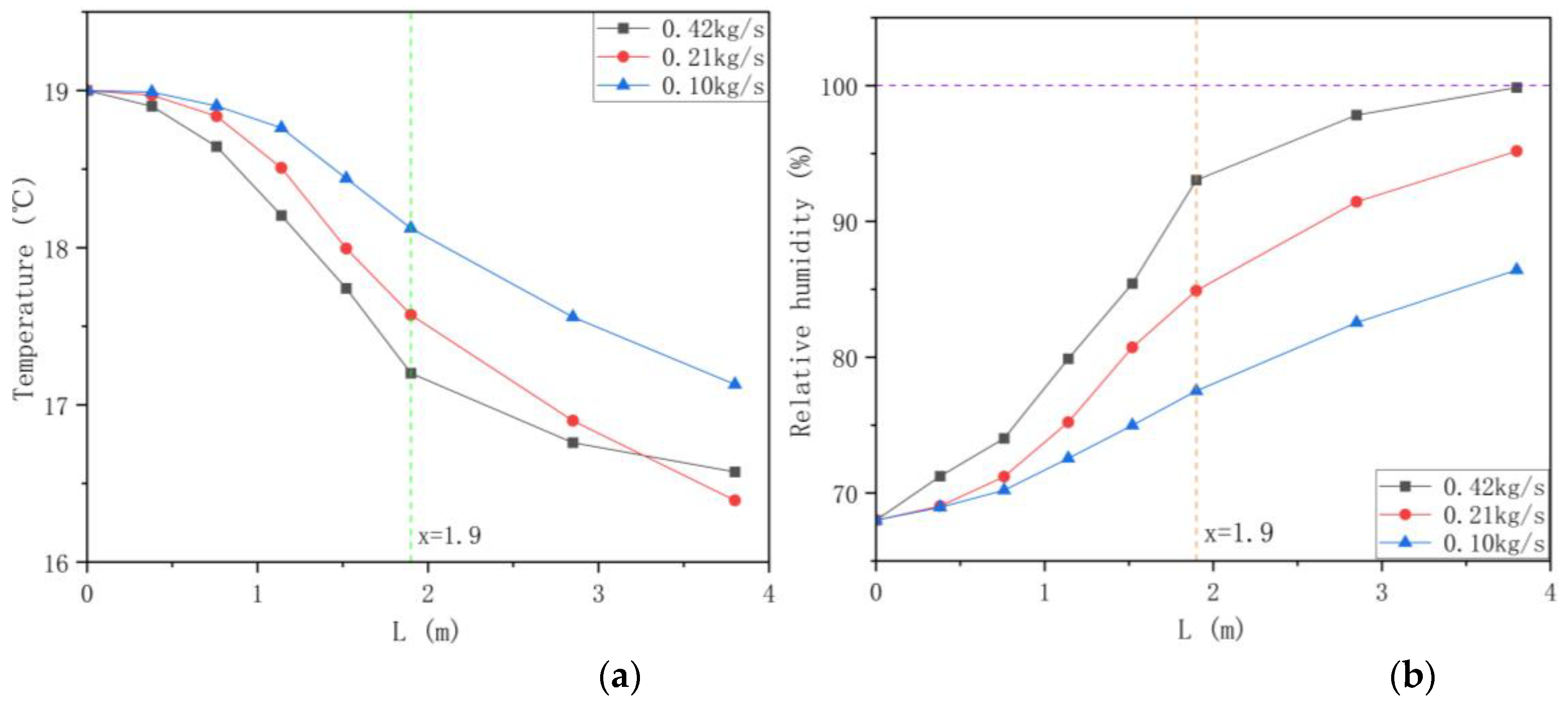

- Extending the domain length significantly enhances cooling efficiency, with the temperature disparity between the inlet and outlet increasing by 85.7% and relative humidity rising by 61%. An increase in the mass flow rate results in a more rapid decline in temperature. However, beyond a certain distance, the evaporation rate declines due to the air becoming saturated, thereby limiting the evaporation process.

- (4)

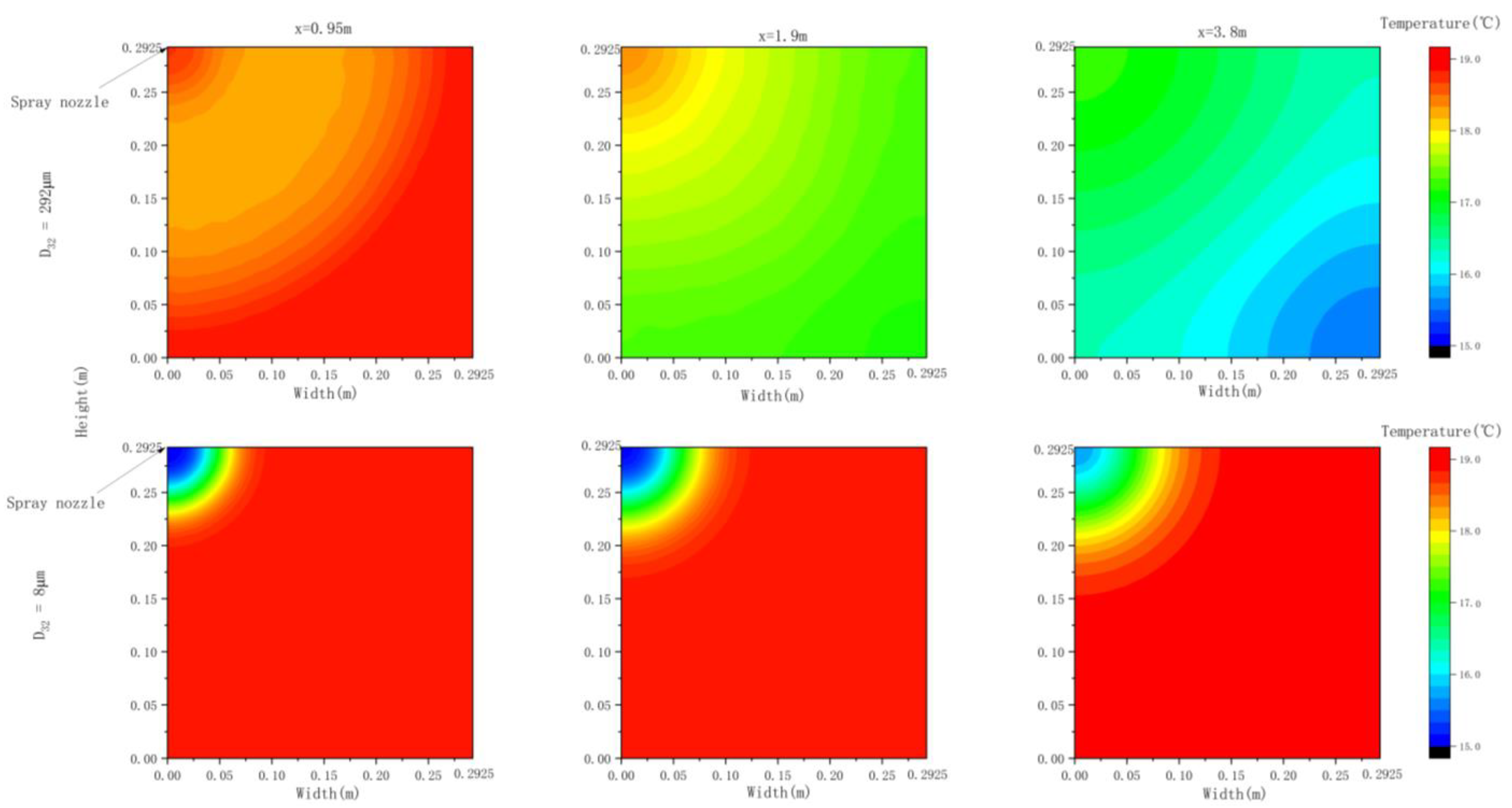

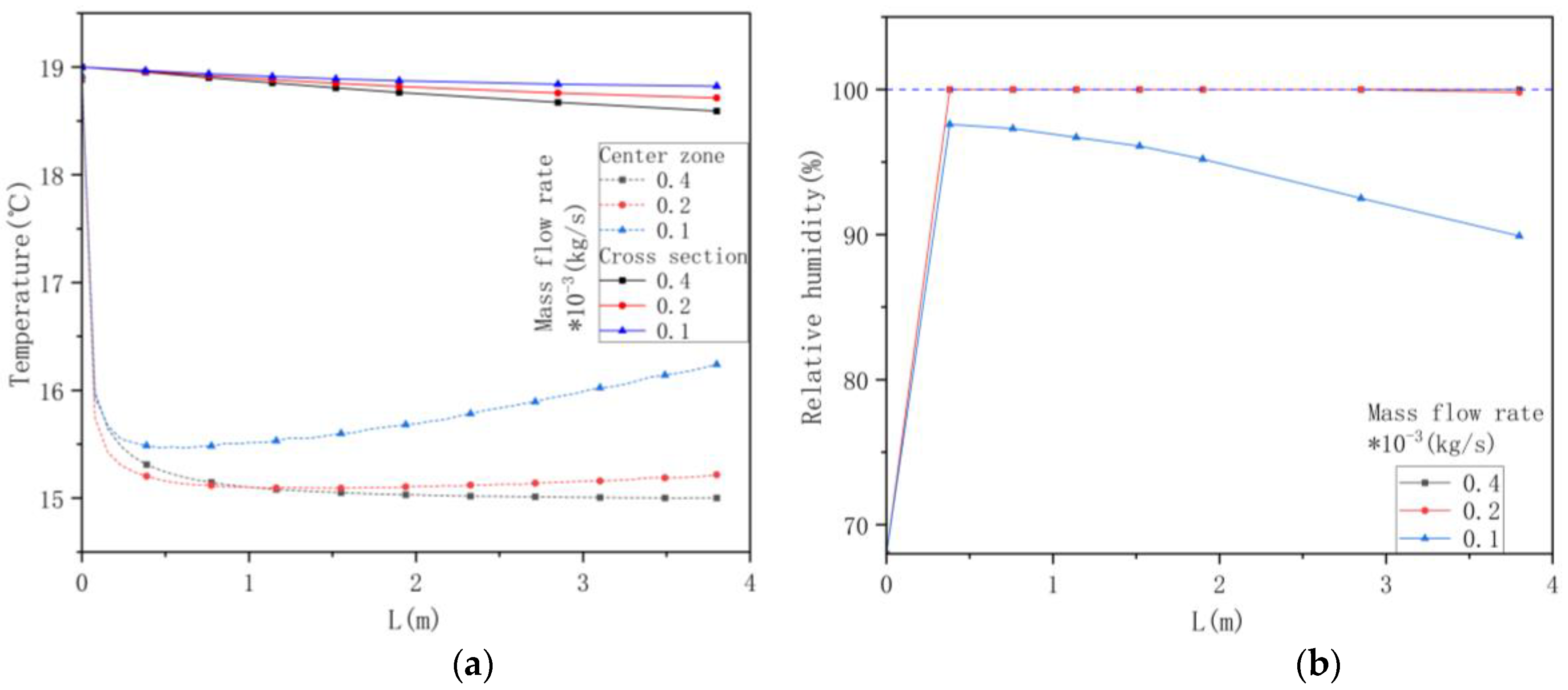

- Larger droplets (D32 = 292 μm, ṁ = 0.21 kg/s) result in a notable reduction in temperature across the domain, with higher temperatures observed in the central region. In contrast, smaller droplets (D32 = 8 μm, ṁ = 0.0001 kg/s) exert a dominant influence on the airflow, resulting in the concentration of cooling in the centre region with minimal temperature change along the domain.

- (5)

- Reducing droplet size also enhances the evaporation rate, with smaller droplets (D32 < 20 μm) exceeding 50% evaporation, and at 8 μm, achieving 100% evaporation. Additionally, smaller droplet sizes reduce water consumption, with D32 = 15 μm using just 3% of the original water volume. The analysis of the coefficient of performance (COP) reveals that smaller droplets and lower mass flow rates result in higher COP, as the efficiency of the whole system is improved.

- (6)

- It was demonstrated that both the evaporation rate and the coefficient of performance (COP) decrease as the size of the droplets increases. This reduction is attributable to the fact that larger droplet sizes reduce the overall surface area available for evaporation under a given water mass flow rate.

Abbreviations

| A | Surface area | m2 |

| Bm | Spalding number | - |

| Turbulence viscosity coefficient | - | |

| Drag coefficient | - | |

| Cv | Nozzle velocity coefficient | - |

| Empirical coefficient | - | |

| Heat capacity | J/ | |

| D | Diameter | |

| Mean diameter | ||

| Di,m | Diffusion coefficient | m2/s |

| G | Gravity term | N |

| g | Gravitational acceleration | m/s2 |

| h | Enthalpy | J/kg |

| I | Turbulent intensity | % |

| k | Turbulent kinetic energy | m2/s2 |

| kc | Mass transfer coefficient | - |

| LHV | Latent heat of water vaporization | KJ/kg |

| l | Turbulent length scale | m |

| m | Mass | kg |

| Mass flow rate | kg/s | |

| Nu | Nusselt number | - |

| P | Pressure | Pa |

| Pk | Production of turbulent kinetic energy | kg/ ms3 |

| Pr | Prandtl number | - |

| Q | Enthalpy change | W |

| Re | Relative Reynolds number | - |

| Source term of energy | W/m3 | |

| Sm | Source term of mass | kg/ m3s |

| Source term of momentum | kg/(m2s2) | |

| Source term for species transport | kg/ m3s | |

| Sc | Schmidt number | - |

| Sh | Sherwood number | - |

| T | Temperature | °C |

| Mean velocity vector | m/s | |

| U0 | Initial nozzle velocity | m/s |

| Volumetric flow rate | m3/s | |

| v | velocity | m/s |

| Mass fraction of species | - | |

| Vapour masa fraction at the surface | - | |

| Vapour masa fraction in the air | - |

Greek Symbols

| Half cone angle | ||

| Kronecker delta | - | |

| dissipation rate | m3/s3 | |

| Mixture thermal conductivity | W/() | |

| Dynamic viscosity | kg/ | |

| Turbulent viscosity | kg/ | |

| Density | kg/m3 | |

| Turbulent dissipation rate | m2/s3 | |

| Dissipation rate | W/m3 | |

| Turbulent Prandtl number for | - | |

| Mass fraction | - | |

| Droplet surface tension | N/m | |

| Specific humidity | - |

Subscripts

| a | Air | |

| COP | Coefficient of performance | |

| d | Droplet | |

| DBT | Dry bulb temperature | |

| i,j | Cartesian coordinate directions | |

| SEP | Surface energy per unit | |

| tur | Turbulent | |

| WBT | Wet bulb temperature |

Author Contributions

Funding

Data Availability Statement

Acknowledgements

Conflicts of Interest

Appendix A

Derivation of Surface Energy Power (SEP)

Appendix B

Sample Calculation for COP

References

- Cai, S.; Gou, Z. Towards Energy-Efficient Data Centers: A Comprehensive Review of Passive and Active Cooling Strategies. Energy and Built Environment 2024, S2666123324000916. [Google Scholar] [CrossRef]

- Key Findings Data Centres Metered Electricity Consumption 2022 - Central Statistics Office. https://www.cso.ie/en/releasesandpublications/ep/p-dcmec/datacentresmeteredelectricityconsumption2022/keyfindings/ (accessed 2024-08-03).

- IEA – International Energy Agency. IEA. https://www.iea.org (accessed 2024-08-03).

- Du, S.; Zhang, Q.; Zou, S.; Meng, F.; Liu, L. Simulation Analysis on Energy Consumption and Economy of CPU Cooling System Based on Loop Heat Pipe for Data Center. Thermal Science and Engineering Progress 2023, 45, 102115. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Yan, Y. A Review of the State-of-the-Art in Electronic Cooling. e-Prime - Advances in Electrical Engineering, Electronics and Energy 2021, 1, 100009. [Google Scholar] [CrossRef]

- Kapilan, N.; Isloor, A. M.; Karinka, S. A Comprehensive Review on Evaporative Cooling Systems. Results in Engineering 2023, 18, 101059. [Google Scholar] [CrossRef]

- McCay, O.; Nimmagadda, R.; Ali, S.M.; Persoons, T. A Parametric Design Study of Natural-Convection-Cooled Heat Sinks. Fluids 2023, 8, 234. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, Z.; Hong, X.; Zhan, Y.; Liu, J.; Dong, J.; Bai, T.; Niu, J.; Deen, M. J. A Survey on Data Center Cooling Systems: Technology, Power Consumption Modeling and Control Strategy Optimization. Journal of Systems Architecture 2021, 119, 102253. [Google Scholar] [CrossRef]

- Zhang, H.; Shao, S.; Xu, H.; Zou, H.; Tian, C. Free Cooling of Data Centers: A Review. Renewable and Sustainable Energy Reviews 2014, 35, 171–182. [Google Scholar] [CrossRef]

- Hnayno, M.; Chehade, A.; Klaba, H.; Polidori, G.; Maalouf, C. Experimental Investigation of a Data-Centre Cooling System Using a New Single-Phase Immersion/Liquid Technique. Case Studies in Thermal Engineering 2023, 45, 102925. [Google Scholar] [CrossRef]

- Bapu, B. R. R.; Kayalvizhi, S.; Murugavalli, S. Two Phase Cooling with Nano-Fluid for Highly Dense Electronic Systems-on-Chip – A Pilot Study. Microelectronics Reliability 2020, 108, 113640. [Google Scholar] [CrossRef]

- Pearlmutter, D.; Erell, E.; Etzion, Y.; Meir, I. A.; Di, H. Refining the Use of Evaporation in an Experimental Down-Draft Cool Tower. Energy and Buildings 1996, 23, 191–197. [Google Scholar] [CrossRef]

- Shehabi, A. Energy Implications of Economizer Use in California Data Centers, 2008.

- Shehabi, A.; Ganguly, S.; Gundel, L. A.; Horvath, A.; Kirchstetter, T. W.; Lunden, M. M.; Tschudi, W.; Gadgil, A. J.; Nazaroff, W. W. Can Combining Economizers with Improved Filtration Save Energy and Protect Equipment in Data Centers? Building and Environment 2010, 45, 718–726. [Google Scholar] [CrossRef]

- Shehabi, A.; Horvath, A.; Tschudi, W.; Gadgil, A. J.; Nazaroff, W. W. Particle Concentrations in Data Centers. Atmospheric Environment 2008, 42, 5978–5990. [Google Scholar] [CrossRef]

- Bao, L.; Wang, J.; Kang, L. The Applied Effect Analysis of Heat Exchanger Installed in a Typical Communication Base Station in Beijing of China. Energy Procedia 2012, 14, 620–625. [Google Scholar] [CrossRef]

- Sureshkumar, R.; Kale, S. R.; Dhar, P. L. Heat and Mass Transfer Processes between a Water Spray and Ambient Air – I. Experimental Data. Applied Thermal Engineering 2008, 28, 349–360. [Google Scholar] [CrossRef]

- Shao, S.; Liu, H.; Zhang, H.; Tian, C. Experimental Investigation on a Loop Thermosyphon with Evaporative Condenser for Free Cooling of Data Centers. Energy 2019, 185, 829–836. [Google Scholar] [CrossRef]

- Tissot, J.; Boulet, P.; Labergue, A.; Castanet, G.; Trinquet, F.; Fournaison, L. Experimental Study on Air Cooling by Spray in the Upstream Flow of a Heat Exchanger. International Journal of Thermal Sciences 2012, 60, 23–31. [Google Scholar] [CrossRef]

- Kachhwaha, S. S., P. L. Dhar, and S. R. Kale. "Experimental studies and numerical simulation of evaporative cooling of air with a water spray—I. Horizontal parallel flow." International Journal of Heat and Mass Transfer 41.2 (1998): 447-464. [CrossRef]

- Kachhwaha, S. S.; Dhar, P. L.; Kale, S. R. Experimental Studies and Numerical Simulation of Evaporative Cooling of Air with a Water sprayII. Horizontal Counter Flow. International Journal of Heat and Mass Transfer 1998, 41, 465–474. [Google Scholar] [CrossRef]

- Montazeri, H.; Blocken, B.; Hensen, J. L. M. Evaporative Cooling by Water Spray Systems: CFD Simulation, Experimental Validation and Sensitivity Analysis. Building and Environment 2015, 83, 129–141. [Google Scholar] [CrossRef]

- Montazeri, H.; Blocken, B.; Hensen, J. L. M. CFD Analysis of the Impact of Physical Parameters on Evaporative Cooling by a Mist Spray System. Applied Thermal Engineering 2015, 75, 608–622. [Google Scholar] [CrossRef]

- Alkhedhair, A.; Gurgenci, H.; Jahn, I.; Guan, Z.; He, S. Numerical Simulation of Water Spray for Pre-Cooling of Inlet Air in Natural Draft Dry Cooling Towers. Applied Thermal Engineering 2013, 61, 416–424. [Google Scholar] [CrossRef]

- Alkhedhair, A.; Jahn, I.; Gurgenci, H.; Guan, Z.; He, S.; Lu, Y. Numerical Simulation of Water Spray in Natural Draft Dry Cooling Towers with a New Nozzle Representation Approach. Applied Thermal Engineering 2016, 98, 924–935. [Google Scholar] [CrossRef]

- Raoult, F.; Lacour, S.; Carissimo, B.; Trinquet, F.; Delahaye, A.; Fournaison, L. CFD Water Spray Model Development and Physical Parameter Study on the Evaporative Cooling. Applied Thermal Engineering 2019, 149, 960–974. [Google Scholar] [CrossRef]

- .Sureshkumar, R.; Kale, S. R.; Dhar, P. L. Heat and Mass Transfer Processes between a Water Spray and Ambient Air – II. Simulations. Applied Thermal Engineering 2008, 28, 361–371. [Google Scholar] [CrossRef]

- Tissot, J.; Boulet, P.; Trinquet, F.; Fournaison, L.; Macchi-Tejeda, H. Air Cooling by Evaporating Droplets in the Upward Flow of a Condenser. International Journal of Thermal Sciences 2011, 50, 2122–2131. [Google Scholar] [CrossRef]

- Climate & Weather Averages in Dublin, Ireland. https://www.timeanddate.com/weather/ireland/dublin/climate (accessed 2024-10-21).

- Li, J.; Kawano, H. Simulating Water-Drop Movement from Noncircular Sprinkler Nozzles. Journal of Irrigation and Drainage Engineering 1995, 121, 152–158. [Google Scholar] [CrossRef]

- Morsi, S. A.; Alexander, A. J. An Investigation of Particle Trajectories in Two-Phase Flow Systems. Journal of Fluid Mechanics 1972, 55, 193–208. [Google Scholar] [CrossRef]

- Palaszewski, S. J.; Jiji, L. M.; Weinbaum, S. A Three-Dimensional Air-Vapor-Droplet Local Interaction Model for Spray Units. Journal of Heat Transfer 1981, 103, 514–521. [Google Scholar] [CrossRef]

- Sazhin, S. S. Advanced Models of Fuel Droplet Heating and Evaporation. Progress in Energy and Combustion Science 2006, 32, 162–214. [Google Scholar] [CrossRef]

- Miller, R. S., K. Harstad, and J. Bellan. "Evaluation of equilibrium and non-equilibrium evaporation models for many-droplet gas-liquid flow simulations." International journal of multiphase flow 24.6 (1998): 1025-1055. [CrossRef]

- ANSYS. ANSYS Fluent Theory Guide; Ansys Inc.: Canonsburg, PA, USA, Version 2023. [Google Scholar]

- Babinsky, E.; Sojka, P. E. Modeling Drop Size Distributions. Progress in Energy and Combustion Science 2002, 28, 303–329. [Google Scholar] [CrossRef]

- Alderliesten, M. Mean Particle Diameters. Part VII. The Rosin-Rammler Size Distribution: Physical and Mathematical Properties and Relationships to Moment-Ratio Defined Mean Particle Diameters. Particle & Particle Systems Characterization 2013, 30, 244–257. [Google Scholar] [CrossRef]

- Handbook of Atomization and Sprays: Theory and Applications; Ashgriz, N., Ed.; Springer US: Boston, MA, 2011. [CrossRef]

- Average Annual Relative Humidity. Center for Sustainability and the Global Environment. https://sage.nelson.wisc.edu/data-and-models/atlas-of-the-biosphere/mapping-the-biosphere/ecosystems/average-annual-relative-humidity/ (accessed 2024-07-30).

| Grid factor | Number of elements |

(℃) | (%) | Computational time (h) |

|---|---|---|---|---|

| M1 | 128,000 | 30.6448 | - | 6 |

| M2 | 302,500 | 30.6973 | 0.55 | 12 |

| M3 | 612,500 | 30.7579 | 0.38 | 20 |

| M4 | 1,083,750 | 30.8077 | 0.18 | 26 |

| M5 | 1,800,000 | 30.8128 | 0.019 | 35 |

| M6 | 2,420,000 | 30.8137 | 0.003 | 43 |

| K1 | K2 | K3 | Re |

|---|---|---|---|

| 24 | 0 | 0 | Re<0.1 |

| 22.73 | 0.0903 | 3.69 | 0.1<Re<1 |

| 29.1667 | -3.8889 | 1.222 | 1<Re<10 |

| 46.5 | -116.67 | 0.6167 | 10<Re<100 |

| 98.33 | -2778 | 0.3644 | 100<Re<1000 |

| 148.62 | -4.57∗104 | 0.357 | 1000<Re<5000 |

| -490.546 | 57.87 | 0.46 | 5000<Re<10000 |

| -1662.5 | 5.4167 | 0.5191 | 10000<Re<50000 |

| Air | Water | Nozzle | |||||

| DBT (℃) | va (m/s) | P (bar) | (kg/s) | Tw (℃) | D (mm) | () | |

| 39.2 | 3 | 0.0052 | 3 | 0.21 | 35.2 | 4 | 18 |

| Design Point | ) | Mass flow rate*10-3 (kg/s) | Evaporated mass flow rate (%) | SEP (W) | Q(W) | (W) |

|---|---|---|---|---|---|---|

| D1 | 292 | 420 | 0.73 | 0.5926 | 7737.9 | 124.8 |

| D2 (O) | 292 | 210 | 1.10 | 0.2963 | 5572.8 | 62.4 |

| D3 | 292 | 100 | 1.44 | 0.1479 | 3656.0 | 31.1 |

| D4 | 121 | 52 | 2.63 | 0.1836 | 3351.2 | 15.6 |

| D5 | 121 | 26 | 3.44 | 0.0918 | 2187.7 | 7.8 |

| D6 | 121 | 13 | 4.47 | 0.0459 | 1422.3 | 3.9 |

| D6 | 65 | 13 | 5.67 | 0.0791 | 1804.6 | 3.9 |

| D7 | 65 | 6.4 | 7.43 | 0.0395 | 1163.1 | 1.9 |

| D8 | 65 | 3.2 | 9.80 | 0.0198 | 767.3 | 0.96 |

| D8 | 32 | 3.2 | 13.75 | 0.0397 | 1076.4 | 0.96 |

| D9 | 32 | 1.6 | 19.67 | 0.0199 | 770.0 | 0.48 |

| D10 | 32 | 0.8 | 27.46 | 0.0099 | 537.4 | 0.24 |

| D11 | 15 | 0.4 | 52.86 | 0.0101 | 517.2 | 0.12 |

| D12 | 15 | 0.2 | 74.00 | 0.0050 | 362.0 | 0.06 |

| D13 | 15 | 0.1 | 91.45 | 0.0025 | 223.7 | 0.03 |

| D13 (OP) | 8 | 0.1 | 98.44 | 0.0047 | 240.8 | 0.03 |

| D14 | 8 | 0.05 | 99.87 | 0.0024 | 122.2 | 0.015 |

| D15 | 8 | 0.025 | 100 | 0.0012 | 61.2 | 0.0075 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).