Submitted:

06 October 2024

Posted:

08 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Brief Description of the Reliability Concept and Metrics to Express It.

- Temperature stress

- Electrical and mechanical stress

- Environment

- Duty cycle

- Quality of components

- Observed - field failure experienced

- Predicted - estimated reliability based on reliability models and predefined conditions

- Demonstrated - statistical estimation based on life tests or accelerated reliability testing

3. Experimental, Materials and Method

- A.

- Workbench fase.

- B.

- Simulation PSPICE fase.

- Temperature - high temperatures can accelerate the degradation of the dielectric material inside capacitors, leading to reduced capacitance and potential failure.

- Voltage - Excessive voltage can cause dielectric breakdown, where the insulating material inside the capacitor fails, leading to short circuits.

- Ripple Current - High ripple currents can cause internal heating, which can degrade the capacitor over time.

- Charge - Discharge Cycles - Frequent charging and discharging can wear out the dielectric material, reducing the capacitor’s effectiveness.

- Humidity - Moisture can penetrate non-hermetic capacitors, leading to corrosion and electrical leakage.

4. Reliability Prediction Using the Two Standards. Methodology Behind It.

4.1. Input Data for Calculus with MIL-HDBK-217standard

- A.

- Reliability calculation for the MOSFETs.

- B.

- Reliability calculation for capacitors.

4.2. Input Data for Calculus with SN 29500 Standard

- A.

- Reference conditions – stated as:

- Failure criterion, i.e., complete failures and changes of major parameters leading to failure in the majority of applications.

- Time interval, i.e., the operating interval of time need to be greater than 1000 h.

- Operating voltage, i.e., about 50% of the maximum permissible voltage.

- Junction temperature θj, stated in Tables 1,2 and 3 (page 4 from SN 29500-3: expected values for discrete semiconductors - Siemens Norm, Edition 2009-06)

- Description of environment, i.e., the same statement like in IEC 60721 parts 3-1,3-2, and 3-3 are valid.

- Operating mode, i.e., continuous duty under constant stress.

| Capacitor type | Temperature |

|---|---|

| PCF0J471MCL6GS – Polymer electrolytic SMD Can-type, ESR = 18 mΩ – from Nichicon | 59 °C |

| GRM32ER60J107ME20 – MLCC, SMD -Class II (X7R) ESR = 8 mΩ - from Murata | 32 °C |

- B.

- Operating stress conditions

-

For polymer capacitor we have: C2 = 1.9; C3 =3; Umax = 6.3 V; Uref /Umax = 0.8; U = 1.2V ;U /Umax =0.19048; A = 0.4; Ea1= 0.14; Ea2 = 0; θUref = 40°C; θ1 = 40°C; θ2 = 28°C (from Table 2 within standard); TUref = 313[°K], T1 =313[°K], T2 = 301 [°K]; zref = -3632327.923 [1/eV], z = -1.478139959 [1/eV] results:λref-polymer electrolytic = 3 ; πU = 2.735932892; πT = 0.542388224; πQ =2;

-

For MLCC capacitor we have: C2 = 1; C3 =4; Umax = 6.3 V; Uref /Umax = 0.5; U = 1.2V; U /Umax =0.19048; A = 1; Ea1= 0.35; Ea2 = 0; θUref = 40°C; θ1 = 40°C; θ2 = 32°C (from Table 2 within standard); TUref = 298[°K], T1 =313[°K], T2 = 305 [°K]; zref = -362327.923 [1/eV], z = -1.478139959 [1/eV] results:λref-MLCC = 2; πU = 3.71; πT = 0.712242068; πQ =2;

-

For ceramic through hole HF capacitor we have: C2 = 1; C3 =4; Umax = 25 V; U = 1.2V ;Uref /Umax = 0.5; U /Umax =0.048; A = 0.4; Ea1= 0.14; Ea2 = 0; θUref = 40°C; θ1 = 40°C; θ2 = 32°C (see Table II.); TUref = 313°K, T1 =313°K, T2 = 301 [°K]; zref = -3632327.923 [1/eV], z = -1.478139959 [1/eV] results:λref-ceramic cap HF = 3; πU = 2.735932892; πT = 0.542388224; πQ =2;

5. Results

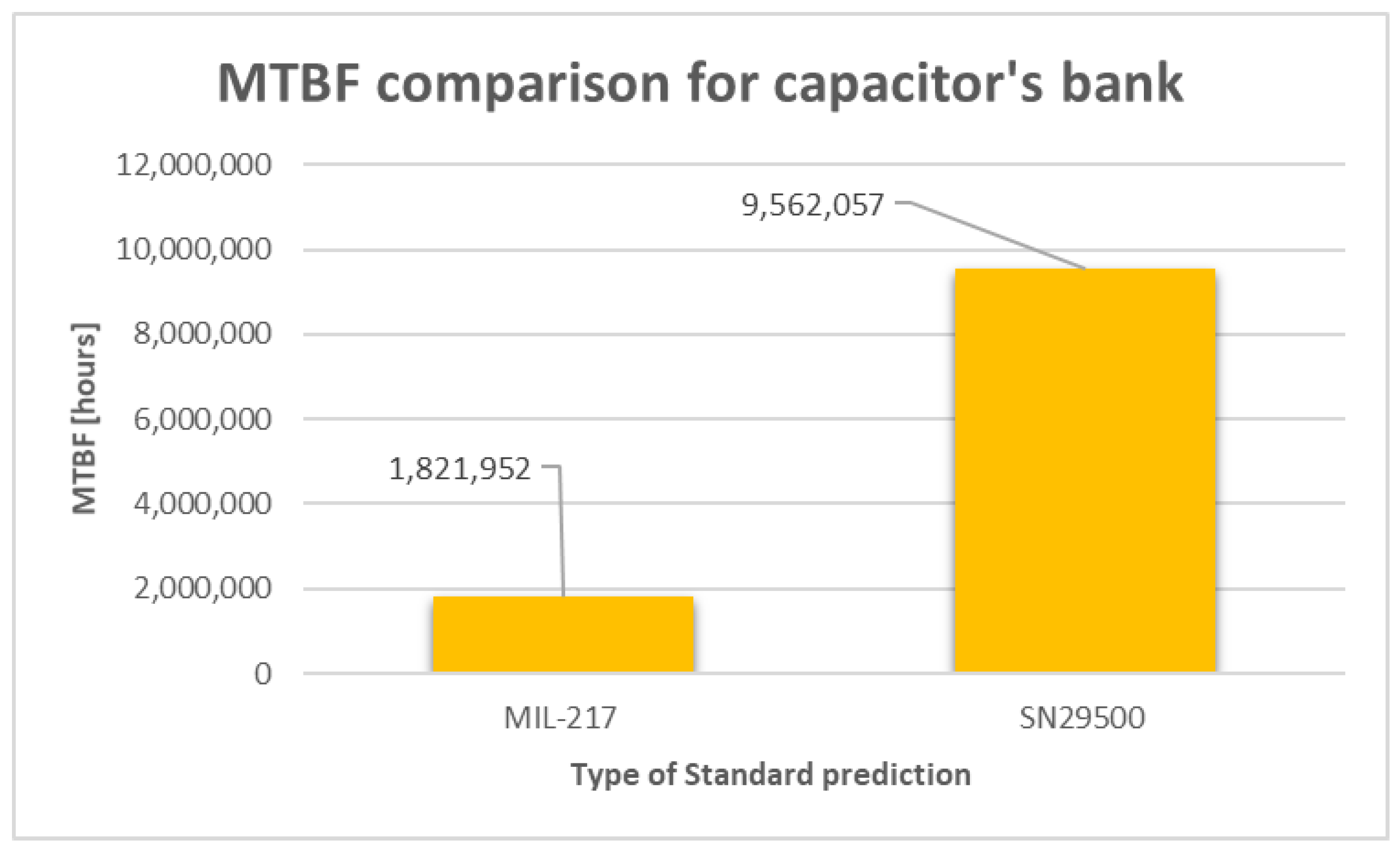

- MTBF capacitor bank - SN 29500 = 14730989 h (38)

6. Discussion

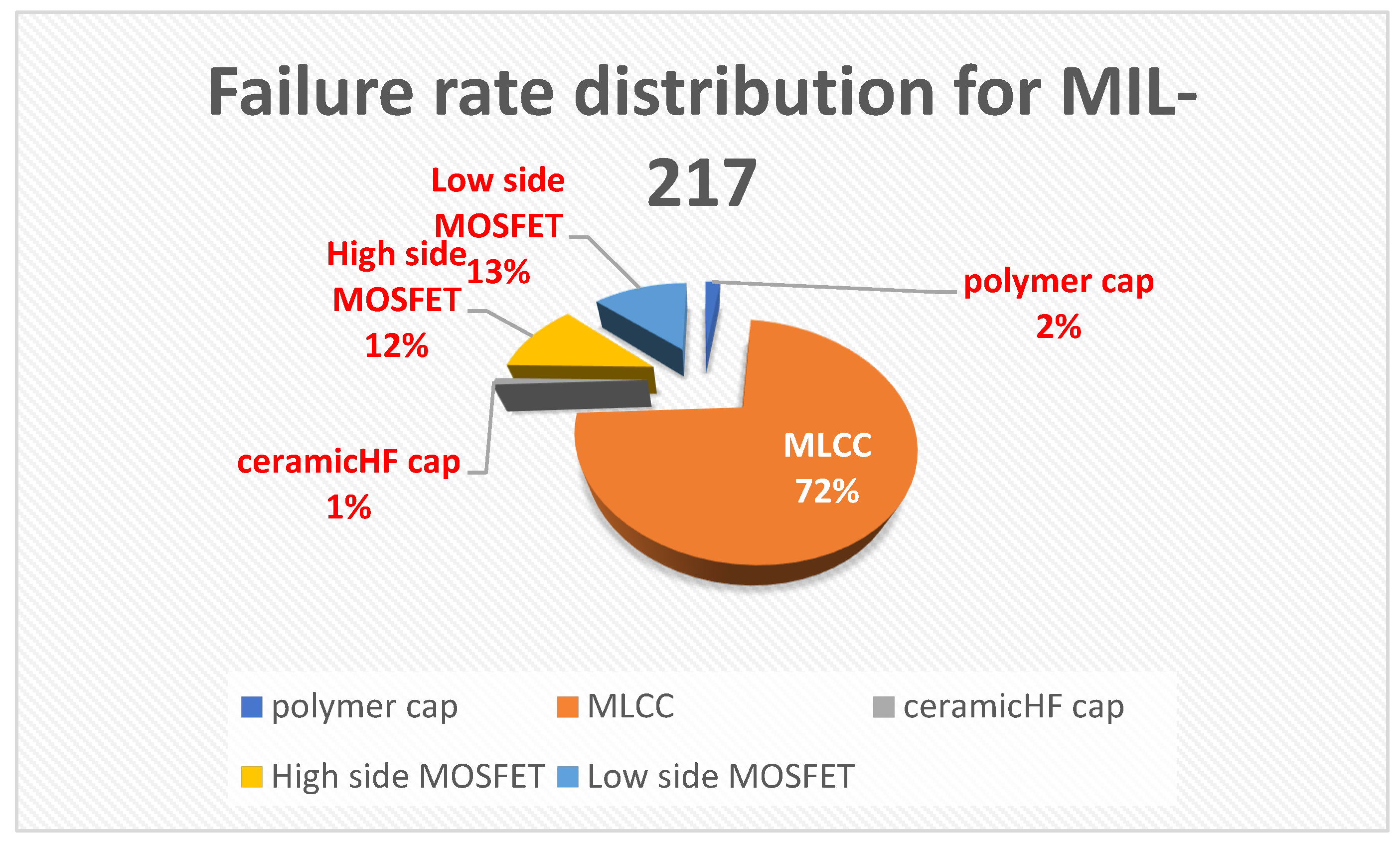

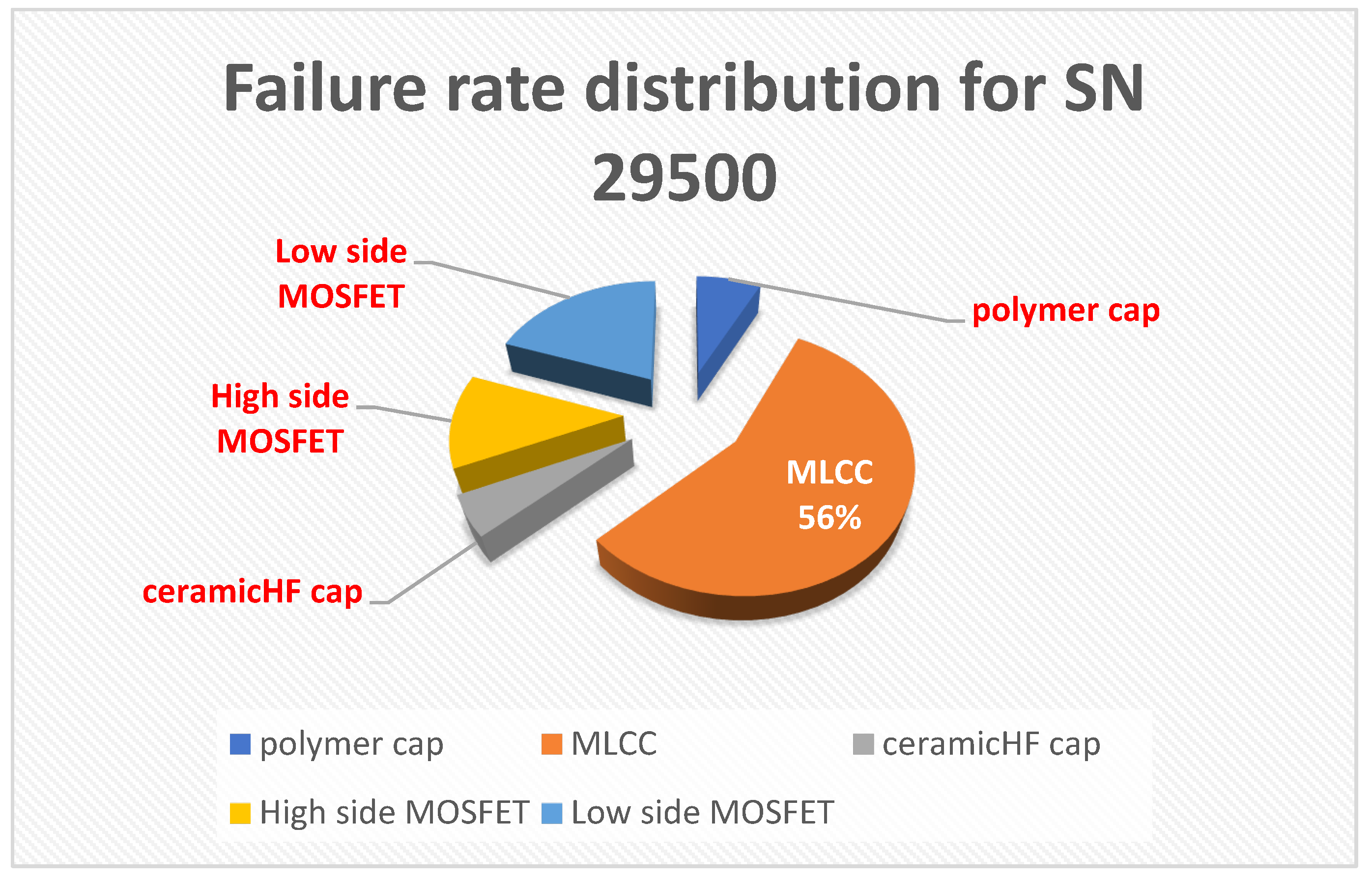

- Firstly a λbase = 0.020 value for MLCC will make the final result of failure rate calculation much bigger compared to SN29500’s result of calculation (548.9 FIT vs. 67.9 FIT)

- The environment that the device will see is a factoralong with the type of packaging technology

- Industrial electronics reliability calculations obtained using Siemens SN 29500, are specific mostly for Europe while Mil 217 is an USA standard.

7. Conclusion

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- D. Butnicu, “POL DC-DC Converter Output Capacitor Bank’s Reliability Comparison using Prediction Standard MIL-HDBK-217F and SN 29500,” 2021 IEEE 27th International Symposium for Design and Technology in Electronic Packaging (SIITME), Timisoara, Romania, 2021, pp. 169-172.Anon., Military Handbook - Reliability Prediction of Electronic Equipment, MIL-HDBK-217F, Notice 2, Feb 28, 1995. [CrossRef]

- Anon., Military Handbook - Reliability Prediction of Electronic Equipment, MIL-HDBK-217F, Notice 2, Feb 28, 1995.

- D. Zhou, Y. Song, Y. Liu and F. Blaabjerg, “Mission profile-based reliability evaluation of capacitor banks in wind power converters,” in IEEE Trans. Power Electron. 34 (5) 4665–4677, May 2019. [CrossRef]

- D. Zhou, Y. Song, Y. Liu and F. Blaabjerg, “Mission profile-based reliability evaluation of capacitor banks in wind power converters,” in IEEE Trans. Power Electron. 34 (5) 4665–4677, May 2019. [CrossRef]

- IEC. TR 62380: Reliability Data Handbook; IEC: Geneva, Switzerland, 2006.

- Anon., http://www.applied-statistics.org/Siemens_SN_29500.html.

- “IEC 61709 (2017): Electric Components - Reliability - Reference Conditions for Failure Rates and Stress Models for Conversion,” 2017.

- Anon., https://telecom-info.njdepot.ericsson.net/site-cgi/ido/docs.cgi?ID=SEARCH&DOCUMENT=SR-332).

- M. G. Pecht and F. R. Nash, “Predicting the reliability of electronic equipment” in Proceedings of the IEEE, vol. 82, no. 7, pp. 992- 1004, July 1994. [CrossRef]

- [10] Dorin O. Neacsu, “Telecom Power Systems ”, ISBN 9781138099302 Published December 8, 2017 by CRC Press.

- J. Falck, C. Felgemacher, A. Rojko, M. Liserre, P. Zacharias, “Reliability of power electronic systems: an industry perspective,” IEEE Ind. Electron. Mag. 12, pp. 24–35, June 2018. [CrossRef]

- D. Butnicu, “A Reliability Comparison between Disrupting eGaN-FET and Cutting Edge Silicon MOSFET Devices in POL Buck Converters,” 2019 International Symposium on Signals, Circuits and Systems (ISSCS), Iasi, Romania, 2019, pp. 1-4. [CrossRef]

- Anon., http://www.nichicon.co.jp/english/products/spice/index.html.

- Anon., https://www.murata.com/englobal/search/productsearch?cate=cgsubCeramicCapacitors&partno=GRM32ER60J107ME20%23&realtime=1.

- Anon., chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.infineon.com/dgdl/irf6617pbf.pdf?fileId=5546d462533600a4015355e853f21a17.

- Anon., chromeextension://efaidnbmnnnibpcajpcglclefindmkaj/https://ro.mouser.com/datasheet/2/196/irf6691pbf-1297981.pdf.

- Butnicu and D., O. Neacsu, “Using SPICE for reliability based design of capacitor bank for telecom power supplies”, 2017 IEEE 23rd International Symposium for Design and Technology in Electronic Packaging (SIITME), pp. 423-426, Constanta, 2017.

- Dan Butnicu, Dorin O. Neacsu, “Using SPICE for multiple-constraint choice of capacitor bank for telecom power supplies”, 2017 IEEE 23rd International Symposium for Design and Technology in Electronic Packaging (SIITME).

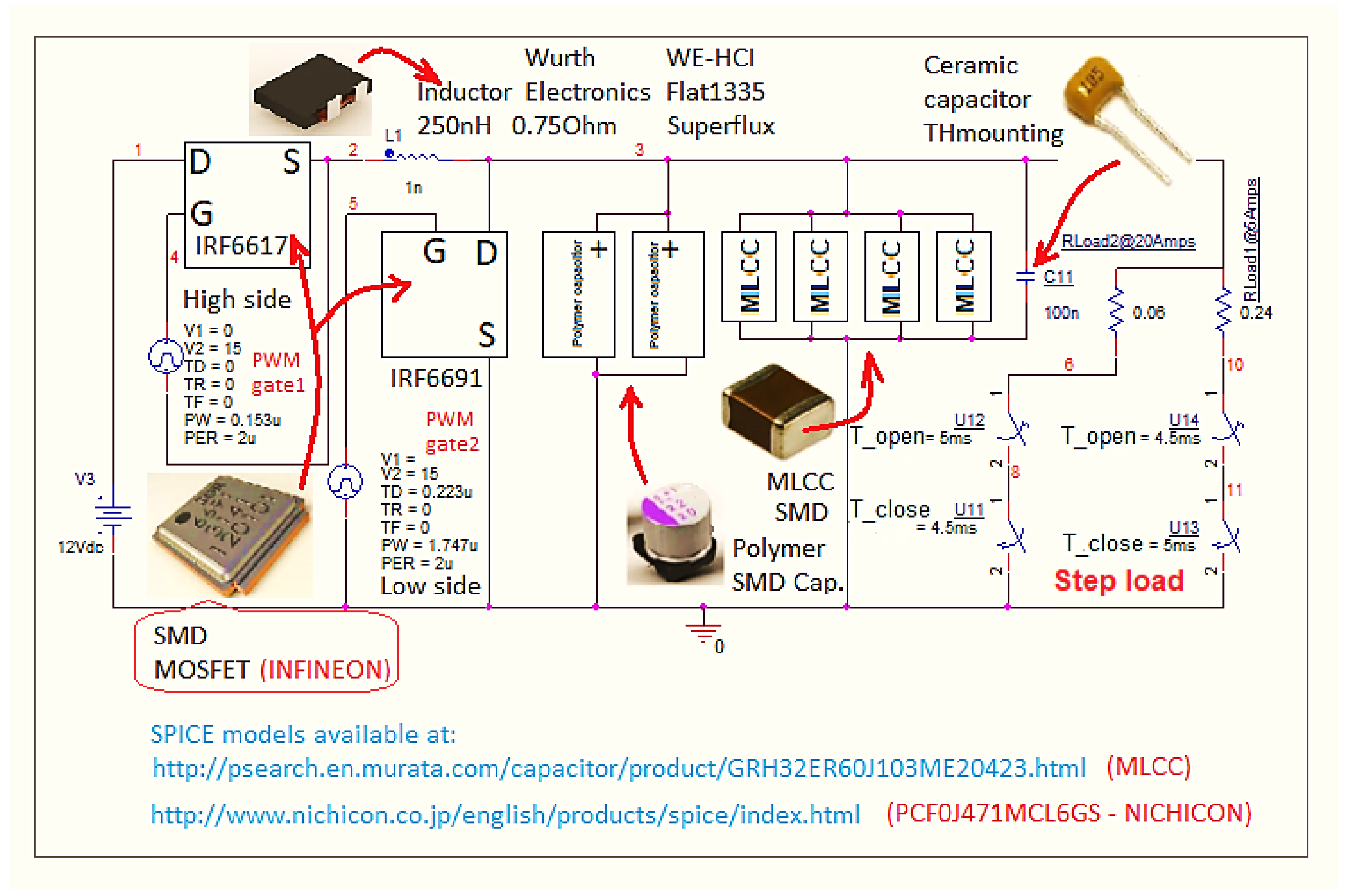

| Parameters of convertor | Value |

|---|---|

| Rated output active power, Po | max. 0.06 Ω ×25 Amp = 37.5 W |

| Input voltage, Vin | 12 V DC with 5% tolerance |

| Output voltage, Vout | 1.2 V DC ± 50 mV |

| Switching frequency, fsw | 500 khz @ Duty cycle = 7.65 % |

| Inductor, L | 250 nH / 0.75 Ω, flat 1335, superflux |

| Output capacitor bank, C | Polymer Electrolytic: 2 pcs. × 470 μF [13] MLCC: 4 pcs. × 100 μF [14] HF-through hole ceramic: 1pcs. × 100 nF HF ceramic: 1 pcs. × 100 nF |

| High side (control) MOSFET | IRF 6617, R(DS)on = 6.2 mΩ, Coss = 430 pF, Rth(J-C) = 20 °C/W [15] |

| Low side (synchro) MOSFET | IRF 6691, R(DS)on = 2.5 mΩ, Coss = 2070 pF Rth(J-C) = 1.4 °C/W [16] |

| Transient load current step | Current variation between : I down = 5A, I up = 25A |

| Ambiant temperature | 27 °C |

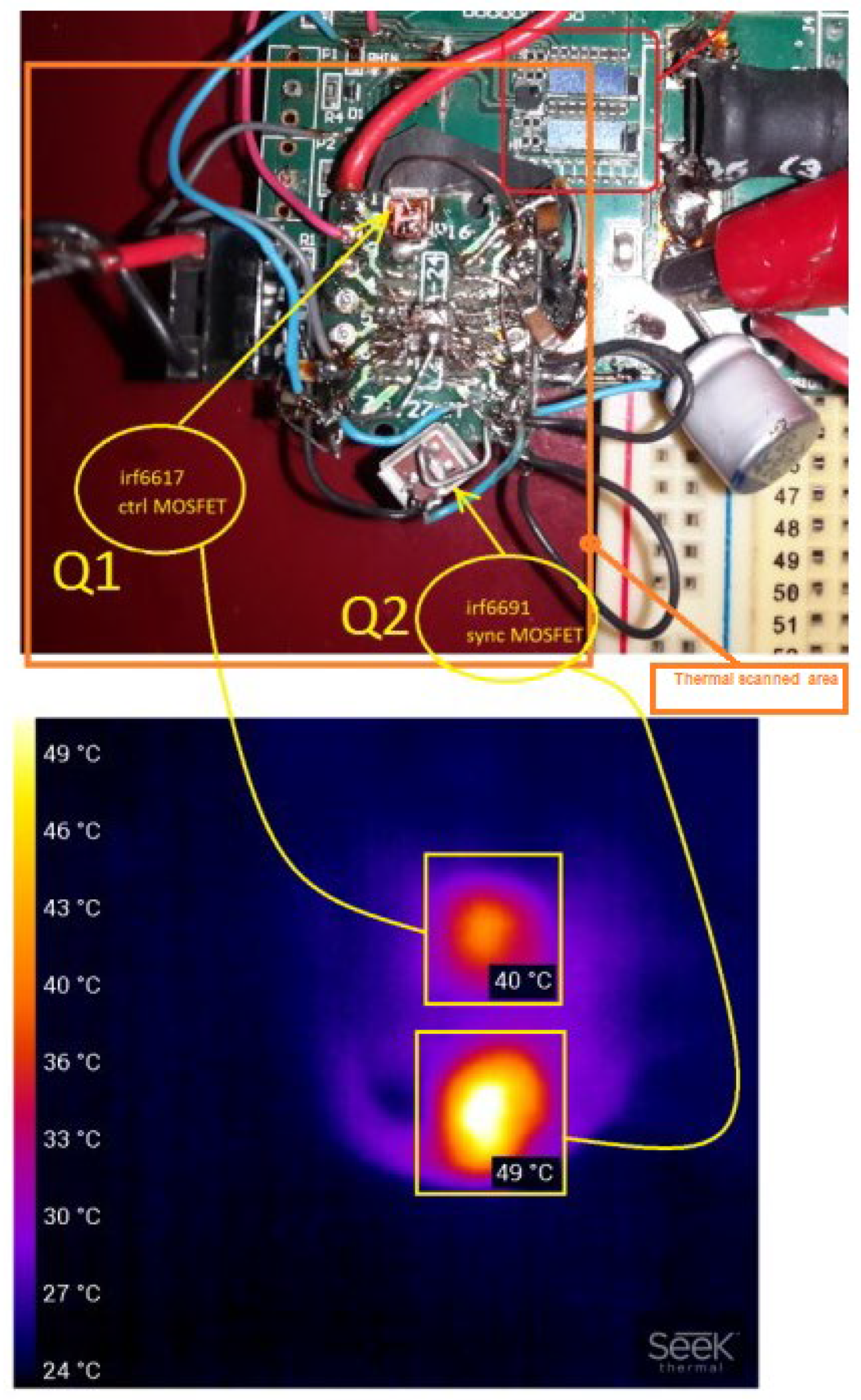

| MOSFET transistor | Capsule’s Temperature |

|---|---|

| Q1: High side (control) MOSFET IRF6617 | 40 °C |

| Q2: Low side (synchro) MOSFET IRF6691 | 49 °C |

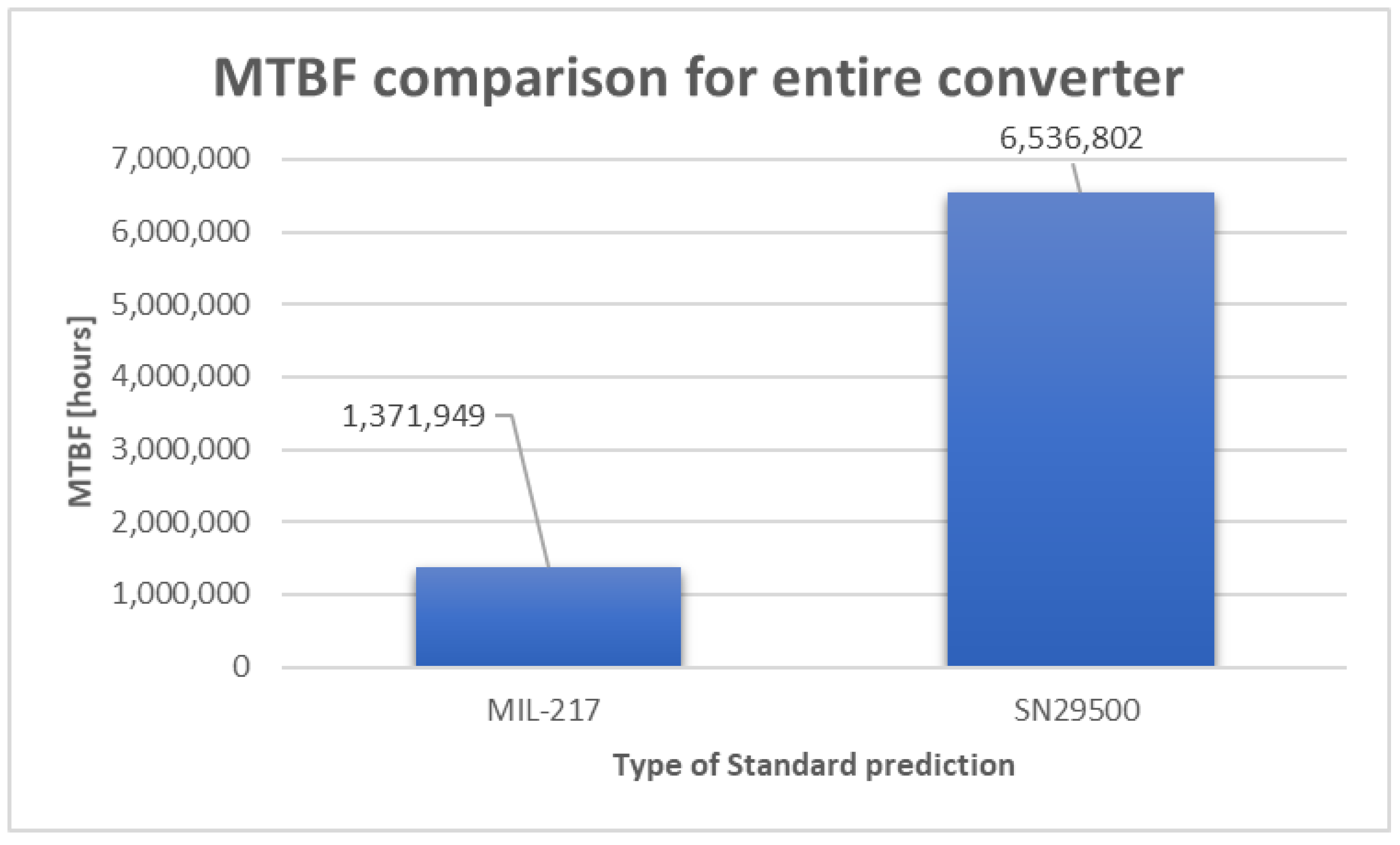

| Component or device | λ MIL-217 [FIT] | πT MIL-217 | πT SN29500 | λ SN29500 [FIT] | MTBF MIL-217 [h] | MTBF SN29500 [h] |

|---|---|---|---|---|---|---|

|

2×polymer electrolytic SMD PCF0J471MCL6GS – Polymer electrolytic SMD Can-type |

15.334 | NA | 0.542388224 | 11.23 | ||

|

4×MLCC SMD GRM32ER60J107ME20 – MLCC, SMD - Class II (X7R) |

525.89 | NA | 0.712242068 | 85.5 | ||

| 1×ceramic through hole HF | 7.666 | NA | 0.542388224 | 7.85 | ||

|

Entire capacitors bank (2×polymer)‖(4×MLCC) ‖(1×ceramic through hole HF) |

1,821,952 h | 9,562,057 h | ||||

|

High side (control) MOSFET IRF6617 |

84 | 2 | 0.092 | 18.4 | ||

| Low side (synchro) MOSFET IRF6691 | 96 | 4.9 | 0.15 | 30 | ||

|

Entire converter Capacitor bank + MOSFETs |

1,371,949 h | 6,536,802 h | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).